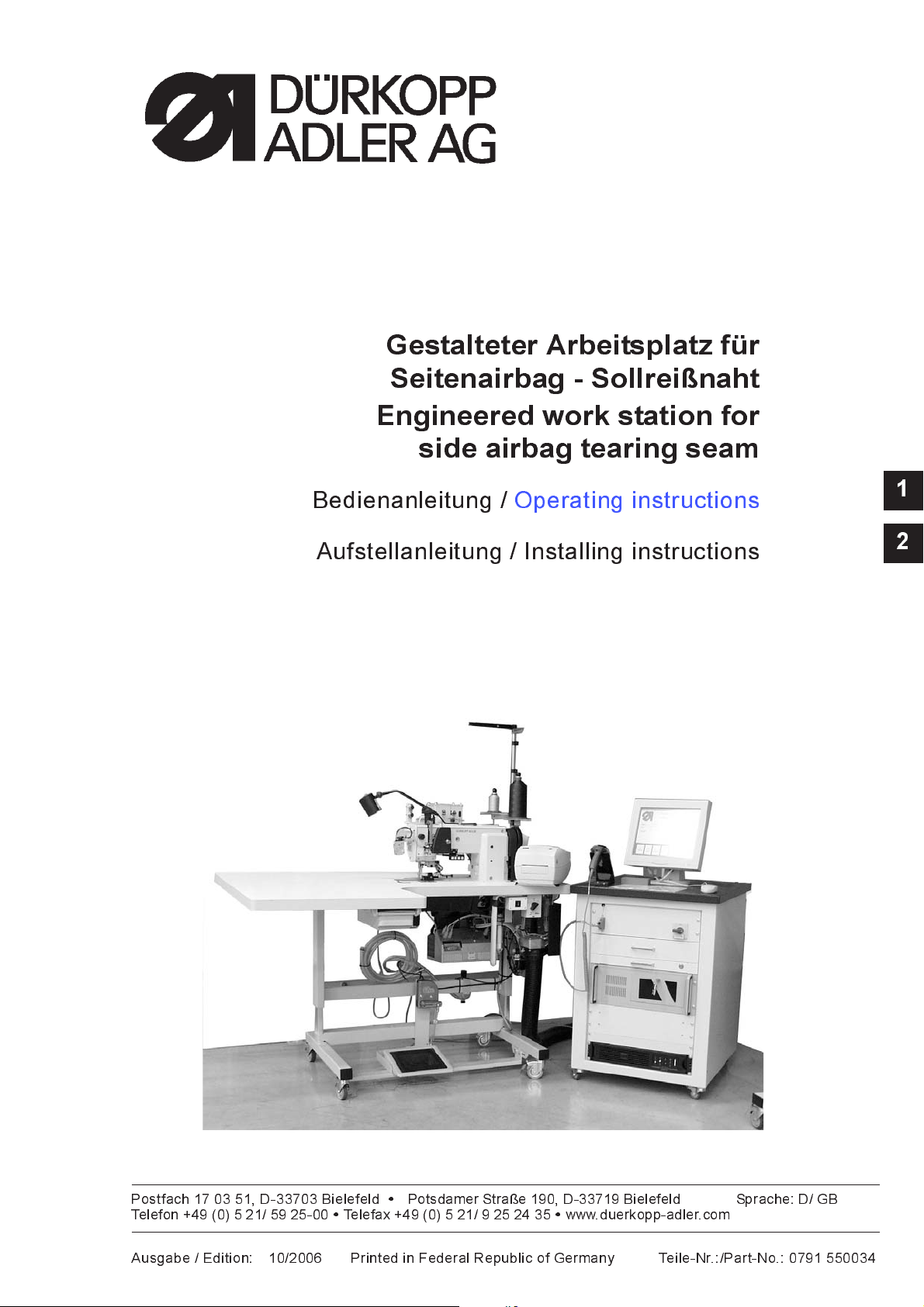

550-767

Gestalteter Arbeitsplatz für

Seitenairbag - Sollreißnaht

Engineered work station for

side airbag tearing seam

Bedienanleitung / Operating instructions

Aufstellanleitung / Installing instructions

Postfach 17 03 51, D-33703 BielefeldPotsdamer Straße 190, D-33719 Bielefeld Sprache: D/ GB

Telefon + 49 (0) 5 21/ 59 25- 00Telefax+49(0)521/9252435www.duerkopp-adler.com

Ausgabe / Edition: 10/2006 Printed in Federal Republic of Germany Teile-Nr.:/Part-No.: 0791 550034

Übersicht Summary

Bedienanleitung

Aufstellanleitung

Serviceanleitung (0791 767651)

Bauschaltplan

9890 550004 B

Operating Instructions

Installation Instructions

Service Instructions (0791 767651)

Interconnection-diagram

9890 550004 B

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruc ti o n m an ual contains i m po rt a nt i nf orm ation on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruc ti o n m an ual must alway s be available at the

machine/sewing unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, i ncl u di n g e qu i pp i ng , t r ou bl e s ho ot i ng du r ing the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair and/or

– Transport.

The user also has to assure that only authorized personnel work on

the machine.

The user is o bl i g ed to c he ck th e m ac h i ne at l ea s t o nc e pe r shi f t f or

apparent da ma ge s and to immedia tl y r e po r t a ny c h an ge s ( inc l u di n g

the performanc e i n se r vi c e), wh i c h im pa i r th e sa fe ty.

The user comp an y mu s t e ns u re that the machi n e i s o nl y o pe r at ed i n

perfect working order.

Never remove or disable any safety devices.

If safety dev i c e s ne ed to be removed for equi pp i ng , r e pa i ri ng or

maintaining, the safety devices must be

remounted directly after completion of the maintenance and repair

work.

Unauthorized modification of the machine rules out liability of the

manufacture r fo r da ma ge res u l ti n g f r om th i s .

Observe all safety and danger recommendations on the machine/unit!

The yellow -and-black str i pe d surfaces desig na t e pe rma ne nd danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

instruction book and operated by persons with appropriate

training.

2. Before putting into service also read the safety rules and

instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of

the machine without the safety devices is not permitted. Observe

all the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot,

needle plate, feed dog and bobbin) when threading, when the

workplace is left, and during service work, the machine must be

disconnected from the mains by switching off the master switch or

disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance

unit.

Exceptions to this are only adjustments and functions checks

made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time

as the entire sewing unit is found to comply with EC directives.

It is absolutely necessary to respect

the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Contents Page:

Preface and general safety instructions

Part 1: Operating Instructions, Class 550-767

1. Items delivered

2- Designated use

3. Equipment

3.1 Basic equipment .............................................. 6

3.2 Additional equipment ........................................... 6

4. Technical data

5. Operation

5.1 Threading the needle thread ....................................... 8

5.2 Adjusting the needle thread tension .................................. 10

5.3 Opening the needle-thread tension ................................... 11

5.4 Winding on the hook thread ....................................... 12

5.5 Threading the bobbin thread ....................................... 13

5.6 Adjusting the bobbin thread tension .................................. 13

5.7 Replacing the needle ........................................... 14

5.8 Liftingandlockingthesewingfeet ................................... 15

5.9 Adjustingthesewing-footstroke..................................... 16

5.10 Sewing-footpressure ........................................... 16

5.11 Adjusting the stitch length ........................................ 17

5.12 Buttonsonsewingarm .......................................... 17

5.13 RFW 13–3 bobbin thread monitor .................................... 18

5.14 HP 13–10 electro-pneumatic rapid stroke adjustment ........................ 20

.............................................. 5

.............................................. 5

............................................... 7

1

6. Operating the rupture-seam visualisation facility

6.1 Accesstothesystem ........................................... 21

6.2 Seam-typefunction ............................................ 25

6.2.1 Createanewseamtype ......................................... 25

6.2.2 Editseamtype ............................................... 30

6.2.3 Copyseamtype .............................................. 31

6.2.4 Deleteseamtype.............................................. 32

6.3 Databank function ............................................. 33

6.4 Checkfunction............................................... 35

6.5 Needle-thread tension tolerance range ................................. 48

6.6 Error codes ................................................. 50

6.7 Setting the end-label barcodes ..................................... 51

6.8 Setting the end-label layouts ....................................... 54

6.9 Adjustingbarcodedefinitions ...................................... 55

7. Sewing

7.1 Label scanner (optional) ......................................... 62

8. Maintenance

8.1 Cleaning ................................................... 63

8.2 Oiling..................................................... 64

1. Product description

The DÜRKOPP ADLER class 550-767 is an engineered sewing station

with the following features:

flat-bed double-lockstitch sewing machine with underfeed, needle

·

feed and alternating-foot overfeed.

single-needle machine with thread cutter under the throat plate.

