Page 1

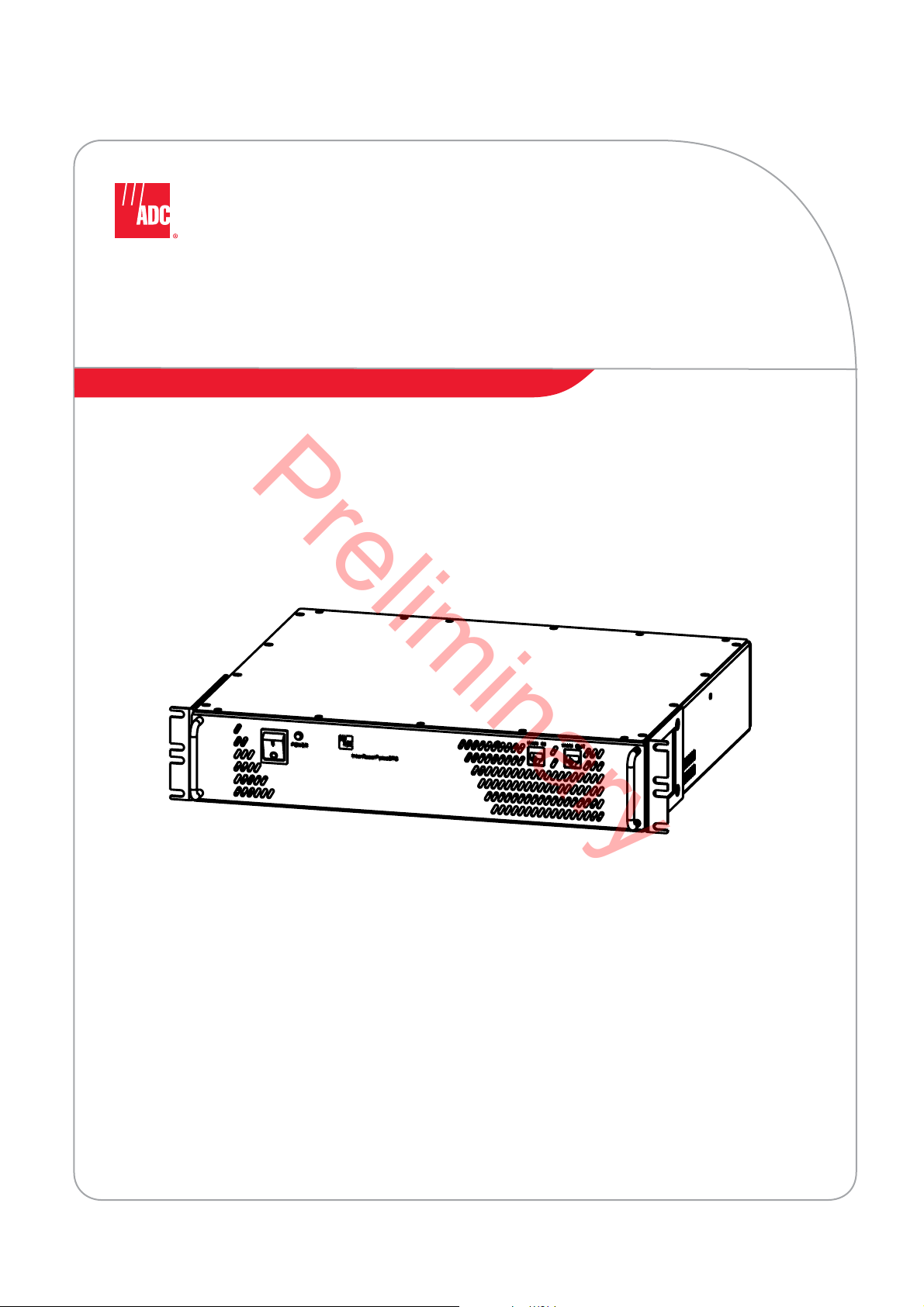

Mobile Network Solutions

InterReach™ picoBTS

Installation and Commissioning Guide

D-620091-0-20 Ver. A

AD235808

ADCP-77-061 • Issue A • 08/2008

Preliminary

Page 2

Preliminary

Page 3

Mobile Network Solutions

UltraWAVE picoBTS

Installation and Commissioning Guide

ADCP-77-061 • Issue A • 08/2008

D-620091-0-20 Ver. A

Preliminary

Page 4

ADCP-77-061 • Issue A • 08/2008 • Preface

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

Preliminary

COPYRIGHT

© 2008, ADC Telecommunications, Inc.

All Rights Reserved

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

A 08/2008 Original

LIST OF CHANGES

The technical changes incorporated into this issue are listed below.

PAGE IDENTIFIER DESCRIPTION OF CHANGE

All New publication

TRADEMARK INFORMATION

ADC is a registered trademark and InterReach, InterReach Unison, InterReach Fusion, WAVEXchange, FlexWave are registered

trademarks and trademarks of ADC Telecommunications, Inc. or LGC Wireless, Inc. a wholly owned subsidiary of ADC. All other

products, company names, service marks, and trademarks mentioned in this document or website are used for identification

purposes only and may be owned by other companies.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891, extension 73476

(in U.S.A. or Canada) or 952-917-3476 (outside U.S.A. and Canada), or by e-mail to wireless.tac@adc.com.

Page ii InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 5

DECLARATIONS OF CONFORMITY

Mailing Address: P.O. Box 1101, Minneapolis, Minnesota 55440-1101

World Headquarters: Minneapolis, Minnesota USA +1.952.938.8080 www.adc.com

EC Declaration of Conformity

Under R&TTE Directive 1999/5/EC

Manufacturer Name : ADC Telecommunications, Inc.

Address : 2495 Leghorn St.

Mountain View, CA 94043, U.S.A.

Declares that the product Ultrawave Base Station Controller System

Product Description : Base Station Controller

Model Number : ASABxxxxxxxxxxxxxxxxxxxxxxxxx

(x = 0-9, A – Z or blank)

Complies with appropriate essential requirements of the Article 3 of the R&TTE directive.

Standard to which conformity is declared :

Protection to Health and Safety: Directive: 73/23/EEC

Protection with respect to EMC: Directive: 89/336/EEC

EMC: ETSI EN 300 386 V1.2.1 (2000-03)

Safety: EN 60950-1:2001+A11

Name of authorized person; Mark Schutzer

Position: Director, Hardware Engineering

Date: 1/6/2008 Signature

Mailing Address: P.O. Box 1101, Minneapolis, Minnesota 55440-1101

World Headquarters: Minneapolis, Minnesota USA +1.952.938.8080 www.adc.com

EC Declaration of Conformity

Under R&TTE Directive 1999/5/EC

Manufacturer Name : ADC Telecommunications, Inc.

Address : 2495 Leghorn St.

Mountain View, CA 94043, U.S.A.

Declares that the product Ultrawave BTS/BSPlus 850/900/1800MHz System

Product Description : GSM Base Transceiver Station

Model Number : AVADxxxxxxxxxxxxxxxxxxxx

(x = 0-9, A – Z or blank)

Complies with appropriate essential requirements of the Article 3 of the R&TTE directive.

Standard to which conformity is declared :

Protection to Health and Safety: Directive: 73/23/EEC

Protection with respect to EMC: Directive: 89/336/EEC

EMC: ETSI EN 301 489-1, 8 V1.4.1 (2002-8)

Safety: EN 60950-1:2001+A11

Radio: ETSI EN 301 502 V8.1.2 (2001-7)

Name of authorized person; Mark Schutzer

Position: Director, Hardware Engineering

Date: 1/6/2008 Signature

Preliminary

ADCP-77-061 • Issue A • 08/2008 • Preface

InterReach picoBTS Installation Guide Page iii

© 2008, ADC Telecommunications, Inc.

Page 6

ADCP-77-061 • Issue A • 08/2008 • Preface

Mailing Address: P.O. Box 1101, Minneapolis, Minnesota 55440-1101

World Headquarters: Minneapolis, Minnesota USA +1.952.938.8080 www.adc.com

EC Declaration of Conformity

Under R&TTE Directive 1999/5/EC

Manufacturer Name : ADC Telecommunications, Inc.

Address : 2495 Leghorn St.

Mountain View, CA 94043, U.S.A.

Declares that the product Ultrawave Micro BTS/BSPlus System

Product Description : Wireless Network System

Model Number : AyADxxxxxxxxxxxxxxxxxxxx

(y=K, L, x = 0-9, A – Z or blank)

Complies with appropriate essential requirements of the Article 3 of the R&TTE directive.

Standard to which conformity is declared :

Protection to Health and Safety: Directive: 73/23/EEC

Protection with respect to EMC: Directive: 89/336/EEC

EMC: ETSI EN 301 489-1, 8 V1.4.1 (2002-8)

Safety: EN 60950-1:2001+A11

Radio: ETSI EN 301 502 V8.1.2 (2001-7)

Name of authorized person; Mark Schutzer

Position: Director, Hardware Engineering

Date: 1/6/2008 Signature

Mailing Address: P.O. Box 1101, Minneapolis, Minnesota 55440-1101

World Headquarters: Minneapolis, Minnesota USA +1.952.938.8080 www.adc.com

EC Declaration of Conformity

Under R&TTE Directive 1999/5/EC

Manufacturer Name : ADC Telecommunications, Inc.

Address : 2495 Leghorn St.

Mountain View, CA 94043, U.S.A.

Declares that the product Ultrawave NIB System

Product Description : Wireless Network System

Model Number : AMADxxxxxxxxxxxxxxxxxxxxxxxxx

(x = 0-9, A – Z or blank)

Complies with appropriate essential requirements of the Article 3 of the R&TTE directive.

