Page 1

ML-175 / ML-190

Service Manual

Phase 6 / Phase 7

Micropr ocessor Controls

American Dryer Corporation

88 Currant Road

Fall River, MA 02720-4781

Telephone: (508) 678-9000 / Fax: (508) 678-9447

E-mail: techsupport@amdry.com

www.amdry.com

ADC Part No. 450431-3

Page 2

Retain This Manual in a Safe Place for Future Reference

This product embodies advanced concepts in engineering, design, and safety. If this product is properly

maintained, it will provide many years of safe, efficient, and trouble free operation.

Only qualified technicians should ser vice this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation

manual included with the dryer.

The following “FOR YOUR SAFETY” caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

We have tried to make this manual as complete as possible and hope you will find it useful. The manufacturer

reserves the right to make changes from time to time, without notice or obligation, in prices, specifications,

colors, and material, and to change or discontinue models. The illustrations included in this manual may

not depict your particular dryer exactly.

POUR VO TRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables à proximité de cet

appareil ou de tout autre appareil.

IMPORTANT

For your convenience, log the following information:

DA TE OF PURCHASE ________________________________________________ MODEL NO. _____________________

RESELLER’S NAME __________________________________________________________________________________

SERIAL NUMBER(S) __________________________________________________________________________________

____________________________________________________________________________________________________

____________________________________________________________________________________________________

Replacement parts can be obtained from your reseller or the ADC factory. When ordering replacement parts

from the factory , you can F AX your order to ADC at +1 (508) 678-9447 or telephone your order directly to the

ADC Parts Department at +1 (508) 678-9000. Please specify the dryer model number and serial number in

addition to the description and part number, so that your order is processed accurately and promptly.

“IMPORTANT NOTE TO PUR CHASER”

Information must be obtained from your local gas supplier on the

instructions to be followed if the user smells gas. These

instructions must be posted in a prominent location near the dryer.

2 American Dryer Corporation 450431- 3

Page 3

IMPORTANT

You must disconnect and lockout the electric

supply and the gas supply or the steam supply

before any covers or guards are removed from

the machine to allow access for cleaning,

adjusting, installation, or testing of any

equipment per OSHA standards.

Please observe all safety precautions displayed

on the equipment and/or specified in the

installation manual included with the dryer .

CAUTION

Dryer(s) should never be left unattended while

in operation.

Table of Contents ________

Important Information ............................................. 4

Safety Precautions ............................................... 4

Routine Maintenance.............................................. 4

Cleaning................................................................ 4

Adjustments ......................................................... 5

Lubrication ............................................................ 5

Installation Requirements ...................................... 5

Enclosure, Air Supply,

and Exhaust Requirements................................... 5

Electrical and Gas Requirements ......................... 6

Operational Service Check Procedure................... 6

“Caution: Label all wires prior to disconnection

when servicing controls. Wiring errors can cause

improper operation.”

«Attention: Au moment de l’entretien des

commandes, étiquetez tous les fils avant de les

débrancher. Des erreurs de câblage peuvent

entraîner un fonctionnement inadéquat et

dangereux.»

WARNING

Children should not be allowed to play on or near

the dryer(s). Children should be supervised if

near dryer(s) in operation.

Under no circumstances should the dryer door

switch(es), lint door/drawer switch(es), or heat

safety circuit(s) ever be disabled.

The dryer must never be operated with any of

the back guards, outer tops, or service panels

removed. Personal injury or fire could result.

Description of Parts ................................................. 6

Servicing.................................................................10

Troubleshooting......................................................20

Phase 6 OPL System Diagnostics .........................2 1

Diagnostic (L.E.D. Display) Failure Codes...........21

L.E.D. Display Indicators .....................................2 2

Phase 6 OPL Microprocessor Controller

(Computer) Relay Output L.E.D. Indicators..........23

Phase 7 OPL System Diagnostics .........................2 4

Diagnostic (L.E.D. Display) Failure Codes...........24

Technical Information ............................................25

The dryer must never be operated without the

lint filter/screen in place, even if an external lint

collection system is used.

FOR Y OUR SAFETY

Do not dry mop heads in the dryer. Do not

use dryer in the presence of dry cleaning

fumes.

The dryers must not be installed or stored in

an area where it will be exposed to water

and/or weather.

The wiring diagram for the dryer is located in

the front electrical control box area.

450431-3 www.amdry.com 3

List of Acronyms _____________________

DSI Direct Spark Ignition

HSI Hot Surface Ignition

in wc Inches of Water Column

L.E.D. Light Emitting Diode

L.P. Liquid Propane

OPL On-Premise Laundry (Non-Coin)

OSHA Occupational Safety and Health Administration

T.E.F.C. Totally Enclosed, Fan-Cooled

Page 4

Important Information ________________

Safety Precautions

Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

Purchaser/user should consult the local gas supplier for

proper instructions to be followed in the event the user smells

gas. The instructions should be posted in a prominent

location.

Dryer must be exhausted to the outdoors.

Although ADC’s dryer is a very versatile machine, there are

some articles, that due to fabric composition or cleaning

method, should not be dried in it.

!

▲ WARNING

Dry only water-washed fabrics. Do not dry

articles spotted or washed in dry cleaning

solvents, a combustible detergent, or “all

purpose” cleaners. Fire or explosion could

result.

Do not dry rags or articles coated with gasoline,

kerosene, paint, or wax.

Do not dry mop heads. Contamination by wax or

flammable solvents will create a fire hazard.

Do not use heat for drying articles that contain

plastic, foam, sponge rubber, or similarly textured

rubberlike materials. Drying in a heated tumbler

may damage plastic or rubber and also may be a

fire hazard.

A program should be established for the inspection and

cleaning of lint in the burner area and exhaust ductwork. The

frequency of cleaning can best be determined from

experience at each location.

!

▲ WARNING

!

▲ WARNING

Articles left in the dryer after the drying and

cooling cycles have been completed can create a

fire hazard.

This dryer is not to be used in the presence of dry cleaning

solvents or fumes.

Read and follow all caution and direction labels attached to

the dryer.

!

▲ WARNING

Children should not be allowed to play on or in

the dryer(s). Children should be supervised if

near dryer(s) in operation.

Do not operate dryers with more than 125 psi (8.62 bar) steam

pressure. Excessive steam pressure can damage steam coil

and/or harm personnel.

Replace leaking flexible steam hoses or other steam fixtures

immediately . Do not operate dryer with leaking flexible hoses.

Personal injury may result.

Routine Maintenance _________________

Cleaning

A program and/or schedule should be established for periodic

inspection, cleaning, and removal of lint from various areas

of the dryer, as well as throughout the ductwork system. The

frequency of cleaning can best be determined from

experience at each location. Maximum operating efficiency

is dependent upon proper air circulation. The accumulation

of lint can restrict this airflow. If the guidelines in this section

are met, an ADC dryer will provide many years of efficient,

trouble free, and – most importantly – safe operation.

The collection of lint in the burner area and

exhaust ductwork can create a potential fire

hazard.

Lint from most fabrics is highly combustible. The

For personal safety, the dryer must be electrically grounded

in accordance with local codes and/or the National Electrical

Code ANSI/NFPA No. 70-LATEST EDITION.

NOTE: Failure to do so will void the warranty.

Under no circumstances should the dryer door or lint drawer

switch(es) or heat safety devices ever be disabled.

!

▲ WARNING

Personal injury or fire could result.

Articles should never be left unattended for an extended

period of time in the tumbler after completion of the drying

and cooling cycles.

4 American Dryer Corporation 450431- 3

accumulation of lint can create a potential fire

hazard.

Keep dryer area clear and free from combustible

materials, gasoline, and other flammable vapors

and liquids.

NOTE: Suggested time intervals shown for average usage,

which is considered six to eight operational (running) hours

per day.

Clean lint drawer/screen every third or fourth load.

NOTE: Frequency can best be determined at each

location.

!

▲ WARNING

Page 5

Daily

(Beginning) of each work shift.

Clean lint from the drawer/screen. Inspect lint screen and

replace if torn.

Weekly

Clean lint accumulation from lint chamber, thermostat, and

microprocessor temperature sensor (sensor bracket) area.

!

▲ WARNING

To avoid the hazard of electrical shock,

discontinue electrical supply to dryer.

Steam Dryers

Clean steam coil fins using compressed air and a vacuum

cleaner with brush attachment.

NOTE: When cleaning steam coil fins, be careful not to

bend the fins. If fins are bent, straighten by using a fin

comb, which is available from local air-conditioning supply

houses.

Adjustments

7 Days After Installation and Every 6 Months

Inspect bolts, nuts, screws, (bearing setscrews),

nonpermanent gas connections (unions, shutoff valves,

orifices, and grounding connections). Motor and drive belts

should be examined. Cracked or seriously frayed belts should

be replaced. Tighten loose V-belts when necessary.

Complete operational check of controls and valves. Complete

operational check of all safety devices (door switch, lint drawer

switch, sail switch, burner and hi-limit thermostats).

Lubrication

The fan shaft bearings should be lubricated every three

months. Use Shell Alvania #2 or its equivalent. The motor

bearings, idler bearings and under normal/most conditions

the tumbler bearings are permanently lubricated. It is

physically possible to re-lubricate the tumbler bearings if

you choose to do so even though this practice is not

necessary. Use Shell Alvania #2 or its equivalent. The

tumbler bearings used in the dryer do not have a grease

fitting. Provisions are made in the bearing housing for the

addition of a grease fitting, which can be obtained

elsewhere, or from ADC by ordering kit P/N 882159, which

includes two fittings.

90 Days

Remove lint from tumbler, drive motors, and surrounding

areas. Remove lint from gas valve burner area with a dusting

brush or vacuum cleaner attachment.

NOTE: To prevent damage, avoid cleaning and/or touching

ignitor/flame-probe assembly.

Remove lint accumulation from inside control box and at rear

area behind control box.

