TKL19 (RTUL19)

Installation Manual

Honeywell Installation manual Pagina 1 di 25

CONTENTS

1.1 Wall Set Up for the Cable Trays.........................................................4

1.2 Electrical Connections........................................................................5

1.3 LONWORKS® Data Cables................................................................7

1.4 Mounting the Wall Bracket..................................................................8

1.5 Cable Connections ............................................................................. 9

1.5.1 LON Cable..............................................................................9

1.5.2 Power Supply Cable +12VDC..............................................10

1.5.3 Input Cable 1 – Door Contact............................................... 11

1.5.4 Input Cable 2 - Button ..........................................................12

1.5.5 Output Cable Relay 1- Door Open....................................... 13

1.5.6 Output Cable Relay 2 – Signal Light.................................... 16

1.6 Mounting the Device on the Wall Bracket.........................................18

1.7 Identification Using the Service Pin..................................................19

1.8 Identification Using the Neuron ID....................................................20

2.1 TemaKey TKL19 (RTU-L19 code 1500154xx) ................................... 21

2.1.1 Supplied Parts......................................................................22

2.1.2 Optional Parts....................................................................... 22

2.2 Recycling.......................................................................................... 23

Page 2 of 25

FFCCCC NNOOTTIICCEE

NOTE: This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in

a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, these is no guarantee that interference will not occur in a particular

installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by tuning the equipment off and on, the

user is encouraged to try to correct the interference by one or more the

following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help.

Caution: any modification or change not expressely approved by the party

responsible for compliance could void the user’s authority to operate the

equipment.

Canadian Compliance Statement

This Class B Digital apparatus meets all the requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numerique de la classe B respecte les exigences du Reglement

sur le material broilleur du Canada.

