Page 1

Additel 672

Digital Pressure Calibrators

Pressure ranges to 60,000 psi (4,200 bar)

HART Communication capability

Measure mA or V, and with 24V loop power

Easy-to-use, inexpensive pressure calibrator with

uncertainty better than 0.02%FS

Pressure / Process Calibration Equipment

OVERVIEW

At rst glance, the 672 series precision pressure calibrators look like an ordinary pressure gauge. But this series is

much more than ordinary, and denitely more than just a pressure gauge—it’s a pressure calibrator! With advanced

microprocessor technology and state-of-the-art silicon pressure sensors, the 672 series precision pressure calibrators

provide a pressure calibration solution for gauges, transmitters, and switches over a wide pressure range. The 672

is the size of a pressure gauge but with the functionality of a calibrator: It measures pressure precisely with a builtin pressure sensor, as well as reads the current or mV produced by a transducer. It can even supply an excitation

voltage to power sensors or transmitters during calibration. In order to reach 0.02%FS accuracy up to 10,000 psi

(700 bar) and 0.1%FS accuracy up to 60,000 psi (4,200 bar), every silicon pressure sensor has been specially aged,

tested, and screened before assembly. The 672 series precision pressure calibrators are unmatched in performance

and reliability.

New Ranges to 60,000 psi (4,200 bar)

Gauge pressure Differential pressure

FEATURES

Pressure ranges to 60,000 psi (4,200 bar)

Measure mA with 0.01% RD + 1.5 μA accuracy

Measure V with 0.01% RD + 1.5 mV accuracy

Power transmitters during test using 24V loop supply

Pressure switch test

HART Communication capability

Advanced temperature compensation

Dual readout

Min/Max/Hold to capture changing measurements

Data logging

Large, easy to read display with 6-digit resolution

Backlit display

Rechargeable battery or AC adapter

ISO17025 accredited calibration with data (Included)

