TR21-WS, TR23-WS, TR21-WK,

TR23-WK, WRECVR

INSTALLATION INSTRUCTIONS

FEATURES

• Wall module to Receiver (point to point) wireless kits

can replace any standard wired sensor

• Wireless Kits (wall module and receiver) are pre-bound

at the factory for quick installation

• Signal Strength LED built into the wall module

• Low battery indication

• Optional dip switches available to bind any wall

module to any receiver

• Approximate 5 year battery life with AA Alkaline

(included), 7.5 year with Lithium

• Locking screw discourages tampering and battery

theft.

APPLICATION

The WRECVR receiver and TR21-WS, TR23-WS, TR21-WK,

and TR23-WK are a family of wireless wall modules and

receiver for use with:

— Spyder Unitary Controllers: PUL, PVL, etc.

— Excel 10 W7750, W7751, W7752, and W7753

controllers

— T7350, T7351, and TB8575 low-voltage SuitePRO™

thermostats

— Will not work with TB7220, TB8220 or TB line voltage

thermostats, XL15s, W7762, W7763 or certain other

XL controllers,

— Will work with WEBs-AX™ I/O Module products if

using a separate transformer

— Compatibility with various other non-Honeywell con-

trollers that accept 10K type2 NTC temperature inputs

NOTE: Refer to the TR21 and TR23 Wall Modules –

Specification Data, form 63-1332, for specific model

features and additional information.

Model No. FCC/IC ID’s

TR21-WS

TR21-WK

TR23-WS

TR23-WK

TR21-WSU

TR23-WSU

WRECVR

WRECVRU

FCC ID: HS9WLKFWM

IC: 573R-WLKF

FCC ID: HS9WLKFRV

IC: 573R-WLKF

SPECIFICATIONS

Models: For specific model information, see Specification

Data, form 63-1332.

Environmental Ratings:

• Wall Module Operating Temperature: 45° to 99°F

(7° to 37°C).

• Receiver Operating Temperature: -40° to 150°F

(-40° to 65.5°C).

• Storage Temperature: -40° to 150°F (-40° to 65.5°C).

• Operating Humidity: 5% to 95% RH (non-condensing)

Accuracy: +/- 1ºF (+/- 0.5ºC) across 12ºC to 30ºC

Setpoint Range for TR23: 56° to 84°F (13° to 29°C)

Accessories: 50007298-001 (pack of 12) medium, cover

plate; 6-7/8 x 5 in. (175 x 127 mm).

Power:

Receiver Voltage: 20 – 30VAC/DC, 50/60Hz; 24VAC typical

Housing:

• Wall Module: UL94-HB

• Receiver: UL94-5VA

Radio Frequency 2.4 GHz (IEEE Std 802.15.4-2003

compliant)