FCC ID: HS9-RTU-L19

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

Page 3 of 25

PPRREEPPAARRAATTIIOONNSS

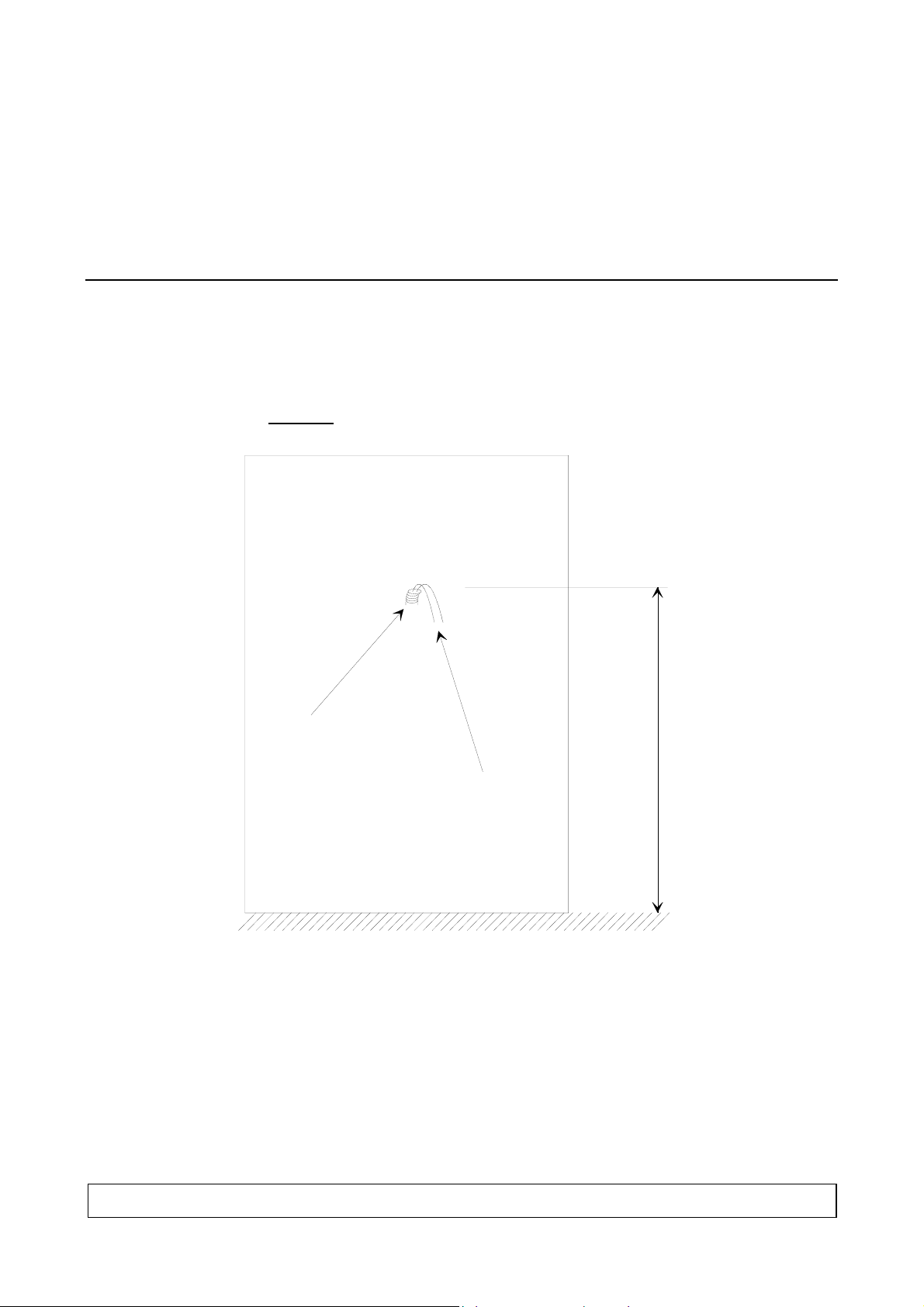

11..11 WWaallll SSeett UUpp ffoorr tthhee CCaabbllee TTrraayyss

The cables must:

1) Protrude from the wall.

2) Come out at

120cm from ground (see Figure 1) (advised).

cable tray

cables

m

c

0

2

1

Version: 1.0 EN

Floor

Figure 1: Wall Set Up for the Cable Trays

Page 4 of 25

11..22 EElleeccttrriiccaall CCoonnnneeccttiioonnss

The RTU is powered at low voltage (12VDC 160mA), preferably using a

power supply module with battery backup (RTU-Qxx), or using an ordinary

power supply having the same characteristics. The power cables must be

dimensioned as indicated in the table below. The maximum allowable voltage

drop on the power cable is 1V.

• Cable length(m) = 1V / (I[A] load x 2 x (res [Ohm/km] /1000))

