Page 1

INSTRUCTION MANUAL

SL250ES-10

10” MEAT SLICER

1/4 HP, 120V

This manual contains important information regarding your Adcraft unit. Please read this manual

thoroughly prior to equipment set-up, operation and maintenance. Failure to comply with regular

maintenance guidelines outlined in this manual may void the warranty.

Page 2

WARNINGS

• Keep hands away from blade and moving parts

• Do not use the meat slicer for boned meat, fish or anything other than food

• Do not use machine with wet hands or bare feet

• Do not use extension cables

• Do not immerse unit, cord or plug in liquid at any time

• Unplug cord from outlet when not in use and before cleaning. Make sure the graduated knob is

in “0” position.

• Plug only into a 3-hole grounded electrical outlet

• Do not operate unattended

• Do not use this unit for anything other than intended use

• Do not use outdoors

• Keep children and animals away from unit

• Always operate on a firm, dry and level surface at least 12” from walls or any other obstruction

• Do not use unit with a damaged cord or plug, in the event the appliance malfunctions, or has

been damaged in any manner

• Any incorrect installation, alterations, adjustments and/or improper maintenance can lead to

property loss and injury. All repairs should be done by authorized professionals only

• Ensure that the power supply you are using is adequate for continual usage and the voltage is

correct

• Do not use device when, after it has been sharpened numerous times or the diameter of the

blade has become 10mm thinner

*In the case of prolonged use of the food slicer or a motor block, the thermic safeguard in the motor is activated. The motor stops automatically; at this point the machine must be turned off. Check

that the warning light is turned off. Give the motor time to cool down before using again.

TO USE

1. Unwrap and place machine with the On/Off switch so that it is in front of the operator.

2. Regulate the thickness of the slice desired by turning the graduated knob.

3. Switch on to activate the blade.

4. Place the food to be sliced on the sliding carriage (pushing against the food holder arm) facing

the blade, making sure that the food is resting against the gauge plate.

5. After use, turn the graduated knob back to position “0”. The food grip should not be removed

unless the shape and size of the food does not allow its use.

Note: For best results, thaw out frozen meat for several hours before slicing.

*If the sharpener is not mounted, proceed as follows:

• Place the sharpener in its support

• Tighten the safety screw

• Block the knob

CLEANING

To maintain cleanliness and increase service life, the machine should be cleaned daily.

• Before cleaning or attempting to move food slicer, unplug from outlet

• Wipe the entire machine and all parts with a clean soft cloth using ordinary neutral detergents.

Use soft cloths for drying.

• When the sliding food tray moves with difficulty, lift the food slicer and place on its side.

• Carefully clean the cylindrical sliding bar and lubricate with Vaseline oil.

• Remove knife guard periodically, unscrewing the screw (in the center of the knife guard) then

clean both the blade and the inside of the knife guard with alcohol

April 2015

Page 3

NOTE - If the blade transmission belt slips, the correct tension can be achieved (This can be seen

when the rotation of the cutting blade can be stopped while cutting). Please see the following:

1. Approach the regulating components on the bottom.

2. Loosen the bolt on the tension belt screws then turn the screws in a clockwise direction to

achieve correct tension of the belt.

3. Tighten the bolt on the screws.

BLADE SHARPENING

Note - The blade is highly resistant, normally needing to be sharpened about once a year when used

regularly. Should the blade become blunt or dull, please see the following:

1. Unplug the unit.

2. Check that the gauge plate is closed (graduated knob in position “0”).

3. Carefully clean the part of the blade sharpened.

4. Reinsert the plug.

5. Loosen the locking knob on the sharpener group.

6. Raise the sharpener, turning it by 140 degrees so that both grinding wheels are in working

position.

7. Lower the sharpener group until it locks. During this procedure, press button to bring the

sharpening wheel into contact with the cutting edge of the blade.

8. Secure the group by turning the locking knob.

9. Set the gauge plate by turning the graduated knob to no. 2.

10. Switch on, letting the blade turn for 1-2 minutes. When the blade is still, check to see if any burr

has formed on the edge.

11. After having verified the presence of burr, switch on and gently press button for about 3 seconds to remove the burr produced during sharpening in (in this last phase both grinding wheels

should be working).

12. Turn the graduated knob back to position “0”.

13. After sharpening, move the sharpener back to its original position, clean the edge of the blade

and the grinding wheels with alcohol.

14. After several sharpening operations, the grinding wheels should be cleaned with a brush to

remove traces of alcohol.