• Open Range: 3000 feet

• Typical Range: 100 feet

• Output power: 16dBm

• Receiver power consumption: <1.5 VA@24VAC

62-0291-07

TR21-WS, TR23-WS, TR21-WK, TR23-WK, WRECVR

CAUTION

M29049

POWER

RFSignal

TEMP

SETPT

LOW BAT

OVERRIDE

EGND

COM

24VAC

1

2

3

4

5

6

7

8

ON ON

ON

CONTROLLER SELECTION

S1

S2 S3

DEVICE

1 2 3 4 5 6 1 2 3 4 5 61 2 3 4 5 6

1 2 3 4 5 61 2 3 4 5 6

1 2 3 4 5 6

ON

ON

ON

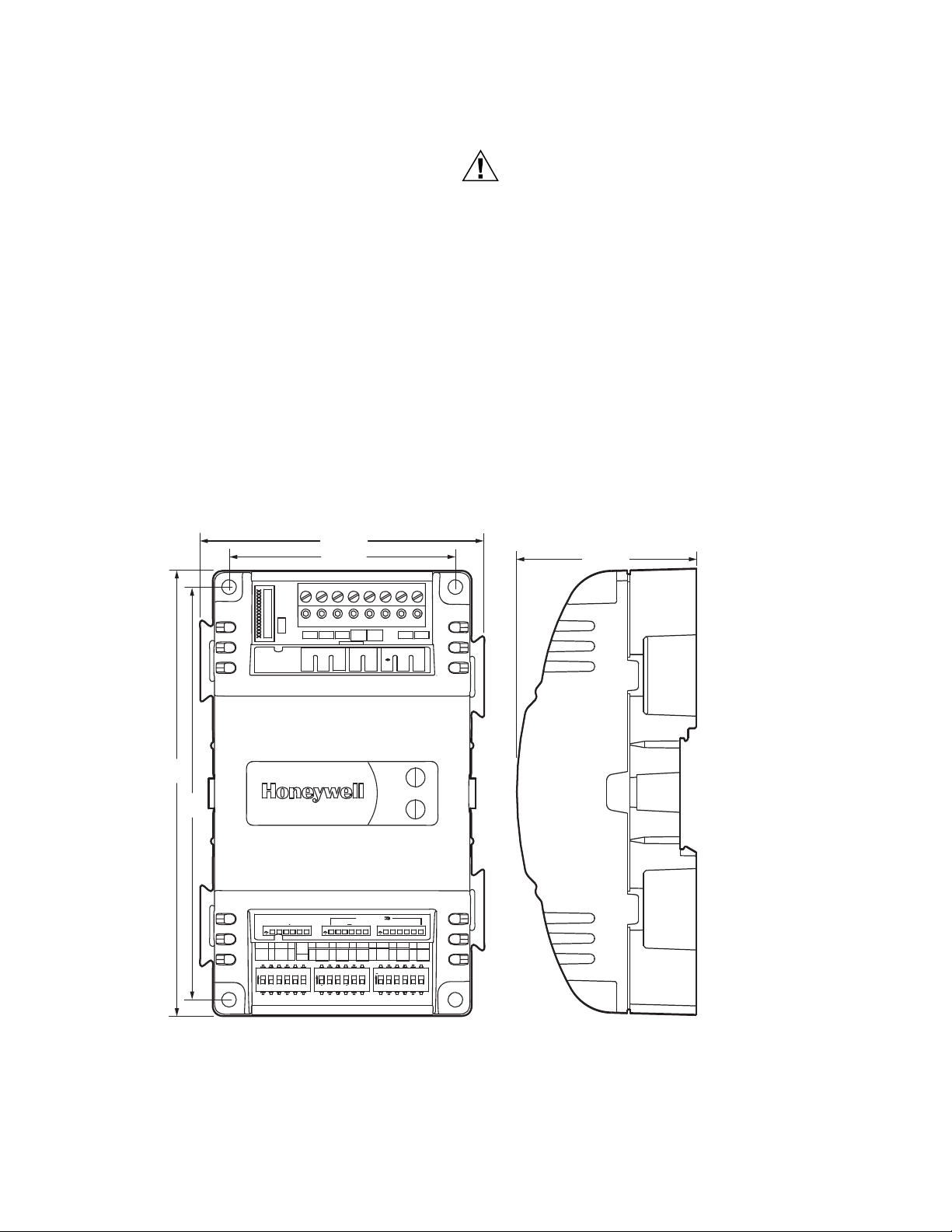

3-13/64 (81)

5-1/2

(140)

2-13/64 (56)

2-25/32 (71)

5-3/32

(129)

Approximate battery life under normal operating

conditions:

• 5 years with two AA Alkaline batteries (included)

• 7.5 years with two AA Lithium Batteries

Transmission interval: 30 seconds

Pressing override button or signal strength button will force an

immediate transmission.

Approvals:

This device complies with Part 15 of the FCC rules. Operation

is subject to the following two conditions:

1) this device may not cause harmful interference, and

2) this device must accept any interference received,

including interference that may cause undesired operation.

Mounting the Receiver

INSTALLATION

Erratic System Operation Hazard.

Failure to follow proper wiring practices can

introduce disruptive electrical interference (noise).

Keep wiring at least one foot away from large inductive

loads such as motors line starters, lighting ballasts,

and large power distribution panels.

Shielded cable is required in installations where these

guidelines cannot be met.

