Modular Terminal

Modular Terminal

Modular TerminalModular Terminal

Installation Manual

Installation Manual

Installation ManualInstallation Manual

Modular terminal

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

FCC NOTICE............................................................................. 4

PRELIMINARY OPERATIONS

PRELIMINARY OPERATIONS ........................

PRELIMINARY OPERATIONSPRELIMINARY OPERATIONS

Mounting Instructions .............................................................. 5

Arranging the Cable Tubes and Junction Boxes............................ 6

Cabling: Recommendations .................................................. 6

Electrical Connections .............................................................. 8

LONWORKS Data Cables......................................................... 9

........................5555

................................................

Mounting the Unit on the Wall ................................................. 11

Horizontal Assembly – Single Module .................................. 11

Horizontal Assembly – Triple Module ................................... 12

Combined Assembly - Single and Triple Modules ................... 13

Fastening the Cables ........................................................ 15

Vertical Assembly............................................................. 16

Channeling the Cables from the Bottom of the Box .............. 17

INSTALLATION

INSTALLATION ................................

INSTALLATIONINSTALLATION

Combining the Modules ........................................................... 18

Reader ............................................................................ 18

Keyboards ....................................................................... 18

Display ............................................................................ 18

Terminals......................................................................... 19

Terminals with Keyboards.................................................. 19

Interactive Terminals ........................................................ 20

Interactive Terminals with Keyboards ................................. 20

.........................................

................................................................

.........18

..................

18

1818

Attaching the Modules to the Wall........................................... 21

Applying the Entry/Exit Labels.................................................. 22

Identification via Bar Code ....................................................... 23

Version: 1.0 US

TABLE OF CONTENTS Page 3

TECHNICAL DATA

TECHNICAL DATA ................................

TECHNICAL DATATECHNICAL DATA

Summary of Modular Devices................................................... 24

RTU-B07 (Proxy Reader for HID Cards)..................................... 25

RTU-C01 (Alphanumeric LCD Module) ....................................... 26

RTU-C02 (Graphic LCD Module) ............................................... 27

RTU-T01 (Numeric Keyboard Module)........................................ 28

Optional Parts ....................................................................... 29

....................................

................................................................

....24

........

24

2424

FCC NOTICE

FCC NOTICE

FCC NOTICEFCC NOTICE

NOTE: This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However these is no guarantee that interference will not occur in a particular

installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by tuning the equipment of and on, the

user is encouraged to try to correct the interference by one or more the

following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

-- Consult the dealer or an experienced radio/TV technician for help.

FCC NOTICE Page 4

PRELIMINARY OPERATIONS

r

Mounting Instructions

Mounting Instructions

Mounting InstructionsMounting Instructions

The cables are attached to an encased box. Make sure that you

place the box at a height of 120cm from the floor (see Figure 1).

