Adler 540-100 Installation Manual

Manual, complete

540 - 100

CNC double lockstitch buttonholer

Operating Instructions

Installation Instructions

Service Instructions

1

2

3

Postfach 17 03 51, D-33703 Bielefeld • Potsdamer Straße 190, D-33719 Bielefeld

Phone + 49 (0) 5 21 / 9 25-00 • Fax + 49 (0) 5 21 / 9 25 24 35 • www.duerkopp-adler.com

Ausgabe / Edition: 04/2006 Printed in Federal Republic of Germany Teile-Nr./Part.-No.: 0791 540001

540 - 100

Manual, complete

Contents

Operating Instructions

Installation Instructions

Service Instructions

Interconnection-diagram

9890 540001 B

Software version

A04.1

B04.1

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruc ti o n m an ual contains i m po rt a nt i nf ormation on how t o

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruc ti o n m an ual must alway s be available at the

machine/sewing unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, i ncl u di n g e qu i pp i ng , troubleshoot i ng du r ing the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair and/or

– Transport.

The user also has to assure that only authorized personnel work on

the machine.

The user is o bl i g ed to c he c k th e machine at lea s t o nc e pe r shi f t f or

apparent da ma ge s and to immedia tl y r e po r t a ny c h an ge s ( i ncl u di n g

the performanc e i n se r vi c e), wh i c h impair the safety.

The user comp an y mu s t e ns u r e t ha t t he ma c hi n e i s only operated i n

perfect working order.

Never remove or disable any safety devices.

If safety dev i c e s ne ed to be removed for equi pp i ng , r e pa i ri ng or

maintaining, the safety devices must be

remounted directly after completion of the maintenance and repair

work.

Unauthorized modification of the machine rules out liability of the

manufacture r fo r da ma ge res u l ti n g f r om th i s .

Observe all safety and danger recommendations on the machine/unit!

The yellow -and-black str i pe d surfaces desig na t e pe rma ne nd danger

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

instruction book and operated by persons with appropriate

training.

2. Before putting into service also read the safety rules and

instructions of the motor supplier.

3. The machine must be used only for the purpose intended. Use of

the machine without the safety devices is not permitted. Observe

all the relevant safety regulations.

4. When gauge parts are exchanged (e.g. needle, presser foot,

needle plate, feed dog and bobbin) when threading, when the

workplace is left, and during service work, the machine must be

disconnected from the mains by switching off the master switch or

disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance

unit.

Exceptions to this are only adjustments and functions checks

made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time

as the entire sewing unit is found to comply with EC directives.

It is absolutely necessary to respect

the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Contents Page:

