Page 1

Issue 1, September 1998

ADCP-62-023

ICX™-250

User Manual

1027494

Page 2

iv Front Matter

REVISION HISTORY

EDITION/ISSUE DATE REASON FOR CHANGE

Issue 1 09/98 Original.

LIST OF CHANGES

The technical changes incorporated into this issue are listed below.

PAGE IDENTIFIER DESCRIPTION OF CHANGE

New Manaul

TRADEMARK INFORMATION

ADC and ADC Telecommunications, are registered trademarks of ADC Telecommunications, Inc.,

ICX is a trademark of ADC Telecommunications, Inc., SLC-96 is a registered trademark of AT&T Technologies, Inc.,

Bellcore is trademark of Bellcore.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no event

shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further disclaims any and

all liability for i ndirect, inciden tal, special, co nsequential or other similar da mages. This d isclaimer of lia bility applies to all

products, publications and services during and after the warranty period.

This publication may be verified at any time by contactin g AD C’s Technical Assistance Center at 1-800-366-3891 , extension 3 223 (in

U.S.A. or Canada) or 612-946-3223 (out side U.S.A. and Ca nada), or by writin g to ADC Telecommunications, I nc., Attn: Technical

Assistance Center, Mail Station #77, P.O. Box 1101, Minneapolis, MN 55440-1101, U.S.A.

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (612) 938-8080

-

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

All Rights Reserved

Printed in U.S.A.

© 1998, ADC Telecommunications, Inc.

Page 3

Front Matter v

TABLE OF CONTENTS

Content Page

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

INDUSTRY CANADA REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

FCC PART 15 INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

FCC REGULATORY REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

UL APPROVED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

CSA APPROVED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

UNPACKING THE ICX-250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

WHO TO CALL FOR HELP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

PRODUCT OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

BENEFITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

TR-08 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ICX-250 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INSTALLING THE ICX-250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CHOOSING A SITE FOR THE ICX-250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

RACK MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

LOCATING THE ICX-250 ON A DESKTOP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

WALL MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

THE ICX-250 UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

INTERNAL LAYOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

INTERNAL DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

DIP SWITCH SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SETUP AND CONFIGURE THE ICX-250 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

FXS SUPERVISION TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

EXTERNAL DIP SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DIP SWITCH SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

CONFIGURATION REFERENCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

CONNECTOR TYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

CONNECTOR PINOUTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

POWER REQUIREMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

POWER INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

ALARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

GROUNDING REQUIREMEN TS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

CABLING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

TESTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

SLIDE SWITCH SETTINGS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

T1 LOOPBACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

DATA PORT 1 AND 2 LOOPBACK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

LED INDICATORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 1

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 4

vi Front Matter

TABLE OF CONTENTS

Content Page

WARRANTY/SOFTWARE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

REPAIR/ADVANCE REPLACEMENT POLICY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

REPAIR CHARGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

REPLACEMENT/SPARE PRODUCTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

RETURNED MATERIAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

SYSTEM INTEGRATION SERVICES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

CUSTOMER SUPPORT SERVICES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 5

Front Matter vii

IMPORTANT SAFETY INSTRUCTIONS

Read and follow all w arning notices and instruc tions mark ed on the product or included in this guide.

1. This product is intended to be used with a three-wire grounding typ e plug. This is a safety feature.

Equipment grounding is vital to ensure safe operation. Do not defeat the purpose of the grounding

type plug by modifying the plug or using an adapter.

2. Prior to installation use an outlet tester or a voltmeter to check the AC receptacle for the presence of

earth ground. If the receptacle is not properly grounded, the installation must not continue until a

qualified electrician has corrected the problem. In addition, a connection for earth or safety grounding

is provided on the chassis. It is a #6 threaded stud located next to the AC inlet receptacle.

3. Slots and openings in the ICX-250 are provided for ventilation. To ensure reliable operation of the

product and to protect if from overheating, these slots and openings must not be blocked or covered.

4.

DO NOT

step or walk on the power cord.

5.

DO NOT

to dangerous high voltage points or other risks. Refer all servicing to qualified service personnel.

6. Special cables, which may be required by the regulatory inspection authority for the installation site,

are the responsibility of the customer.

7. When installed in the final configuration, the product must comply with the applicable Safety Standards

and regulatory requirements of the country in which it is installed. If necessary, consult with the

appropriate regulatory agencies and inspection authorities to ens ure compliance.

8. A rare phenomenon can create a voltage potential between the earth grounds of two or more buildings.

If products installed in separate buildings are interconnected, the voltage potential may cause a

hazardous condition. Consult a qualified electrical consultant to determine whether or not this

phenomenon exists and, if necessary, implement corrective action prior to interconnecting the product.

allow anything to rest on the power cord and do not locate the product where persons could

attempt to service this product yourself, as opening or removing covers may expose you

INDUSTRY CANADA REQUIREMENTS

NOTICE:

The Canadian Industry Canada label identifies certified equipment. This certification

means that the equipment meets certain telecommunications network protective, operational and

safety requirements. The Department does not guarantee the equipment will operate to the user’s

satisfaction.

Before installing this equipment, users should ensure that it is permissible to be connected to the

facilities of the local telecommunications company. The equipment must also be installed using an

acceptable method of connection. In some cases, the company’s inside wiring associated with a

single line individual service may be extended by means of a certified connector assembly (telephone extension cord). The customer should be aware that compliance with the above conditions

may not prevent degradation of service in some situations.

Repairs to the certified equipment should be ma de by an authorized Canad ian maint ena nce f ac il it y

designated by t he supplier. Any repai rs or alterations made by the user to thi s eq uipment, or equipment malfunctions, may give the teleco mmunica tions company cause to request t he user t o discon nect the equipment.

Users should ensure for their own protection that the electrical ground connections of the power

utility, telephone lines and internal metallic water pipe system, if present, are connected together.

This precaution may be particularly important in rural areas.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 6

viii Front Matter

CAUTION:

Users should not attempt to make such connections themselves, but should contact

the appropriate electric inspection authority, or electrician, as appropriate.

The Ringer Equivalence Number (REN) assigned to each terminal device denotes the percentage

of the total load to be connected to a telephone loop which is used by the device, to prevent overloading. The termination on a loop may consist of any combination of devices subject only to the

requirement that t he tot al REN of all the devices does not exceed 5. The RInger Eq uivalen ce Number of this unit is Not Applicable.

FCC PART 15 INFORMATION

This device has been tested and found to comply with FCC Part 15 “Class A” regulations for digital devices. Operation is subject to the following two conditions: (1) This device may not cause

harmful interference and (2) This device must accept any interference that may cause undesired

operation.

These FCC limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy, and, if not installed and used in accordance with this User Manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area may cause harmful interference. If this happens, the user would be required to correct

the interference at his own expense.

FCC REGULATORY REQUIREMENTS

Notice to Users of T1 Service

The following instructions are provided to ensure compliance with the Federal Communications

Commission (FCC) Rules, Part 68. FCC Regulartory Number: 1H5USA-32637-DE-N.

1. Before connecting your unit, you must inform the telephone company of the following information:

Port ID REN/SOC FIC USOC

T1 Line 6.0N 04DU9-BN RJ48C / Dual Bantam Jacks

T1 Line 6.0N 04DU9-DN RJ48C / Dual Bantam Jacks

T1 Line 6.0N 04DU9-1KN RJ48C / Dual Bantam Jacks

T1 Line 6.0N 04DU9-1SN RJ48C / Dual Bantam Jacks

2. If the unit appears to be malfunctioning, it should be disconn ected from the telephone lines until you

learn if your equipment or the telep hone line is the source of t he trouble. If y our equipm ent needs repair,

it should not be reconnected until it is repaired.

3. If the telephone company finds that this equipment is exceeding tolerable parameters, the telephone company

can temporarily disconnect service, although they will attempt to give you advance notice if possible.

4. Under the FCC Rules, no customer is authorized to repair th is equipment. This restriction applies

regardless of whether the equipment is in or out of warranty.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 7

Front Matter ix

5. If the telephone company alters their equipment in a manner that will affect use of this device,

they must give you advance warning so as to give you the opportunity for uninterrupted service.

You will be advised of your right to file a complaint with the FCC.

6. An affidavit must be completed by the installer.

7. In the event of equipment malfunction, all repairs should be performed by our Company or an

authorized agent. It is the responsibility of users requiring service to report the need for service

to our Company or to one of our authorized agents.

UL APPROVED

The ICX-250 has been designed and tested in accordance with the requirements of UL1950.

CSA APPROVED

The ICX-250 has been designed and tested in accordance with the requirements of CSA C22.2

No. 950.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 8

CHAPTER 1

Welcome 1

Welcome

This chapter introduces you to the features and benefits

of ICX-250.

Contents

Unpacking the ICX-250 . . . . . . . . . . . . . 2

Product Overview. . . . . . . . . . . . . . . . . . 3

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 9

2 Welcome Unpacking the ICX-250

Unpacking the ICX-250

This product is shipped as a complete package. Be very careful when

unpacking th e carton. Check to se e if all items are inclu ded in the box by

checking against the list shown below (Kit of Parts). In the event any items

are missing, contact your dist ri butor for further instructions.

Opening Up the Carton

Keep all the pa ckaging materials for future use in case th e unit has to be

returned for maintenance and/or replacement.

Kit of Parts

• 2 Mounting brackets

• A 3-Conductor DC power plug

• A 2-Conductor alarm closure plug

• 6 6 x 5/16” self-tapping screws

• 4 12/24 x 1/2” screws

• 1 AC power cord

ICX-250 User Manual (this book)

The

ICX-250 U ser Manual

maintenance, and testing of the unit

Hardware and Cabling

contains common t asks: configurat ion, installa ti on,

.

The ICX-25 0 unit comes packaged with an AC power cord to provide power

to the unit. It is als o shipped with two angle brackets and scr ews to rack mount

your ICX-250

(this is explained further in Chapter 2 of this manual)

.

Who to Call for Help

Contact ADC Telecommunications if any items are missing or you want to order another ICX-250

unit. For technical support for your

366-3891, extension 3223 (in U.S.A. or Canada) or 612-946-3223 (outside U.S.A. and Canada)

ICX-250 unit call the BBG T echnical Assistance Center at 1-800-

.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 10

Product Overview Welcome 3

Product Overview

Bundled Service deployment is a snap thanks to the ICX-250 from ADC Telecommunications.

ADCs’ ICX-250 allo ws c ost-e f fec ti ve and quick deplo yment of an alo g v oice and da ta ser vices on a

single T1 access trunk.

The ICX-250 sports a slee k, lo w prof i le cha ssis and is co nf igur ed via DIP swi tches, elimi nating the

need for PC ba sed craft i nterface and sp ecialize d training. L EDs are provid ed for monit oring the

status of ICX-250 under normal operation as well as under test conditions. Maintenance and

diagnostics are further enhanced via loopbacks and test patterns, all configurable from the DIP

switches. Additionally, network loopbacks can be used to test from a remote office.

ICX-250 addresses access needs for sites requiring economical adaptation of FXS analog voice

based key systems and PBXs to T1 services. ICX-250 supports TR-08 as well as ESF and D4

framing. Additionally, ICX-250 provides two high speed EIA530A/V.35 ports for insertion of

Routers or other data traffic in bundled service arrangements. For sites needing up to 24 analog

lines, with or without data requirements, ADC’s ICX-250 is an ideal solution.