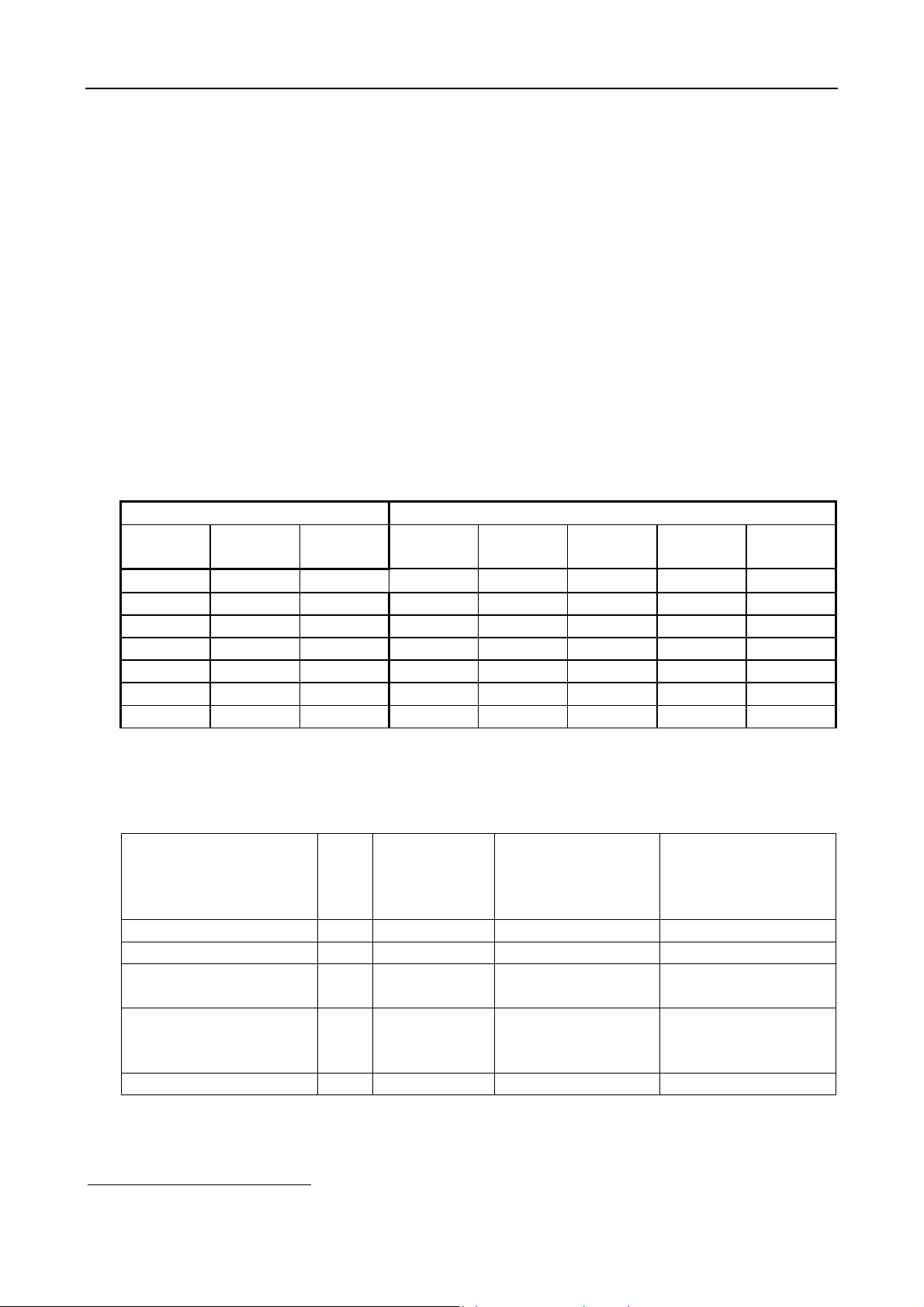

Cabl e Type

AWG mm2 ohm/ Km 160 [ mA] 320 [ mA]

12 3. 3 5. 7 548 274

14 2 8. 8 355 178

16 1. 3 14 223 112

18 0. 9 21 149 74

200.6349246

22 0. 35 52 60 30

240.2853718

Ext ensi on [ m] based on l oad

The device is equipped with 2 non-removable cables of 2m length:

• Two-pole, twisted, unpolarized cable dedicated to the LON line

connection

- LON a 0,325 mm

- LON b 0,325 mm

2

white

2

orange

• Ten-pole cable, providing the following signals:

2

- +12VDC 0,34 mm

- GND 0,34 mm

- INPUT 1 + 0,22 mm

- INPUT 2 + 0,22 mm

- RELAY 2 contact C 0,22 mm

- RELAY 2 contact NC 0,22 mm

- RELAY 2 contact NO 0,22 mm

- RELAY 1 contact C 0,56 mm

- RELAY 1 contact NC 0,56 mm

- RELAY 1 contact NO 0,56 mm

red

2

black

2

green / white

2

gray / green

2

brown

2

white

2

blue

2

green

2

yellow

2

gray

The signals must be connected using a shunt box with IP protection level

in conformance with the type of environment in which it is to be used:

- IP55 for moist environments

- Recessed box or IP31 at least for inside installations

The shunt box must be positioned within the perimeter controlled by the

access control system.

If necessary, the repeater relays must be inserted inside the box for

electrical locking commands and the signal light.

2-pole LON

Page 5 of 25

Figure 2: Position and dimensions of the non-removable cables

Shunt Box

2 meters

4,20 cm

RTUL19

Cable +12VDC

Cable LON

Cable IN 1

Cable IN 2

Cable OUT 1

Cable OUT 2

Figure 3: Shunt Box

Page 6 of 25

®

L

11..33 L

N

OON

W

W

OORRKKS

®

S

DDaattaa CCaabblleess

• The LONWORKS®1 data cables must be double twisted-pair cables

• In a free topology configuration, the overall length of the sections must not

exceed 500m

• In a bus configuration, the overall length of the sections must not exceed

2700m

• In the free topology configuration, the 50ohm terminator must be enabled

by inserting the appropriate jumper into the FTT10A plug-in on the CTUPLG06 board inside the TemaServer

• In a bus configuration, two terminators must be inserted at the two ends of

the bus (resistance of 100ohm 1% ½W)