Part 2: Installation Instructions Class 540-100

1. Scope of delivery.............................................. 3

2. General and Transportation Safety

2.1 Ringbolt ................................................... 3

3. Equipment

3.1 Structure of equipment ........................................... 4

3.2 Available equipment ............................................ 5

4. Optional equipment

4.1 Positioningaids............................................... 7

5. Assembling the sewing automat

5.1 Makingthetabletop ............................................ 8

5.2 Mounting the frame ............................................. 9

5.3 Completion and mounting of table top .................................. 10

5.4 Settingtheworkingheight......................................... 11

5.5 Setting up the machine head ....................................... 11

5.5.1 Lengthwise installation ........................................... 11

5.5.2 Widthwiseinstallation............................................ 11

5.5.3 Swivel device (optional) .......................................... 12

5.5.4 Needle cooler (optional) .......................................... 13

5.6 Mounting the control unit .......................................... 15

5.7 Mounting the waste container ....................................... 15

5.8 Mounting the maintenance unit and the set value initiator ..................... 15

5.9 Mounting the pedal and the traction rod ................................ 15

2

6. Electrical connection

6.1 Plug connections at the multiple pin strip (4-fold) ........................... 16

6.2 Plug connections at the multiple pin strip (15 fold) .......................... 17

6.3 Potential compensation .......................................... 17