6 Months

Inspect and remove lint accumulation in customer furnished

exhaust ductwork system and from dryer’s internal exhaust

ducting.

!

▲ WARNING

The accumulation of lint in the exhaust ductwork

can create a potential fire hazard.

Do not obstruct the flow of combustion and

ventilation air. Check customer furnished back

draft damper in exhaust ductwork. Inspect and

remove any lint accumulation, which can cause

damper to bind or stick.

NOTE: A back draft damper that is sticking partially closed

can result in slow drying and shut down of the heat circuit

safety switches or thermostats.

When cleaning dryer cabinet(s), avoid using harsh

abrasives. A product intended for the cleaning of

appliances is recommended.

Installation Requirements ____________

Installation should be performed by competent technicians

in accordance with local and state codes. In the absence of

these codes, the installation must conform to applicable

American National Standards: ANSI Z223.1-LATEST

EDITION (National Fuel Gas Code) or ANSI/NFPA NO. 70LATEST EDITION (National Electrical Code) or in Canada,

the installation must conform to applicable Canadian

Standards: CAN/CGA-B149.1-M91 (Natural Gas) or CAN/

CGA-B149.2-M91 (L.P. Gas) or LATEST EDITION (for

General Installation and Gas Plumbing) or Canadian

Electrical Codes Parts 1 & 2 CSA C22.1-1990 or LATEST

EDITION (for Electrical Connections).

Enclosure, Air Supply , and Exhaust Requirements

NOTE: The following information is very brief and general.

For detailed description, refer to the “ML-175 Installation

Manual” (ADC P/N 113070).

Bulkheads and partitions around the dryer should be made

of noncombustible materials. Allowances should be made

for the opening and closing of the control door and lint drawer.

Also, allowances should be made in the rear for ease of

maintenance. (Refer to appropriate Installation Manual for

recommended distances and minimum allowances required.)

When the dryer is operating, it draws in room air, heats it,

passes this air through the tumbler, and exhausts it out of

the building. Therefore, the room air must be continually

replenished from the outdoors. If the make-up air is

inadequate, drying time and drying efficiency will be adversely

affected. Ignition problems and sail switch “fluttering”

problems on gas dryers may result, and you also could have

premature motor failure from overheating. The air supply

must be given careful consideration to ensure proper

performance of each dryer.

450431-3 www.amdry.com 5

Page 6

IMPORTANT: Make-up air must be provided from a

source free of dry cleaning fumes. Make-up air that is

contaminated by dry cleaning fumes will result in

irreparable damage to motors and other dryer

components.

Exhaust ductwork should be designed and installed by a

competent technician. Improperly sized ductwork will create

excessive back pressure, which will result in slow drying,

increased use of energy , and shut down of the burner by the

airflow (sail) switch, burner hi-limit or lint chamber hi-heat

protector thermostat. (Refer to appropriate Installation

Manual for more details.)

CAUTION: Improperly sized or installed

exhaust ductwork can create a potential fire

!

hazard.

Compressed Air Requirements

The dryer requires an external supply of air (2.5 cfm @ 80

psi [0.07 cmm @ 5.52 bar) on the steam models, the air is

necessary to operate the damper system. On both steam,

as well as the gas model, the air is necessary/required for

the blower air jet operation to clean lint from the impellor/

fan (squirrel cage type).

Electrical and Gas Requirements

It is your responsibility to have all electrical connections

made by a properly licensed and competent electrician to

assure that the electrical installation is adequate and

conforms to local and state regulations or codes. In the

absence of such codes, all electrical connections, materials,

and workmanship must conform to the applicable

requirements of the National Electrical Code ANSI/NFPA NO.

70-LATEST EDITION or in Canada, the Canadian Electrical

Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION.

IMPORTANT: Failure to comply with these codes or

ordinances and/or the requirements stipulated in this

manual can result in personal injury or component failure.

The dryer installation must meet the American National

Standard, National Fuel Gas Code ANSI Z223.1-LATEST

EDITION, or in Canada, the Canadian Electrical Codes Parts

1 & 2 CSA C22.1-1990 or LATEST EDITION (for Electrical

Connections) as well as, local codes and ordinances, and

must be done by a qualified technician.

NOTE: Undersized gas piping will result in ignition

problems and slow drying and can create a safety hazard.

The dryer must be connected to the type of gas (natural or

L.P.) indicated on the dryer data label. If this information

does not agree with the type of gas available, contact the

reseller who sold the dryer or contact the factory.

The gas input ratings shown on the dryer data label are for

elevations up to 2,000 feet (610 meters), unless elevation

requirements of over 2,000 feet (610 meters) were specified

at the time the dryer order was placed with the factory. The

adjustment for dryers in the field for elevations over 2,000

feet (610 meters) are made by changing the burner orifices.

If this adjustment is necessary, contact the reseller who

sold the dryer or contact the factory.

Operational Service Check Procedure

Turn on electric power to the dryer.

To start dryer:

Display will read “READY.”

Press “E” on the keypad of microprocessor controller

(computer).

The dryer will start to run.

NOTE: Pressing keypad “A,” “B,” “C,” “D,” or “F” will also

start the dryer. Six preprogrammed drying cycles (“A”

through “F”) have been stored in the computer’s memory.

(Refer to Computer Operator’s Manual for details.)

Make a complete operational check of all the operating

controls to assure that the timing is correct, temperature

selection switches are functioning, etc.

Make a complete operational check of all safety-related

circuits: door switch(es), hi-limit thermostat, sail switch,

cycling thermostats, etc.

For gas dryers, a gas pressure test should be taken at the

gas valve pressure tap of each dryer to assure that the water

column pressure is correct and consistent.

NOTE: Water column pressure requirements (measured

at the pressure tap on the gas valve body):

Natural Gas – 3.5 in wc; L.P. Gas – 10.5 in wc

If computer program changes are required, refer to the

Phase 6 OPL Operator’s Manual (ADC P/N 113022) for

details.

The dryer should be operated through one complete cycle

to assure that no further adjustments are necessary and

that all components are functioning properly.

Check the electric service phase sequence. While the dryer

is operating, check to see if the tumbler is rotating in the

proper direction. Looking from the front, the tumbler should

spin in the clockwise direction. If so, the phasing is correct.

If the phasing is incorrect, reverse two leads at connections

L1, L2, or L3 of power supply to the dryer.

Description of Parts __________________

Control Panel (Microprocessor)

Opening the control panel will allow access to the major

components, which include the computer board and keypad.

The keypad inputs to the computer what temperature and

program has been selected. The computer controls the

entire operation of the machine. It accepts inputs and gives

outputs to various parts throughout the machine.

NOTE: Any burner changes must be made by a qualified

technician.

6 American Dryer Corporation 450431- 3

Page 7

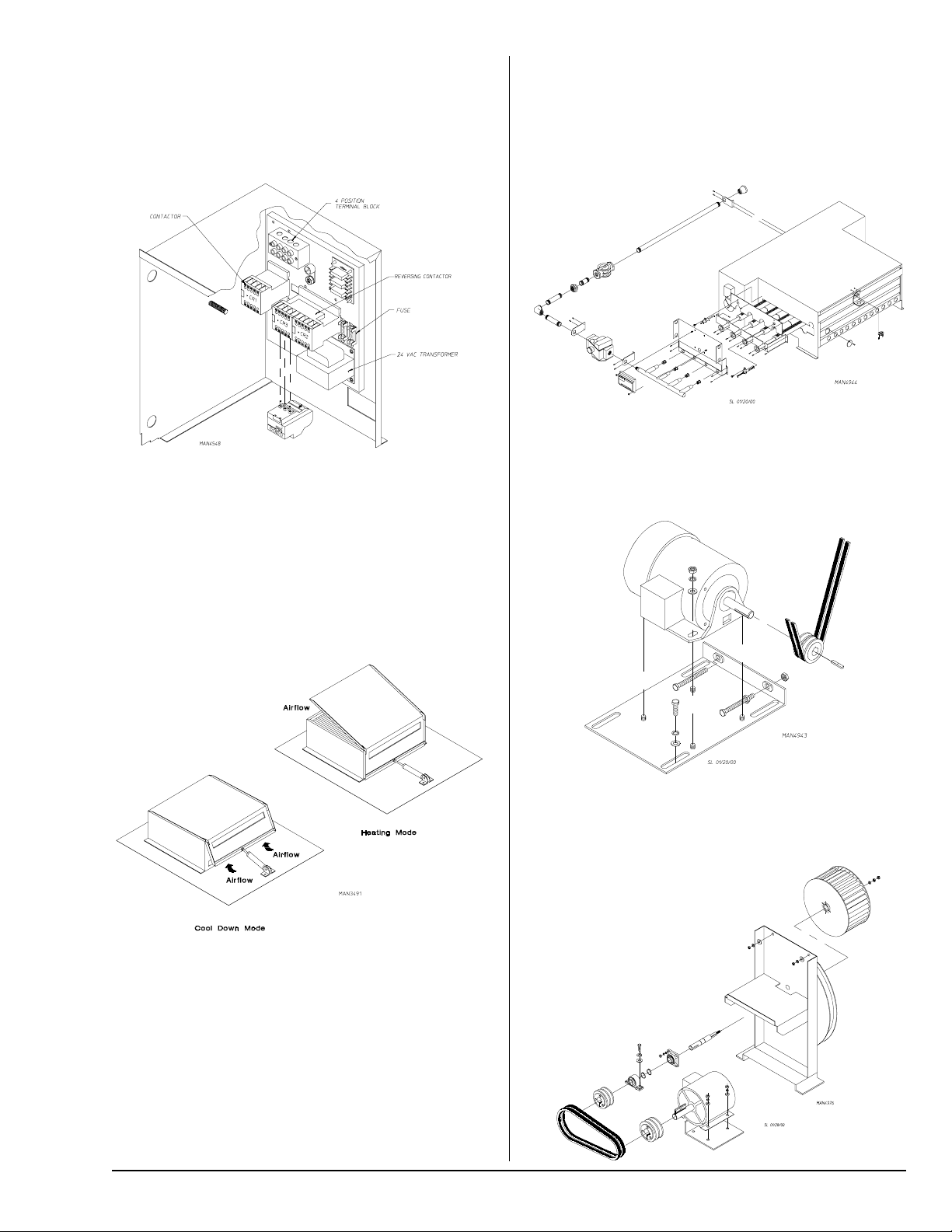

Reversing Relay Panel

Lifting the control door will reveal the reversing relay box.