April 2015

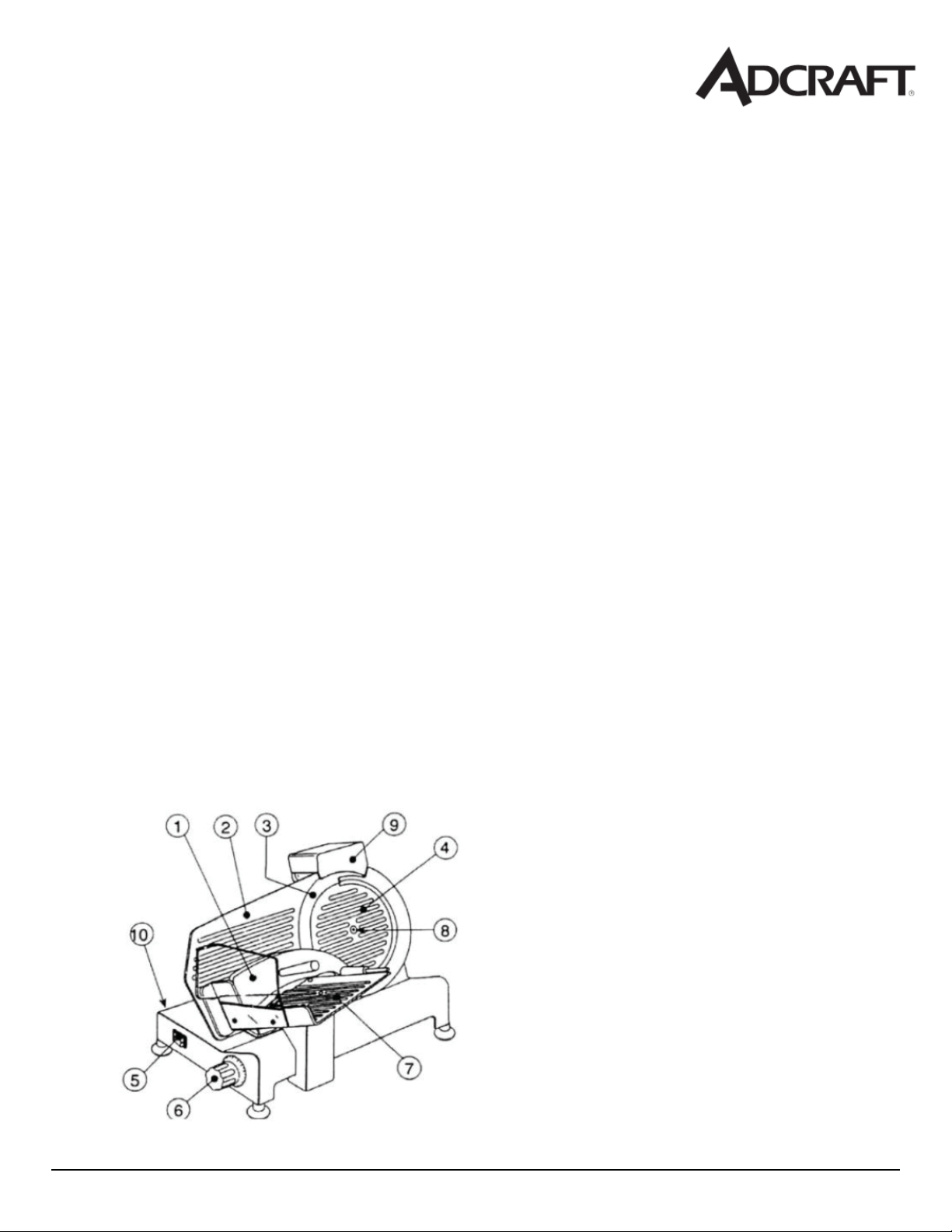

1. Food holder

2. Gauge Plate

3. Blade

4. Blade Guard

5. On/Off Switch

6. Graduated Knob

7. Carriage

8. Blade Guard Bolt

9. Sharpener

10. Body

Page 4

Page 5

SL250ES-10

Parts Diagram and Replacement Parts for the Meat Slicer

April 2015

Page 6

Replacement Parts for the Meat Slicer

Diagram # Description

1 Encloser

2 Active Clapboard

3 Food Salver

4 Blade Guard Disc

5 Blade

6 Blade Guarding Ring

7 Tray Bracket

8 Food and Fixed Arm

9 Fixed Arm Bushing

10 Fixed Arm Handle

11 Plastic Granule

12 Motor

13 Motor Briquetting

14 Fixed-Arm Pin 12x185

15 Blade Guard Bolts

16 Ball Bearing 6202

17 Blade Belt Wheel 66

18 Pin of Belt Wheel

19 BeltSV.330

20 Slide Mulch

21 Power Line

22 Slide Axel

23 Knob with Scale

24 Spring Gasket

25 Cam

26 Cam Osculant Staff

27 Slider

28 Slide Axle Briquetting

29 Spring of Towing Bracket Slide Axle

30 Towing Bracket Axle

31 Quadrate Axis

32 Towing Bracket

33 M8x35 Hexcagonal Screw

34 Ball Bearing 607

35 Towing Bracket Cover Knob

36 Relay

37 Capacitor

38 Capacitor Retainer

39 Button Mulch

40 Button Switch

Diagram # Description

41 Motherboard

42 Meat scraper

43 Sharpener Mulch

44 Sharpener Base of Subassembly

45 Sharpener Base of Assembled

46 Button of Sharpener

47 Fine Grinding Wheel 45

48 Crude Grinding Wheel 45

49 Pin of Rubbingstone

50 Spring

51 Pin of Sharpener Bracket

52 Sharpener Tighten Knob

53 Active Clapboard Mandril

54 Rubber Foot

55 Pin of Blade Guarding Ring

56 Tray Finger Plate Guard

57 Slide Axle Bracket

58 Small Belt of Wheel Motor

59 Slide Driver

60 Belt Wheel Module

61 Sharpener Module

62 Spring Gasket for Bearing 15

63 Spring Gasket for Hole 35

64 Blade Guard Disc Square-Head Nut

65 Fixed-Arm Handle Bolt

66 Finger Baffl e Bolt

67 Finger Baffl e Nut

68 Bracket Knob Bolt

69 Under Spring Gasket

70 Motor Impacted Bolt

71 Meat Scraping Shim

72 Meat Scraper Bolt

73 Capacitor Fixation Clamp Bolt

74 Tray Bearing Cover A

75 Meat Board Basket

76 Tray Bearing Cover B

77 Cross Recessed countersunk head M6x12

78 Slide Axle Briquetting Bolt

79 Quadrate Axis Locking Screw

80 Slider Adjust Bolt

April 2015

Page 7

ACE

Equipment

One Year Limited

Warranty

Admiral Craft Equipment Corp. (ACE) warrants its equipment against defects in materials and workmanship, subject

to the following conditions:

ACE Equipment is warranted for one year, effective from the date of purchase by the original owner. A copy of the