tube

cables

floo

Figure 1: Space requirements for moun ting

m

c

0

2

1

Mounting Instructions Page 5

Arranging the Cable Tubes and Junction

Arranging the Cable Tubes and Junction

Arranging the Cable Tubes and JunctionArranging the Cable Tubes and Junction

Boxes

Boxes

BoxesBoxes

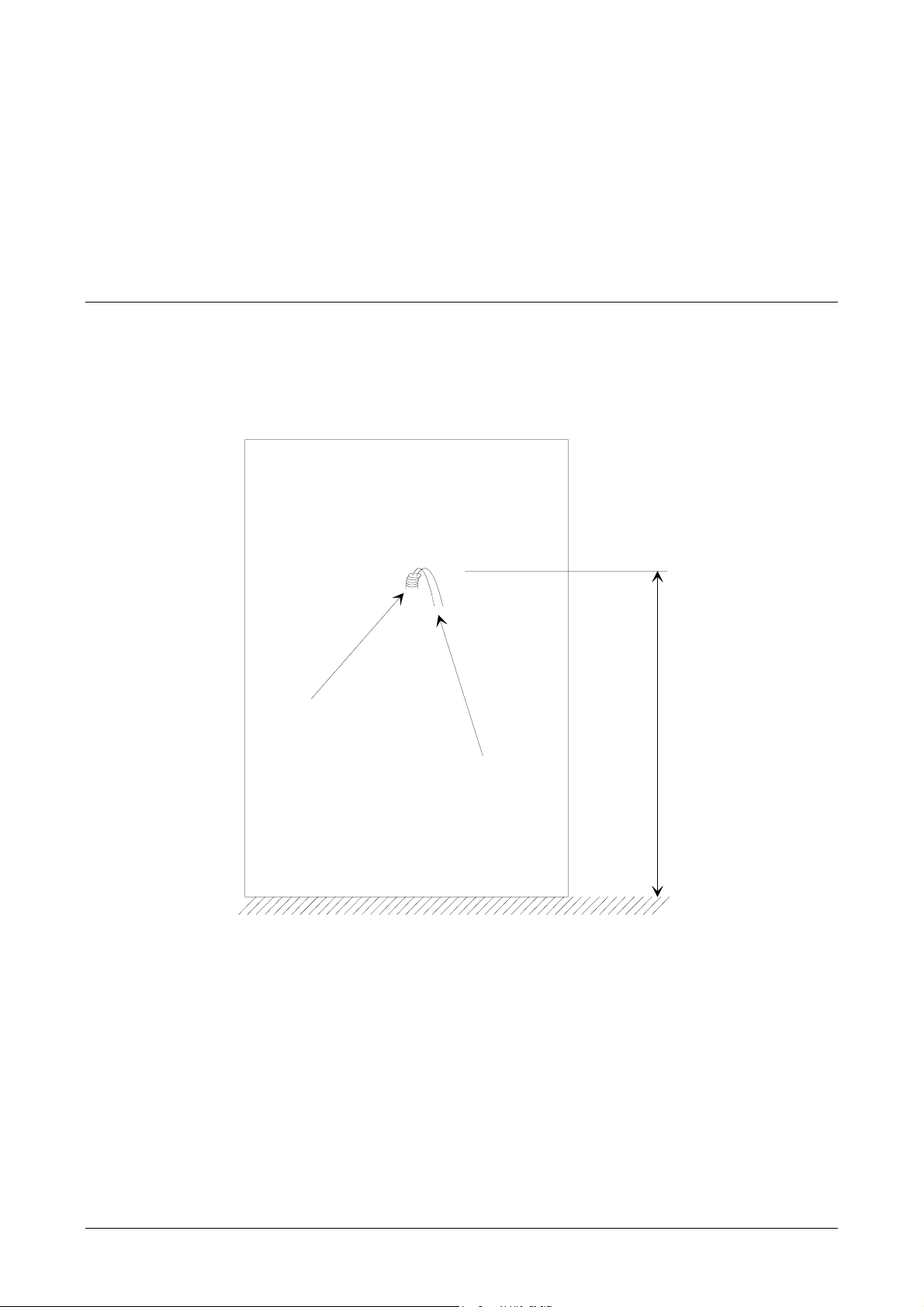

All the cables consist of 4 wires that must be connected in parallel

from one node to the next. It is possible to link nodes in free topology,

i.e. by means of a star or bus configuration.

Cabling: Recommendations

Cabling: Recommendations

Cabling: RecommendationsCabling: Recommendations

Figure 2 provides an example of a typical free topology installation.

ower

P

ma

TemaServer

Figure 2: Example of a free topology installa tion

T

e

Arranging the Cable Tubes and Junction Boxes Page 6

If you want to mount the tubes on the surface of the walls, it is

advisable to place the junction boxes under each terminal (see

example in Figure 3).

Figure 3: Location of the junction boxe s

Arranging the Cable Tubes and Junction Boxes Page 7

Electrical Connections

7

7

7

7

0

7

2

0

2

Electrical Connections

Electrical ConnectionsElectrical Connections

The RTU is powered at low voltage (12VDC 120mA) by a batteryoperated power supply module (RTU-Qxx). When determining the

correct size for power cables, refer to the table below.

