Contents: Page:

Home

Preface and General Safety Information

Part 1: Operating Instructions cl. 550-12-23; -24; -26

1. Product Description

1.1 Brief Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Designated Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Lc Noise Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Subclasses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Operating Elements and their Function

2.1 Elements on the Sewing Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Elements on the Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3. Operating the Controls

3.1 Manual Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Sewing with a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Model Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Sewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Partial Program Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Changing Crimping Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4.1 Changing All Crimping Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4.2 Changing a Single Crimping Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.5 Editing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.1 Altering a Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.2 Inserting a Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5.3 Deleting a Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.6 Deleting a Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.7 Generating a Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4. Operating the Sewing machine

4.1 Threading the Needle Thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2 Needle Thread Quantity for Sure Stitch Formation . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3 Threading the Hook Thread . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Setting the Hook Thread Take-up Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.5 Setting the Pressure Foot Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.6 Switching the Edge Cutter On and Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.7 Calling Up Crimping Va lues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.8 Setting of Standard Stitch Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.9 Threading of Lower Tape Feed (only 550-12-16) . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5. Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

1. Product Description

1.1 Brief Description

1.2 Proper Use

550-12-23; -2 4

The

precrimping of up holstery piec es.

The work statio ns a re e qu i pp ed wi t h a si ng l e-n ee dl e do ub l e lo c k ed

stitch mach i ne wi t h a di fferential drop fe ed (two independentl y adjustable f ee d dogs) and a differe nt i ab l e, al t er n at i ng to p f ee d.

Via a keypad strip 15 different crimping values and 16 intermediate

values can be selected. A knee switch turns them on and off again. In

order to achieve a securer d raw i ng of the stitches a second needl e

thread tension is switched on when a crimping value is turned on. The

moment of swi t c hi n g o n a s eco nd needle thread te ns ion can be

preselected between crimping values 1 and 5 inclusive.

Drive and cont rol o f t he wo r k s ta ti o n o cc urs vi a a 3 ph as e mo to r i n

conjunctio n w i th a M i c roc o nt r ol control.

To increase the crimping intensity the work station is equipped with an

upper and /or lo we r ta pe fe ed an d t en si on i ng . Th e f i xi ng tap e wi d th is

2,25 mm by the s ub -c l ass e s 55 0- 1 2-1 3; -12-14 and 3 mm by t he

sub-class 550-12-16.

The tape tensi o n c a n b e t ur n ed on v ia a key and turned o ff t hro ug h the

knee switch when the crimping value is switched off.

550-12-23; -2 4

The

be used for se wi n g l ight to medium hea v y s ew i ng ma te r ial .

Such material is, as a rule, fabric composed of textile fibers or leather.

These sewing materials are used in the garment, furniture and car

upholstery ind us t r i es.

Furthermore, it may be possible to also execute so-called technical

seams with this special sewing machine. Here, however, the operator

(DürkoppAdler AG would be applications are, on the one hand,

relatively rare and, on the other, their variety is immense. Depending

on the result s of th i s eva l ua ti o n i t ma y be ne c es sa r y to ad op t

appropriate s af et y me asures.

In general, on ly dry m at eri a l ma y be wo rk ed wit h t hi s sp ec i a l ma c hi n e.

The material may not be thicker than 10 mm when it is pressed

together by th e lo we r ed un it c o ul d on ly be al l o we d t o b e ope r at ed wi t h

eye protection. Such eye protection is not available at this time.

The seam is generally made with sewing yarns of textile fibers with

dimensions up to 15 /3 Ne B (c ot to n t hre ad s ) , 2 0/ 3 N m (s yn th et i c

threads) or 25/4 Nm (core spun threads). Those wishing to use other

threads must also first evaluate the dangers arising herefrom and, if

necassary, take safety measures.

This specia l s ew i ng ma c hine may only be a ins t al l e d a nd op er a te d i n

dry and clea n a rea s . I f the sewing uni t i s e mp l oye d i n other areas,

which are not dr y a nd c l ea n, ot her, to be agreed upon, measu r es m ay

become neces s ary ( se e E N 60204-3-1: 19 90 ).