01

Phone: 714-998-6899 Fax: 714-998-6999 Email: sales@additel.com

Corporate Headquarters

2900 Saturn St #B

Brea, CA 92821, USA

Salt Lake City Office

1364 West State Rd. Suite 101

Pleasant Grove, UT 84062, USA

Page 2

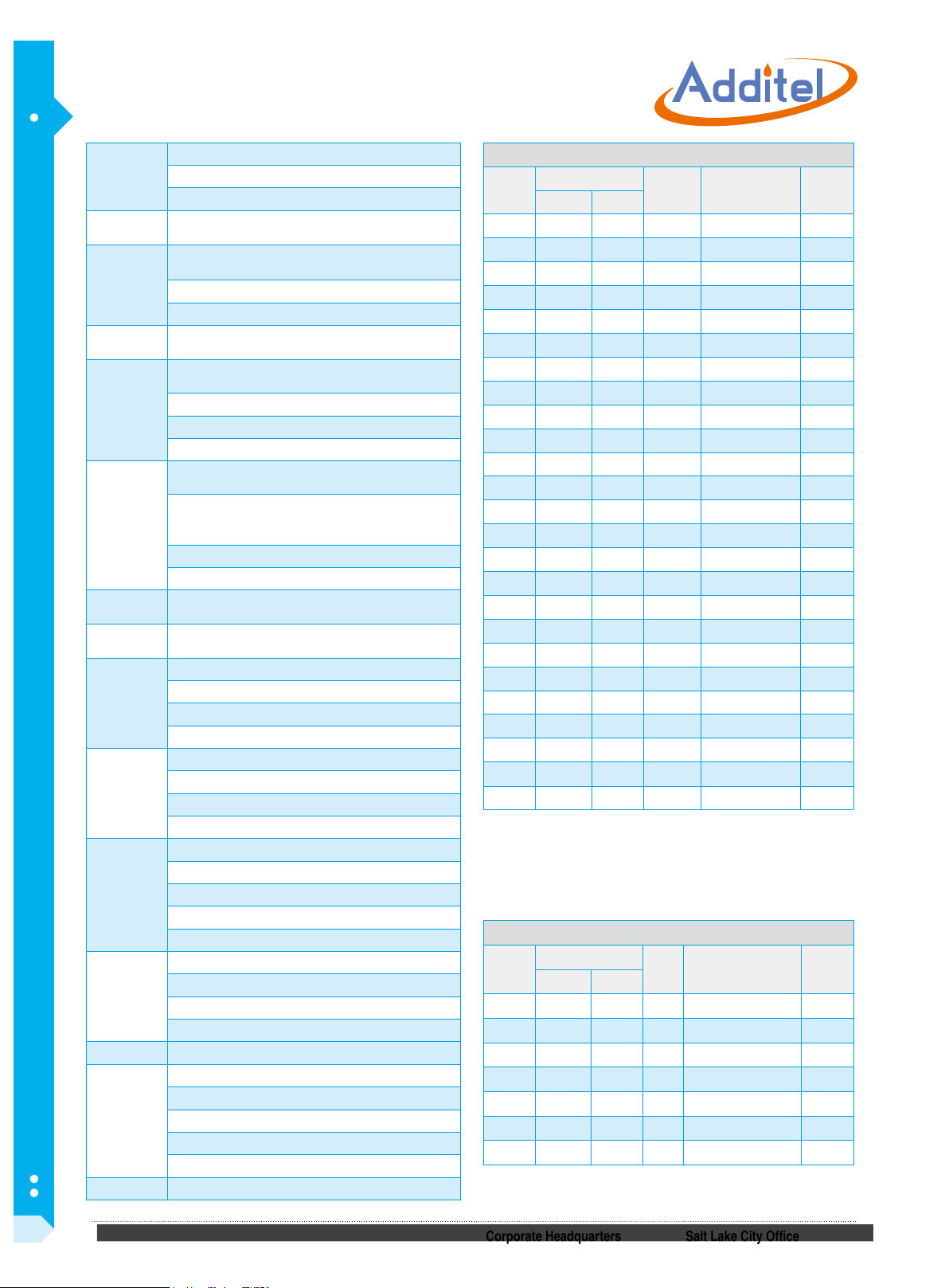

SPECIFICATIONS PRESSURE RANGE

ADT672-02: 0.02% of full scale

Accuracy

Gauge Types

Display

Pressure Units

Pressure / Process Calibration Equipment

Environmental

Pressure Port

Over Pressure

Warning

Electrical

Connection

Electrical

Measurement

Accuracy

Power

Enclosure

Data Logging

Compliance

Communication

Warranty

[1] 1V~12V if switch has detective voltage

ADT672-05: 0.05% of full scale

>20,000 (1,400 bar): 0.1% FS

Gauge pressure, compound pressure, absolute pressure,

differential pressure

Description: Dual-line 6 full digit FSTN LCD with LED

Backlight

Display rate: 3.5 readings per second (Default setting).

Numeral display height: 16.5mm (0.65")

Pa, kPa, MPa, psi, bar, mbar, kgf/cm2, inH2O@4°C

mmH2O@4°C, inHg@0°C, mmHg@0°C

Compensated Temperature: 14°F to 122°F (-10°C to

50°C)

Operating Temperature: 14°F to 122°F (-10°C to 50°C)

Storage Temperature: -4°F to 158°F (-20°C to 70°C)

Humidity: <95%

≤15,000 psi: 1/4NPT male, 1/2NPT male, 1/4BSP

male, 1/2BSP male, M20×1.5 male

>15,000 psi: 1/4HP female or 1/4HP male

*1/4HP female: Autoclave F-250-C, 9/16" - 18 UNF-2B

*1/4HP male: Autoclave M-250-C, 9/16" - 18 UNF-2A

Differential Pressure: 0.236 inch (Ø6 mm) test hose

Other connections available per request

120%

0.156 inch (Ø4mm) sockets

Voltage DC: ±30.0000V, ± (0.01%RD + 1.5 mV)

Current DC: ±30.0000mA, ± (0.01%RD + 1.5 μA)

DC 24V: 24V±0.5V, MAX:50mA, Protect at: 120mA

[1]