·

apparatus slide in the base plate for the rapid change of different

·

apparatus.

2. Designated use

maximum clearance of

·

stroke of alternating sewing feet adjustable to a

·

maximum of

automatic, unpressurised oil-recirculating lubrication with sight

·

glasses for oil level and circulation inspection

, shuttle lubrication integral to the circulation.

large two-piece vertical shuttle with bobbin-housing lift.

·

safety coupling to avoid displacing or damaging the shuttle if the

·

thread gets jammed in the shuttle track.

The class

for sewing light to medium-heavy material. Such material is generally

made of textile fibres, but it may also be leather. It is used in the

clothing industry and for domestic and motor-vehicle upholstery.

This sewing machine can also be used to produce so-called technical

seams. In this case, however, the operator must assess the possible

dangers which may arise (with which

happy to assist), since such applications are on the one hand relatively

unusual and, on the other, they are so varied that no single set of

criteria can cover them all. The outcome of this assessment may

require appropriate safety measures to be taken.

Generally only dry material may be s ewn with this sewing unit. The

material may be no thicker than

lowered sewing feet. The material may not contain any hard objects,

since if it does the machine may not be operated without an

eye-protection device. No such device is currently available.

The seam is generally produced with textile-fibre sewing thread of up

to gauge 11/3 NeB (cotton), 11/3 Nm (synthetic) or 11/4 Nm (covered

yarn). Before using any other thread the possible dangers arising must

be assessed and appropriate safety measures taken if necessary.

This sewing unit may be set up and operated only in dry,

well-maintained premises. If the sewing machine is used in other

premises which are not dry and well-maintained it may be necessary to

take further precautions (which should be agreed in advance

– see EN 60204-31: 1999 ).

As manufacturers of industrial sewing machines we proceed on the

assumption that personnel who work on our products will have

received training at least sufficient to acquaint them with all normal

operations and with any hazards which these may involve.

7mm

550767

machine is an engineered sewing station designed

16 mm

by programming function.

under the sewing feet when raised.

DÜRKOPP ADLER AG

10 mm

when compressed by the

would be

1

5

3. Equipment

3.1 Basic equipment

3.2 Additional equipment

The class

equipment:

RAP 13-2

HP 13-10

RFW 13-3

798 500088

907 487519

9822 510001

The following additional equipment can be supplied for the ?class

550-767

0467 367959

0767 590129

0767 100134

0767 490214

0767 490224

9800 330010

550767

Electro-pneumatic bar tack and sewing-foot lift,

foot-operated.

Electro-pneumatic rapid stroke adjustment by

knee switch (switch and touch operation) to maximum

stroke height with simultaneous stitch-rate limit.

Automatic infinitely-variable stitch-rate limit as a

function of the stroke height set.

residual-thread monitor

Sewing light transformer

Mounting kit for sewing light

Sewing lamp (halogen)

sewing unit:

pneumatic needle-cooling unit NK 13-1

Uninterruptible power supply 230 V/1000 A

DS 2200-1100 5 V barcode scanner for end-label

recognition

DS 2200-1100 5 V barcode scanner for

shuttle thread recognition

DS 2200-1100 5 V barcode scanner for

needle thread recognition

Operating panel EFKA V820

sewing unit is supplied with the following basic

$

4. Technical data

Stitch type: 301 / double lockstitch

Number of needles: 1

Needle system: 134-35

Needle size

Thread thicknesses

: 110-170 Nm

- Cotton: 12/3 NeB

- Synthetic sewing thread: 11/3 Nm?

- Covering thread: 11/3 Nm

Bobbin capacity

with synthetic sewing thread

- 30/3 max. 35 m

- 11/3 max. 12 m

Stitch rate

- equipment with HP: max. 3500 min-1

- on delivery: 3200 min-1

Stitch length

:0-9mm

Stroke height of sewing feet: max. 7 mm

(on delivery): 6 mm

Clearance under sewing feet

- Sewing: 7 mm

- Raised: 16 mm

Handwheel groove (average diameter): 80 mm

Operating pressure: 6 bar

Air consumption: approx. 0.7 Nl per working cycle

Nominal voltage: 1~ 190-240 V, 50/60 Hz

Input power: 1 kVA

Dimensions (including PC table): 2100 x 1150 x 1500 mm

Working height : 685-1085 mm

(to upper edge of table plate)

Weight (head only): approx. 60 kg

1

Workplace-related emission value to DIN 45635-48-A-1-KL2:

Lc = 83 dB (A)

Stitch length: 5.0 mm, sewing-foot stroke: 1.6 mm, stitch rate: 2 500 min

material G1 DIN 23328 4-ply

Lc = 80 dB (A)

Stitch length: 7.2 mm, sewing-foot stroke: 5.6 mm, stitch rate: 1.500 min

material 2-ply Skai 1.6 mm 900 g/m2 DIN 53352

accordingtoENo.