Ground shield only to grounded controller case.

IMPORTANT

All wiring must comply with local electrical codes and

ordinances or as specified on installation wiring

diagrams.

— Receiver wiring can be sized from 16 to 22 AWG

(1.31 to 0.33 sq. mm) depending on the application.

— The maximum length of wire from a device to a receiver is

100 ft. (30.5 m).

Fig. 1. Receiver dimensions in in. (mm).

The receiver can be mounted on any surface using screws

(No. 6 or No. 8) appropriate for the mounting surface. The

receiver can also be mounted to the Spyder controller using

the mounting slots and tabs (dovetails), and can be mounted

to a DIN rail.

62-0291—07 2

TR21-WS, TR23-WS, TR21-WK, TR23-WK, WRECVR

CAUTION

M29050

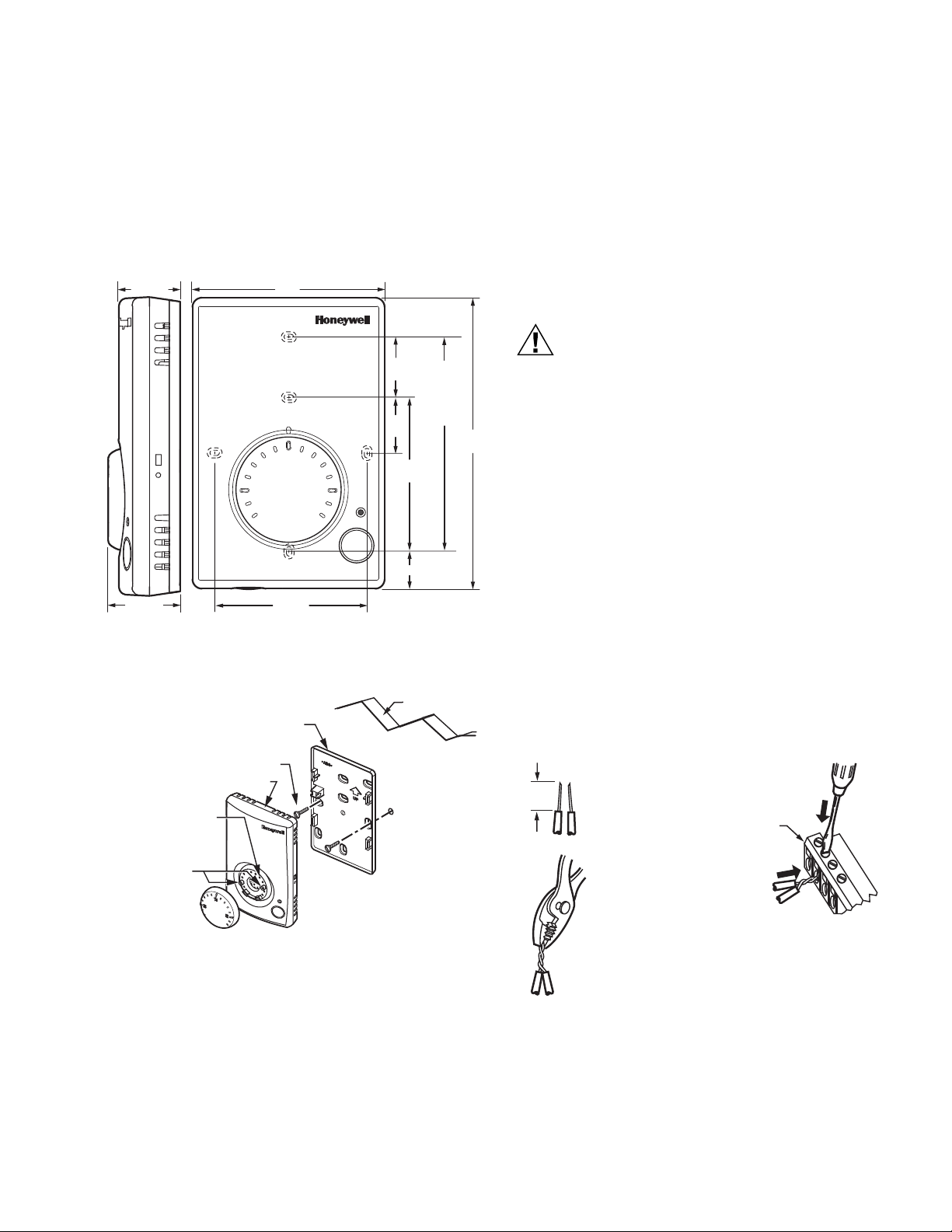

60

70

80

3 (77)

