Page 1

CBS-2

Coffee Brewer

This manual contains impor t a nt i nfor m a t ion regarding your

Admiral Craft unit. Please read this manual thoroughly prior to

equipment set-up, operation a nd m ai nt e na nc e. Failure to comply

with regular maintenance guidelines outl ined in this manual may

void the warranty. MUST READ!!!

Page 2

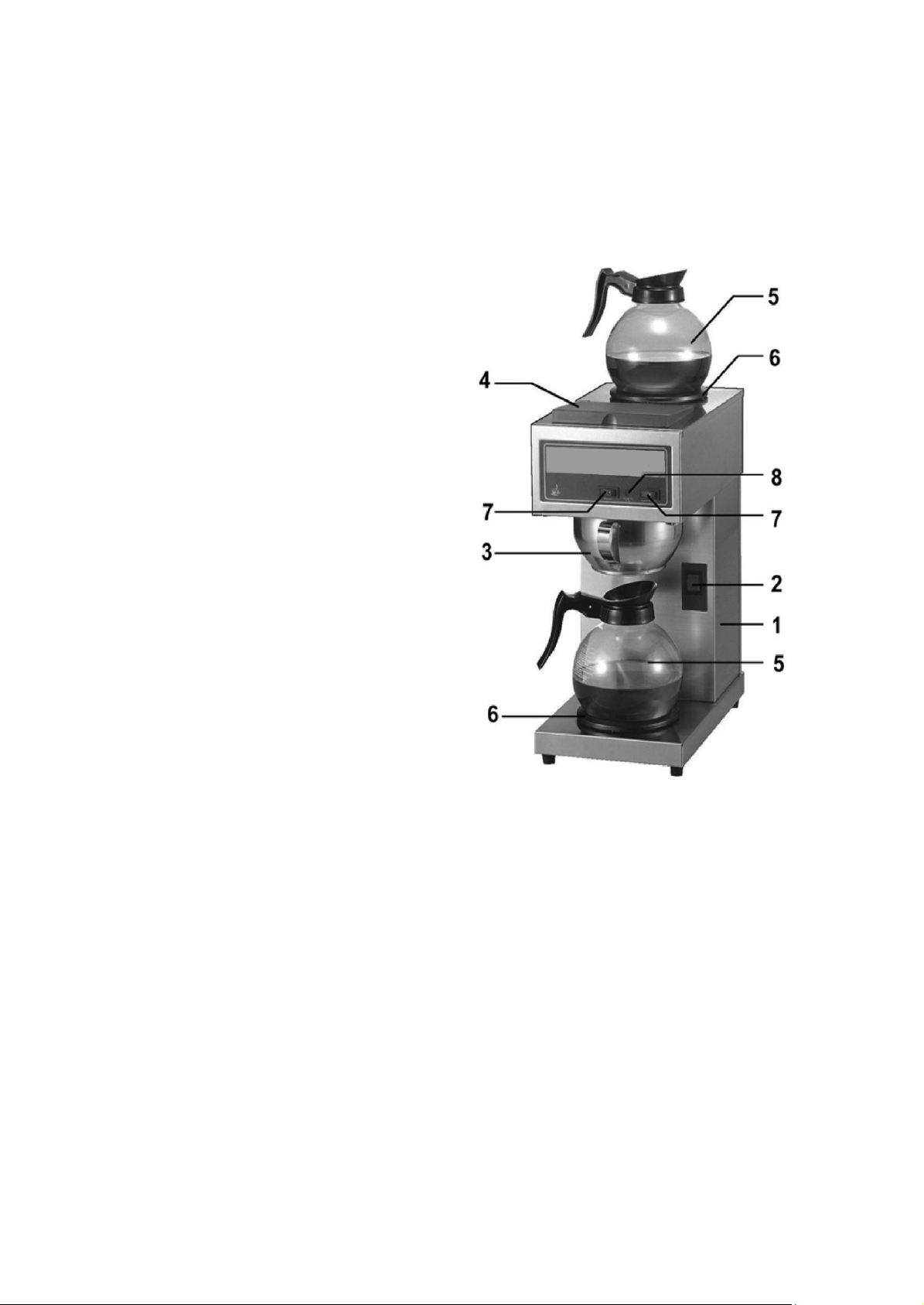

Please refer to the following parts and diagram when reading the

remainder of this manual.