Standard to which conformity is declared :

Protection to Health and Safety: Directive: 73/23/EEC

Protection with respect to EMC: Directive: 89/336/EEC

EMC: ETSI EN 301 489-1, 8 V1.4.1 (2002-8)

Safety: EN 60950-1:2001+A11

Radio: ETSI EN 301 502 V8.1.2 (2001-7)

Name of authorized person; Mark Schutzer

Position: Director, Hardware Engineering

Date: 1/6/2008 Signature

Preliminary

Page iv InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 7

TABLE OF CONTENTS

Preliminary

Content Page

TABLE OF CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

1.1 UNPACKING AND INSPECTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.1 Unpacking and Inspecting the picoBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 ELECTROSTATIC DISCHARGE (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Identifying the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 ANALYZING SITE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.2 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3 Chassis Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 MOUNTING THE PICOBTS CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Rack Mount Advisory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.3 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 CONNECTING THE GROUNDING CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 CONNECTING THE POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 CONNECTING THE DISTRIBUTED ANTENNA SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 NETWORK CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7 POST INSTALLATION CABLING AND CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ADCP-77-061 • Issue A • 08/2008 • Preface

CHAPTER 1 -

UNPACKING AND CONFIGURATION VERIFICATION

CHAPTER 2 -

INSTALLATION

CHAPTER 3 -

COMMISSIONING AND CONFIGURATION

InterReach picoBTS Installation Guide Page v

3.1 PRE-COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.1 On-Site Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 COMMISSIONING OF THE PICOBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.1 Connecting the PC to the picoBTS Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.2 Setting Up a Serial Connection to the picoBTS Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.3 Power On LED Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3 CONFIGURING THE ETHERNET ADDRESS AND BOOT PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4 SOFTWARE VERIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4.1 Verifying the Current Software Version and Patch Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4.2 Verifying the Software License . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

© 2008, ADC Telecommunications, Inc.

Page 8

ADCP-77-061 • Issue A • 08/2008 • Preface

Preliminary

3.4.3 Rebooting the picoBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.4 Terminating Serial Communications with the picoBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.5 PREPARING FOR ON-LINE COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 PRE ON-LINE COMMISSIONING REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2 ON-LINE COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2.1 Testing the picoBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.2 Recovery Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.3 TCH Timeslot Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.4 RX Signal Quality Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3 POST ON-LINE COMMISSIONING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

CHAPTER 4 -

ON-LINE TESTING

Page vi InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 9

ABOUT THIS MANUAL

Preliminary

Welcome to the InterReach picoBTS Installation Guide. It describes how to perform local

installation and commissioning of the picoBTS at the customer’s site.

This document is intended for an ADC trained field service engineer (FSE) or operator who

performs local installation and commissioning at the customer’s site. The FSE or operator

should be equipped with the necessary tools for installation and commissioning, and a basic

understanding of the GSM cellular network. The FSE or operator should also be familiar with

the use of the Craft PC and procedures conducted using the Craft PC.

ADC assumes that pre-installation project planning has occurred, and is documented via a site

survey report. This site survey should include items such as the location of antennas, chassis,

power connections and other interface accesses and temperature control equipment.

RELATED PUBLICATIONS

Listed below are related manuals, their content, and their publication numbers. Copies of these

publications can be ordered by contacting the Technical Assistance Center at 1-800-366-3891,

extension 73476 (in U.S.A. or Canada) or 952-917-3476 (outside U.S.A. and Canada).

ADCP-77-061 • Issue A • 08/2008 • Preface

Title/Description ADCP Number

Mobile Network Solutions Documentation Index ADCP-76

UNITED STATES FEDERAL COMMUNICATIONS COMMISSION REQUIRED USER INFORMATION

Located on the equipment is a label that contains, among other information, the FCC registration number. If requested, this information must be provided to the telephone company.

The UltraWAVE BTS Series AUAC series complies with Part 22 of the FCC Rules.

The 1900 MHz WAVEXpress Series M50 complies with Part 24 of the FCC Rules.

The WAVE2000 BS Plus 800 MHz complies with Part 22 of the FCC Rules.

The WAVE2000 Pico BS Plus (800 MHz and 1900 MHz) comply with Part 22 and Part 24 of

the FCC Rules and UL 1950 safety certification.

This equipment cannot be used on the telephone company-provided coin service. Connection

to Party Line Service is subject to State Tariffs.

If this equipment causes harm to the telephone network, the telephone company will notify

you in advance that temporary discontinuance of service may be required. If advance notice

isn't practical, the telephone company will notify the customer as soon as possible. Also, you

will be advised of your right to file a complaint with the FCC if you believe it is necessary.

The telephone company may make changes in its facilities, equipment, operations, of procedures that could affect the operation of the equipment. If this happens, the telephone company

will provide advance notice in order for you to make the necessary modifications in order to

maintain uninterrupted service.

InterReach picoBTS Installation Guide Page vii

© 2008, ADC Telecommunications, Inc.

Page 10

ADCP-77-061 • Issue A • 08/2008 • Preface

Preliminary

If the trouble is causing harm to the telephone network, the telephone company may request

you to remove the equipment from the network until the problem is resolved.

It is recommended that the customer install a surge arrester in the AC outlet to which that

device is connected. This is to avoid damaging the equipment caused by local lightning strikes

and other electrical surges.