Located on the back of the relay box is the reversing relay

panel. Included on this panel is a 4-position terminal block,

blower overload, blower contactor, reversing contactor, 24

VAC transformer, fuse or circuit breaker, ground lug, and

possibly an arc suppressor board.

Steam Coil and Damper System

The steam coil is constantly charged, thereby eliminating

repeated expansion and contraction and also provide instant

heating to start the drying process. The steam damper,

located on top of the steam coil, is the only temperature

controlling device in this system. When the steam damper

is open, ambient air is drawn through the coil providing

heat to the dryer. When the steam damper is closed, ambient

air is drawn directly into the tumbler, bypassing the coil,

allowing a rapid cool down.

Gas Burner Assembly

Gas heated dryers are equipped with a gas burner assembly

consisting of four burner tubes, gas valve, ignitor, flameprobe, sail switch, and hi-limit thermostat. The inlet piping

enters through the rear of the dryer on the left-hand side

(viewing from the front) and runs to the front of the dryer

where the gas valve is located.

Drive Motor

The T.E.F.C. drive motor is located in the right front hand

corner of the dryer. It sits on an adjustable base so that the

motor can be easily adjusted to the left or right.

Blower Motor and Impellor (Gas and Steam)

The impellor is shaft driven. The blower motor drives the

shaft on which the impellor is mounted.

NOTE: With the dryer off or no air supply to the damper

piston, the damper is in the cool down mode.

Steam Coil pH Level

NOTE: The normal pH level for copper type steam coils

must be maintained between a value of 8.5 to 9.5. For

steel type steam coils the pH level must be maintained

between a value of 9.5 to 10.5. These limits are set to

limit the acid attack of the steam coils.

IMPORTANT: Coil failure due to improper pH level will

void the warranty.

450431-3 www.amdry.com 7

Page 8

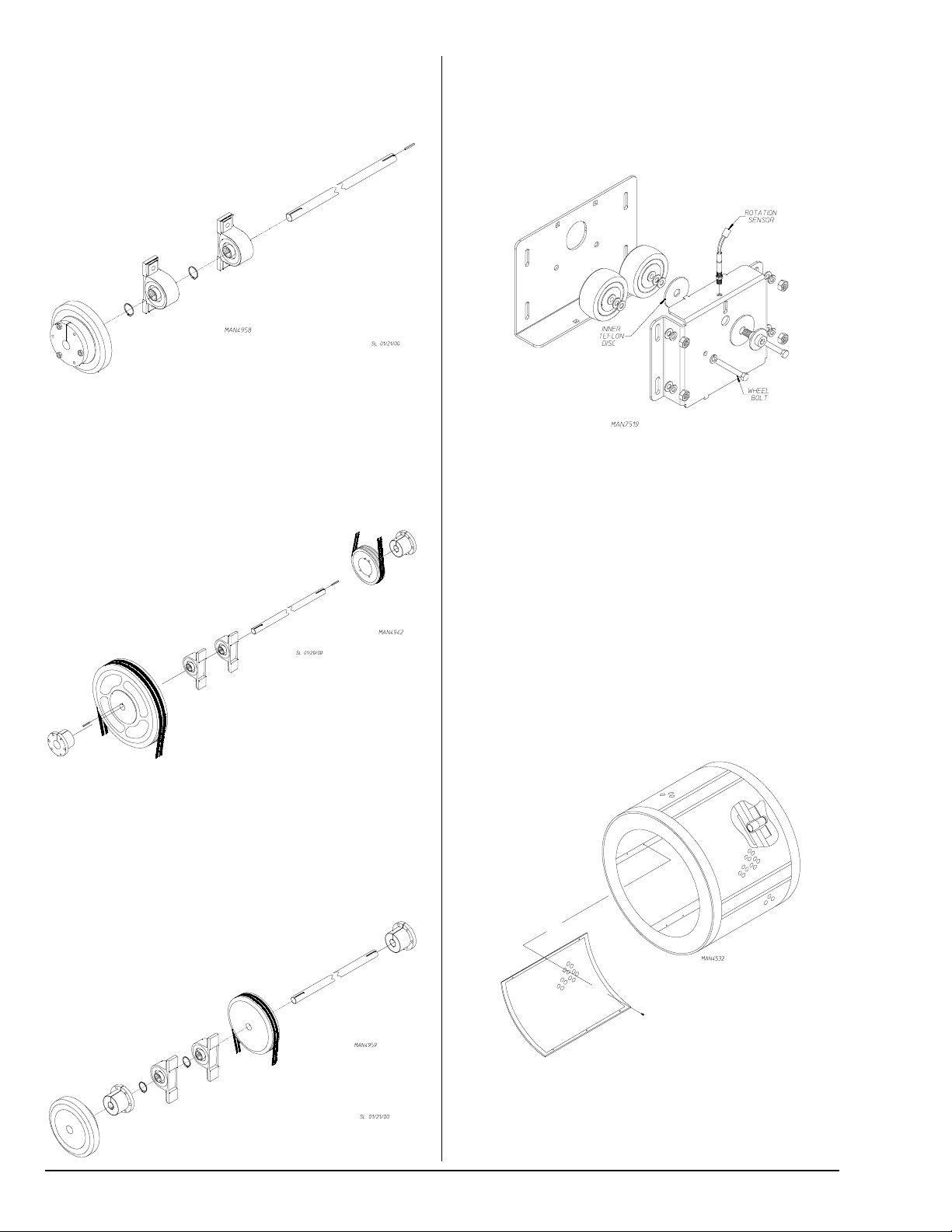

Idler Shaft Assembly

The idler shaft is located on the left side of the machine and

is just above the blower motor. The idler shaft assembly

consists of one 1 1-inch (27.94 cm) drive wheel and two pillow

block bearings.

Speed Reducing Shaft

The speed reducing shaft is located on the right side and is

above the drive motor. The idler assembly consists of two

idler pulleys. The idler’s main purpose is to reduce the

speed and increase torque provided to the tumbler.

Tumbler Shaft Support

The tumbler shaft support is located in the rear,

approximately at the center of the dryer. The arrangement

consists of a tumbler shaft support bracket, two high impact

wheels, tumbler adjustment plate, Teflon

rotational sensor assembly.

®

discs, and a

Rotational Sensor Assembly

The rotational sensor assembly is located in the rear of the

dryer. It consists of a magnet and rotational sensor switch,

which is mounted to the bearing cap. The magnet is

screwed to the shaft.

The magnetic rotational sensor switch senses the rotation of

the tumbler.

Drive Shaft

The drive shaft is located on the right side and is above the

drive motor. The drive shaft consists of one 11-inch (27.94

cm) drive wheel, one pulley, and two pillow block bearings.

The purpose of the drive shaft is to drive the tumbler.

Tumbler

The tumbler consists of four ribs and four perforated panels,

along with a front and back, which are welded together as an

assembly. The tumbler also consists of a trunnion, which

supports the tumbler in the rear.

8 American Dryer Corporation 450431- 3

Page 9

Main Door Switch

The main door switch is located near the main door hinge.

When the main door opens, the switch will also open,

preventing the dryer from operating. The main door switch

is a safety device and should never be disabled.