1 Body of Machine

2 Power Switch

3 Filter Basket

4 Water Entrance

5 Coffee Pot ( **Not Included**)

6 Heating Plate

7 Heating Plate Power Switch

8 "Ready" Indicator

Warnings:

-

Never immerse the machine in water. If the machine has been

immersed, it must be dried and checked by an authorized

technician before being used again.

-

Never pour hot water into the water entrance.

-

When the machine is in use, some parts of the machine are

very hot, please ensure the power cord does not touch hot

parts. The user should also be careful not to touch the hot parts.

-

Remain in the vicinity of the machine while machine is in

operation

.

Page 3

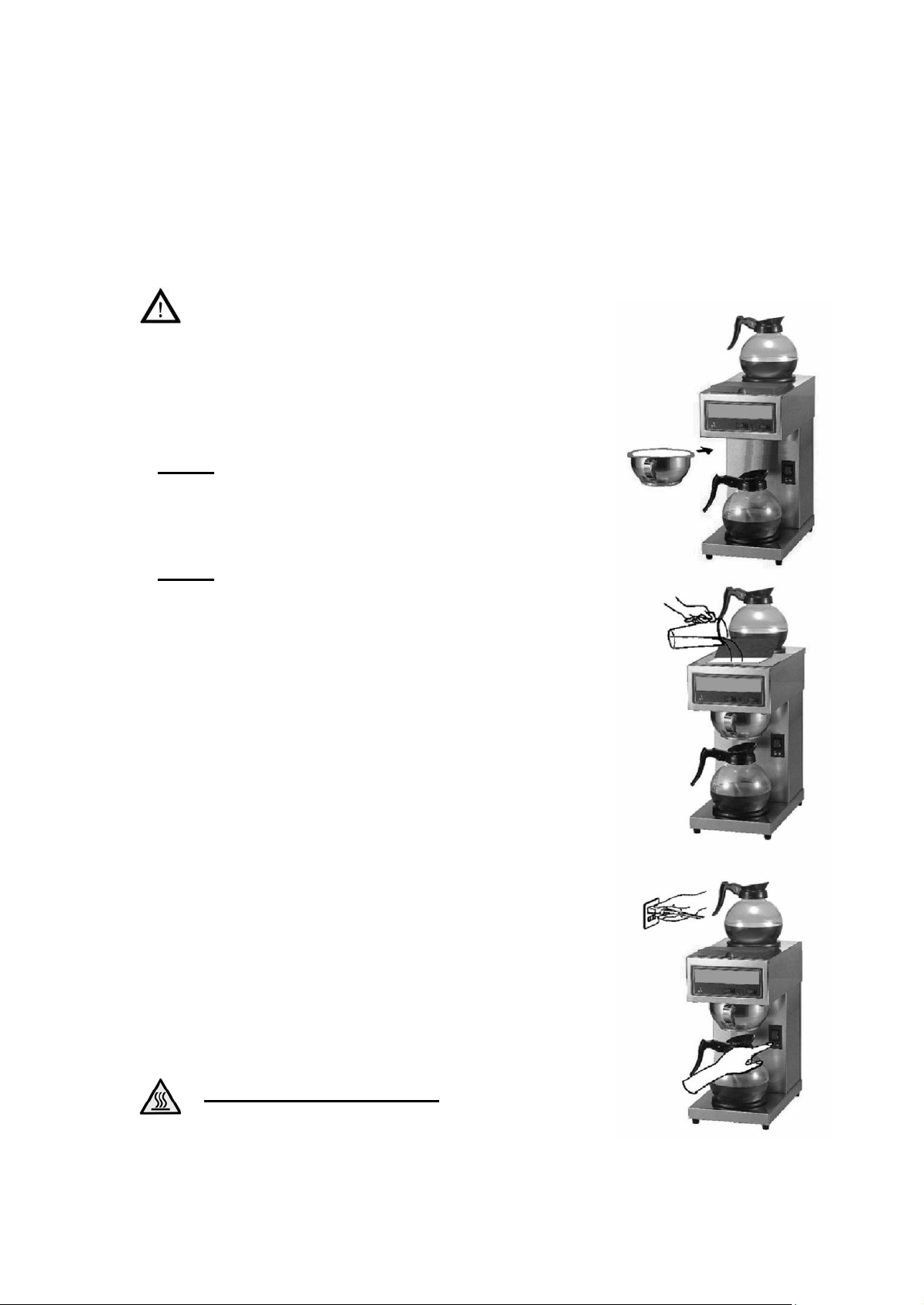

Installation: (When the machine is used for the first time)

ELECTRICAL REQUIREMENTS

The brewer has an attached cord set rated 120 volts AC, 60 Hz, 15 Amps,

single phase, and with a grounding pin. Improper electrical installation will

damage electronic components.

