Page 1

p

plication Note

A

TurboMAX BTS

Installing and Configuring

Application Note

Date

Products Covered

Applicable System

Release

Subject

Intended Audience

Number of pages

1.1 Objective

The TurboMAX BTS is being introduced as part of System Release 5.0. This document describes the

TurboMAX, and gives instructions on how to install and configure it.

1.2 Audience

Network Planners, Installers, and End Users.

AN – 16

December 13, 2000

TurboMAX

5.0

TurboMAX Application Note

Network Planners, Installers, and End Users

15

1.3 Scope

This document is applicable to System Release 5.0.

Application Note 16 – version 1.1

page 1

Page 2

p

plication Note

A

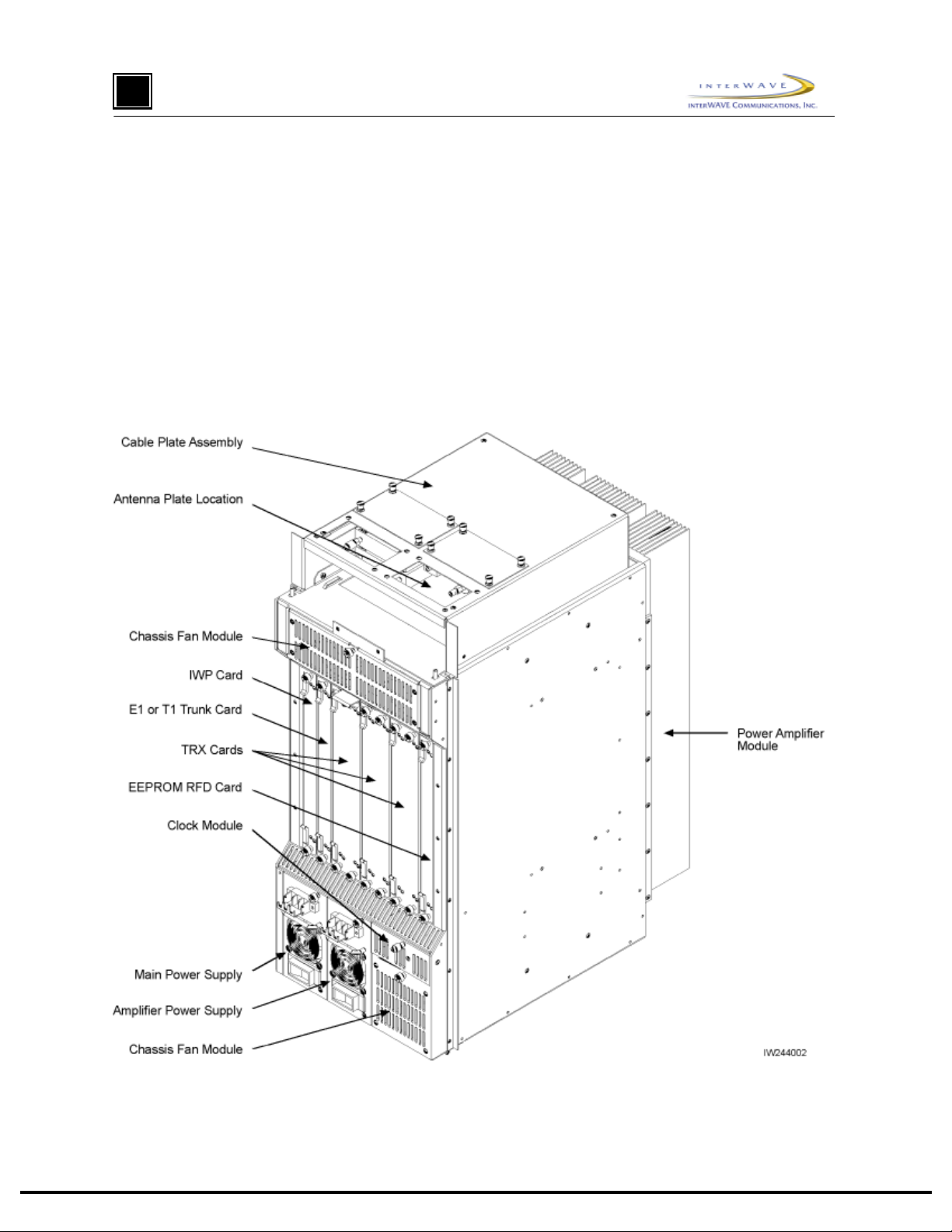

2 Description

The interWAVE TurboMAX is a high-power, low-cost, compact BTS used to provide WLL (Wireless

Local Loop), microcell expansion, and specialty GSM deployment. It complies with all relevant GSM

specifications related to Abis and Air (Um) Interfaces, so it can be used with any other GSM-compliant

BSCs and mobile stations. The TurboMAX is 25” (63.50 cm) tall, 11” (27.94 cm) wide, and 19” (48.26 cm)

deep.

The TurboMAX consists of a chassis, one IWP card, one E1 or T1 Trunk card, two or three TRXs, an

EEPROM RFD card, one Main Power Supply module, one Amplifier Power Supply module, one Clock

module, two Fan modules, a high-power Amplifier module, and a CMA (Cable Management Assembly),

which contains combiners, diplexers, and/or filters, and which routes external cabling into the TurboMAX

chassis. Figure 1 shows the front view of a fully-loaded TurboMAX.

Figure 1. Typical Fully-Loaded TurboMAX

Application Note 16 – ve rsi on 1.1

page 2

Page 3

p

plication Note

A

3 Installation

3.1 Mounting the Chassis

1) Mount the TurboMAX chassis as you would any other interWAVE chassis, either in an equipment

