Page 1

Contents Page:

Home

Preface and General Safety Notes

Part 1: Operating Instructions Cl. 558

1. Product Description

1.1 Short Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Sub-classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Technic al Speci fication . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Sewing Devic es . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.1 Device Summary Table and Function Characteristics 578 E... /... . . . 9

1.4.2 Device Summary Table and Function Characteristics 558 E ... / ... . . . 11

1.5 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. Operation

2.1 Removal and Placement o f the Clamp Plates . . . . . . . . . . . . . . . 15

2.2 Turnin g On - Quick Stop - Restart . . . . . . . . . . . . . . . . . . . . . . 19

2.3 End Position of the Sewing Machine . . . . . . . . . . . . . . . . . . . . 23

2.4 Needles, Threads and Gimps . . . . . . . . . . . . . . . . . . . . . . . . 24

2.5 Threading of the Underthread (Hook Thread) . . . . . . . . . . . . . . . 27

2.6 Threading the G imps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.7 Threading of the Upper Thread (Needle Thread) . . . . . . . . . . . . . . 37

2.8 Thread Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2.9 Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

2.1 0 Blocking the Clamp Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

2.11 Buttonhole Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2.1 2 Cutti ng Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.1 3 Cutti ng Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

2.1 4 Cutti ng Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.1 5 Spreading of t he Material . . . . . . . . . . . . . . . . . . . . . . . . . . 59

2.16 Sti tch Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2.17 Seam Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.18 Buttonhole Fo rm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.19 Changeover to Cutting Before or After Sewing . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Maintenance

3.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.2 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.3 Oiling Positions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Page 2

4. Malfunction Remedies

. . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5. Optional Equipment Electromagnetic Upper Thread Catcher

5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

5.2 Electrical Conn ection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.3 Function Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.4 Turn-on Interlocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5.5 Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.5. 1 Lift of the Electromag net . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

5.5.2 Base Position of the Upper Thread Catcher . . . . . . . . . . . . . . . . . 87

5.5.3 Lowering Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

5.5.4 Gripping Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5.5 .5 Switc hes for the Upper Th read Catcher Controls . . . . . . . . . . . . . . 92

5.6 Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

5.6.1 Pre-assembling the Wiring Distributor . . . . . . . . . . . . . . . . . . . . 97

5.6.2 Laying the Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

5.6 .3 Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.6 .4 Mounting Switch b 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

5.6 .5 Mounting the Switching Rail for Switch b2 . . . . . . . . . . . . . . . . . 103

5.6.5 Mounting the Upper Thread Catcher on the Machine Arm . . . . . . . . . 104

. . . . . 79

The illustrations used in these instructions are of differing sub-classes of the

buttonhole machine 558 !

Please note that your buttonhole may deviate from the illustrations !

Page 3

1. Product Description

1.1 Short Description and Proper Use

The

DÜRKOPP ADLER 558

Buttonholes with or without eye and with or without taper bar can be sewn.

The buttonhole form i s determined by 2 exchangeable disc cams with

•

corresponding knives. The upper disc cam determines the form of the eye. The disc

cam lying thereunder determines for buttonholes with taper bar the taper bar form

and the buttonhole length.

The smallest and largest butto nhole width for each sewing device (E no.) is

•

established by the position of the lim i t plate.

Pendulum swing of the needle bar from the rest position one-sided to the right

•

when sewing the right and one-sided to the left when sewing the left buttonhole

seam.

Automatic adaption of the upper cloth clamp pressure to differing material

•

thicknesses th rough spring -hangered clamp frame.

The safety devices do no t have to be removed when ti l ting up the mac h i ne.

•

The combined finger-eye protection device increases safety.

•

It is held in the work position by springs.

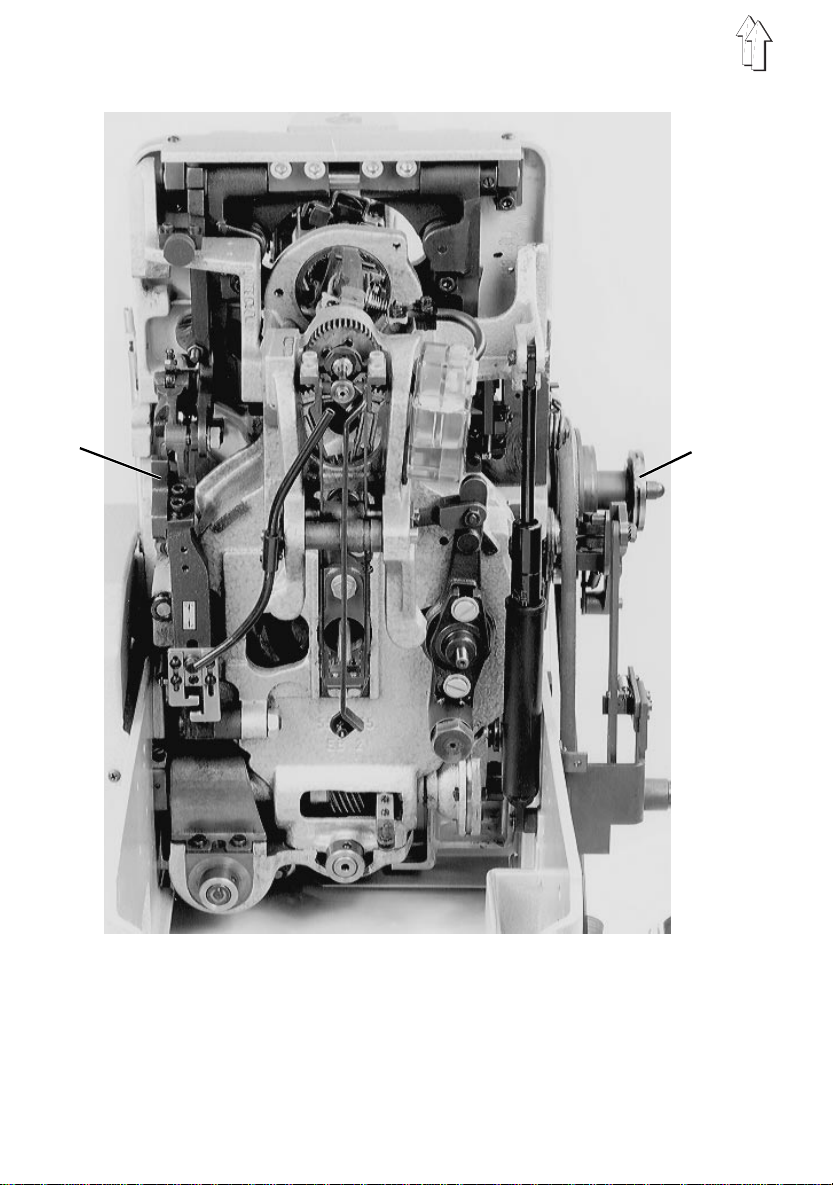

The gas pressure spring aids tilting up and effects a sure, slow lowering. The stop

•

position makes an unhindered threading of the hook thread possible.

The machine is equipped with a central oil wick lubrication from 2 oil reservoirs

•

(the positions marked in red must also be oi led).

In the next chapter the individual sub-classes are described.

is a double chain stitch buttonh ol e machine.

5

Page 4

1.2 Sub-classes

558 - 211241

With automatic trimmers.

The upper thread, the underthread and the gimp fed in from the bottom are cut so short

that no thread ends are vi si ble. Cleaning is unnecessary.

Cutting open the buttonhole after sewing.

Cutting length 20 mm

558 - 221301

With automatic trimmers.

The upper thread is cut off short. The underthread and the gimp fed in from the bottom

are cut off l ong (about 30 m m).

Cutting open the buttonhole depending on E no. before or after sewing, as desired.

This sub-class has the electromagnetic upper thread catcher as standard equipment.

Cutting length 10...38 mm

558 - 231391

With automatic trimmer.

Only the upper thread is cut short. The sewing piece can be easily removed from the

sewing position or, with buttonholes lying in a row, simply pulled a bit to the left. The

underthread and the lower gimp are then trimmed by hand.

With this sub-class the sewing pi ece is positioned 12 mm further forward than with

-221301 and -251301.

Cutting open of the buttonhole, depending on the E no., as desired, before or after

sewing.

Cutting length 10...38 mm

558 - 241291

The sewing piece is positioned 9.5 mm further forward than with sub-classes -221301

and - 251301. This means a better view and more freedom when positioning the sewing

pieces.

With automatic trimmers.