4-11/16

(119)

1-5/32 (29)

63/64 (25)

STANDARD

UTILITY

CONDUIT

BOX (2 X 4)

MOUNTING

HOLES

9/16 (14)

2-3/8

(60)

7/8

(22)

7/8

(22)

2-3/8 (60)

M29054

SUBBASE

NO. 6 SCREW

FRONT COVER

TEMPERATURE LIMIT

END STOPPER

LOCATIONS

END STOPPERS

WALL

Mounting the Wall Module

Mount the wall module on an inside wall approximately 54 in.

(1372 mm) from the floor (or in the specified location) to allow

exposure to the average zone temperature. Do not mount the

wall module on an outside wall, on a wall containing water

pipes, or near air ducts. Avoid locations that are exposed to

discharge air from registers or radiation from lights,

appliances, or the sun. When mounting to drywall, use the

horizontal mounting screw locations, as shown in Fig. 3.

Fig. 2. Wall Module subbase dimensions in inches (mm)

(TR23 shown).

If desired, insert the two red end stoppers into temperature

scale to set the desired temperature range limit. See Fig. 3.

For TR23 models, insert the desired dial through the opening

in the cover. Align the keyed shaft on the knob with the keyed

slot into the fitting on the subbase, then press down until it

snaps into place.

WIRING

Attach the wires from the device terminals to the appropriate

receiver terminals.

Improper Electrical Contact Hazard.

Screw type terminal blocks are designed to accept

no more than one 16 AWG (1.31 sq. mm)

conductor.

Connect multiple wires that are 16-18 AWG

(1.31-0.82 sq. mm) with a wire nut. Include a pigtail

with this wire group and attach the pigtail to the

individual terminal block.

Wire the terminal block as follows:

1. For single wires, strip 3/16 in. (5 mm); for multiple wires

going into one terminal, strip 1/2 in. (13 mm) insulation

from the conductor.

2. If two or more wires (18 to 22 AWG only) are being

inserted into one terminal, twist the wires together

before inserting.

NOTE: When two or more wires are being inserted

into one terminal, be sure to twist them

together. Deviation from this rule can result

in improper electrical contact. See Fig. 4.

3. Insert the wire in the required terminal location and

tighten the screw to complete the termination.

4. Review and verify the terminal connection wiring and

DIP switch settings.

Fig. 3. Mounting the wall module on the wall and

temperature limit set screw locations (TR23 shown).

There is a locking screw option to prevent tampering and

access to batteries. The screw is provided with the wall

module, and screws into the slot shown in Fig. 9 after the

device is snapped onto the subbase.

1.

1/2

(13)

STRIP 1/2 IN.

(13 MM) FROM

WIRES TO BE

ATTACHED AT

ONE TERMINAL.

2.

TWIST WIRES

TOGETHER

WITH PLIERS

(A MINIMUM OF

THREE TURNS).

CONTROLLER OR

RECEIVER

E-BUS CONNECTOR

TERMINALS

3.

CUT TWISTED END OF WIRES TO

3/16 IN. (5 MM) BEFORE INSERTING

INTO TERMINAL AND TIGHTENING

SCREW. THEN PULL ON EACH WIRE

IN ALL TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

M29055

Fig. 4. Attaching two wires (18 to 22 AWG) to

receiver terminals.