: Status OPEN/CLOSED

Switch

Battery: Rechargeable Li-ion polymer battery

Li-Battery working time: 40 hours

Recharge time: 4 hours

External power: 110V/220V power adapter (DC10V)

Case material: Aluminum alloy

Wetted parts: 316L SS

Dimension: Ø120mm X 46mm depth X 184mm height

Weight: 0.7kg

Protection Level: IP30

Storage capacity: 30 les, 40 records per le

Mode: manual and automatic

Hourly-record: record the data every hour

Interval-record: set by user

CE Marked

RS232 (DB9/F, environmentally sealed)

Baud rate: 1200, 2400, 4800, 9600

Data length: 8 bits

Stop bit: 2 bits

Address: from 1 to 112

1 year

02

Phone: 714-998-6899 Fax: 714-998-6999 Email: sales@additel.com

Gauge Pressure

P/N

V15 -15 -1.0 G 0.02 (0.05) 3×

GP2 2 0.16 G 0.05 3×

GP5 5 0.35 G, L 0.05 3×

GP10 10 0.7 G, L

GP15 15 1.0 G, L

GP30 30 2.0 G, L

GP50 50 3.5 G, L 0.02 (0.05) 3×

GP100 100 7.0 G, L 0.02 (0.05) 3×

GP150 150 10 G, L 0.02 (0.05) 3×

GP300 300 20 G, L 0.02 (0.05) 3×

GP500 500 35 G, L 0.02 (0.05) 3×

GP600 600 40 G, L 0.02 (0.05) 3×

GP1K 1,000 70 G, L 0.02 (0.05) 3×

GP2K 2,000 140 G, L 0.02 (0.05) 3×

GP3K 3,000 200 G, L 0.02 (0.05) 3×

GP5K 5,000 350 G, L 0.02 (0.05) 3×

GP10K 10,000 700 G, L 0.02 (0.05) 3×

GP15K 15,000 1,000 G, L 0.05 (0.1) 2×

GP20K 20,000 1,400 G, L 0.05 (0.1) 1.5×

GP25K 25,000 1,600 G, L 0.1 1.5×

GP30K 30,000 2,000 G, L 0.1 1.5×

GP36K 36,000 2,500 G, L 0.1 1.5×

GP40K 40,000 2,800 G, L 0.1 1.35×

GP50K 50,000 3,500 G, L 0.1 1.2×

GP60K 60,000 4,200 G, L 0.1 1.1×

[1] Sealed gauge pressure for above 1,000 psi

[2] G=Gas, L=Liquid

[3] 0.02% FS for gas media only

[1]

Pressure Range

(psi) (bar)

Media

[2]

Accuracy(%FS)

[3]

0.02 (0.05) 3×

[3]

0.02 (0.05) 3×

[3]

0.02 (0.05) 3×

Pressure

Compound Pressure

P/N

CP2 ±2 ±0.16 G 0.05 3×

CP5 ±5 ±0.35 G 0.02 (0.05) 3×

CP10 ±10 ±0.7 G 0.02 (0.05) 3×

CP15 ±15 ±1 G 0.02 (0.05) 3×

CP30 -15 to 30 -1 to 2 G 0.02 (0.05) 3×

CP100 -15 to 100 -1 to 7 G, L 0.02 (0.05) 3×

CP300 -15 to 300 -1 to 20 G, L 0.02 (0.05) 3×

[1] FS specication applies to the span of the range

Corporate Headquarters

2900 Saturn St #B

Brea, CA 92821, USA

Pressure Range

(psi) (bar)

M e d i a Accuracy(%FS)

Salt Lake City Office

1364 West State Rd. Suite 101

Pleasant Grove, UT 84062, USA

[1]

Pressure

Burst

Burst

Page 3

Absolute Pressure

P/N

A P5 5 0.35 G 0.1 3×

AP10 10 0.7 G 0.1 3×

AP15 15 1.0 G 0.1 3×

AP30 30 2.0 G 0.1 3×

AP50 50 3.5 G 0.1 3×

Pressure / Process Calibration Equipment

AP100 100 7.0 G , L 0.05 (0.1) 3×

AP300 300 20 G , L 0.05 (0.1) 3×

AP500 500 35 G , L 0.05 (0.1) 3×

AP1K 1,000 70 G , L 0.05 (0.1) 3×

A P 3 K 3,000 200 G , L 0.05 (0.1) 3×

AP5K 5 , 0 0 0 350 G , L 0.05 (0.1) 3×

Pressure Range

(psi) (bar)