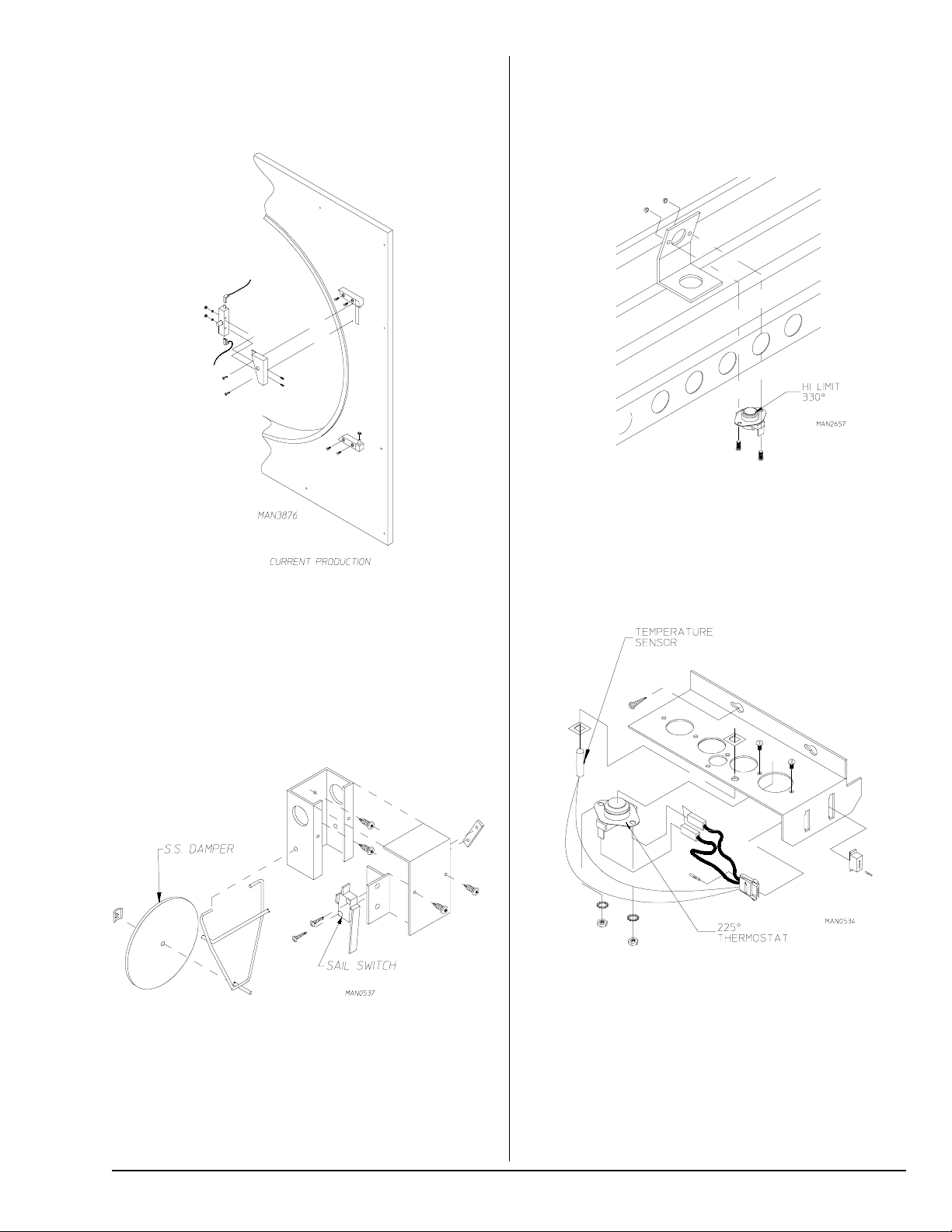

Burner Hi-Limit (Gas Models Only)

A burner hi-limit thermostat is located on the burner. This is

a manual reset disc-type thermostat set at 330° F (165° C).

If the flame in the burner should get too hot, this thermostat

will shut off the burner. This is generally caused by low

airflow through the dryer.

Sail Switch (Gas Models Only)

The sail switch is located on the front of the burner box. A

sail switch consists of a round damper plate on a lever arm,

which is in contact with an electric switch. When the fan/

blower comes on, it draws air through the burner box. This

creates a negative pressure inside the burner box, and this

negative pressure pulls in the round damper and activates

the sail switch.

Tumbler Hi-Limit

This is located in the lint compartment above the lint drawer .

This bracket consists of two devices. One is a temperature

sensor probe and the other is a hi-limit thermostat, which is

set at 225° F (107° C).

450431-3 www.amdry.com 9

Page 10

Lint Drawer

The lint drawer is located at the bottom of the dryer in the lint

compartment. Simply grab the lint drawer handle, slide out

the drawer, brush off the lint, and slide the drawer back in.

Lint Drawer Switch

The lint drawer switch is located in the lint compartment and

attached to the side of the lint drawer track. The lint drawer

switch ensures that the dryer will operate only when the lint

drawer is completely closed. This is a safety device and

should never be disabled.

Servicing ______________________________

Introduction

All electrical/mechanical service or repairs should be made

with the electrical power to the dryer disconnected (power

off).

!

▲ WARNING

Personal injury could result.

The information provided in this section should not be

misconstrued as a device for use by an untrained person

making repairs. Service work should be performed by

competent technicians in accordance with local, state, and

federal codes.

When contacting the factory for assistance, always have the

dryer model and serial numbers available.

CAUTION: Observe all safety precautions

displayed on the dryer or specified in this

!

manual before and while making repairs.

Before considering replacement, make sure that all

connectors are in place and making proper contact.

Computer Controls

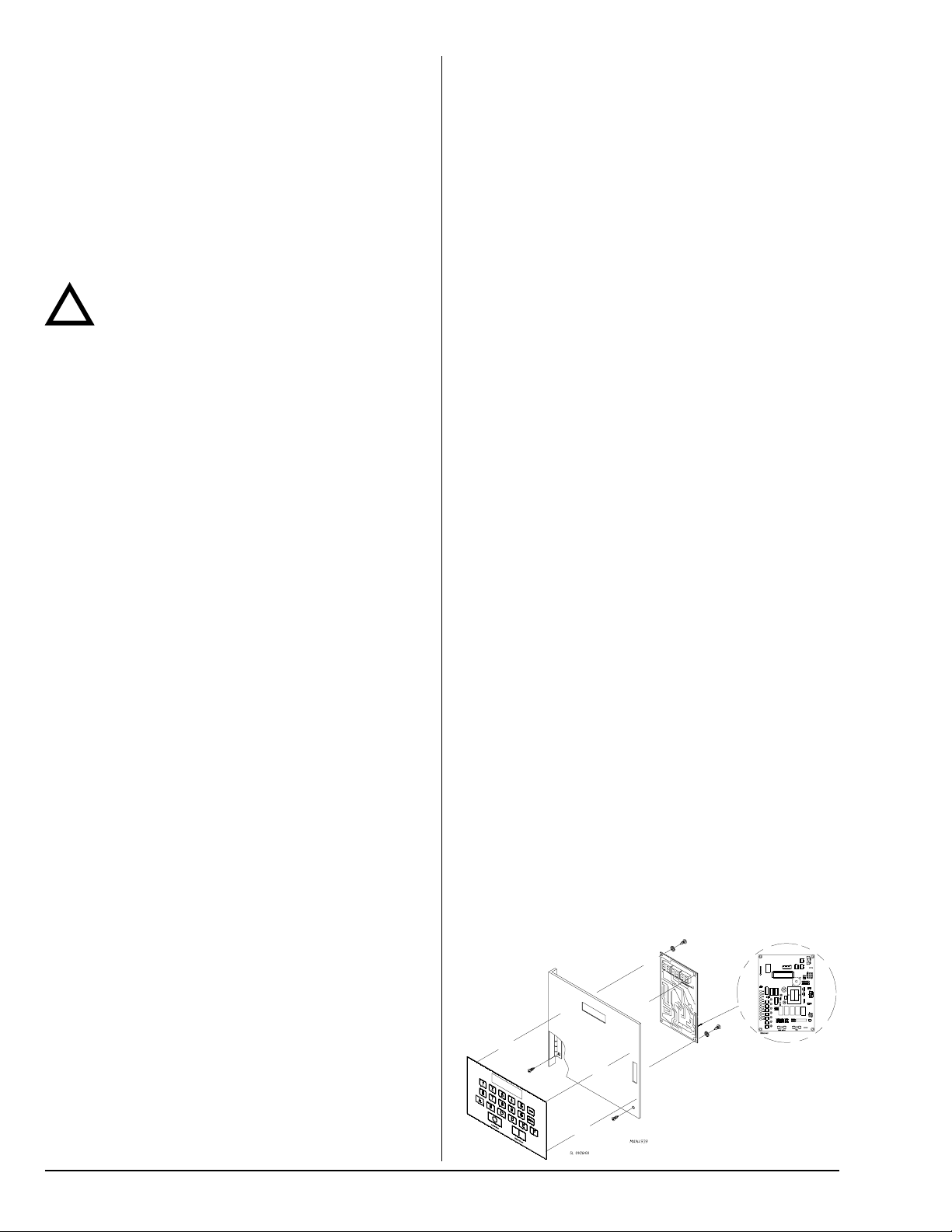

To Replace Computer

Disconnect electrical power to the dryer.

Disconnect main power harness, along with the three other

connectors located on the computer board, from rear of

computer by squeezing locking tab and pulling connector

straight back.

Disconnect the “green” ground wire and the air jet wire from

the computer.

Disconnect keypad ribbon from the computer.

Remove the screws securing the computer to the sheet

metal control panel. Remove the board by pulling the other

two corners off the clinch studs.

Install new computer by reversing this procedure.

When replacing the computer, the “A” and “B” factors must

be reprogrammed. (Refer to “Computer Operator’s Manual”

for details.)

NOTE: The “A” and “B” factors are printed on a label located

on the rear of the control panel (refer to illustration).

Reestablish electrical power to the dryer.

10 American Dryer Corporation 450431- 3

Page 11

To Replace Keyp ad Label Assembly

Discontinue electrical power to the dryer.

Unplug keypad ribbon from rear of computer.

Slowly peel off and remove keypad label assembly from

control panel.

Peel paper backing off new keypad label assembly.

Holding the new keypad label assembly close to the panel,

insert the keypad ribbon through the rectangular slot in the

control panel. Align label assembly into position by matching

the red viewing window on the label to the rectangular cutout

in the panel and gently press into place.

Connect keypad ribbon to the computer.

Reestablish electrical power to the dryer.

Disconnect the two “orange” wires from the high heat

(225° F [107° C]) thermostat, and remove modular bracket

connector, wires, and probe from bracket assembly.

Install new sensor probe assembly (ADC P/N 880251) by

reversing procedure.

Reestablish electrical power to the dryer.

NOTE: If, when power is reestablished, the computer

display reads “Temp Sensor Check Temp Sensor Fuse,”

check for a loose connection in the wiring.

Ignition Controls

To Remove HSI Ignitor

Discontinue electrical power to the dryer.

Disconnect the two “white” ignitor wires going to the HSI

module.

Disassemble HSI ignitor from burner by removing the self-

tapping screw.

Reverse procedure for installing new ignitor.

To Replace Microprocessor Temperature Sensor Probe

Discontinue electrical power to the dryer.

Remove lint drawer. Remove six screws securing lint door

and remove lint door.

Remove microprocessor sensor bracket assembly from dryer.

Disconnect sensor bracket harness connector.

Remove the four Hex head screws securing bracket

assembly to dryer and remove bracket from dryer.

Disassemble sensor probe from bracket assembly by

removing the top push-on fastener securing the probe from

bracket. Use a small screwdriver to slowly pry the fastener

off.

To Remove HSI Flame-Probe Assembly

Discontinue electrical power to the dryer.

Disconnect the “red” wire from the flame sensor probe, which

goes to S2 on the HSI module.