depends on stitch length and stroke height of the sewing feet

-1

-1

7

5. Operation

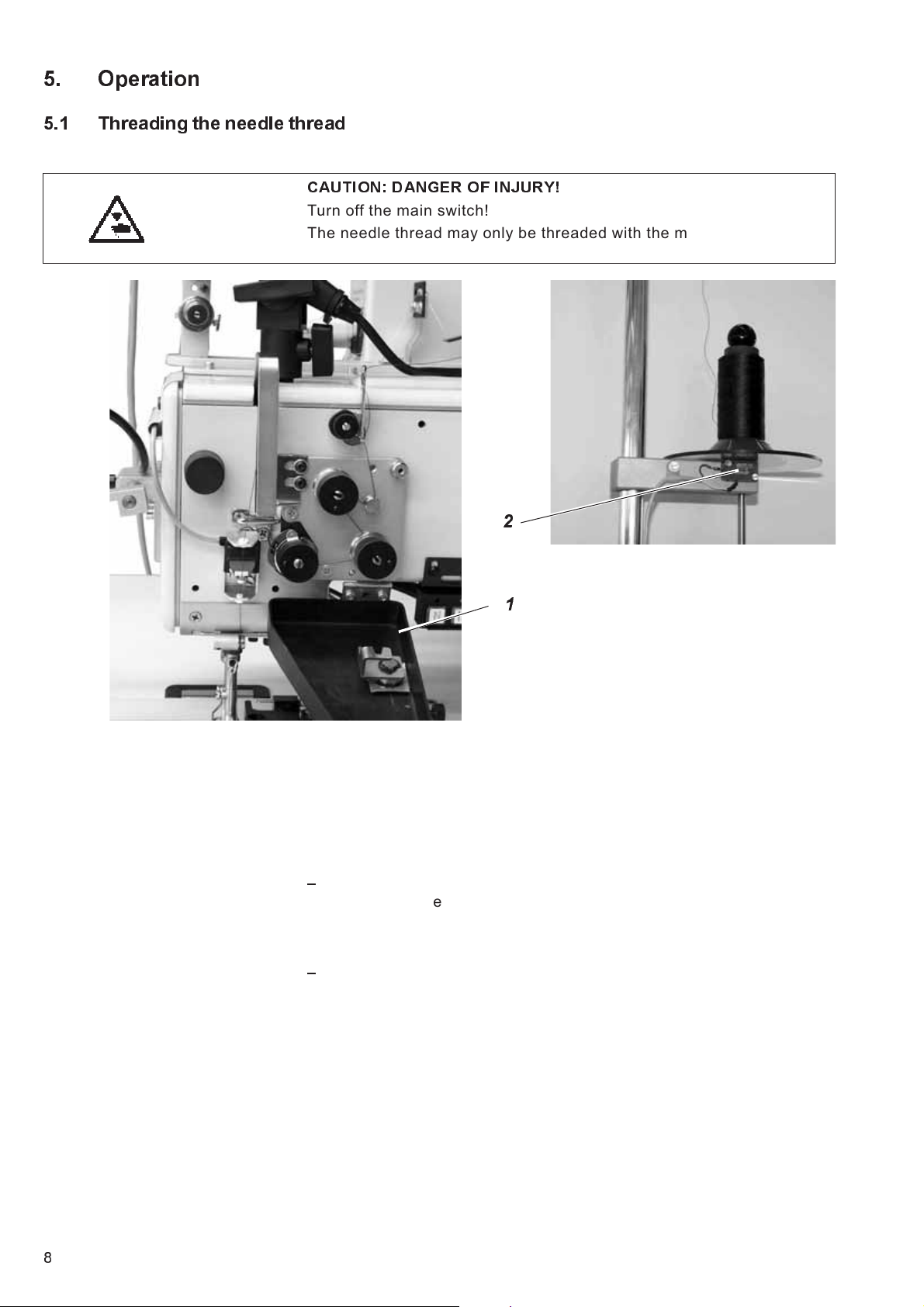

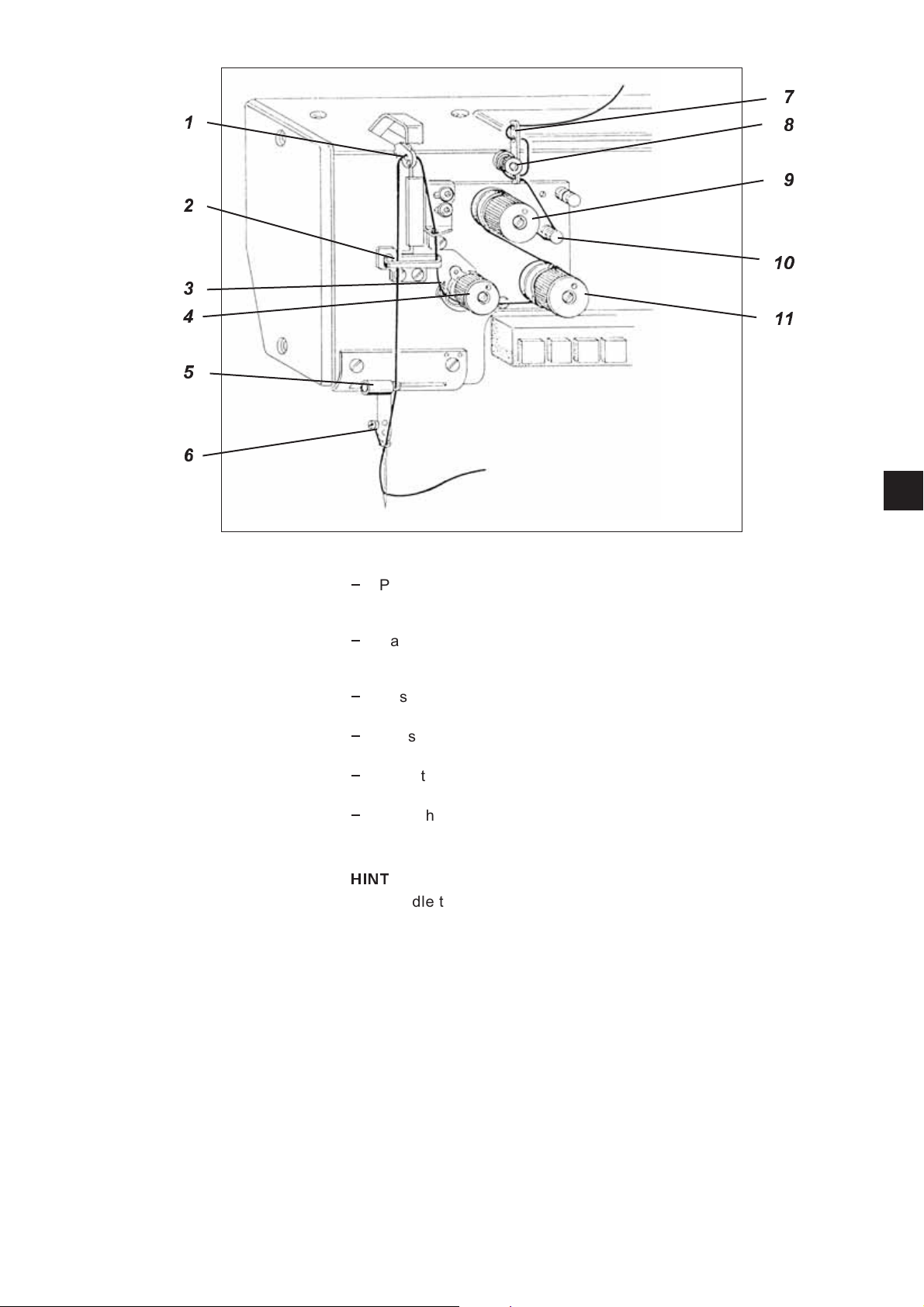

5.1 Threading the needle thread

CAUTION: DANGER OF INJURY!

Turn off the main switch!

The needle thread may only be threaded with the machine turned off.

Versions with switch 2:

Before placing the needle-thread cones on the stand they must be

scanned by the manual scanner. If a needle-thread bobbin is removed,

this is recognised by the control via switch 2 and the scanning process

is to be repeated.

Version with optional thread-barcode scanner:

`

Place the thread bobbin on the stand while ensuring that the

barcode of the thread bobbin can be read by the optional

thread-barcode scanner.

If the barcode is not recognised by the scanner, an error message

will be displayed on the monitor.

`

Open and fold back cover 1.

&

%

&

'

!

"

#

$

1

`

Pass the thread through guide 7 and anti-clockwise around

prethread-tensioning spring-tensioner 8. Pass the thread through

guide 7 again.

`

Pass the thread around guide 10 and then anti-clockwise around

the main tensioner 9. Pass the thread clockwise around main

tensioner 11.

`

Pass the thread clockwise around the thread tensioning unit 4, past

the check spring 3 and through the guide 2.

`

Pass the thread through take up lever 1 and through guides 2, 5

and 6.

`

Pass the thread through the needle; pull out several centimetres of

thread and cut.

`

Pass the needle thread through the needle from the right, pull out a

few centimetres of thread and cut.

HINT

The needle thread can be threaded without opening cover 1 by tying

the new needle thread to the residual needle thread and pulling it

through the thread tensioner.