original receipt or other proof of purchase is required to obtain warranty coverage. This warranty applies to the original

owner only, and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this

warranty, at ACE’s discretion, such product will be repaired, replaced with a refurbished unit, or replaced with a new

unit by ACE, after defective unit has been inspected and defect has been confirmed. ACE does not assume any liability

for extended delays in replacing any item beyond its control. This warranty does not apply to rubber and non-metallic

synthetic parts that may need to be replaced due to normal usage, wear or lack of preventative maintenance.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska

and Canada. Warranty coverage on products used outside the 48 contiguous United States, Hawaii and metropolitan

areas

of Alaska and Canada may vary. Contact ACE for details at 1-800-223-7750

The following conditions are not covered by warranty:

•

Equipment failure relating to improper installation, improper utility connection or supply and problems due to

improper ventilation.

•

Equipment that has not properly been maintained, damage from improper cleaning, and water damage

to controls.

•

Equipment that has not been used in an appropriate manner, or has been subject to misuse, neglect, abuse,

accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot, or act of God.

•

Equipment that has the model number or serial number removed or altered.

•

Equipment on which the security seal has been broken.

If the equipment has been changed, altered, modified, or repaired without express written permission from ACE, then the

manufacturer shall not be liable for any damages to any person or to any property, which may result from the use of this

equipment thereafter.

This equipment is intended for commercial use only and this warranty is void if equipment is used in other than a

commercial application.

For warranty and non-warranty related issues, technical support, purchase replacement parts and warranty registration

visit

www.admiralcraft.com

. Please have your model number, serial number and proof of purchase ready. It is not

necessary to contact the place where you originally purchased your product from.

“THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILTY OR FITNESS FOR PARTICULAR

PURPOSES AND CONSTITUES THE ENTIRE LIABILITY OF ACE. IN NO EVENT DOES THE LIMITED

WARRANTY EXTEND BEYOND THE TERMS STATED HEREIN.”

VER1212

April 2015

Loading...

Loading...