Adler 550-12-12 Operating Instruction

Contents Page:

Home

Preface and General Safety Notes

Part 1: Operating Instructions Cl. 550-12-12

1. Product Description

1.1 Short Description and Proper Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Technical Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Operation

2.1 Threading the Needle Thread (Upper Thread) . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Threading the Hook Thread (Lower Thread) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Thread Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Upper Thread Quantity for Sure Stitch Formation . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Optional Equipment reinforcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.2 Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5.3 Operating Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5.4 Loading the reinforcement tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.5 Adjustments on the tape unwinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5.6 Replacing the presser foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. Maintenance

3.1 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Lubricating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1. Product Description

1.1 Short Description and Proper Use

DÜRKOPP ADLER 550-12-12

The

the programmed advance crimping of shoulders and sewing on of the

sleeve joining.

With the app rop r i at e o pt i on al e qu i pm en t i t c an al so be us e d f or

selvedges on armholes, neckholes, etc.

The sewing s t at i on i s eq ui p pe d with a single ne ed l e-d ou bl e c ha i n

•

stitch sewing machine with differential bottom transport and foot

upper transp ort .

The upper transport and forward feed dog of the differential bottom

•

transport work synchronized. They can be set and switched

different to the r e ar f ee d d og .

Electro-pn eu ma tic t hre ad tr i m me r fo r up pe r an d l o we r th r ead.

•

Pressure foot stroke and stitch condensation at seam beginning

•

and seam end.

A microprocessor control assumes the automatic multi-width

•

regulation w i th pr o gra mable follow- up sw itching.

The memory capacity of the controls allows the pre-programming

•

of 20 sewing pro gr a ms i n cl ud i ng th e c o mp l et e g r ad ua te d s i ze s et s .

Each sewing pr o gra m c a n c o nt ai n up to 13 s te ps p er seam run.

Each step can have its own designated crimp value.

is a configured sewing station for

1.2 Optional Equipment

Mirroring left-right sewing piece via the push of a button.

•

Very simple programming via an operating terminal with graphic

•

monitor. The operating surface of the monitor can be called up in

10 languages by pushing a button.

With a memo ry c ard pr o gram transfer to other sewing stations, as

•

well as program retention, can occur.

Proper Use !

DÜRKOPP ADLER 550-12-12

The

crimping of shoulders, the sewing on of sleeve joinings and, with the

appropriate optional equipment, for selvedge work with materials of

textile fibers and leather.

DÜRKOPP ADL ER 55 0- 1 2-12

If the

armholes, ne c kholes, etc., th en i s mu st b e e qu i pp ed wi t h t he op ti o na l

equipment listed in chapter 2.5.2.

may only be used for the advance

is to be used f or b ord er i n g o f

5

1.3 T e chnical S pecifi cation

Machine head: Class 935 - 9 40 - 6

Needle system: 934 SIN

Needle thickness: Nm 90

Threads: As needle and hook thread spun monofilament

Stitch type: 401 double chain stitch

Number of stitches: 3200 / min (recommended number of stitches

Stitch length: 2.5 mm for rear feed dog (fixed setting)

