Page 1

HRM-238 List 1 HiGain Retrofit Management Shelf

User Manual

Product Catalog: HRM-238 L1

CLEI: T1MFW004

Page 2

LTPH-UM-1237-04

Revision History

To order copies of this manual, use document catalog number LTPH-UM-1237-04. (Copies of this publication

can be downloaded from the ADC website at www.adc.com. To order a hard copy, please contact your sales

representative.)

Issue Release Date Revisions Made

1 May 9, 2003 Initial release

2 March 31, 2004 Updated Certificate and Warranty and Product Support Sections.

3 April 28, 2004 Misc technical updates

4 July 21, 2004 Misc technical updates/additions.

Copyright

July 21, 2004

© 2004 ADC Telecommunications, Inc. All rights reserved.

Trademark Information

ADC and HiGain are registered trademarks of ADC Telecommunications, Inc. No right, license, or interest to such trademarks

is granted hereunder, and you agree that no such right, license, or interest shall be asserted by you with respect to such

trademark.

Other product names mentioned in this document are used for identification purposes only and may be trademarks or

registered trademarks of their respective companies.

Disclaimer of Liability

Information contained in this document is company private to ADC Telecommunications, and shall not be modified, used,

copied, reproduced or disclosed in whole or in part without the written consent of ADC.

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice.

In no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits, and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

ii July 21, 2004 HRM-238 List 1

Page 3

LTPH-UM-1237-04 Using This Manual

USING THIS MANUAL

The following conventions are used in this manual where applicable:

• Monospace type indicates screen text.

• Keys you press are indicated by small icons such as or . Key combinations to be pressed

simultaneously are indicated with a plus sign as follows: + .

Y ENTER

CTRL ESC

• Items you select are in bold.

The following types of messages, identified by icons, may appear in text.

Notes provide information about special circumstances.

General cautions indicate the possibility of personal injury, product failure, or equipment

damage if instructions are ignored or not completely followed.

An Electrostatic Discharge (ESD) caution indicates that a device or assembly is susceptible

to damage from electrostatic discharge.

An electrical shock warning indicates the presence of a dangerous level of electrical power

and the potential for serious personal injury or equipment damage.

For a list of abbreviations used in this document, refer to “Appendix C - Abbreviations” on page 15.

INSPECTING SHIPMENT

Upon receipt of the equipment:

• Unpack each container and inspect the contents for signs of damage. If the equipment has been damaged in

transit, immediately report the extent of damage to the transportation company and to ADC

Telecommunications, Inc. Order replacement equipment, if necessary.

• Check the packing list to ensure complete and accurate shipment of each listed item. If the shipment is short

or irregular, contact ADC as described in “Appendix B - Product Support” on page 14. If you must store the

equipment for a prolonged period, store the equipment in its original container.

HRM-238 List 1 July 21, 2004 iii

Page 4

Inspecting Shipment LTPH-UM-1237-04

iv July 21, 2004 HRM-238 List 1

Page 5

LTPH-UM-1237-04 Table of Contents

TABLE OF CONTENTS

Overview ____________________________________________________________________________ 1

Features..............................................................................................................................................1

Operational Capabilities.....................................................................................................................2

Application ..........................................................................................................................2

Management Cabling...........................................................................................................4

Installation_______________________________________________________________________ ____ 5

Inspecting Your Shipment .................................. ...............................................................................5

Installing the HRM-238 Shelf............................................................................................................5

Installing Frame Ground and Battery Power .....................................................................................5

Installing Communication Wiring .....................................................................................................6

Connect NMA Wiring .........................................................................................................7

Connect to a LAN or Interconnect Shelves.........................................................................9

Connect to a Computer, Terminal, or Modem......................................... ............................9

Identifying Alarms...........................................................................................................................11

Turning Up the System....................................................................................................................11

Insert Fuse..........................................................................................................................11

Verify Cabling................................. .................................... ..............................................12

Secure Cabling...................................................................................................................12

Installing the Management Unit(s) ..................................................................................................12

Appendix A - Specifications____________________________________________________________ 13

Appendix B - Product Support _________________________________________________________ 14

