Adler 550-12-12 Service Manual

Contents Page:

Home

Part 3: Service Instructions Cl. 550-12-12

1. General

2. Setting the Machine Head

2.1 Arm Shaft Crank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Position of the Lower Timing Belt Pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Rocker Bolt and Left Lower Shaft Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Hook Drive Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Inserting the Hook in the Hook Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Looping Stroke and Needle Bar Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.1 Looping Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.2 Symmetry of Looper Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6.3 Needle Bar Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.6.4 Setting with the Stroke Tongue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.7 Needle Avoidance Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.8 Needle Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. Differential Bottom Feed

3.1 Main Feed Dog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Differential Feed Dog and Step Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3 Height of the Feed Dogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Feed Dogs Lengthwise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Advancing Movement of the Feed Dogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6 Lift Movement of the Feed Dogs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7 Stitch Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4. Stitch Length Controlled Lower Thread Take-up Lever

5. Take-up Lever Disc

6. Top feed

6.1 Height of the Transport Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 Pressure Setting for the Top Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3 Lift Level Alteration for the Top Feed System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4 Advancing Movement of the Top Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.5 Transport Foot Lengthwise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.6 Lift Movement for the Transport Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.7 Stopping Angle for the Transport Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7. Pressure Foot Lift Stroke

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . 23

8. Thread T rimmer

8.1 Retaining Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.2 Cutting Pressure and Thread Gripper Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.3 Left End Position of the Hooked Knife . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.4 Right End Position of the Hooked Knife . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9. Puller for the Hook Thread

10. Tension Release

11. Puller for the Needle Thread

12. Thread Guide on the am Machine Arm

13. Service Settings at the Electrical Components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

. . . . . . . . . . . . . . . . . . . . . . . . . 43

1. General

ATTENTION !

The tasks described in the service instructions may only be conducted

by specialists o r ap pro priately traine d p ers o nn el !

Caution Risk of Injury !

During repa ir, conversion and m aintenance work tu rn the main switch

off and discon ne c t t he s ewing un it fr o m t he pn eu ma ti c s up ply li ne.

Adjustment work and funct ion tests with the m ac h in e running are to b e

conducted only while observing all safety measures and with extreme

caution.

E

A

B

21

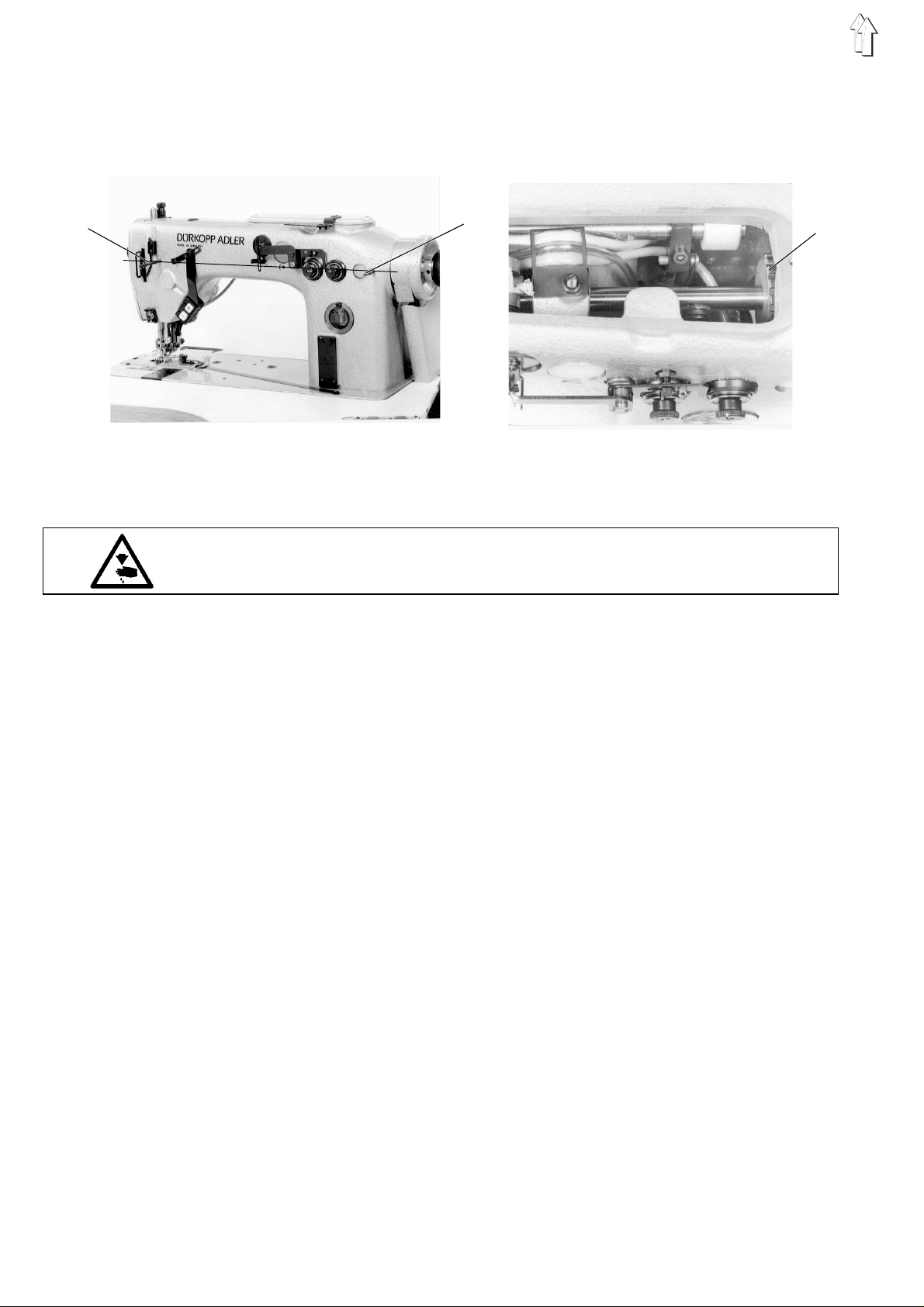

The machine head is equipped with setting aids which make it possible

to set the machine quickly and easily.