Stitch condensation: 1.5 mm

Operating pressure: 6 bar

Air consumption: approx. 0.5 NL per work cycle

Nominal voltage: 1 x 220 - 240 V, 50 / 60 Hz

Dimensions: (H x W x D) 1600 x 15 30 x 95 1 m m

2. Operation

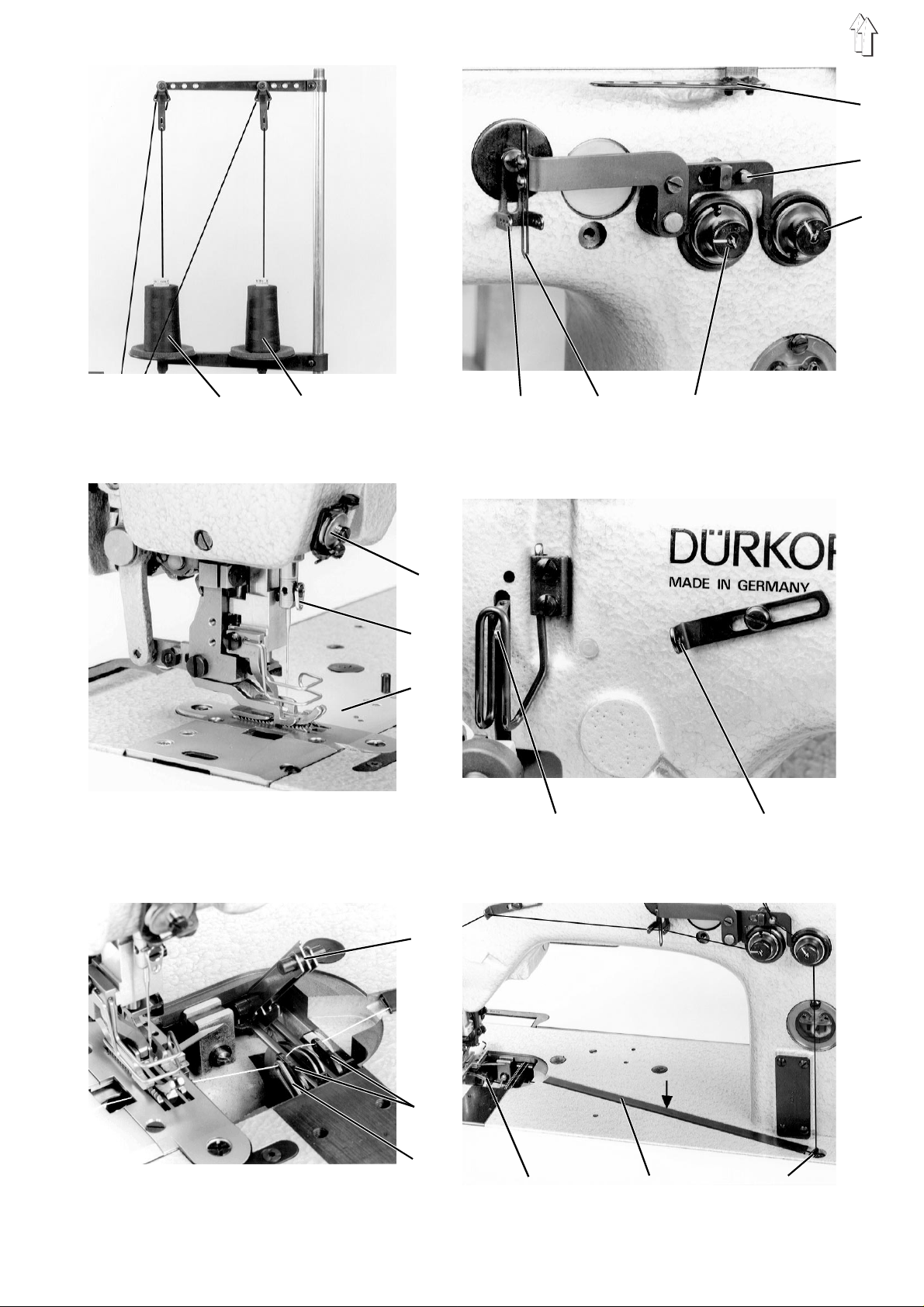

2.1 Threading the Needle Thread (Upper thread)

sewing yarns

ex works)

Transport length for forward feed dog and

transport fo ot ad j us t ab l e u p t o 6 mm

Caution Risk of Injury !

Turn main switch off.

Thread the upper thread only with the machine switched off.

–

Place the thr e ad s po ol 1 on th e t hr e ad s ta nd .

–

Guide the thread as shown through the holes and tension discs in

the thread guide plate.

–

Guide the thr ea d i n order through guid e plate 3, thread gu i de 4,

thread tension 8, thread guide 6 and thread drawing plate 7.

–

Guide the thr ea d t hr o ug h t hr e ad gu i de 13 an d t hr e ad drawing lever

12.

–

Guide the thread through pre-tension 9, thread guide 10 and

needle eye. Cut off the excess t hread end.

2.2 Threading the Hook Thread (Lower Thread)

Caution Risk of Injury !

Turn main switch off.

Thread the l ow er t hread only with t he ma c hi n e switched off.

–

Place the thr e ad s po ol 2 on th e t hr e ad s ta nd .

–

Guide the thread as shown through the holes and tension discs in

the thread guide plate.

–

Guide the thread in order through the guide plate 3, thread guide

4, thread tens io n 5 an d l o we r th r ea d g uid e 1 9.

–

Feed the threa d t hr o ug h t he s l ot ( see ar row) in the thread gutter 18.

–

Remove cover plate 11 and swing holder 14 up out of its catch.

Guide the thread through thread guides 15 and thread drawing

hook 16.

Swing hol de r 14 ba c k an d a l l ow to c at c h.

–

Pull the thr ea d t hr o ug h t he ho ok 1 7 w i th a tweezers and p ull t i gh t.

Insert cover plate 11 again.

6

3

4

5

12

67 8

9

10

11

12 13

14

15

16

17 18 19

7

Loading...

Loading...