The ICX-250’s primary function is to allow for remote termination of lines from a centrallylocated switch. Data ports are also provided on the unit for those applications where high speed

data deployment would be required.

The ICX-250 product is co mplimentary to the leading ICX-500 and Integrated Communic ations

Access server (ICX).

The ICX-250 from ADC Telecommunications - never before have bundled services been so

economical and easy to install and maintain.

Features

• Voice and data channel bank with integral CSU/DSX Interface

• Sleek, low profile, one rack unit (1 RU) chassis

• Choice of 12 or 24 FXS analog voice ports

• Two high speed EIA530A/V.35 data ports

• Extensive diagnostics

• LED status indicators for maintenance

• DIP switch configuration

• TR-08 support

Benefits

• Minimal Installation Costs - DIP switch based configuration simplifies

installation, el i minates need for a computer terminal, and reduces t ra ini ng costs.

• 1 RU design allows easy installation in tight spaces. Rack, wall or desktop

mounting options are available.

• Simplified Maintenance - manual test DIP switches, maintenance test and LED

status indicators, all si mplify maintenance operations.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 11

4 Welcome Product Overview

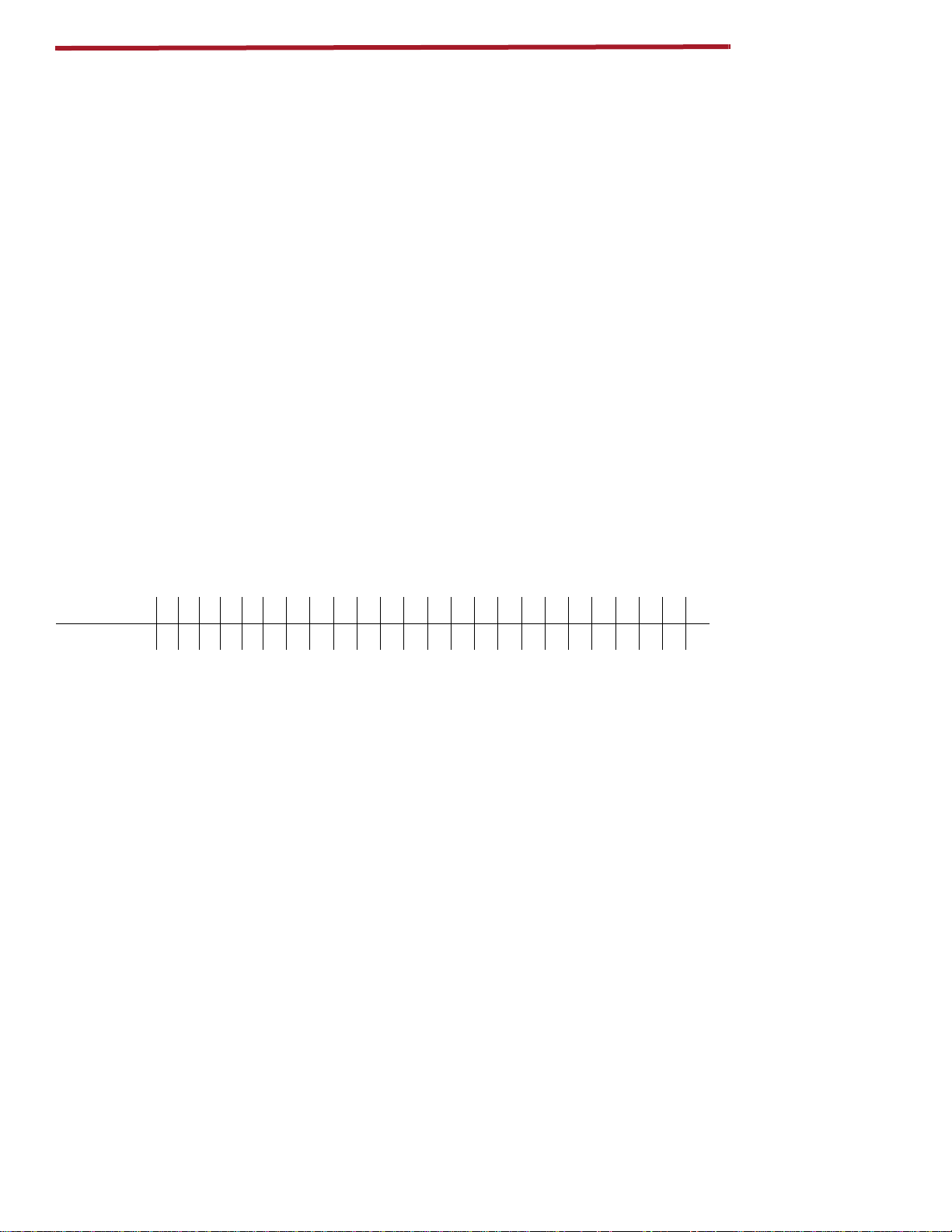

TR-08

The TR-TSY-000008 BellcoreTM standard (commonly referred to as TR-08) describes the generic

requirements for interfacing between local digital switches and remote digital terminals via the

SLC 96

TR-08 has three operational modes (ICX-250 supports mode I):

Although commonly referred to as the TR-08 standard, the R T channel numbering scheme supported

by the ICX-250 unit is described in section 9.9 of the Bellcore publication TR-TSY-000057.

The ICX-250 provides SLC-96 Frame Format and Data Link.

When a T1 port is configured for TR-08 format, the v oice channels as signed to this port are identifi ed

by “channel number” (according to the TR-TSY-000008 document), which may be different from

the T1 time slot number . The ICX-250 supports only Group A. The re lation between a channel number

and corresponding slot number for TR-08 is shown in the following table.

TM

digital loop carrier system.

• Modes I & III are non-concentrated and provide unique mapping between channel

numbers and DS1 time slots.

• Mode II is concentrated and there are no pre-determined relationships between the

channels and timeslots . This allocation of channe ls to t ime s lo ts i s made pos sible by the

exchange of messages between the Local Digital Switch (LDS) and remote terminal (RT).

Channel Numbers123456789101112131415161718192021222324

Time Slots 135791113151719212324681012141618202224

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 12

Product Overview Welcome 5

ICX-250 Specifications

Chassis

Specification

Installation

Power Supply

Ring Generator

Environment

Regulatory

Compliance

FCC Regulatory #

Product Numbers

T1 Interface

FXS Interface

Data Interface

Diagnostics

DIP Switch

Settings

Height

Width

Depth

Weight

AC

DC

Operating Temperature

Storage Temperature

Relative Humidity

240212

240224

Physical

Frame Format

Line Code

CSU Line Build Out

(LBO)

DSX Line Length

Clocking

FDL

Physical

FXS Supervision Mode

FXS Signaling

TLP

Impedance

Ringing Voltage

Physical

Data Rate

1.75 inches (with feet 2 inches)

17.25 inches

12 inches

Approximately 10 pounds

Desktop

Wa ll Mount

Rackmount

120V .6A Max. 60Hz (104 - 140 VAC)

–48V, –24V, or +24 V 1. 8A Max. (22.5 - 57 VDC)

Integrated AC/DC converter and Ringing Generator

Nominal 50 VRMS

Frequency 20 +/–1 Hz

DC component: –30 volts nomi nal

Crest factor cf, where 1.2=< cf= <1.6

Ringing Capability: 40 Vrms across 1 REN at the end of a 400 ohms loop.

0

C to 400 C

0

0

C to 660 C

–40

5 to 85% Humidity, Non-Condensing

FCC Part 15 Class A

UL 1950 and CSA C22.2 950

FCC Part 68 and Industry Canada CS-03

1H5USA-32637-DE-N

12 FXS ports, 2 EIA530A/V.35 data ports

24 FXS ports, 2 EIA530A/V.35 data ports

One RJ48

D4, ESF, TR-08

AMI, B8ZS

0 dB, –7.5 dB, –15.0 dB

0.6 dB at 0-266 ft., 1.8 dB at 266 - 533 ft., 3.0 dB at 533 - 655 ft.

Internal Stratum 4, L ine

Per ANSI T1.403 and AT&T TR62411

One 50-pin Female Amphenol

FXS, FXS-DN, FXS-DN-Wink, TR-08

Loop Start, Ground Start, Lo op St art w/ forward Disconnect, Ground

Start Immediat e, G round Start Automatic, Universal Voice Grade,

Universal Voice Grade Automatic, Single-Party

–3 dB/–9 dB on Rx, + 3 dB/+9 dB on Tx

600 Ohm

50 Vrms

On hook transmission for Caller ID support

Two (2) EIA530A/V.35 ports (DB25)

Nx56K, Nx64K (N = 1 to 24)

Extensive power-up self test

LED Indicators

QRSS Test Pattern on T1

2047 Test Pattern on Data ports

Loopbacks for FXS, T1 and Data ports

CSU Loopback detection

Performance statistics over FDL

Bantam jacks for in-sessi on T1 monitoring and line te sting

FXS, T1, Data port Loopbacks, CSU Loopback Detection, Clocking,

T1 Frame Format, T1 Line Code, T1 Line Build Out, FXS TLP, FXS

Supervision, FXS Signaling, Trunk Conditioning, Test Patterns, Data rate.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 13

System Basics 7

CHAPTER

2

System Basics

This chapter gives you quick, simple instructions to get you up

and running. You will also learn how to install and mount the

ICX-250 unit.

Contents

Installing the ICX-250. . . . . . . . . . . . . . . 8

The ICX-250 Unit . . . . . . . . . . . . . . . . . .13

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 14

8 System Basics Installing the ICX-250

Installing the ICX-250

The ICX-250 unit can be installed in a rack, on a desktop or attached to a

wall using appropriate wall anchors and brackets. It is necessary to read

the information that follows to ensure proper reliability of unit.

Choosing a Site for the ICX-250

When choosing a site for your ICX-250 unit make sure that the

instructions on installing the unit are followed. Provide adequate

ventilation and ample room for cable routing.

Temperature Specifications

Shipping and storage –40o C to +66o C

Precautionary Procedures

Operating temperature range 0

o

C to +40o C

Relative Humidity 5 to 85% Non-Condensing

The ICX-250 is equipped with a fan to ensure

Note:

proper cooling and reliability. In the event that the

installation environment temperature exceeds the

standards above, it is recommended that adjustments

be made. Improper operation outside of these temperatures may

result in performance degradation.

There are se veral precauti ons to take before in stalling and/or ser vicing the

ICX-250 unit.

CAUTION

Never install telephone wiring during a lightning

storm.

Never install telephone jacks in wet locations unless the jack is

specifically designed for this purpose ONLY.

Never touch uninsulated telephone wires or terminals unless the

telephone line has been disconnected at the network interface.

Use CAUTION

when installing or modifying telephone lines.