rack, on a wall, or on a table, as described in the WAVEXpress BTS Installation and Commissioning

Guide.

3.2 Verifying and Configuring the E1 or T1 Card

2) When your TurboMAX is equip ped with an E1 Trunk card, ver ify that the trunk impedanc e is set

correctly on the eight-position DIP switch on the edge of the E1 card. For 75 Ohm coaxial cable,

DIP switches 1, 2, 3, 5, 6, and 7 must be set to ON, and DIP switches 4 and 8 must be set to OFF, as

indicated on the DIP switch housing. For 120 Ohm twisted pair, all the DIP switches must be set to

ON.

If you have set the E1 Trunk card for 75 Ohm coaxial cable, you may also need to ground the E1

coaxial cable shields. Note that only one side of the coaxial cables should be grounded to avoid

ground loops. To ground the Port 0 Transmit shield, place a jumper across P9 pins 1 and 2. To

ground the Port 0 Receive shield, place a jumper across P8 pins 1 and 2. To ground the Port 1

Transmit shield, place a jumper across P10 pins 1 and 2. To ground the Port 1 Receive shield, place

a jumper across P11 pins 1 and 2.

3) When your TurboMAX is equip ped with a T1 Trunk card, configure the trunk for the cable distance

to the DSX1 T1 demarcation point using the eight-position DIP switch on the edge of the T1 card.

For Port 0, use DIP switch pins 1 – 4, and for Port 1, use DIP switch pins 4 – 8.

For Port 0, when the TurboMAX is connected directly to another WAVEXpress chassis or if it is

connected to a T1 DSX1 demarcation point at 0-133ft (0-40m), set DIP switch 1 to OFF, and set

DIP switches 2, 3, and 4 to ON, as indicated on the DIP switch housing. When the TurboMAX is

connected to a T1 DSX1 demarcation point at 133-266ft (40-80m), set DIP switches 1 and 2 to OFF,

and set DIP switches 3 and 4 to ON. When the TurboMAX is connected to a T1 DSX1 demarcation

point at 266-399ft (80-120m), set DIP switches 1 and 3 to OFF, and set DIP switches 2 and 4 to ON.