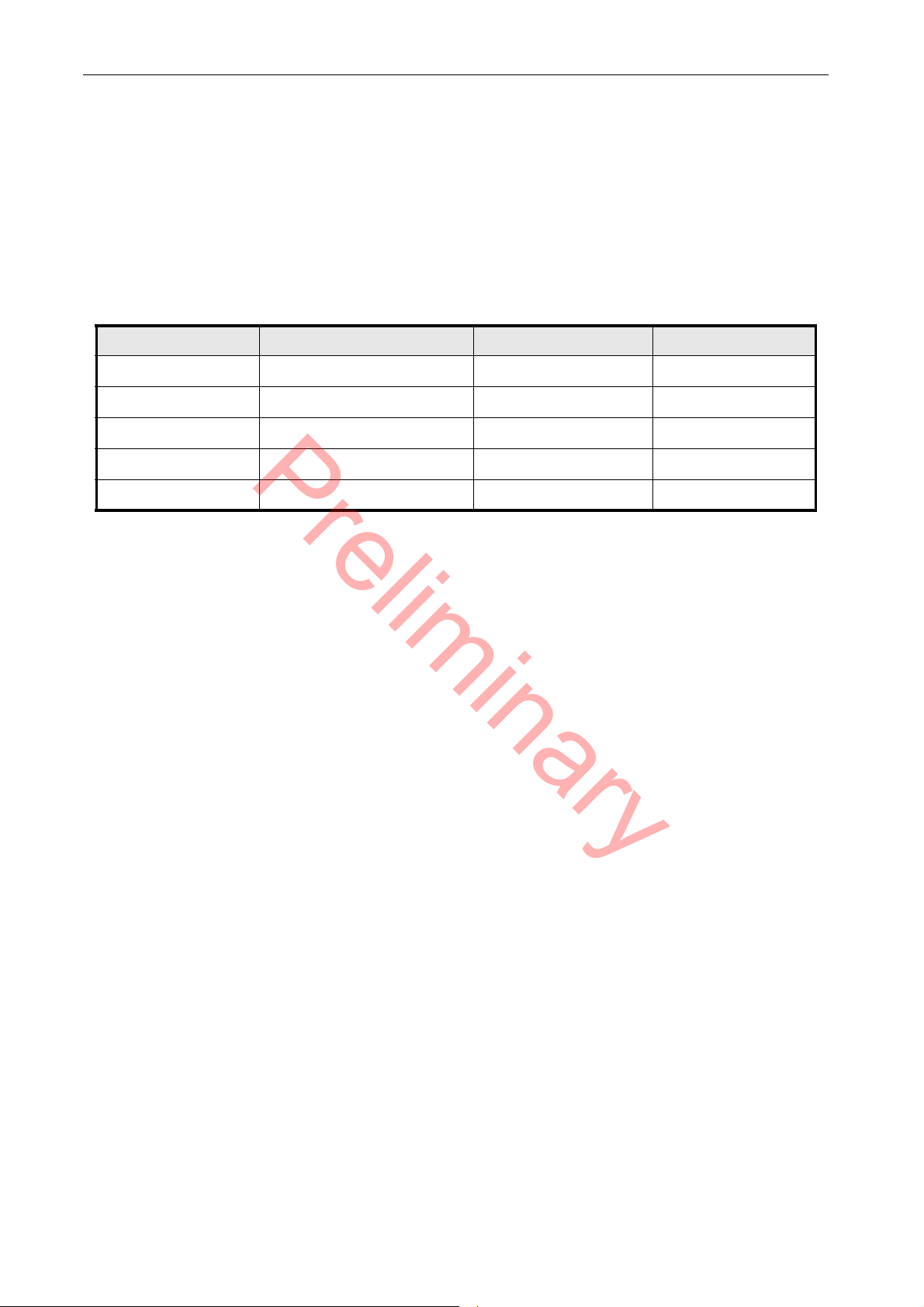

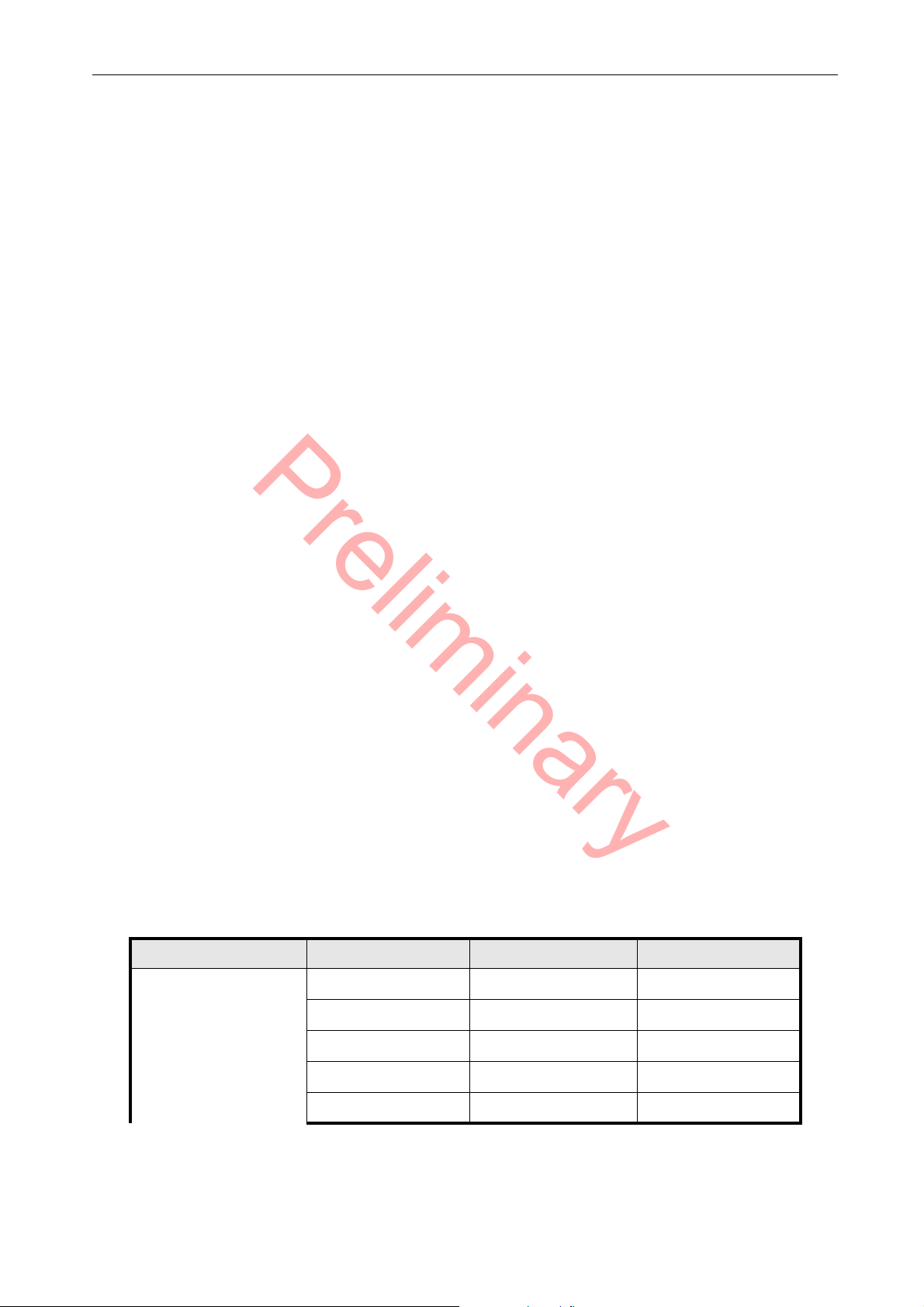

This equipment uses the following USOC jacks and codes:

MODEL NAME FACILITY INTERFACE CODE SERVICE ORDER CODE JACK TYPE

340122/340133 04DU9-BN 6.ON RJ-48C

340122/340133 04DU9-DN 6.ON RJ-48C

340122/340133 04DU9-1KN 6.ON RJ-48C

340122/340133 04DU9-1SN 6.ON RJ-48C

340122/340133 04DU9-1ZN 6.ON RJ-48C

Note: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his

own expense.

Changes of modifications not expressly approved by ADC can void the user's authority to

operate the equipment. FCC and IC certification labels denoting the product specific certification numbers may be found on the product.

INDUSTRY CANADA REQUIRED USER INFORMATION

CP-O1, Issue 8, Part 1, Section 14.1

NOTICE: The Industry Canada label identifies certified equipment. This certification means

that the equipment meets certain telecommunications network protective, operational and

safety requirements as prescribed in the appropriate Terminal Equipment Technical Requirements document(s). The Department does not guarantee the equipment will operate to the

user's satisfaction.

Page viii InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 11

ADCP-77-061 • Issue A • 08/2008 • Preface

Preliminary

Before installing this equipment, users should ensure that it is permissible to be connected to

the facilities of the local telecommunications company. The equipment must also be installed

using an acceptable method of connection. The customer should be aware that compliance

with the above conditions may not prevent degradation of service in some situations.

Repairs to certified equipment should be coordinated by a representative designated by the

supplier. Any repairs or alterations made by the user to this equipment, or equipment malfunctions, may give the telecommunications company cause to request the user to disconnect the

equipment.

Users should ensure for their own protection that the electrical ground connections of the

power utility, telephone lines and internal metallic water pipe system, if present, are connected

together. This precaution may be particularly important in rural areas.

CAUTION: Users should not attempt to make such connections themselves, but should

contact the appropriate electric inspection authority, or electrician, as appropriate.

The standard connecting arrangement (telephone jack type) for this equipment is CA81A.

CP-01, Issue 8, Part 1, Section 14.2

NOTICE: The Ringer Equivalence Number (REN) assigned to each terminal device provides

an indication of the maximum number of terminals allowed to be connected to a telephone

interface. The termination of an interface may consist of any combination of devices subject

only to the requirement that the sum of the Ringer Equivalence Numbers of all the devices

does not exceed 5.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numerique de la classe A est conforme a la norme NMB-003 du Canada.

This device complies with Industry Canada RSS-133 and SRSP-510 or RS132 & SRPS-503.

DISPOSAL OF ELECTRONIC AND ELECTRICAL WASTE

Pursuant to the WEEE EU Directive electronic and electrical waste must not be disposed of

with unsorted waste. Please contact your local recycling authority for disposal of this

product.

InterReach picoBTS Installation Guide Page ix

© 2008, ADC Telecommunications, Inc.

Page 12

ADCP-77-061 • Issue A • 08/2008 • Preface

Preliminary

ADMONISHMENTS

Important safety admonishments are used throughout this manual to warn of possible hazards

to persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times.

These warnings are flagged by use of an alert icon (seen below), and are listed in descending

order of severity of injury or damage and likelihood of occurrence.

DANGER: Danger is used to indicate the presence of a hazard that will cause severe personal injury,

death, or substantial property damage if the hazard is not avoided.

WARNING: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor personal

injury or property damage if the hazard is not avoided.

CONVENTIONS USED IN THIS MANUAL

The following type and style conventions are used in this manual:

Conventions Used in This Manual

CONVENTION MEANING

Body Text

Bold

Command Indicates computer generated text and prompts

User Input Indicates user input

<hostname> In command syntax, indicates user-specified command line parameters

<variable> In body text, indicates user-specified command line parameters

[BRACKETS] Indicates a key on the keyboard or instrument

Used for regular body text

Indicates a menu or button choice

Note: Provides relevant additional information

Page x InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 13

ADCP-77-061 • Issue A • 08/2008 • Chapter 1 - Unpacking and Configuration Verification

Preliminary

CHAPTER 1 - UNPACKING AND CONFIGURATION VERIFICATION

Content Page

1.1 UNPACKING AND INSPECTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.1 Unpacking and Inspecting the picoBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 ELECTROSTATIC DISCHARGE (ESD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Identifying the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

This chapter provides instructions for opening the shipping container and inspecting the contents. When you have completed the procedures in this chapter you will have confirmed that

the hardware arrived undamaged, and that everything you ordered is present and configured

correctly.

InterReach picoBTS Installation Guide Page 1

© 2008, ADC Telecommunications, Inc.

Page 14

ADCP-77-061 • Issue A • 08/2008 • Chapter 1 - Unpacking and Configuration Verification

Preliminary

1.1 UNPACKING AND INSPECTING

The InterReach picoBTS is packed with great care, and all containers are inspected prior to

shipment. Upon receipt of these packages, immediately inspect the outside of the shipping

containers. If there is any visible damage, insist that a representative of the carrier be present

when unpacking the contents.

Carefully inspect the system as it is unpacked. If any damage such as dents or broken connections is noticeable, immediately notify the carrier as well as ADC Customer Service.

Store the shipping containers for future use. If the unit has to be returned for upgrade or

service, the specially designed shipping containers assure adequate protection for the equipment. If for some reason the containers are not reusable or if they are misplaced, please contact

ADC to order new containers.

1.1.1 UNPACKING AND INSPECTING THE PICOBTS

The InterReach picoBTS is shipped in a specially designed shipping box. The system should

remain in the packaging until shipped to its final destination.

• Open shipping box and remove the picoBTS chassis.

• Note part numbers on the back of the unit correspond to the shipping documentation.

Carefully inspect the system as it is unpacked. If any damage such as dents or broken connections is noticeable, immediately notify the carrier as well as ADC Customer Service.

Store the shipping containers for future use. If the unit has to be returned for upgrade or

service, the specially designed shipping containers assure adequate protection of the equipment. If for some reason the containers are not reusable or if they are misplaced, please contact

ADC to order new containers.

The picoBTS shipment will include the following items:

• picoBTS chassis

• Mounting brackets

• Eight mounting bracket screws

If you have ordered an InterReach distributed antenna system, it will be shipped in a separate

container. Please refer to the Quick Start Guide and packing slip included with its shipment.