Never attempt to service this product unless you are an

authorized service technician. Doing so can result in injury or

damage to the unit and void all warranties.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 15

Installing the ICX-250 System Basics 9

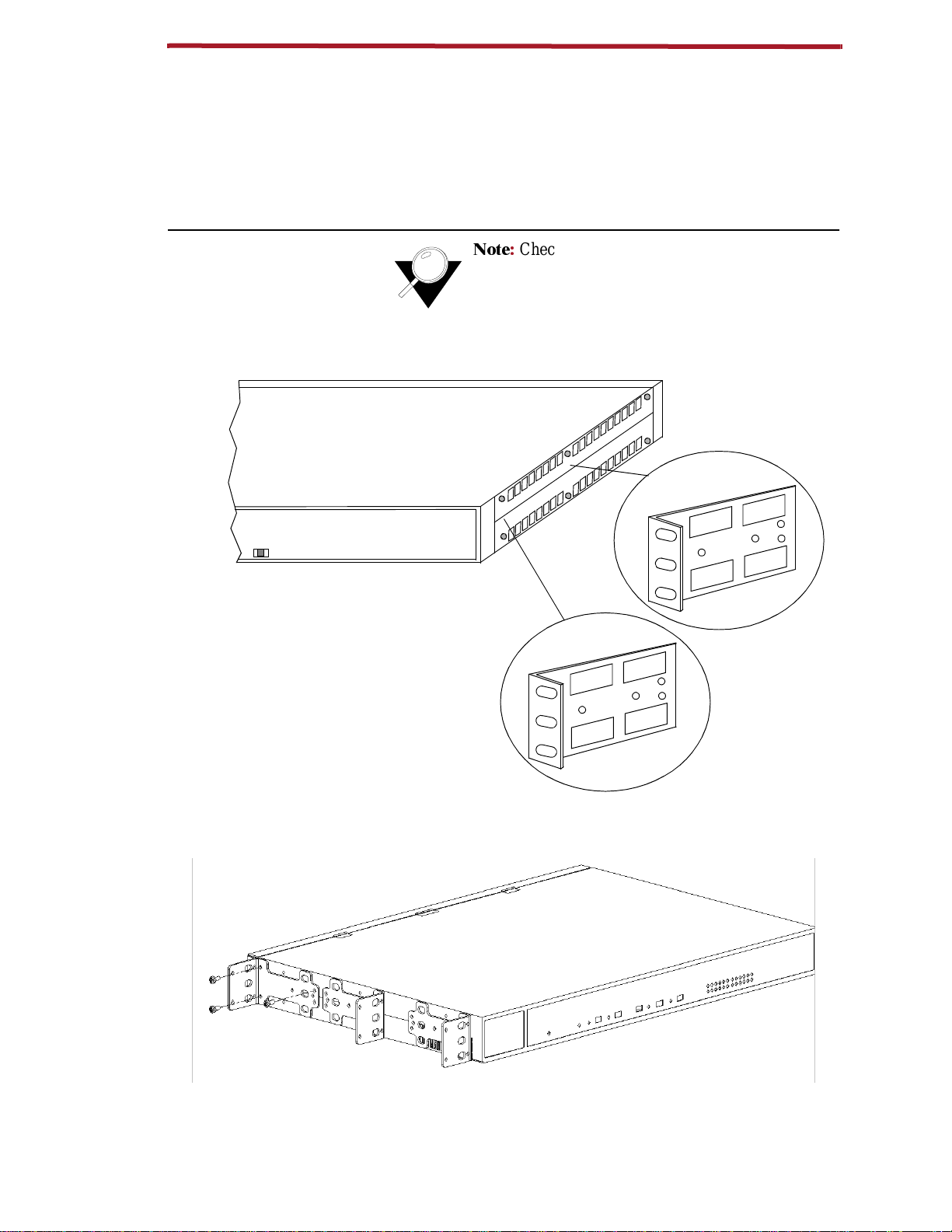

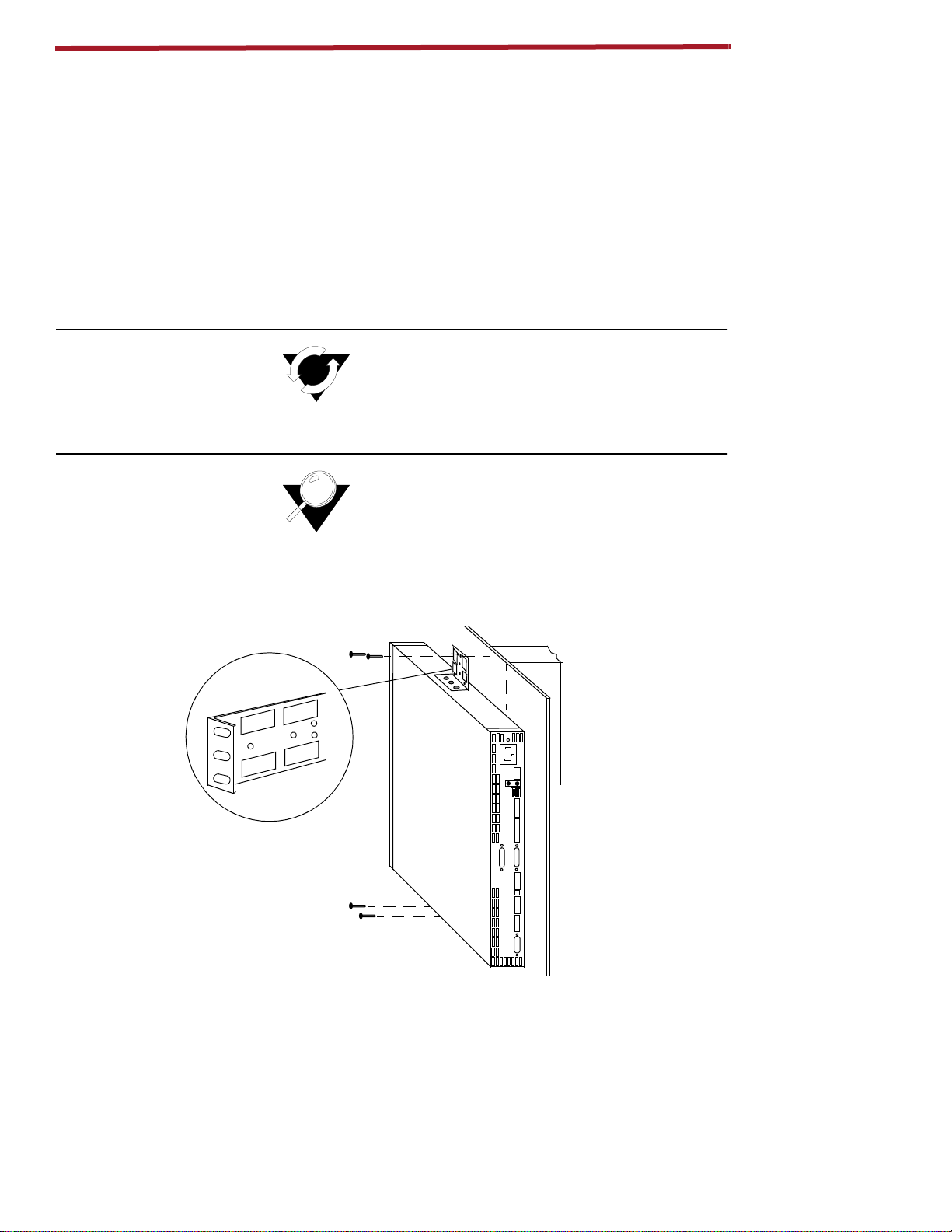

Rack Mounting

The chassis comes with brackets for rack mounting. The installation site

for rack mounting should provide proper room for ventilation and cable

routing. Provide at least 2 inches of clearance between each ICX-250 unit

to allow for removal of the to p if necessary for resetti ng of switches.

Check all grounding instructions when

1RWH

installing the ICX-250 unit in a rack. Proper

grounding is mandatory at all times.

Center Mount

Data Loop 2

Lcl. Off Net.

FXS Channel Sta tus

1 3 5 7 9 11 13 15 17 19 21 23

2 4 6 8 10 12 14 16 18 20 22 24

Flush Mount

The following figure depicts a 19” rack mount configuration.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 16

10 System Basics Installing the ICX-250

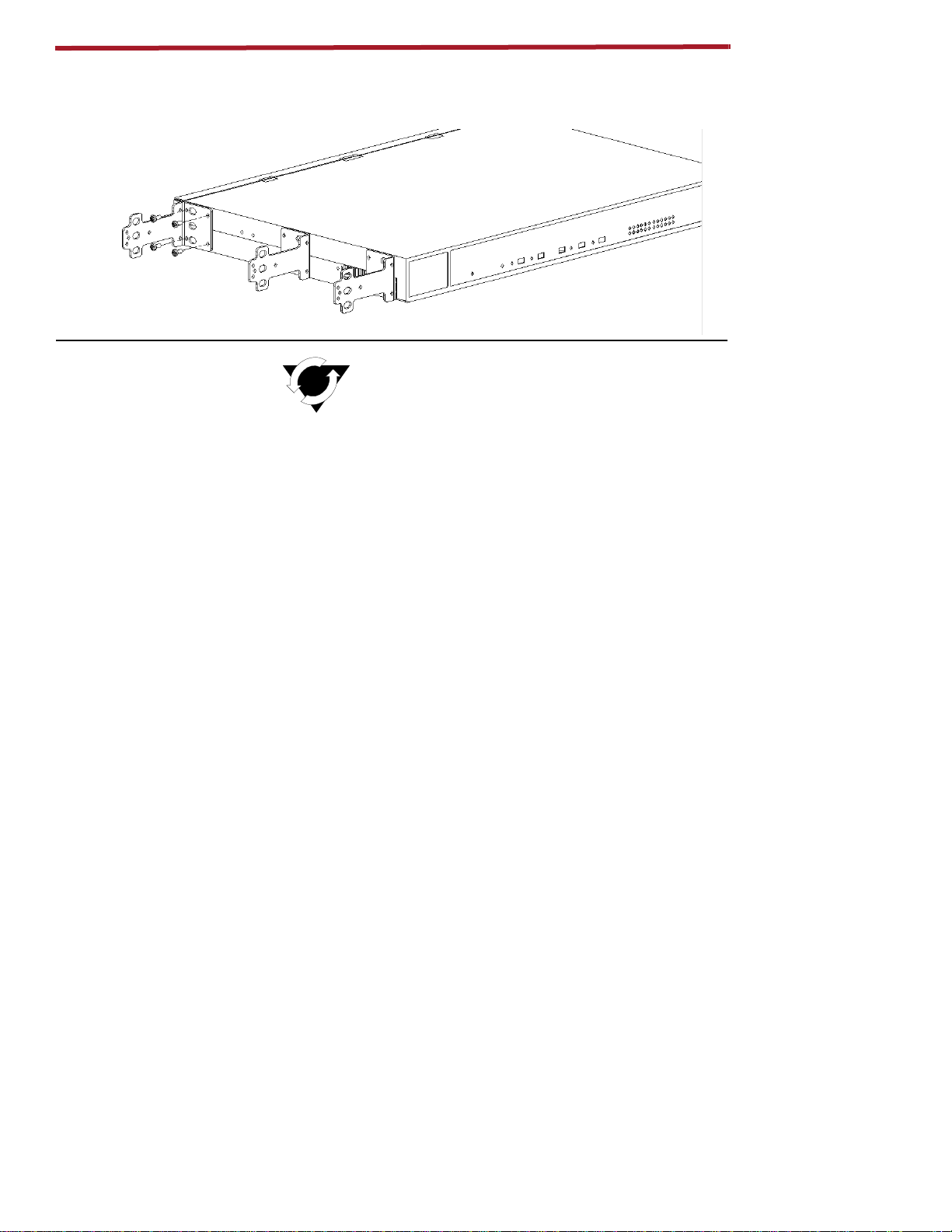

The following figure depicts a 23” rack mount configuration.