9

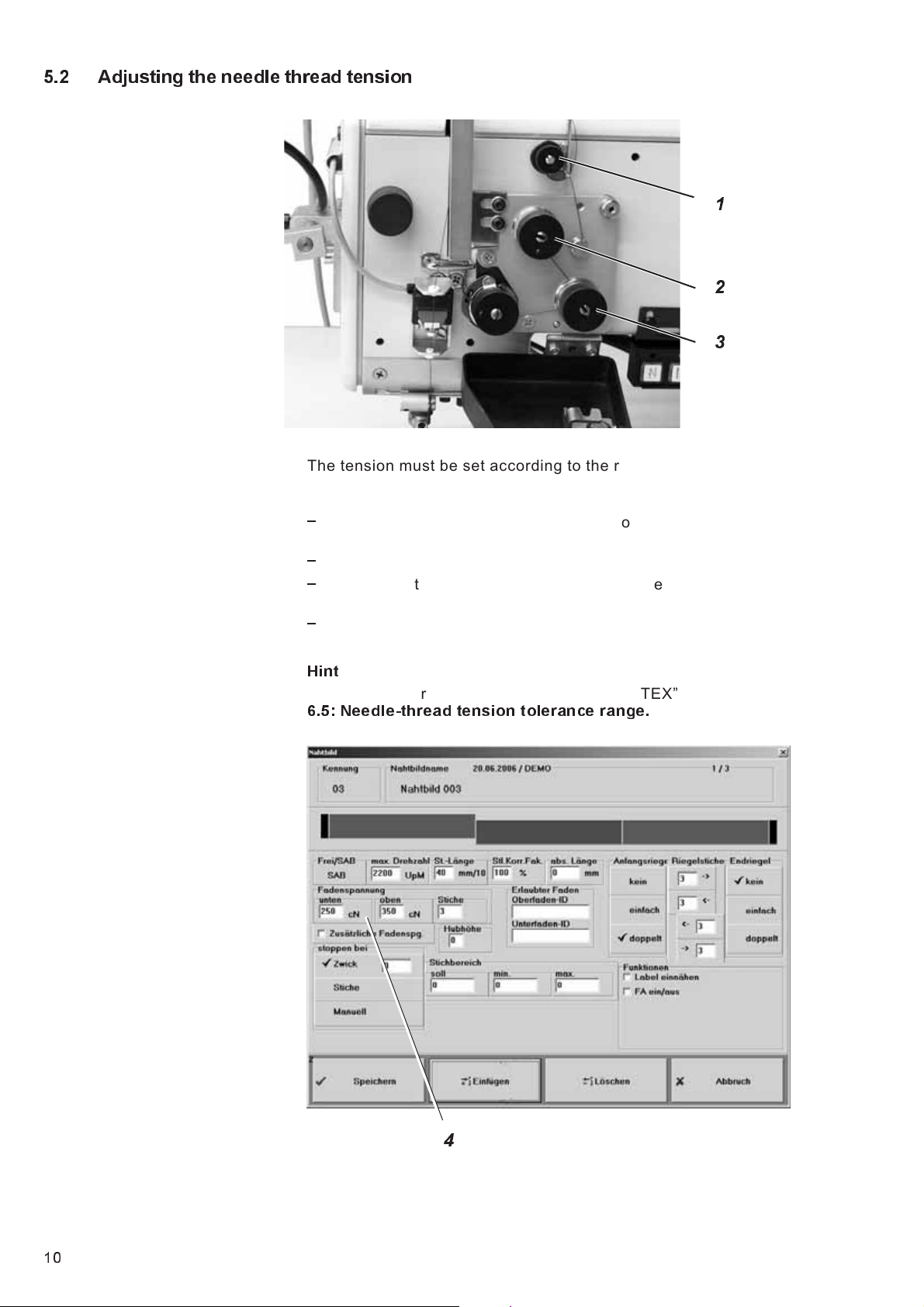

5.2 Adjusting the needle thread tension

The tension must be set according to the requirements of the

manufacturer of seat-covers. The cross-over point should be in the

centre of the material.

`

Adjust the pre-tension 1. The pre-tensioning should be set lower

than at the main tensioners 2 and 3.

`

Adjust the main tension 2 and 3.

`

Adjust the tolerance range 4 (window) for seam monitoring via the

Touch Screen Monitor.

`

0 = monitoring deactivated.

!

Hint

The required thread tension is s et via the “ELTEX” menu. See section

6.5: Needle-thread tension tolerance range.

"

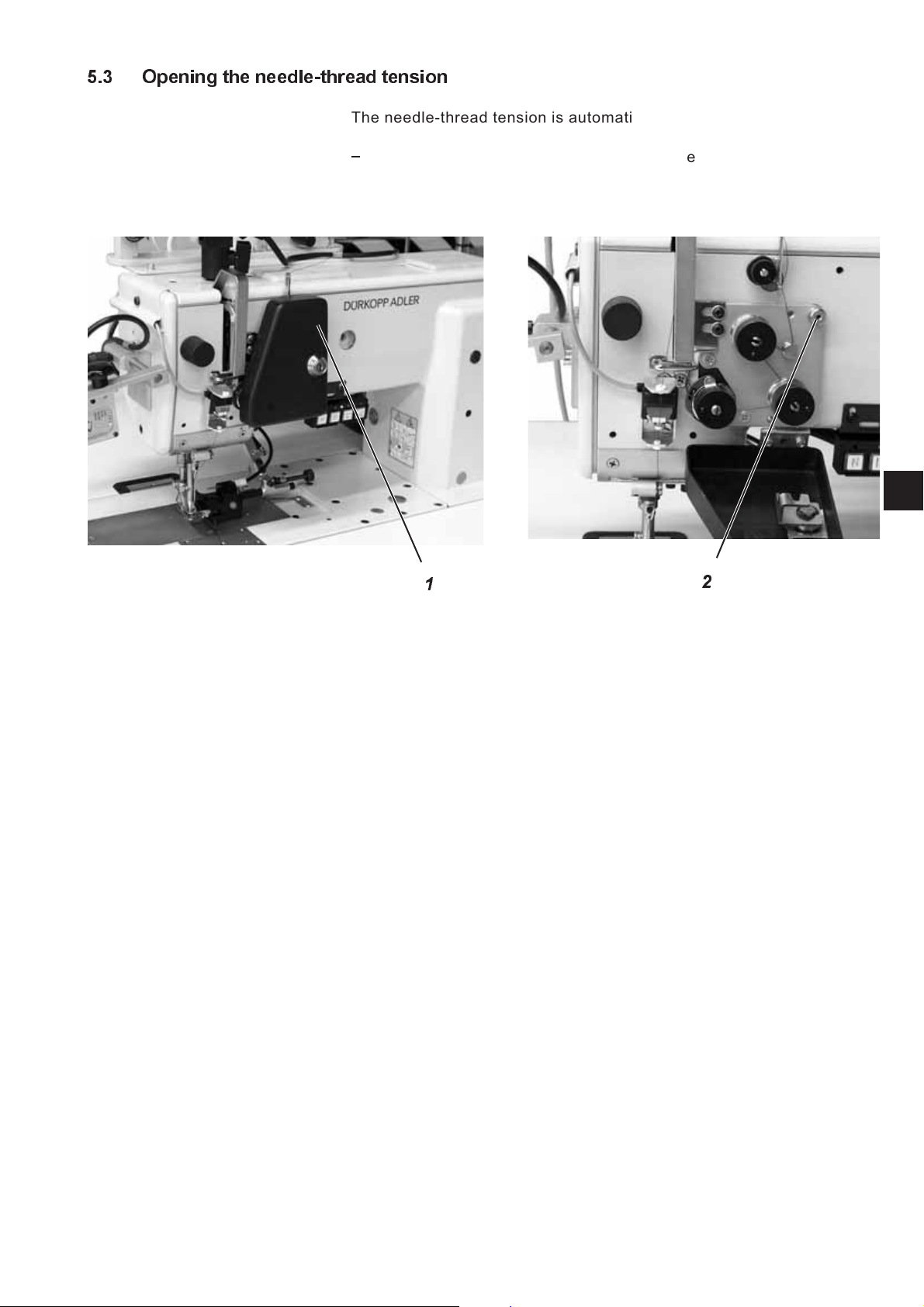

5.3 Opening the needle-thread tension

The needle-thread tension is automatically opened when the thread is

cut.

`

Press button 2 manually or press down the upper right-hand corner

of cover 1. The needle-thread tension remains opened for as long

as the button or cover is held down.