Page 2 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 15

ADCP-77-061 • Issue A • 08/2008 • Chapter 1 - Unpacking and Configuration Verification

Preliminary

1.2 ELECTROSTATIC DISCHARGE (ESD)

Electrostatic discharge is the movement of normally motionless electrical charges which can

destroy common electrical and electronic equipment.

ADC recommends that you use an anti-static wrist strap when handling boards and

components.

By using an anti-static wrist strap, static electricity is constantly dispersed, via the snug-fitting

wrist-band, down the cable and to the grounded connection at the other end, leaving hands free

to work.

• Use either the provided anti-static wrist strap or an ESD mat.

• Otherwise, touch the metal chassis to drain off any static electricity before touching the

cards.

• Do not wear wool or polyester clothing.

• Dry air can prevent dangerous charges from harmlessly dissipating. ADC recommends a

relative humidity of 50-60% when working on this equipment.

• Handle the cards as little as possible and only by the edges.

Warning: Make sure you use anti-static precautions before starting any of the following procedures.

1.2.1 IDENTIFYING THE SYSTEM

The picoBTS system can be idenitifed using the main identification label. This label also

provides the relevant compliance information for the system when it was assembled.

• Locate the identification label, shown in Figure 1-1, on the rear of the chassis.

This configuration label provides the model and serial numbers for your chassis. These identification details are required if you encounter any problems with the system and need to contact

Customer Service.

InterReach picoBTS Installation Guide Page 3

© 2008, ADC Telecommunications, Inc.

Page 16

ADCP-77-061 • Issue A • 08/2008 • Chapter 1 - Unpacking and Configuration Verification

MODEL: InterReach picoBTS

CONFIG: ADCIR-BTS-1800

SERIAL:

P/N:

REVISION:

INPUT POWER:

MFG DATE: 08/2008

100-240 VAC ~50-60 Hz, 0.6A

AD235809

Preliminary

Figure 1-1: Identification Label

• Record your model number and configuration.

Page 4 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 17

CHAPTER 2 - INSTALLATION

Preliminary

Content Page

2.1 ANALYZING SITE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Environmental Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.2 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3 Chassis Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 MOUNTING THE PICOBTS CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Required Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.2 Rack Mount Advisory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.3 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 CONNECTING THE GROUNDING CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.4 CONNECTING THE POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 CONNECTING THE DISTRIBUTED ANTENNA SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 NETWORK CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7 POST INSTALLATION CABLING AND CHECKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

This chapter will guide you through the complete installation and configuration of the InterReach picoBTS hardware.

InterReach picoBTS Installation Guide Page 5

© 2008, ADC Telecommunications, Inc.

Page 18

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

2.1 ANALYZING SITE REQUIREMENTS

Before a site is chosen or equipment installed, a site survey must be carried out. The site

survey checklist assists the surveyor with the inspection and the collection of site specific

information such as environmental conditions, electrical requirements, and mechanical

requirements. This site survey should also include the location of the InterReach picoBTS and

InterReach Unison or Fusion distributed antenna system (DAS) including the placement of the

distributed antenna system remote radio heads throughout the target structure.

The site survey checklist must be completed before installation begins. The InterReach DAS

documentation provides additional detailed site requirements.

The site readiness checklist assists the field service engineer or operator to ensure that the site

is ready for equipment installation. It includes information about:

• Environmental conditions

• Electrical requirements

• Chassis requirements

2.1.1 ENVIRONMENTAL CONDITIONS

The picoBTS is designed to operate indoors only. To facilitate long-term operability and durability of the picoBTS, observe specific environmental constraints.

Before installing the picoBTS, ensure that the operating environment maintains a temperature

within the range shown in Table 2-1.

Caution: Make sure the ambient temperature around the unit (which may be higher than the room tem-

perature) is within the limit specified for the unit.

Table 2-1: picoBTS Operating Environment

Maximum 90% 45 degrees 113 degrees

RANGE

HUMIDITY

(NON-CONDENSING)

TEMPERATURE

(CELSIUS)

TEMPERATURE

(FAHRENHEIT)

Minimum 10% -5 degrees 23 degrees

2.1.2 ELECTRICAL REQUIREMENTS

The picoBTS is specified to operate on AC power. This document defines the electrical

requirements for the picoBTS only.

Page 6 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 19

2.1.2.1 Power Options

Preliminary

Main power supply options for the picoBTS are:

• 100 to 240 VAC auto-ranging, 50-60 Hz, 0.6A

Table 2-2 shows the power requirements for the picoBTS.

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Table 2-2: Estimated Power Requirements

PRODUCT

CONFIGURATION

picoBTS 60 watts 60 watts

Table 2-3: picoBTS Power Specifications

POWER REQUIREMENTS SPECIFICATION

picoBTS voltage range: 110 VAC 85 to 264 VAC

picoBTS power protection: 110 VAC 1 amp circuit breaker

picoBTS voltage range: 220 VAC 90 to 264 VAC

picoBTS power protection: 220 VAC 1 amp circuit breaker

110 VAC 220 VAC

InterReach picoBTS Installation Guide Page 7

© 2008, ADC Telecommunications, Inc.

Page 20

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

2.1.3 CHASSIS REQUIREMENTS

Before installing the picoBTS, ensure that adequate clearance space is allowed around the unit.

Enough clearance should be provided from the back of the chassis to allow adequate cooling

and cable connections to the distributed antenna system.

This requires at least 7.9 inches (20.0 cm) from the rear panel. The minimum clearance

required from the front and on either side of the chassis is 3.9 inches (10.0 cm). This unit is

designed to be rack mount and there is no minimum clearance required above or below the

chassis.

These mounting clearances should provide ample clearance for the RF and Ethernet cables to

be attached to the connectors at the front and rear of the chassis.

The picoBTS should be installed indoors away from salt spray and in an area where there are

minimal vibrations.

Table 2-4 lists the weight and dimensions of the picoBTS chasiss.

Table 2-4: Chassis Weight and Dimensions

SCALE

Metric 11.2 kg 9.0 cm 48.3 cm 40.6 cm

Imperial 25.0 lbs 3.5 inches 19.0 inches 15.0 inches

(MAXIMUM CONFIGURATION)

WEIGHT

HEIGHT WIDTH DEPTH

Page 8 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 21

2.2 MOUNTING THE PICOBTS CHASSIS

Preliminary

The picoBTS chassis is shipped with the appropriate hardware to be installed in a 19” rack.

This section describes all the necessary steps for installing a picoBTS.

Note: Ensure that:

• The ambient temperature around the unit (which may be higher than the room temperature) is within

the limit specified for the unit.

• There is sufficient airflow around the unit.

• The electrical circuits are not overloaded - consider the name plate rating of all the connected

equipment and make sure you have over current protection.

• The 19” equipment rack is properly grounded.

2.2.1 REQUIRED MATERIALS

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

• 4 standard 19” (48.26 cm) rack mount screws (customer-provided)

2.2.1.1 Optional Materials

• Cable ties

2.2.1.2 Required Tools

• Phillips screwdriver

2.2.2 RACK MOUNT ADVISORY

CAUTION:

To prevent bodily injury when mounting or servicing this unit in a rack, you must take special

precautions to ensure that the system remains stable. The following guidelines are provided to

ensure your safety:

• This unit should be mounted at the bottom of the rack if it is the only unit in the rack.

• When mounting this unit in a partially filled rack, load the rack from the bottom to the top

with the heaviest component at the bottom of the rack.

• If the rack is provided with stabilizing devices, install the stabilizers before mounting or

servicing the unit in the rack.

Attention: Pour éviter toute blessure corporelle pendant les opérations de montage ou de réparation de cette unité en casier, il convient de prendre des précautions spéciales afin de

InterReach picoBTS Installation Guide Page 9

© 2008, ADC Telecommunications, Inc.

Page 22

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

maintenir la stabilité du système. Les directives ci-dessous sont destinées à assurer la protection du personnel:

• Si cette unité constitue la seule unité montée en casier, elle doit être placée dans le bas.

• Si cette unité est montée dans un casier partiellement rempli, charger le casier de bas en

haut en plaçant l'élément le plus lourd dans le bas.

• Si le casier est équipé de dispositifs stabilisateurs, installer les stabilisateurs avant de

monter ou de réparer l'unité en casier.

Warnung: Zur Vermeidung von Körperverletzung beim Anbringen oder Warten dieser

Einheit in einem Gestell müssen Sie besondere Vorkehrungen treffen, um sicherzustellen, daß

das System stabil bleibt. Die folgenden Richtlinien sollen zur Gewährleistung Ihrer Sicherheit

dienen:

• Wenn diese Einheit die einzige im Gestell ist, sollte sie unten im Gestell angebracht

werden.

• Bei Anbringung dieser Einheit in einem zum Teil gefüllten Gestell ist das Gestell von

unten nach oben zu laden, wobei das schwerste Bauteil unten im Gestell anzubringen ist.

• Wird das Gestell mit Stabilisierungszubehör geliefert, sind zuerst die Stabilisatoren zu

installieren, bevor Sie die Einheit im Gestell anbringen oder sie warten.