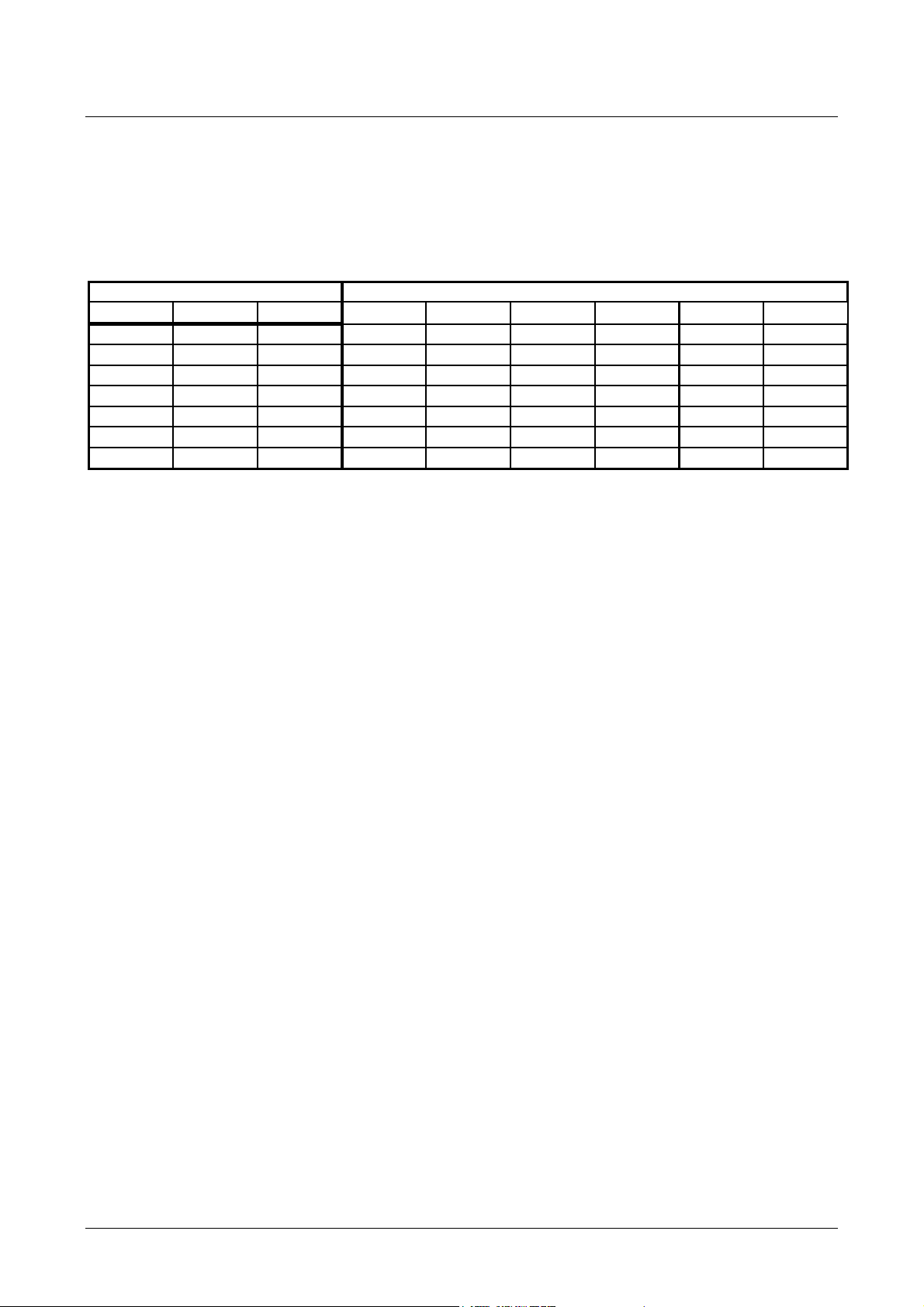

Type of cable Length (m) in relation to effective load

AWG mm2 ohm/Km 100 [mA] 200 [mA] 500 [mA] 1 [A] 2 [A] 5 [A]

12 3,3 5,7 1754 87

14 2 8,8 1136 568 22

16 1,3 14 714 35

180,9214762389548241

20 0,6 34 294 14

22 0,35 52 19

24 0,2 85 118 59 24 1

96 38 19 1

351 175 88 35

114 5

143713614

59 29 15 6

62

23

4

Electrical Connections Page 8

LLLLON

ONW

ONON

WORKS

ORKS Data Cables

ORKSORKS

WW

Data Cables

Data Cables Data Cables

• The LONWORKS1 data cable must be twisted pair

• In a free topology configuration, the sum total of the sections must

not exceed 500m

• In a bus configuration, the sum total of the sections must not

exceed 2700m

• In a free topology configuration, activate the 50ohm terminator by

placing the appropriate jumper on the FTT10A plug-in of the CTUPLG06 board inside the TemaServer

• In a bus configuration, place two terminators (with resistance

values of 100ohm 1% ½W) at each end of the bus

• Check that the length of the L

to the norms indicated in Table 1.