The upper thread, the underthread and the gimp fed in from the bottom are trimmed so

short t hat no thread ends are visible. No cleaning is necessary.

Cutting open the buttonhole after sewing.

Cutting length dependent on the length package 14...32 mm

558 - 251301

With automatic trimmer.

Only the upper thread is cut short. The sewing piece can be easily removed from the

sewing position or, with the buttonholes lying in a row, simply pulled a bit to the left. The

underthread and the lower gimp are then trimmed by hand.

Cutting open the buttonhole can be switched between cutting before or after sewing.

Cutting length 10...50 mm

6

Page 5

1.3 T echnical Specification

Number of stitches: 1.650 Stitches/min

Type of stitch: Double chain stitch

Sewing length: max. 50 mm

Cutting length: max. 50 mm

Needle system: 558

Needle thickness: Nm 90...110

Looping stroke: 2.7...3.2 mm

Material thicknesses: max. 10 mm with sub-class -221301

Sewing thread th ickness: Upper thread max. Nm 50

Nominal voltage: - 2410591 3 ~ 400 V + N, 50/60 Hz

Noise: Lc = 80 dB (A)

Dimensions: (H x W x D) 1570 x 630 x 520 mm (Standard)

Weight: 128 kg (complete w i t h m achine head,

55 kg (only frame and motor)

Work height: 760...1060 mm (Top edge of table)

Depending on the type of sewing thread and the material.

Depending on the sewing device (E no.).

max. 12 mm with all othersub-classes

Underthread max. Nm 30

- 2410575 3 ~ 230 V, 5 0/60 Hz

- 2410540 1 ~ 230 V, 5 0 H z

- 2410478 1 ~ 230 V, 6 0 H z

The machine is de l i vered with one of the listed drive

packages appropriate to the nominal voltage.

by sewing cycle 5.0 s on an d 1.4 s off

to DIN 45635-48-B-1

1570 x 1060 x 520 mm (Wide model)

frame and motor)

7

Page 6

1.4 Sewing Devices

The devices parts for the differen t butt onhole forms and cutting lengt hs are established

under device numbers (E no.’s).

After the E no. behind a slash the cutting length or the setting range in mm is given.

Example:

For sewing the various buttonhole len gths different cu tting blocks, cloth clamps and disc

cams are required. The appropriate or der numbers can be found in the device sheet for

the

.

558

The device summary table on the following page lists the currently available devices.

The most suitable device for a specific buttonhole form and a certain type of material

can be chosen quickly from the t a ble.

ATTENTION :

For the

558

For the

558

There are two di fferent groups of butto nhole machines:

578 E2107 / 20 or 578 E209 / 10 - 38

558 E209 / 10 - 38

after July 1994 the device numbers for the 578 apply ( Chapter 1.4.1 ).

up to June 1994 t he device numbers for the 558 apply ( Chapter 1.4.2 ).

Only cutting

Cutting

before or after

For conversion of the buttonhole machine to a further buttonhole form or cutting length

the following points are to be consi dered:

1. Only those parts are to be ordered and at tached whose o rder numbers do not agree

with those o f the device available.

See the device sheets for the 558 and the 578.

2. The cutting lengths can only be selected appropriate to the device or the setting

range.

By devices which have only one digit behind the slash the cutting length is not

adjustable.

3. By machines wh i ch are switched over to cutting before or aft er sewing, the

appropriate sections of these instructions are to be observed.

4. The setting values, buttonhole width and looping stroke, are interdependent and must

be observed when changin g to another device (E no.).

If values deviating fr om the table arise, the adaption is to be made by a special i st as

per the Service Instructions.

after

sewing.

sewing as desired.

8

Page 7

mm mm mm mm

for width area stroke

Cutting Short trimmer Buttonhole Cutting Looping

before after min. max.

Buttonhole form

Gimp long

20 Under th., Gimp

10 - 38

Buttonholes similar to E209 / ---> N Upper thread, 4,1 5,2 0,4 3,0

handworked quality 10 - 38 Under thread,

High quality clothing of E212 / E213 / V <-- ---> N " 5,0 7,0 - / 0,4 2,7

variing thicknesses 10 - 38 10 - 38

Loose, coarse weave cloth

Buttonholes similar to handworked E309 / ---> N Upper thread 4,1 5,2 0,4 3,0

quality in outerwear 18 + 24

Small buttonholes in elastic material E311 / * ---> N " 4,1 5,2 0,4 3,2

(e.g. knitware) with round or flat gimp 6 - 34

Materials of variing quality and E312 / E312 / V <--- ---> N " 5,0 7,0 - / 0,4 2,7

Garment leather E327 / V <--- ---> N " 5,0 7,0 - / 0,6 3,2

Waistbands on jeans, E328 / ---> N " 4,5 5,8 0,4 3,0

graduated cloth clamps 16 - 20

Fine, tightly woven materials E334 / V <--- " 6,0 7,0 - 2,7

(e.g. poplin) 10 - 38

558 Material

1.4.1 Device Summary Table and Function Characteristics 578 E . . . / . . .

- 211241 Loose, coarse weave cloth E2107 / ---> N Upper thread, 4,5 5,8 0,4 2,7

- 221301

- 231391 thickness 10 - 38 12 - 34

* The construction set upper gimp guide 578 5101 must be ordered additionally.

9

Page 8

for width area stroke

Cutting Short trimmer Buttonhole Cutting Looping

mm mm mm mm

before after min. max.

Buttonhole form

10

558 Nähgut

L1 - L3 Under th., Gimp

Loose, coarse weave cloth E2407 / ---> N Upper thread, 4,5 5,8 0,4 2,7

L1 - L3

Buttonholes in elastic material

(e.g. knitware)

Waistbands on jeans and similar E2417 / ---> N " 4,5 5,8 0,4 3,0

- 241291

Loose, coarse weave cloth, E2431 / ---> N " 4,5 5,8 0,4 2,7

plastic stitch formation L1 - L4

thickness 10 - 50 12 - 50

- 251301 Materials of variing quality and E512 / E512 / V <--- ---> N Upper thread 5,0 7,0 / 0,4 2,7

Page 9

mm mm mm mm

for width area stroke

Cutting Short trimmer Buttonhole Cutting Looping

before after min. max.

Buttonhole form

Gimp long

20 Under th., Gimp

10 - 38

Buttonholes similar to E209 / ---> N Upper thread, 4,1 5,2 0,4 3,0

handworked quality 10 - 38 Under thread,

High quality clothing of E212 / E213 / V <-- ---> N " 5,0 7,0 - / 0,4 2,7

variing thicknesses 10 - 38 10 - 38

Loose, coarse weave cloth

Buttonholes similar to handworked E309 / ---> N Upper thread 4,1 5,2 0,4 3,0

quality in outerwear 18 + 24

Small buttonholes in elastic material E311 / * ---> N " 4,1 5,2 0,4 3,2

(e.g. knitware) with round or flat gimp 6 - 34

Materials of variing quality and E312 / E312 / V <--- ---> N " 5,0 7,0 - / 0,4 2,7

Garment leather E327 / V <--- ---> N " 5,0 7,0 - / 0,6 3,2

Waistbands on jeans, E328 / ---> N " 4,5 5,8 0,4 3,0

graduated cloth clamps 16 - 20

Fine, tightly woven materials E334 / V <--- " 6,0 7,0 - 2,7

(e.g. poplin) 10 - 38

558 Material

1.4.2 Device Summary Table and Function Characteristics 558 E . . . / . . .

- 11241 Loose, coarse weave cloth E107 / ---> N Upper thread, 4,5 5,8 0,4 2,7

- 21301

- 31391 thickness 10 - 38 12 - 34

* The construction set upper gimp guide 578 5101 must be ordered additionally.

11

Page 10

for width area stroke

Cutting Short trimmer Buttonhole Cutting Looping

mm mm mm mm

before after min. max.

Buttonhole form

12

558 Nähgut

L1 - L3 Under th., Gimp

Loose, coarse weave cloth E407 / ---> N Upper thread, 4,5 5,8 0,4 2,7

L1 - L3

Buttonholes in elastic material

(e.g. knitware)

Waistbands on jeans and similar E417 / ---> N " 4,5 5,8 0,4 3,0

- 41291

Loose, coarse weave cloth, E431 / ---> N " 4,5 5,8 0,4 2,7

plastic stitch formation L1 - L4

thickness 10 - 50 12 - 50

- 51301 Materials of variing quality and E512 / E512 / V <--- ---> N Upper thread 5,0 7,0 / 0,4 2,7

Page 11

1.5 Optional Equipment

558 - 10012 Electromagnetically operated upper thread catcher

The electromagnetically operated upper thread catcher immediately after the thread

trimming procedure grips the upper thread. It holds this clamped and inserts it in the

right seam during sewing of the next buttonhole.

