Adler 274, 271 Installation Instruction

Contents Page:

Home

Part 2: Install ation Ins tructions Cl. 271 to 274

1. General Information

1.1 Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Machine Operation without Material . . . . . . . . . . . . . . . . . . . . 2

1.3 Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. Assembling the Frame

3. Completing and Screwing On the Table

4. Connecting the Sewing Drive to the Table

4.1 General No tes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Motor Type for each Sub-class and Optional Equi pment . . . . . . . . . 7

4.3 Drive Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.4 Number of Stitches for 3-phase Drives depend ent on the Median

Belt Pulley Diamet er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.5 Setting the Motor Protection Switch . . . . . . . . . . . . . . . . . . . . 9

5. Inserting the Machine Head, V-belt Placement, Attaching the

Belt Guard, Handwheel and Pedal

6. Establishing Plug Connections to the Motor Control and

Attaching the Synchronizer

7. Connecting the Compressed Air Maintenance Unit

8. Making the Machine Operational and Conducting a Sewing Test

9. Notes prior to Commissioning a Sewing Drive with Digital

Control Technology

9.1 Mains Connection and Direction of Rot ation of a Direct Current

Sewing Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.2 Cor rection of the S et Value s (Parameters) . . . . . . . . . . . . . . . . . 1 5

9.3 Light Barrier Func tion with Quick . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . 12

. . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10. Keys on the Arm Head

11. Setting the Synchronizer

11.1 Positioning Drive without External Co ntrol Pane l . . . . . . . . . . . . . 19

11.2 Positioning Drive With External Control Pan el . . . . . . . . . . . . . . . 20

12. Lifting and Lowering Functions of the Carrier Roller by

Classes 273 and 274

13. On and Off Switching Functions of the Edge Cutter by

Classes 272-640142 and -740142 . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

25

1. General Information

1.1 Safety Notes

For Special Attention!

The mains volt age and the operating voltage shown on

the motor rating plate must be in agreement.

All work on electrical components is only to be conducted

by authorized personnel and with the mains plug

disconnected.

The safety instructions are to be observed.

Installation is to proceed according to the following

instructions.

–

The electrical connections are to be found in the

circuit diagram.

–

The sub-class specific arrangement of inputs and

outputs, as well as the appropriate parameter no.s

are listed on t he data sheet.

–

All required parts are included in the accessories

package.

1.2 Machine Operation without Material

In this case the pressure feet must first be locked in the

raised posit i on.