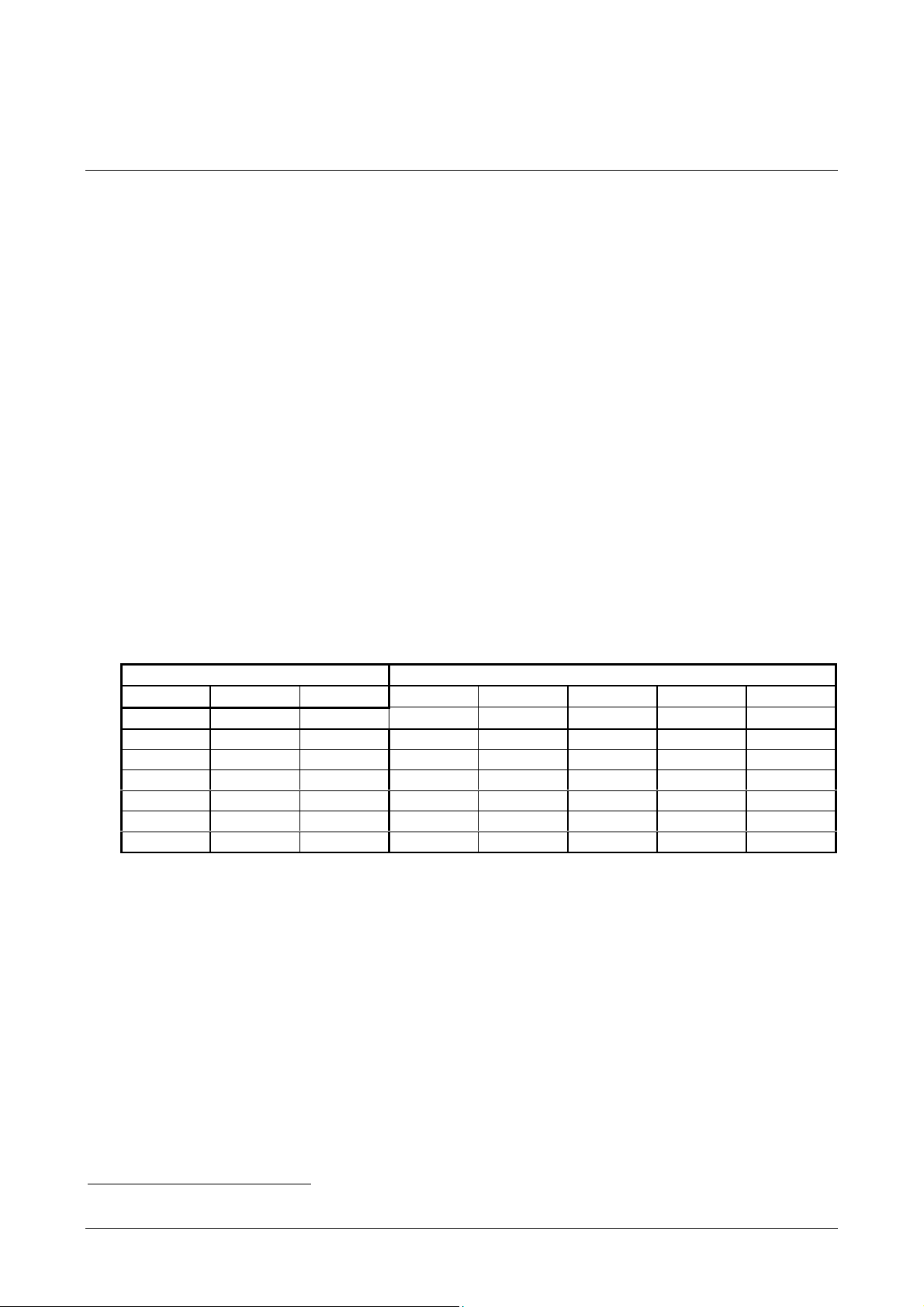

Type of cable Length [m] in relation to cable capacity

AWG mm2 Ohm/Km 50nF/Km 100nF/Km 200nF/Km 500nF/Km 1uF/Km

12 3,3 5,7 2676 1892 1338 846 598

14 2 8,8 2153 1523 1077 681 482

16 1,3 14 1707 1207 854 540 382

18 0,9 21 1394 986 697 441 312

20 0,6 34 1096 775 548 346 245

22 0,35 52 886 626 443 280 198

24 0,2 85 693 490 346 219 155

Table 1: Length/capacity of L ON WORKS data cables (m)

ONWORKS data cable corresponds

1

LONWORKS® is a trademark of Echelon Corporation

LONWORKS( Data Cables Page 9

• The FTT10A Echelon v1.2 User Guide recommends the cables

indicated in Table 2.

Manufacturer and

model

Belden 85102 16 2700 500

Belden 8471 16 2700 400

Level IV (twisted pair,

typically solid and

unshielded)

JY (St) 2x2x0.8 (4-wire

helical twist, solid

shielded)

AWG Connection to bus -

maximum total length [m]

22 1400 400

20 900 320

Connection in free topology –

maximum node-node length

max. [m]

Table 2: Recommended LONWORKS cables

LONWORKS( Data Cables Page 10

Mounting the Unit on the Wall

Mounting the Unit on the Wall

Mounting the Unit on the WallMounting the Unit on the Wall

Horizontal Assembly – Single Module

Horizontal Assembly – Single Module

Horizontal Assembly – Single ModuleHorizontal Assembly – Single Module

To assemble the unit in a horizontal position, follow these steps:

1. Drill two holes in the wall (to accommodate the 2 plastic dowels),

so that the frame will cover the hole through which the cables

pass.

2. Insert the cables in the cable clamp without pulling out the screws.

3. Use the dowels to fasten the frame to the wall. Make sure that

the lamellar connector is in the UP position.

4. Adjust the length of the cables so that they protrude by ~10cm

from the wall, and fasten them to the cable crimp.

5. Fasten the cable crimp to the contacts in the direction shown in

Figure 4.

6. Place the remainder of the cable inside the frame and lock the cable

clamp.

Figure 4: Wall position — horizontal position (single module)

Mounting the Unit on the Wall Page 11

Horizontal Assembly – Triple Module

Horizontal Assembly – Triple Module

Horizontal Assembly – Triple ModuleHorizontal Assembly – Triple Module

To assemble the unit in a horizontal position, follow these steps:

1. Drill two holes in the wall (to accommodate the 2 plastic dowels),

so that the frame will cover the hole through which the cables

pass.

2. Insert the cables in the cable clamp without pulling out the screws.

3. Use the dowels to fasten the frame to the wall. Make sure that

the lamellar connector is in the UP position.

4. Adjust the length of the cables so that they protrude by ~10cm

from the wall, and fasten them to the cable crimp.

5. Fasten the cable crimp to the contacts in the direction shown in

Figure 5.

6. Place the remainder of the cable inside the frame and lock the cable

clamp.

NET1

NET2

GND

+12V

Figure 5: Wall position — horizontal position (t riple m odule)

Mounting the Unit on the Wall Page 12

Combined Assembly - Single and Triple Modules

Combined Assembly - Single and Triple Modules

Combined Assembly - Single and Triple ModulesCombined Assembly - Single and Triple Modules

A combined wall assembly of single and triple modules allows you to

create units consisting of 2, 4 and 5 units. This procedure consists

of the following steps:

1. Drill the necessary holes in the wall (2 plastic dowels for each

module), so that the lower plate will cover the hole through which

the cables pass.

2. Insert the cables in the cable clamp without pulling out the screws.

3. Link the frames together by inserting the two enclosed attachment

clips at the rear of the frames (see Figure 6 and Figure 7).

4. Use the dowels to fasten the frame to the wall. Make sure that

the lamellar connector is in the UP position.

5. Adjust the length of the cables so that they protrude by ~10cm

from the wall, and fasten them to the cable crimp.

6. Intertwine the terminators of the cables from the wall and the

extension cable terminators, and fasten them to the cable crimps.

7. Fasten the cable crimp to the contacts in the direction shown in

Figure 6 and Figure 7.

8. Place the remainder of the cable inside the frame and lock the cable

clamp.

NET1

NET2

Attachment

clip

GND

+12V

NET1

NET2

GND

+12V

Attachment

clip

Figure 6: Combined assembly of two single module wall units

Mounting the Unit on the Wall Page 13

NET1

NET2

Attachment

clip

GND

+12V

NET1

NET2

GND

+12V

Attachment

clip

Figure 7: Combined assembly of single and triple module wall units

Mounting the Unit on the Wall Page 14

Fastening the Cables

Fastening the Cables

Fastening the CablesFastening the Cables

Fasten the cable clamps to the cable bar so that the cables are

arranged towards the inside of the frame (see Figure 8).