This means:

Secure seam b eginning even with lig ht , loose cloth.

•

Beginning sti tches pulled t i ght.

•

Neating the u nderside of the butt onhole is unnec es sary becaus e t he beginning

•

thread is sewn over.

The sub-class 558 - 221301 ha s t he upper thr ead catcher as standard equip ment. It is

available on request for all other sub-classes.

558 1501 Thread oiler

For improving thread glide in extremely thickness material.

557 1103 Gimps roller holder on the table top

For lower Gimps which are stiff and hard to bend.

558 3001 Thread unreeler, complete

For holding thread or wool cones. The attachment is to the middle traverse of the table

frame.

558 1731 Stop for buttonhole interval from 70 - 330 mm

App. 1062 Halogen sewing light

App. 1541 Mounting kit

798 500088 Sewing light transformer

Stops for the clearance between material edge and buttonhole are available in different

lengths on request.

13

Page 12

1

4

2

3

2

5

6

7

2

8

9

7

2

8

9

10

14

10

Page 13

2. Operation

2.1 Removal and Placement of th e Clamp Plates

Caution Risk of Injury !

Pull the mains plug.

Remove or place the clamp plates only with the machine

turned off.

The removal or placement of the clamp pl ates 3 and 5 occur s i n the machine end

position (see Chapter 2.3).

The clamp operating lever 1 must be open !

This is the case when it is pushed to the back until it hits.

ATTENTION !

In order to avoid damage to the needle the combined

finger-eye protection 4 must remain swung down.

Sub-class -231391 and -251301:

Removing the clamp plates

–

Swing the clamp plate holder 2 away to the side.

–

Reach under each nail slit 6 and lift the c l amp plate.

–

Remove the clamp plates to the front.

Placing the clamp plates

–

The clamp operators 8 must reach into the forks of the clamp arms.

–

Push the clamp plates to the right or left against the pressure screws 7 and plate

edges 9.

–

Place the clamp plates over the setbolt 10 on the material support plate.

–

Swing the clamp plates holder 2 back over the clamp plates.

The clamp plates are secured against li fting.

–

Check by closing the clamp operating lever 1 if the clamps open and close correctly.

15

Page 14

-221301

1

1

2

3

-211241 und -241291

1

2

3

16

1

Page 15

Sub-classes -211241, -221301 and -241291:

Removing the clamp plates

–

Swing the clamp plate holder 1 away to the side.

–

Pull the spring mounted slide 3 in the direction of the arrow and remove the right

clamp plate.

–

Reach under t he nail slit 2 and remove the left cl amp plate.

Placing the clamp plates

–

Place first the left, then the right clamp plate.

–

The clamp operators 5 must reach into the forks of the clamp arms.

–

Push the clamp plates to the right or left against the pressure screws 4 and plate

edges 6.

–

Place the clamp plates over the setbolt 7 on the the material support plate.

Hereby pull the spring mounted slide 3 in the direction of the arrow and let catch in

groove 8.

–

Swing the clamp plate holder 1 over the clamp plates again.

The clamp plates are secured against li fting.

–

Check by closing the clamp operating lever if the clamps op en and close correctly.

4

1

5

6

7

4

1

5

6

7

8

17

Page 16

1

2

18

Page 17

2.2 Turning On - Quick Stop - Restart

Caution Risk of Injury !

Do not reach in to the area of m oving machine parts,

particularly not under the knife and t he cloth clam ps.

Turning on

Turn on the drive motor with the hand shift lever 1.

–

Loosen the ha nd shift lever 1 out of i ts catch by

bring into position

The catch prevents an unwanted turni ng on of the dri ve m ot or.

Turning off

Turn off the drive motor,

–

Place the hand shift lever 1 in position

The hand shift lever catches in this position.

–

Step forward on pedal 2.

.

"I"

as desired,

Caution Risk of Injury !

As long as the operator is not yet fa miliar with the machine,

she should turn off the motor with t he pedal or hand shift

lever after sewing each butt onhole.

restarting should occur only after the cloth has been

repositioned and the clamp are closed.

with the hand shift lever 1 or the pedal 2.

"0"

pulling up

.

on the ball head and

Quick stop

The safety system of the 558 has two possibilities for an

s

ewing process

–

Put the hand shift lever 1 in position

–

Step pedal 2 forward.

by operating errors or malfunctions (e.g. needle or thread breakage):

.

"0"

immediate stop during the

19

Page 18

1 2

3

4

5

20

6

Page 19

Restart

In order to avoid damage to the machine, when restarting after a quick stop it is

essential to proceed as follows:

–

Lift the idle lever 5 until it jumps off of the nose 4 of the length setting slide 6.

Attention !

This point is only to be carried out if the machine was turned off immediately after

the first sewing stitches.

–

Pull the turn-off lever 1 forward.

ATTENTION !

Before turning on the machine always bring th e needle into

the high posit i on by catching in the handwheel 3. A bending

of the needle or damage to the material is thus avoided.

Exception:

The handwheel m ay not , however, be turned at that

moment in which, after the end of the sewing sequence,

the cutting movement of the upper thread knife begins and

this lies under t he needle hole of the needle p l ate.

–

Tur n the handwheel 3 in the dir ection of the a rrow until it catches.

The handwheel is arrested in this position by brake lever 2.

The needle is in its highest position.

–

Open the clamp pl ates and remove material.

–

Close the clamp plates again.

–

Turn on the machine with the hand shift lever.

The material support plate moves to its end position.

The needle remains in its highest position.

ATTENTION !

Only turn the hand crank of the high-speed wheel when the

handwheel ha s caught in the direction of turn.

21

Page 20

1

2

22

Page 21

2.3 End Position of the Sewing Machine

–

Turn handwheel 2 u ntil it catches.

The needle is in its highest position.

ATTENTION !

Before turning the hand cran k i t is essential that the needle

be brought into its high position by moving the handwheel

into its catch.

A bending of the needle or damage to the material is thus

avoided.

Exception:

The handwheel m ay not , however, be turned at that

moment in which, after the end of the sewing sequence,

the cutting movement of the upper thread knife begins and

this lies under t he needle hole of the needle p l ate.

–

Turn the hand crank until the clamp closing lever 1 automatically opens the clamp

arms.

Depending on the setting of the machine to cutting

occurs before or after operation of the cutter bar 3.

–

The machine is in the end position.

before

or

after

sewing opening

3

23

Page 22

2.4 Needles, T hreads and Gimps

T able: Threads and Gimps

1

2

Needle thread type

and thickness

Hook thread type

and thickness

Lower gimp type

and thickness

Upper gimp type

and thickness

24

558-221301

558-231391

558-251301

Polye ster fiber thread,

schappe-spun

70/3

Polye ster fiber thread,

schappe-spun

70/3

Tube or

wire gimp

not required

Sub-class

558-211241

558-241291

Polye ster fiber thread,

schappe-spun

70/3

Polye ster fiber thread,

schappe-spun

30/3

not required

Twist gi mp

15/3

Page 23

Needles

Needle system: 558

Needle thickness: Nm 90 - 110

Replacing the needle

–

Swing up the combined fing er-eye protection.

The needle is accessable without hinderance.

–

Loosen screw 1 and remove the needle.

–

Push the new needle as far as possible into the hole in the needle bar 2.

Attention !

The furrow of the needle must show to the front with the machine in its end position.

–

Tighten screw 1 again.

–

Swing the com bi ned finger-eye protection back again .

Threads

As needle and hook thread, spun, synthetic fiber thread or silk thread can be used.

The appearance o f the buttonhole i s c onsiderably influenc ed by

–

the thread used.

–

the use of differe nt strengths for need l e and hook thread.

Dependent on type of sewing thread and material.

Caution Risk of Injury !

Pull the mains plug.

Replace the needle only with the machine turned off.

Gimps

The gimp should stabilize the buttonhole and at the same time by it form.

It should have the following character i stics:

–

not too thick, but pliable and firm

–

uniform diameter

The recommend ed threads and gimps i n t he table along si de are only guide li n es.