We, as a manufacturer of industrial sewing machines, as that, at a

minimum, semi-skilled operating personel work on our products so that

all normal o pe rations and, wher e ap pl ic a bl e , t he i r da ng ers c a n b e

presumed to be k no wn .

and

and

-12-26

-26

are configured work stations for the

is a configu red sewing stati o n w hi c h c an

5

1.3 Noise level Lc

Workstation related emmission according to DIN 45635-48-A-1-Kl 2

Number of stitches: 2.140 min -1

stitc h le ngth: 5,0 mm

alternating s ew i ng fe ed s tr o k e: 5, 6 m m

Sewing ma ter ial: Uphol stery v lies with upper c loth 674g/ m

Lc = 83 dB (A)

1.4 Subclasses

550-12-23 Configured work station with pneumatic pressure foot stroke.

550-12-24 Configured wo rk s ta ti o n w i th pn eu ma ti c p r ess u r e f oo t s t rok e an d

additional p ne umatic edge cut te r.

550-12-26 Configured work station with pneumatic pressure foot stroke,

pneumatic edge cutter, tape feed and tape scissors for the partial

undersewing of 3- m m- w i de rei n fo r c ing tape

1.5 T echnica l Data

Needle system: 933

Maximum numb er o f s t i tc h es : 3000 r/min

2

Maximum sti t c h l e ng th : Top feed 8 mm

Drop feed normal stitch 5 - 2.5 mm

Drop feed differential 8 mm

Maximum pressure foot lift: 2-7 mm

Clearance under the pressure feet:

When sewing: 10 mm

When raised: 15 mm (max. 17 mm)

Cutt ing cleara n ce (only -12-24/26): 4,5 mm

Kni f e stro ke hei ght (only -12-24/26):8 m m (conv ertible to 6 mm)

Maximum thread thickness: 20/3 Nm

Operating p res s u r e: 6 +/- 0.5 bar

Line press ure : 7-10 bar

Air consumption per work cycle: 0,1 NL

Through-put area: 280 x 108 mm

1.6 Optional Equipment

N900 040026 Edge stop for 550-12-23

N900 003471 Upper tape tens io ne r with Roller Holde r fo r 55 0-1 2-2 3/ - 24

N900 003511 Lower tape tens io ne r with Roller Holde r fo r 55 0-1 2-2 3/ - 24

0196 104008 Rear sole of the intermittent feed foot, Teflon covered.

For better gli d e c h ar a cteristics whe n w or k in g l e ather and simil ar.

0797 003031 The workstation is supplied without a compressed-air connection hose,

coupler plug & socket and hose socket. A 9-mm connection hose 5 m

long with hose socket, clamp, plug and socket can be ordered if

required. Or de r no .: 07 97 00 30 31 .

NB:

One of the tape tensioners is supplied with the workstation.