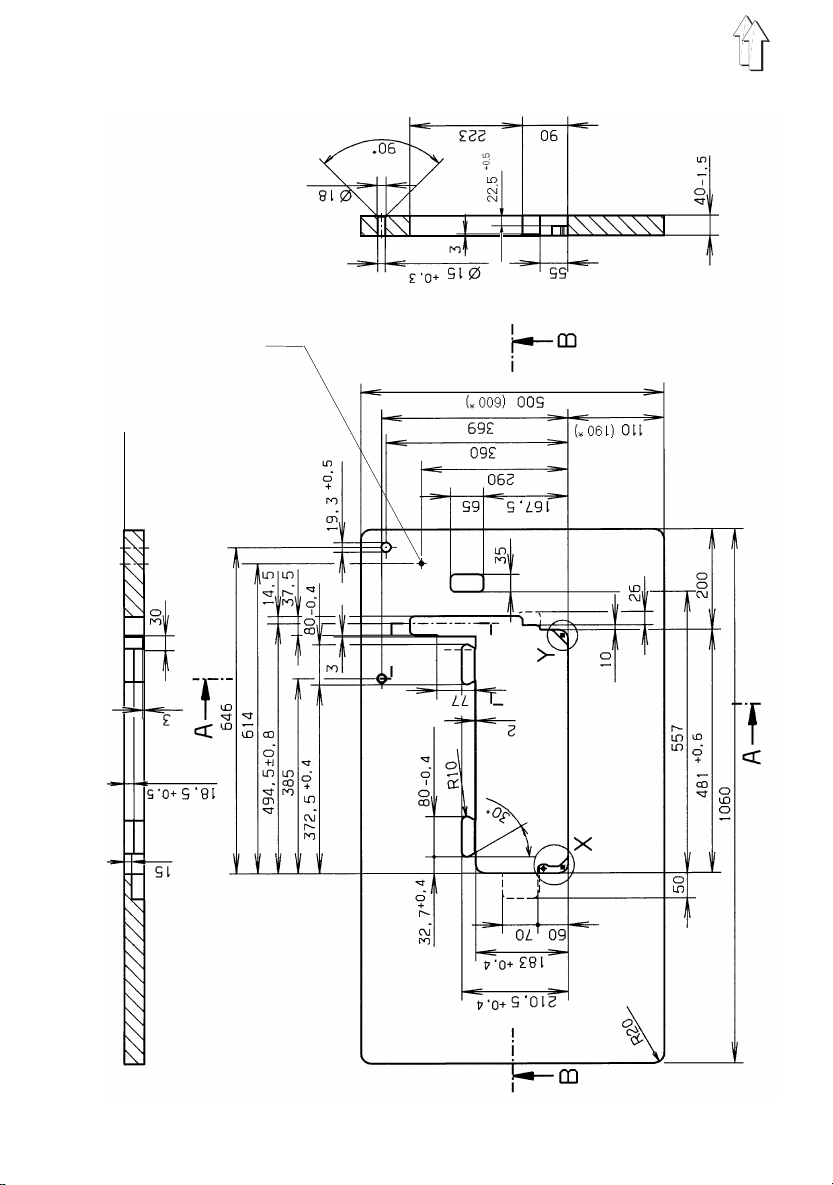

1.3 T ables

The cutouts in t ables made in-house m ust have the

dimensions shown in the sketches.

The tables m ust also have the necessary load capacity

and stability.

2. Assembling the Frame

Assemble the frame parts as shown in the illustration.

Slide on the enclosed frame feet 1.

A stable positioning of the frame can be a ch i eved after

loosening t he screws 2.

The desired work height and a horizontal working plane

can be set after loosening screws 3.