Dependent on sewing device (E no.) and mat erial other t hreads and th read thicknesses

may also be required.

25

Page 24

a

b

c

26

e

d

c

Page 25

2.5 Threading of the Underthread (Hook Thread)

Caution Risk of Injury !

Pull the mains plug.

Thread the underthread only with the machine turned off.

The threading of the underthreads 1 (Page 28) is conducted as shown in the

illustrations on pages 26 and 28

–

Bring the machine in its end position (see Chapter 2.3).

In the end position the hook bracket with the underthread te nsion must point t o the

front (to the seamstress).

–

Remove the clamp plates (see Chapter 2.1).

–

Tilt up the machine head.

The gas pressu re spring ai ds the tilting and holds the machine head i n i ts position.

–

Place the thread spool on the thread stand and guide the thread through hole a.

–

Guide the thread through the thread guide b in the thread guide tube c on the back

of the housing.

–

Guide the thread through the thread guide tube d.

–

Guide the thread with the ai d of the threading wire from the accessor i es pack into

the spreader drive spindle e.

For this insert the threading wire into the spreader drive spindle from above.

–

Lead the thread over the guide pin f and past behind the tension plate g.

–

Lead the thread between the t wo t ension discs of the underthread tensi on h up

over the guide pin i.

–

Guide the thread through the eye of the torsion spring k.

–

With sub-classes

through the hole of the br i ng-forward lever l.

–

Lead the thread up through the thread guide tube m.

–

Lead the thread through the spreader stop n.

–

Guide the thre ad from below through hole o in the hook an d needle hole p of the

needle plate. Hereby let an approx. 25 mm long underthread end hang out of the

needle hole.

-211241, -221301

in alphabetical order of the letters

and

-241291

additionally guide the thread

:

= Gimp thread (Page 28)

2

27

Page 26

m

-231391

-251301

-211241

-221301

-241291

k

l

f

i

g

h

12

p

28

o

n

Page 27

Path of the underthread when using yarn or wool cones:

If yarn or wool cones are used as hook thread then these are t o be set on the as

optional equipment available thread unreeler 1 (Order no. 558 3001) underneath the

table.

–

Lead the thread through the thread guides under the table.

–

Lead the thread up through the thread tub e.

–

The threading of the machine a bove th e t able is conducted as described above.

1

29

Page 28

a

1

2

30

3

Page 29

2.6 Threading the Gimp

Caution Risk of Injury !

Pull the mains plug.

Thread the lower an d upper gimp onl y w i th the machine

turned off.

–

Place tube and wire gimp rolls on the gimp roll holder 1.

Place the gimp rolls with crosswinding vertically on the yarn plate 2 for an easy pull

off of the gimp or thread.

–

For stiff and difficult to bend lower gimps choose the short feed over the as

optional equi pment available gimp roll holder 3 (Order no. 557 1103).

Lower gimp threading

The threading of the lower gimp is conducted as shown in the lllustrations on pages 30,

32 and 33

in the alphabetical order of the letters

:

Sub-classes -211241, -221301, -231391 and -251301

–

Remove the clamp plates (see Chapter 2.1).

–

Thread the gimp from the gimp r ol l holder 1 or the yarn plate 2 th rough hole a in

the thread stand.

–

Lead the gimp in order through the gimp guide b and the gimp guide tubes c and d.

–

Thread the gimp through gimp guide e.

–

With sub-class

Through the draw spring the loosening gimp thread is held taut during

simultaneous turning movement of the hook bracket and ope rat i on of the gripper

knife.

–

Thread the gimp through the g i m p hole g of the needle pl ate.

Allow an approx. 25 mm long gimp en d to hang out of t he gimp hole.

4 = Hook thread (Page 32)

5 = Gimp thread (Page 32)

–

Replace the clamp plates again (see Chapter 2.1).

-221301

the gimp must also be threa ded through the draw spring f.

:

31

Page 30

b

c

45

d

e

f

g

32

Page 31

Sub-class -241291

This sub-class is equipped with gimp pulling device.

Before the start of sewing it pulls the gimp back to the correct starting length.

For correct positioning see the Service Instructions.

–

Remove the clamp plates (see Chapter 2.1).

–

Tur n the hand crank drehen until the hook bracket reaches the position shown.

The gimp pulling device 1 faces forward (to the seamstress).

–

Lead the gimp 2 from the lower gimp roll holder 4 through the side recess a in the

machine housing.

3 = Hook thread

–

Thread the gimp through the holes of the gimp pulling device 1.

For threading through the hole b press the brake flap 5 lying behind a little to the

back.

–

Thread the gimp 2 through the holes of the gimp guide c and gimp hole d of the

needle plate.

With the gimp pulling device in low position let an approx. 4 mm long gimp end look

out of the gimp hole of the needle plate.

–

Replace the clamp plates again (see Chapter 2.1).

:

1

4a

2 3

d

c

b

5

1

33

Page 32

a

b

c

34

d

f

e

Page 33

Upper gimp threading

The feed of the uppe r gimp is possible wit h a gimp guider p l aced in front of t he needle.

The threading of the upper gimp is conducted as shown in the illustrations alongside

the alphabetical order of the letters:

–

Thread the gimp from the gimp roll holder a through gimp guide b.

–

Lead the gimp through the gimp guide angle c and between the tension discs of

the gimp pre-tensioning d.

–

Thread the gimp through the g i m p guide e and the gimp gui der f.

The assembly for round and flat gimps is available under the Order no.: 578 5101.

in

35

Page 34

a

b

36

dih1g

ec f 2

Page 35

2.7 Threading of the Upper Thread (Needle Thread)

Caution Risk of Injury !

Pull the mains plug.

Thread the upper thread only with the machine turned off.

The threading of the upper thread is conducted as shown in the illustrations on pages

36 and 38

–

–

–

–

–

–

–

–

–

in the alphabetical order of the letters:

Bring the mac hi ne into its end position (see Chapter 2.3).

In the end p osition the ho ok bracket with the und erthread tension must face

forward (to the seamstress).

Close the clamps with the aid of the clamp operating lever and swing up the

combined finger-eye protection.

The needle bar and needle are accessable unhindered.

Place the thread spool on the thread stand and guide the thread through hole a.

Guide the thread in order through the thread guide b and under th read guide c.

Lead the thread between the tension discs d of the upper thread tension and over

guide pin e.

Guide the thread through the hole of the lever f and the thread lever g.

Lead the thread through the thread gripper h and thread guide i.

Guide the thread with the ai d of the threading wire from the accessor i es pack

through nee dl e bar k.

Lead the thread past behind the tension disc of the pre-ten sioning l and through

the eye of the needle.

Subsequent pulling of the upper thread by hand

The upper thread is trimmed after the last stitch automatically.

For subsequent pulling of the upper thread:

–

Operate the release lever 2 or push button 1 and subsequently pull the upper

thread by hand.

37

Page 36

k

l

38

Page 37

Threading by difficult to unreel thread rolls

To achieve an easy pull off of the upper and underthread from the thread plate:

–

Additionally g ui de the underthread th rough the holes 1 and 2.

–

Additionally guide the upper thread through hole 3

1 2

3

39

Page 38

1234

5 6 7

40

Page 39

2.8 Thread T ension

Upper thread ten sion

The upper thre ad tension on th e m achine arm must generally be set tighter than the

underthread tension.

It is set by turning the knurled nut 6.

Tension increase = turn to the right

Tension decrease = turn to the left

The upper thre ad tension is executed as a du al tension:

–

Remaining rest tension 1

It serves to tauten the upper thread during the cutting procedure under the

needle plate as well as to achieve the desi red length of upper thread en d.

The rest tension must, depending on the elasticity of the upper thread used, be

so set that upper thread end hanging out of the needle is long enough to assure

a secure sewing start.

The setting oc curs by turning the sleeve 2.

Longer thread end = turn to the left

Shorter thread end = turn to the right

ATTENTION !

Do not heighten the cutti ng effect of the upper thread knife

by further increasing the rest tension.

To heig hten the cutting effect shar pen the knife.

If the upper thread end rem ains too long then work must be conducted wi thout

tension rele ase. This can, for example, be the case with firm and hardly flexible

upper thread .

For the appropri ate settings see Service Instructi on 558.

–

Main tension 5

This should be appropriately corrected after changing the rest tension.

The thread gripper 3 remains closed in the end position.

During removal of the sewing pieces this avoids a subsequent pulling of the

upper thread out of the thre ad tension.