ATTENTIO N

!!

Set all options prior to installing

!!

mounting brackets, top cover cannot be removed

once brackets are in place.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 17

Installing the ICX-250 System Basics 11

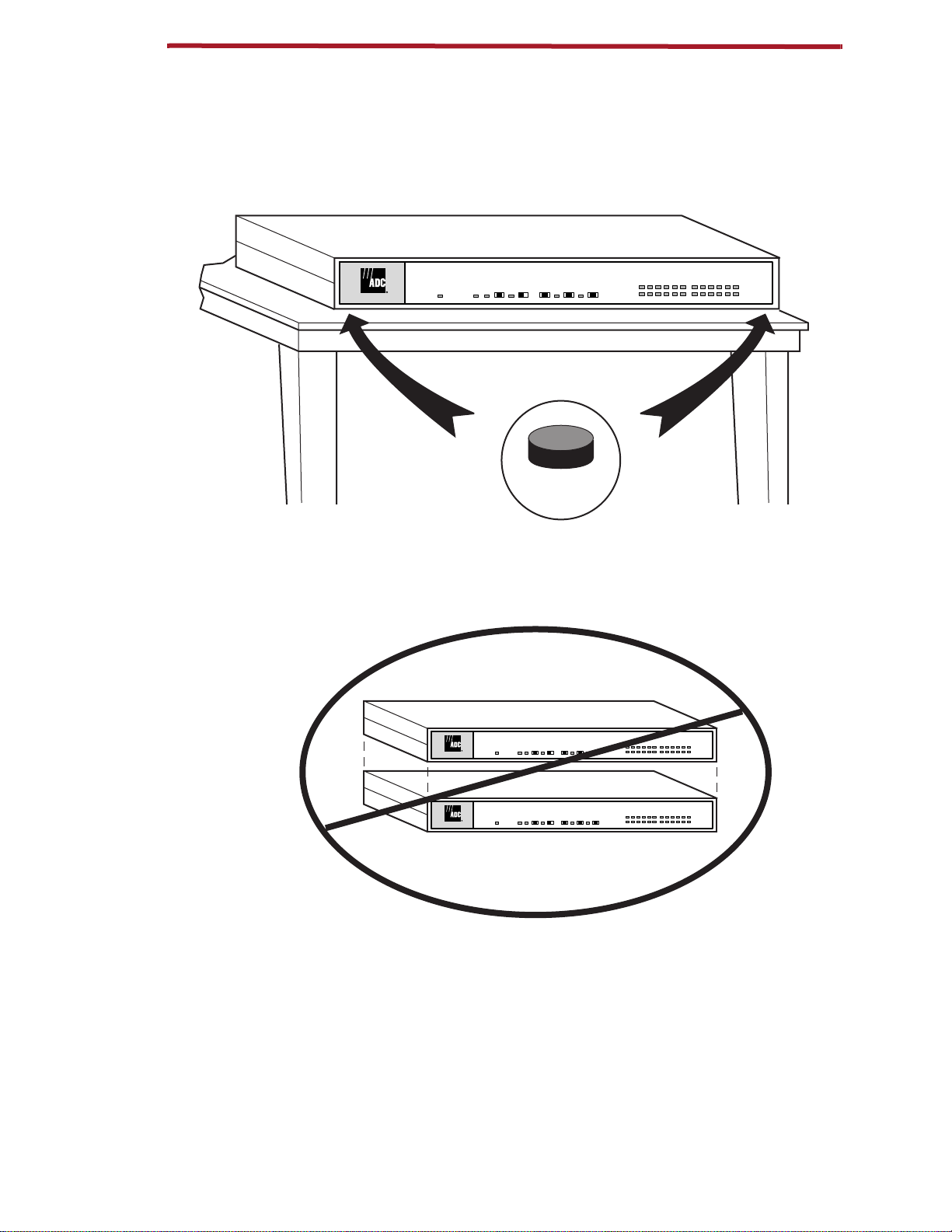

Locating the ICX-250 on a Desktop

Each unit can be easily set on top of a desk or table. A stable environment

is necessary for peak performance of each unit.

FXS Status Channel

1357911131517192123

2 4 6 8 10 12 14 16 18 20 22 24

ICX-250

Self Check

Test Pattern

T1 Status

T1 Loop

T1 Test

Test Pattern

(Four)

Rubber Feet

Rubber feet are necessary for proper ventilation and air flow of the unit

when mounted on a flat surface. Removing them may damage the unit.

DO NOT Remove Rubber Feet

FXS Status Channel

ICX-250

ICX-250

Self Check

Self Check

Test Pattern

T1 Status

T1 Loop

T1 Test

Test Pattern

T1 Status

T1 Loop

T1 Test

Test Pattern

Test Pattern

1357911131517192123

2 4 6 8 10 12 14 16 18 20 22 24

FXS Status Channel

1357911131517192123

2 4 6 8 10 12 14 16 18 20 22 24

11263-A

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 18

12 System Basics Installing the ICX-250

Wall Mounting

Prior to wall mou nting check to see if the environme nt is stable an d free

from any extreme temperatures, humidity or vibrations of any sort. The

unit should be mounted with the fan to the top with at least 2 inches of

clear space on the sides, above, and below for adequate air flow. Allow at

least 6 inches for cable clearance and access to switches.

When attaching unit(s) to a wall ma k e sure that appropriat e fasteners such

as masonry anchors, heavy duty wood screws or expansion bolts are used

for heavy objects.

small piece of 3/4” plywood be fastened to the wall before

attaching the unit. This will help ensure a m ore stable environment

ANGLE BRACKET

!!ATTENTION!!

Set all options prior to installing

mounting brackets, top cover cannot be removed

once brackets are in place.

Additional support hardware may be necessary

Note:

(not included with unit) to secure the unit properly to

the wall. If the surface is not solid enough to hold the

unit and attached cabling, it is recommended that a

Wall

.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 19

The ICX-250 Unit System Basics 13

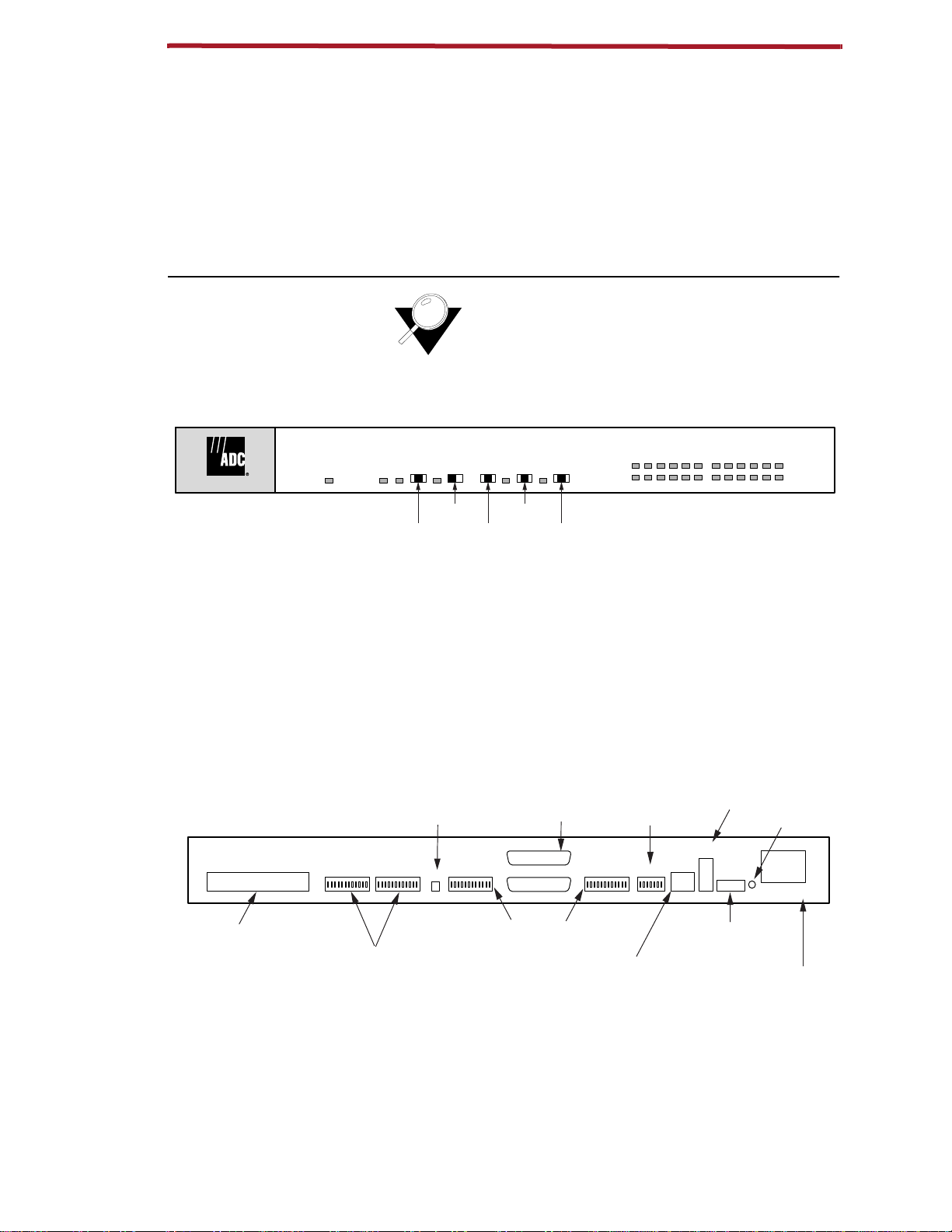

he ICX-250 Unit

T

The ICX-250 comes equipped with either 12 FXS (model 240212) or 24

FXS (model 240224) analog voice ports depending on which model you

purchase. Each unit is designe d to allo w ea sy ac cessi bili ty to swi tches a nd

electrical connectors. The diagrams below illustrate the front and rear

layout of the unit. The diagram on the next page illustrates the internal

layout of the unit.

The 12 FXS or 24 FXS models are not field

Note:

upgradeable.

ICX-250 - Front Panel

FXS Status Channel

1357911131517192123

2 4 6 8 10 12 14 16 18 20 22 24

11261-A

ICX-250

Self Check

T1 Status

T1 Test

T1 Loop

Net. / Off / Lcl.

T1 Loop

Data Loop 1

Lcl. / Off / Net.

Test Pattern

1 / Off / 2Off / QRSS

Data Loop 2

Lcl. / Off / Net.

Test Pattern

ICX-250 - Rear Panel

FXS Loop Pairs

25 PAIR AMPHENOL

CONNECTOR FOR 24

FXS TIP AND RING PAIRS

ALARM RELAY

FOR EXTERNAL

ALARM SYSTEM

FXS Loopback

DIP SWITCHES TO SET

LOOPBACK FOR EACH

FXS CHANNEL

TWO DB25 FEMALE

CONNECTORS FOR

DATA PORT 1 AND 2

SIGNALS

Data 1

Alm.