• The LONWORKS®1 data cables must be dimensioned according to the

indications in

Table 1

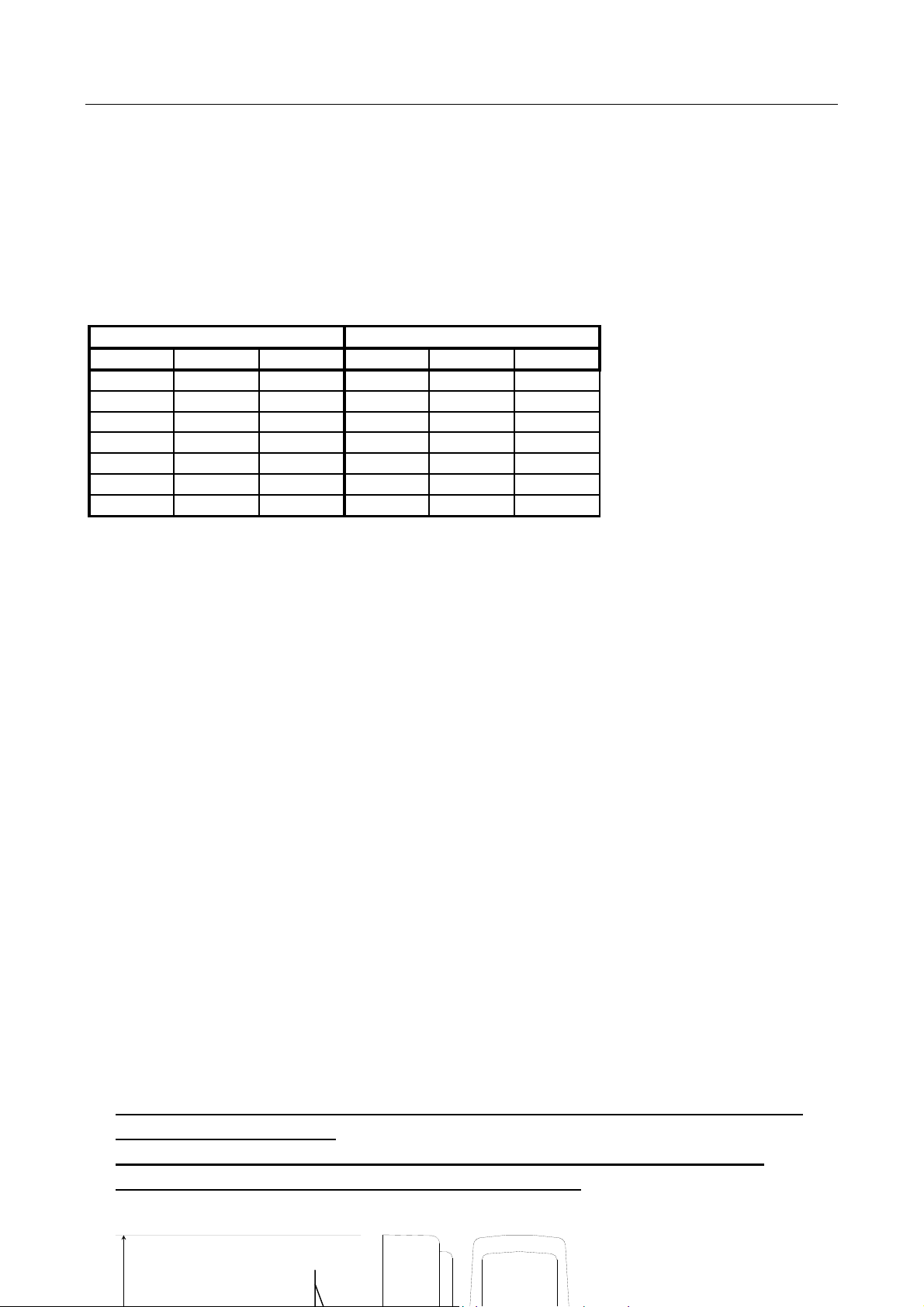

Cable Type Extension [m] based on cable capacitance

AWG mm

12 3.3 5.7 2676 1892 1338 846 598

14 2 8.8 2153 1523 1077 681 482

16 1.3 14 1707 1207 854 540 382

18 0.9 21 1394 986 697 441 312

20 0.6 34 1096 775 548 346 245

22 0.35 52 886 626 443 280 198

24 0.2 85 693 490 346 219 155

Table 1: Length/Capacitance of LONWORKS

• The FTT10A Echelon

2

Ohm/Km 50nF/Km 100nF/Km 200nF/Km 500nF/Km 1uF/Km

®

1

Cables

®

v1.2 User’s Guide suggests using the cables as

indicated in Table 2.