2

3

2

1

Schnitt - Selection

A - A

unbemaßte Radien R9

undimension radius R9

Ankörnung für Befestigung

des Gestells auf Tischplat-

tenunterseite

Ref. mark for fastening the

stand on the r eserve of the

table

* auf Wunsch

Oberseite

Top side

* on request

Schnitt - Selection

B - B

3

Schnitt / Section

C - C

Einzelheit / Detail

X

791 1012

1

791 1011

Auflagepunkt /

Supporting point

2

ab/from

bis/till

10/93

9.93

Einzelheit / Detail

Y

3

4

5

8

7

6

4

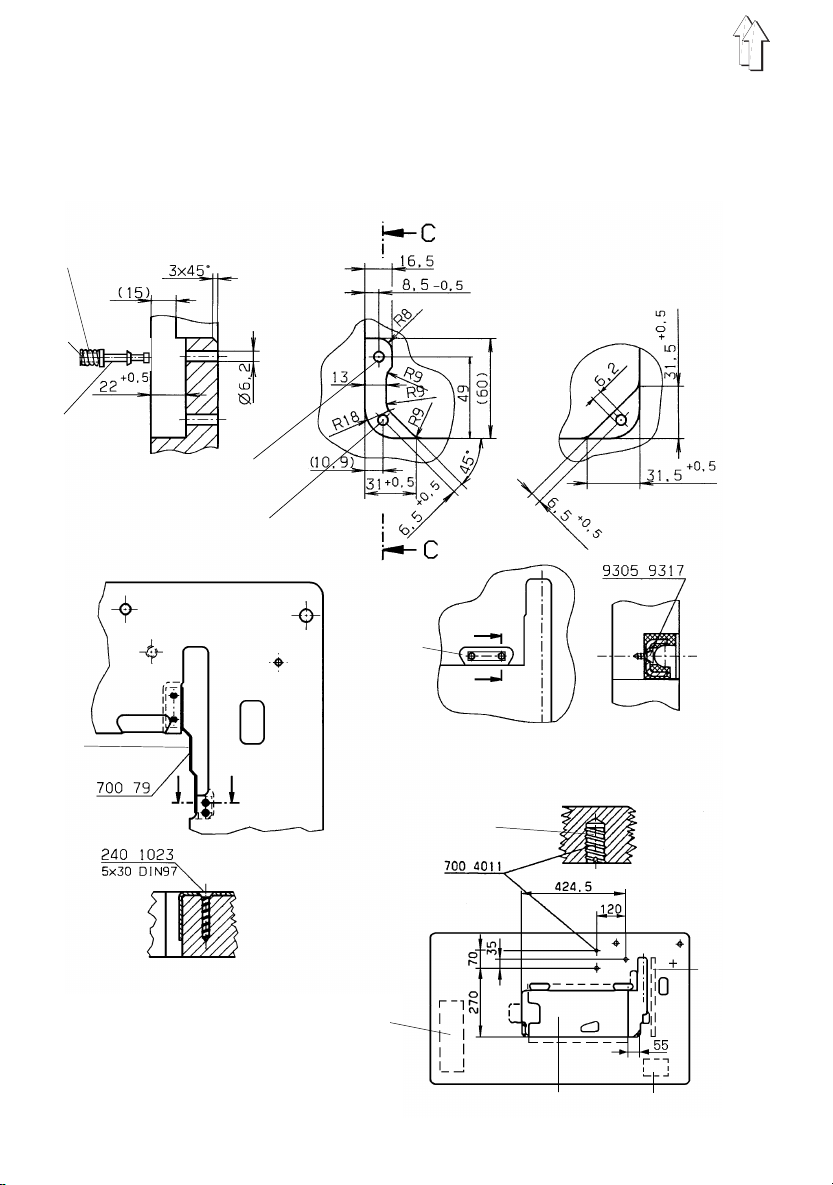

3. Completing and Screwing on the T able

–

Screw on the reinforcement brace 2 between the

cutouts for the machine head and the motor belt.

–

Screw the cable c hannel 5 and the mounting for the

wiring tension relief to the underside of the table.

–

Screw on the main switch 6.

–

Screw on the sewing light transformer, if included.

–

Lay the elect ri cal wiring.

–

Screw on the drawer 8 with its mounting.

–

Screw the table onto the frame with B8x35 wood

screws. The positioning of the table to the frame can

be seen in the reference mark on the underside of

the table. See the dimension s ketch.

–

Press the bott om hinge parts 3 for the machine

hinges into the recesses in th e t able and screw fas t.

–

For the forward rest of the machine head insert two

rest plugs into the table and slide on pressure

springs. The left plug 1 must be inserted into the

hole as per section C-C and the right plug into the

hole as per detail Y. The ends of the plugs protruding

on the bottom of the table are to be cut off.

Technical Feature!

Through the p ositioning of the le ft retainer plug 1 a

lifting of the left machine hinge by ca. 1mm results

and thus an uncoupling from the table.

–

Screw the oil baffle 7 under the t able with wood

screws in such a way that there is a gap of 55 mm

between th e right edge of the oil baffle and the right

edge of the table cutout. Align the oil baffle to the

front and rear edge of the table cutout in such a way

that the machine head does not hi t when tilted over.

The knee lever should later not hit the oil baffle in

any of its possible settings.

5

4. Connecting the Sewing Drive to the T able

4.1 General Notes

Complete dri ve packages for the 271, 272, 273 and 27 4

consisting of the sewing drive, the main switch wi t h

wiring, the V-belt pulleys, the V-belt and diverse parts are

available.