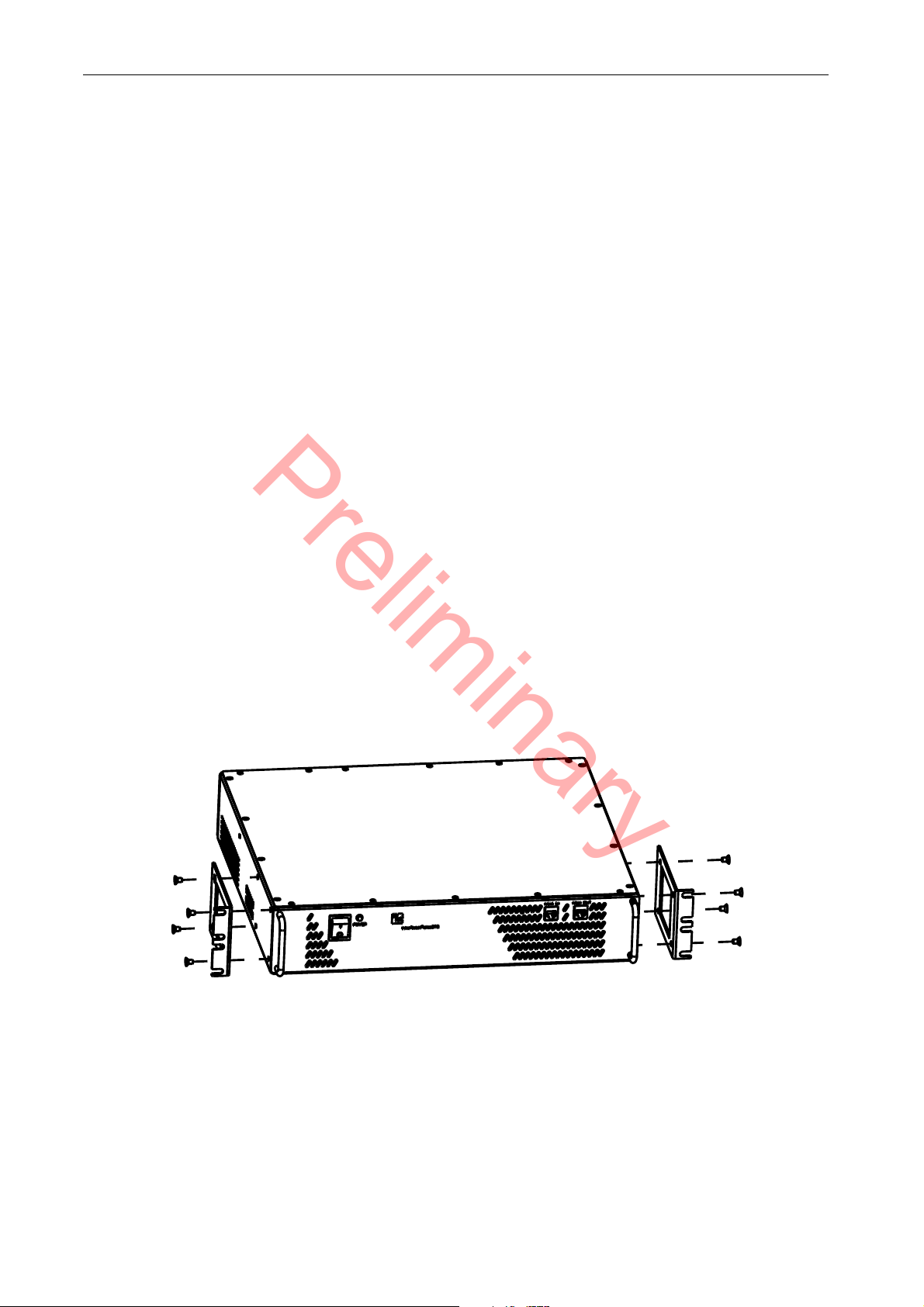

2.2.3 INSTALLATION INSTRUCTIONS

1 Using the screws provided. attach a mounting bracket to each side of the picoBTS, as

shown in Figure 2-1.

AD235807

Figure 2-1: Mounting Brackets

2 The rack mount brackets have cutouts to accommodate the 19" (48.26 cm) rack screws.

Using two people, carefully align the chassis with the rack holes.

Page 10 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 23

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

3 Carefully mount and secure the picoBTS using customer-provided rack screws, as shown

in Figure 2-2

Figure 2-2: picoBTS Rack Mount

Note: Ensure that all rack mount screws are securely tightened.

4 If you are mounting an InterReach Unison or Fusion DAS hub, use the same procedure to

align and mount the unit directly above or below the picoBTS in the rack using

customer-provided screws. Figure 2-3 shows a DAS hub mounted in a rack with a

picoBTS.

Figure 2-3: picoBTS and DAS Mounting Location

5 You have completed the hardware installation, proceed to the next section to continue the

picoBTS connections.

InterReach picoBTS Installation Guide Page 11

© 2008, ADC Telecommunications, Inc.

Page 24

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

2.3 CONNECTING THE GROUNDING CABLE

Use this section to connect your earth ground and power cable to the picoBTS cabinet.

Caution: Grounding circuit continuity is vital for safe operation of machine. Never operate machine

with grounding conductor disconnected.

Attention: Un circuit de terre continu est essentiel en vue du fonctionnement sécuritaire de l'appareil.

Ne jamais metre l'appareil en marche lorsque le cable de mise à la terre est débranche.

Warnung: Achtung, Hoher Ableitstrom! Schutzleiteranschluß vor dem Netzanschluß herstellen.

The rack unit in which the picoBTS chassis is being mounted should be properly grounded to

the site earth ground ring. You must attach a ground strap to each subrack and to the rack unit

or directly to the site ground ring.

1 Locate the ground lug on chassis. See Figure 2-4 for its location.

Figure 2-4: picoBTS Ground Lug and Power Connector

2 Remove the nut from the ground lug and connect a ground lead to the chassis. Secure the

nut tightly on each subrack assembly using a 7/16 (11mm) wrench as shown in Figure 2-5.

Page 12 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 25

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

Figure 2-5: Ground Cable Connection

3 Attach the ground cables to the properly grounded rack assembly or to the closest earth

ground bus.

InterReach picoBTS Installation Guide Page 13

© 2008, ADC Telecommunications, Inc.

Page 26

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

2.4 CONNECTING THE POWER SUPPLY

In this section, you will connect the picoBTS to your power source.

Warning: This product relies on the building's installation for short-circuit (overcurrent) protection.

Ensure that a fuse or circuit breaker no larger than 220 VAC, 1A; 110 VAC, 1A is used on the phase

conductors (all current-carrying conductors).

Attention: Pour ce qui est de la protection contre les courts-circuits (surtension), ce produit dépend de

l'installation électrique du local. Vérifier qu'un fusible ou qu'un disjoncteur de 220 VAC, 1A alt., 110

VAC, 1A alt. est utilisé sur les conducteurs de phase (conducteurs de charge).

Warnung: Dieses Produkt ist darauf angewiesen, daß im Gebäude ein Kurzschluß- bzw. Überstrom-

schutz installiert ist. Stellen Sie sicher, daß eine Sicherung oder ein Unterbrecher von nicht mehr als

220 V Wechselstrom, 1 A; 110 V Wechselstrom, 1 A an den Phasenleitern (allen stromführenden

Leitern) verwendet wird.

1 Verify the ground connection you made in Section 2.3 is secure.

2 Make sure that the power switch located on the front of the chassis in the OFF (

3 Use a local IEC standard power cable to connect the power connector shown in Figure 2-4

to your AC power supply. Figure 2-6 shows the power connection to both the picoBTS

and DAS systems.

Figure 2-6: Power Supply Connection

0)position.

4 Do not apply power to the chassis at this time. Wait until you are performing the

commissioning procedures in the next chapter.

Page 14 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 27

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

Caution: The power supply cord is used as the main disconnect device, ensure that the socket-outlet is

located/installed near the equipment and is easily accessible.

Attention: Le cordon d'alimentation est utilisé comme interrupteur général. La prise de courant doit

être située ou installée à proximité du matériel et être facile d'accés.

Warnung: Das Netzkabel dient als Netzschalter. Stellen Sie sicher, das die Steckdose einfach zugän-

glich ist.

InterReach picoBTS Installation Guide Page 15

© 2008, ADC Telecommunications, Inc.

Page 28

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

2.5 CONNECTING THE DISTRIBUTED ANTENNA SYSTEM

The chassis provides access to the female N-type connectors for your distributed antenna

system (DAS) or other external antennas.

The antenna cabling for the picoBTS will typically be configured for connection to an InterReach DAS system. Your site specific DAS system and configuration was determined during

the network planning stage of implementation.

Table 2-5: Adapters and Cabling

IDENTITY CABLE TYPE CORRESPONDING CABLE PLUGS

RF cable (15 in.) Coaxial N-type, Male

Note: Two 15 inch cables are provided to connect the picoBTS to a DAS. If your configuration is

different from the standard installation, you must provide the proper RF cables.

1 Verify the power is OFF on both the picoBTS and DAS chassis.

2 Using one RF cable, connect the

DOWNLINK connector on the DAS chassis. Tighten the connectors by hand until snug.

3 Using the second RF cable, connect the

UPLINK connector on the DAS chassis. Tighten the connectors by hand until snug.

4 Figure 2-7 illustrates the connections between the picoBTS and the DAS. Verify the

connections are correct and all connectors are tight.

TRANSMIT N-type connector on the picoBTS to the

RECEIVE connector on the picoBTS to the

Figure 2-7: Antenna Cabling for Standard picoBTS Configurations

Page 16 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 29

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

WARNING: All RF cabling must be completed with the chassis powered off and, preferably, with the

power cable disconnected from the cabinet.

Do not disconnect RF coaxial connectors on the ADC equipment or antenna systems while the radio

equipment is operating.

equipment is transmitting.