Make and Model AW

G

Belden 85102 16 2700 500 500

Belden 8471 16 2700 400 500

Level IV (twisted pair,

solid, unshielded)

JY (St) 2x2x0,8 (4

solid wires, spiraltwisted, shielded)

TIA Cat5 / 900 250 450

22 1400 400 500

20 900 320 500

Bus

Connection

Max Length

total [m]

Free Topology

Connection Nodeto-Node Max

Length [m]

Free Topology -

Connection

Max Length total

[m]

Table 2: Suggested LONWORKS® Cables

1

LONWORKS® is a trademark of the Echelon Corporation

Page 7 of 25

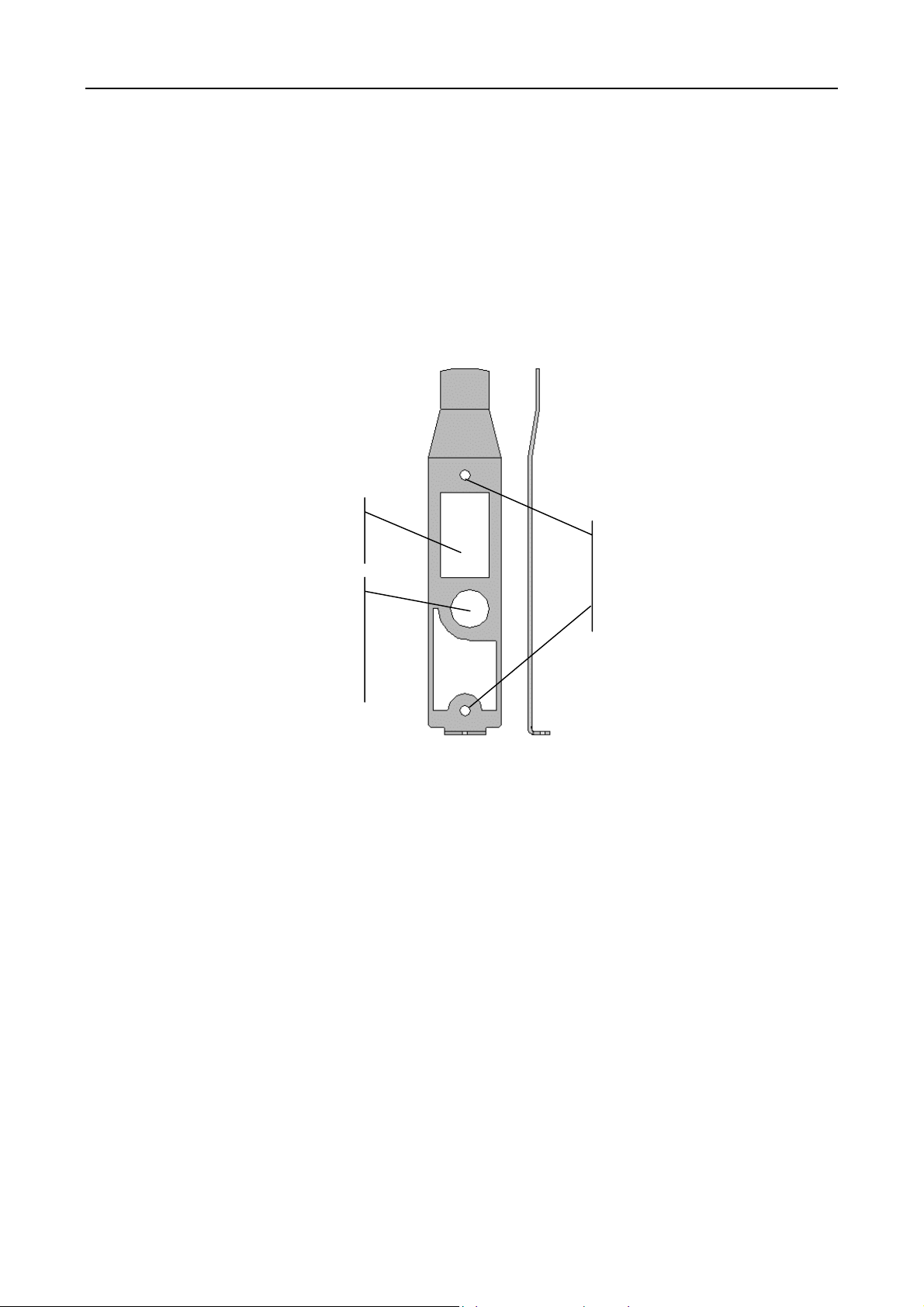

11..44 MMoouunnttiinngg tthhee WWaallll BBrraacckkeett

Mount the bracket onto the wall as follows:

1. Placing the bracket against the wall to indicate the proper positions of the

holes, make the holes for the two bolts that will go into the wall to hold the

bracket (the bolts are included in the installation kit)

2. Make sure that the cable tray bathces with the hole for the passage of the

cables

3. Screw in the bolts.

Hole for Cables

Holes for wall

mounting

Hole for inserting bolt and

screw to press against the

anti-removal/anti-open

tamper

Figure 4: Wall Bracket: Front View and Side View

Page 8 of 25

11..55 CCaabbllee CCoonnnneeccttiioonnss

1.5.1 LON Cable

LON A

LON B

Note: connection

not polarized

2 meters

6,10 cm

Figure 5: LON (1) Cable Connection

Page 9 of 25

1.5.2 Power Supply Cable +12VDC

12VDC (red)

GND (black)

2 meters

6,10 cm

Figure 6: Power Supply Connection

Page 10 of 25

1.5.3 Input Cable 1 – Door Contact

The balanced input 1 is dedicated to door status control; the balancing

resistances must be positioned near the clean sensor contact.