For the next sewing seque nce there is the n always an uniformly long star ting

thread available.

Subsequent pulling of the upper thread by hand

Open the thread gripper 3 by hand and subsequent l y pull the threa d.

For this either hold the button 4 down or swing t he release lever 7 down.

41

Page 40

1

4

2

5

6

3

42

Page 41

Underthread tension

The underthread tension is set by turni ng the knurled nut 3 on the hook bracket.

Tension increase = turn to the right

Tension decrease = turn to the left

Thread pull-on spring for the underthread

The thread pull-on spring 1 influences the pull-on of the underthread through its stopper

width and pre-tension and thus the form and beading of the buttonhole.

Setting the stopper width: Loosen screw 5 and turn the angle 4.

Setting the pre-tension: Loosen screw 6 and turn angle 2.

Gimps

The upper and lower gimp should be pulled easily an d uniformly from t he guide hole i n

the needle plate and the gimp guider.

For a faultless appearanc e of the buttonhole a braking or clam pi ng of the gimp on its

way to the sewing station is to be avoided.

43

Page 42

1

2

3

44

Page 43

2.9 Sewing

–

Place a work piece under the clamps and align precisely.

The alignment can be made with markings or the stops available as optional

equipment (see Chapter 1.5).

Caution Risk of Injury !

Keep hands out from under the lowering cloth clamps !

–

Pull the clamp operating lever 1 to the front until it touches.

The work piece i s fi xed by the c l am ps.

–

Turn on the motor with hand shift lever 3.

For this loosen the hand shift lever out of its catch by

and bring into position

–

Press start lever 2 down.

The machine, depending on se tting, automatically conducts the following wo rk

steps in order:

With the setting "cutting before sewing":

–

The cutting knife cuts the buttonhole slit.

–

The material support plate moves quickly wi th the clamped in work piec e so far

forward until the b eginning of the but tonhole slit is exactly under the needle.

–

At the same time the clamp plat es are drawn apart.

The buttonhole slit is opened a little.

–

The sewing unit is turned on and the buttonhole sewn.

–

After the left seam row is completed the needle stops outside the cloth.

–

The material support plate moves quickly to its end position, thereby opening the

clamps.

"I"

.

pulling up

on the ball head

With the setting "cutting after sewing":

–

The material support plate moves quickly wi th the clamped in work piec e so far

forward until the p osition where th e buttonhole is to s t art is exactly under the

needle.

–

At the same time the clamp plat es are drawn apart.

The cloth lies t aut for the sewing of th e buttonhole.

–

The sewing unit is turned on and the buttonhole sewn.

–

After the left seam row is completed the material support plate moves quickly in the

cutting position. The bu ttonhole slit is c ut.

–

The material support plate moves quickly to its end position, thereby opening the

clamps.

45

Page 44

1

2

3

4

56

46

Page 45

Caution Risk of Injury !

As long as the seamstress is not yet familiar with the

operation of t he machine sh e should tur n off the mot or with

the hand shift lever 3 or the pedal after sewing each

buttonhole.

Work procedure for the experienced seamstress

After a suitable learning period the closing of the clamp operating lever 1 and the

turning on and off of the motor with every buttonhole through the seamstress can be

eliminated.

Instead the experienced seamstress proceeds as follows:

–

Place the work piece exactly under the clamps by eye or with stops and hold the

cloth fixed in thi s position.

Caution Risk of Injury !

Keep hands out from under the lowering cloth clamps !

–

With the left i n dex finger press th e start l ever 2 down.

The machine cl oses the clamp s by itself and runs through al l described work

procedure automatically.

Taking out the finished work piece

–

If necessary a little subsequent pulling of the upper gimp and then trimming. The

work piece can be pushed further or removed.

–

For removal of work pieces with sub-classes -231391 and -251301 Guide the

underthread (hook t hread) and lower gimp under the th read gripper 5 .

Pull both threads from right to left along the knife 6.

The threads a re trimmed.

2.10 Blocking the Clamp Lif t

Normally, after the ending of the sewing process the clamps are automa t ically lifted

(opened).

If they should not be lifted, proceed as follows:

–

Push button 3 immediately and hold pressed until the machine shuts off.

47

Page 46

1

2

3

48

4

Page 47

2.11 Buttonhole length

Caution Risk of Injury !

Pull the mains plug.

Set the buttonhole length only with the machine turned off.

ATTENTION !

The changing of the buttonhole length requires a

simultaneous change of the cutting length and thus the

mounting of a different cutti ng block (see Chapter 2.12) !

Buttonholes without Taper Bar

By buttonholes without taper bar the buttonhole length is determined through the

position of the length setting slide 3:

–

Loosen clamp s crew 4.

–

Set the desired buttonhole length.

Longer buttonhole length = Pull the length setting slide 3 forward

Shorter buttonhole length = Push the length setting slide 3 to the rear

–

The scale 1 and m arking lines 2 s erve for setting a sp ecific buttonhole length.

–

Tighten clamp s cr ew 4 again.

ATTENTION !

Set only the through the sewing device (E no.) allowable

minimum and maximum buttonhole lengths.

Sub-classes -221301 and -241291:

With these sub-classes an exceeding of the maximum sewing length is prevented by a

stop.

With the setting of the length setting slide at max. sewing length the stop piece must lay

in at the guide slit at the front.

ATTENTION !

Scale plate, leng th setting slide and stop piece have been

correctly set at the factory.

They may not be altered.

49

Page 48

Example:

E407/L2

resp.

E2407/L2

1

Sewing len g th

Cutting length

Taper bar length

minimum

Sewing len g th

maximum

Sewing length

50

Sewing len g th

Page 49

Buttonholes with Taper Bar

By buttonholes with taper bar the different buttonhole lengths are achieved through

insertion of the appropriate lower disc cam 1.

It determi nes taper bar form and length.

For exchanging the lower di sc cam see Chapter 2.18.

The order numbe rs for the different lower disc cams can b e found on the device sheets

for the 558 and 578.

The shortening, lengthening or complete shutting off of the taper bars occurs as

described above through adjusting the length setting slide and mounting of the

correspondin g cutting block.

ATTENTION !

Do not set the taper bar length below the minimum or

beyond the maximum buttonhole length.

When setting the length of buttonholes with taper bar along with the cutting length the

taper bar length must also be added in.

Example: 18 mm cutting l ength + 4 mm tape r bar length = 22 m m sewing length

Special characteristic by sub-class 558-241291:

With this sub-class buttonhole length, cutting length and taper bar length can be

changed.

For this four different

L1 for cuttin g lengths of 14 - 20 mm

L2 for cuttin g lengths of 18 - 24 mm

L3 for cuttin g lengths of 22 - 28 mm

L4 for cuttin g lengths of 26 - 32 mm

cutting length packages

(L1...L4) can be requested:

Each cutting l ength package inc l udes:

–

3 lower disc cams an d cutting blocks for sewing buttonholes with 3 different cutting

lengths

–

a corresponding clamp plate set

The clamp plate sets are differentiated by differing lengths for cloth clamps and thread

scissors with operating element for the short trimming of thread.

In order to assure a secure gripping and short trimming of thread and gimp the

difference in the buttonhole lengths which can be sewn with one cutting length package

cannot exceed 2 mm .

Example:

578 E 2407/L2 (S ewin g device E2407 combine d with cutting le ngth package L2)

Allowable sewing lengths: minimum 24 mm

maximum 26 mm.

51

Page 50

1

2

3

4

5

6

52

7

8

Page 51

2.12 Cutting Length

The cutting length is determined by the length of the cutting block.

It can be altered by changing the cutting block.

The order numbers for the different cutting blocks are, taking into account the sewing

device used (E no.), to be found on the device sh eets for the 558 or 578.

Changing the cutting block

Caution Risk of Injury !

Pull the mains plug.

Change the cutting block and cutti ng knife only with t he

machine turned off.

Cutting block 3 and cutting knife 4 ar e designed so that two configurations are possible:

–

Configuratio n

–

Configuratio n

To change the cutting block:

–

Loosen screw 2 or 8 and remove the cutting block or cutting k ni fe entfernen.

–

Insert the new cutting block and cut ting knife and tight en screws 2 and 8 agai n.

Attention !

When inserting push the new cutting block to t he back until tou ching on the stop 5

or 7.

(on cutter bar 1)

top

bottom

(below the clamp plates on the anvil body 6)

ATTENTION !