RF signal levels that give rise to hazardous radiation levels can exist within the transmitter, power

amplifiers, associated RF multiplexers and antenna systems.

Never place any body part over or look into any RF connector while the radio

InterReach picoBTS Installation Guide Page 17

© 2008, ADC Telecommunications, Inc.

Page 30

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

2.6 NETWORK CONNECTION

External cabling is dependent upon the customer site-specific requirements. The picoBTS

system carries OAM and VoIP traffic over Ethernet and should be connected on an isolated

Ethernet subnet for best performance.

The picoBTS has two 100baseT RJ-45 connectors Ethernet connection on the front panel

labeled

WAN IN and WAN OUT, as shown in Figure 2-8.

Figure 2-8: Network Connection

• To make the connection, an Ethernet patch cable into the port and set up the Ethernet

connection as described in Section 3.3.

Page 18 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 31

2.7 POST INSTALLATION CABLING AND CHECKS

Preliminary

Before proceeding to the next chapter and commissioning the equipment, make sure that:

• The chassis and mounting rack are properly grounded.

• The power cable is properly connected to the chassis and input power supply.

• The chassis power is turned off.

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

InterReach picoBTS Installation Guide Page 19

© 2008, ADC Telecommunications, Inc.

Page 32

ADCP-77-061 • Issue A • 08/2008 • Chapter 2 - Installation

Preliminary

Blank

Page 20 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 33

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

CHAPTER 3 - COMMISSIONING AND CONFIGURATION

Content Page

3.1 PRE-COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.1.1 On-Site Visual Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.2 COMMISSIONING OF THE PICOBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.1 Connecting the PC to the picoBTS Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.2 Setting Up a Serial Connection to the picoBTS Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2.3 Power On LED Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.3 CONFIGURING THE ETHERNET ADDRESS AND BOOT PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.4 SOFTWARE VERIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4.1 Verifying the Current Software Version and Patch Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.4.2 Verifying the Software License . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.3 Rebooting the picoBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4.4 Terminating Serial Communications with the picoBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5 PREPARING FOR ON-LINE COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3333

***********THIS CHAPTER IS TBD AND WILL INCLUDE BASIC NANO SETUP.

This material is currently covered in ADCP 75-310 Issue 2.

InterReach picoBTS Installation Guide Page 21

© 2008, ADC Telecommunications, Inc.

Page 34

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

The commissioning process includes the following steps:

• Pre off-line commissioning, where you ensure that the system is in an appropriate state.

This includes:

- Visual inspection

- Compliance checks

• Startup Verification, where you verify that the system comes up correctly by observing the

LEDs on the front panel.

• Configuration includes setting up the site-specific local IP address for the picoBTS.

The rest of this chapter includes the detailed instructions for these steps.

WARNING: Under normal operating conditions, ADC Telecommunications radio equipment

complies with the limits for human exposure to radio frequency (RF) fields adopted by the Federal

Communications Commission (FCC). All ADC Telecommunications, Inc. radio equipment is designed

so that under normal working conditions radio frequency radiation directly from the radio is negligible

when compared with the permissible limit of continuous daily exposure recommended in the United

States of America by ANSI/IEEE C95.1-19991 (R1997), Safety Levels with Respect to Human

Exposure to Radio Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

Radio frequency signal levels that give rise to hazardous radiation levels can exist within the transmitter, power amplifiers, associated RF multiplexers and antenna systems.

Do not disconnect RF coaxial connectors on the ADC equipment or antenna systems while the radio

equipment is operating.

equipment is transmitting.

Caution: The BSS software used in the is highly complex. Before proceeding, contact Customer

Service to verify that you have the latest available software. You must

CD-ROM and

picoBTS. Contact your Level 2 support representative for additional assistance.

know the current patch level for your software version before commissioning the

Never place any body part over or look into any RF connector while the radio

have the correct software

Page 22 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 35

3.1 PRE-COMMISSIONING

Preliminary

This section must be completed before doing the commissioning. The commissioning of the

chassis should take place on-site after the physical installation of the picoBTS. Use the appropriate lists depending on where the off-line commissioning is being performed.

3.1.1 ON-SITE VISUAL INSPECTION

If you are doing your visual inspection on-site, check that:

• The chassis has been securely installed at the appropriate site.

• The power to the chassis is OFF.

• The chassis is connected to a suitable power source.

• The chassis is correctly grounded.

• All cables are available and secured in their correct positions.

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Caution: DO NOT turn the power supply ON until you have a DAS or external antenna connected to

EACH antenna port.

InterReach picoBTS Installation Guide Page 23

© 2008, ADC Telecommunications, Inc.

Page 36

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

3.2 COMMISSIONING OF THE PICOBTS

This section describes the commissioning procedures for the picoBTS. It includes Power-on

LED tests and software verification procedures. These check and configure the software and

run power on self tests (POST) and check the results.

In this chapter, you will use a laptop PC or other computer with serial session capability to

verify the software configuration and other aspects of the picoBTS operation.

3.2.1 CONNECTING THE PC TO THE PICOBTS CHASSIS

You will be making a serial connection from the laptop computer to the picoBTS. This connection is used for checking the software version installed on the system, verifying and

changing boot parameters and monitoring test results.

3.2.1.1 Required Hardware

The following hardware is required to connect the laptop to the picoBTS using a serial

connection.

• One standard DB9 to DB9 serial cable

• Laptop USB to DB9 serial adapter (if necessary)

3.2.2 SETTING UP A SERIAL CONNECTION TO THE PICOBTS SERIAL PORT

1 Connect one end of the serial cable to picoBTS connector labeled Serial on the rear of

the chassis.

2 Connect the opposite end of the cable to the DB9 serial connector or serial adapter on the

laptop, as shown in Figure 3-2.

Figure 3-1: Connecting to the Serial Port

The PC uses serial communications for basic control of the picoBTS, including bootChange

configuration and monitoring of the boot-up process.

Page 24 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 37

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

1 If not already done, connect the laptop to the picoBTS as described in Section 3.2.2,.

2 You may use any available application to open a serial connection. This procedure

decribes how to use HyperTerminal. Navigation to the program may differ depending on

the operating system you have installed.

A Launch the application by navigating: Start -> Programs -> Accessories ->

HyperTerminal -> HyperTerminal

BEnter

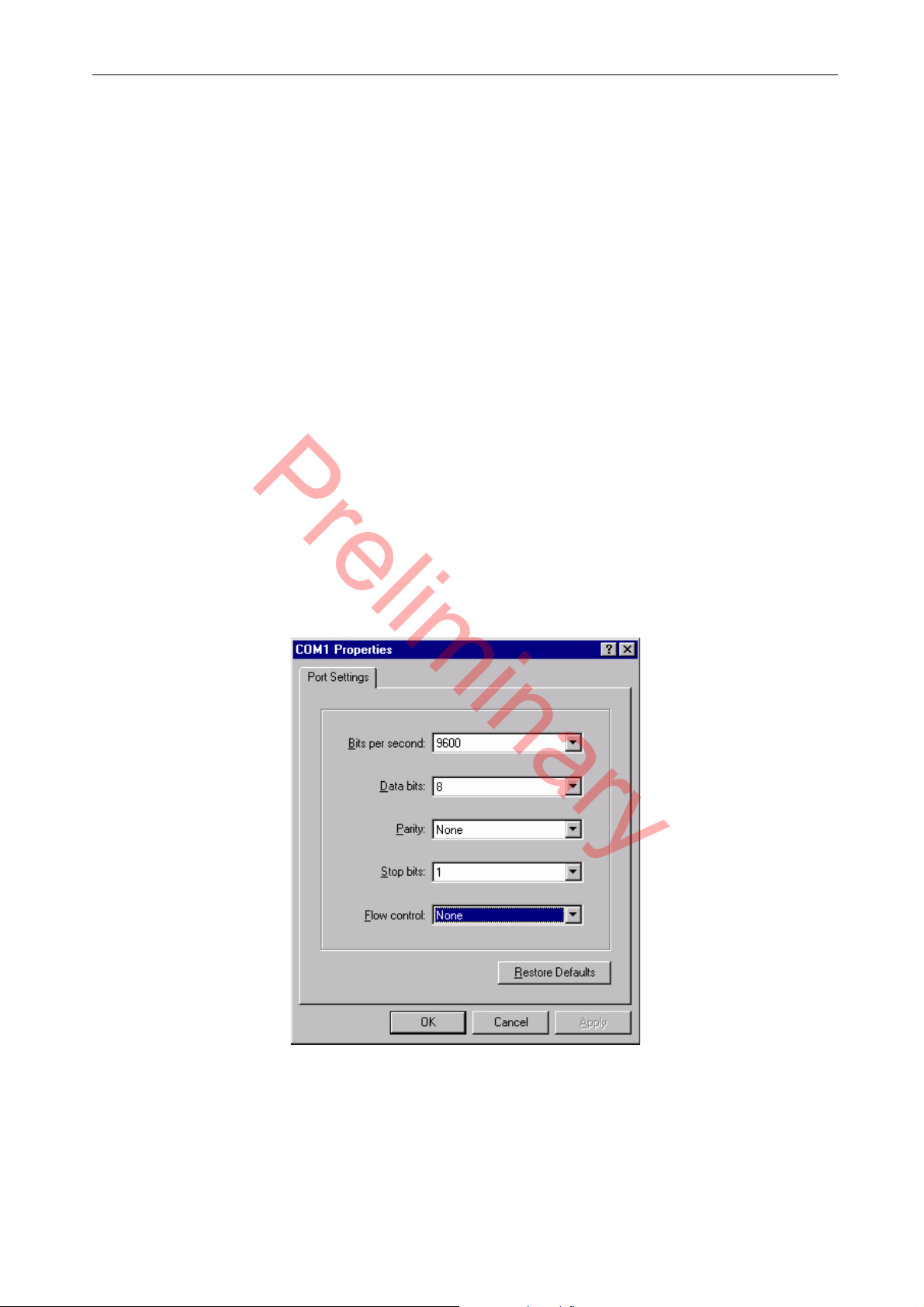

C The Connect To dialog box displays. Select COM1 from the

D The COM1 Properties dialog box displays. Set the following properties and click the

BSS for the connection name and select an icon. Then click the OK button.