DIP SWITCHES USED FOR DATA

PORT 1 AND 2 CONFIGURATION

DIP SWITCHES

USED FOR T1

INTERFACE

CONFIGURATION

T1 Line

T1Data 2Data 2Data 11121324

TERMINAL BLOCK FOR

RJ48 CONNECTOR

FOR TRANSMIT AND

RECEIVE TIP AND

RING PAIRS

DUAL BANTAM

JACK

(MONITOR JACKS)

EARTH GROUND

T1

24/48 VDC

Rx

+ – G

Tx

DC POWER SUPPLY

120 VAC–.6A 60Hz

POWER INPUT FOR

120 VA C RECEPTACLE

11264-A

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 20

14 System Basics The ICX-250 Unit

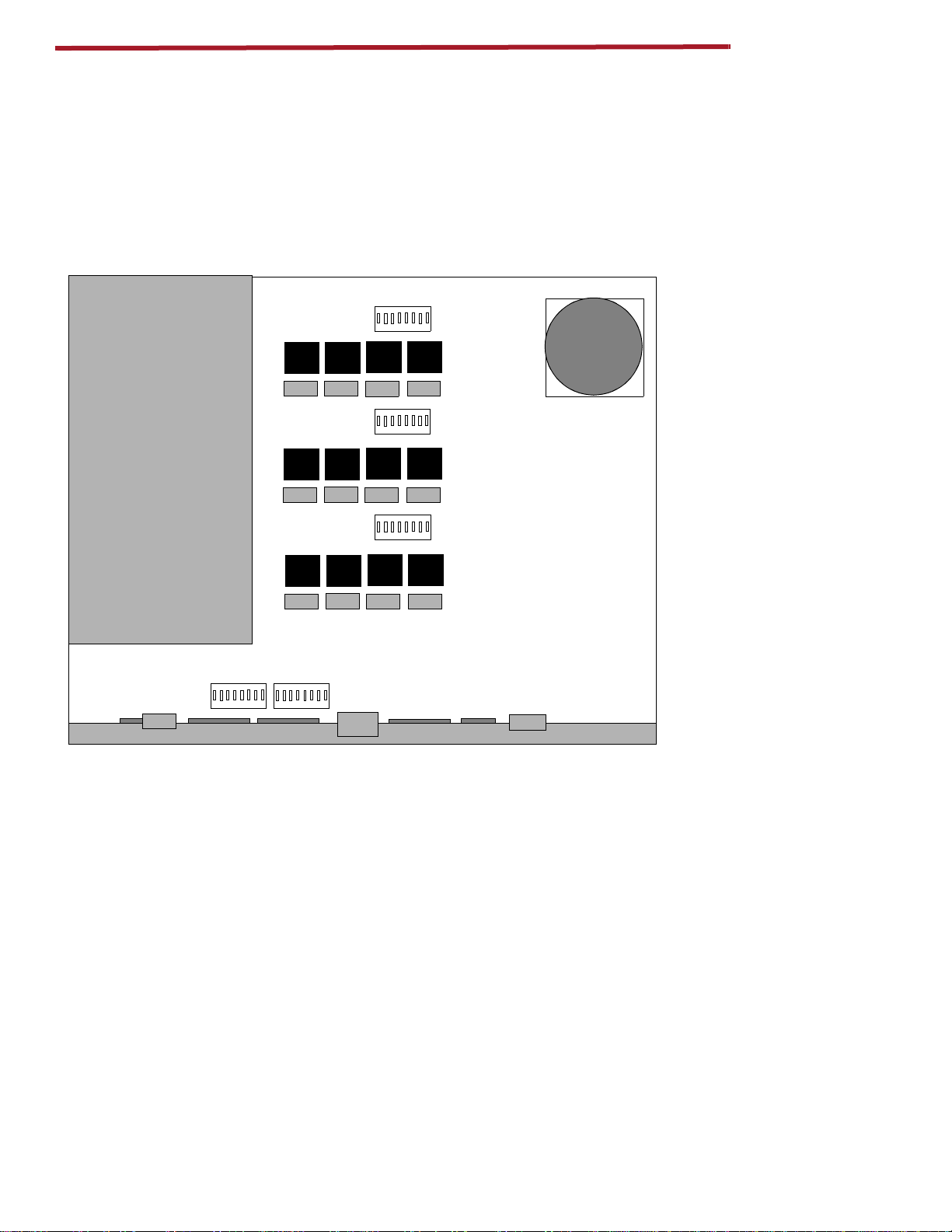

Internal Layout

12 FXS Analog Voice Ports

The illustration below shows the internal layout of the 12 FXS analog

voice port unit.

FRONT

ON DIP

1 2 3 4 5 6 7 8

S16

FAN

ON DIP

1 2 3 4 5 6 7 8

S15

S4 S5

S7

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S3

ON DIP

1 2 3 4 5 6 7 8

S14

S6

S2

S1

BACK

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 21

The ICX-250 Unit System Basics 15

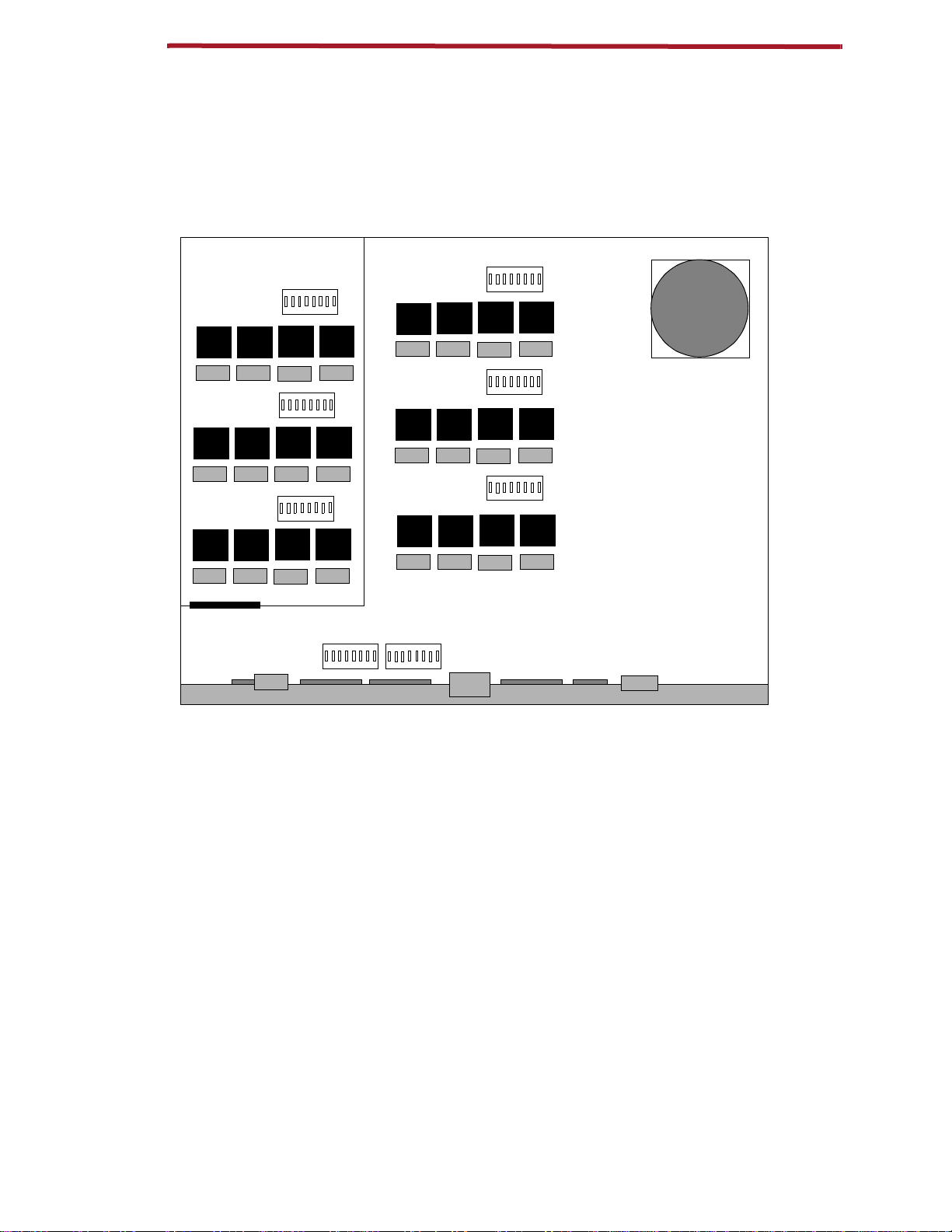

24 FXS Analog Ports

The illustration below shows the internal layout of the 24 FXS analog

voice port unit.

FRONT

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S19

ON DIP

1 2 3 4 5 6 7 8

S18

ON DIP

1 2 3 4 5 6 7 8

S17

S16

ON DIP

1 2 3 4 5 6 7 8

S15

ON DIP

1 2 3 4 5 6 7 8

S14

FAN

S4 S5

S7

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S3

S6

S2

S1

BACK

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 22

Configuring the ICX-250 17

CHAPTER

3

Configuring the

ICX-250

Inside this chapter you w ill learn how to co nfigure th e ICX-25 0

unit using internal and external switch settings.

Contents

Internal DIP Switches. . . . . . . . . . . . . . .18

Setup and Configure the ICX-250 . . . . .20

Switches. . . . . . . . . . . . . . . . . . . . . . . . .20

External DIP Switches . . . . . . . . . . . . . .31

Configuration Reference Data . . . . . . . .41

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 23

18 Configuring the ICX-250 Internal DIP Switches

Internal DIP Switches

The ICX-250 comes equipped with eit her 12 FXS or 24 FXS an alog voice

ports depending on which model you purchase. For illustration purposes

the 24 FXS port model is shown. There are a total of eight internal DIP

switches

board)

DIP Switch Settin gs

Locate the DIP switch internally that describes the function you wish to

effect. The t op cover of t he unit displays the co nfigurable opti ons . Use t he

tip of a small object to change the switch settings. The switches will glide

easily into place.

(five on the main circuit board, and three on the auxiliary

.

The individual switches on each switch

Note:

assembly operate independently of one another.

TIP

CAUTION

Access to the internal switches is accomplished by

opening the case. Use care when opening the case to

avoid damaging the internal components.

Switch setting

changes will

take effect

immediately.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 24

Internal DIP Switches Configuring the ICX-250 19

FRONT

S19

S18

S17

ON DIP

ON DIP

1 2 3 4 5 6 7 8

S7

ON DIP

1 2 3 4 5 6 7 8

S19

1 2 3 4 5 6 7 8

S18

S17

S4 S5

S7

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S3

ON DIP

1 2 3 4 5 6 7 8

S16

ON DIP

1 2 3 4 5 6 7 8

S15

ON DIP

1 2 3 4 5 6 7 8

S14

S6

S16

S15

S14

S6

S2

S1

BACK

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 25

20 Configuring the ICX-250 Setup and Configure the ICX-250

Setup and Configure the ICX-250

To configure the ICX-250 for your operati ng environment, switch settings

are easily accessible. There are internal and external control dip and slide

switches.

Switches

The ICX-250 unit is equipped with internal and external DIP switches.

The following table describes the switches that are used to configure the

ICX-250 for operation. Refer to the silkscreen on the cover of the unit for

location of switches. Parenthetical references indicate the page number

that detail the operation.