Disassemble flame sensor probe from burner by removing

the self-tapping screw.

Reverse procedure for installation of new flame sensor

probe.

To Replace S p ark Ignitor and Flame-Probe

Discontinue power to the dryer.

Disconnect high voltage connector and flame-probe

connection from ignitor.

Disassemble ignitor from burner by removing the two

self-tapping screws.

Reverse procedure for installing the new ignitor probe.

NOTE: Before reestablishing power to the dryer, visually

check the following: (refer to the illustration on the next

page).

450431-3 www.amdry.com 11

Page 12

To Replace Gas V alve

(Refer to burner illustration on the next page)

Discontinue electrical power to the dryer.

Close shutoff valve(s) in gas supply line.

Disconnect gas valve wiring.

NOTE: Identify location of each wire for correct

reinstallation.

Break union connection before gas valve.

Loosen and remove screws (4) securing pipe brackets to

burner.

Remove gas valve/manifold assembly from dryer.

Remove valve mounting bracket, manifold, and piping from

gas valve.

Reverse procedure for installing new gas valve.

To Test and Adjust Gas (Water Column) Pressure

There are two types of devices commonly used to measure

water column pressure. They are spring/mechanical-type

gauges and manometers. The spring/mechanical-type gauge

is not recommended, because it is easily damaged and not

always accurate. A manometer is simply a glass or

transparent plastic tube with a scale in inches. When filled

with water and pressure applied, the water in the tube rises

showing the exact water column pressure.

NOTE: Manometers are available from the factory by

ordering ADC P/N 122804.

To Test Gas Water Column Pressure:

Connect water column test gauge connection to gas valve

pressure tap (1/8” N.P.T.). This pressure tap is located on

the outlet (manifold) side of the valve.

Start dryer . W ith burner on, the correct water column reading

in inches would be:

Natural Gas – 3.5 in wc; L.P. Gas – 10.5 in wc

To Adjust W ater Column Pressure (natural gas only, L.P. gas

must be regulated at source):

Remove the slotted vent cap on the top of the valve.

Turn the slotted adjustment screw, located on the top of the

valve next to the terminals clockwise to increase manifold

pressure and counterclockwise to decrease.

NOTE: If correct water column pressure cannot be

achieved, problem may be due to an undersized gas

supply line, a faulty or underrated gas meter, etc.

!

▲ WARNING

Test all connections for leaks by brushing on a

soapy water solution.

Never test for leaks with a flame!!!

To Replace Main Burner Orifices

Refer to “To Replace Gas Valve” and follow the steps until

manifold is removed then unscrew main burner orifices and

replace.

NOTE: Use extreme care when removing and replacing

orifices. These orifices are made of brass and are easily

damaged.

Reversing the removal procedure for reinstalling.

!

▲ WARNING

Test all connections for leaks by brushing on a

soapy water solution.

Never test for leaks with a flame!!!

12 American Dryer Corporation 450431- 3

Page 13

To Convert from Natural Gas to L.P. Gas

NOTE: All dryers are sold as natural gas, unless otherwise

specified at the time the dryer order was placed. For L.P.

gas the dryer must be converted as follows.

Remove the four screws which secure the top cap assembly .

This assembly contains the regulator adjustment screw and

the terminal connections.

Replace the top cap assembly with the L.P. version.

To install the new L.P. orifices refer to “Replace Main Burner

Orifices”.

NOTE: Use extreme care when removing and replacing

orifices. These orifices are made of brass and are easily

damaged.

Reverse the procedure for reinstalling valve assembly to the

dryer.

!

▲ WARNING

Test all connections for leaks by brushing on a

soapy water solution.

Never test for leaks with a flame!!!

!

▲ WARNING

Test all connections for leaks by brushing on a

soapy water solution.

Never test for leaks with a flame!!!

To Replace HSI Module / DSI Module

Discontinue electrical power to the dryer.

Remove the wires connected to the terminal strip at the

bottom of the module.

Remove the two pal nuts securing the module to the mounting

bracket.

Replace module by reversing procedure.

Reestablish electrical power to the dryer.

NOTE: There is no regulator provided in an L.P. dryer.

The column pressure must be regulated at the source

(L.P. tank) or an external regulator must be added to each

dryer.

To Replace Burner Tubes

Refer to “Replace Gas Valve” and follow the instructions up

to “Remove gas valve/manifold assembly from dryer”.

Remove four screws securing manifold rest and remove

rest.

Remove the screws securing the front flanges of the burner

tubes to the burner tube rest.

Remove the screws securing the burner tube rest to the

oven and remove this rest.

Remove screws securing the burner box cover plate to the

oven and remove this plate.

Remove burner tubes by sliding them out.

Replace by reversing procedure.

Thermostats

To Replace Burner Hi-Limit Thermost at

(Gas Models Only)

IMPORTANT: Under no circumstances should heat circuit

safety devices ever be disabled.

Discontinue electrical power to the dryer.

Disconnect wires from hi-limit thermostat.

Remove screw, washer, and nut securing thermostat to the

bracket. Remove thermostat.

450431-3 www.amdry.com 13

Page 14

Reverse procedure for installing new thermostat.

Reestablish electrical power to the dryer.

To Replace Lint Comp artment

Hi-Heat Protector (225° F [107° C) Thermostat

IMPORTANT: Under no circumstances should heat safety

devices be disabled.

Discontinue electrical power to the dryer.

Remove lint drawer. Remove two screws securing lint door

and remove lint door.

Locate sensor bracket assembly and the four Hex head

screws securing bracket assembly to the tumbler wrapper.

Disconnect sensor bracket harness connector and remove

bracket assembly from dryer.

Disconnect the two “orange” wires from the thermostat.

Disassemble thermostat from bracket assembly by removing

the two mounting screws, washers, and nuts.

Reverse this procedure for installing a hi-heat protector

thermostat.

Reestablish electrical power to the dryer.

To Adjust Sail Switch

With the dryer operating at a high temperature setting, pull

the sail switch away from the burner. The sail switch should

open and extinguish the burner. Let the sail switch damper

return to the burner wall. The sail switch should close to

restart the burner ignition cycle. If the sail switch circuit does

not operate as described, bend the actuator arm of the sail

switch accordingly until proper operation is achieved. To

check proper “open” position of sail switch, open main door,

manually depress main door switch, and start dryer. With

the main door open and the dryer operating, the sail switch

should be open, and the burner should not come on.

IMPORTANT: Under no circumstances should heat safety

devices be disabled.

Front Panel and Main Door Assemblies

To Replace Main Door Switch

Discontinue electrical power to the dryer.

Open main door.

Remove the two Phillips head screws holding the main

door switch bracket assembly in place.

Remove door switch bracket and disconnect wiring from

switch.

Disassemble door switch from bracket by removing the two

#6-32 nuts. Remove door switch from bracket.

Reverse this procedure for installing new door switch.

NOTE: This is a manual reset thermostat. Before

changing the thermostat make sure the reset button is in to

determine if the thermostat has failed.

Sail Switch Assembly (Gas Models Only)

To Replace Sail Switch

Disconnect electrical power to the dryer.

Remove the two screws which hold sail switch box cover to

sail switch box.

Disconnect the two wires from the switch.

Disassemble sail switch from mounting bracket by removing

the two screws securing switch in place.

Reverse this procedure for installing new sail switch. Adjust

sail switch as described in the next section.

14 American Dryer Corporation 450431- 3

Reestablish electrical power to the dryer.

IMPORTANT: Under no circumstances should the door

switch be disabled.

To Replace Main Door Assembly

Remove two Allen head screws holding the top main door

hinge block to the front panel.

Remove the main door by lifting up and off of bottom hinge

block.

Reverse this procedure for reinstalling new main door

assembly.

Page 15

To Inst all New Main Door Glass

Remove main door assembly from dryer (follow main door

removal procedure).

Lay main door on flat surface with front of door face up.

Remove the four #10-32 Acorn nuts.

Remove glass and clean all old sealant off main door. This

area must be completely cleaned for correct bonding.

Apply a narrow bead of silicone (ADC P/N 170730) all around

main door area where glass will rest.

Install glass onto door/adhesive and slightly press glass in

place.

IMPORTANT: Do not press hard or silicone thickness

between the glass and door will be reduced, resulting in

poor bonding.

Remove the twelve Phillips head screws securing front panel

to dryer.

Pull wires up through front panel door switch wire channel

and gently remove front panel assembly.

Reverse this procedure for installing new front panel.

Reestablish electrical power to the dryer.

Pulleys

To Replace Drive Shaf t Pulleys

Discontinue electrical power to the

dryer.

Remove the lint drawer.

Remove the lint door.

Remove right lint coop wall.

Loosen V-belts, then rot ate pulley and

roll V-belts out of its’ grooves.

Remove cap screws from the

bushings.

Insert cap screws in tapped removal

holes and tighten evenly until bushing

becomes loose on shaft. Refer to

figure “A.”

Remove bushing, pulley, and key.

Assemble bushing and sheave as

shown in figure “B”. When cap screws

are loosely inserted, bushing

remains fully expanded to provide a

sliding fit on the shaft.

Insert key on the shaft, then slide

sheave to desired position with cap

screw heads to the outside.

Secure the four #10-32 Acorn nuts to hold the glass.

The door assembly should now be put in an area where it

will not be disturbed for at least 24 hours. Depending on

the conditions, the curing time of this adhesive is 24 to 36

hours.

After 24-hour curing period, install main door on dryer by

reversing the first step.

To Replace Front Panel

Discontinue electrical power to the dryer.

Remove main door switch and bracket assembly.

Follow procedure for removal of main door assembly.

Open control (service) door.

Remove lint drawer and open lint door by removing six

screws.

Unplug the door switch wires at the bottom of the front panel.