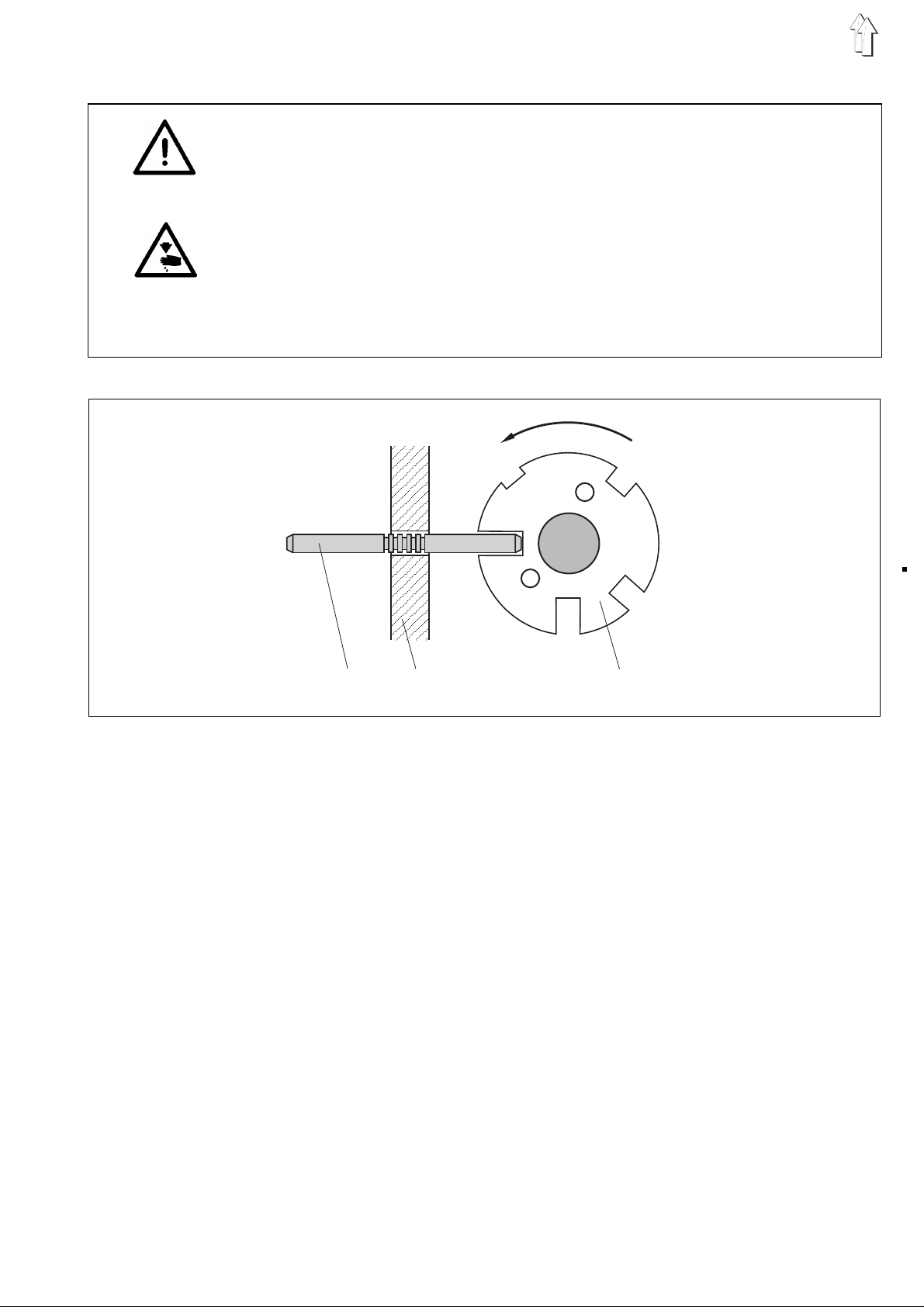

With the timing pi n 1 an d a n a dj us t me nt di s c 3 a tt ac h ed to th e t im in g

belt pulley of th e a rm shaft the s ewing un it c an be ar re s te d i n 5 s et ti ng

positions.

Depending on t he s el ected position 1 to 5 n ot c he s of th e t im in g p in 1

are visible (2 = housing wall).

A

= 1 notch visible. Adjustment disc to the arm shaft crank.

D

C

3

B

= 2 notches visible. Thread take-up disc.

C

= 3 notches visible. Stroke and advance cam.

D

= 4 notches v is ible. Setting lower timi ng be lt pulley.

Looping stroke and needle bar height.

E

= 5 notches v isi ble. Sym me try of loop er motion.

3

2. Setting the Machine Head

2.1 Arm Shaft C rank

1

The markin g gro ove of th e a rm shaft cran k an d t he s lo t A of the

adjustment disc must be in line.

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

–

Inser t the timing pin 1 in to th e m arking hole an d let it catch in the

marking groove of the arm shaft crank.

Instead of t he ti mi ng pi n a ny ot h er p in or a 5 m m s p iral drill can be

used.

–

Check to see if, in this p os i ti on , t he ti mi ng pi n 2 can be inser te d

into position A (1 notch visible).

If not, the setting must be corrected.

2

3

Setting

–

Remove the arm cover.

–

Push the timing belt to the left on the upper timing belt pulley 3 and

loosen the s cr ew s.

–

Arrest the a djus t me nt disc in positio n A (1 notch visible) with

timing pin 2.

–

Insert timing pin 1 into the marking hole and in let it catch in the

marking groove of the arm shaft crank.

–

Press the up pe r ti mi ng be lt pu ll ey 3 g en tl y to th e right against t he

timing pin 2.

Tighten bot h s c rew s.

–

By turning the handwheel move the timing belt to the middle of the

timing belt pulley again.

–

Replace the arm cover.

4

2.2 Position of the Lower Ti ming Belt Pulle y

The screws of the lower timing belt pulley should be in the position

shown when the sewing unit is arrested in position D (4 notches

visible).

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

–

Arrest the machine head in po s it io n D (4 notches visible).

–

With an incorrect setting of the screws first set the position of the

upper timing be lt pu ll ey (s ee c ha pt er 2 .1 ).

–

Remove the timing belt from the upper timing belt pulley.

–

Turn th e l ower ti ming belt pulley until t he s c rews a r e i n t he po s it ion

shown.

–

All following sett ings must be checked o r r es e t.

5

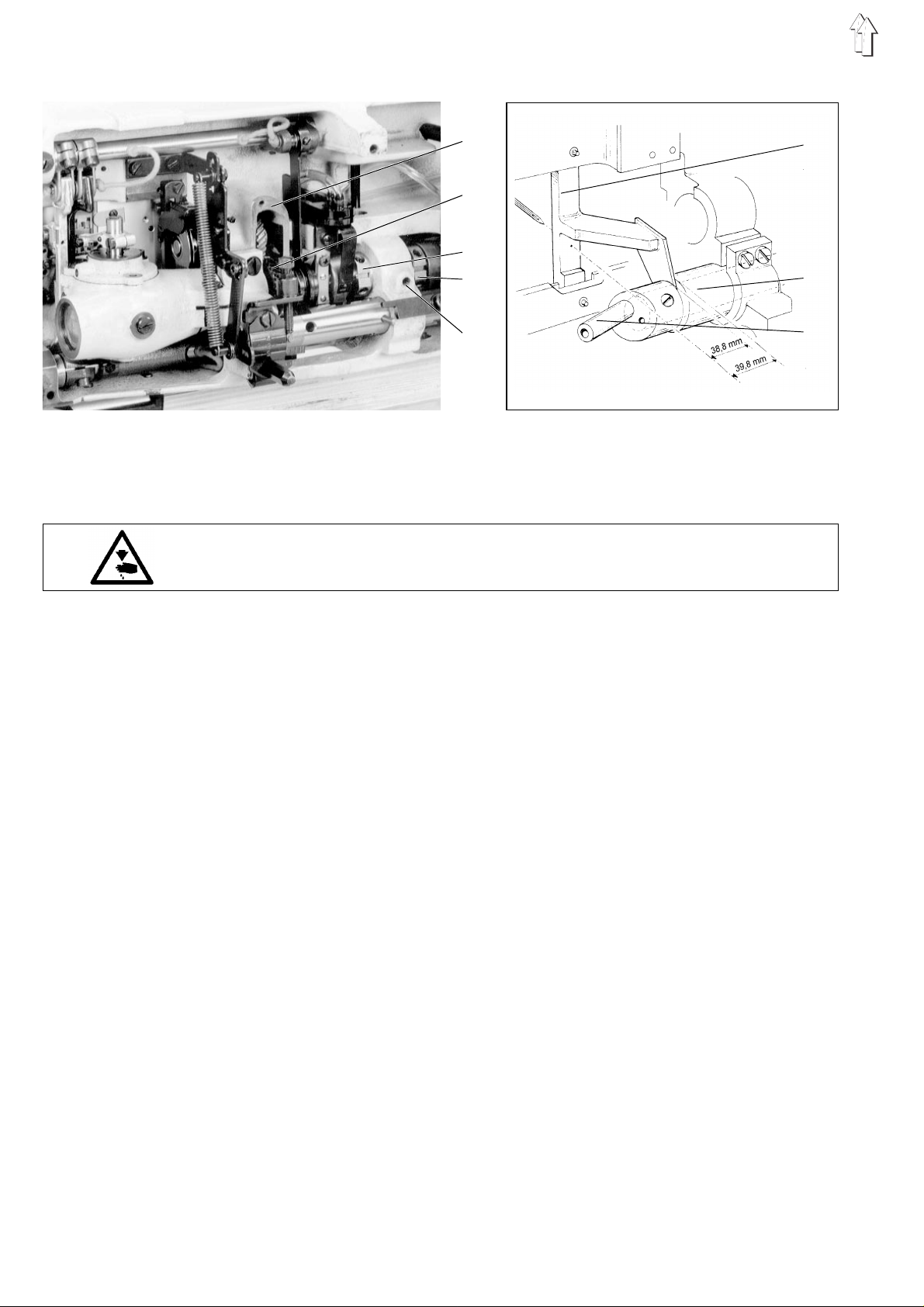

2.3 Rocker Bolt and Left Lower Shaft Bearing

1

2

3

4

5

The clearance f r om th e c e nt er of the needle to th e s t art of the le ft

lower shaft bea ring should be s ol l 3 9. 8 m m .