IN1 (green / white)

NC CONTACT

White

Yellow

magnetic door contact

GND (black)

Figure 7: Connection for Balanced Input 1 – Door Contact

Page 11 of 25

1.5.4 Input Cable 2 - Button

Balanced input 2 is dedicated to status control of the Open button; the

balancing resistances must be positioned near the clean contact of the

button.

IN2 (green / gray)

NO CONTACT

White

Yellow

button contact

GND

Figure 8: Connection for Balanced Input 2 - Button

Page 12 of 25

1.5.5 Output Cable Relay 1- Door Open

The Relay 1 output is used for door control. It makes both NO and NC

contacts available.

The external load can be powered directly by AC or DC, in accordance

with the following limits:

- Minimum Load: 12VDC / 10mA

Voltage Working Current Peak Current

Suppressor

max 0.5 Sec

(inductive load)

12VDC 3A 10A 1N4004 Diode

30VDC 2A 10A 1N4004 Diode

42VDC 0.5A 7A 1N4004 Diode

42VAC 0.5A 7A MOV 75Vrms

• Inductive load with direct current:

In this case it is

mandatory to use the 1N4004 diode, which is provided,

(or an equivalent) in parallel to the coil of the electrical locking device, to

increase the life of the relay inside the RTU – see

Figure 9.

• Inductive load with alternating current:

In this case it is

mandatory to use the MOV (75VAC), which is provided,

(or an equivalante) in parallel to the coil of the electrical locking device,

to increase the life of the relay inside the RTU − see

Figure 10.

• Life: assuming the relay is activated 200 times a day and that the

voltage/current limits of the preceding table are respected, the life is

guaranteed for at least 6 years; if the relay is activated less frequently,

the life of the relay increases proportionally.

In case of excessive use (> 200 operations / day) it is suggested to use

an external relay.

Page 13 of 25

1N4004

Diode Transient

Suppresso

r

VEXT _+VDC

VEXT_GND

Relay 1

Green = C

Yellow = NC

Gray = NO

coil for electrical lock ing de vic e/r ep ea ter

Figure 9: Connection for Output Relay 1 (NO) – Door Open – DC Voltage

VEXT_Vac1

Mov75Vac

Soppressore

di transienti

VEXT _Vac2

Rele 1

Green = C

Yellow = NC

Gray = NO

Bobina elettroserratura / relè di ripetizione

Figure 10: Connection for Output Relay 1 (NO) – Door Open – AC Voltage

Page 14 of 25

1.5.5.1 Using an External Relay

In case of excessive use or use under elevated current or voltage, you must

insert a relay capable of supporting the load for a higher number of

operations.

The coil for the repeater relay must always be equipped with transient

suppressors, as can be seen in Figures 9 and 10.

It is also suggested to use a transient suppressor on the load in order to

prolong the life of the external relay.

Mov75Vac

Transient

Suppressor

Vac

Transient Suppressor

Vac

VEXT_relay

C

NC NO

VEXT _relay

coil for electrica l lo cking device/repeater

Vext AC = Mov75Vac

Vext DC = diodo 1N4004

coil for repe ater relay

:

Relay 1

Figure 11: Connection for Output Relay 1 (NO) – External Relay

Page 15 of 25

1.5.6 Output Cable Relay 2 – Signal Light

Output Relay 2 is used for signaling the status of the door (gateway

occupied / free ) and provides both NO and NC contacts.

The external load can be powered directly from AC or DC power, in

accordance with the following limits:

Voltage Working Current Peak Current (max

Suppressor

0.5 Sec)

30VDC 0.5 A 2 A 1N4004 Diode

30VAC 0.5 A 2 A MOV 75Vrms

• Inductive load with direct current:

In this case, it is mandatory to use a repeater relay and a 1N4004 diode

in parallel to the coil for the electrical locking device in order to increase

the life of the relay inside the RTU − see Figure 12.