When the TurboMAX is connected to a T1 DSX1 demarcation point at 399-533ft (120-160m), set

DIP switches 1, 2, and 3 to OFF, and set DIP switch 4 to ON. When the TurboMAX is connected to

a T1 DSX1 demarcation point at 533-655ft (160-200m), set DIP switches 1 and 4 to OFF, and set

DIP switches 2 and 3 to ON.

For Port 1, when the TurboMAX is connected directly to another WAVEXpress chassis or if it is

connected to a T1 DSX1 demarcation point at 0-133ft (0-40m), set DIP switch 5 to OFF, and set

DIP switches 6, 7, and 8 to ON, as indicated on the DIP switch housing. When the TurboMAX is

connected to a T1 DSX1 demarcation point at 133-266ft (40-80m), set DIP switches 5 and 6 to OFF,

and set DIP switches 7 and 8 to ON. When the TurboMAX is connected to a T1 DSX1 demarcation

point at 266-399ft (80-120m), set DIP switches 5 and 7 to OFF, and set DIP switches 6 and 8 to ON.

When the TurboMAX is connected to a T1 DSX1 demarcation point at 399-533ft (120-160m), set

DIP switches 5, 6, and 7 to OFF, and set DIP switch 8 to ON. When the TurboMAX is connected to

a T1 DSX1 demarcation point at 533-655ft (160-200m), set DIP switches 5 and 8 to OFF, and set

DIP switches 6 and 7 to ON.

Application Note 16 – ve rsi on 1.1

page 3

Page 4

p

plication Note

A

3.3 Verifying the Internal Cabling

4) Verify that the clock, antenna, and the other RF cable ends are correctly tightened to 7 to 10 in. lbs.

(79 to 113N.cm).

5) Verify the cable from the IWP card ENET connector to the external alarm terminal block on the

front of the TurboMAX chassis.

Application Note 16 – ve rsi on 1.1

page 4

Page 5

p

plication Note

A

3.4 Connecting External Cabling

6) Connect the E1 or T1 cabling directly to the E1 or T1 card using individually-shielded twisted-pair

cables, using the st andard RJ-48C pinout. The RJ-48C pinout is as follows: Pin 1 – Receive

Ring/Shield; Pin 2 – Receive Tip; Pin 4 – Transmit Ring/Shield; Pin 2 – Transmit Tip.

When you are connecting the TurboMAX directly to another TurboMAX or another piece of

equipment via an E1 or T1 port, make sure you use a crossover cable that connects the Receive leads

to the Transmit leads.

7) The TurboMAX comes in two configurations: low-power, with a single antenna, or high-power, with

up to three antennas.

When you are adding an antenna to a low-power TurboMAX, connect the antenna to the N-type

connector on the Antenna Plate Assembly on top of the TurboMAX.

When you are adding antennas to a high-power TurboMAX, make sure you connect one antenna to

each of the three N-type connectors on the Antenna Plate Assembly on top of the TurboMAX. Since

one antenna is shared by the receive paths for all TurboMAX TRXs, and since one antenna for the

transmit path for each TRX, you must connect an antenna to all available N-type antenna connectors.

8) If required by local codes, ground the TurboMAX chassis by loosening a nut inside the Cable

Management Assembly and tighteni ng t he grounding wire under the nut, per local requirements.

9) Connect any customer-defined alarm inputs to the external alarm terminal block as follows: Make

sure the external alarm inputs use normally-open relay contacts. For Alarm Input 1, connect the

alarm relay across terminal block pins 5 and 6. For Alarm Input 2, connect the alarm relay across

terminal block pins 5 and 7. For Alarm Input 3, connect the alarm relay across terminal block pins 5

and 9.

10) Connect external power to the two (Main and Amplifier) power supply units as follows:

When you connecti ng –48VDC to the two chassis power supplies, (1) set the circuit breaker on both

power supplies to OFF, and (2) connect the –48VDC leads from the power source to the terminal

blocks on the front of both power supplies. Leave the circuit breakers OFF.