6.4 Control connection to main switch .................................... 18

7. Pneumatic connection

7.1 Connecting the maintenance unit .................................... 19

7.2 Connecting the waste container ..................................... 19

8. Oil lubrication

8.1 Filling the oil reservoir ........................................... 20

9. Software installation

9.1 Standard delivery .............................................. 21

9.2 Softwareinstallation ............................................ 21

9.2.1 General .................................................... 21

9.2.2 Loading the program ............................................ 22

9.2.3 Dongle-Update via Internet ........................................ 23

9.3 Language setting .............................................. 23

10. Sew ing test ................................................. 24

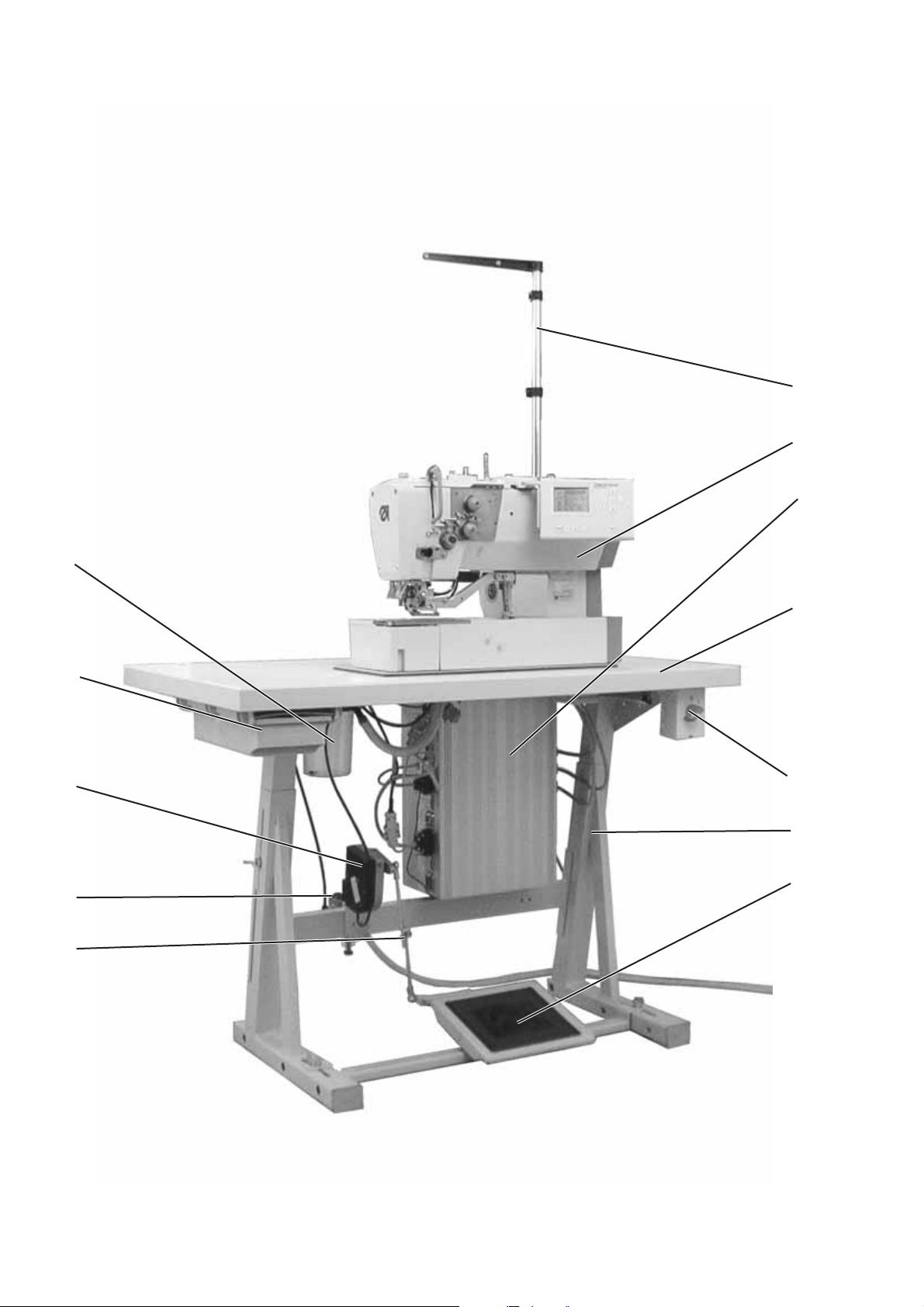

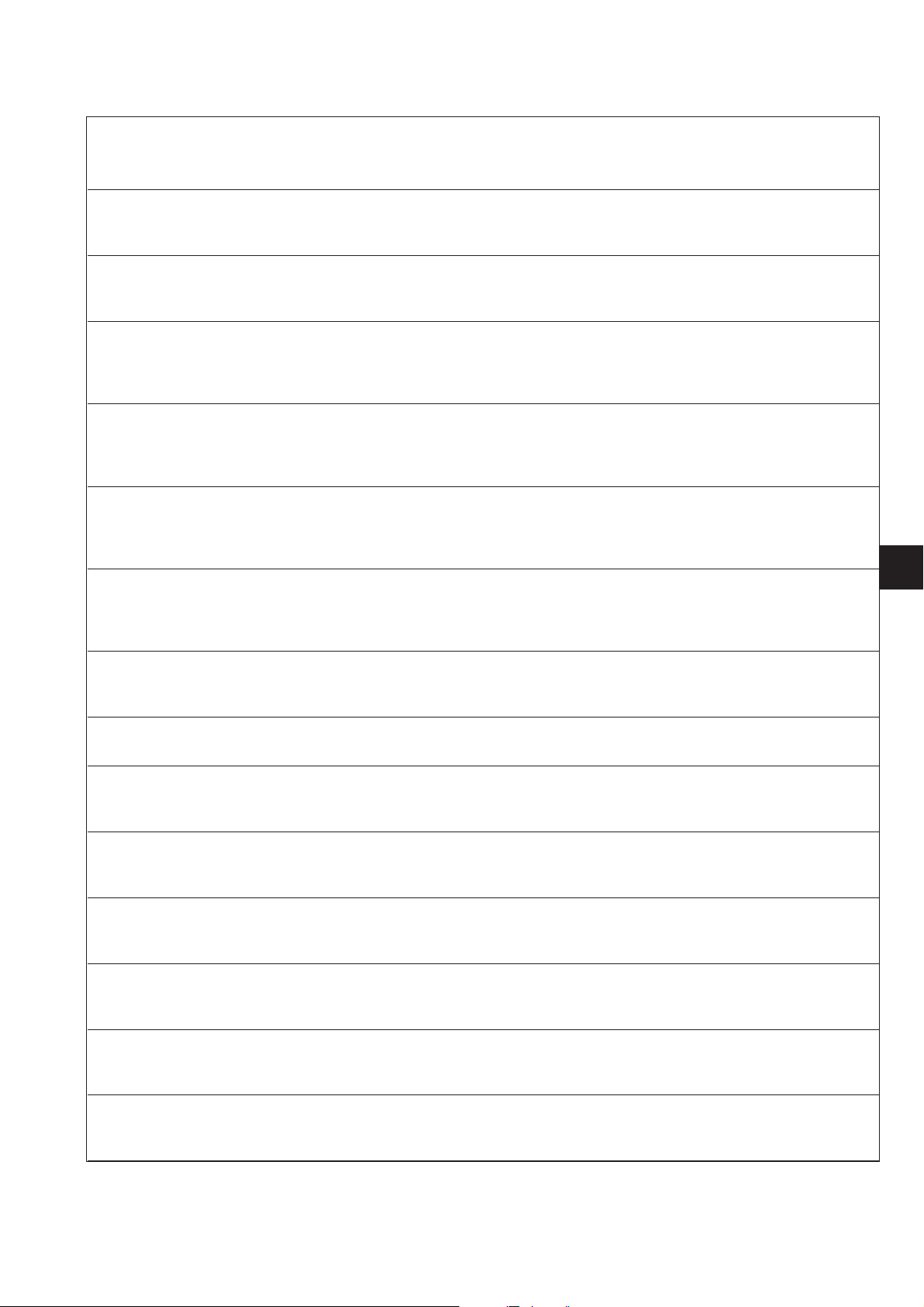

12

8

1

2

5

11

4

3

6

7

9

10

1. Scope of delivery

The scope of delivery is dependent upon your order.

Please check that all necessary parts are present.

–

1 Machine head

–

2 Control

–

3 Maintenance unit

–

4 Set value initiator

–

5 Waste container

–

6Tractionrod

–

7Mainswitch

–

8 Thread stand

–

Small parts in the accessories pack

Only with delivery of frame (optional)

–

9Frame

–

10 Pedal

–

11 Table top

–

12 Drawer

2. General and Transportation Safety

ATTENTION !

The sewing automat 540 must only be installed by trained

specialist staff !

Transport securing devices

If you have bought an assembled buttonholer; the following transport

securing devices have to be removed:

Securing tapes and wood battens at machine head, table and stand.