6

2. Operating Elements and their Function

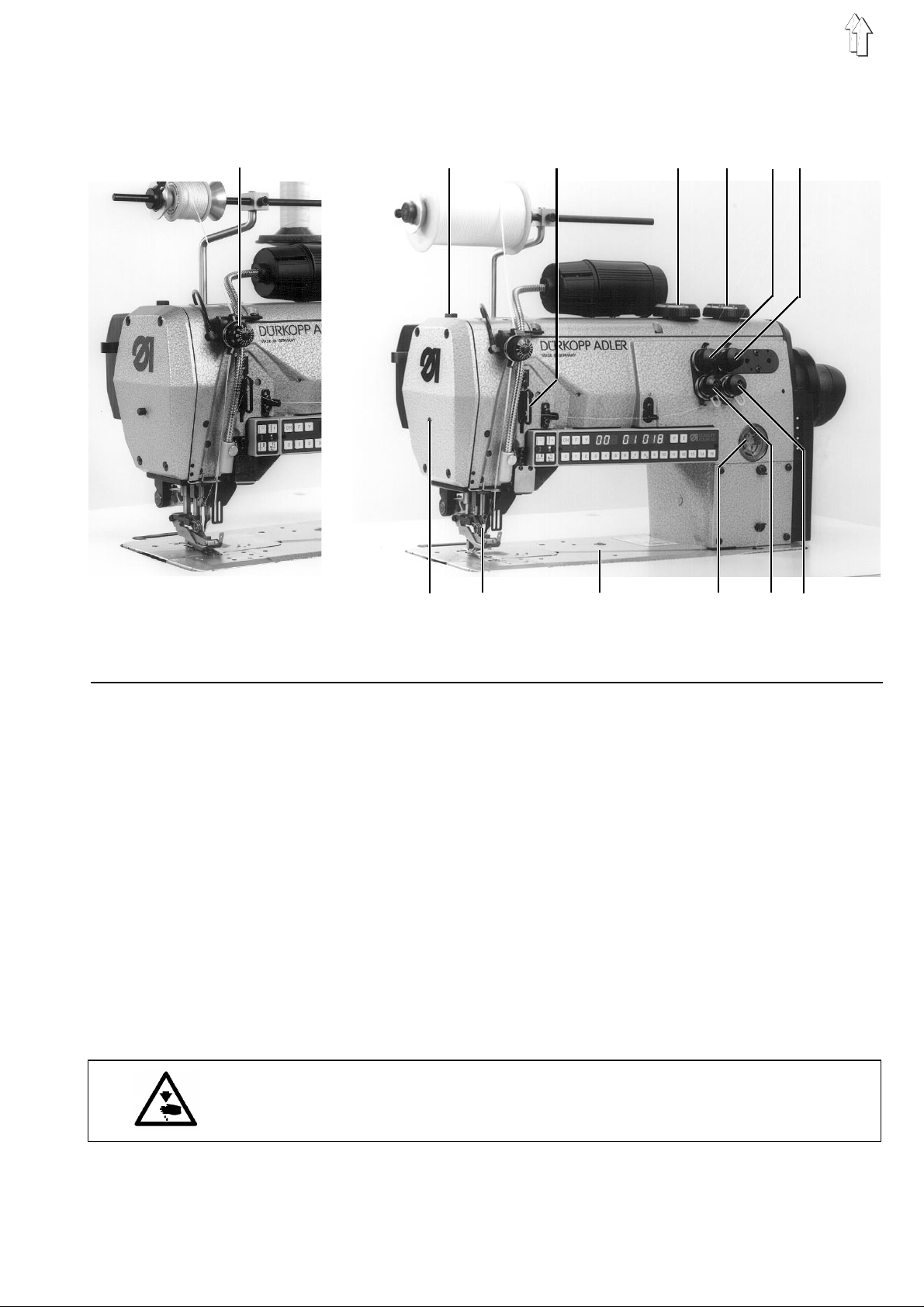

2.1 Elements on the Sewing Head

1

2

3

4567

13

Element Function

1 - Dial - Setting the upper tape tension (only -23/-24)

2 - Screw - Screw for the pressure foot pressure. It is completely screwed

in at the fact ory. Do not adjus t t he s cr ew !

3 - Thread regulator - Setting the correc t ne ed l e t hr e ad qu an ti t y

4 - Setting wheel - Setting increased pressure foot lift height

5 - Setting wheel - Setting pressure foot lift

6 - Knob - Second needle-thread tensioner for firmer stitch drawing

7 - Knob - Second hook-thread tensioner for firmer stitch drawing

8 - Knob - Setting hook-thread tension

9 - Knob - Setting needle-thread tension

10 - Viewing glass

with filling opening - Shows the oil level in the reservoir. The oil level should not fall

below "MIN". If necessary fill "SP N K 10" oil to the "MAX" mark.

11 - Pl at e - Thread guide for the ho ok t hr e ad

12 - Needle - 933

12

11

10 9

8

Caution Risk of Injury!

When threading or replacing the needle

it is imperative to turn the main switch off.

13 - Button - Arrest the pressure foot in the raised position.