1

11

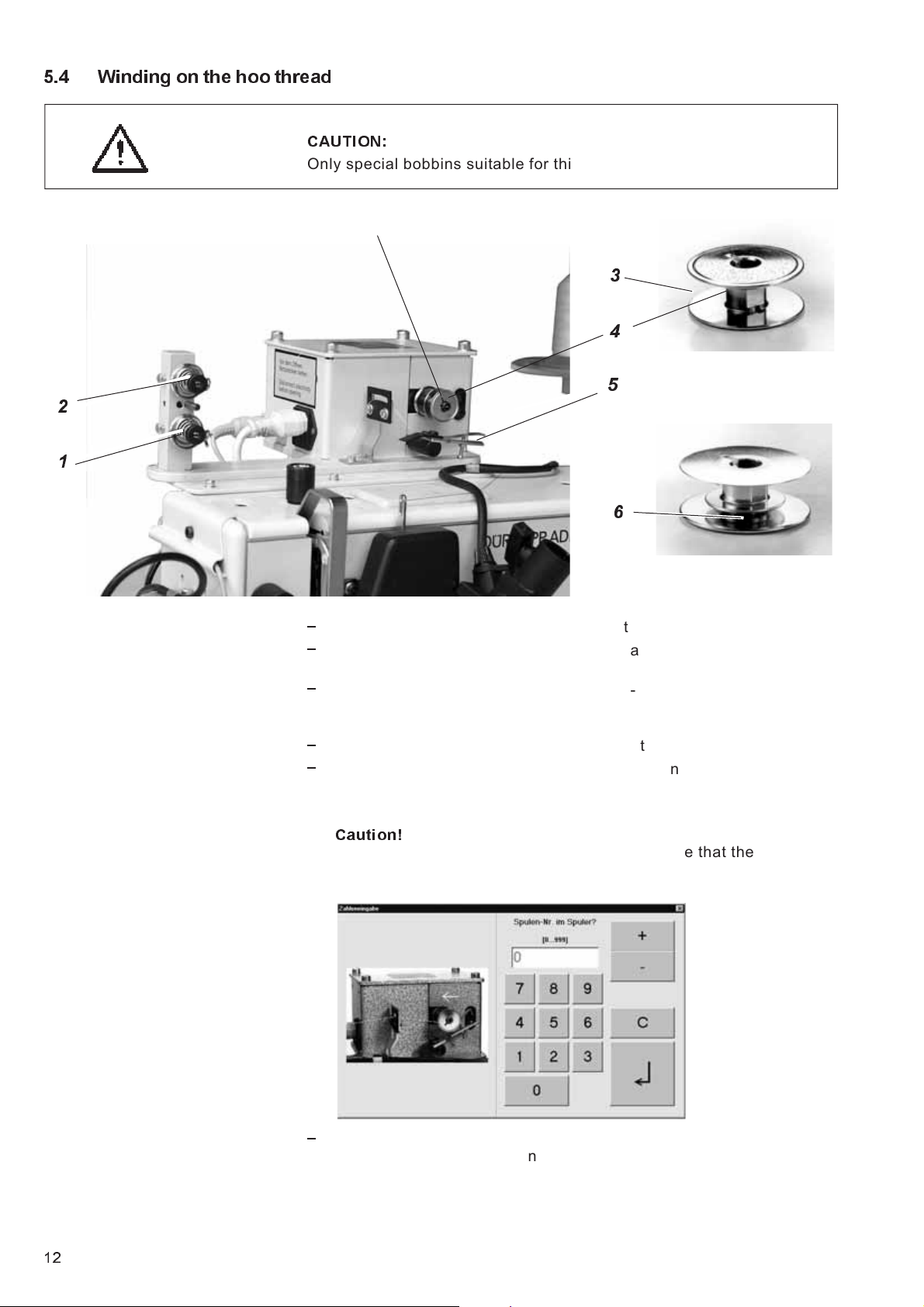

5.4 Winding on the hoo thread

CAUTION:

Only special bobbins suitable for this type of machine may be used!

The matt side of the bobbin

!

"

#

$

`

Place the needle-thread cone onto the thread stand.

`

Pass the needle thread through the thread guide on the take-up

arm and through pre-tensions 1 and 2 as shown in the illustration.

`

Carefully wind a few turns of thread anti-clockwise onto the reserve

groove 6 of the bobbin by hand and place the bobbin on the thread

stand with the ring 3 and the matt surface towards the operator.

`

Swivel the bobbin-winder lever 5 against the empty bobbin.

`

Enter the bobbin number via the Touch Screen Monitor.

When the bobbin is full, winding is automatically stopped by the

bobbin-winder lever 5.

Caution!

Before you press the ENTER key, please ensure that the number

entered does in fact correspond to the number engraved on the

bobbin.

`

Adjust pre-tensions 1 and 2.?

The thread should be wound on at as low a tension as possible.

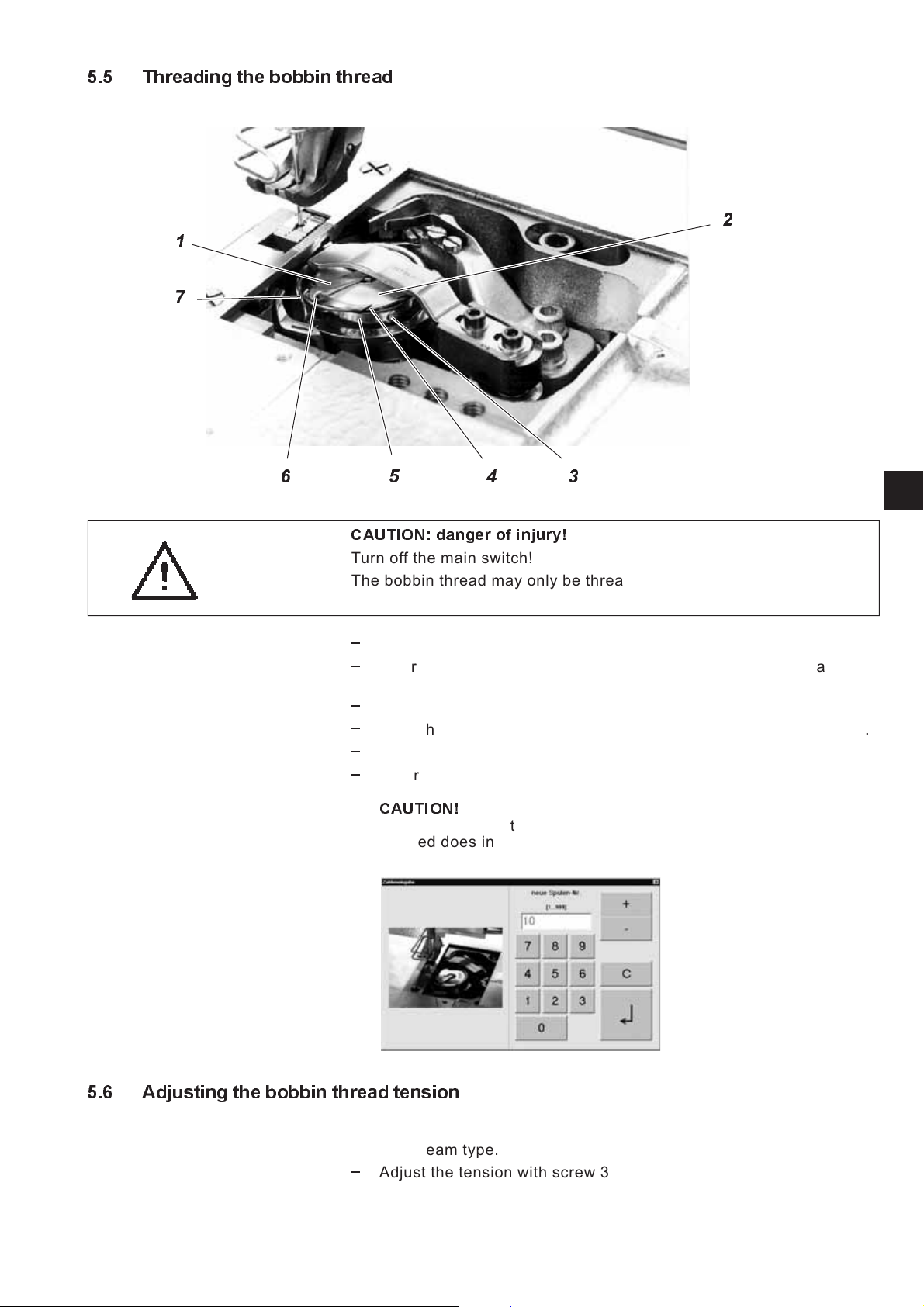

5.5 Threading the bobbin thread

%

$#"!

1

CAUTION: danger of injury!