Appendix C - Abbreviations ________ ___________________________________________________ 15

Certification and Warranty______________________________________________ Inside Back Cover

HRM-238 List 1 July 21, 2004 v

Page 6

List of Figures LTPH-UM-1237-04

LIST OF FIGURES

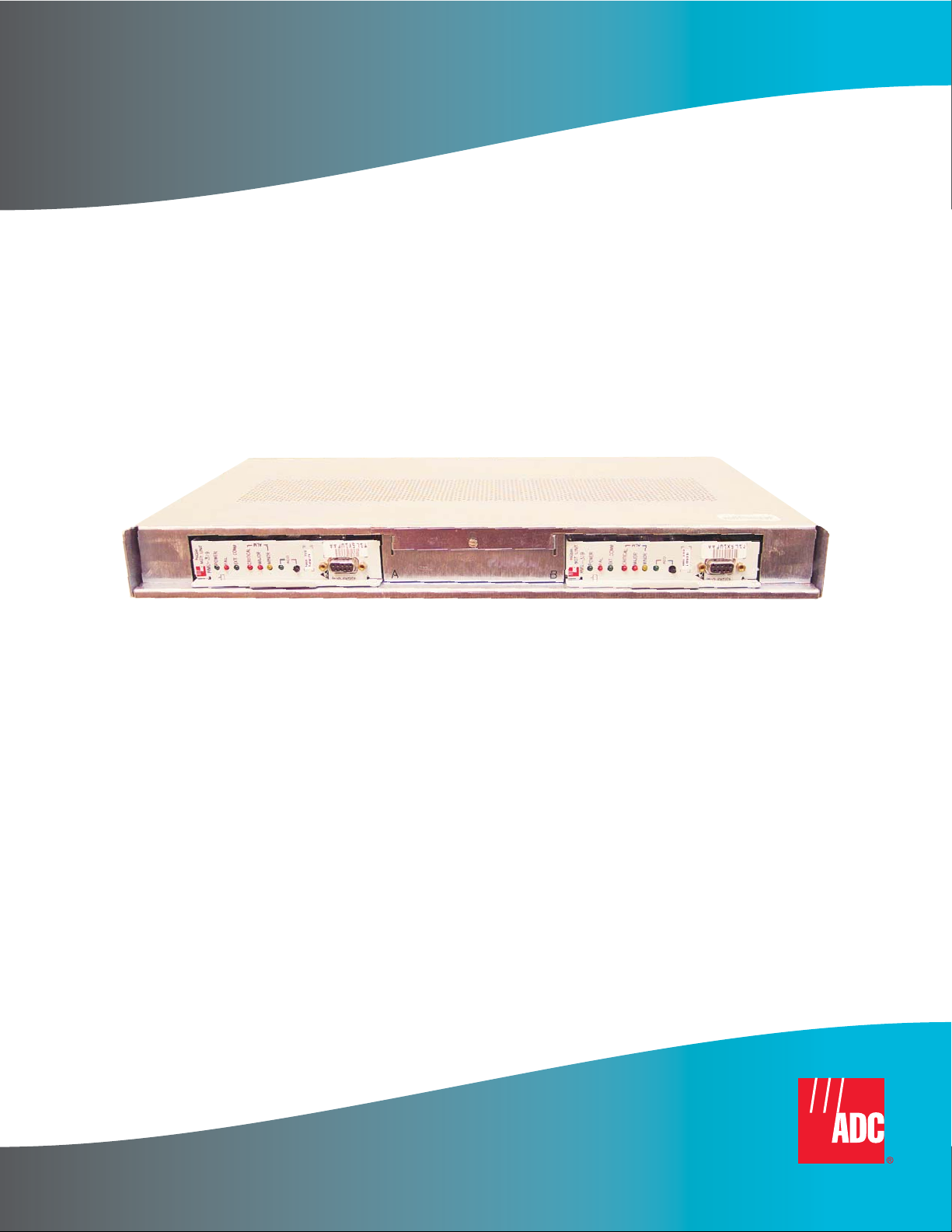

1. HRM-238 List 1 (front view) ........................................................................................................................1