7

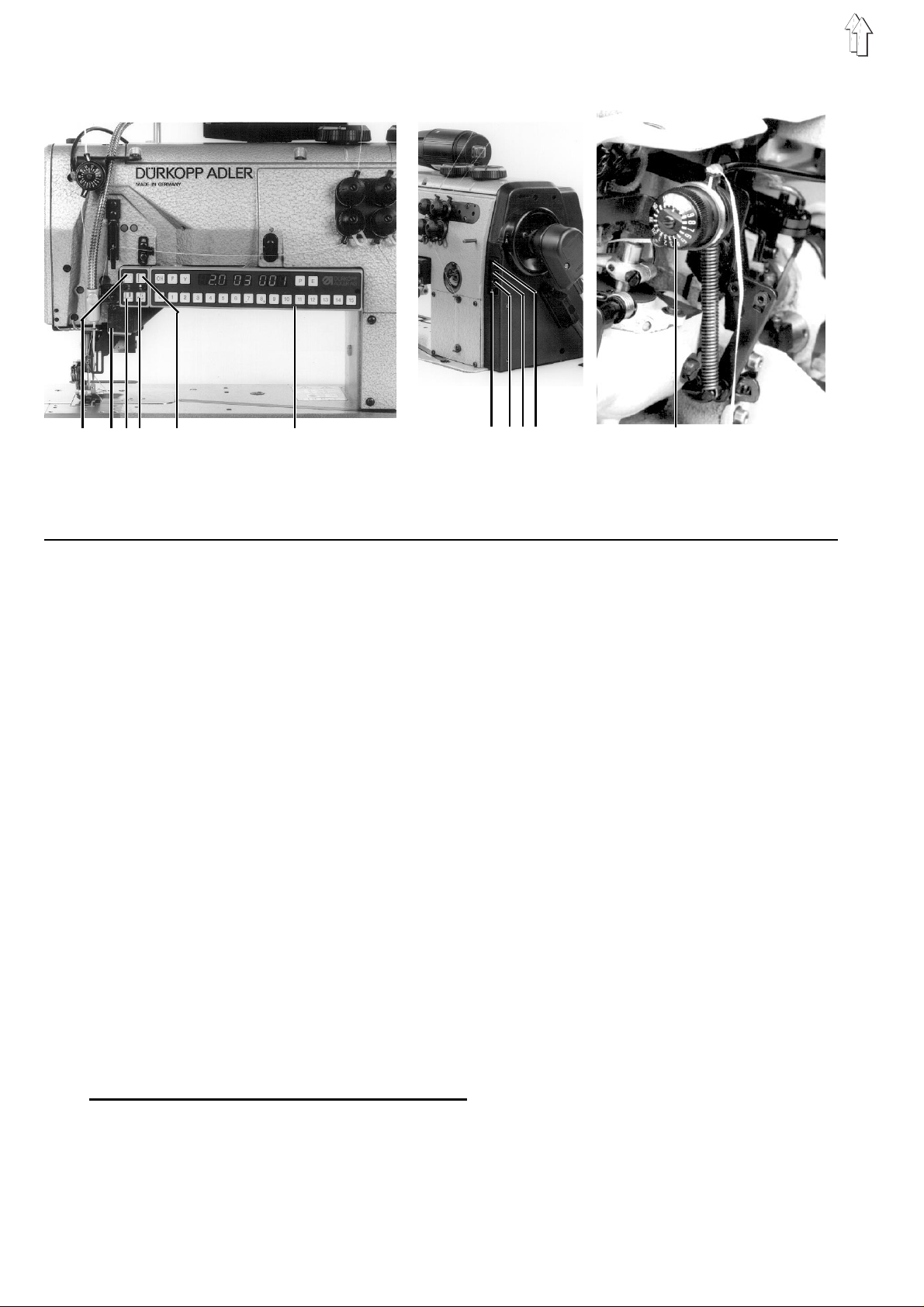

15dcb

Element Function

14 - Key block

Key F - Switching on tape tension

Key Y - Special functions

Key P - Programming key/Program number entry

Key E - Entry of pa rti a l pr o gra m number

Key OH - O-dist an c e w i th ta pe

Key O - O-distance without tape

Keys 1-15 - Calling up crimping values

Display - Disp l ay o f t he s el e ct e d cr i m pi n g values 1...15 1/ 2/ 3/4/5/6/7/8/9/ 10 /. ..

a - Key - Needle high position

b - Key - Switching high pressure foot lift on/ off

c - Key - Switching edge cutter on/ off (-14/-16 only)

d - Key - Switching stitch condensation on/ off (-13/-14 only)

a

14

Display of the current program step

Display of the selected model

- Rel ea si ng ta pe clamp to thre ad rei n fo r c ing tape.

Closing tape clamp, simultaneously severing reinforcing

tape lengthways.