Turn off the main switch!

The bobbin thread may only be threaded when the sewing machine is

switched off.

`

Raise flap 1 and remove the empty bobbin using a magnet.

`

Insert bobbin 2 so that it turns anti-clockwise when the thread is

drawn off.

`

Pass the thread through slit 4 and pull beneath spring 5.

`

Pass the thread through slit 6 and pull out approx. 3 cm of thread.

`

Close flap 1 and pull the thread through the guide 6 of flap 1.

`

Enter the bobbin number engraved on the bobbin 7.

CAUTION!

Before you press the ENTER key, please ensure that the number

entered does in fact correspond to the number engraved on the

bobbin.

5.6 Adjusting the bobbin thread tension

The bobbin thread tension must be adjusted in accordance with the

required seam type.

`

Adjust the tension with screw 3.

13

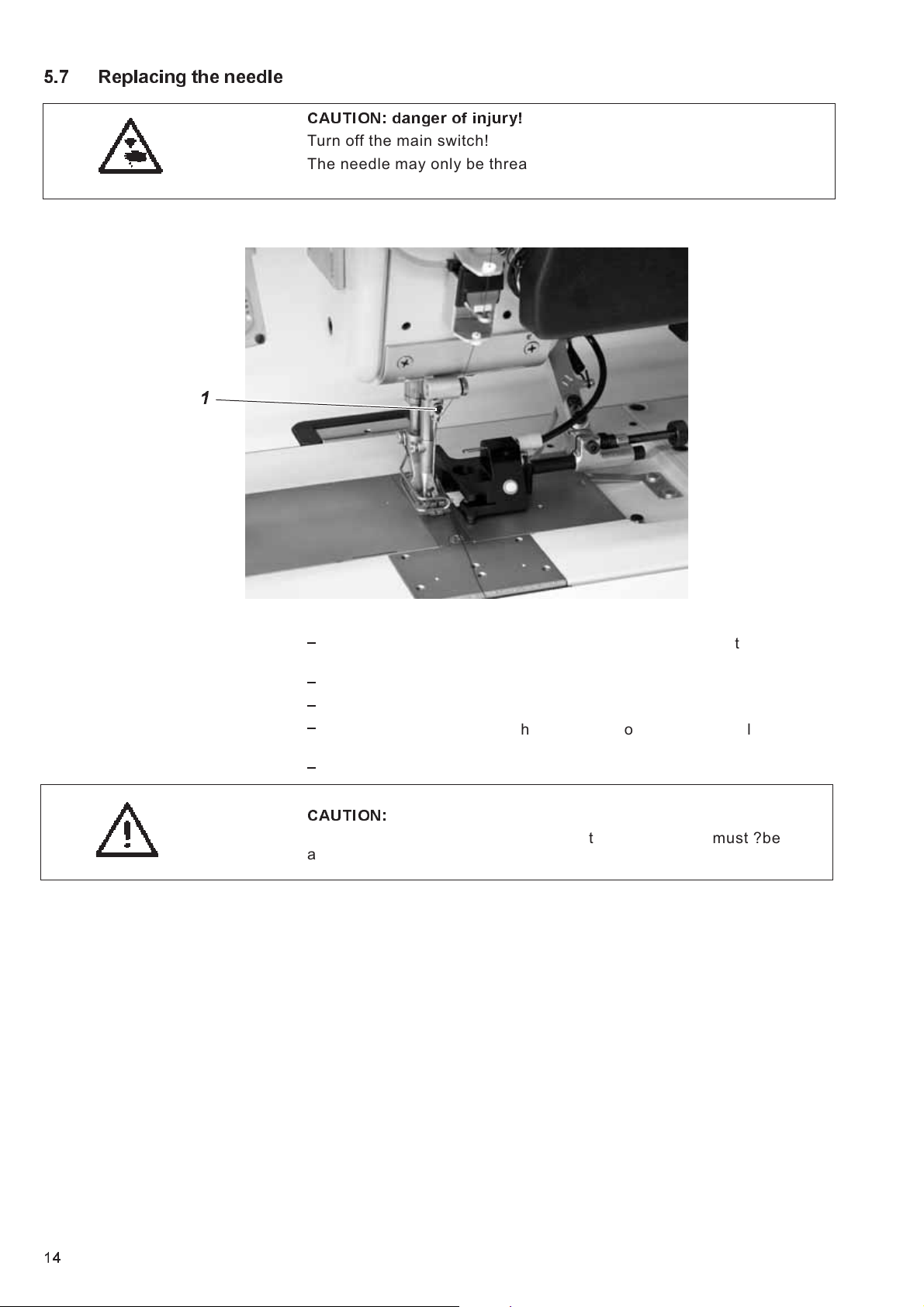

5.7 Replacing the needle

CAUTION: danger of injury!

Turn off the main switch!

The needle may only be threaded and replaced when the sewing

machine is switched off.

`

Turn the handwheel until the needle bar has reached its top dead

centre.

`

Undo screw 1.

`

Remove needle.

`

Insert the new needle with its channel towards the shuttle and push

it up as far as it will go.

`

Tighten screw 1.

CAUTION:

If a needle of a different thickness is fitted the settings must ?be

altered as specified in the servicing instructions.

A thinner needle may cause faulty stitches or damage to the thread.

A thicker needle may damage the hook point itself.

"