3 62-0291—07

TR21-WS, TR23-WS, TR21-WK, TR23-WK, WRECVR

1234567 8 9101112

24 VAC

COM

OUT 1

OUT 2

E-BUS

W7751H

WALL MODULE

EARTH

GND

SENSOR

BYPASS

LED

NOT EARTH GROUND

MICROBRIDGE

DP SENSOR

TRIAC

EQUIVALENT

CIRCUIT

SET PT

M29051

TEMP

SETPT

LOW BAT

OVERRIDE

COM

24VAC

1

2

3

4

5

6

7

8

POWER

EGND

TEMP

SETPT

LOW BAT

OVERRIDE

COM

24VAC

1

2

3

4

5

6

7

8

EGND

AO-1

COM

AO-2

AO-3

COM

UI-1

COM

UI-2

UI-3

COM

UI-4

UI-5

COM

UI-6

DI-1

DI-2

COM

DI-3

20V DC

DI-4

NET-2

NET-1

SHLD

EGND

24 VAC

24VAC COM

DO-1

COM

DO-2

DO-3

DO-4

DO-5

COM

DO-6

COM

123456

78

109 2345678 09

11 1111111 21

123456

7809

22 2222222 33

123456

7809

333333334

DO-7

DO-8

COM

SBUS1

SBUS2

M29052

TEMP

SETPT

LOW BAT

OVERRIDE

COM

24VAC

1

2

3

4

5

6

7

8

POWER

EGND

TEMP

SETPT

LOW BAT

OVERRIDE

COM

24VAC

1

2

3

4

5

6

7

8

EGND

Fig. 5. Wiring receiver to Excel 10.

Fig. 6. Wiring receiver to Spyder Unitary Controller.

62-0291—07 4

TR21-WS, TR23-WS, TR21-WK, TR23-WK, WRECVR

M28646

TEMP

SETPT

LOW BAT

OVERRIDE

COM

24VAC

1

2

3

4

5

6

7

8

POWER

EGND

TEMP

SETPT

LOW BAT

OVERRIDE

COM

24VAC

1

2

3

4

5

6

7

8

EGND

RCX

SUBBASE

W1 GY1

W2 Y2

AUXRH

T5 T6 T7 T4 T3

OSOS ASAS

WHEN USING THE WIRELESS TR23 SENSOR WITH THE T7350 BE SURE TO

USE THE RELATIVE SCALE SETPOINT KNOB.

WHEN USING THE WIRELESS TR21 SENSOR WITH THE T7350, DO NOT WIRE

TERMINAL 5 AND TERMINAL 6.

NOTE 1.

NOTE 2.

Fig. 7. Wiring receiver to T7350 thermostat.

DIP Switch Labels

This device is packed with tear-off DIP switch labels you can attach to the receiver and indicate which DIP switches are on and

off.

CONTROLLER SELECTION

S1 S2 S3

ON

ON ON

1 2 3 4 5 6

S1 DIP

Fig. 8. Wall module DIP switches and Receiver DIP switches S1, S2, and S3. Figure shows an example of sensor DIP

switches matching S2 and S3 DIP switches on receiver.

TESTING FOR SIGNAL STRENGTH

When the receiver is powered and batteries are placed in the

wall module, communication will begin automatically within 2

seconds. The receiver RF signal light will flash every 30

seconds to confirm each transmission. You can force

immediate communication by pressing the signal strength

button on the side of the wall module with a 1-1.6 mm

ON

1 2 3 4 5 6 1 2 3 4 5 61 2 3 4 5 6

DEVICE

ON

S2 DIP

POWER

RFSignal

ON

1 2 3 4 5 61 2 3 4 5 6

S3 DIP

ON

1 2 3 4 5 6

ON

1 2 3 4 5 6

M29053

diameter probe with flat or rounded face (a common paperclip

will do) (see Fig. 9). This may be required to initiate

communication when replacing a wall module.

The signal strength LED next to the signal strength button will

light up on the side to show the relative signal strength. The

signal strength LED will initially light amber when the signal

strength button is pressed to verify that you are pressing the

signal strength button. When you release the signal strength

button, the light will behave as shown in Table 1.