Disconnect the wires connecting the “EMERGENCY STOP”

(E-Stop). The easiest place to do this would be in the left

hand electrical box. Once the wires are disconnected, push

them through the inner top.

Tighten cap screws progressively. There should remain a

gap between the sheave hub and the flange of the bushing.

450431-3 www.amdry.com 15

Page 16

IMPORTANT: Tighten screws evenly and progressively.

Never allow the sheave to be drawn in contact with the

flange of the bushing. This gap should measure from 1/8”

to 1/4”. Proper cap screw torque is 30 ft.-lb. If greater

tightening forces are applied, excess pressures will be

created in the hub of the mounted sheave, which may

cause it to crack.

To Replace Motor Pulley

Discontinue electrical power to the dryer.

Remove the lint drawer.

Remove the lint door.

Loosen V-belts, then rotate pulley and roll V-belts out of its’

grooves.

Remove cap screws from bushing.

Tighten the two bolts under the drive shaft clockwise to raise

the tumbler and counterclockwise to lower the tumbler. The

bolts should be tightened in even increments in order to

ensure that the shaft runs parallel with the base of the dryer.

IMPORTANT: Side to side adjustment of the tumbler

should be equal on either side of the front panel, but

vertically the top of the tumbler should have a larger gap

than the bottom to compensate for the load.

Be sure to tighten the left idler side to the same height as

the right side/drive side. This length can be determined by

taking measurements from the bottom of each pillow block

bearing to the top of the bearing pad.

Insert cap screws in tapped removal holes and tighten evenly

until bushing becomes loose on shaft. Refer to figure “A”

on the previous page.

Remove bushing, pulley, and key.

Assemble bushing and sheave as shown in figure “B” on

the previous page. When cap screws are loosely inserted,

bushing remains fully expanded to provide a sliding fit on

the shaft.

Insert key on the shaft, then slide sheave to desired position

with cap screw heads to the outside.

Tighten cap screws progressively. There should remain a

gap between the sheave hub and the flange of the bushing.

IMPORTANT: Tighten screws evenly and progressively.

Never allow the sheave to be drawn in contact with the

flange of the bushing. This gap should measure from 1/8”

to 1/4”. Proper cap screw torque is 6 ft.-lb., if greater

tightening forces are applied, excess pressures will be

created in the hub of the mounted sheave, which may

cause it to crack.

Tumbler Alignment

Discontinue electrical power to the dryer.

Remove the lint drawer.

Remove the lint door.

Remove both the left hand and right hand lint coop walls.

Loosen the V-belts on drive shaft, then rotate pulley and roll

V-belts out of its’ grooves.

NOTE: If the axle height is not the same on the drive and

idler side, then the tumbler will be either more to the right

or left side, depending on which axle is higher.

Tighten locking nuts on the adjustment bolts.

Reverse the first five steps for reassembly.

Check tumbler drive belt for proper tension. Adjust if

necessary.

Reestablish electrical power to the dryer.

Bearings

To Replace Drive/Idler Shaf t Pillow Block Bearings

Discontinue electrical power to the dryer.

Remove the lint drawer.

Remove the lint door.

Loosen and roll V-belts of f that connect speed reducing shaft

to drive shaft.

Place a piece of wood between the tumbler and wrapper to

support the tumbler when shaft is removed.

Remove the four bolts holding the drive shaft assembly in

the dryer.

Remove cap screws from bushing of drive wheel.

Insert cap screws in tapped removal holes and tighten evenly

until bushing becomes loose on shaft.

Remove bushing and key.

Remove wheel from shaft.

Loosen the four setscrews in the pillow block bearings.

16 American Dryer Corporation 450431- 3

Page 17

To Replace Rear Tumbler Shaft Support Wheels

Disconnect electrical power to the dryer.

Remove the four nuts securing the rear support box to the

dryer.

®

Remove the center Allen head bolt and Teflon

washer.

Loosen the individual wheel bolts so the rear of the box can

be removed.

Remove the damaged wheel.

Replace with new wheel.

Reverse steps to replace support box.

Reestablish electrical power to the dryer.

Clean the shaft and slide the pillow block bearings off of the

shaft.

Reverse these steps to install new pillow block bearings.

NOTE: Check belt adjustment and readjust if necessary.

To Replace S peed Reducing Shaf t Bearings

Discontinue electrical power to the dryer.

Remove the lint drawer.

Remove the lint door.

Loosen and roll V-belts of f that connect speed reducing shaft

to drive shaft.

Loosen and roll V-belts of f that connect speed reducing shaft

to the drive motor.

Remove the four bolts holding the two speed reducing shaft

pillow block bearings in place and remove shaft assembly

from dryer.

To remove front or rear pulley follow steps in “To Replace

Drive Shaft Pulleys”.

Loosen and remove the two setscrews in the front/rear pillow

block bearing.

Clean the shaft and slide the bearings off of the shaft.

Install new bearing by reversing these procedures.

Reestablish electrical power to the dryer.

NOTE: Don’t over tighten wheel bolts, which could bind

bearings.

Rotational Sensor Switch Replacement

Discontinue electrical power to the dryer.

Remove the bearing cap from the dryer.

Remove the adjustment nut from the bearing cap.

Remove the magnetic rotational sensor switch from the

bearing cap.

Depress the tabs on the rotational sensor harness plug

and pull apart, then remove the sensor switch.

To install a new sensor switch, connect the plug of the new

sensor switch to the sensor harness.

Place one adjustment nut onto the sensor switch and insert

into the bearing cap.

Place the second adjustment nut on but do not tighten. The

magnet on the flange bearing and the sensor switch must

be in a horizontal line to one another.

The gap between the magnet and the sensor switch must

be 1/8-inch.

Tighten the adjustment nuts installed.

Reestablish electrical power to the dryer.

450431-3 www.amdry.com 17

Page 18

Basket and Support

To Replace T umbler and Tumbler Support

Discontinue electrical power to the dryer.

Follow procedure for removal of main door assembly.

Follow procedure for removal of front panel assembly.

Remove bearing back guard.

To remove tumbler assembly and support, loosen the two

setscrews on flange bearing models or remove the Allen

head bolt and Teflon

wheels.

Remove the retaining ring from the groove of the tumbler

shaft.

Remove the rotational sensor magnet from the tumbler

support shaft.

Remove the tumbler and support assembly from the front of

the dryer. If the tumbler cannot be removed freely, clean the

shaft area and spray WD-40 or similar lubricant. With a

block of wood against the shaft end, strike the block of wood

with a hammer or mallet to move the shaft past any burrs

made by the setscrews.

IMPORTANT: Never strike the shaft directly with a

hammer.

Reverse these steps for installation of new tumbler and

tumbler support.

Reestablish electrical power to the dryer.

®

washer on models with shaft support

V-Belt Replacement

(Drive Shaft T o Speed Reducing Shaft )

Discontinue electrical power to the dryer.

Remove the lint drawer.

Remove the lint door.

Loosen two bolts securing rear pillow block bearing on the

drive shaft.

Loosen adjustment bolt that is securing the rear pillow block

bearing of the drive shaft.

Loosen two bolts securing rear speed reducing shaft

bearing.

Loosen adjustment bolt supplying pressure to the rear

bearing on the speed reducing shaft.

Remove old V-belts.

Reverse these steps to install new V-belts.

NOTE: After tensioning the V-belts, check to make sure

both the drive shaft and speed reducing are parallel or

level to the base of the dryer.

V-Belt Replacement

(Motor T o Speed Reducing Shaft)

Discontinue electrical power to the dryer.

Remove the lint drawer.

Remove the lint door.

Loosen two bolts securing front bearing on speed reducing

shaft.

Loosen tension bolt that is under the front bearing of the

speed reducing shaft.

Remove the V-belts.

Replace V-belts by reversing the above procedures.

V-Belt Replacement

(From The Blower Motor To The Fan)

Loosen the four bolts securing the motor to the base of the

dryer.

Loosen the tension bolts.

Remove old V-belts.

Reverse these steps to replace V-belts.

NOTE: Always replace V-belts in pairs.

V-Belts

(See illustrations in “Pulleys” section)

V-Belts should have proper tension. If the pulleys are not

properly aligned, excessive belt wear will result. Proper

belt tension will allow 1/2” displacement under normal

thumb pressure at mid span of belt.

NOTE: Belts must always be replaced in pairs (matched

sets).

Motors

To Replace Drive Motor

Discontinue electrical power

to the dryer.

Remove the lint drawer.

Remove the lint door.

Remove the left lint wall.

Remove the drive V-belts. Follow V-belt replacement from

motor to speed reducing shaft.

Loosen the four bolts securing the motor to the base of the

dryer.

Disconnect the motor wiring.

18 American Dryer Corporation 450431- 3

Page 19

Remove old motor pulley and bushing and place on new

motor. Follow “To Replace Motor Pulley”.

Reverse these steps to replace drive motor.

To Replace Impellor Motor

(Fan Shaft Drive – 50/60 Hz Gas and Steam Models)

Discontinue electrical power to the dryer.

Remove the lint drawer.

Loosen the four bolts securing the fan shaft assembly to

the base of the dryer.

NOTE: Models with rear access, it may be easier to

remove this plate, to remove the two rear fan shaft

assembly bolts.

Remove the fan assembly through front access hole.

Loosen the setscrews in each bearing.

Loosen the four flange bolts and two pillow block bolts.

Using a pulley, remove the bearing needing replacing.

Reverse the procedures to reinstall new bearing.

Impellor

Discontinue electrical power to the dryer.

Remove the left side lint wall if necessary for easier access.

Remove the six nuts securing the inlet cone to the blower

housing.

Remove the two left-handed jam nuts that hold the impellor

to the fan shaft.

Remove the impellor, washers, and the key.

Replace the impellor, key, washers, left-handed jam nuts,

and the side panel.

Reestablish electrical power to the dryer.

Remove the lint door.

Remove the left hand lint wall.

Loosen the four mounting bolts securing the motor.