The clearance f r om th e c e nt er of the needle to th e e nd of th e r o cker

bolt should be 38.8 mm.

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

6

7

8

–

Remove the needle plate, thread trim me r, needle gu ard and hook

with hook holder.

–

Drain the oil from the hook drive housing and remove the hook

drive housing.

–

Place gauge 6 ( Order no. 933 000735 ) on the needle plate

support on the base p la te an d s c rew tight.

–

By axially displacing the left lower shaft bearing 7 push it onto the

gauge 6 (dimension 39.8 mm) and screw tight.

–

Remove the housing cover from 1 and the oil pan from 5.

Loosen the ca ms 3 an d 4 an d the sprocket 2.

–

By axially displacing rocker bolt 8 push it onto the gauge 6

(dimension 38.8 mm) and screw tight.

–

Tighten cams 3 and 4.

Align the s pr o cket 2.

If necessary also align the timing belt pulley sideways.

–

Remount the ho ok d rive housing and the ot he r pa rts removed.

ATTENTION !

When remounting the setting notes in these service instructions

are to be observed.

–

Fill the hook drive housing with

upper mark on the viewing glass.

ESSO SP- NK 10

oil up to the

6

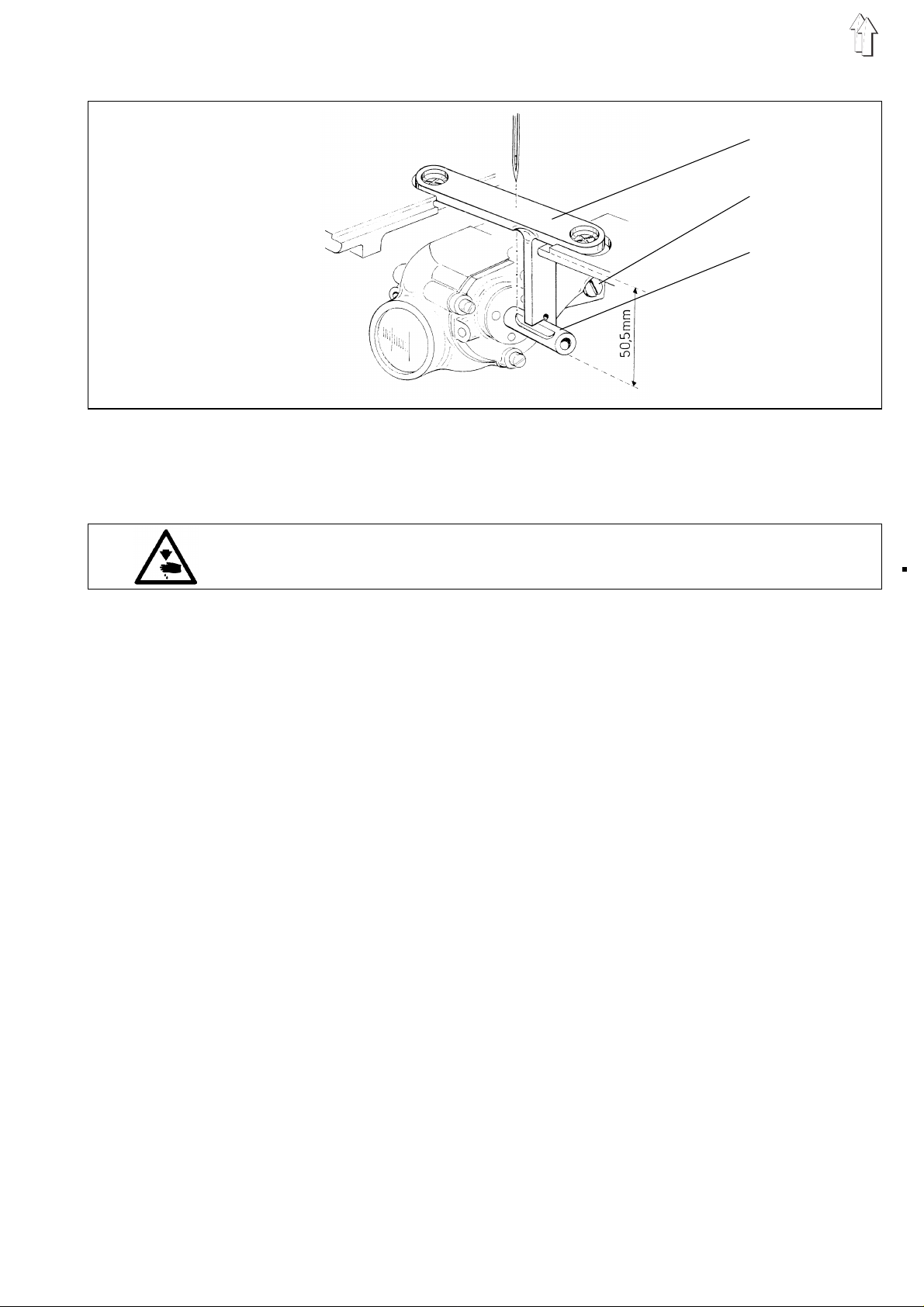

2.4 Hook Drive Housing

1

2

3

The needle tip point to the middle of the hook shaft. The hook shaft

lower edge runs parallel to the bottom of the needle plate.

The clearance from the top of the needle plate support to the hook

shaft lower edge is 50.5 mm.

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

–

Remove the needle plate, thread trimmer, needle guard and hook

with hook holder.

–

Place gauge 1 ( Or de r no. 933 000739k) on the n ee dl e p la te

support of the base plate and screw tight.

–

Press hook s h af t 3 on to the gauge and sc r ew th e h oo k ho us i ng

tight with screw 2.

–

Remount the o ther removed par t s.

ATTENTION !

When remounti ng th e s e tt in g n otes in these se rvice instructions

are to be observed.