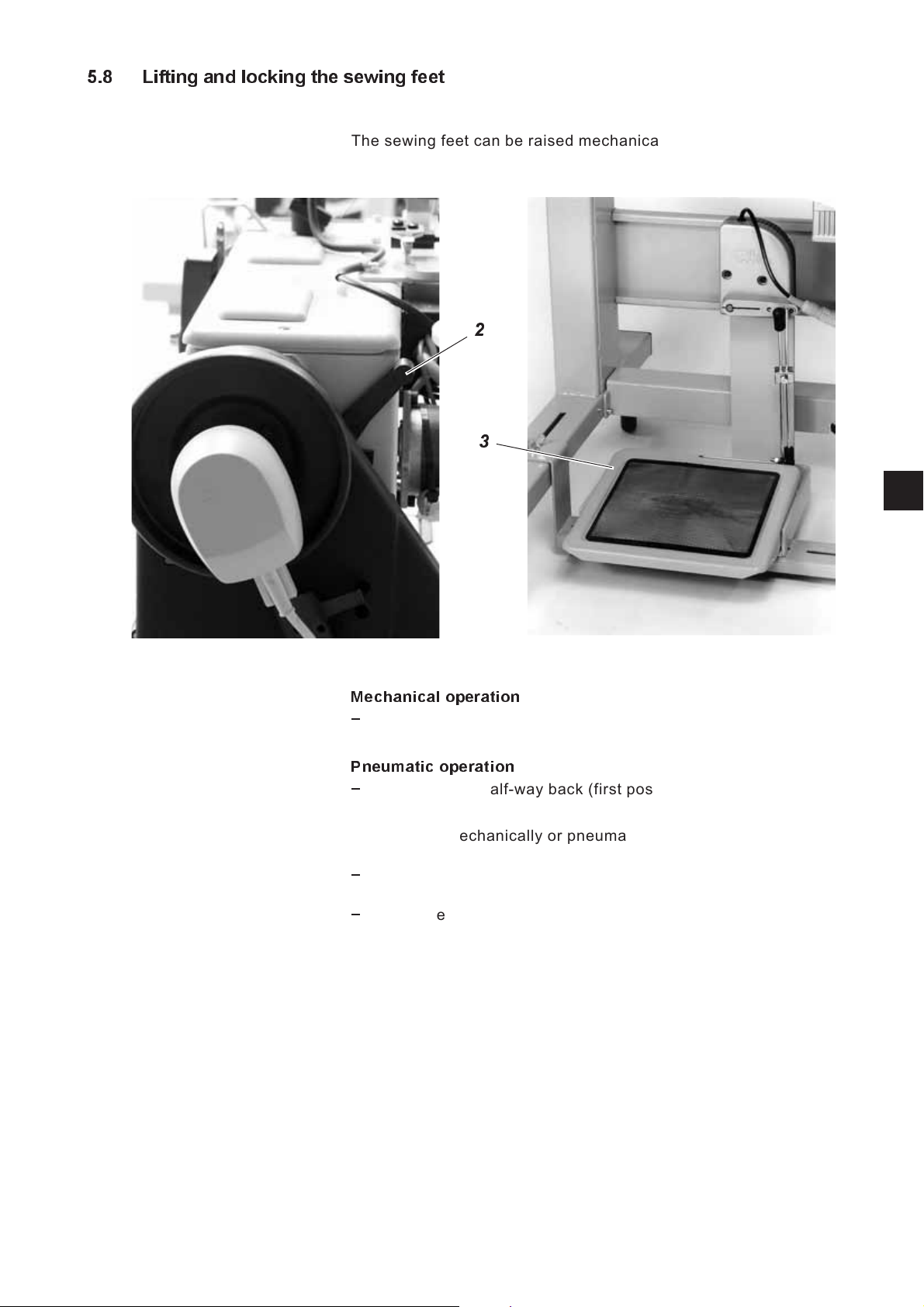

5.8 Lifting and locking the sewing feet

The sewing feet can be raised mechanically or pneumatically.

!

1

Mechanical operation

`

Swivel lever 2 downwards.

Pneumatic operation

`

Push pedal 3 half-way back (first position back).

Once raised mechanically or pneumatically, the sewing feet can be

secured in raised position using lever 2.

`

Swivel lever 2 downwards.

The sewing feet are secured in the raised position.

`

Swivel lever 2 downwards.

The sewing feet are released.

15

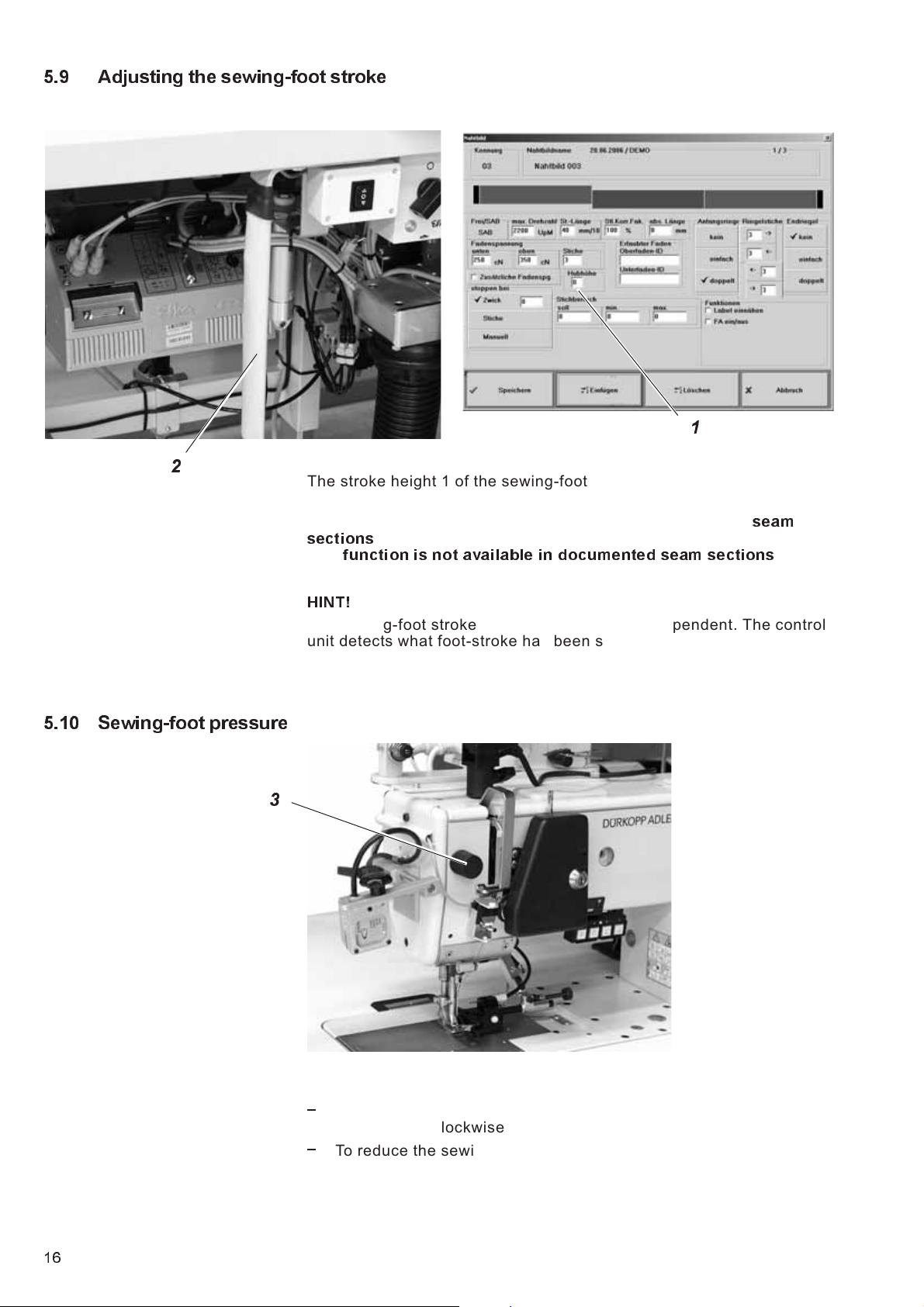

5.9 Adjusting the sewing-foot stroke

5.10 Sewing-foot pressure

!

The stroke height 1 of the sewing-foot can be adjusted via the Touch

Screen Monitor in the “seam types” menu in four steps (0, 1, 2, 3).

The maximum stroke can be activated during s ewing in free

sections

This

HINT!

The sewing-foot stroke and stitch rate are interdependent. The control

unit detects what foot-stroke has been set by means of a potentiometer

and restricts the stitch rate accordingly. The values are pre-set in the

control unit.

with the knee switch 2.

function is not available in documented seam sections

seam

.

$

The required sewing-foot pressure is set using rotary knob 3.

`

To increase the sewing-foot pressure

:turnknob3clockwise

`

To reduce the sewing-foot pressure

:turnknob3clockwise

HINT!

The sewing-foot pressure can only be altered when knob 3

(clamping block) is released: see the Servicing instructions.

5.11 Adjusting the stitch length

The stitch length is adjusted in the ”Seam types” menu on the Touch

Screen Monitor.