Loosen the tension bolts.

Remove V-belts.

Disconnect motor wiring.

Remove the motor pulley and bushing.

Reverse these steps for installation of new motor.

Lint Drawer Assembly

To Replace Lint Screen

Pull out lint drawer.

Remove lint screen from lint drawer.

Drop new lint screen in place.

Slide lint drawer back into dryer.

To Replace Fan Shaf t and/or Fan Shaf t Bearings

To remove from the front, follow the instructions from “To

Replace Impellor Motor”.

Remove the two left-handed jam nuts that hold the impellor

to the fan shaft.

Remove the impellor, washers, and the key.

450431-3 www.amdry.com 19

Page 20

T o Replace Lint Drawer Switch

Disconnect electrical power to the dryer.

Remove lint drawer and lint door.

Disconnect both 4-pin connectors at the rear of the lint switch

cover.

Remove the one or two screws holding the lint switch cover

on.

Remove lint switch cover and disconnect the two terminals

of the switch.

Remove switch by pressing tabs together and push switch

out.

Install new switch by reversing procedure.

No L.E.D. display on microprocessor controller

(computer)...

Open circuit breaker switch or blown fuse.

Tripped blower motor overload.

Faulty wiring connection.

Faulty transformer.

“Emergency Stop” (E-Stop) button is depressed.

Faulty microprocessor controller (computer).

Computer will not accept keypad entries...

Keypad ribbon is not plugged into computer securely.

Faulty keypad.

Faulty microprocessor controller (computer).

Dryer will not start, but computer

L.E.D. indicators are on...

Failed contactors.

Failed arc suppressor board.

Failed microprocessor controller (computer).

Failed motors.

Troubleshooting ______________________

IMPORTANT: You must disconnect and lockout the

electric supply and the gas supply or the steam supply

before any covers or guards are removed from the

machine to allow access for cleaning, adjusting,

installation, or testing of any equipment per OSHA

standards.

The information provided will help isolate the most probable

component(s) associated with the difficulty described. The

experienced technician realizes, however, that a loose

connection or broken/shorted wire may be at fault where

electrical components are concerned...and not necessarily

the suspected component itself.

IMPORTANT: When replacing blown fuses, the

replacement must be of the exact rating as the fuse being

replaced. The information provided should not be

misconstrued as a handbook for use by an untrained

person in making repairs.

!

▲ WARNING

All service and troubleshooting should be

performed by a qualified professional or service

agency.

While making repairs, observe all safety

precautions displayed on the dryer or specified in

this manual.

Blower motor runs, burner is on,

but tumbler will not turn...

Broken, damaged or loose V-belt.

Damaged or misadjusted drive wheels.

Loose or broken pulley.

Dryer operates but is taking too long to dry ...

Improperly programmed microprocessor controller

(computer).

An inadequate exhaust ductwork system.

Restriction in exhaust system.

Insufficient make-up air.

Dirty or clogged lint screen.

Washing machine extractors are not performing properly.

The supply gas may have a low heating value, check with

local gas supplier.

Failed temperature sensor (temperature calibration is

incorrect).

Failed microprocessor controller (computer).

Thermal overload for drive motor is tripping...

Either an exceptionally low or high voltage supply.

Motor bearing failure.

Motor vents are blocked with lint.

Failed motor.

Failed overload.

Insufficient make-up air.

20 American Dryer Corporation 450431- 3

Page 21

Overload for impellor (fan) motor is tripping...

Either an exceptionally low or high voltage supply.

Motor bearing failure.

Motor vents are blocked with lint.

Failed motor.

Failed overload.

Out of balance impellor (fan).

Insufficient make-up air.

Burner hi-limit safety thermostat is tripping...

Insufficient exhaust ductwork, size or restriction in exhaust

system.

Insufficient make-up air.

Lint screen needs cleaning.

Damaged impellor.

L.E.D. display reads “Temp Sensor Failure Check Temp

Sensor Fuse.” or “Open Exhaust T emperature Probe.”...

Check 1/8-amp fuse on microprocessor controller

(computer). (Phase 6 units only.)

Faulty microprocessor controller (computer) temperature

sensor probe.

Open circuit or short in either one of two wires leading from

the sensor probe to the computer...

Faulty microprocessor controller (computer).

Dryer does not start. Display reads “main door”

or “lint door” with an audio indication...

Main door is open.

Lint drawer is open.

Faulty main door or lint door switch.

Open circuit in either main door or lint drawer switch

harnesses.

Faulty 24 V AC transformer.

There is excessive vibration coming from the tumbler...

Tumbler is out of adjustment.

Drive shaft or idler shaft is out of alignment.

Faulty pillow block bearing or 4-inch (10.16 cm) rear wheel.

Faulty tumbler wheel.

Drive motor and shaft not aligned.

Phase 6 OPL System Diagnostics ___

IMPORTANT: You must disconnect and lockout the

electric supply and the gas supply or the steam supply

before any covers or guards are removed from the

machine to allow access for cleaning, adjusting,

installation, or testing of any equipment per OSHA

standards.

All major circuits, including door, microprocessor

temperature sensor, heat and motor circuits are monitored.

The Phase 6 OPL microprocessor controller (computer) will

inform the user, via the L.E.D. display of certain failure codes,

along with indicators both in L.E.D. display and at the output

of each relay (and door switch circuit) to easily identify

failures.

Diagnostic (L.E.D. Display) Failure Codes

SAIL SWITCH FAIL – This routine will prevent start up on the

machine unless the sail switch is in the correct position. If

the sail switch is closed prior to start up the display will read

“SAIL SWITCH FAIL” along with an audio indication.

No AIRFLOW – If the sail switch opens during cycle operation

the display will read “No AIRFLOW” along with an audio

indication. The machine will continue to run with no heat for

3 minutes or until the temperature drops below 100º F (38º

C). Upon failure the machine will shut down and display

“No AIRFLOW” with an audio indication.

bURNER SAFETY F AIL – Routine monitors the temperature

above the burner. If the burner hi-limit switch opens the

display will read “bURNER SAFETY F AIL.” The machine will

run with no heat for 3 minutes or until the temperature drops

below 100º F (38º C). Upon failure the machine will shut

down and display “bURNER SAFETY FAIL” with an audio

indication.

dRUM SAFETY FAIL – This routine monitors the tumbler

temperature if the tumbler hi-limit switch opens prior or

during the cycle while the heat was on the machine will

display “dRUM SAFETY F AIL.” The machine will continue to

run with no heat for 3 minutes or until the temperature drops

below 100º F (38º C). Upon failure the machine will shut

down and display “dRUM SAFETY FAIL” with an audio

indication.

No HEAT – This routine monitors the burner ignition. If the

burner misignites (does not light) the ignition module will

check to see of the microprocessor program has any retries

left. The standard retry count is 2. If the module notices that

there are retries left it will purge for 1 minute then try to ignite

the burner again. The ignition module will try this for a total

of 3 times or until there are no retries left. If the burner does

not ignite after 3 attempts the L.E.D. display will display the

error code “no heat” with an audio indication. When this

occurs the machine will run with no heat for 3 minutes or

until the temperature drops below 100º F (38º C).

IMPORTANT: For other countries, such as Australia, the

retry count may not apply due to local approvals.

450431-3 www.amdry.com 21

Page 22

bURNER CONTROL F AIL – This routine monitors the ignition

control’s gas valve output response. If the valve output signal

is not present from the ignition control within the valve time

limits the Phase 6 microprocessor controller (computer)

determines the ignition control has failed. If this occurs

when the cycle is active the machine will display “bURNER

CONTROL F AIL.” If the tumbler temperature is above 100º F

(38º C) the machine will continue to display “bURNER

CONTROL FAIL.” The machine will run with no heat for 3

minutes or until the temperature drops below 100º F (38º

C). If the tumbler temperature is below 100º F (38º C) upon

failure the machine will shut down and display “bURNER

CONTROL FAIL” with an audio indication.

bURNER FLAME FAIL – This routine allows 2 flame out retries

to occur before proceeding into the error. The count of 2 will

be established every time the call for heat was to occur.

Only if it reaches the count of 2 before the tumbler temperature

has reached the set temperature will this error be triggered.

The machine will run with no heat for 3 minutes or until the

temperature drops below 100º F (38º C). If the tumbler

temperature is below 100º F (38º C) upon failure, the

machine will shut down and display “bURNER FLAME FAIL”

with an audio indication. This process will occur every time

the heat output is active.

MAIN DOOR – This monitors the door circuit. If the machine

was not active and the main door was opened the display

would read “REAdY.” If a program attempt was made with

the main doors open the display will read “MAIN dOOR” with

an audio indication. If the machine is active and the main

door was opened the display would read “MAIN dOOR” with

no audio indication and the dryer will shut down. Once the

main door has closed the display would read “PRESS

START” press the “ENTER/START” key and it will continue

the programmed cycle.

LINT dOOR – This monitors the lint drawer and door circuit.

If the machine was not active and the lint drawer and door

was opened the display would read “REAdY.” If a program

attempt was made with the lint drawer and door open the

display would read “LINT dOOR” with an audio indication. If

the machine is active and the lint drawer and door was

opened the display would read “LINT dOOR” with no audio

indication and the dryer will shut down. Once the lint door

was closed the display would read “PRESS START” press

the “ENTER/STA RT” key and it will continue the programmed

cycle.

TEMP SENSOR FAIL CHECK TEMP SENSOR FUSE – This

routine monitors the tumbler temperature. When the

temperature sensor or fuse opens with the machine not

active the display will read “TEMP SENSOR FAIL CHECK

TEMP SENSOR FUSE” with an audio indication. If the

machine was active at the time that the temperature sensor

or fuse opened the display would read “TEMP SENSOR

FAIL CHECK TEMP SENSOR FUSE.” The display will

continue to read “TEMP SENSOR FAIL CHECK TEMP

SENSOR FUSE” an audio indication will sound for

approximately 5-seconds, every 30-seconds until the

problem is corrected or the power to the dryer is

disconnected (and the problem is corrected).