When you connecting 110 through 230 VAC to the two chassis power supplies, (1) set the circuit

breaker on both power supplies to OFF, and (2) connect the AC cables from the power source to the

IEC 320 receptacles on the front of both power supplies. Leave the circuit breakers OFF.

3.5 Off-Line Commissioning

11) Turn on power to the TurboMAX chassis by setting the circuit breakers on both power supplies to

ON.

Application Note 16 – ve rsi on 1.1

page 5

Page 6

p

plication Note

A

12) Monitor the Power On Self Test (POST) by watching the front-panel LED sequence to verify proper

POST indications. Figure 2 shows the normal TurboMAX LED boot sequence. Note that the TRXs

are tested sequentially.

Power on the TurboMAX. Initial LED display is:

IIIIIIIIIIIIIIIIIIIIIIIII

P/N XXXXXX

IIIIIIIIIIIIIIIIIIIIIIIII

S/N XXXXXX

SCN

PWR

ON

LINE

FLT

RST

CON

ENET

EXT

XREF

PWR

ON/LINE

FLT

ALARMS

12

PORT 0

ALARMS

12

PORT 1

PWR

ON

LINE

FLT

SCN

PWR

ON LINE

FLT

PORT 0

PORT 1

N/A

N/A

IWP E1/T1LEDs

ON

ON

OFF

ON

N/A

ON

ON

ON

ON

ON

LED display after 30 seconds is:

SCN

PWR

ON LINE

FLT

PORT 0

PORT 1

TX

IWP code loads. LED display during download is:

LEDs

SCN

PWR

ON LINE

FLT

PORT 0

PORT 1

IWP downloads code to E1/T1 card. LED display

LEDs

RX

SCN

PWR

ON LINE

FLT

PORT 0

PORT 1

IWP E1/T1 #1LEDs

ON

ON

FLASH

OFF

N/A

N/A

IWP

ON

ON

ON

OFF

N/A

N/A

(1 minute for each card) during download is:

IWP

ON

ON

ON

OFF

N/A

N/A

N/A

E1/T1

N/A

E1/T1

N/A

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

FLASH

FLASH

OFF

OFF

TRX

N/A

N/A

N/A

TRX

N/A

N/A

N/A

TRX

N/A

N/A

N/A

TRX

N/A

N/A

N/A

ON

OFF

ON

ON

OFF

ON

ON

OFF

ON

ON

OFF

ON

IWP E1 or T1

TRX

TRX code downloads from remote BSS IWP hard drive.

LEDs

SCN

PWR

ON LINE

FLT

PORT 0

PORT 1

LEDs

SCN

PWR

ON LINE

FLT

PORT 0

PORT 1

Note that the TRX FLT LED will stay illuminated until the TRX software

LED display during download is:

IWP

ON

ON

ON

OFF

N/A

N/A

BSS IWP completes TRX code download to each

card sequentially. The final LED display is:

IWP

ON

ON

ON

OFF

N/A

N/A

has been downloaded from the hard drive.

Figure 2. TurboMAX LED Sequence During the Boot Process

Application Note 16 – ve rsi on 1.1

page 6

E1/T1

N/A

E1/T1

N/A

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

TRX

N/A

N/A

N/A

TRX

N/A

N/A

N/A

ON

FLASH

OFF

ON

OFF

OFF

IW249001

Page 7

p

plication Note

A

13) After bootup, verify that the front-panel LEDs are lit as follows: SCN (on IWP card only) lit, PWR

lit, ON LINE on IWP and E1 or T1 cards lit, FLT not lit. Note that the ON LINE LEDs on the TRX

cards are not lit until they are unlocked by the OMC operator.

If the LED displays are different than that shown in this and the previous step, the TurboMAX has

not passed the POST. Contact Technical Support for further information.

14) Set up a Craft PC with dedicated ethernet and serial connections as shown in Figure 3 and 4,

respectively.