Insert only the cutting blocks corresponding to each cutting

knife.

Cutting knife for "cutting before sewing " have a larger eye form than a cutting

knife for "cutting after sewing".

In order to avoid having two different knife impressions on one cutting block the

cutting block corresponding to the cutting knives mu st always be inserted.

Cutting knives wi t h two different kn i fe impressions cause buttonholes to not be

cleanly cut and must be trued again (see Chapter 2.13).

53

Page 52

12

21

54

3

4

Page 53

Mounting the cutting block at the top or bottom ?

The mounting of the cutting block 2 and the cutting knife 1 is dependent on the

sub-class with its sewing device (E no.) for cutting "before" or "after sewing":

A. Sewing device for "cutting before sewing":

–

Cutting block at bottom and cutting knife at top

–

The material is supported by the cutting block during the cutting procedure.

In this way an unwanted pressing down of the edges of the buttonhole slit by thick

material (as in configuration b) is avoided.

Attention !

With the cutting knife mounted at the top the waste pipe 3

for collection of cutting waste must be mounted on the

cutter bar 4.

B. Sewing device for "cutting after sewing":

–

Cutting block at the top and cutting knife below

–

The sewn buttonhole seam glides down the slim sides of the cutting knife without

resistance during the cutting procedure.

In this way an unwanted deformation through pressure exerted on the buttonhole

seam (as with configuration a) is avoided.

C. Sewing device for "cutting before and after sewing":

–

Cutting block at the top and cutting knife below

–

Exception:

With the set ting "cutting before sewing" and at t he same time p rocessing of th ick

material the reverse configuration (cutting block at the b ottom and cutting knife

above) is to be chos en.

In this way an unwanted pressing down of the edges of the buttonhole slit (as with

configuration b) is avoided.

ATTENTION !

For the change-over from "cutting before sewing" to

"cutting after sewing" it is essential to obderve Chapter

2.19.

55

Page 54

56

12 3

Page 55

2.13 Cutting Blocks

Caution Risk of Injury !

Pull the mains plug.

Remove the cutting block only with the machine tur ned off.

A trueing (filing) of the cutting block becomes necessary,

–

when the cutting block has been too strongly cut into by the cutting knife.

–

when two different cutting knife forms have worked on the cutting block (Illus. 2).

When trueing the cutting block care is to be taken:

–

The cutting block must be so filed that the impression of the knife blade is to

be seen everywhere very fine and exactly uniform

ATTENTION !

The trueing of the cutting block must be conducted very

precisely.

Use only flawless, straight bastard files !

–

The height of the cutting blocks may only be reduced by a

through filing.

–

To achieve a uniform distribution of the cutting pressure the cutting block must hit

parallel onto the cutting knife (see sketch).

One-sided cu tting pressure, particul arly in the area of the eye, can cause the

cutting knife to break off.

Illustration 1 shows a correctly filed, illustration 3 a badly filed cutting block.

–

After true i n g one cutting blo ck, a l l other cutti ng block used must also be reworked

to the

same height dimension

work continue with the sam e cutting pressure. Otherwise there is a d anger of

breaking the cutting knife by a change of the cutting block !

. Only in this way can, after a cutting block change,

( Illus. 1).

maximum 1.5 mm

Malfunctions during cutting

After a longer period of operation the sharpness of the cutting knife is reduced. The

blade is blunt and the knife no longer c uts precisely in spite of a cor rectly trued cutting

block.

–

Send the knife to one of the

DÜRKOPP ADLER AG

for r e working .

57

Page 56

2.14 Cutting Pressure

The cutting pressure is set with screw 1:

Increase cutting pressure = turn to the right

Decrease cutting pressure = turn to the left

1

After each adjustment of screw 1 the cutting pressure must be checked.

Checking the cutting pressure

–

Turn the machine with the hand crank.

The cutting pressure may only be set so high that the hand crank can be turned at

the moment o f cutting without exerting t oo much energy !

ATTENTION !

Excessive cutting pressure leads to unnecessary wear of

the cutting tools !

–

If even with this setting of the cutting pressure the cloth can still not be cleanly cut:

True the cutting block or check the sharpness of the knife blade (see Chapter 2.13).

58

Page 57

2.15 Spreading of the Material

1

2

Caution Risk of Injury !

Pull the mains plug.

Set the spreading only with the machine turned off.

At the setting

start of the material support plate . The material is draw n t aut.

At the setting

cutting. The buttonhole slit is ope ned a little. The stitching needle can cle an l y sew both

seam rows without stitching into the cut edge of the material.

Normally a spreading of

–

Remove the clamp plates (see Chapter 2.1).

–

Loosen screws 1 an d 3 and move the stops 2 and 4.

Increase spreading = move the stops inward

Decrease spreading = move the stops outward

"cutting after sewing"

"cutting before sewing"

1.5 mm is sufficient

the clamp plates are drawn apart after the run

the clamp plates are drawn apart only after the

.

3

4

ATTENTION !

So that both seam rows are equally wi de the left an d right

stops must be m o ved equal distances.

–

Tighten screws 1 and 3 again.

–

With unequal seam widths correct the spreading accordingly

59

Page 58

A

A

B

1

2

3

60

B

4

Page 59

2.16 Stitch Density

Caution Risk of Injury !

Pull the mains plug.

Set the stitch density only with the machine turned off.

For the whole buttonhole length

The stitch density is adjustable between 0.9 and 2 mm.

It is determined by the required strength and the appearance of the buttonhole, as well

as the thread s i ze us ed.

–

Loosen screw 2.

–

Move the transport lever 1.

Movement in direction A = stitches become denser

Movement in direction B = stitche are farther apart

–

Tighten screw 2 again.

In the eye of the buttonhole

This setting has no influence on the stitch density in both seam rows.

Stitch density in the buttonhole eye to be

–

Loosen screw 4.

–

Move the stitch length regulator rail 5 in the direction of the arrow.

–

Tighten screw 4 again.

Stitch density in the buttonhole eye to be

–

Loosen screw 4.

–

Replace the old stitch length regulator rail 5 with the stitch length regulator rail 3

found in the accessories pack.

–

Tighten screw 4 again.

3

smaller

greater

:

:

5

61

Page 60

B

1

2

A

3

62

Seam width

Cutting area

Buttonhole width

Page 61

2.17 Seam Width (Buttonhole Width)

Caution Risk of Injury !

Pull the mains plug.

Set the seam w i dth only with the machine turned off.

At the setting "cutting after sewing" the buttonhole width is arrived at as follows:

Buttonhole width = Cutting area + 2 x seam width

Setting the seam width

–

Loosen the win g nut 2.

–

Move the connecting rod 3.

Movement in direction A = wider seam

Movement in direction B = narrower seam

–

Tighten the wing nut 2 again.

Setting for sewing with gimp thread

–

Select the seam width so that the gimp thread is not pierced by the needle tip but

rather just still overcast.

Smallest and greatest allowable seam width

The smallest and greatest allowable s eam width for the s ewin g device used (E no.) is

determin ed by the limit plate attached wi t h screw 1.

ATTENTION !

Do not loosen screw 1 under any circumstances.

There is a

clamps, hook, spreader and n eedle plate !

Should the ma chine be converted to another sewing device (E no.) umgerüstet werden,

then the allowable butto nhole widths for it ar e to be found in the table in Chapter 1.4.

The conversion is to b e m ade per the Service Inst ructions.

danger of breakage

for the needle, cloth

63

Page 62

1

2

3

4

64

Page 63

2.18 Buttonhole Form

The buttonhole form i s determined by the two exchangeable disc cams 1 and 2:

–

The upper disc cam 1 determines the eye form.

–

The lower disc cam 2 determines, by taper bar buttonholes, the taper bar form and

buttonhole length.

Disc cams, cutti ng blocks and cutting knife for the different buttonhole forms and

buttonhole lengths are to be found in the device sheet for the 558 and 578.

Exchanging the disc cams

–

Bring the machine into the end position (see Chapter 2.3).

In the end position the roll er bolt 4 is held in position by the underly i ng cam plate 3.

The disc cams can be removed unhinder ed.

–

Remove and exchange the disc cams.

After the exchange of the disc cams it is essenti al that the following points be

checked:

1. Are the corresponding cutting knife and the appropriately long cutting block

mounted ?

If necessary exchange the cutting knife and cutting block (see Chapter 2.12)

2. Is the correct buttonhole length set as per Chapter 2.11 ?

If necessary set the correct buttonhole length at the length setting slide (see

Chapter 2.11).