5 62-0291—07

TR21-WS, TR23-WS, TR21-WK, TR23-WK, WRECVR

M29048

LED

TEMPERATURE

DIAL,

FAHRENHEIT

DIAL SHOWN

BYPASS

(OVERRIDE)

BUTTON

60

70

80

SIGNAL LED

SIGNAL STRENGTH BUTTON

LOCKING

SCREW SLOT

Fig. 9. Wall module features (TR23 shown).

Table 1. Signal Strength LED.

LED Signal Strength

Remains Green for 5 seconds Strong

Remains Amber for 5 seconds Weaker (still acceptable)

Amber blinks for 5 seconds No signal

If no signal is received, test the wall module in a different

location until a suitable signal strength is received by the

receiver. Pressing the signal strength button on the wall

module will cause a five-second flash on the RF signal LED

on the receiver, and pressing the override button will cause a

single flash on the receiver.

If communication is lost between the wall module and

receiver, the receiver will try three times to reestablish

communication. After 3 tries (90 seconds), the receiver will go

into a sleep mode, and will retry to communicate every 10

minutes. Output from the receiver will be an open circuit for

temperature and setpoint output (simulating cut wires on a

wired sensor). Communication will re-establish automatically

once signal is within range.

remove and re-install one battery, leaving it out for 10 seconds

OR you can initiate communication by pressing the signal

strength button on the sensor (using paperclip).

Each wireless kit has a unique binding, so even though

multiple wireless kits have S2 and S3 switches all in the OFF

position, each device will only communicate to the device to

which it was paired and shipped as a kit.

There may be times when you want to bind a receiver to a wall

module using the DIP switches. This is done simply by

matching any S2/S3 DIP switch settings on the receiver with

the DIP switch settings on the wall module. Wall modules in

close proximity must have different DIP switch settings

(except when modules are using the all-OFF default binding).

DIP switches S2/S3 are provided for two reasons:

• If the wall module needs to be replaced, a TR21-WS or

TR23-WS wall module can be purchased. To bind any wall

module and receiver, simply set the DIP switches S2/S3 on

both the receiver and the wall module to any matching DIP

configuration. To prepare for this ahead of time, the

receiver and wall module in the WK kit can be set with a

matching dip switch configuration when mounted. The tear

off tab on the receiver allows the installer to write down the

on/off DIP configuration. Then the new wall module’s DIP

switches can be set by matching the old wall module’s DIP

switches, without having to set or check the DIP switches

on the receiver.

• If wall modules and receivers get mixed up in the field

(even though they are marked with matching numbers from

the factory), DIP switches can be used to bind any wall

module to any receiver simply by matching the S2/S3 DIP

switches. If setting DIP switches, be sure that each

wireless sensor/receiver pair in a given building has a

unique DIP switch setting to prevent cross-talk.

Fig. 8 shows matching DIP switch settings binding the wall

module and receiver.

Controller Matching

The TR21 and TR23 wireless wall modules can be used with

many different controllers. The S1 switch on the receiver can

be set for a number of different controller requirements. See

Table 2 for DIP switch settings, and see Table 3 for a

description of the controller.

BINDING THE WALL MODULE AND RECEIVER TO EACH OTHER

The TR21-WK and TR23-WK wireless kits include a wall

module and receiver that have already been bound in the

factory to automatically communicate with each other. They

can be identified as matching by the identical bind numbers

printed on the labels. The S2 and S3 DIP switches on the

receiver (used to bind the two devices) and the 12 DIP

switches on the wall module will all be in the OFF position. As

soon as power is applied to the receiver and the batteries are

installed in the wall module, the two devices start to talk to

each other. If the two devices don’t communicate immediately,

62-0291—07 6

Table 2. S1 DIP Switch Settings.

S1 DIP Switches

Controller

1. Spyder/ComfortPoint

123456

ON OFF OFF OFF OFF OFF

20Kohm, XL10

2. XL600, 500, 100, 80 OFF ON OFF OFF OFF OFF

3. 10K type 2, 3-wire ON ON OFF OFF OFF OFF

4. 10K type 2, see I&I OFF OFF ON OFF OFF OFF

5. 10K type 2, 4-wire ON OFF ON OFF OFF OFF

6. 10K type 2, 3-wire OFF ON ON OFF OFF OFF

TR21-WS, TR23-WS, TR21-WK, TR23-WK, WRECVR

Table 3. Controller Descriptions.