The bold highlighted selection under “Options” is the Factory Setting.

Function Switch

FXS Supervision

Mode

(for entire bank of 12

lines)

(see page 23)

FXS Supervision

Type (for entire bank

of 12 lines)

(see page 24)

S6, S7

positions 1 and 2

S6, S7

positions 3, 4 and 5

Switch

Location

Option Description

FXS PORTS:

Internal FXS

Internal Loop Start

FXS-DN

FXS-DN-Wink

TR-08

Single Party

Ground Start

Ground Start

Automatic

Ground Start

Immediate

Universal Voice

Grade

Universal Voice

Grade Autom a tic

Loop Start-Forward

Disconnect

FXS: Foreign Exchange Subscriber.

FXS-DN: Foreign Exchange

Subscriber-Defined Network.

FXS-DN-WINK: Foreign

Exchange Subscriber- D efined.

Network-Wink Start Operation.

TR-08: Frame Format Signaling

and Data Link as o utlined in TRTSY-000008 Mode 1 for circuits

using AT&T Subscriber Loop

Carriers (SLC-96) faci lities.

Loop Start: Used wi th traditional

telephone stat ions and simple PB X

trunks.

Single Party: SLC-96 Single Party

Service.

Ground Start: Used with two -w ay

PBX trunks.

Ground Start Automatic: Used

with equipment requiring fastresponse time to the central office

(CO).

Ground Start Immediate: Used

with equipment requiring fastresponse time to the station or PBX.

Universal Voice Grade: Toll

quality voice for SLC-96.

Universal Voice Grade Automatic: Used with some non-Bell

switches.

Loop Start-Forward Disconnect:

Provides disconnect when FXS

is connected to voice messaging

system.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 26

Switches Configuring the ICX-250 21

The bold highlighted selection under “Options” is the Factory Setting.

Function Switch

FXS Ports

Transmit

for 12 port model

(see page 26)

FXS Ports

Receive

for 12 port model

(see page 26)

FXS Ports

Transmit

for 24 port model

(see page 26)

FXS Ports Receive

for 24 port model

(see page 26)

Trunk Conditioning

(per group of 12

lines)

(see page 28)

FXS Ringback Tone

(see page 29)

FXS Timeslot

Assignment

(see page 30)

FXS Ports

Loopback Operation

and/or Channel

Unassigned

(per line)

(see page 39)

S14, S15, S16

positions 2, 4, 6

and 8

S14, S15, S16

positions 1, 3, 5

and 7

S17, S18, S19

positions 2, 4, 6

and 8

S17, S18, S19

positions 1, 3, 5

and 7

S6, S7

position 6

S6-S7

position 7

S7 Only

position 8

S4-S5

S5 1-12 = 1-12

S4 1-12 = 13-24

Switch

Location

Internal 3 dB

9 dB

Internal 3 dB

9 dB

Internal 3 dB

9 dB

Internal 3 dB

9 dB

Internal Idle

Idle Imm./Busy

Internal On

Off

Internal Off

Swap

Back On

Off

Option Description

3 dB: Transmit path attenuated by

3 dB (+/– .5).

9 dB: Transmit path attenuated by

9 dB (+/– .5).

3 dB: Receive path attenuated by

3 dB (+/– .5).

9 dB: Receive path attenuated by

9 dB (+/– .5).

3 dB: Transmit path attenuated by

3 dB (+/– .5).

9 dB: Transmit path attenuated by

9 dB (+/–.5).

3 dB: Receive path attenuated by

3 dB (+/– .5).

9 dB: Receive path attenuated by

9 dB (+/– .5).

Idle: In the event of an alarm condition in the T1 connect ion to the network, the FXS Ports will be put into

the idle state immediately and

remain in this conditi on until the T1

has been restored.

Idle Immediate/Busy: In the event

of an alarm condi ti on in the T1 connection between th e ICX-250 and

the network, the FXS Ports will be

put into the Idle state immediately

for 3 seconds and then put in the

Busy state and remain in this condition until the T1 has been restored.

On: Ringback tones will be sent

on the corresponding DS0’s for the

duration of ringing on the line.

Off: Ringback provided by PBX

or Switch.

Off: FXS Ports 1-12 are mapped

onto T1 timeslots 1-12 and FXS

Ports 13-24 are mapped onto T1

timeslots 13-24.

Swap: FXS Ports 1-12 are mapped

onto T1 timeslots 13-24 and FXS

Ports 13-24 are mapped onto T1

timeslots 1-12.

Depending on the services provided by your carrier for voice

and data, you may need to reassign the FXS timeslots of the 12

FXS port model. Timeslots 13 to

24 will be assigned in order to

allocate data to the lower

timeslots.

On: Breaks the connec ti ons to

and from the FXS and loo ps th e

receive data back onto the t ransmit

path towards the T1 . In the case

of unassigned channels, provides

an idle termination.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 27

22 Configuring the ICX-250 Switches

The bold highlighted selection under “Options” is the Factory Setting.

Function Switch

T1 Interface

Frame Format

(see page 32)

T1 Interface

Line Code

(see page 32)

T1 Interface

T1 Clock

(see page 33)

T1 Interface

CSU Loop Code

Recognition

(see page 34)

T1 Interface

Line Build Out

(see page 34)

S1

positions 1 and 2

S1

position 3

S1

position 4

S1

position 5

S1

positions 6 and 7

Switch

Location

Option Description

T1 INTERFACE:

Back D4 (SF)

Back AMI

Back Line

Back Accept

Back 0 dB

ESF

TR-08

B8ZS

Internal

Ignore

–7.5 dB

–15.0 dB

Selects the T1 fram e format and

data link format to be either D4

(SF), ESF, or TR-08. (No data link

with D4).

Selects the li ne code on the T1

interface.

Line: Clock for the T1 interface

will be recovered from the line

(receive signal).

Internal: Clock for the T1 interface

will be taken from an on-board

1.544 MHz clock meeting the

Stratum 4 requirements.

Accept: ICX-250 will respond to

network generated loop requests

that are received over the FDL.

Ignore: ICX-250 will ignore

network generated loop requests.

Selects one of three line build

out options for short (–15.0 dB),

medium (–7.5 dB) and long (0 dB)

loops.

Data Ports 1 and 2

Number of Ti meslot s

(see page 35)

Data Ports 1 and 2

Starting Timeslot

(see page 37)

Data Ports 1 and 2

Interface Type

(see page 38)

Data Ports 1 and 2

Data Rate

(see page 39)

S2 - dataport 2

positions 1, 2, 3, 4

and 5

S3 - dataport 1

positions 1, 2, 3, 4

and 5

S2 - dataport 2

positions 6, 7, 8, 9

and 10

S3 - dataport 1

positions 6, 7, 8, 9

and 10

S2, S3

position 11

S2, S3

position 12

DATA PORTS:

Back 0

1, 2, 3, ....24

Back 0

1, 2, 3, ....24

Back EIA530A

V.3 5

Back 64 Kbps

56 Kbps

Selects the number of time slot s

that data from Data Port 1

and/or 2 will be mapped onto.

Selects first T1 timeslot that data

from Data Port 1 and/or 2 wil l be

mapped.

EIA530A: Ports 1 and/or 2 use

the EIA530A standard.

V.35: Ports 1 and/or 2 use the V.35

standard.

64Kbps: Ports 1 or 2 receive

and transmit data at a multiple

of 64 Kbps.

56Kbps: Ports 1 or 2 receive

and transmit data at a multiple

of 56 Kbps.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 28

Switches Configuring the ICX-250 23

The function and speed of Data Ports 1 and 2

Note:

are independent of each other. This allows one to

operate as EIA530A while the other operates as a

V.35 interface. The speeds can also be set as 56K on

one port and 64K on the other.

FXS Supervision - Mode

S19

S18

S17

ON DIP

1 2 3 4 5 6 7 8

S19

ON DIP

1 2 3 4 5 6 7 8

S18

ON DIP

1 2 3 4 5 6 7 8

S17

(

DIP switches - internal

FRONT

)

ON DIP

1 2 3 4 5 6 7 8

S16

ON DIP

1 2 3 4 5 6 7 8

S15

ON DIP

1 2 3 4 5 6 7 8

S14

S16

S15

S14

see FXS Supervision Table

S7

S4 S5

S7

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S3

S6

S6

S2

S1

BACK

Description:

S6 and S7 positions 1 and 2 select the FXS Mode. Options are: FXS, FXS-DN,

FXS-DN-WINK, and TR-08.

Factory Settin g:

Foreign Exchange Subscriber.

FXS:

FXS-DN:

Foreign Exchange Subscriber-Defined Network.

FXS-DN-WINK:

TR-08:

Signaling as outlined in TR-TSY-000008 Mode 1 for circuits using AT&T Subscriber

FXS

Foreign Exchange Subscriber-Defined Network-Wink Start Operation.

Loop Carrie rs (SLC-96) facilities.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 29

24 Configuring the ICX-250 Switches

FXS Supervision - Type

S19

S18

S17

ON DIP

1 2 3 4 5 6 7 8

S19

ON DIP

1 2 3 4 5 6 7 8

S18

ON DIP

1 2 3 4 5 6 7 8

S17

(

DIP switches - internal

FRONT

)

ON DIP

1 2 3 4 5 6 7 8

S16

ON DIP

1 2 3 4 5 6 7 8

S15

ON DIP

1 2 3 4 5 6 7 8

S14

S16

S15

S14

see FXS Supervision Table

S7

S4 S5

S7

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S3

S6

S6

S2

S1

BACK

Description:

S6 and S7 positions 3, 4 and 5 determine the FXS type. Options are: Loop Start,

Single Party, Ground Start, Ground Start Automatic, Ground Start Immediate, Universal Voice

Grade, Universal Voice Grade Automatic and Loop Start Forward Disconnect.

Factory Settin g:

Loop Start:

Loop Start-Forward Disconnect:

system

.

Ground Start:

Ground Start Automatic:

LOOP START

Tip and Ring closure used with traditional telephone stations and simple PBX lines.

Provides disconnect when FXS is connected to voice messaging

Used with two-way PBX lines.

Used with equipment requiring fast-response time to the central

office (CO).

Ground Start Immediate :

Used with equipment req uiring fast-r esponse time to the station or PBX.

Single Party:

Universal Voice Grade:

Universal Voice Grade Automatic:

Single Part Service for SLC-96.

Toll quality voice for SLC-96.

Used with some non-bell switches.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 30

Switches Configuring the ICX-250 25

FXS Supervision Table

(Mode) 1, 2

FXS 00 LS LS-fd GS GSa GSi

FXS-DN 01 LS LS-fd GS GSa GSi

FXS-DN-WINK 10 LS LS-fd GS GSa GSi

TR-08 11 SP - -- UVG UVGa ---

Legend: (e.g. S1 position 5 = 01001 means Mode = FXS-DN / Type = LS-fd)

!!ATTENTION!!

Changing the Supervision type

switches will result in al l FXS call s on the a f fec ted 12

FXS line group to be rese t to t he id le state each t ime a

DIP switch setting is changed. This means any active

calls in that FXS line group will be dropped.