3Com Combo

transceiver

PCMCIA

card slot

Craft PC

RG-58 coaxial cable

BNC

T-Connector

BNC T-Connector

50 Ohm terminators

Ethernet

Port

IWP, 64MEG, MMU

HARD DISK

RST

SCN

PWR

PWR

ON

ON/LINE

LINE

FLT

FLT

ALARMS

12

CON

ENET

EXT

XREF

PORT 0

ALARMS

12

PORT 1

AUI-BNC

Transceiver

Figure 3. Connecting the Craft PC to the TurboMAX via the Ethernet Port

IW206002

Application Note 16 – ve rsi on 1.1

page 7

Page 8

p

plication Note

A

RST

IWP, 64MEG, MMU

HARD DISK

SCN

PWR

PWR

ON

ON/LINE

LINE

FLT

FLT

DB-9 port

connector

ALARMS

12

CON

ENET

PORT 0

ALARMS

12

EXT

XREF

PORT 1

DB-9 extension cable

Craft PC

computer

DB-9 port

connector

Figure 4. Connecting the Craft PC to the TurboMAX via the Serial Port

IW206001

15) Power up the Craft PC, and allow the Linux operating system to bootup.

16) Logon as ‘build’, and start XWindows by entering ‘startx’.

17) Establish serial communications with the TurboMAX by entering ‘cu –l ttyS0 –s 9600’. The

TurboMAX responds with ‘Connected’. Press the [ENTER] key to display the ‘bts:A->’ prompt.

Application Note 16 – ve rsi on 1.1

page 8

Page 9

p

plication Note

A

18) Verify the boot parameters by entering ‘bootChange’. A list of parameters appears as you press the

[ENTER] ke y, a s shown in Figure 5.

’.’ = clear field; ’-’ = go to previous field; ^D = quit

boot device : qu

processor number : 0

host name : craftpc

file name : /home/target/vxWorks

inet on ethernet (e) : 172.16.80.42:fffff000

inet on backplane (b):

host inet (h) : 172.16.80.43

gateway inet (g) :

user (u) : target

ftp password (pw) (blank = use rsh):

flags (f) : 0xa

target name (tn) : bts

startup script (s) : /home/target/iwvstart

other (o) :

Figure 5. Verifying/Changing TurboMAX Boot Parameters

Make sure the parameters include the listed values. If so, continue with the next step. If not, reenter

‘bootChange’, press the [ENTER] key to display the desired line, press period ‘.’ to delete the

incorrect entry, type in the correct entry, and press the [ENTER] key to continue with the next

parameter. When all the bootChange parameters display the correct values, continue with the next

step.

19) Reboot the TurboMAX by pressing the [CTRL][x] key combination. Verify the current software

version and patch level by pressing [RETURN] to display the ‘bts:A->’ prompt. Then enter

‘iwversion’. The TurboMAX responds with the BSX code version, the software release, the

encryption status, and the patches currently installed. Verify that you have the software version

iw05_00.132 or later installed.

20) Verify the images loaded in the TurboMAX IWP flash version by entering ‘printConfigBlocks’. The

resulting parameters display the Primary Config Block imageCurrent and Secondary Config Block

imageCurrent entries in the form ‘iwXX_YY.ZZZ’, which indicates the IWP flash version. Contact

Technical Support to ensure you have IWP flash version iw05_00.132 or later installed.

21) Run the E1 or T1 POST diagnostics by disconnecting all E1 and T1 lines from the TurboMAX,

entering ‘reboot’ at the ‘bts:A->’ prompt. Verify that the resulting seven sequential tests appear as

‘PASSED’. If the E1 or T1 Trunk card fails any of these t ests, the E1 or T1 card is defective; ret urn

the E1 or T1 card to interWAVE, and redo this test with the replacement E1 or T1 Trunk card.

22) Terminate any existing telnet and/or rlogin session by logging in as root (bts:A-> su – root), clearing

existing sessions (# /sbin/arp –d iwbox), and logging out of root (# exit).