3

4

1

2

16

15 - Hand switch

1-4 - LED Indicator

Active LEDs Max. revolutions r/min

1234 3000

234 2500

34 2000

16 - Dial

8

- Running through the program steps

- Indicates the current rpm

- Swit c hin g o n l o we r ta pe te ns i o n (- 1 3/ -14 on l y)

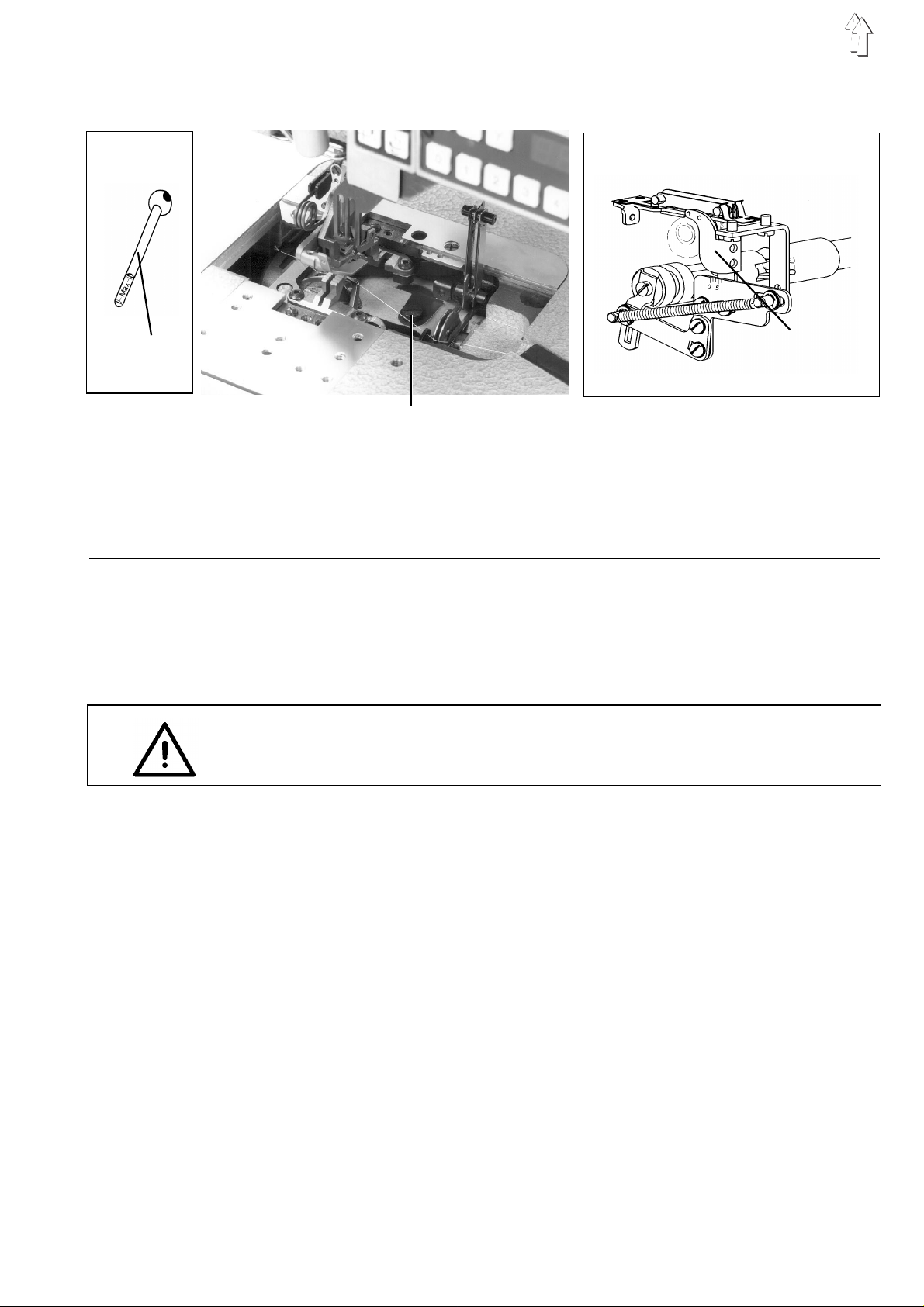

17

18

Element Function

17 - Dip stick - Measuring the oil level in the hook drive housing.

Dip stick is in the accessories pack.

18 - Screw To check the oil level screw out screw 18 and place

the dip stick 17 in the opening. The oil level must lie between

the markings. Only fill Esso "SP-NK 10"-type oil.

Attention!

If too much oil is filled the excess oil will exit through the

vent hole in s c rew 18.