Media Accuracy(%FS)

Burst

Pressure

Differential Pressure

Pressure Range

P/N

(inH

O) (mbar)

2

DP1 ±1 ±2.5 G 0.05

DP2 ±2 ± 5. 0 G 0.05

DP5 ±5 ±10 G 0.05

DP10 ±1 0 ±25 G 0.05

DP20 ±20 ±50 G 0.05 20× ±10 psi

DP30 ±30 ±75 G 0.05 20× ±10 psi

DP50 ±50 ±160 G 0.05 3× ±10 psi

DP150 ±150 ±350 G 0.02 3× 50 psi

DP300 ±300 ±700 G 0.02 3× 50 psi

[1] FS specication applies to the span of the range. Accuracy includes

one year stability.

[2] 0.05%FS accuracy (incl 6 months stability). One year accuracy is

0.05%FS calibration accuracy combined with 0.05%FS one year stability.

Media

Accuracy

[1]

(%FS)

Pressure

[2]

100× ±10 psi

[2]

[2]

[2]

Burst

100× ±10 psi

50× ±10 psi

20× ±10 psi

Static

Pressure

Range

ORDERING INFORMATION

Model Number

ADT672 GP300 PSI02 N

Model

Accuracy:

02-0.02% of full scale

05-0.05% of full scale

10-0.1% of full scale

Range type:

PSI-range by psi

BAR-range by bar

O-range by inH2O

H

2

Pressure port type:

N-1/4NPT male

N2-1/2NPT male

B-1/4BSP male

B2-1/2BSP male

M-M20X1.5 male

AF-Autoclave F-250-C female

AM-Autoclave M-250-C male

Accessories Included

110V/220V external power adapter (DC 10V)

2 pieces test leads (1.5-meter) and 2 pieces alligator clips

2 pieces 0.236 inch (Ø6 mm) test hose

(for differential pressure gauge only)

Additel/Land software

(free download at www.additel.com)

Manual

ISO17025 accredited calibration certicate

Optional Accessories

Model

number

9702 Spare rechargeable Li-ion polymer battery for 672

9816

9502

9530-BASIC

9530-NET

9050 USB to RS232 (DB9/M) Adapter

9050-EXT RS 232 (DB9/M) extension cable, 9 feet

Spare 110V/220V external power adapter (DC 10V)

for ADT22X and ADT672 calibrator

Additel/Log II real time data logging and graphical

software for 681 and 672

Additel/Acal Automated calibration software with

asset management, basic version

Additel/Acal Automated calibration software with

asset management, network version, Includes server

installation and 1 user license

Description

03

Pressure range P/N:

See pressure range table

Phone: 714-998-6899 Fax: 714-998-6999 Email: sales@additel.com

9900-672 Carrying Case for one 672 digital pressure gauge

9022

Corporate Headquarters

2900 Saturn St #B

Brea, CA 92821, USA

Spare 2 pieces test leads (1.5-meter) and 2 pieces

alligator clips

Salt Lake City Office

1364 West State Rd. Suite 101

Pleasant Grove, UT 84062, USA

Page 4

Application Note

Understanding Accuracy Specifications for Digital Pressure Sensors – Percentage of Full Scale Versus

Percentage of Reading

Specications for digital pressure gauges can sometimes seem confusing or overwhelming, especially, if you are

unfamiliar with the terminology. Some pressure sensors will specify accuracy as a percent of full scale (FS) while

others provide the specication as a percent of reading. So why are there different ways of specifying the accuracy of

pressure sensors and is percent of reading more accurate than percent of full scale or vise versa? This brief technical

note will discuss the two differences and answer these questions.