CAUTION: The brewer must be disconnected

from the power source throughout the initial setup, except when specified in the instructions.

1. Place the Machine on a firm and horizontal table.

2. Put spring and wedge it on the bottom of the

Basket.

3. Slide the Filter Basket into the rails.

4. Place a decanter at the base of machine, under the

Basket.

5. Pour 5 liters of cool water into the machine

through the Water Entrance (#4). Allow approximately

two minutes between each carafe to flow into the

tank.

6. Allow the water to flow into the pot or server, wait

approximately 5 minutes after the water stops

flowing.

7. Discard the water in the pot or server and replace it

on the base or the Lower Hot Plate.

8. The brewer is now ready for use.

9. Plug the power cord into the power outlet and turn

power switch to the "ON" position, the brewer will

begin heating.

10.When the "Ready to Brew" indicator lights up, the

machine is ready for use.

CAUTION : Hot Surface.

Page 4

COFFEE BREWING

-

Make sure the “Spring” is wedged well at the

bottom of 3 Filter Basket.

-

Insert a 12 cup filter into the Filter Basket.

-

Pour selected coffee grounds into the filter and

shake it gently to level the bed of grounds.

-

Slide the Filter Pan into position, and ensure that

there is an empty pot or server on the base (or on

the Lower Hot Plate).

-

Confirm the "Ready to Brew" Indication is lit.

-

Pour one pot of tap water into the screened area on

top of the brewer.

-

Coffee will flow out from the Filter Basket into the

server very quickly.

-

When brewing is completed, the coffee can be

served immediately.

-

Discard the grounds and filter.

-

The "Ready to Brew" indication will turn off, and

the Boiler will start heating again.

-

When the "Ready to Brew" indication lights up,

another pot of coffee can be brewed at any time.

During operation, it is normal to hear hissing or

sizzling sounds as the water is heating.

Always turn power switch “OFF”, when brewer is

not in use

If steam appears from around the Filter Basket

during stand-by condition, then the control

thermostat may need to be adjusted downward to

compensate for high altitudes. Please refer to the

adjustment process instructions on the “Adjustment

Instructions” page.

Page 5

CLEANING

1. Use of a damp cloth with a mild, non-abrasive, liquid

detergent is recommended for cleaning all surfaces

of Brewer.

2. Check and clean the “spray head”, ensure that the

spray head holes remain open.

3. You may open the “spray head” to clean if

water-scales (limestone) have covered the holes.

4. In hard water areas, user may need to check the

“spray head” every day. It will help prevent liming problems.

The brewer can not be cleaned by a water jet.

Ensure that the silicon seal on the “spray head” remains in

De-sediment

In areas with hard water, chalk and limestone will accumulate when the

machine is used. To keep the machine in the best condition and ensure each

brew tastes consistent, we recommend that the user De-sediment when the

Machine has brewed for about 600 cycles, or has been used for 6 months,

whichever is first.

The De-sediment process must be conducted by trained professional

personnel, and it is suggested that a service technician be contacted to

perform the service. The De-sediment process is completed as follows;

1. Add 500-ml condensed lemon juice or De-scaler into 1 liter of water.

2. Slide Filter Pan into position.

3. Place an empty Decanter at the correct position under the Filter Pan.

4. Pour the lemon juice solution into the machine.

5. Wait 20~30 minutes to enable the De-scale solution to run through with

6. Open the Top cover and unscrew the lid of water tank.

7. Take off the lid on water tank carefully, there are components

8. Take off the tank, pour the water away and wash it several times.

9. Replace the Tank, Lid, back and screw the lid on.

10. Repeat the Installation steps. (Fill up the tank).

11. The machine is ready for use.

place at all times.

sediments and disconnected the plug from the power source.

mounted on the lid. The operator should avoid touching or bumping them.

There is silicon seal on the groove of Lid, ensure it is always in

place.

Page 6

Adjustment Instructions

Adjust the temperature:

Warning: This adjustment should be process

by qualified technician or service person only.

Adjustment Water Temperature:

The temperature of machine has been set

between 94 – 96 º C. To adjust this

setting;

Open the top cover of machine so that

the temperature controller can be seen.

Turn it very slowly. An accessory knob with temperature ratings is

available for service personnel to assist in setting the thermostat.