CONNECTIONS

NET1 (green)

NET2 (yellow)

GND (black)

+12V (red)

Figure 8: Fastening the cables

Mounting the Unit on the Wall Page 15

Vertical Assembly

Vertical Assembly

Vertical AssemblyVertical Assembly

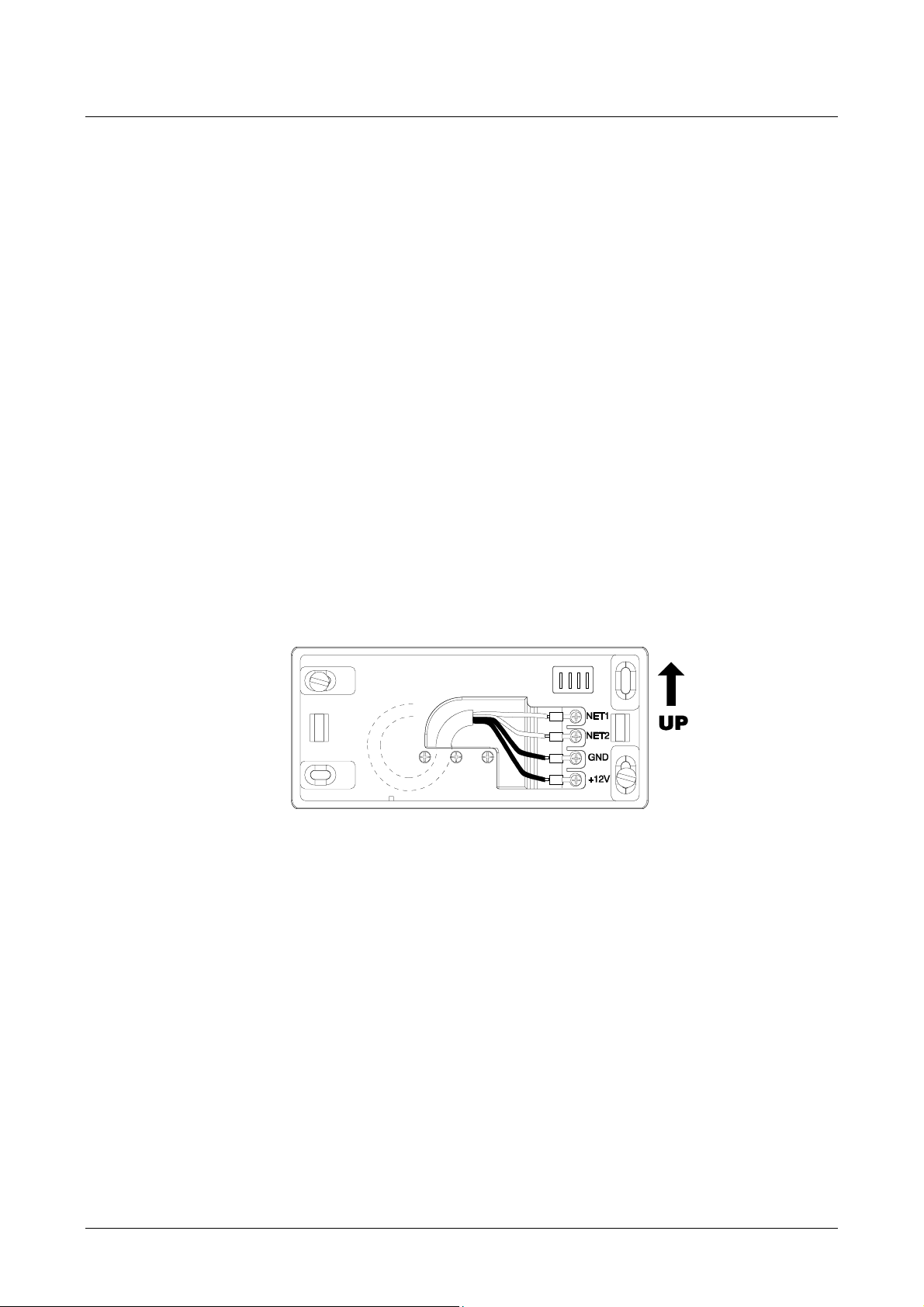

To assemble the unit in a vertical position, follow these steps:

1. Drill two holes in the wall (to accommodate the 2 plastic dowels),

so that the frame will cover the hole through which the cables

pass.

2. Insert the cables in the cable clamp without pulling out the screws.

3. Use the dowels to fasten the frame to the wall. Make sure that

the lamellar connector is in the UP position.

4. Adjust the length of the cables so that they protrude by ~10cm

from the wall, and fasten them to the cable crimp.

5. Fasten the cable crimp to the contacts in the direction shown in

Figure 9.

6. Place the remainder of the cable inside the frame and lock the cable

clamp.

GND

NET1

+12V

NET2

GND

NET1

+12V

NET2

Figure 9: Wall position — vertical assembly

GND

NET1

+12V

NET2

Mounting the Unit on the Wall Page 16

Channeling the Cables from the Bottom of the Box

Channeling the Cables from the Bottom of the Box

Channeling the Cables from the Bottom of the BoxChanneling the Cables from the Bottom of the Box

As an alternative, you can channel the cables so that they exit from

the bottom of the frame. This alternative procedure consists of the

following steps:

1. Drill a hole in the wall so that the hole from which the cables exit is

in the center of the lower plate.

2. Break off the lower removable tab from the upper support.

3. Break off the upper and lower tab from the lower support.

4. Insert both the cables from the wall and the remainder of the cable

in the cable clamp (be careful not to pull out the screws).

5. Use the dowels to attach the frame to the wall.

6. Adjust the length of the cables so that they protrude by ~10cm

from the wall.

7. Roll up the terminators of the cables from the wall and the

extension cables, and fasten them to the cable crimps (see Figure

10).