7

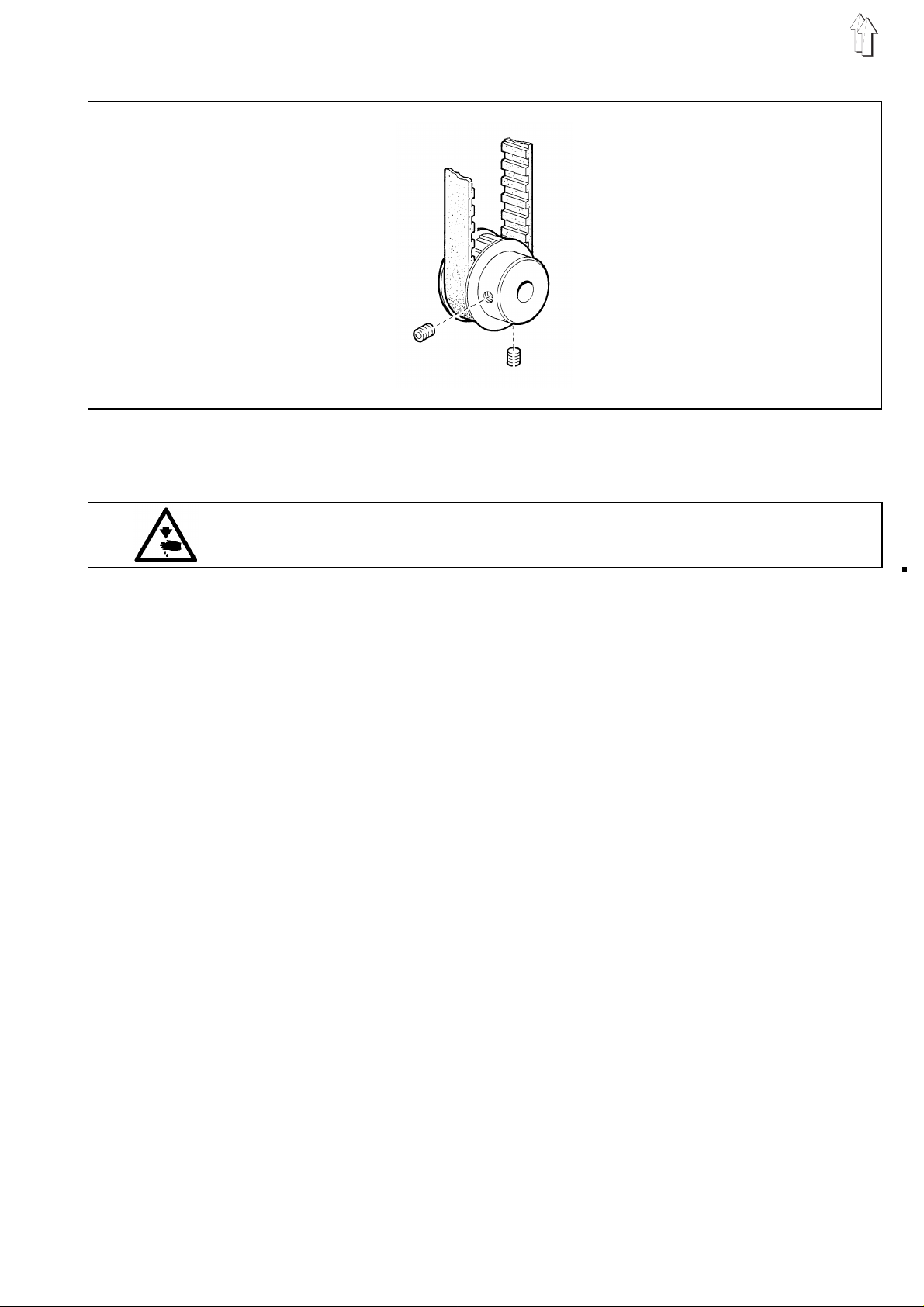

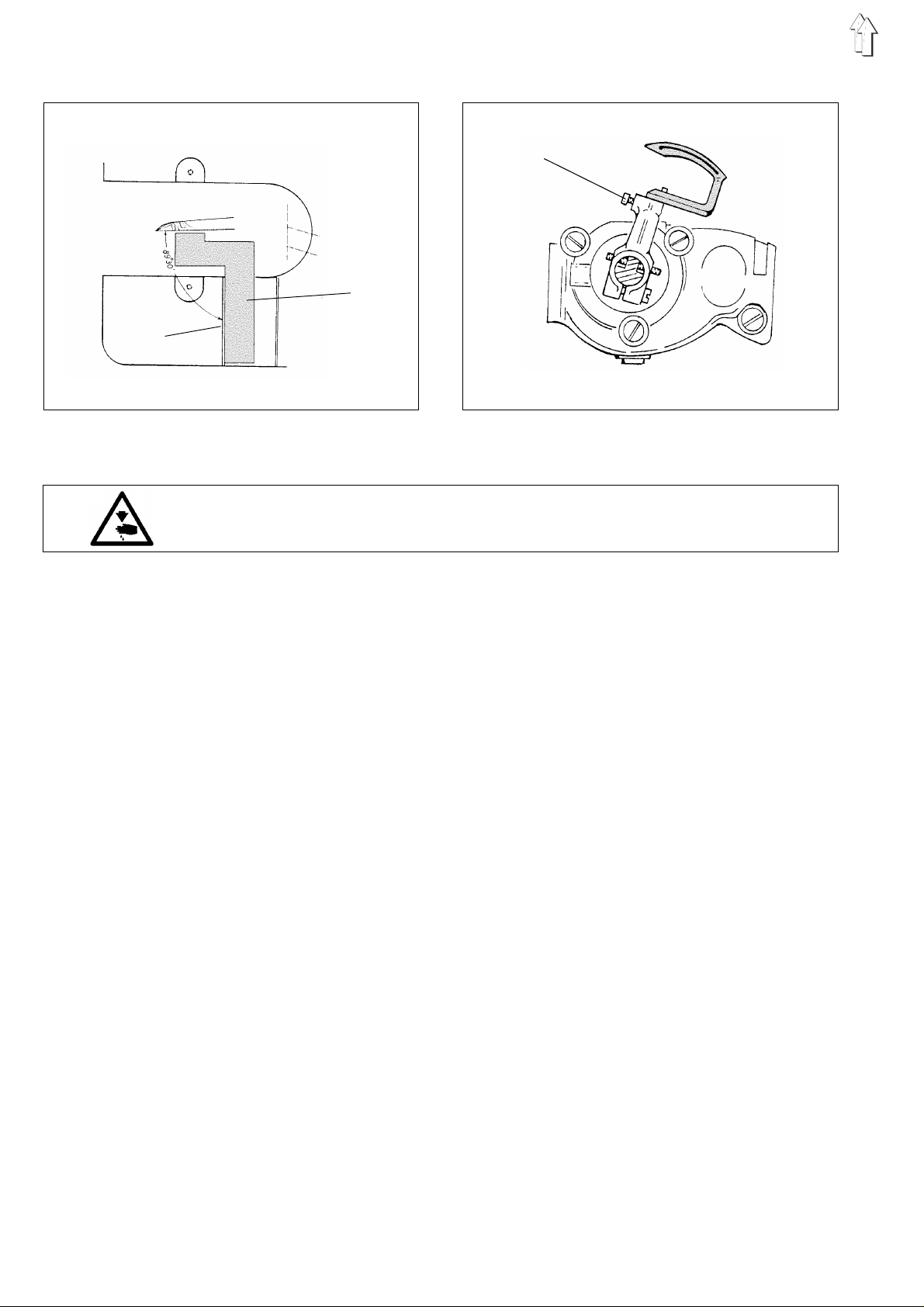

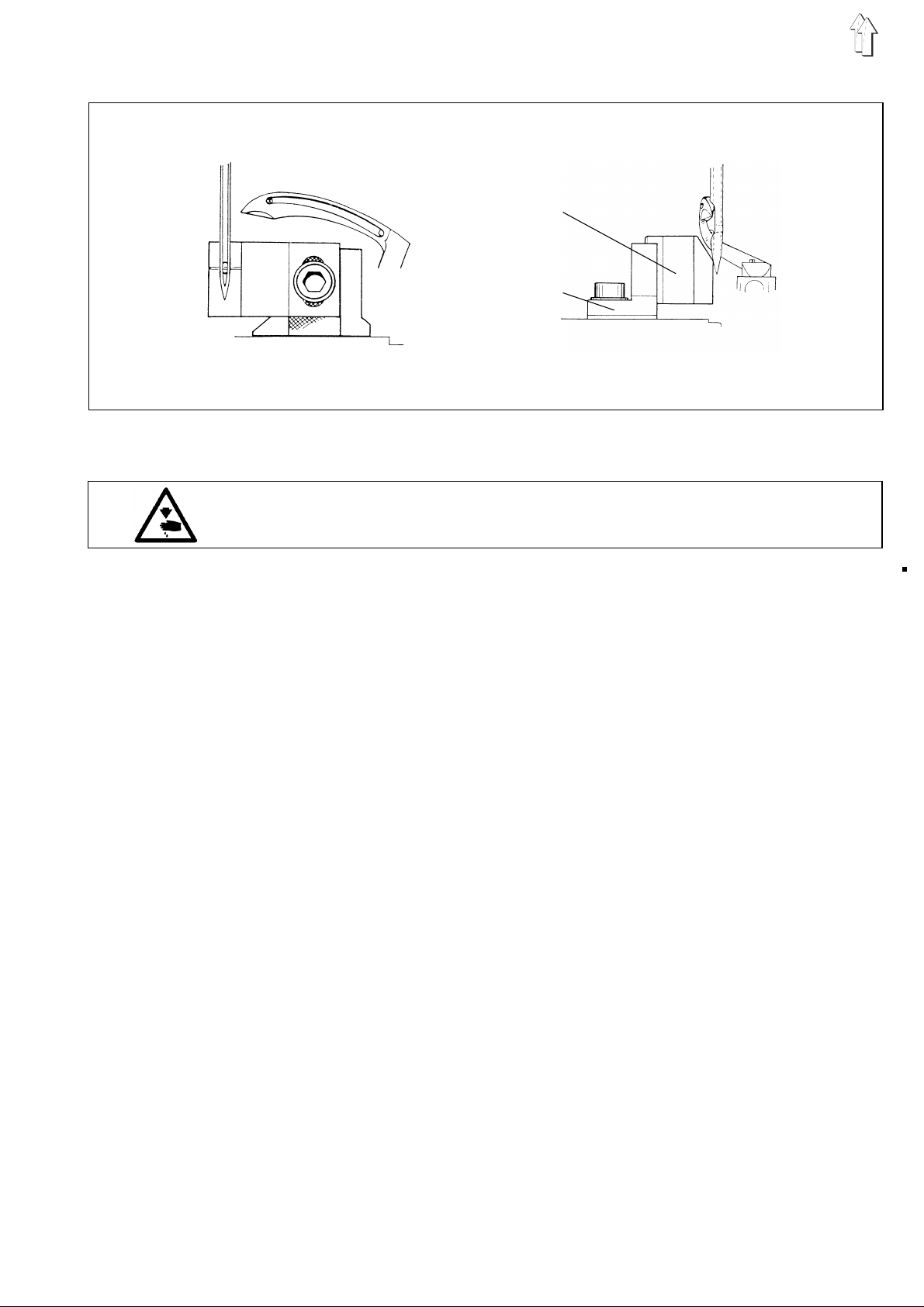

2.5 Inserting the Hook in the Hook Hol der

2

1

The front of the hook should be at an angle of 89° 30’ to edge 1 of the

apparatus open in g.

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

3

–

Screw out screw 3 of the hook.

–

Place gauge 2 (Order no. 933 000750) on the edge 1 and bring the

hook into the correct position.

–

Tighten screw 3 of the hook.

8

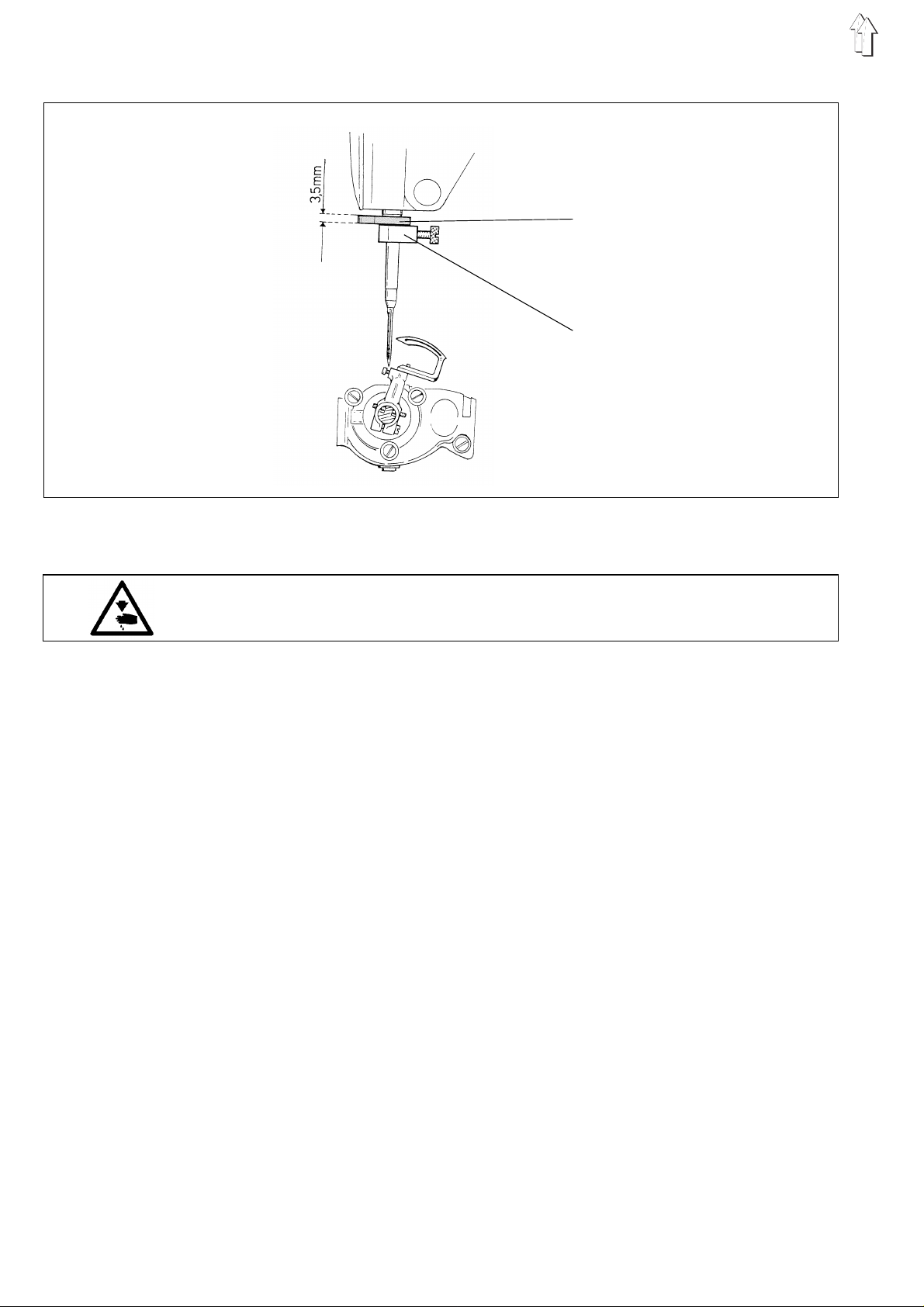

2.6 Looping Stroke and Needle Bar Height

2.6.1 Looping Stroke

2

1

3

The looping s t r oke i s 3.5 mm.

This means th at wh en th e n ee dl e i s rais e d 3 .5 mm ou t o f t he lowes t

point by turn in g the handwheel i n t he di rec t io n o f turn the hoo k ti p

must stand at th e ce nter of the needle.

This position must also be reached when, by turning the handwheel in

the other direction, the needle rises 3.5 mm out of its lowest point.

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

–

Arrest the machine head in po s it io n D (4 notches visible).

–

Loosen screw 3.

–

With the butt sc r ews 1 an d 2 set the position of th e h oo k .

–

Tighten screw 3.