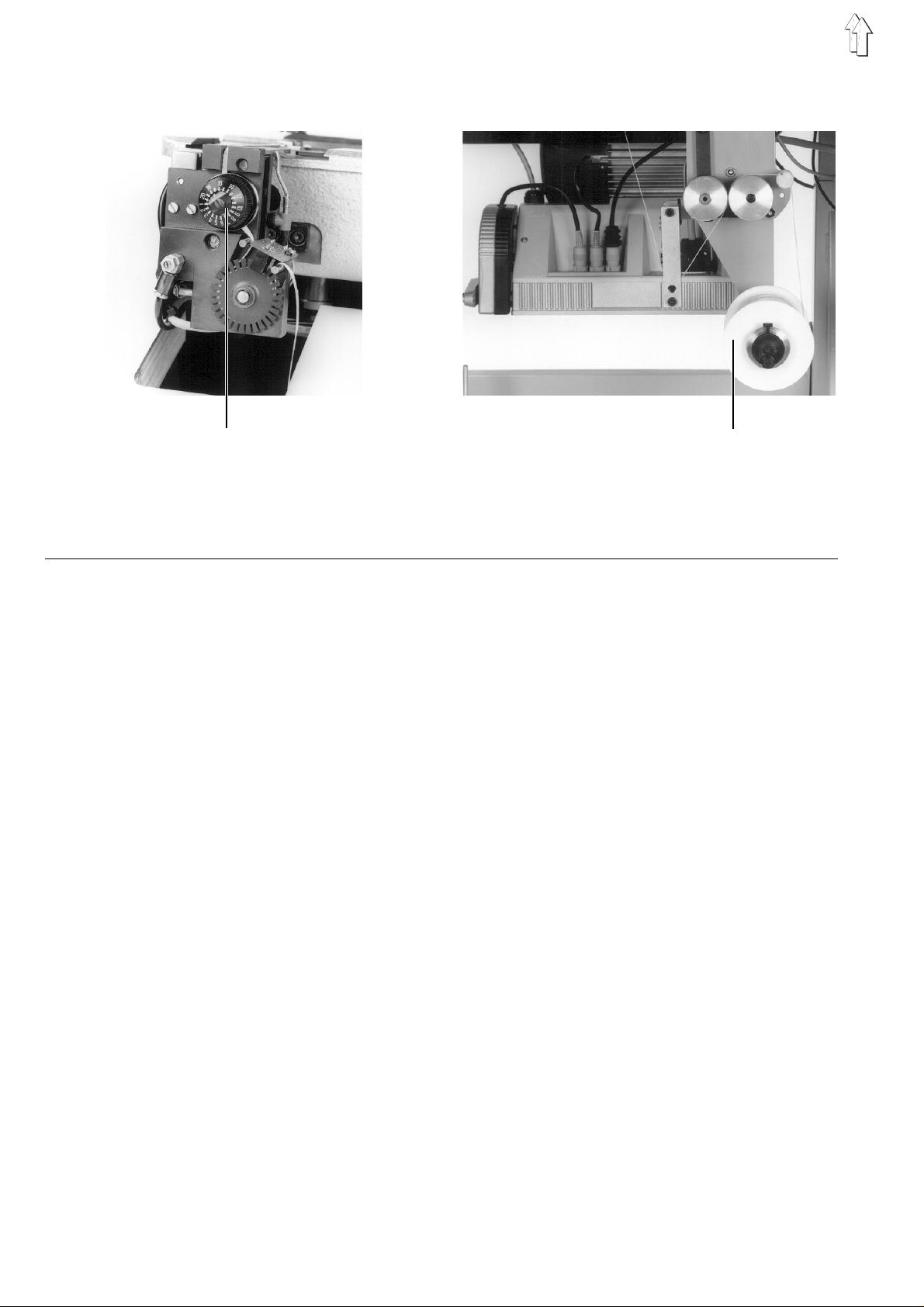

19

19 - Thread take-up lever - Automatic adaption of the hook thread quantity to the set stitch

length. Settings for firm, normal and highly elastic seams see

section 3.5.

9

20

Element Function

20 - Kn ob - Setting lower tape tens io n ( -2 6 o nl y )

21 - Spool - Tape feed

21

10

Loading...

Loading...