Connect using

drop-down list. If you know that your serial port is configured on a different port,

select that port from this drop-down list.

OK button. See Figure 3-2.

Bits per second: 9600

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

Figure 3-2: Serial Session Properties

InterReach picoBTS Installation Guide Page 25

© 2008, ADC Telecommunications, Inc.

Page 38

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

E Select OK to connect to the chassis. At this time, you will not see a prompt. Proceed

to Section 3.2.3 to power on the chassis.

3.2.3 POWER ON LED TESTS

This section describes how to power-on the picoBTS and verify that the system comes up

properly by viewing the LEDs on the front of the chassis. The purpose of these tests is to verify

that the LEDs come up in the correct state, indicating that the system is operating normally.

Use the following procedure:

1 Turn the power to the chassis on by switching on the power switch on the front panel.

Caution: DO NOT turn this power supply on until you have a DAS system or an external antenna con-

nected to EACH antenna port.

2 Verify that the front-panel LEDs flash in the sequence shown in Figure 3-3.

Figure 3-3: LED Sequence During the Boot Process

3 When the sequence is completed, verify that the LEDs appear as shown in the following

table:

Table 3-1: LED Normal Indications

LED DESCRIPTION

Green LED, lit when system has power supplied.

PWR

ON LINE

The PWR LED of the controller and TRX cards will be lit after all cards have completed

the boot-up process.

Green LED, lit when card is on-line, and card BOOT process has been performed

successfully.

The On-Line LED of the Controller card will be lit after all cards have completed the

boot-up process.

The TRX cards will not go on-line until they are unlocked by the OMC operator

FLT Red LED, lit when card detects a fault or is not downloaded.

4 If your LEDs appear as described above, you are done with the LED Power up tests.

Contact Customer Service.

Page 26 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 39

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

5 You can monitor the status of the boot process using the serial session opened in

Section 3.4.

Once the LEDs on the processor cards have reached their final online status, press the

[ENTER] key in the HyperTerminal window. The prompt now changes to the following:

HD:iwbox->

InterReach picoBTS Installation Guide Page 27

© 2008, ADC Telecommunications, Inc.

Page 40

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

3.3 CONFIGURING THE ETHERNET ADDRESS AND BOOT PARAMETERS

In this section, you configure the boot parameters to modify the IP address of the system. After

changing the boot parameters, the chassis must be reset before the changes take effect.

1 If not already done, establish serial communications with the picoBTS as described in

Section 3.2.2.

2 Once the picoBTS boots normally, press the

HD:iwbox->

3 Display the boot parameters, by typing:

bootChange [ENTER]

4 The boot parameters display individually after pressing the [ENTER] key. Each param-

eter can be modified by simply entering the new values after the existing value is

displayed and pressing the

this window. Edit the parameter values using the following commands:

Table 3-2: Changing Boot Parameters

COMMAND ACTION

[ENTER] Accepts the current parameter value and proceeds to the next parameter.

. [ENTER] Erases the current parameter value and proceeds to the next parameter.

- [ENTER] Returns to the previous parameter.

[CTRL][d] Aborts all changes and reverts to the current values.

[ENTER] key. You cannot use the backspace or delete keys in

[ENTER] key to show the prompt:

Figure 3-4 shows the default bootChange parameters for the system.

Page 28 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 41

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

'.' = clear field; '-' = go to previous field; ^D = quit

boot device : ata.0

processor number : 0

host name :

file name : hd0:/vxWorks

inet on ethernet (e) : 172.16.80.42:fffff000

inet on backplane (b):

host inet (h) :

gateway inet (g) :

user (u) : target

ftp password (pw) (blank = use rsh):

flags (f) : 0x0

target name (tn) : iwbox

startup script (s) : /hd0/iwvstart

other (o) : motfcc

value = 0 = 0x0

HD:iwbox-> _

Figure 3-4: Default Boot Parameters

It is necessary to change the default picoBTS Ethernet address to match your site-specific

network configuration. Use the following steps to modify the IP address and target name of the

picoBTS.

5 Type the bootChange command to edit the boot parameters. The parameters will be

displayed one line at a time.

bootChange [ENTER]

'.' = clear field; '-' = go to previous field; ^D = quit

boot device : ata.0

processor number : 0

host name :

file name : hd0:/vxWorks

inet on ethernet (e) :

inet on backplane (b):

host inet (h) :

gateway inet (g) :

user (u) :

ftp password (pw) (blank = use rsh):

flags (f) : 0x0

target name (tn) :

startup script (s) : /hd0/iwvstart

other (o) : motfcc

value = 0 = 0x0

HD:iwbox-> _

XXX.XXX.XXX.XXX:fffff000

YYY.YYY.YYY.YYY

TARGETNAME

Figure 3-5: Boot Parameters Requiring Changes

InterReach picoBTS Installation Guide Page 29

© 2008, ADC Telecommunications, Inc.

Page 42

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

6 Figure 3-5 shows the IP address parameters which must be modified to add your picoBTS

to your Ethernet network.

XXX.XXX.XXX.XXX is the IP address. Replace it with the site-specific Ethernet IP

address for your network. The IP address is followed by ‘

subnet mask as a hexadecimal value. To modify the subnet mask of the processor

card, determine the proper hexadecimal value and enter following the colon. For

example to use a subnet of 255.255.255.0, you would follow the IP address with

‘:ffffff00’. The value displayed in the example ‘

255.255.240.0.

-

YYY.YYY.YYY.YYY is the gateway router IP address. Enter the IP address of the

gateway router.

- TARGET NAME sets the IP name. The default is “iwbox”. The TARGET NAME

parameter sets the IP name. The default is “iwbox”. You should enter a different name

for each system.

Note: Use the IP name and IP address you received from your network administrator.

:fffff000’ which is the

:fffff000’ is equal to

7 Ensure that all other boot parameters are configured exactly as shown in the previous

figures.

Caution: You should ONLY change the inet on ethernet, target name and gateway

inet parameters. All other parameters should NOT be modified.

8 If you have changed anything, for the new parameters to take effect, reboot the chassis by

pressing the key combination

[ENTER] to display the HD:iwbox-> prompt.

press

9 Connect an Ethernet RJ-45 patch cable to the WAN port on the front of hte chassis.

10 Notify the OMC operator that the picoBTS is connected to the Ethernet, and give the

OMC operator the IP address and IP Name.

[CTRL][x]. If you do not receive a prompt after reboot,

Caution: The OMC operator MUST have the correct picoBTS IP address, or the OMC will not be

able to communicate with the BS Plus.

Page 30 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 43

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

3.4 SOFTWARE VERIFICATION

You should use the following commissioning procedures to verify the software installed on the

picoBTS.

3.4.1 VERIFYING THE CURRENT SOFTWARE VERSION AND PATCH LEVEL

Note: The following section describes procedures performed using the Craft PC. For more information

pertaining to the use of the Craft PC, please refer to the GSM Craft PC User Guide.

1 If not already done, establish serial communications with the picoBTS as described in

Section 3.2.2.

2After the

level by typing:

The following software information will be displayed:

BSC code version: iw07_05.ZZZ

Release number: 7.5

ABIS version: 1.1

Packages Installed:

Encryption: A5/1

Patches Installed:

patch<#> <file directory> <patch size> <iw07_05.ZZZ>

The current software version is displayed, represented above by the parameter iw07_05.ZZZ.

This number should correspond to the software version detailed in the release notes included

with the CD-ROM. Keep this number for your records.

3 Verify under

cable. Refer to the GSM Craft PC User Guide for procedures to install required patches. If

you are unsure if you require software patches, contact your Level 2 support representative for additional assistance.

Note: If the displayed software version number does not coincide with the software version being run

on the network for which this

on how to install a different software version.

HD:iwbox-> prompt appears, verify the current software version and patch

iwversion [ENTER]

Patches Installed: that the most current patch is installed, if appli-

picoBTS is going to be used, contact Customer Service for instructions

InterReach picoBTS Installation Guide Page 31

© 2008, ADC Telecommunications, Inc.

Page 44

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

3.4.2 VERIFYING THE SOFTWARE LICENSE

In this section you will complete the following procedures:

• Backup the software license files from the processor card to the PC or OMC.

• Verify the software license files are compatible with the system.

1 Verify the serial cable is connected to the chassis and you have an open serial session as

detailed in Section 3.2.2.

2 Verify the license file using the following command:

printLicenseKey

The following output is a sample of properly configured license file:

License Keys :

printLicenseKey

GENERAL : VALID

GPRS : VALID

FREQHOP : VALID

XTNDCELL : VALID

SECTOR : VALID

TRX_84 : VALID

PDCH_60 : VALID

value = 1 = 0x1

HD:iwbox-> Done.

The licenses will vary depending based on your sales order and your network

configuration. Your license will not have all of the the entries listed above and may

display an error message similar to the following:

1219117434.733 (tShell) VerifyKey: key not found 4

This is normal, however if your license does not have any VALID entries. The file may be

corrupt or not properly installed, contact Customer Service.