2. Recommended Network Setup for 220 Type Shelves................................................................................... 2

3. Recommended Network Setup for 3190 Type Shelves................................................................................. 3

4. Recommended Network Setup for DDM+ Type Shelves .............................................................................3

5. HRM-238 Shelf Backplane Connectors (back view) ....................................................................... ............. 4

6. Shelf with Brackets Positioned for 19-inch Rack.......................................................................................... 5

7. Connect -48 Vdc and Frame Grounds to TB1............................................................................................... 6

8. Connect NMA Wiring ................................................................................................................................... 7

9. Using BNC Connector................................................................................................................................... 9

10. AUX or OS Connectors.............................................................. ...................................................................9

11. Alarm Relay Wire-Wrap Pins..................................................... ..................................... ............................11

vi July 21, 2004 HRM-238 List 1

Page 7

LTPH-UM-1237-04 List of Tables

LIST OF TABLES

1.HRM-238 Connectors ......................................................................................................................................4

2.Terminal Block (TB1)............................................................. ..................................... ....................................6

3.P1 and P6 NMA Connectors............................................................................................................................8

4.BNC Connector J1 and J3................................................................................................................................9

5.AUX P3 and P5 Connectors...........................................................................................................................10

6.OS Port P2 and P4...................... ....................................................................................................................10

7.Alarm J13 and J14 Pinouts.............................................................................................................................11

HRM-238 List 1 July 21, 2004 vii

Page 8

List of Tables LTPH-UM-1237-04

viii July 21, 2004 HRM-238 List 1

Page 9

LTPH-UM-1237-04 Overview

OVERVIEW

The HiGain® HRM-238 List 1 is a two-slot HiGain Retrofit Management (HRM) shelf. This shelf fits into either

a 19- or 23-inch Central Office (CO) equipment rack. It accommodates up to two HiGain management units

(HMU-319s). It is used in conjunction with 220-type, unmanaged 3190 type, and DDM+ type mechanic shelves

to manage HiGain line units.

The HRM-238 shelf, with two management units installed, provides network mana gement capabilities for a

maximum of 56 HiGain line units (one 3190 or DDM+ or two 220 shelves). Each management unit in the

HRM-238 shelf can manage up to 28 line units.

The HMU-319 management unit installs horizontally into the 4 ¾-inch slots labeled A or B on the HRM-238 shelf

(Figure 1). Each management unit connects to the shelf backplane through a 96-pin DIN connector.

96-pin DIN

connector (J2)

AB

Figure 1. HRM-238 List 1 (front view)

96-pin DIN

connector (J4)

H0543-A

FEATURES

Standard features include:

• 50-pin Amp-type connectors for connection between the management units in the HRM-238 shelf and

previously unmanaged HiGain line units in 220 , 3190, or DDM+ mechanics shelves.

• DB-25 connectors for connection to a computer, terminal, or modem

• British Naval Connector (BNC) for connection to a Local Area Network (LAN) or to a HMU-319 multi-shelf

connection

• screw-type terminals for -48 Vdc power connection and grounding

• 23 wire-wrap pins to monitor alarm relay activity

HRM-238 List 1 July 21, 2004 1

Page 10

Overview LTPH-UM-1237-04

OPERATIONAL CAPABILITIES

Application

With two HMU-319 management units installed, the HRM-238 shelf provides network management for up to 56

HiGain line units.

Recommended Network Setup for 220 Type Shelves

The configuration shown in Figure 2 is the recommended setup for 220 type mechanics shelves. Position the

HRM-238 shelf between the 220 type shelves, with up to two 220-type shelves above and two below. This limits

the distance for the wire leads between the connectors for the management units and the line units they manage.

Figure 2 shows the HRM-238 shelf from the rear view with the A-side connectors on the right and the B-side

connectors on the left. The leads from the HRM-238 shelf connector attach to the Network Management Agent

(NMA) pins on the rear of the 220-type mechanics shelves for each line unit managed. The NMA pin on 220 type

chassis is pin 46.