• Inductive load with alternating current:

In this case, it is mandatory to use a repeater relay and the MOV

(75VAC) in parallel to the coil for the electrical locking device in order to

increase the life of the relay inside the RTU see

Figure 13.

• Life: assuming the relay is activated 200 times a day and that the

voltage/current limits of the preceding table are respected, the life is

guaranteed for at least 6 years; if the relay is activated less frequently,

the life of the relay increases proportionally.

• In case of excessive use (> 200 operations / day) it is suggested to use

an external relay.

Page 16 of 25

VEXT

Signaling Device (LED)

VEXT

Relay 2

Brown = C

White = NC

Blue = NO

Figure 12: Connection for Output Relay 2 (NO) – Resistive Load – AC/DC

Voltage

Mov x Vac

Transient

Suppressor

Vac_lamp

Transient Suppressor

Vac_lamp

VEXT_relay

C

NC NO

VEXT _relay

Vext AC = Mov75Vac

Vext DC = diodo 1N4004

coil for repeater relay

:

Relay 2

Brown = C

White = NC

Blue = NO

Figure 13: Connection for Output Relay 2 (NO) – Inductive Load – Repeater

Relay

Page 17 of 25

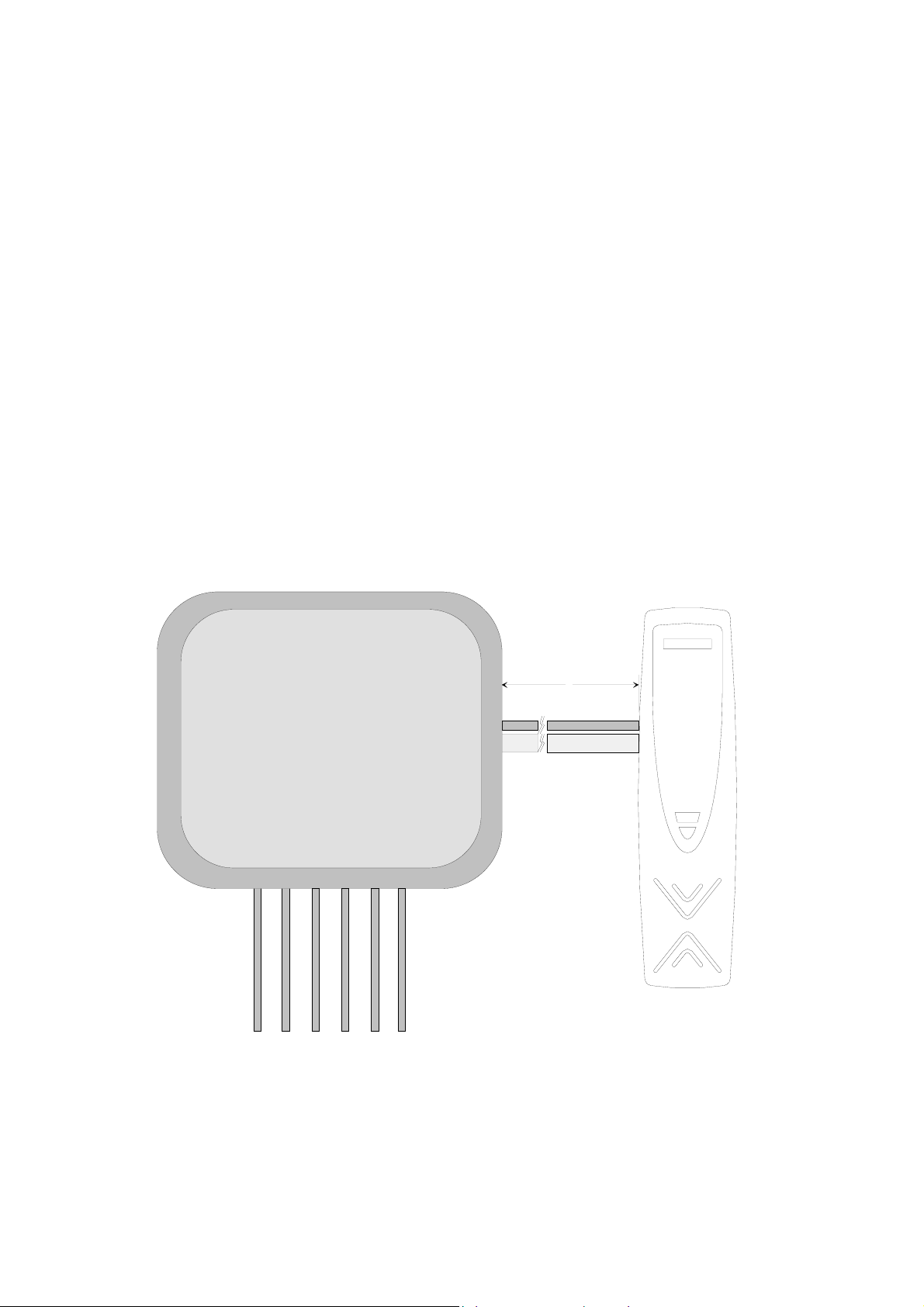

11..66 MMoouunnttiinngg tthhee DDeevviiccee oonn tthhee WWaallll BBrraacckkeett

Figure 14: Mounting

1) The RTUL19 is positioned atop the wall bracket protrusion

2) The back part is aligned with the wall by rotating

3) The RTUL19 is mounted onto the bracket using screws

Page 18 of 25

ACTIVATION

11..77 IIddeennttiiffiiccaattiioonn UUssiinngg tthhee SSeerrvviiccee PPiinn

To identify the node, you can call the service pin using the relay-reed found

inside the device (see

1. Place a small magnet as indicated in

Figure 15). Use the following steps for this procedure:

Figure 15 to call the service pin. The

signal is linked to the yellow service LED (at the center), which will blink

throughout the operation.

2. The TemaServer will send a wink command in response to the service pin,

which lights the yellow LED and the buzzer three times. This allows you to

verify that communications are operational to and from the TemaServer.

3. Check to see that the service LED is off at the end of the operation.

Position of

magnet

The LED

goes

yellow

Figure 15: Calling the Service Pin Using a Magnet

Page 19 of 25

11..88 IIddeennttiiffiiccaattiioonn UUssiinngg tthhee NNeeuurroonn IIDD

The label with the neuron ID that comes with the kit must be applied by the