3, 4, 5 (Type)

000 001 100 101 110

LS = Loop Start

LS-fd = Loop Start-Forward Disconnect

GS = Ground Start

GSa = Ground Start Automatic

GSi = Ground Start Immediate

SP = Single Party

UVG = Universal Voice Grade

UVGa = Universal Voice Grade Automatic

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 31

26 Configuring the ICX-250 Switches

FXS Ports (per line) - Transmit / Receive

FRONT

S7

ON DIP

1 2 3 4 5 6 7 8

S19

ON DIP

1 2 3 4 5 6 7 8

S18

ON DIP

1 2 3 4 5 6 7 8

S17

S4 S5

S7

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S3

S6

S19

S18

S17

(

DIP switch - internal

ON DIP

1 2 3 4 5 6 7 8

S16

ON DIP

1 2 3 4 5 6 7 8

S15

ON DIP

1 2 3 4 5 6 7 8

S14

S16

S15

S14

4 3 2 1

9 dB

ON DIP

1 2 3 4 5 6 7 8

3 dB

S6

S2

S1

)

FXS Ports

4 3 2 1

FXS Ports

Receive

Attenuation

(or Loss)

Transmit

Loss

BACK

Description:

These are eight position DIP switches used to set Transmit and Receive FXS

attenuation (TLP Setting).

Factory Setting:

3 dB (OFF) The DIP switch layout shown above is an example using 3 dB of

attenuation on the Transmit side (positions 2,4,6,8 off) and 9 dB on the Receive side (positions

1,3,5,7 on). If it is necessary to change the Transmit setting to attenuate the line by 9 dB, the related

switch position(s) would be set to the “On” setting. Receive side settings would be changed from

9 dB to 3 d B b y m oving the related switch position to “Off.” See the cha rt on page 27 for more de tail

on the switch settings.

Transmit / Receive path will be attenuated by 3 dB (+/– 0.5).

3dB:

9dB:

Transmi t / Receive path will be attenuated b y 9 dB (+/–0.5).

!!ATTENTION!!

The above FXS Port settings are

repeated for each of the 12 or 24 lines.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 32

Switches Configuring the ICX-250 27

Switch Settings for FXS Port Transmit and Receive Attenuation

The table below represents the FXS port transmit and receive attenuation

(loss) control settings.

FXS Port

Switch

Number

3 dB Attenuation 9 dB Attenuation

Transmit Receive Transmit Receive

1 S14 8 = OFF 7 = OFF 8 = ON 7 = ON

2

3

4

5 S15 8 = OFF 7 = OFF 8 = ON 7 = ON

6

7

8

9 S16 8 = OFF 7 = OFF 8 = ON 7 = ON

10

11

12

13 S17 8 = OFF 7 = OFF 8 = ON 7 = ON

14

15

16

17 S18 8 = OFF 7 = OFF 8 = ON 7 = ON

18

19

20

21 S19 8 = OFF 7 = OFF 8 = ON 7 = ON

22

23

24

6 = OFF 5 = OFF 6 = ON 5 = ON

4 = OFF 3 = OFF 4 = ON 3 = ON

2 = OFF 1 = OFF 2 = ON 1 = ON

6 = OFF 5 = OFF 6 = ON 5 = ON

4 = OFF 3 = OFF 4 = ON 3 = ON

2 = OFF 1 = OFF 2 = ON 1 = ON

6 = OFF 5 = OFF 6 = ON 5 = ON

4 = OFF 3 = OFF 4 = ON 3 = ON

2 = OFF 1 = OFF 2 = ON 1 = ON

6 = OFF 5 = OFF 6 = ON 5 = ON

4 = OFF 3 = OFF 4 = ON 3 = ON

2 = OFF 1 = OFF 2 = ON 1 = ON

6 = OFF 5 = OFF 6 = ON 5 = ON

4 = OFF 3 = OFF 4 = ON 3 = ON

2 = OFF 1 = OFF 2 = ON 1 = ON

6 = OFF 5 = OFF 6 = ON 5 = ON

4 = OFF 3 = OFF 4 = ON 3 = ON

2 = OFF 1 = OFF 2 = ON 1 = ON

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 33

28 Configuring the ICX-250 Switches

FXS Ports - Trunk Conditioning

S7

ON DIP

1 2 3 4 5 6 7 8

S19

ON DIP

1 2 3 4 5 6 7 8

S18

ON DIP

1 2 3 4 5 6 7 8

S17

S4 S5

S7

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S3

S19

S18

S17

(

DIP switches - internal)

FRONT

ON DIP

1 2 3 4 5 6 7 8

S16

ON DIP

1 2 3 4 5 6 7 8

S15

ON DIP

1 2 3 4 5 6 7 8

S14

S6

S6

S2

S16

S15

S14

IDLE

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

IDLE/BUSY

S1

BACK

Description:

Factory Settin g:

In the event of an alarm condition in the T1 connection to the network, the FXS Ports will be

Idle:

S6 position 6 and S7 position 6 selects the trunk conditioning state.

IDLE

put into the id le state immed iately and remain in this condition unt il the T1 has been restored.

Idle Immediate/Busy Delay:

In the event of an alarm condition in the T1 connection between the

ICX-250 and the network, the FXS Ports will be put into the Idle state immediately for 3 seconds

and then put into the Busy state and remain in this condition until the T1 has been restored.

The DIP switch settings shown in the illustration above are for Switch S6 and S7.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 34

Switches Configuring the ICX-250 29

FXS Ports - FXS Ringbac k Tone

ON DIP

ON DIP

1 2 3 4 5 6 7 8

S7

ON DIP

1 2 3 4 5 6 7 8

S19

1 2 3 4 5 6 7 8

S18

S17

S4 S5

S7

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S3

S19

S18

S17

(

DIP switches - internal

FRONT

ON DIP

1 2 3 4 5 6 7 8

S16

ON DIP

1 2 3 4 5 6 7 8

S15

ON DIP

1 2 3 4 5 6 7 8

S14

S6

S6

S2

)

S16

S15

S14

ON

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

OFF

S1

BACK

Description:

S6 position 7 and S7 position 7 provides ringback tone when it is not available from

the PBX or Switch.

Factory Settin g:

Ringback tones will be sent to the applicable FXS channels by the unit if not provided by the

ON:

OFF

Switch or PBX for the duration of ringing on the line.

Ringback provided by PBX or Switch.

OFF:

The DIP switch settings shown in the illustration above are for Switches S6 and S7.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 35

30 Configuring the ICX-250 Switches

FXS Ports - FXS Time Slot Assignment

S7

ON DIP

1 2 3 4 5 6 7 8

S19

ON DIP

1 2 3 4 5 6 7 8

S18

ON DIP

1 2 3 4 5 6 7 8

S17

S4 S5

S7

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

S3

S6

S19

S18

S17

(

DIP switch - internal

FRONT

ON DIP

1 2 3 4 5 6 7 8

S16

ON DIP

1 2 3 4 5 6 7 8

S15

ON DIP

1 2 3 4 5 6 7 8

S14

S6

S2

)

S16

S15

S14

ON

ON DIP

1 2 3 4 5 6 7 8

ON DIP

1 2 3 4 5 6 7 8

OFF

S1

BACK

Description:

Factory Settin g:

FXS Ports 1-12 are mapped onto T1 time slots 1-12 and FXS Ports 13-24 are mapped onto

OFF:

S7 position 8 selects the timeslot assignments.

OFF

T1 time slots 13-24.

Swap (ON):

FXS Ports 1-12 are mapped onto T1 time slots 13-24 and FXS Ports 13-24 are

mapped onto T1 time slots 1-12. Swap is available only on switch 7 and is applicable only on the

12 port model.

Depending on the services provided by your carrier for voice and data, you may need to reassign

the FXS timeslots of the 12 FXS port model. Timeslots 13 to 24 will be assigned in order to

allocate data to the lower timeslots.

The DIP switch setting shown in the illustration above is for Switch S7

ONLY

.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 36

External DIP Switches Configuring the ICX-250 31

External DIP Switches

The ICX-250 is equipped with five external DIP switches

switches, and one - 7 dip switch)

These switc he s ar e us ed f or D a ta P or t a nd T1 Co n figura tio n . E ac h switch

is set to a preconfigured factory setting when shipped. The illustration

below outlines the location of these DIP switches.

ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

FXS Loopback

S5 S4 S3 S2 S1

DIP Switch Settings

Alm.

(four - 12 dip

located on the rear panel of the unit.

The individual switches on each switch

Note:

assembly operate independently of one another.

Data 1

T1Data 2Data 2Data 11121324

T1 Line

T1

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11265-A

TIP

Locate the DIP switch on the rear panel that describes the function you

wish to effect. Use the tip of a small object to change the switch settings.

The switches will glide easily into place.

Switch setting

changes will

take effect

immediately.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 37

32 Configuring the ICX-250 External DIP Switches

T1 Interface - Frame Format

ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

T1

ON DIP

1234567

D4 (SF)

Description:

S1 positions 1 and 2 are used to select the T1 frame format.

Factory Settin g:

Framing:

Selects the T1 frame format to be either D4 (SF), ESF, or TR-08. (No data link with D4)

ESF

FXS Loopback

S5 S4 S3 S2 S1

(

DIP switch - back

Alm.

ON DIP

1234567

T1

ESF

)

Data 1

T1Data 2Data 2Data 11121324

T1 Line

T1

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11266-A

T1

ON DIP

1234567

TR-08

Selections:

D4 (SF), ESF and TR-08. (Note: Posit ion 1 and 2 t o ON is not a v a lid s etting a nd could

cause slips on the T1.)

T1 Interface - Line Code

ICX-250 - Rear Panel

FXS Loop Pairs

S5 S4 S3 S2 S1

Description:

Factory Settin g:

S1 position 3 is used to select the T1 line code.

B8ZS

(

DIP switch - back

)

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loopback

Alm.

Data 1

T1Data 2Data 2Data 11121324

T1

ON DIP

1234567

AMI

T1

T1 Line

Rx

Tx

ON DIP

1234567

24/48 VDC

+ – G

T1

B8ZS

120 VAC–.6A 60Hz

11267-A

Line Code:

Selections:

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Selects the line code on the T1 interface.

AMI, B8ZS.

Page 38

External DIP Switches Configuring the ICX-250 33

T1 Interface - T1 Clock

(

DIP switch - back

)

ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

Description:

S1 position 4 is used to select the T1 clock source.

Factory Settin g:

Clock for th e T1 interface will be recovered from the line (receive signal).

Line:

FXS Loopback

Alm.

S5 S4 S3 S2 S1

LINE

Data 1

T1

ON DIP

1234567

LINE

T1

T1 Line

T1Data 2Data 2Data 11121324

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11268-A

T1

ON DIP

1234567

INTERNAL

Internal:

Clock for the T1 interface will be taken from an on-board 1.544 MHz clock meeting the

Stratum 4 requirements.

Failure of external clock causes unit to switch

Note:

to internal clock. When external clock is restored, the

unit will switch back to external clock source.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 39

34 Configuring the ICX-250 External DIP Switches

T1 Interface - CSU/DSX Interface

Selection (

ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

Description:

Factory Settin g:

SlimLine will exhibit DSX interface characteristics.

DSX:

S1 position 5 is used to select whether the T1 acts as a CSU o r DSX interface.

CSU

FXS Loopback

Alm.

S5 S4 S3 S2 S1

Dip switch - back

Data 1

T1

ON DIP

1234567

ACCEPT

)

T1

T1 Line

T1Data 2Data 2Data 11121324

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11269-A

T1

ON DIP

1234567

IGNORE

SlimLine will exhibit CSU interface characteristics.