3. During t he exchange of the k ni ves was the corresponding cutting block als o

mounted ?

ATTENTION !

When changing to a different cutting knife form

it is essential to also install the corresponding cutting

block !

When using the wrong cutting block two differing cutting knife impressions appear in it.

This leads to a bad cutting of the buttonhole slit. In this case true the cutting block again

(see Chapter 2.13).

65

Page 64

66

1

2

Page 65

2.19 Change-over to Cutting Before or After Sewing

Caution Risk of Injury !

Pull the mains plug.

Conduct the change-over to "cutt ing before" or "cutting

after sewing" only with the machine turned off vornehmen.

The change-over from "cutting before" to "cutting after sewing" is only possible with

sub-classes wi t h the appropriate sewing device (E no.) (see Device Table in Chapter

1.4).

All machine elements which must be adjusted are marked by the following bi-lingual

sticker with the following meaning:

Adjustment in direction of arrow = cutting before sewing

Adjustment in direction of arrow = cutting after sewing

Note:

CA and CB are the English language abbreviations.

CA = Cut after CB = Cut before

Change-over to "cutting before" or "cutting after sewing"

The settings for c utting before and cutting afte r sewing are each li m i ted by two stops.

ATTENTION !

The stops have been se t.

They may not be altered !

1. Timing of the cut

–

Loosen screw 2.

–

Slide the turn-off bolt 1 in the appropriate arrow direction.

Press the high-speed wheel inward for easier setting of the turn-off bolt.

–

Tighten screw 2 again.

67

Page 66

12 34

68

5

6

Page 67

2. Timing of the closing and opening of the clamps

–

Tilt the machine head up.

–

Loosen screw 2.

–

Push the clamp closing lever 1 in the appropriate arrow direction up to the stop.

–

Tighten screw 2 again.

3. With or without cutting room between the seam rows

–

Loosen screws 5.

–

Slide the lever 4 in the appropriate arrow direction up or down up to the st op.

Attention !

The amount th at the lever has to be moved is ver y s m al l .

–

Tighten screws 5 agai n.

4. Cutting knife and cutting block

–

Slide the cutting knife 4 in the appropriate arr ow di rection up to the stop.

The configurati on of the cutt i ng at the top or below occurs hereby as per the

instructions in Chapter 2.12.

–

Insert the cutting block 3 corresponding to the cutting knife used and slide to the

back up to the stop (see Chapter 2. 12).

ATTENTION !

Only mount the cutting block corresponding the cutting

knife used !

When using the wrong cutting block two different cutting knife impress i ons are

made.

This leads to a bad cut of the buttonhole slit.

5. Exchanging the upper disc cam

–

Bring the machine in its end position bringen (see Chapter 2.3).

In end posit ion the roller bolt is held in i t s position by the underlying cam plate.

The upper disc c am can be removed unhind ered.

–

Remove and exchange the upper disc cam.

(see Chapter 2.19)

69

Page 68

3. Maintenance

1

Caution Risk of Injury !

Pull the mains plug.

Maintain the machine only when it is turned off.

3.1 Cleaning

A clean machine protects against malfunctions !

Daily cleaning:

Clean the area under the clamp plates, particularly around the hook bracket 1, of

sewing dust, thread rests and cutting refuse.

ATTENTION !

It is to be avoided that cutting refuse enters into the

housing of the main disc cam at the back. If a vacuum is

available this is recommended.

–

Take off the clamp plates (see Chapter 2.1) and remove cutting waste.

–

Tilt up the machine head and r em ove cut t i ng waste from the base.

70

Page 69

3.2 Lubrication

12

For lubrication of the machine only

SP-NK 10 is available at the

Check the oil level in the oil reservoirs

–

The lubrication of all moving parts the machine on the machine arm and hook

bracket is through a central oil wick lubrication ou t of the oil reservoirs 1 and 2.

If necessary fill oil through the filling plug up to the "max." marking.

Weekly lubrication of the buttonhole machine

–

The marked positions on the material support plate and the control curve housings

are to be given a few drop of oil weekly.

The positions are shown in the pictures on the following page.

ESSO SP-NK 1 0

DÜRKOPP ADLER AG

lubricating oil is to be used.

sales offices.

71

Page 70

3.3 Oiling Positions

*

*

*

*

*

*

*

*

*

*

72

*

Page 71

*

*

*

*

*

*

*

*

*

73

*

*

*

*

Page 72

*

*

74

*

*

*

*

*

Page 73

*

*

75

Page 74

4. Malfunction Remedies

Malfunction Remedy

1. Machine does not start or

runs unevenly.

a) V-belt from the motor to the

high-speed wheel or to the

handwheel is too loose.

b) Machine is in front of the

cutting position at the time of

starting.

2. Clamp closing lever cannot

be closed or opened

Material support plate is not i n

the end positi on.

3. Cloth clamp pressure is

too high or too low.

4. Buttonhole is not cleanly

cut open.

a) Cutting block has been cut into

too deeply by the knife.

b) Knife blade is blunt or broken.

c) Exit opening in the knife is

blocked by cloth waste.

d) Cutting pressure is not

correctly set.

e) The cutting block

correspondin g to the cutting

knife is not mount ed.

.

Tension V-belt as per Installation Instructions for

the 558.

With the main witch turned off and the needle high

bring the machine into its end position with the

hand crank.

Reduce cutting pressure as per Chapter 2.14.

With the hand crank bring the material support

plate into the end pos i ti on. W i t h a re peat of this

malfunction have a specialist reset the turn-off

timing (see Service Instructions for the 558).

When changin g over to cutting before or cutting

after sewing always slide the turn-off bolt up to the

stop.

Reset the cloth clamp pressure (see Chapter

2.17).

Tr ue the cutting block (see Chapter 2.13) and

reset the cutting pressure (see Chapter 2.14).

Insert a new knife or send the old knife to one of

the

reworking.

Remove the knife and clea n t he exit opening in

the knife and knife holder or cutter bar.

Reset the cutting pressure (see Chapter 2.14).

Always mount the cutting block corresponding to

the cutting k ni fe us ed !

DÜRKOPP ADLER AG

business offices for

76

Page 75

Malfunction Remedy

5. Unequal stitch lengths or

stitch positions.

a) V-belt is too loose.

b) Gimp is too taut, jams or does

not pass easily through the

gimp hole of the needle plate .

6. Missing stitches

a) Needle is blunt, bent or not

correctly inserted.

b) Upper or underthread is

not correctly threaded.

c) Thread tension is set

too taut.

d) Thread unwinds badly from

the thread rolls.

e) Hook or spreader have

become misadjusted.

f) Material is not held or spread

correctly.

7. Loose stitches.

a) Thread tensions are not set

correctly.

b) Upper or underthread is not

threaded correctly.

8. Thread breakage.

a) Upper or underthread is not

threaded correctly.

b) Needle is incorrectly inserted,

bent or sharp-edged.

c) Thread used is u ns ui table

(knotted, hard or too thick).

d) Thread tensions are set too

taut.

e) Needle plate, hook or

spreader are damaged.

Tension V-belt as per Installation Inst ructions for

the 558.

Use thinner gim p or insert a needle pla t e with

larger gimp hole.

For stiff and inflexible gimps use gimp roller holder

on the table (Order no. 557 1103).

Insert a new, flawless needle (see Chapter 2.4).

Check the threading path of the upper or

undert hread (see Chap ter 2.5 and 2.7).

Reset thread tension (see Chapter 2.8).

See Chapter 2.7.

Readjustmen t only through a specialist !

Check the spread i ng of the material (see Chapter

2.17) and pressure of the upper cloth clamps.

Reset thread tensions (see Chapter 2.8).

Check the threading path of the upper or

undert hread (see Chap ter 2.5 and 2.7).

Check the threading path of the upper or

undert hread (see Chap ter 2.5 and 2.7).

Insert a new, flawless needle (see Chapter 2.4).

Use a different thread. See recommendations in

Chapter 2.6 .

Reset thread tensions. (see Chapter 2.8)

Replace damag ed parts through new ones or

have reworked by a specialist.

77

Page 76

Malfunction Remedy

9. Needle breakage.

a) Needle thickness is unsuitable

for the material or the thread.

b) Needle is hitting the c l ot h

clamps.