8. Fasten the cable crimp to the contacts in the direction shown in

Figure 10.

9. Place the remainder of the cables inside the frame and lock the

cable clamps.

Figure 10: Channeling the cables from the bottom of the box

Mounting the Unit on the Wall Page 17

INSTALLATION

Combining the Modules

Combining the Modules

Combining the ModulesCombining the Modules

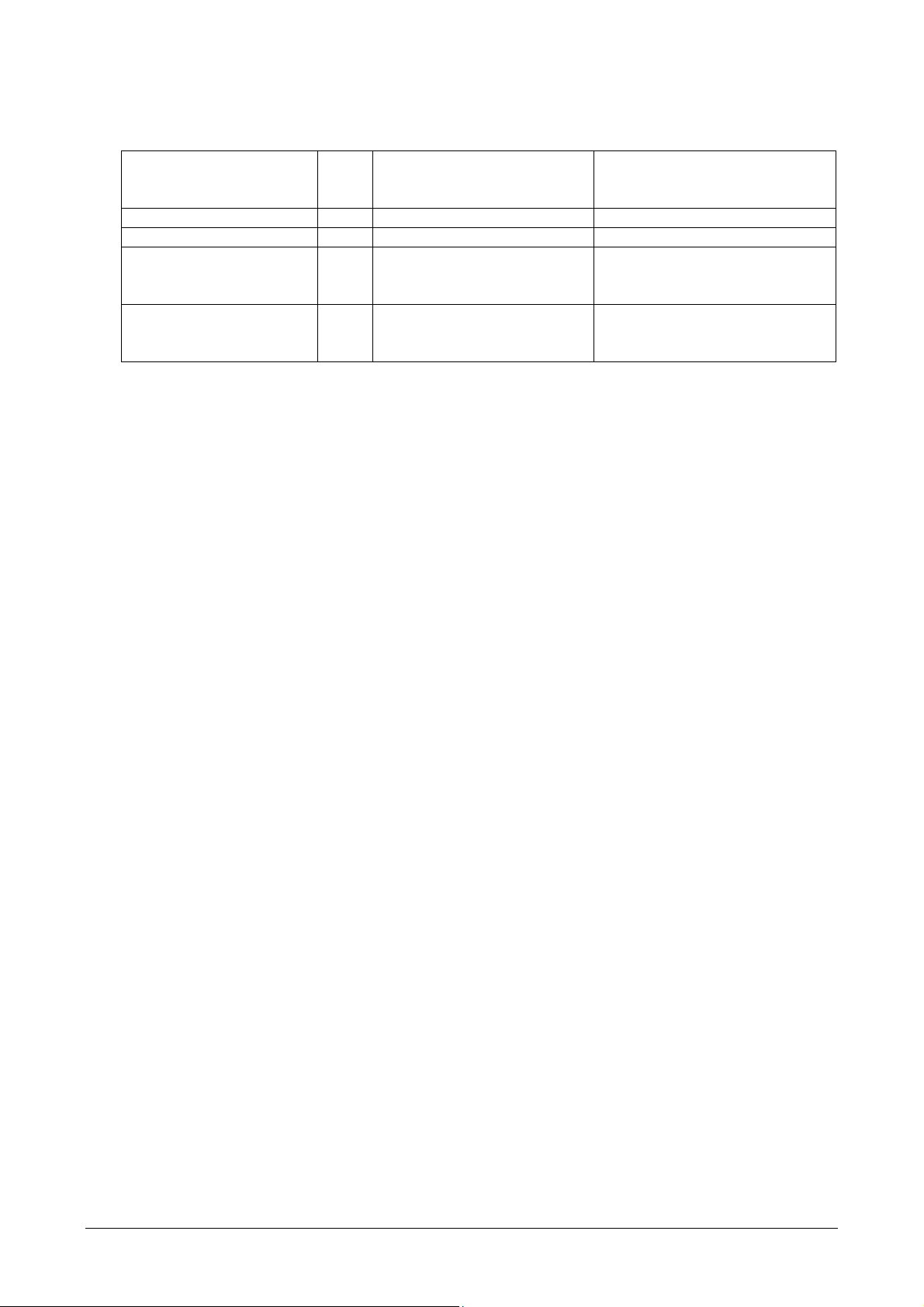

Each TemaKey consists of one or more RTU modules that must be

positioned and connected to their respective wall attachment frames

(RTU-Sxx) as indicated in the table below.