Application Note 16 – ve rsi on 1.1

page 9

Page 10

p

plication Note

A

23) Verify telnet communications with the IWP card by terminating the serial connection by entering

‘~.’ (tilde .), which returns the prompt to ‘build@craftpc:~>’.

After the serial connection is terminated, enter ‘telnet bts’ to display the ‘bts:A->’ prompt. This

shows that you are able to set up a telnet session with the TurboMAX.

Terminate the telnet session by entering ‘logout’. This causes the TurboMAX to display ‘Connection

closed by for eign host’ and the prompt changes back to ‘build@craftpc:~>’.

24) Reestablish a serial connection with the TurboMAX by entering ‘cu –l ttyS0 –s 9600’. The

TurboMAX responds with ‘Connected’. Press the [ENTER] key to display the ‘bts:A->’ prompt.

25) At the ‘bts:A->’ prompt, enter ‘runtrxpost’ to test the TRX card(s). The resulting output contains the

output for the various TRX tests, including one line for each TRX that reads: ‘TRX CARD IN SLOT

<2, 4, or 6>: COMPLETED TRX POST OFFLINE TEST: <PASSED/FAILED>’.

26) Review the E1/T1 and BTS POST test results by entering ‘postReportE1Trx’. The TurboMAX

displays a summary of the E1/T1 and TRX test results, which should all appear as ‘PASSED’ except

those which appear as ‘NOT-RUN’.

27) Reboot the TurboMAX after running the POST t ests by entering ‘reboot’ at the ‘bts:A->’ prompt.

28) Have the E1 or T1 link provider certify that the links pass a BER (Bit Error Rate or Bit Error Ratio)

test at 10

29) Reconnect all E1 or T1 cables disconnected to run the POST tests.

-8

or better over 20 minutes.

3.6 Performing Racal Tests

30) Perform the Racal Test procedures for the TurboMAX as described in the interWAVE Field

Maintenance Guide for the 16W TurboWAVE. The only difference is that the output power of the

TurboMAX is slightly higher.

3.7 Off-Line Commissioning of a TurboMAX Daisy Chain

This is an optional section, and is only required if multiple TurboMAXs are to be daisy-chained off of a

BSC, BS Plus, or NIB. If this configuration is used, each TurboMAX must be installed separately, and must

have off-line commissioning procedures independently performed. Once each TurboMAX is installed and

commissioned, the TurboMAXs can be daisy chained together.

31) Before connecting any TurboMAXs, ensure that they are all installed and off-line commissioned.

32) Ensure that all the TurboMAXs have been tested using the Racal Test Set.

33) Ensure that a different Abis link has been set for each TurboMAX using the Abis Manager time slot

has been set for each TurboMAX as follows:

After each TurboMAX has been Racal tested, enter ‘getFlashE1Chan’ at the Craft PC ‘bts:A->’

prompt. The TurboMAX displays the timeslot reserved for the LAPD signaling timeslot (default =

16).

To change this value, enter ‘setFlashE1Chan <timeslot>’ at the Craft PC ‘bts:A->’ prompt,

where<number> is any unassigned E1 or T1 timeslot between 1 and 31, or between 1 and 24,

respectively.

Note that interWAVE recommends the following Abis timeslot assignments: First TurboMAX in the

daisy chain, Abis timeslot = 16. Second TurboMAX in the daisy chain, Abis timeslot = 17. Third

Application Note 16 – ve rsi on 1.1

page 10

Page 11

p

plication Note

A

TurboMAX in the daisy chain, Abis timeslot = 18. Fourth TurboMAX in the daisy chain, Abis

timeslot = 19.

Verify that the Abis timeslot has been changed correctly. Enter ‘getFlashE1Chan’ at the ‘bts:A->’

prompt. The TurboMAX displays the timeslot reserved for the LAPD signaling timeslot.

34) Reboot each TurboMAX by entering ‘reboot’ at the ‘bts:A->’ prompt.

35) After all TurboMAXs in a daisy chain have been assigned unique Abis LAPD links, connect them to

each other and to the associated BSC, BS Plus, or NIB with E1 or T1 links as described in Section

3.4.