2.1 Ring bolt

The ring bolt makes it easier to lift the automat onto the frame. You can

lift the automat using a ceiling crane or two people can lift the automat

using a stable bar putting it through the ring bolt. The ring bolts are in

the accessories pack.

–

Screw the ring bolt in the case lid of the machine head.

–

Lift the machine head onto the table plate.

–

Remove the ring bolt.

2

3

3. Equipment

3.1 Structure of Equipment

Equipment: E 126/22

Cutting

Throat plate/basket

1 = Cutting equipment with slit

in the throat plate

1 = blouses, shirts

raised throat plate (0,6 mm); basket sole

cross toothed

2 = working clothes, heavy material

flat throat plate; basket sole cross toothed

3 = ties, cuffs

flat throat plate; basket sole cross toothed,

narrow

4 = polo shirts

flat throat plate; basket sole cross toothed,

single side narrow, sewing basket steep sided

5 = ladies outer wear, working clothes, sports and leisure

wear with varying material thickness throat plate

not raised;

basket sole layered with Vulkollan foam

to even out level differences

6 = knitwear

throat plate sharply raised (1,6 mm); basket sole

toothed

Stitch row width

Sewing area and basket length

3.1.1 Sewing automat equipment components

3 = stitch row width max. 3 mm

4 = stitch row width max. 4 mm

6 = stitch row width max. 6 mm

22 = Buttonhole length to max. 22 mm

35 = Buttonhole length to max. 35 mm

48 = Buttonhole length to max. 48 mm

70 = Buttonhole length to max. 70 mm

The components for up-to-date equipment can be found at

www.duerkopp-adler.com in the Dow nload area.

4

3.2 Available equipment

540 E 113/22 Sewing equipment for buttonholes in shirts and blouses,

closely woven material, max. buttonhole width 3 mm, max.

buttonhole length 22 mm.

540 E 114/22

540 E 114/35

540 E 154/22

540 E 154/35

540 E 156/35

540 E 133/22

Sewing equipment for buttonholes in shirts and blouses,

closely woven material, max. buttonhole width 4 mm, max.

buttonhole length 22 mm.

Sewing equipment for buttonholes in shirts and blouses,

closely woven material, max. buttonhole width 4 mm, max.

buttonhole length 35 mm.

Sewing equipment for buttonholes in ladies outer wear,

working clothes, sportswear and casual wear with cloth

presser basket compensating the height differences, max.

buttonhole width 4 mm, max. buttonhole length 22 mm.

Sewing equipment for buttonholes in ladies outer wear,

working clothes, sportswear and casual wear with cloth

presser basket compensating the height differences, max.

buttonhole width 4 mm, max. buttonhole length 35 mm.

Sewing equipment for buttonholes in ladies outer wear,

working clothes, sportswear and casual wear with cloth

presser basket compensating the height differences, max.

buttonhole width 6 mm, max. buttonhole length 35 mm.

2

Sewing equipment for buttonholes in collars of shirts and

blouses and cuffs, with a narrow cloth presser basket,

max. buttonhole width 3 mm, max. buttonhole length 22

mm.

540 E 134/22

540 E 146/22

540 E 166/22

540 E 166/35

540 E 126/22

540 E 126/35

540 E 126/48

540 E 126/70

Sewing equipment for buttonholes in collars of shirts and

blouses and cuffs, with a special cloth presser basket , max.

buttonhole width 4 mm, max. buttonhole length 22 mm

Sewing equipment for buttonholes in Polo shirts, max.

buttonhole width 6 mm, max. buttonhole length 22 mm.

Sewing equipment for buttonholes in woven and knitted

fabrics, max. buttonhole width 6 mm, max. buttonhole

length 22 mm.

Sewing equipment for buttonholes in woven and knitted

fabrics, max. buttonhole width 6 mm, max. buttonhole length

35 mm.

Sewing equipment for buttonholes in working clothes,

medium weight material, max. buttonhole width 6 mm, max.

buttonhole length 22 mm.

Sewing equipment for buttonholes in working clothes,

medium weight material, max. buttonhole width 6 mm, max.

buttonhole length 35 mm.

Sewing equipment for buttonholes in working clothes,

medium weight material, max. buttonhole width 6 mm, max.

buttonhole length 48 mm.

Sewing equipment for buttonholes in seat belt openings in

stroller and infant safety seat, max. buttonhole width 6 mm,

max. buttonhole length 70 mm.

5

Loading...

Loading...