For best tasting coffee results;

Use distilled water, or soft and/or filtered water

Choose a quality coffee supplier

Use fresh coffee grounds

Keep coffee grounds in a sealed container, and keep them cool.

Page 7

CBS-2

VER811

Page 8

CBS-2

VER811

Page 9

Coffee Brewer - CBS-2

Reference

Number Part Number Description

1 CBS-1 Foot

2 Bottom Cover

3 Base Frame

4 Power Cord Ring

5 CBS-5 Plug , Power Cord, Strain Releif, Power Cord Clip

6 CBCP-6 Indicator Light, Red

10 CBS-10 Power Switch

11 Outside Switch Holder

12 Inside Switch Holder

13 Body Frame

14 Outflow Pipe

15 Draining Pipe Copper Tube

17 Rear Cover

18 CBS-18 Thermomstat

19 Hold-Down Strap

20 CBS-20 Main Heater

21 CBS-21 Adjustable Thermostat

22 Fever Partition

23 Mica Heater Fixer

25A CBS-25 Mica Heater

26A Warming Plate

28 Shaft for Metal Lid of Water Resivior

29A Lid of Water Reservoir

30A Mesh of Water Entrance

32A Upper Cover

33 Steam Hose

34 Inflow Pipe

35 Outflow Pipe

36 Lid of Tank

38 Block-Thermostat Tube

39 CBS-39 Tank Gasket

41 Water Basin

42 Boiler Tank

44 CBS-44 Relay

45 Upper Frame

46 Indicate Panel

47 CBS-47 Switch for Warming Plate

49 Outflow Pipe

50 Elbow-Out

51A Sprinker Holder

53 CBS-53 S/S Filter Pan and "W" Spring

55 CBS-55 Spinkler Gasket

56 Sprinkler

57 Screw of Sprinkler

VER811

Page 10

ACE

Equipment

One Year Limited

Warranty

Admiral Craft Equipment Corp. (ACE) warrants its equipment against defects in materials and workmanship, subject

to the following conditions:

ACE Equipment is warranted for one year, effective from the date of purchase by the original owner. A copy of the

original receipt or other proof of purchase is required to obtain warranty coverage. This warranty applies to the original

owner only, and is not assignable.

Should any product fail to function in its intended manner under normal use within the limits defined in this

warranty, at ACE’s discretion, such product will be repaired, replaced with a r efurbished unit, or replaced with a ne w

unit by ACE, after defective unit has been inspected and defect has been confirmed. ACE does not assume any liability

for extended delays in replacing any item beyond its control. This warranty does not apply to rubber and non-metallic

synthetic parts that may need to be replaced due to normal usage, wear or lack of preventative maintenance.

This warranty covers products shipped into the 48 contiguous United States, Hawaii, and metropolitan areas of Alaska

and Canada. Warranty coverage on products used outside the 48 contiguous United States, Hawaii and metropolitan

areas of Alaska and Canada may vary. Contact ACE for details at 1-800-223-7750

The following conditions are not covered by warranty:

•

Equipment failure relating to improper installation, improper utility connection or supply and problems due to

improper ventilation.

•

Equipment that has not properly been maintained, damage from improper cleaning, and water damage

to controls.

•

Equipment that has not been used in an appropriate manner, or has been subject to misuse, neglect, abuse,

accident, alteration, negligence, damage during transit, delivery or installation, fire, flood, riot, or act of God.

•

Equipment that has the model number or serial number removed or altered.

•

Equipment on which the security seal has been broken.

If the equipment has been changed, altered, modified, or repaired without express written permission from ACE, then the

manufacturer shall not be liable for any damages to any person or to any property, which may result from the use of this

equipment thereafter.

This equipment is intended for commercial use only and this warranty is void if equipment is used in other than a

commercial application.

For warranty and non-warranty related issues please call ACE at 1-800-223-7750 ext 3 to speak to technical support.

When calling please have your model number, serial number and proof of purchase ready. To purchase replacement

parts, receive online technical support or fill out a warranty claim visit

necessary to contact the place where you originally purchased your product from.

“THE FOREGOING WARRANTY IS IN LIEU OF ANY AND ALL WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILTY OR FITNESS FOR PARTICULAR

PURPOSES AND CONSTITUES THE ENTIRE LIABILITY OF ACE. IN NO EVENT DOES THE LIMITED

WARRANTY EXTEND BEYOND THE TERMS STATED HEREIN.”

VER0112

www.admiralcraftequipment.com. It is not

Loading...

Loading...