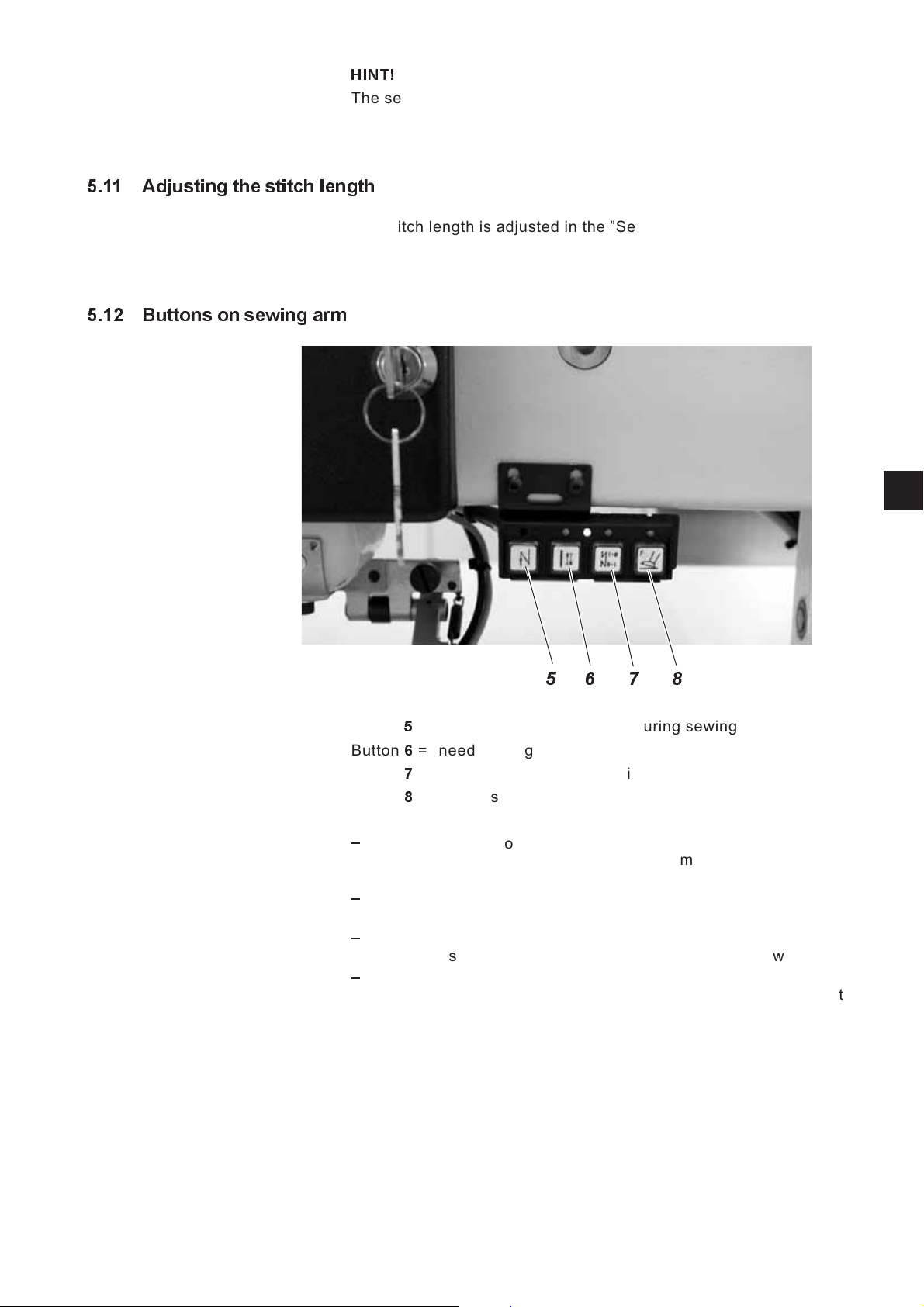

5.12 Buttons on sewing arm

1

#$ % &

Button5= intermediate lock-stitches during sewing

Button

Button

Button

`

`

`

`

6

= needle in high or low position

7

= suppresses starting or finishing lock-stitches

8

= authorises thread-cutting in the monitored r egion

Press and hold down button 5.

An intermediate lock-stitch is sewn. The machine sews backwards

for as long as the button is held down.

Press button 6.

The needle is raised or lowered.

Press button 7.

The next starting or finishing lock-stitch will not be sewn.

Press button 8.

The thread can now be severed in the monitored region using the

pedal. This enables the material to be removed in the event of a

fault. The program issues an error message.

17

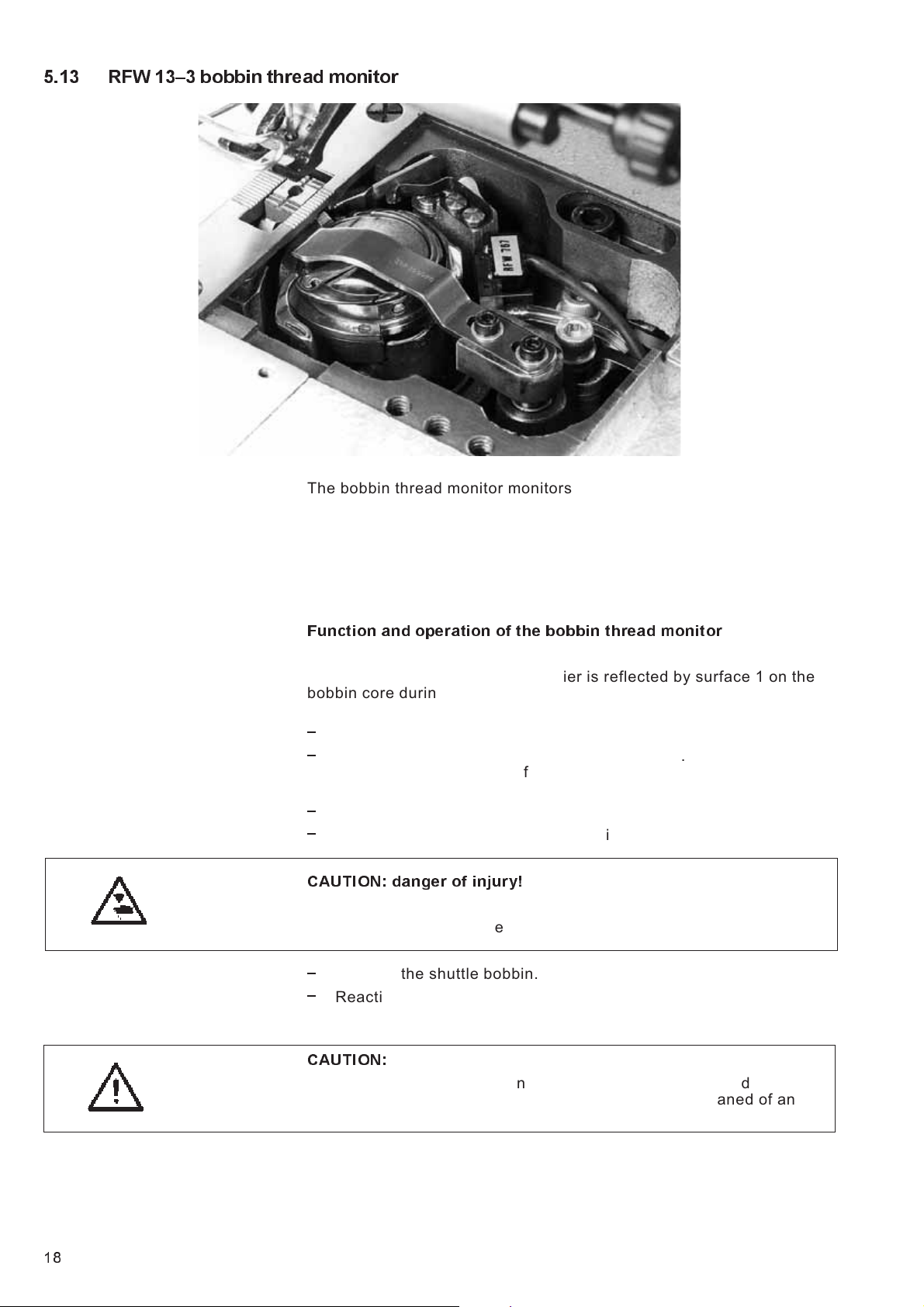

5.13 RFW 133 bobbin thread monitor

The bobbin thread monitor monitors the quantity of thread on the

shuttle bobbin. A signal is issued on the PC when only a small quantity

of thread remains.

The operator can finish the seam and fit a new bobbin, thus avoiding

damage to the material and the need for repairs.

Function and operation of the bobbin thread monitor

If the light beam from the light barrier is reflected by surface 1 on the

bobbin core during sewing, a s ignal is displayed on the PC and sewing

is interrupted.

`

Acknowledge the message on the PC screen.

`

Release the pedal, then push it forwards again. The seam will be

continued. The quantity of thread in reserve groove 2 of the shuttle

bobbin is normally sufficient to finish it.

`

At the end of the seam push the pedal back. The thread is cut.

`

Terminate sewing mode on the PC with “Back”.

CAUTION: danger of injury!

Turn off the main switch!

The bobbin may only be replaced with the machine turned off!

`

Replace the shuttle bobbin.

`

Reactivate sewing mode on the PC with “Sew”.

A new seam can be sewn.

CAUTION:

The bobbin must be placed in position with ring 3 downwards. The area

around the bobbin housing and light barrier must be cleaned of any

fluff!

&

Loading...

Loading...