3.8 Shutting Down the Craft PC and Disconnecting the Serial and

Ethernet Connections

36) Terminate the serial connection with the TurboMAX by entering ‘~.’ (tilde .), which returns the

prompt to ‘build@craftpc:~>’.

37) Exit the XWindows session by pressing [CTRL][ALT] and [BACKSPACE] simultaneously. At the

‘build@craftpc:~>”’ prompt, enter ‘exit’.

38) At the ‘craftpc login:’ prompt enter ‘root’ to display the ‘craftpc:~#’ prompt.

39) Shut down the Craft PC operating system by entering ‘shutdown –h now’. After about one minute,

the Craft PC displays ‘System halted’ and ‘INIT: No more processes left in runlevel 0’.

40) Turn off the Craft PC by toggling the power switch. The serial and ethernet connections can now be

removed between the Craft PC and the TurboMAX.

41) Inform the OMC operator that the TurboMAX is ready for on-line commissioning.

3.9 On-Line Commissioning

On-line commissioning of the TurboMAX requires that an on-site field engineer work with the OMC

operator, after installation and off-line commissioning.

42) Verify that the TurboMAX is fully commissioned, that it is connected to a BSC, BS Plus, or NIB

network element, and that the OMC is communicating with the connected network element.

43) Have the operator verify that the RF frequencies are cleared to transmit.

44) Have the OMC operator download the Tur boMAX configuring and correc t software version a nd

operational parameters as defined in the WAVEView OMC Operations and Maintenance Guide and

the interWAVE Network Implemetation Manual.

45) Have the OMC operator perform the following:

Create a planned cell in the OMC database corresponding to this TurboMAX. The planned cell

should at minimum include the Cell ID and LAC for the TurboMAX.

Define neighbor relationships for the planned cell.

Create a managed cell from the planned cell.

Set the TurboMAX parameters, including its base station identity code.

Set the TurboMAX Abis parameters, including the corresponding E1 or T1 card slot and Abis

LAPD link.

Application Note 16 – ve rsi on 1.1

page 11

Page 12

p

plication Note

A

Define the TurboMAX beacon TRX, and assigning ARFCN for each TRX.

When the TurboMAX is daisy chained, setting the ‘E1 use type’, ‘Previous TurboMAX node’, and

‘Next TurboMAX node’ in the TurboMAX Manager View, and setting the ‘E1 Chan’ as the Abis

channel in the Abis Manager View as described in the WAVEView OMC Operations and

Maintenance Guide.

The rest of the TurboMAX on-line commissioning requires that an on-site field engineer work with the

OMC operator as shown in Figure 6.

Procedures for OMC Operator

Unlock the Abis

interface

Unlock the

TurboMAX and

RCARRIER

Check state of

TurboMAX

Unlock the

TurboMAX

OMC

Lock E1 or T1

Ports

Verify Database

Open TurboMAX

alarm and event

list views

Check state of

TurboMAX

Check state of

TurboMAX

Check alarm and

event detailed

views

Check for

cleared events

and alarm in all

views

Procedures for TurboMAX

Field Engineer

Step 46

Provide

TurboMAX

information

Step 47

Turn

TurboMAX

power OFF

Step 48

Turn TurboMAX

power ON

Step 51

Disconnect E1

or T1 cables

Step 52

Reconnect E1

or T1 cables

BSS

Check for

TurboMAX state

Verify external

alarms

Verify TRX

timeslots

Lock the

TurboMAX

Figure 6. On-Line Commissioning Procedures

Application Note 16 – ve rsi on 1.1

Step 53

Test external

alarms

Step 54

Use mobile to

verify timeslots

IW249002

page 12

Page 13

p

plication Note

A

46) Provide the OMC operator with all part, revision, and serial numbers for the TurboMAX cards and

modules.

47) Power down the TurboMAX by setting the Main and Amplifier Power Supply module switches to

OFF. Have the OMC operator verify the changed state of the TurboMAX.