Controller Description

1. Spyder/ComfortPoint

20Kohm, XL 10

2. Honeywell Other For use with XL600/500/100.

3. 10K type 2 10K ohm NTC type 2 output, 2K-3K ohm knob span:

4. 10K type 2 10K ohm NTC type 2 output, 1K -11K ohm knob span.

5. 10K type 2 10K ohm NTC type 2 output, 0-10K ohm knob span:

6. 10K type 2

(ComfortPoint 10K

ohm controllers)

Default setting. For use with Spyder and Comfort Point 20K ohm controllers

For use with XL10 VAV, W7750, W7751, etc.

• Common

• Temperature (Override button temporarily shorts the temperature output)

• Setpoint

• 10K out

• Common (for temperature, override, and setpoint)

• Override

• Setpoint

10K ohm NTC type 2 output, 0-9500 ohm knob span:

• Common

• Temperature (Override button temporarily shorts the temperature output)

• Setpoint

Low Battery Signal

When there are approximately 2 months of battery life

remaining, the LED on the front of the wall module (next to the

Override button) will flash red every 15 seconds. In addition,

the LOW BAT digital output from the receiver will close. This

LOW BAT output signal can be sent to an unused DI on the

controller to let the user know that there is a low battery

condition. Replace the batteries whenever the LOW BAT

contact closes, or flashing red light is seen next to the

Override LED on the face of the wall module. Normal

operation will automatically resume.

NOTE: If the batteries go dead, the LOW BAT digital output

(open/close) signal will open again. The LOW BAT

digital output will close only when batteries are running low, not when they are completely dead, or are

not installed. This ensures that a lack of signal is not

confused with dead or missing batteries. Whenever

there is no signal, or batteries have gone completely

dead, the receiver LOWBAT output will send an open

circuit reading to the controller for temperature (and

set point, if applicable).

Override Button

To save battery life, the override button LED will only light

when the button is pressed. It will not remain lit, as on

standard wired TR23 and TR24 models. Override will still be

activated when the button is pressed. If using with the XL10,

pressing and briefly holding the override button will cause it to

behave like other standard wired TR23s. The LED will

remain lit for 9 seconds max. to confirm it has been pressed

from 1-4 seconds.

REPLACING A WALL MODULE

When replacing a wall module, set the DIP switches the same

as the wall module being replaced. If the previous wall module

DIP switches are all set to OFF, it will be necessary to reset

the S2 and S3 receiver dip switches to any configuration not

being used by other receivers in the area, and then set the

wall module DIP switches to the same setting. At least one of

the 12 DIP switches must be set to the ON (up) position.

General Rules for Installing Wireless Wall Modules

Communication between the wall module and receiver can be

influenced by a number of factors. Type and thickness of

building materials and the way in which they are oriented in

relation to the wall module and receiver will affect

communication.

Do not place either the wall module or receiver inside metal

cabinets or enclosures.Try to orient the wall module and

receiver so that if they are separated by a wall(s), the direction

of signal travel is as perpendicular to the wall(s) as possible.

This reduces the effective wall thickness.

When mounting the receiver on a metal duct, stronger

communication is possible if the wall module is on the same

side of the duct so the signal doesn’t need to travel through

the metal duct.

Reduce as much as possible the amount of metal (ducts, file

cabinets, etc.) between the sensor and the wall module.

Standard drywall (gypsum board) does not greatly affect

signal strength.

For the most robust wireless link, install the wall module in

locations with the strong signal (Green light as described in

Table 1).

7 62-0291—07

TR21-WS, TR23-WS, TR21-WK, TR23-WK, WRECVR

Warning: Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to

operate the equipment.

LONWORKS® is a registered trademark of Echelon® Corporation.

LONMARK® and the LonMark Logo are trademarks of the LonMark Association.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2009 Honeywell International Inc.

62-0291—07 E.K. Rev. 06-09

Loading...

Loading...