CSU:

T1 Interface -

CSU/DSX Line Build Out (CSU) or Line Length (DSX) (

ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

T1

ON DIP

1234567

0 dB

Description:

S1 position 6 and 7 are used to select CSU/DSX line build out or line length.

Factory Settin g:

CSU 0dB

FXS Loopback

Alm.

S5 S4 S3 S2 S1

ON DIP

1234567

–7.5 dB

T1

Data 1

DIP switch - back

T1

T1 Line

T1Data 2Data 2Data 11121324

24/48 VDC

Rx

+ – G

Tx

T1

ON DIP

1234567

–15.0 dB

)

120 VAC–.6A 60Hz

11270-A

Line Build Out:

Selects one of thr ee line build out a nd l ine length options for ei t her CSU

or DSX interfaces.

Selections:

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

CSU 0 dB, –7.5 dB and –15.0 dB; DSX 0.6 dB at 250 ft, 1.8 dB at 500 ft, 3.0 dB at 700 ft.

Page 40

External DIP Switches Configuring the ICX-250 35

Data Port 1 and 2 - Number of Timeslots

(

DIP switch - back

)

IICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

Description:

FXS Loopback

Alm.

S5 S4 S3 S2 S1

Data 1

T1Data 2Data 2Data 11121324

Data 1 / Data 2

ON DIP

10123456789101112

S2 positions 1, 2, 3, 4 and 5 (Data 2 - DIP switch) sets the port parameters for Data

T1 Line

T1

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11271-A

Port 2. S3 positions 1, 2, 3, 4 and 5 (Data 1 -DIP switch) sets the port parameters for Data Port 1.

Both DIP switches are used for Network Data Bandwidth.

Factory Settin g:

All switches are set to zero (data ports inactive).

Number of Timeslots:

Selects the number o f cons ecutive timeslots that data from Data P ort 1 and /

or 2 will be mapped onto. Please refer to Decimal/Binary Conversion Table (see page 36) for Data

Port Configura tion t o aid i n selec ting N. Drawing abov e indicates switch settings if timeslot N = 13.

Selected quantity of timeslots x 64K = Data Port Bandwidth.

Binary numbers are used to select the number

Note:

of timeslots and starting timeslots.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 41

36 Configuring the ICX-250 External DIP Switches

Decimal / Binary Conversion Table for Data Port Configuration

The table show n bel ow illustrates the binary equivalent of Timeslots 1-24.

Note: 1 = ON and 0 = OFF.

Bandwidth Timeslot Switch Setting Bandwidth Timeslot Switch Setting

-- 0 00000 832K 13 01101

64K 1 00001 896K 14 01110

128K 2 00010 960K 15 01111

192K 3 00011 1024K 16 10000

256K 4 00100 1088K 17 10001

320K 5 00101 1152K 18 10010

384K 6 00110 1216K 19 10011

448K 7 00111 1280K 20 10100

512K 8 01000 1344K 21 10101

576K 9 01001 1408K 22 10110

640K 10 01010 1472K 23 10111

704K 11 01011 1536K 24 11000

768K 12 01100

Starting T/S6789

1 off off off off

3 off off off on

5 off off on off

7offoffonon

9 off on off off

11 off on off on

13 off on on off

15 offononon

19 on off off on

21 on off on off

23 on off on on

This table is used for selecting the starting timeslots for each data port.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 42

External DIP Switches Configuring the ICX-250 37

Data Port 1 and 2 - Starting Timeslot

ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

FXS Loopback

Alm.

S5 S4 S3 S2 S1

(

DIP switch - back

)

Data 1

Data 1 / Data 2

ON DIP

10123456789101112

Note:

Starting time slots will always be odd

numbered (i.e. 1, 3, 5, 7, 9, etc.).

T1

T1 Line

T1Data 2Data 2Data 11121324

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11272-A

Description:

S2 position 6, 7, 8 and 9 selects the starting timeslot (1,3,5,7,9,etc.) for Data Port 2.

S3 position 6, 7, 8 and 9 selects the starting timeslot (1,3,5,7,9,etc.) for data port 1.

Factory Settin g:

Starting Timeslot:

All switches are set to zero (data ports not active).

Selects first T1 timeslot that data from Data Port 1 and/or 2 will be mapped.

(1,3,5,7,9....23). Please refer to Decimal/Binary Conversion Table (see page 36) to aid in selecting

the starting ti meslot. Drawing abov e indicates switch sett ings using timeslot 6 as the st arting timeslot.

Factory Setting:

All switches are set to zero (data

ports not active).

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 43

38 Configuring the ICX-250 External DIP Switches

Data Port 1 and 2 - Clock Inversion -

(DIP switch - back

)

ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

Description:

FXS Loopback

Alm.

S5 S4 S3 S2 S1

Data 1

T1Data 2Data 2Data 11121324

Data 1 / Data 2

ON DIP

10123456789101112

DTE clocking will usually require an off setting (S2 & S3 position 10 off).

T1 Line

T1

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11645-A

If synchronization problems occur, clock inversion should be selected (S2 & S3 position 10 on).

Factory Settin g:

Data Port 1 and 2 - Data Interface Type -

Clock set to OFF

(DIP switch - back

)

ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

Description:

Factory Settin g:

EIA530A:

Data Ports 1 or 2 use the V.35 standard.

V.35:

S2 and S3 position 11 selects the data interface for Data Ports 2 and 1.

V.35

Data Ports 1 or 2 use the EIA530A standard.

FXS Loopback

S5 S4 S3 S2 S1

Data 1

ON DIP

10123456789101112

Data 1

T1 Line

Alm.

T1Data 2Data 2Data 11121324

Data 2

ON DIP

10123456789101112

V.35 EIA530A

T1

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11273-A

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 44

External DIP Switches Configuring the ICX-250 39

Data Port 1 and 2 Data Rate ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

Description:

S2 and S3 position 12 selects the data rate for Data Ports 2 and 1, respectively.

Factory Settin g:

64 Kbps:

56 Kbps:

Data Ports1 or 2 receive and transmit data at a multiple of 64 Kbps.

Data Ports 1 or 2 receive and transmit data at a multiple of 56 Kbps.

56Kbps

FXS Loopback

S5 S4 S3 S2 S1

ON DIP

10123456789101112

(

DIP switch - back

Alm.

Data 1

64 Kbps 56 Kbps

)

Data 1

T1 Line

T1Data 2Data 2Data 11121324

Data 2

ON DIP

10123456789101112

T1

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11274-A

The options shown on this page do not ha ve to be matche d. i.e. Port 1 can have a different interface

and speed than Port 2.

FXS Ports (per line) - Loopback Operation and/or Channel Unassigned

ICX-250 - Rear Panel

(

DIP switch - back

)

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

FXS Loopback

ON DIP

10123456789101112

Description:

Used to set loopback for each FXS channel.

Factory Settin g:

OFF

FXS Loopback

Data 1

Alm.

S5 S4 S3 S2 S1

FXS Loopback

ON DIP

10123456789101112

T1Data 2Data 2Data 11121324

T1 Line

T1

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11275-A

Breaks the connections to and from the FXS Ports and loops the receive data back onto the

ON:

transmit path towards the T1. In the case of unassigned channels, provides an idle termination.

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 45

40 Configuring the ICX-250 External DIP Switches

It is recommended t hat all unassigned chan nel s

Note:

be provided an idle termina tion.

T1 Network

Transmit Receive

ICX-250

FXS 1

FXS 1 Loopback

ICX-250

T24 Network

Transmit Receive

FXS 24

FXS 24 Loopback

The selected DS0 is looped after leaving the framer before reaching the FXS Interface.

The CPU is used to control this loopback via the Time Slot Assigner (TSA, a part of the

CPU). Subsystems T1 Line Interface Unit, T1 Framer, and CPU are exercised.

11276-A

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 46

Configuration Reference Data Configuring the ICX-250 41

Configuration Reference Data

11658-A

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

{

13579111315171921

23

12 11 10 9

Ports

24 23 22 21

Ports

FXS Supervision

12 11 10 9

12345678

Ports

12345678

24 23 22 21

Ports

View From Top Rear

21

3

(Ports 1-12)

4

16 15 14 13

Ports

12345678

Ports

FXS Transmission Level

12345678 12345678

01101

01110

01111

10000

10001

10010

10011

10100

10101

10110

10111

11000

1314151617181920212223

00000

00001

00010

00011

00100

00101

00110

0123456789101112

(Ports 13-24)

16 15 14 13

12345678

Ports

FXS Transmission Level

00111

01000

01001

01010

24

01011

01100

12345678

Ports 8 7 6 5

Ports 20 19 18 17

4321

Ports 8 7 6 5

Ports

12345678

Ports 20 19 18 17

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 47

Electrical Installation 43

CHAPTER

4

Electrical

Installation

When you are ready to go beyond the basics of the ICX-250

unit, use this chapter to learn specifics on grounding, cabling,

and the necessary power requirements for operation.

Contents

Connector Type . . . . . . . . . . . . . . . . . . .44

Power Requirements . . . . . . . . . . . . . . .47

Issue 1, September 1998 ADCP-62-023

© 1998, ADC Telecommunications, Inc.

Page 48

44 Electrical Installation Connector Type

Connector Type

The ICX-250 product is equipped with several types of electrical

connections to the network and power sources. The table below lists each

one of the connectors along with their functionality.

ICX-250 - Rear Panel

Switch numbers S1 through S5 are shown on the board within the unit.

FXS Loop Pairs

FXS Loopback

Alm.

Data 1

T1Data 2Data 2Data 11121324

T1 Line

T1

Rx

Tx

24/48 VDC

+ – G

120 VAC–.6A 60Hz

11264-A

Connector Name Connector Type Description

FXS Loop Pairs 25 Pair Amphenol 24 FXS Tip and Ring pair

Alm. 2 position

Data 1 and Data 2 DB25 Female Data Port 1 signals and Data Port 2 signals.

T1 Line RJ48 Transmit and Receive pairs.

T1 Dual Bantam Jack (monitor jacks) For bridged access onto the T1 transmit and receive pairs.

24/48VDC (+– G)

1.8 / .9A Max.

120 VAC -.6A 60Hz AC Receptacle Power input when external 120 V AC 60Hz is used to power the unit.

(plug included with Kit of Parts)

3 position

(plug included with Kit of Parts)

Earth Ground Permanent Earth Ground Connection.

Signals: TIPn, RINGn

switch for FXS.

A relay closure that sends alarms out to an external alarm system.

For DC power input.

: FXSGND must be connected to earth ground regardless of

Note

powering method used.

ADCP-62-023 Issue 1, September 1998

© 1998, ADC Telecommunications, Inc.

Page 49

Connector Type Electrical Installation 45

Connector Pinouts

DCE DB25 Female Connector (Data Ports 1 and 2)

Pin Signal Name Mnemonic Source V.35 EIA-530A

1 Shield X

2 Transmit Data TXD+ BA (A) DTE X X

3 Receive Data RXD+ BB (A) DCE X X

4 Request to Send RTS+ CA (A) DTE X X

5 Clear to Send CTS+ CB (A) DCE X X

6 DCE Ready DSR+ CC DCE X X

7 Signal Common AB X X