48) Power on the TurboMAX by setting the Main and Amplifier Power Supply module switches to ON.

Have the OMC operator verify the changed state of the TurboMAX.

49) Have the OMC operator lock the E1 or T1 ports, and verify that TurboMAX alarms clear.

50) Have the OMC operator unlock the E1 or T1 ports carrying the OAM link, and verify the state of the

TurboMAX.

51) Label and remove the E1 or T1 cables from the TurboMAX. Have the OMC operator monitor the

OAM link and confirm it is ‘disconnected’.

52) Reconnect the E1 or T1 cables to the TurboMAX. Have the OMC operator verify that the OAM link

is restored.

53) Test external alarms as follows:

Whether or not the external alarms are to be used, short pins 5 and 6 on the TurboMAX external

alarm input terminal block. Have the OMC operator verify that after a delay, the first customerdefined alarm shows an alarm event.

Remove the short between pins 5 and 6 on the TurboMAX external alarm input terminal block. Have

the OMC operator verify that after a delay, the first customer-defined alarm event clears.

54) Refer to the debug mobile documentation for operating procedures. Use the debug mobile to debug

mode, and ensure that the debug mobile displays that the timeslot being used corresponds to the

timeslot that was unlocked by the OMC operator. Place a mobile-to-mobile call using the debug

mobile and the TRX under test, and verify that a two-way call can be made on this timeslot with

good audio quality, power, and low interference. End the call.

This test checks the performance of each timeslot contained within each TurboMAX TRX.

Sequentially perform the same test on all TCH timeslots as outlined in Table 1 or Table 2. No te that

the number of timeslots to be tested are different for a two TRX TurboMAX and a three TRX

TurboMAX.

Application Note 16 – ve rsi on 1.1

page 13

Page 14

p

plication Note

A

Table 1. Testing Timeslots in a Two-TRX TurboMAX

TRX Number Timeslot Number Channel Type Testing Necessary

First TRX (Note)

Second TRX (Note)

Note: The BCCH can be assigned to any TRX in the TurboMAX. The label ‘First TRX’

applies to the TRX to which the BCCH is assigned. The OMC operator determines which

physical TRX is ‘First’ or ‘Second’.

0 BCCH No

1 SDCCH No

2TCHYes

3TCHYes

4TCHYes

5TCHYes

6TCHYes

7TCHYes

0TCHYes

1TCHYes

2TCHYes

3TCHYes

4TCHYes

5TCHYes

6TCHYes

7TCHYes

Table 2. Testing Timeslots in a Three-TRX TurboMAX

TRX Number Timeslot Number Channel Type Testing Necessary

First TRX (Note)

0 BCCH No

1 SDCCH No

2TCHYes

3TCHYes

4TCHYes

5TCHYes

6TCHYes

7TCHYes

Application Note 16 – ve rsi on 1.1

page 14

Page 15

p

plication Note

A

Table 2. Testing Timeslots in a Three-TRX TurboMAX (continued)

Second TRX (Note)

Third TRX (Note)

Note: The BCCH can be assigned to any TRX in the TurboMAX. The label ‘First TRX’

applies to the TRX to which the BCCH is assigned. The OMC operator determines which

physical TRX is ‘First’, ‘Second’, or ‘Third’.

0TCHYes

1TCHYes

2TCHYes

3TCHYes

4TCHYes

5TCHYes

6TCHYes

7TCHYes

0TCHYes

1TCHYes

2TCHYes

3TCHYes

4TCHYes

5TCHYes

6TCHYes

7TCHYes

Troubleshooting

Other than the POST testing done in Section 3.5, the TurboMAX TRXs, EEPROM RFD card, high-power

Amplifier module, and CMA (Cable Management Assembly) combiners, diplexers, and/or filters are

replaced as a unit. Contact Technical Support for detailed troubleshooting information.

Application Note 16 – ve rsi on 1.1

page 15

Loading...

Loading...