9

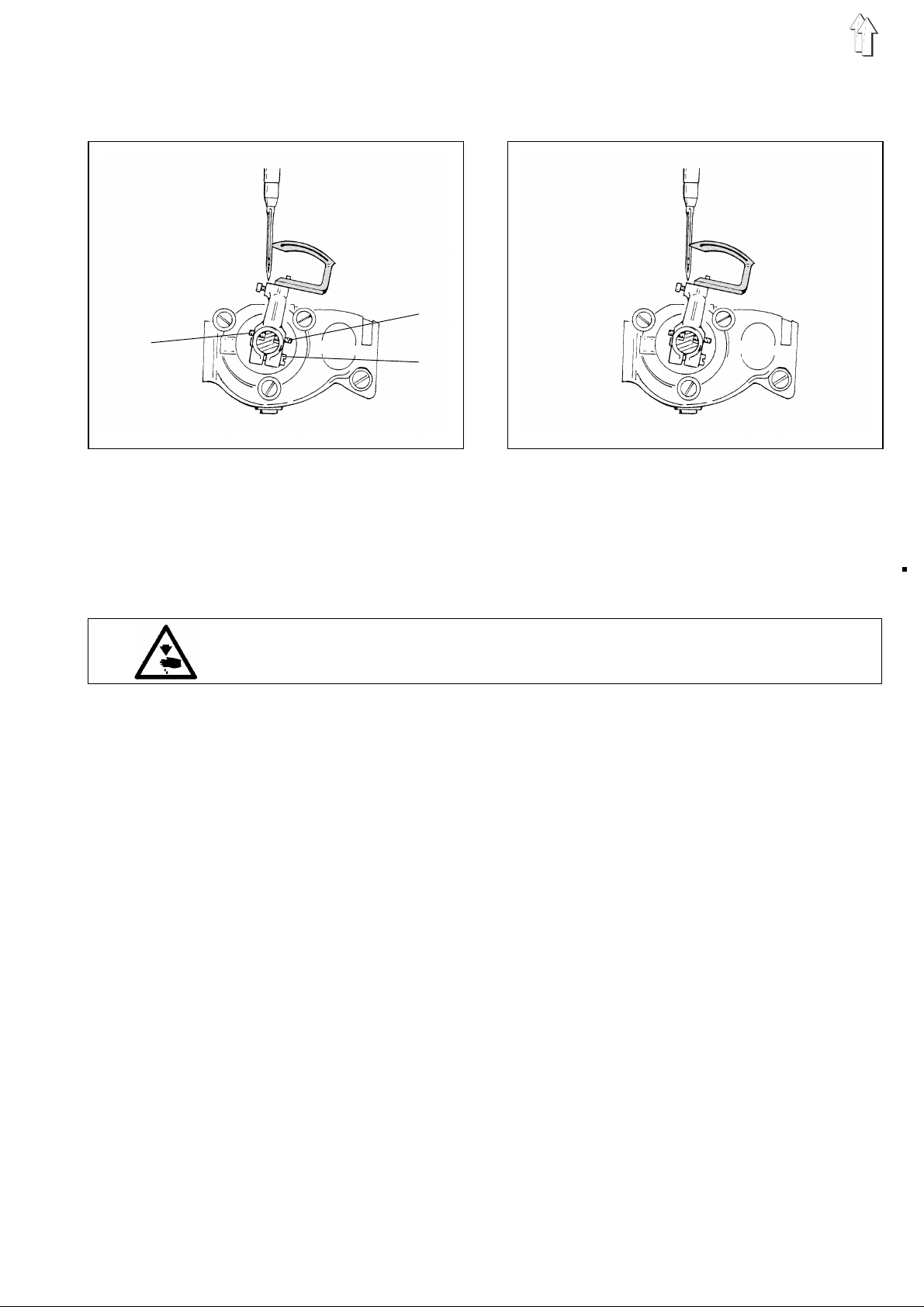

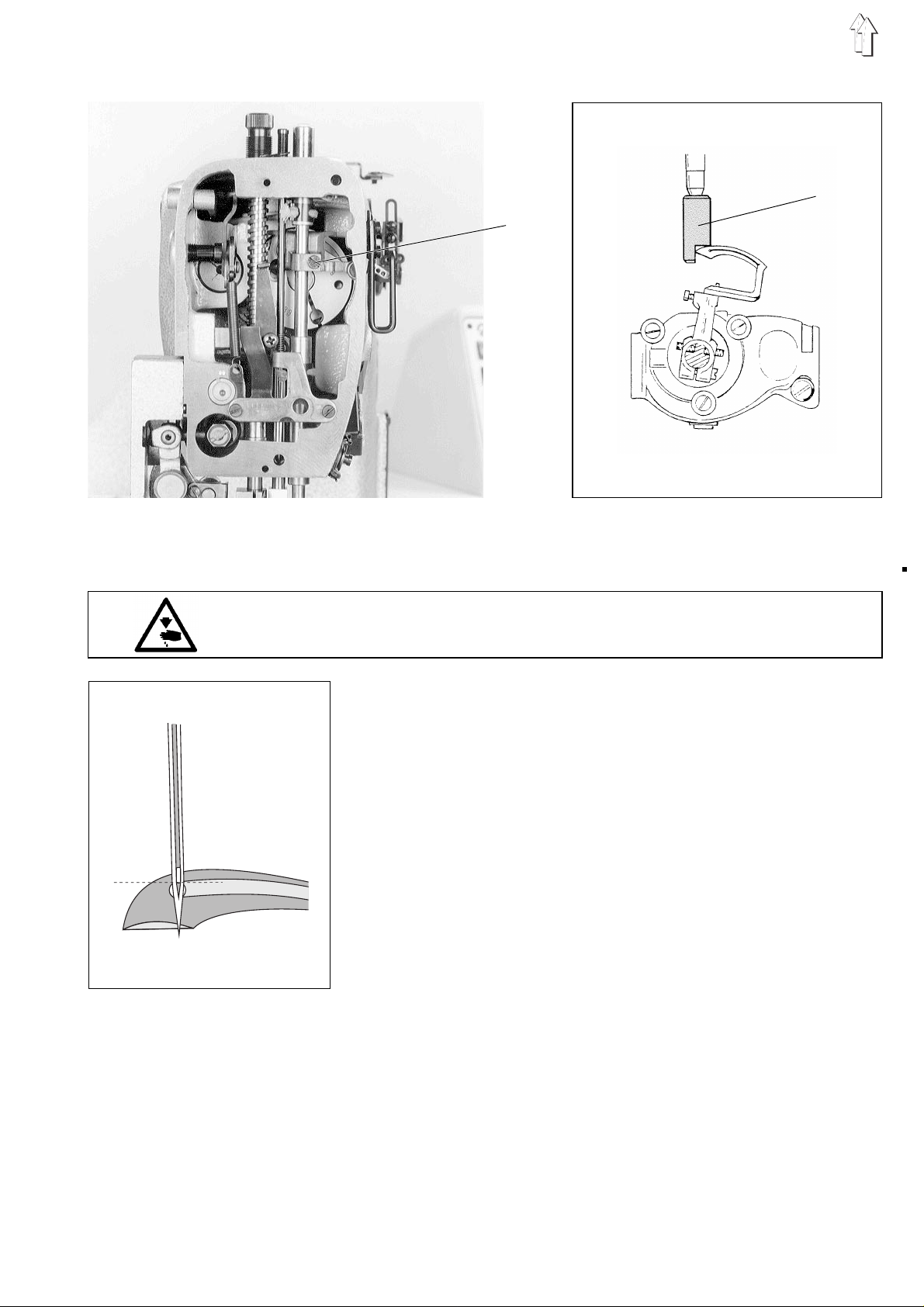

2.6.2 Symmetry of Looper Motion

1

2

The symmetry of looper motion is set with the gauges 1 and 2

(Order no. 933 080192).

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

–

Arrest the machine head in position D (4 notches visible).

–

Attach the pointer 1 and angle 2 (see illustration).

Align the po in ter to the slit in b the angle.

–

Pull out the tim in g p in an d by t urning the ha nd wh ee l m ove the

sewing unit to position E (5 notches visible) and arrest.

The pointer 1 s ho uld have made a pendulum movement t o t he le ft

and back to the slit again.

If not the loosen the fastening screws on the lower timing belt

pulley 3.

By turn in g t he lower shaft reduc e t he di s ta nc e be twe en th e p oi nt er

and the slit by

Adjust angle 2 (slit to the pointer).

Repeat the setting until, in position D and position E, the pointer 1

stands dire ctl y ab ove the sl it .

half

.

3

10

2.6.3 Needle Bar Height

2

1

The height of the needle bar is correctly set when the hook eye lies at

the needle center

upper edge of th e h oo k eye.

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

–

Screw off the he ad cover.

–

Insert gauge 2 (O rder no. 9 33 000755a) until its lays on in the

needle bar and faste n

–

Arrest the machine head in po s it io n D (4 notches visible).