Pressure / Process Calibration Equipment

Percentage of Reading Accuracy

Figure 1 - Percent reading accuracy example

Full scale: 0 to 100 psi

Accuracy: 20 to 100% FS: 0.1% of reading

0 to 20% FS: 0.02% of FS

psi

Accuracy

(psi)

Accuracy as a percentage of reading is accomplished by multiplying

the accuracy percentage by the pressure reading. Thus, the lower

the pressure measurement, the better the accuracy. Instruments that

have a percent reading specification are accompanied with a floor

specication. The oor specication takes into account uncertainties

such as resolution and measurement noise which may be negligible

at higher pressures but are of much more significance at lower

pressures.

0 0.02

20 0.02

30 0.03

40 0.04

50 0.05

60 0.06

70 0.07

80 0.08

90 0.09

100 0.10

For example, an accuracy specification may read 0.1% of reading

0.02%FS10 0.02

for 20 to 100% of range and 0.02% of full scale below 20% of the

range. The 0.02% of full scale specication is considered the oor

specication. To understand the accuracy of the sensor, the user is

then required to know where the oor spec is applicable and the full

0.1% of

Reading

scale of the sensor.

This method of specication is often used because it aligns well with

the typical performance of pressure gauges. Typically, the closer you

measure to barometric pressure the better the performance of the

gauge. Figures 1 and the graph below show an example specication

for a 100 psi gauge and its accuracy in psi.

04

Phone: 714-998-6899 Fax: 714-998-6999 Email: sales@additel.com

Corporate Headquarters

2900 Saturn St #B

Brea, CA 92821, USA

Salt Lake City Office

1364 West State Rd. Suite 101

Pleasant Grove, UT 84062, USA

Page 5

Percentage of Full Scale Accuracy

psi

0 0.05

10 0.05

20 0.05

Pressure / Process Calibration Equipment

30 0.05

40 0.05

50 0.05

60 0.05

70 0.05

80 0.05

90 0.05

100 0.05

Accuracy

(psi)

A Comparison of Percent of Full Scale and Percent of Reading Accuracies

0.05%FS

Accuracy as a percentage of full scale is calculated by multiplying the

accuracy percentage by the full scale pressure of the gauge. This is

obviously a more simple method of specication and is most commonly

used in industry because it is easy to calculate and interpret. Denoting the

accuracy as percent full scale is a more conservative way of specifying

the pressure sensor because typically the sensor doesn't perform the

same over its full range. It usually will perform more accurately as you

approach barometric pressure. This type of specication is most common

for industrial gauges which make it easier to compare one gauge versus

another. Figure 2 is an example specication for a 100 psi gauge and its

accuracy in psi.

Accuracy

psi

10 0.02 0.05 0.02

20 0.02 0.05 0.02

30 0.03 0.05 0.02

40 0.04 0.05 0.02

50 0.05 0.05 0.02

60 0.06 0.05 0.02

70 0.07 0.05 0.02

80 0.08 0.05 0.02

90 0.09 0.05 0.02

100 0.10 0.05 0.02

0.1% of

Reading

0 0.02 0.05 0.02

(psi)

0.05% of FS 0.02% of FS

So you may ask, "Which is more accurate?" The answer is that it depends

on the pressure being measured. In the two examples given, the gauge

specied at 0.1% of reading is more accurate as you measure lower

pressures in its range. However, as you move above 50% of the range,

the gauge specied at 0.05% of full scale becomes more accurate than

the 0.1% of reading gauge. This can be seen clearly in the chart (left)

and graph (below) where the two gauges are compared in terms of psi

accuracy. To properly compare these, two gauges you should convert the

accuracy to pressure units, such as psi or bar. Then they can be properly

matched one against another in like units of measure.

In conclusion, one method of specication is not better than another, it

is just different. Given this difference it becomes important to know how

to interpret the different specications types and be able to compare one

versus another.

05

Phone: 714-998-6899 Fax: 714-998-6999 Email: sales@additel.com

Corporate Headquarters

2900 Saturn St #B

Brea, CA 92821, USA

Salt Lake City Office

1364 West State Rd. Suite 101

Pleasant Grove, UT 84062, USA

Loading...

Loading...