Reader

Reader

ReaderReader

Code Grouping Horizontal Vertical Notes

TK-S07

1 x RTU-B07

1 x RTU-S01

Weight=0.45Kg

Power=0.8W

Current=60mA

Keyboards

Keyboards

KeyboardsKeyboards

Code Grouping Horizontal Vertical Notes

TK-S31

1 x RTU-T01

1 x RTU-S01

Display

Display

DisplayDisplay

Code Grouping Horizontal Vertical Notes

TK_S21

1 x RTU-C01

1 x RTU-S01

TK-S22

1 x RTU-C02

2 x RTU-S01

NO Weight=0.45Kg

NO

Weight=0.4Kg

Power=0.4W

Current=30mA

Power=1.9W

Current=140mA

Weight=0.95Kg

Power=5.2W

Current=380mA

Combining the Modules Page 18

Terminals

Terminals

TerminalsTerminals

Code Grouping Horizontal Vertical Notes

TK-D07

1 x RTU-C01

1 x RTU-B07

2 x RTU-S01

Code Grouping Horizontal Vertical Notes

TK_T09

1 x RTU-C01

1 x RTU-B07

1 x RTU-B01

1 x RTU-S03

Terminals with Keyboards

Terminals with Keyboards

Terminals with KeyboardsTerminals with Keyboards

NO

NO

Weight=0.9Kg

Power=2.7W

Current=200mA

Weight=1.15Kg

Power=3.1W

Current=230mA

Code Grouping Horizontal Vertical Notes

TK_D37

1 x RTU-T01

1 x RTU-B07

2 x RTU-S01

Code Grouping Horizontal Vertical Notes

TK-T07

1 x RTU-C01

1 x RTU-T01

1 x RTU-B07

1 x RTU-S03

NO

Weight=0.85Kg

Power=1.2W

Current=90mA

Weight=1.15Kg

Power=3.1W

Current=230mA

Combining the Modules Page 19

Interactive Terminals

Interactive Terminals

Interactive TerminalsInteractive Terminals

Code Grouping Horizontal Vertical Notes

TK-D27

1 x RTU-C02

1 x RTU-B07

1 x RTU-S03

NO

Interactive Terminals with Keyboards

Interactive Terminals with Keyboards

Interactive Terminals with KeyboardsInteractive Terminals with Keyboards

Code Grouping Horizontal Vertical Notes

TK_T27

1 x RTU-C02

1 x RTU-T01

1 x RTU-B07

1 x RTU-S03

1 x RTU-S01

NO

Weight=1.25Kg

Power=6W

Current=440mA

Weight=1.65Kg

Power=6.4W

Current=470mA

Combining the Modules Page 20

Attaching the Modules to the Wall

Attaching the Modules to the Wall

Attaching the Modules to the WallAttaching the Modules to the Wall

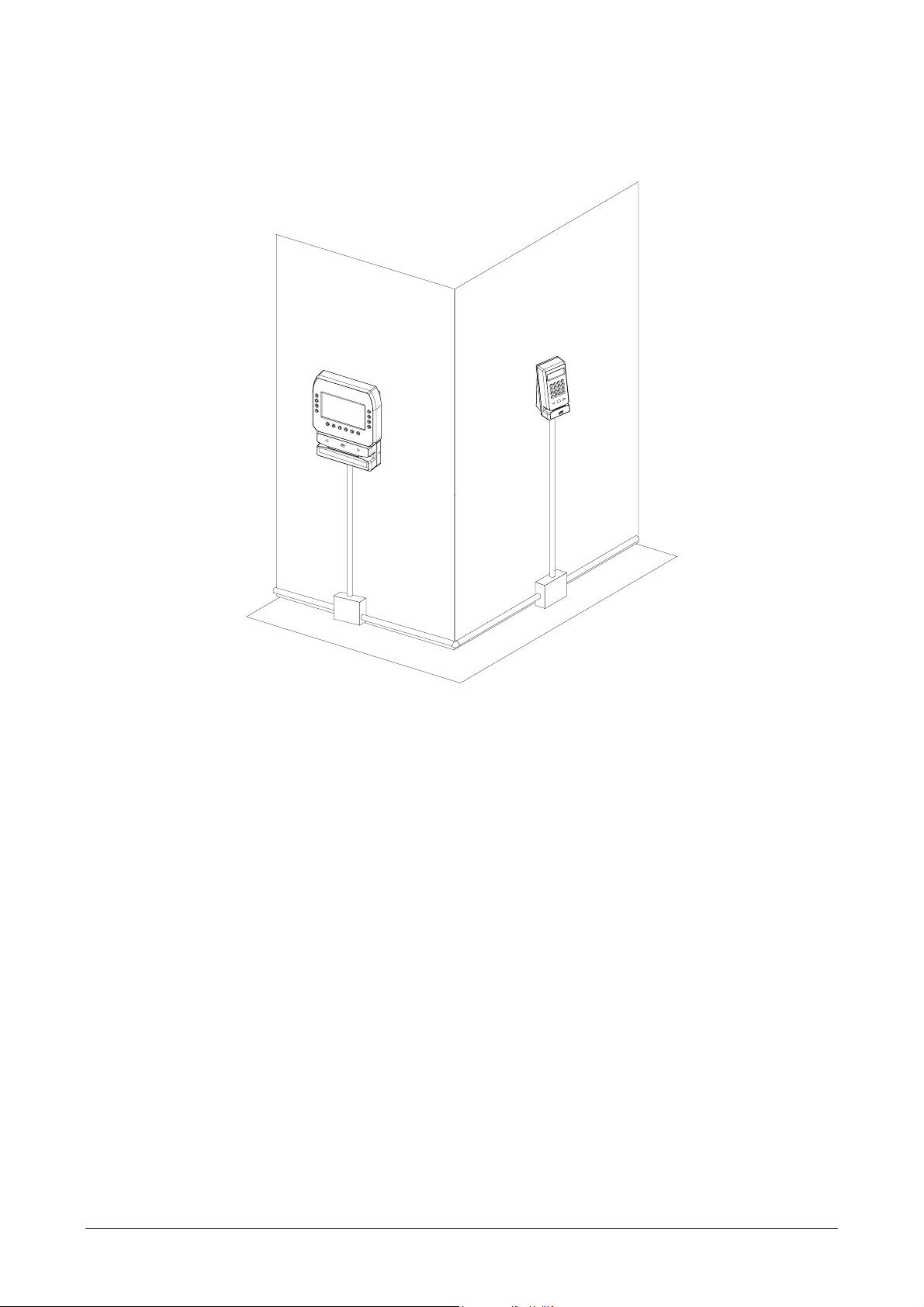

All tEmaline modules are equipped with a simple attachment

mechanism; the module clicks into position without the need for tools.