The 3-phase clutch motors are normally laid out for

3x380-400V 50 Hz. The number of revolutions is 2800

rpm. -phase m otors for other m ains voltages are available

on request.

Direct current drives for these machines are operated

with a "single phase alternating current". Therefore , with

multiple machines the connections must equally

distributed to the individual phases of the 3-phas e m ains

circuit. Otherwise this can cause o verloading of indivi dual

phases.

The motor type required for each sub-class and v arious

optional equipment can be seen in the table following in

Section 4.2.

Attention!

When sewing d rives for the 273 a nd 274 are attach ed it

should be ch ecking during subs equent commissioni ng if

the correct functions for the carrier roller have been

entered into the motor controls. See Section 12.

If the electrical equipment was not supplied b y DÜ RKOPP

ADLER testing should be conducted t o EN 60204-3-1 or

JEC 204-3-1.

6

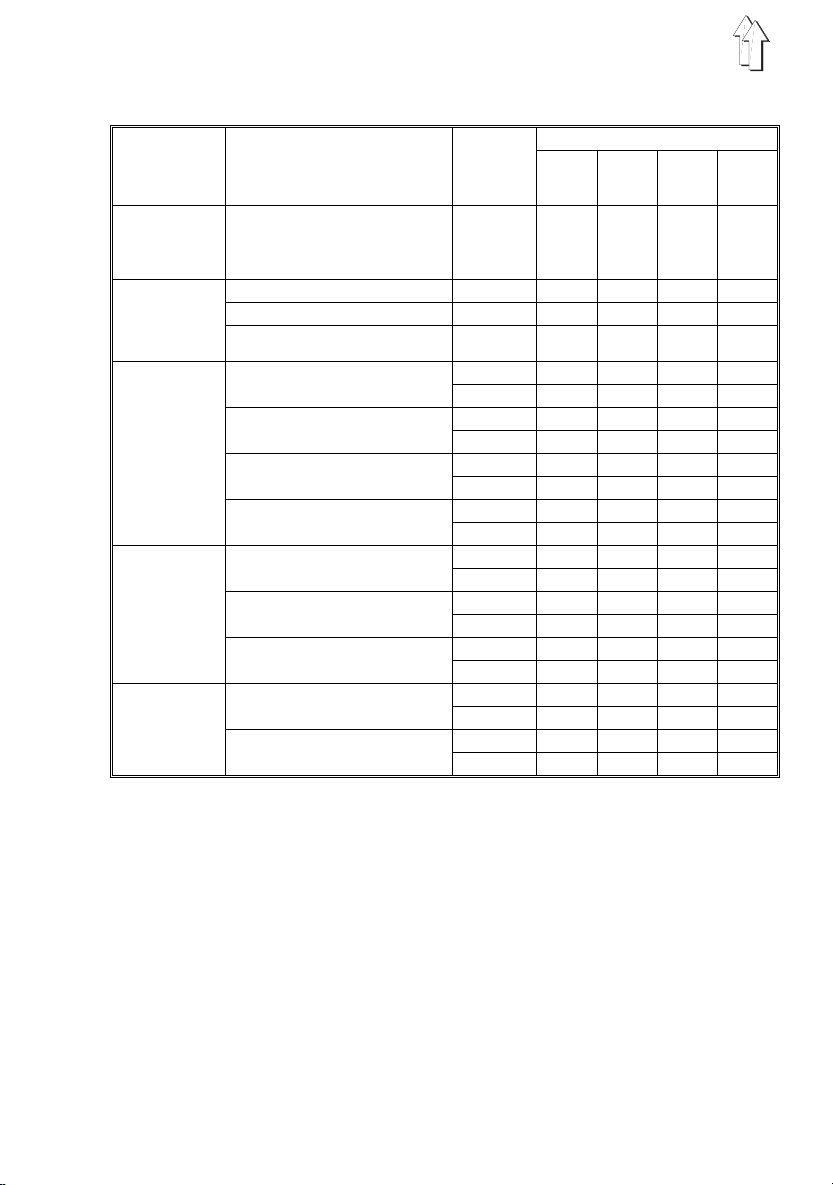

4.2 Motor Type for each Sub-class and Option al Equipment

271 272

273 274

Sub-class

-140041

-640141

-140042

-160062

-240042

-640142

-140042

-160062

-240042

-640142

-740142

-140042

-160062

Control

Motor Type

FIR 1100F-ZT37

Efka VD552/6F62AV

Efka DC1600/DA62AV

Quick QD552/D21K01

FIR 1180F70 670 x - - -

Efka VD552/6F62AV V62 x - - -

Efka DC1600/DA62AV (V62) x - - -

Efka VD552/6F72CV20491)

Quick QD552/D40K021)

Efka DC1600/DA82CV1 )2)

Quick QE6040/D40S021)2)

Efka VD552/6F72CV2049

Efka DC16 00/DA82CV3201

Quick QE6040/D40S02

Efka DC1600/DA82AV2)

Quick QE6040/D50S012)

3201

3207

1) For the classes 273 und 274 only the drives marked

with 1) may be used.

2) Direct current-positioning drives for connection to

1x220-240V 50/ 60Hz

3) Not for classes 273 und 274

Panel

( )on

request

- x---

V720 x - - x

V730 x x - x

DB4x---

DB5 x x - V720 x - - x

V730 x x - x

DB4 x - - x

DB5 x x - x

V720 x - - o

V730 x x - o

V720 x - - o

V730 x x - o

DB4 x - - o

DB5 x x - o