installer on the appropriate identification sheet. You also must indicate the

location of the terminal in the appropriate box (see example in Table 3).

Description of Location

Entrance to Offices, First Floor,

Stairway E

Description of TemaServer

Panel2, Entrance, First Floor,

Stairway E

RTUL19

Table 3: Example of Compiled Identification Sheet

Page 20 of 25

TECHNICAL DATA

TTeemmaaKKeeyy TTKKLL1199

((RRTTUU--LL1199 ccooddee

11550000115544xxx

)

x

)

Parameter Value

Power Supply

12V

±15% 100mA nominal (1.4W),

DC

160mA max (2W)

Weight 0.3 kg

Dimensions 156 Lu x 40 La x 27 sp mm

Degree of Protection IP55

Operational

-20 to 60 °C

Temperature

Storage Temperature

Relative Humidity of

-20 to 70 °C

0 to 95 % without condensation

Storage

LED 1 LED tricolor Red / Green / Yellow

Buzzer 1

Inputs

2 balanced inputs with 4 statuses:

normal, alarm, cut, short

Output Relay 1

Output Relay 2

Electrical Locking Device Command

• Contacts: C / NC / NO (see page 13)

Lamp Command

• Contacts: C / NC / NO (see page 16)

Antenna proxy 125KHz for HID cards

reading distance 0 to 40 mm

(MD-15W internal controller)

LONWORKS®2

Connection

"Free Topology" type connected with

unshielded double twisted pair cable

FT3120 Smart Transceiver, 78Kbps

Conformance to Norms

Directive EMC 89/336/EEC, 92/31/EEC,

Low Voltage Directive 72/23/EEC, 93/68/EEC:

EN60950 / EN55022-B / ETSI EN300-330 / EN55024

FCC

FCC ID: HS9-RTU-L19

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

2

LONWORKS® is a trademark of the Echelon Corporation

Page 21 of 25

1.8.1 Supplied Parts

KIT of resistances for

input balancing

Fisher bolts for wall

2 White resistances

2 Yellow resistances

2 (S4 type) + screws

mounting

Fisher bolt for tamper 1 (S4 type) + screws

1N4004 Diode 2

MOV 75Vrms 2

1.8.2 Optional Parts

TORX TX10 Screwdriver Code 1500108AA

Page 22 of 25

11..99 RReeccyycclliinngg

In application of directive 2002/96/EC regar din g elect rical and elect ro nic wast e devi ces, in vigor from 13 August 2005,

Honeywell engages, when requested by the customer, to the collection, treatment, recovery, and proper disposal of all

devices produced.

All users within the European Union are hereby informed of the requirement for the proper elimination of the product as

regulated by laws, rules, and local procedures.

Page 23 of 25

Notes:

Page 24 of 25

Figure 16: Temakey TKL19

Page 25 of 25

Loading...

Loading...