To attach the module to the frame, follow these steps:

1. Check that the fitting at the back of the RTU modules is positioned

correctly.

2. Attach each RTU module to the wall-mout frame as illustrated in

Figure 11.

Figure 11: Attaching the module to the wall-mount frame

Attaching the Modules to the Wall Page 21

Applying the Entry/Exit Labels

Applying the Entry/Exit Labels

Applying the Entry/Exit LabelsApplying the Entry/Exit Labels

Apply the two entry/exit labels to the magnetic reader according to

the pre-configured transit direction. Make sure that you place the

labels in the appropriate hollows (see details in Figure 12 and Figure

13).

OUT

IN

EXIT ENTRY

Figure 12: Entry/exit labels

IN

ENTRY EXIT

OUT

Figure 13: Entry/exit labels

Applying the Entry/Exit Labels Page 22

Identification via Bar Code

Identification via Bar Code

Identification via Bar CodeIdentification via Bar Code

The components enclosed in the packaging include a bar code label.

The person responsible for installing the terminal must apply this label

to the corresponding identification form, and indicate the location of

the terminal in the appropriate box (see example in Table 3).

Description of location

Office entrance area, first floor - staircase E

Description of TemaServer

Panel 2 entrance area, first floor – staircase E

RTU

RTU

RTU

RTU

C01

T01

B07

-

Table 3: Example of completed identification form

Identification via Bar Code Page 23

TECHNICAL DATA

Summary of Modular Devices

Summary of Modular Devices

Summary of Modular DevicesSummary of Modular Devices

This section contains technical data regarding the modular devices:

• RTU-B07 (Reader module for HID proxy cards)

• RTU-C01 (Alphanumeric LCD module)

• RTU-C02 (Graphic LCD module)

• RTU-T01 (Numeric keyboard module)

Summary of Modular Devices Page 24

RTU-B07

RTU-B07 (Proxy Reader for HID Cards)

RTU-B07 RTU-B07

for HID Cards)

for HID Cards)for HID Cards)

Code 1520145

Parameter

Parameter Value

ParameterParameter

Value

ValueValue

DC power supply

Weight

Dimensions

IP Protection Rating

Operating temperature

Proxy receiver

LONWORKS® connection

Signaling

12V

±15% 60mA

DC

0.30 Kg

72 x 160 x 52 mm

IP55

0-50 °C

For HID cards

Double-antenna receiver (bidirectional)

Unshielded twisted pair cable

(transceiver FTT10A, 78Kbps

2 LED tricolor (green/red/yellow)

1 buzzer

Service LED

Service Pin

RTU-B07 (Proxy Reader for HID Cards) Page 25

RTU-C01

RTU-C01 (Alphanumeric LCD Module)

RTU-C01 RTU-C01

Alphanumeric LCD Module)

Alphanumeric LCD Module)Alphanumeric LCD Module)

Code 1500105

Parameter

Parameter Value

ParameterParameter

Value

ValueValue

DC power supply

Weight

Dimensions

IP Protection Rating

Operating temperature

Display

Keyboard

LONWORKS® connection

Signaling

12V

±15% 140mA (nominal)

DC

70mA (backlight off)

0.30 Kg

72 x 160 x 52 mm

IP55

0-50 °C

Alphanumeric LCD with backlight

2 rows of 16 characters format

4 keys with symbols

Unshielded twisted pair cable

(transceiver FTT10A, 78Kbps

1 LED yellow

1 buzzer

Service LED

Service Pin

RTU-C01 (Alphanumeric LCD Module) Page 26

RTU-C02

RTU-C02 (Graphic LCD Module)

RTU-C02 RTU-C02

Graphic LCD Module)

Graphic LCD Module)Graphic LCD Module)

Code 1500101

Parameter

Parameter Value

ParameterParameter

Value

ValueValue

DC power supply

Weight

Dimensions

IP Protection Rating

Operating temperature

Display

Keyboard

LONWORKS® connection

Signaling

12V

±15% 380mA (nominal),

DC

140mA (backlight off)

0.65 Kg

166 x 190 x 52 mm

IP55

0-50 °C

Graphic LCD with backlight

240 x 128 pixels format

14 function keys

Unshielded twisted pair cable

(transceiver FTT10A, 78Kbps

1 LED yellow

1 buzzer

Service LED

Service Pin

RTU-C02 (Graphic LCD Module) Page 27

RTU-T01

RTU-T01 (Numeric Keyboard Module)

RTU-T01 RTU-T01

Code 1500104

Parameter

Parameter Value

ParameterParameter

Value

ValueValue

)

))

DC power supply

Weight

Dimensions

IP Protection Rating

Operating temperature

Keyboard

LONWORKS® connection

Signaling

12V

±15%

DC

30mA (nominal), 50mA (max)

0.25 Kg

72 x 160 x 52 mm

IP55

0-50 °C

16 keys with symbols

Unshielded twisted pair cable

(transceiver FTT10A, 78Kbps

2 LED bicolor (red/green/yellow)

1 buzzer

Service LED

Service Pin

RTU-T01 (Numeric Keyboard Module) Page 28

Optional Parts

Optional Parts

Optional PartsOptional Parts

Unlocking tool

code 3900695AB

Optional Parts Page 29

This page is intentionally left blank

Optional Parts Page 30

This page is intentionally left blank

Optional Parts Page 31

This page is intentionally left blank

gзмСлзСмX>бммиXMMсссLмСеДгазСLЗйе

Loading...

Loading...