V720 x - x3) V730 x x x3) -

DB4 x - x3) -

DB5 x x x3) -

Optional Equipment

Z120

Z133

1801

371

Z116

6741

Z124

401

Z120181

Z133371

Z1166741

Z124401

o

–

Thread wiper

–

Light barrier for sewing stop at seam end with

follow-up functions

–

Device for sewing with two pres et needle thread

tension values. See under 1.3 Opt i onal equipment.

–

Electropneumatic operation for switching the edge

cutter on and off via keys for 272-640142.

–

Standard by sub-class -740142.

7

4.3 Drive Mounting

–

Fasten the drive with its foot to the underside of the

table. Heret o screw the 3 hexa gon head screws,

M8x35, into the nuts 4 (see table dimension sketch).

–

With the ground cable 2 found in the drive package

make a connection between the motor foot and the

underside of t he machine.

–

Here fasten the cable eye with a M4 screw to the

threaded hole in the motor foot.

–

Lead the cable through the o i l baffle and attach the

flat plug 1 to the connector st rip as shown in the

illustration.

–

The ground cable serves to conduct the static charge

on the machin e head to ground vi a the motor.

–

Fasten the V-belt pulley to the motor shaft.

–

Check the arrangement of the connections on the

sewing drive t ransformer and correct appropriate to

the available mains voltage, if necessary. See

enclosed circuit diagram.

1

2

4.4 Number of Stitches dependent o n the Belt Pulley Diameter

Number of Stitches for 3-phase Drives

Stitches/min 50 Hz 60 Hz

3800

4000

4200

4500

4800

5000

5500

Direct current drives

belt pulley diameter is to be chosen here.

As a rule of thumb:

Belt pulley diameter for alternating current drives minus 30% gives the suitable

diameter fo r direct current sewing drives.

The motor revolutions can also be regulated at the control panel.See motor operation

instructions.

8

80 mm

85 mm

90 mm

95 mm

100 mm

106 mm

112 mm

reach much higher rpm than 3-phase drives. Therefore a smaller

67 mm

71 mm

75 mm

80 mm

85 mm

90 mm

95 mm

Loading...

Loading...