NOTE: Once the Phase 6 microprocessor controller

(computer) detects a problem in the heat circuit, it

updates every 30-seconds, so that if the problem was a

loose connection in the circuit, which corrected itself, the

“TEMP SENSOR FAIL CHECK TEMP SENSOR FUSE”

condition would automatically be cancelled and the

display will return to “REAdY.”

ROTA TE SENSOR F AIL – Indicates a rot ational sensor circuit

failure meaning that there is a fault somewhere in the

tumbler rotating circuit, or the Phase 6 OPL microprocessor

controller (computer) program related to this circuit (program

location 2) is set incorrectly. In the active mode it should be

(ROTATE SENSOR ACTIVE), if the dryer is not equipped with

the optional rotational sensor it should be set in the

nonactive mode (No ROTATE SENSOR).

NOTE: RPM – This routine monitors the timing response

from the existing rotational sensor input and derives a

RPM measurement. To display this RPM measurement

(press the “ENTER/START” key once and release, then

press the “ENTER/START” key a second time and hold.

This will display the RPM measurement). The rotational

sensor must be active for operation of this feature.

CHECK MAIN FUSE – Indicates that the circuit fuse protection,

which is located on the back side of the Phase 6

microprocessor controller (computer) the display would

read “CHECK MAIN FUSE.” If the display continues after

the fuse has been replaced then it is the fault of the Phase

6 microprocessor controller (computer).

L.E.D. Display Indicators

The L.E.D. indicator dots located on the top portion of the

display indicate the various Phase 6 OPL computer output

functions while a cycle is in progress. These indicator dots

(as shown in the illustration below) do not necessarily

mean that the outputs are functioning. They are only

indicating that the function output should be active (on).

L.E.D. Display Indicator Number 1

For Optional Reversing Models:

This indicator dot is on when the drive (tumbler) motor is

operating in the forward mode (clockwise direction).

L.E.D. Display Indicator Number 2

For Optional Reversing Models:

This indicator dot is on when the drive (tumbler) motor is

operating in the reverse mode (counterclockwise direction).

L.E.D. Display Indicator Number 3

Heat Circuit Indicator:

This indicator dot is on whenever the Phase 6 OPL

microprocessor controller (computer) is calling for the

heating circuit to be active (on).

L.E.D. Display Indicator Number 4

On Indicator

This indicator dot is on whenever a cycle is in progress.

Additionally, when the Anti-Wrinkle program is active, the

indicator dot will be on whenever the Phase 6 OPL

microprocessor controller (computer) is in the Guard On

Time program.

22 American Dryer Corporation 450431- 3

Page 23

L.E.D. Display Indicator Number 5

Air Jet Circuit Indicator – OPTIONAL

This indicator dot is on at the end of each cycle for

approximately 60-seconds.

Phase 6 OPL Microprocessor Controller (Computer) Relay Output L.E.D. Indicators

There are a series of five L.E.D. indicators (ORANGE

LIGHTS) located at the backside of the Phase 6 OPL

microprocessor controller (computer). These are identified

or labeled (from top to bottom in the illustration below as:

FAN-BLOWER, FOR-FORW ARD, REV -REVERSE, AIR-AIRJET, HT1-HEAT OUTPUT. There are a series of 7 L.E.D.

indicators (red lights) FUSE-MAIN FUSE, LINT-LINT DOOR,

MAIN-MAIN DOOR, DRUM-TUMBLER HI-LIMIT, SAIL-SAIL

SWITCH, BURN-BURNER HI-LIMIT, FLAME-FLAME

PROBE). The L.E.D. in the center of the board (red light)

indicates power supplied to the Phase 6 OPL

microprocessor controller (computer). These L.E.D.’s

indicate the inputs and outputs of the Phase 6 OPL

microprocessor (computer) as it monitors the safety circuits.

“FOR” (FORW ARD) Output L.E.D. Indicator

(for optional reversing model ONL Y)

If the dryer is started and the blower motor is operating, but

the drive (tumbler) motor is not, yet the Phase 6 OPL

microprocessor controller (computer) display “FORWARD”

indicator dot is on, the “FOR” (FORWARD) motor output

L.E.D. is off; then the fault is the Phase 6 OPL

microprocessor controller (computer) itself.

If the drive tumbler motor is not operating and the forward

indicator dot and output L.E.D. is on; then the problem (fault)

is elsewhere (i.e., external of the Phase 6 OPL

microprocessor controller [computer]).

“REV” (REVERSE) Output L.E.D. Indicator

(for optional reversing models ONL Y)

If the dryer is started and the blower motor is operating but

the drive tumbler motor is not, yet the Phase 6 OPL

microprocessor controller (computer) displays “REVERSE”

indicator dot is on but the “REV” (REVERSE) motor output

L.E.D. is off; then the fault is of the Phase 6 OPL

microprocessor controller (computer) itself.

If the drive tumbler motor is not operating and reverse

indicator dot and output L.E.D. is on; then the problem (fault)

is elsewhere (i.e., external of the Phase 6 OPL

microprocessor controller [computer]).

“FAN” (BLOWER) Output L.E.D. Indicator

If the dryer is started and the blower motor is not operating,

yet the Phase 6 OPL microprocessor controller (computer)

display fan indicator dot and power supply input L.E.D. are

on, but the fan output L.E.D. is off, then the fault is the Phase

6 OPL microprocessor controller (computer) itself.

If the motor is not operating. The fan indicator dot and output

L.E.D. are also on, then the problem (fault) is elsewhere

(i.e., external of the Phase 6 OPL microprocessor controller

[computer]).

“AIR” (AIR JET) Output L.E.D. Indicator – OPTIONAL

“AIR” is on with the display dot at the end of the dry cycle

once the display reads “dONE,” it is on for approximately

60-seconds and the output L.E.D. indicator and the display

dot go out. If the air jet does not energize it is not the fault of

the Phase 6 OPL microprocessor controller (computer). If

the output L.E.D. or dot do not go on it is the fault of the

Phase 6 OPL microprocessor controller (computer).

“HT1” (HEAT) Output L.E.D. Indicator

If the dryer is started and there is “No Heat” yet the Phase 6

OPL microprocessor controller (computer) display heat

circuit indicator dot is on, but the “HT1” output L.E.D. indicator

is off; then the fault is in the Phase 6 OPL microprocessor

controller (computer) itself.

If the dryer is started and there is “No Heat” yet both the

Phase 6 OPL microprocessor controller (computer) display

indicator dots and the “HT1” output L.E.D. indicator are on;

then the problem (fault) is elsewhere (i.e., external of the

Phase 6 OPL microprocessor controller [computer]).

“FUSE” (MAIN FUSE) Input L.E.D. Indicator

Should be on all the time (even if the dryer is not running). If

the L.E.D. is not on; then the display will read “CHECK MAIN

FUSE.” If the main fuse is good then the fault is on the

Phase 6 microprocessor controller (computer).

“LINT” (LINT DOOR) Input L.E.D. Indicator

Should be on all the time (unless the lint door is opened

then the “LINT” L.E.D. indicator will go out).

450431-3 www.amdry.com 23

Page 24

If the dryer is active (running) and the lint door is opened the

“LINT” L.E.D. indicator will go out and the display will read

“LINT dOOR.” The dryer will stop until the lint drawer has

been closed, at which time the L.E.D. display will read

“PRESS START.” At this time, to resume the drying cycle

press “ENTER/STAR T” key.

“MAIN” (MAIN DOOR) Input L.E.D. Indicator

Should be on all the time (unless the lint door is open or the

main door is opened then the “MAIN” L.E.D. indicator will go

out).

If the dryer is active (running) and the main door is opened

the “MAIN” L.E.D. indicator will go out and the display will

read “MAIN dOOR.” The dryer will stop until the main door

has been closed, at which time the L.E.D. display will read

“PRESS START.” At this time, to resume the drying cycle

press “ENTER/STAR T” key.

“DRUM” (TUMBLER HI-LIMIT) Input L.E.D. Indicator

Should be on at all times (unless the tumbler hi-limit switch

opens prior during the cycle while the heat was on the display

would read “dRUM Safety FAIL”). The machine will run with

no heat for 3 minutes or until the temperature drops below

100º F (38º C). Then the machine will shut down still

displaying “dRUM SAFETY FAIL” with an audio indication.

“SAIL” (SAIL SWITCH) Input L.E.D. Indicator

This routine will prevent start up on the machine unless the

sail switch is in the correct position. If the sail switch is in

the closed position prior to start, the “SAIL” output L.E.D.

indicator will be off, the machine will not start and the display

will read “SAIL SWITCH F AIL” along with an audio indication.

If the sail switch opens during the cycle the “SAIL” output

L.E.D. will go out and the display will read “NO AIRFLOW.”

The machine will run with no heat for 3 minutes or until the

temperature drops below 100º F (38º C). Then the machine

will shut down still displaying “NO AIRFLOW” along with an

audio indication.

“BURN” (BURN HI-LIMIT) Input L.E.D. Indicator

This routine monitors the temperature of the burner. If the

burner hi-limit opens during the cycle while the heat was on

the “BURN” output L.E.D. indicator goes out and the display

reads “bURNER SAFETY FAIL.” The machine will run with

no heat for 3 minutes or until the temperature drops below

100º F (38º C) then the machine will shut down still

displaying “bURNER SAFETY FAIL” with an audio indication.

“FLAME” (bURNER CONTROL FAIL) Input L.E.D. Indicator

This routine monitors the ignition control’s gas valve output

response. If the valve output signal is not present from the

ignition control within the valve time limits the

microprocessor determines the ignition control has failed.

If this occurs when the cycle is active the “FLAME” output

L.E.D. indicator will go out and the display will read