10. No clean seam beginning or

unthreading of the upper

.

thread

a) Rest tension for the upper

thread is set too taut. Start

thread for the next sewing

beginning is t hus too short.

b) Thread gripper on the upper

thread tension does not

clamp the upper thread in

the machine end position.

Use a needle thickness as per Chapter 2.6 or as

per sewing device ( E no.).

The max. buttonhole width li s ted in the table on

page 8 for each sewi ng device (E no.) may not be

exceeded. Resetting by service personnel as per

Service Instructions for the 558.

Reset the rest tension fo r the upper thread (see

Chapter 2.8).

Reset the thread gripper a s per Service

Instructions for the 558.

78

Page 77

5. Optional Equipment

Electromagneticall y Operated Upper Thread Catcher

5.1 General

The sub-class 55 8-221301 has the the electro-m agnetically operated upper th read

catcher as standard equipment.

All other sub-classes can, on request, be outfitted with it at the factory or have it

retrofitted.

Function

The electroma gnetically operated upper thread catcher grabs the upper thread

immediately after the thread cutting procedure and hold it clamped. When sewing the

next buttonhole it places it in th e right seam.

The means:

Secure seam beginning even in light, loose weaves.

•

Beginning sti tches drawn fast.

•

Trimming of the underside of the buttonhole is unnecessary because the starting

•

thread is overcast .

Parts set required for the retrofitting

Retrofitti ng attachmen t : Order no. 558 10002

Factory attachment: Order no. 558 10012

ATTENTION !

By equipment wi th the upper t hread catcher in the indivi dual sub-classes the following

points are to be observed:

558-231391 The maximum sewing length wi th thread catc her function is 3 2 m m .

For sewing lengths above 32 mm the upper thread catche r must be

deactivated (see chapter 2.2).

558-251301 The max. sewing length with thread catcher function is 42 mm.

For sewing lengths above 42 mm the thread catcher must be deactivated.

79

Page 78

80

b3

12

3

4

5

Page 79

5.2 Electrical Connection

ATTENTION

All work on the electrical components of the upper thread

catcher may only be conducted by electricians or

appropriately trained personnel. The mains plug must be

pulled.

The transformer in the controls of the upper thread catchers is equipped with

connections for foll owi ng mains voltages:

1 ~ 200 V

1 ~ 220 V

1 ~ 380 V

1 ~ 415 V

At the factory

–

With other mains voltages change the connection on the primary side of the

transformer accordingly before commissioning.

the transformer is connected to 1 ~ 380 V.

5.3 Function Sequence

–

After the machine is turned on the switching piece mounted on the material

support plate operates switch b3.

Thread catcher 1 lowers with the c l am ped upper thre ad 2 to the mate rial.

–

Appropriate to the set butt onhole length the sewing dr i ve turns on and begins with

the right seam.

The upper thread end placed by the thread catcher is thereby overcast and sewn in.

–

Shortly before reaching the buttonhole eye switch b3 falls off of the switching piece.

Thread catcher 1 moves back into its upper position.

–

During sewing of the buttonhole eye the u pper toothed segment 5 with stopper

angle 4 leaves its extreme right position.

The slewably bearinged thread catcher changes from the inse rtion to the catch

position, e.g. from the right to the left buttonhole seam.

–

After finishing the left buttonhole seam the sewing drive turns off in the needle high

position.

The upper thread is trimmed.

(Continuation see the following page)

81

Page 80

6

b2

7

82

8

Page 81

–

The cam 6 connected with the length setting slide operates the switch b2. The

thread catcher lowers.

Through the sl i de of the opene r lever 8 ont o the opener 7 the thread cat cher is

opened.

Via the curve plate 3 it is swung in f ront of the needle to grip the upper thread .

–

During further lowering the opener lever 8 falls off the opener 7.

The thread catcher closes.

–

After cam 6 has run over the switch b2 the thread catcher with the clamped thread

moves back into the upper position.

Opener lever 8 thereby slides past

opener 7 without being operated.

behind

83

Page 82

b4

1

84

b1

b5

Page 83

5.4 T urn-on Interlocks

Switch b4

With the cloth clamps opened the machine c an only be turned on in it s end position. For

this cams 1 op erates the switch b4 .

Switch b1

In all other m achine positions with the cloth clamps opened a turni ng on and thus also

the thread catcher function are blocked by switch b1.

The safety switch b1 is bypa ssed by the activated switch b4.

The machine, with

Example:

The sewing sequen ce is interrupted with th e hand shift lever.

During the subsequent release of the cloth clamps switch b1 opens.

The switch interlock in the thread catcher controls switches the motor off.

To restart:

–

Pull the turn-off lever forward (see chapter 2.2).

–

Tur n the handwheel until it ca tches.

The needle is in its highest position.

–

Remove material.

–

Close the cloth clamps.

–

Bring the hand shift lever into position

–

Tur n on the motor by operating the push button b5.

The machine moves back into its end position.

opened cloth clamps,

can only be started in i t s end position.

.

"I"

Deactivating the upper thread catcher

By pulling the plug from the electromagnet the upper thread catcher is deactivated.

ATTENTION !

Do not block the thread catcher by pulling the plug from the

thread catcher controls. The power supply for the sewing

drive is interrupted otherwi s e.

85

Page 84

3

1

4

2

5

86

10

11

6

7

12

13

8

14

9

15

Page 85

5.5 Setting

Caution Risk of Injury !

Pull the mains plug.

Make setting only with the machine turn ed off.

5.5.1 Lift of the Electroma gnet

The lift of the electromagnet should be 20 mm.

Measured is the di stance between t he upper edge of the protecti ve sleeve 4 and t he

upper edge of the anchor 3 in both positions (ON and OFF). The difference must be

20 mm.

–

Loosen lock nut 6.

–

Screw anchor 3 further i n or out.

–

Tighten lock nut 6 again.

5.5.2 Base Position of the Upper Thread Catcher s

The forward edge 5 of the magnet must be in line with the face 2 of the machine arm.

–

Loosen screws 1 an d 12.

–

Align the magnet.

–

Tighten screws 1 and 12 again.

Opener lever 13 and guide piece 11 must lie parallel to one another.

–

Loosen clamp s crew 9.

–

Tur n the opener l ever 13 wi th thread cat cher 10 and set parallel to the guide piece

11.

–

Tighten clamp s cr ew 9 again.

So that the thread catcher 10 can close securely there must be a little play between the

lower part 14 of the opener lever and the movable leg 15.

–

Bring the machine into the end position (see chapter 2.2.3).

–

Screw out the stop screw 7 so far that during retreat of the opener lever before

operation of the movable leg 15 a clearance of approx. 0.3 mm is still felt between

bracket 8 and stop screw 7.

87

Page 86

2

3

1

45 6

7

88

89

Page 87

5.5.3 Lowering Movement

Opener setting

After the closi ng of the thread gripper 1 the opener lever 3 must move past be hi nd the

opener 2 unhindered.

Thread gripper 1 must thereby remain closed.

–

Check the unhindered movement of the op ener lever 1.

–

If necessary, set opener 2 accordingly with screw 9.

Insertion position

When sewing the right buttonhol e seam and simul t aneous manual operation of the

magnet the ins erted upper thread en d s hould be overcast.

–

Set the insertion position accordingly with setting screw 8.

Thread catcher height

The clearance between

This setting applies for medium-weight material. With thicker or thinner materials a

correction m ay be necessary.

–

Loosen screws 6 an d 7.

–

Set the thread catcher height.

–

Tighten screws 6 and 7 again.

–

Check the insertion position again and correct, if necessary.

lowered thread gripper

and material should be 3 - 4 mm.

Opener

The clearance between the back of the opener 2 and the opener lever 3 must be about

0.5 mm.

–

Set the distance accordingly by turning the setting screw 8.

Slewing movement

Shortly before reaching its lowest position wird thread gripper 1, through the curve plate

5, is swung close in front of the needle.

In this posit i on the distance between thread gripper 1 and needle must be about 3 mm .

–

Loosen screws 4.

–

Set the curve plate 5 higher or lower.

–

Tighten screws 4 agai n.

89

Page 88

12 3

45 6

7

89

90

Page 89

5.5.4 Gripping Movement

Bringing the thread gripper in gripping position

After sewing the l eft buttonhole seam the thre ad gripper 3 mu st be set in the precise

gripping posi tion for the upper thread.

–

Tur n the handwheel until the sewi ng sequence for the left buttonho le seam is

completed a nd the handwh eel catches.

–