–

Set the need le ba r as to height and tigh te n the needle bar

fastening screw 1.

and

the lower edge of th e n eedle eye stands at the

11

2.6.4 Setting with the Stroke Tongue

1

2

Setting the looping stroke can al s o b e co nducted with the s e tt in g block

and the stroke to ng ue.

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

Prerequisite for the setting of the looping stroke with the stroke tongue

is the corre c t s e tt ing of the need le ba r he ig ht ( s ee 2. 6. 3) .

–

Turn the handwheel until the needle is in the 1st position

–

Attach the stroke tongue 1 and the setting block 2 as shown.

–

Pull the stro ke tong ue away.

–

Set the sett in g block ti gh t by t urning the ha nd wh ee l.

–

Set the hook with the butt screws (see 2.6.1).

Setting block Order no. 223 000531

Stroke tongue Order no. 223 000536k

(UT)

.

12

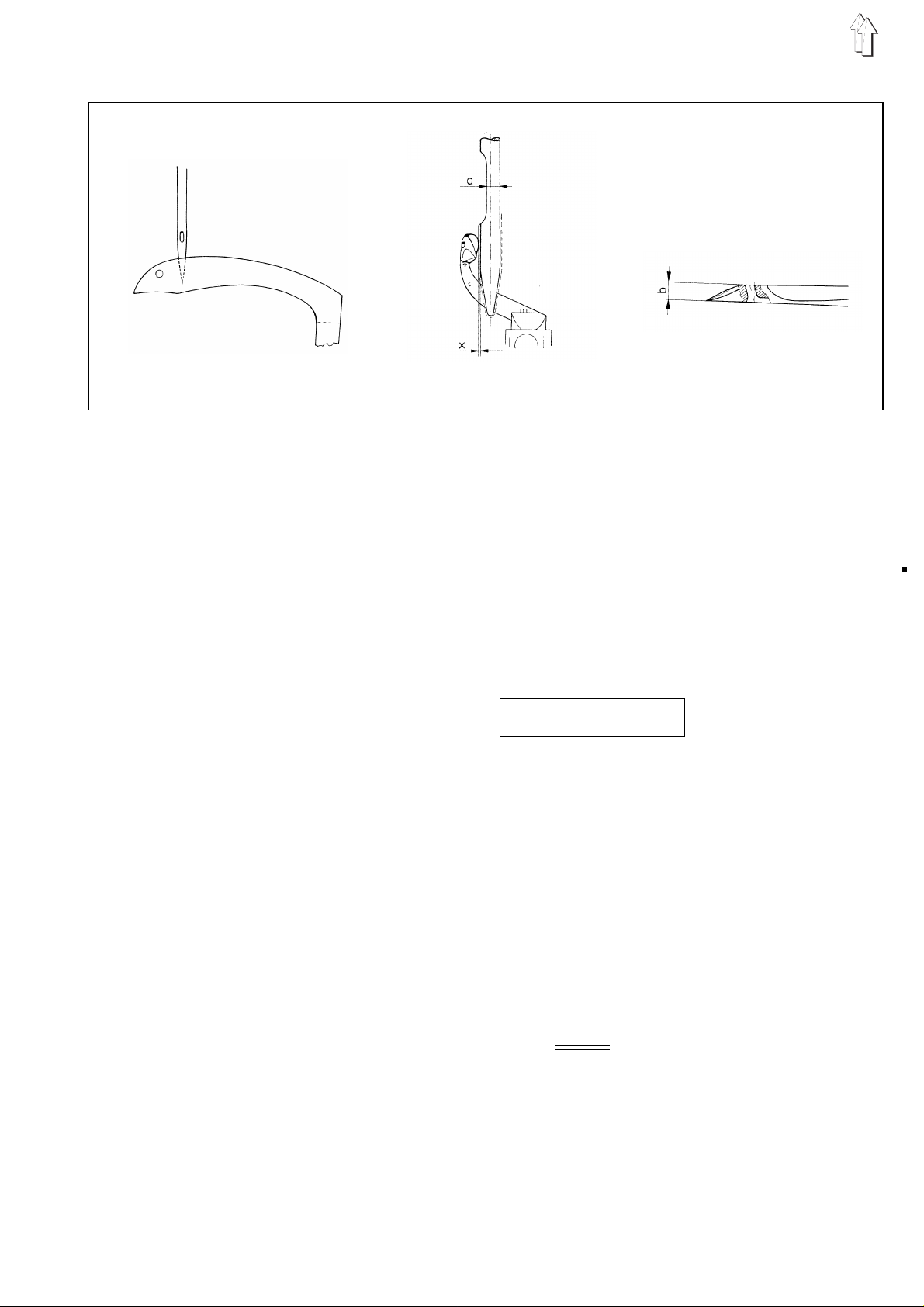

2.7 Needle Avoidance Movement

a) b) c)

With needle avoidance movement (ellipse widt h) i s me an t the

movement, which the hook conducts i n o der to pass in it s movemen t

from right to lef t

needle.

The ellipse width is dependent on the needle system and the needle

thickness.

The ellipse widt h is c orr e ctl y set wh en wi th ho ok m ovement

to left

needle.

With hook movement

the position s hown , t ou c h t he ba ck o f t he ho ok .

behind

(see b )there i s a cl ea ra nc e of 0. 1 m m b et w ee n h oo k ti p a nd

the needle an d f r om le ft to right

from left to right

(see a )the ne edle should, in

in front

from right

of the

Calculation of the ellipse width:

E = a + b + 0,1 + x

E [mm] Ellipse width

a [mm] Needle thickness in the area of the furrow

b [mm] H oo k thickness in the a rea of the thread guid e

hole at the hook tip

0,1 [mm] Cle aran c e b et w ee n h oo k tip and needle

with movement from right to left

x [mm] Quantity by greater needle thicknesses

x = 0 for needles up to Nm 100

x = 0,1 for needles up to Nm 120

x = 0,2 for needles up to Nm 130

Example for a needle 934 Sin/ Nm 110

E = 0,7 + 1,4 + 0,1 + 0,1 =

a = 0,7 mm Ellipse width

b = 1,4 mm Need le th ick ne ss in th e a r ea of th e furrow

1,0 mm Clearance between hok point and needle

x = 0,1 mm Quan ti ty by gre at er n ee dl e t hi cknes se s

2.3 mm

13

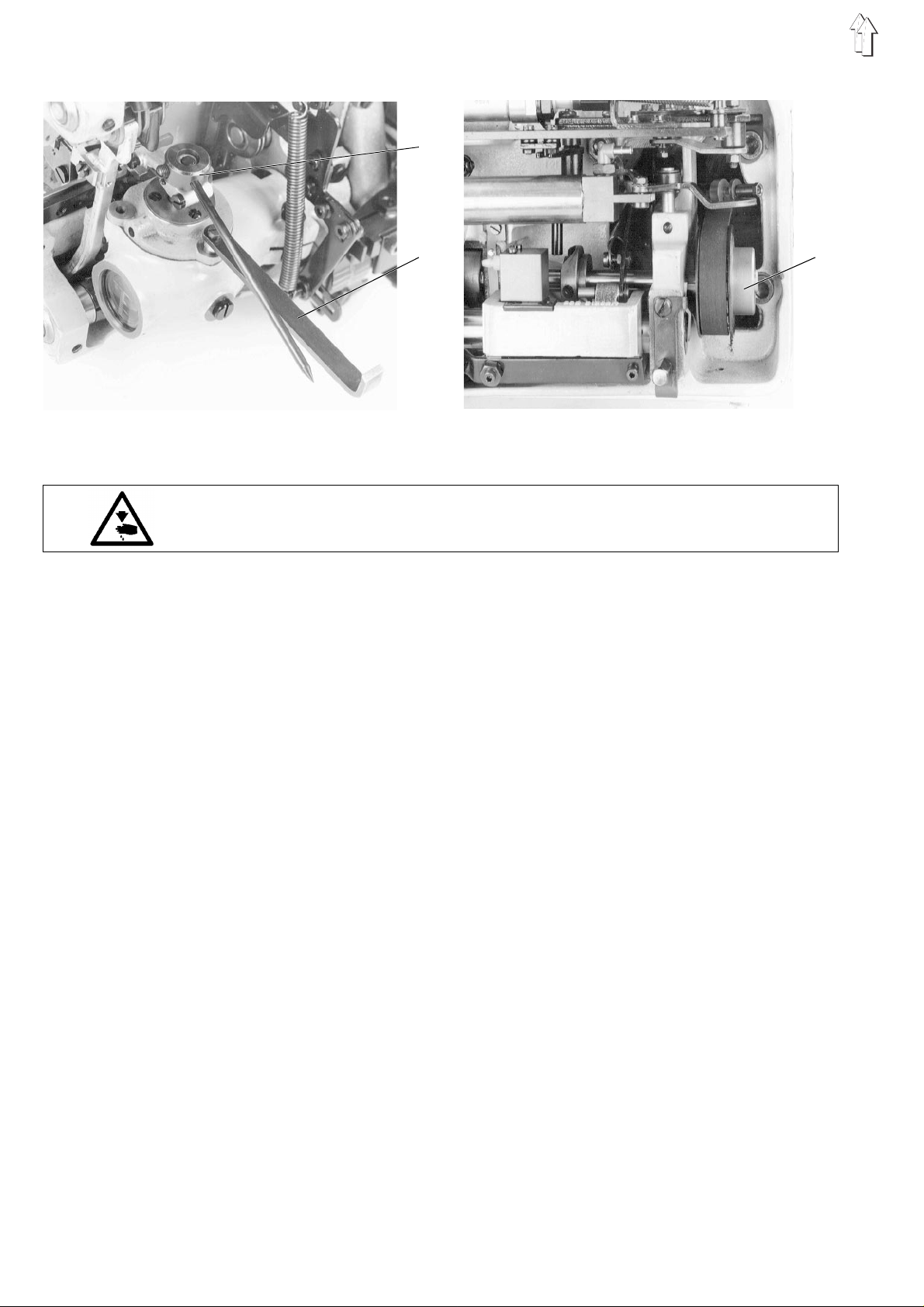

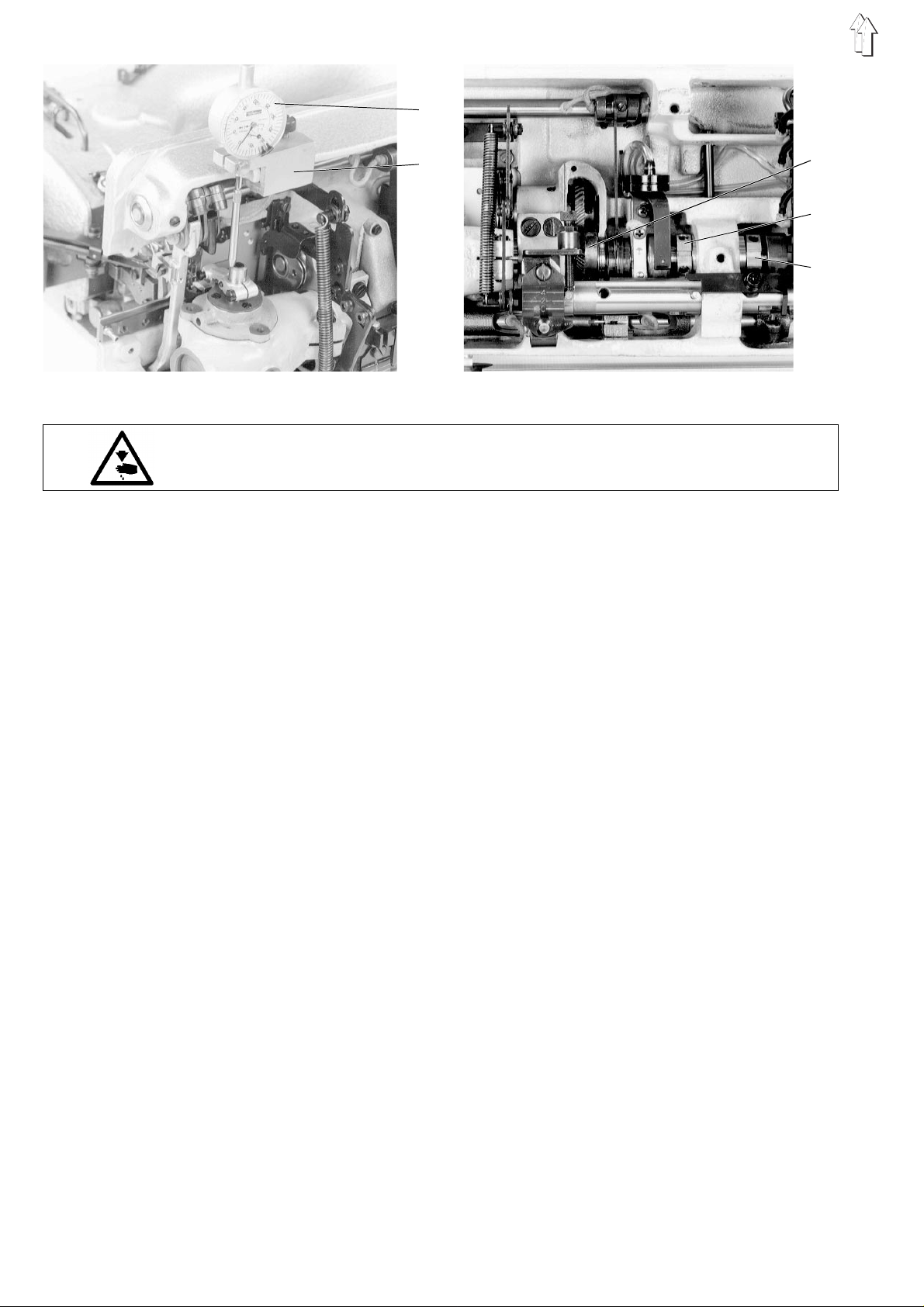

1

2

Caution Risk of Injury !

Before measuring and setting turn the main switch of f.

Measuring the ellipse width

–

Attach gaug e 1 wi th pa rts set 2 ( Or d er no. 933 0 00 74 3) .

–

By turning the handwheel set the lowest and the highest point.

The difference must correspond to the ellipse width.

If not then th e e ll ip se width must be set ag ai n.

3

4

5

Setting the ellipse width

–

Axially displace the lower shaft (see chapter 2.3 ).

The ellipse width is changed by only half the amount that the lower

shaft was displaced !

To the right: Ellipse width becomes smaller

To the left : Ellipse widt h b eco mes greater

–

Then set the ad vanc in g cams 4 and 5 on the l ower shaft bearing

tight again !

Do not turn the advancing cams ! If so they must be set again.

–

Realign sprocket 3.

Do not turn the sprocket ! If s o th e t hr e ad ta ke-up di s c mus t be s et

again.

–

Check the positi on of th e r e ta in in g ring (see cha pt er 8 .2 ) and the

timing belt pulley in the axial direction.

14

2.8 Needle Guard

a) b)

1

2

The needle guar d 1 i s to hi nd er a di versi on of th e n ee dl e i nt o t he pa th

of the hook.

Caution Risk of Injury !

Tu rn off main switc h before adj ust ing.

Preparation

–

Remove the needle plate and feed dog.

1. Setting the Height

–

Move the needle guard 1 in the block 2.

See a) .

In the lowest needle position the upper half of the needle eye must

remain free.

2. Setting the Position

–

Align the needle block on the hook housing.

See b) .

When the hook t ip moves fr om r ig ht to left and reaches t he ne ed le

then the needl e t ip should touch the ne ed le guard.

The hook must m ove behind the needle witho ut to uc h ing i t.

When lowering the needle should not be diverted by the needle

guard so that t he loop formation i s no t i mp ai red .

15

Loading...

Loading...