3.4.3 REBOOTING THE PICOBTS

• Using the serial session window, reboot the picoBTS by typing:

reboot [ENTER]

The entire chassis will now reboot.

Page 32 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 45

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

3.4.4 TERMINATING SERIAL COMMUNICATIONS WITH THE PICOBTS

• To terminate serial communications, use the disconnect menu within HyperTerminal or

other application.

3.5 PREPARING FOR ON-LINE COMMISSIONING

The following procedure is necessary to ensure that the picoBTS is ready for use and ready for

on-line testing.

1 Power on the picoBTS if it is not already on. Verify that all PWR and On-Line LEDs are

green.

2 Using the appropriate documentation, ensure the distributed antenna system (DAS) is

properly connected, cabled and configured.

3 Inform the OMC operator that the picoBTS is ready for network configuration.

4 After the OMC operator has configured the picoBTS, continue with on-line commis-

sioning tests in the next chapter.

InterReach picoBTS Installation Guide Page 33

© 2008, ADC Telecommunications, Inc.

Page 46

ADCP-77-061 • Issue A • 08/2008 • Chapter 3 - Commissioning and Configuration

Preliminary

Blank

Page 34 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 47

CHAPTER 4 - ON-LINE TESTING

Preliminary

Content Page

4.1 PRE ON-LINE COMMISSIONING REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2 ON-LINE COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.2.1 Testing the picoBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.2 Recovery Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.3 TCH Timeslot Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2.4 RX Signal Quality Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3 POST ON-LINE COMMISSIONING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

On-line commissioning tests the air interface to the picoBTS and takes place on-site after

installation and commissioning. Its purpose is to verify that the equipment is operational and

can be integrated into the telecommunications network.

On-line commissioning requires the participation of one or two people; a field technician who

operates and tests the picoBTS on-site and an OMC-R operator who has commissioned the

picoBTS on the BSC. These two must work together to get the RF interface up and the system

ready to make calls.

ADCP-77-061 • Issue A • 08/2008 • Chapter 4 - On-Line Testing

Radio Frequency Radiation Warning

Under normal operating conditions, ADC radio equipment complies with the limits for human exposure

to radio frequency (RF) fields adopted by the Federal Communications Commission (FCC). All ADC

Telecommunications, Inc. radio equipment is designed so that under normal working conditions RF

radiation directly from the radio is negligible when compared with the permissible limit of continuous

daily exposure recommended in the United States of America by ANSI/IEEE C95.1-19991 (R1997),

Safety Levels with Respect to Human Exposure to Radio Frequency Electromagnetic Fields, 3 kHz to

300 GHz.

RF signal levels that give rise to hazardous radiation levels can exist within the transmitter, power

amplifiers, associated RF multiplexers and antenna systems.

Do not disconnect RF coaxial connectors on the ADC equipment or antenna systems while the radio

equipment is operating.

equipment is transmitting.

Never place any body part over, or look into any RF connector while the radio

InterReach picoBTS Installation Guide Page 35

© 2008, ADC Telecommunications, Inc.

Page 48

ADCP-77-061 • Issue A • 08/2008 • Chapter 4 - On-Line Testing

Preliminary

4.1 PRE ON-LINE COMMISSIONING REQUIREMENTS

Before on-line commissioning begins, the field technician or the OMC-R operator must verify

that:

• The picoBTS, BSC and the MSC are fully commissioned, in service and connected to each

other.

• The BSC is in service and connected to the picoBTS.

• The OMC-R operator has successfully created and configured the picoBTS object on the

OMC-R and downloaded this information to the picoBTS. Refer to the procedures

described in the FlexWave BSS documentation.

• The RF frequencies are cleared to transmit.

• The BSC-picoBTS Ethernet link is properly configured and operational.

• The HLR subscriber data has been entered into the MSC HLR. In particular, the HLR

must be configured to support the SIM cards of the mobiles used by the field technician.

Page 36 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 49

4.2 ON-LINE COMMISSIONING

Preliminary

The network commissioning procedures must be performed using the OMC-R and with in the

coverage area provided by the picoBTS. This requires one or two persons working from at

least two different documentation sets:

• A field technician who is on-site within the coverage area of picoBTS and DAS system.

They must have a copy of this manual and the appropriate DAS documentation.

• An OMC-R operator who uses the FlexWave OMC-R or BSC Configuration Manager to

configure and enable the picoBTS in the network. They must have the appropriate

FlexWave documention for the procedures they are perfoming.

The flowchart shown in Figure 4-1 provides a high-level view of the procedures. The procedures in the following sections provide detailed, numbered steps.

Note: Before starting any of the following procedures, the field technician needs to ensure that

anti-static precautions are taken. Refer to

ADCP-77-061 • Issue A • 08/2008 • Chapter 4 - On-Line Testing

Section 1.2.

InterReach picoBTS Installation Guide Page 37

© 2008, ADC Telecommunications, Inc.

Page 50

ADCP-77-061 • Issue A • 08/2008 • Chapter 4 - On-Line Testing

Procedures for OMC Operator

AD235811

Procedures for Field

Technician (at picoBSS)

Step 2

Reconnect

WAN Cable

Step 1

Disconnect

WAN Link Cable

Configure Cell

Configure Abis

interface to BSC

Create picoBSS

on OMC or BSC

Verify

Status Changes

Check Alarm

Event Log

Check Alarm

Event Log

Enable Cell

Check State

Verify Test Calls Make Test Calls

Site Clean-up

Step 3

Check LEDs are

Green and Steady

Preliminary

Figure 4-1: On-Line Commissioning Procedures

Page 38 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 51

4.2.1 TESTING THE PICOBTS

Preliminary

Before disconnecting the physical Ethernet cable, the field technician must make sure that the

cable is labeled in a way that clearly identifies its origin and destination.

• Provide the OMC-R operator with all part, revision and serial numbers for the picoBTS.

4.2.2 RECOVERY TESTS

The OMC-R operator should add the picoBTS to the GUI, configure the Abis to the BSC and

configure the Cell information on the OMC-R or BSC. Then perform the following steps:

1 At the picoBTS, disconnect the physical Ethernet cable.

2 Coordinate with the OMC-R operator to ensure the proper alarms have appeared on the

OMC-R.

3 Reconnect the physical Ethernet cable to the picoBTS.

4 Coordinate with the OMC-R operator to ensure the proper alarms have cleared on the

OMC-R.

ADCP-77-061 • Issue A • 08/2008 • Chapter 4 - On-Line Testing

4.2.3 TCH TIMESLOT TESTS

1 In this test, the OMC-R operator unlocks individual TCH timeslots and the field

technician places a mobile-to-mobile call over each timeslot using a mobile handset in

debug mode. Refer to the documentation provided by the module handset manufacturer

for the proper procedures.

For each timeslot, the commissioner should verify that:

- The timeslot displayed on the handset corresponds to the timeslot unlocked by the

OMC-R operator.

- A two-way call is completed successfully.

- The call has good audio quality and power, and low interference.

The number of timeslots to be tested will be for two TRXs. Table 4-1 provides the

sequence for two or more TRXs.

Table 4-1: Timeslots Requiring Testing in picoBTS

TRX NUMBER TIMESLOT NUMBER CHANNEL TYPE TESTING NECESSARY

First TRX (Note) 0 BCCH No

1 SDCCH No

2TCHYes

3TCHYes

4TCHYes

InterReach picoBTS Installation Guide Page 39

© 2008, ADC Telecommunications, Inc.

Page 52

ADCP-77-061 • Issue A • 08/2008 • Chapter 4 - On-Line Testing

Preliminary

Table 4-1: Timeslots Requiring Testing in picoBTS, continued

TRX NUMBER TIMESLOT NUMBER CHANNEL TYPE TESTING NECESSARY

5TCHYes

6TCHYes

7TCHYes

Second TRX (Note) 0 TCH Yes

1TCHYes

2TCHYes

3TCHYes

4TCHYes

5TCHYes

6TCHYes

7TCHYes

Note: The BCCH can be assigned to any TRX within the picoBTS. The label “First TRX” applies to the

TRX to which is assigned the BCCH. All TCH timeslots on the secondTRX must be tested.

4.2.4 RX SIGNAL QUALITY MEASUREMENTS

The objectives of this test are to verify the performance of the Receive path of the picoBTS

and the operation of the RX module in the TRX. Before these tests can take place, the picoBTS

must be returned to its original “on air” working state with call processing possible.

1 From an Xterm window on the OMC-R, telnet to the picoBTS to be tested, or alternatively

connect directly using a serial session to the picoBTS with the laptop PC.

THIS SECTION FROM HERE IS TOO BE DETERMINED.

2 From the picoBTS prompt type the following to activate the RX RSSI and quality data

logging:

HD:iwbox-> log_none [ENTER]

HD:iwbox-> ho_log_on_bts [ENTER]

Page 40 InterReach picoBTS Installation Guide

© 2008, ADC Telecommunications, Inc.

Page 53

ADCP-77-061 • Issue A • 08/2008 • Chapter 4 - On-Line Testing

Preliminary

3 Place a mobile to mobile call through the BS Plus. The RSSI and Quality for the call will

be displayed, as illustrated in Figure 4-2.

210 (bts ) (4 0xe)UL:63/63 0/0 F AVG 63 0 DL:63/63 0/0 F AVG 63 0 NBR

211 (bts ) (4 0xe)UL:63/63 0/0 F AVG 63 0 DL:63/63 0/0 F AVG 63 0 NBR

212 (bts ) (4 0xe)UL:63/63 0/0 F AVG 63 0 DL:63/63 0/0 F AVG 63 0 NBR