NMA 1 to 14 B

NMA 15 to 28 B

NMA 1 to 28 B

HCS-417/418

HCS-417/418

CO -48V

Supply

TB1

Network B Network A

-48V A

-48V B

-48V A

-48V B

HRM-238

HCS-417/418

HCS-417/418

-48V A

-48V B

-48V A

-48V B

H0544-B

NMA 1 to 28 A

NMA 1 to 14 A

NMA 15 to 28 A

Figure 2. Recommended Network Setup for 220 Type Shelves

2 July 21, 2004 HRM-238 List 1

Page 11

LTPH-UM-1237-04 Overview

Recommended Network Setup for 3190 Type Shelves

The configuration shown in Figure 3 is the recommended setup for 3190 type mechanics shelves. Position the

HRM-238 shelf below the 3190 type shelves. This limits the distance for the wire leads between the connectors

for the management units and the line units they manage. Figure 3 shows the HRM-238 shelf from the rear view

with the A-side connectors on the right and the B-side connectors on the left. The leads from the HRM-238 shelf

connector attach to the Network Management Agent (NMA) pins on the rear of the 3190-type mechanics shelves

for each line unit managed. The NMA pin on 3190 type chassis is pin 7.

NMA 1 to 28 A

3190

-48V A

-48V B

NMA 1 to 28 B

NMA 1 to 28 B

3190

CO -48V

Supply

TB1

Network B Network A

HRM-238

-48V A

-48V B

NMA 1 to 28 A

H0544-C

Figure 3. Recommended Network Setup for 3190 Type Shelves

Recommended Network Setup for DDM+ Type Shelves

The configuration shown in Figure 4 is the recommended setup for DDM+ type mechanics shelves. Position the

HRM-238 shelf below the DDM+ type shelves. This limits the distance for the wire leads between the connectors

for the management units and the line units they manage. Figure 4 shows the HRM-238 shelf from the rear view

with the A-side connectors on the right and the B-side connectors on the left. The leads from the HRM-238 shelf

connector attach to the Network Management Agent (NMA) pins on the rear of the DDM+ type mechanics shelves

for each line unit managed. The NMA pin on DDM+ type chassis is pin 104.

NMA 1 to 28 A

DDM+

-48V A

-48V B

NMA 1 to 28 B

NMA 1 to 28 B

DDM+

CO -48V

Supply

TB1

Network B Network A

HRM-238

-48V A

-48V B

NMA 1 to 28 A

H0544-D

Figure 4. Recommended Network Setup for DDM+ Type Shelves

HRM-238 List 1 July 21, 2004 3

Page 12

Overview LTPH-UM-1237-04

)

B-sid

A-sid

Management Cabling

Figure 5 shows the location for each connector on the HRM-238 shelf backplane. Table 1 lists the shelf connector

types and management functions available to the HMU-319 management units through those connect ors.

50-pin Amphenol

connector (P6)

e connectors

AUX port DB-25

connector (P5)

OS port DB-25

connector (P4)

AUX port DB-25

connector (P3)

e connectors

OS port DB-25

connector (P2)

Alarm relay pins (J13)Terminal block (TB1 )Alarm relay pins (J14) BNC connector (J3)

50-pin Amphenol

connector (P1)

H0545-A

BNC connector (J1

Figure 5. HRM-238 Shelf Backplane Connectors (back view)

Table 1. HRM-238 Connectors

Connector Purpose Type Gender

P1, P6 Provides connection from the HRM-238 shelf for the management

units to each individual card that they manage.

P2, P3, P4, P5 Provides 4 connection points (two for each management unit) for a

terminal, computer, or modem. There is one AUX port and one OS port

connector for each management unit.

TB1 Provides separate -48 Vdc connection from the CO battery source

to each management unit. Also provides battery common ground and

a frame ground.

J13, J14 Provides connection for alarm relay contacts. Wire-wrap

J1, J3 Provides a 10BASE-2 connection to a LAN. BNC Female 1

Amphenol

Male 50

(CHAMP)

DB-25 Female 25

Terminal

N/A 6

block

Male 23

pins

No. of

Pins

4 July 21, 2004 HRM-238 List 1

Page 13

LTPH-UM-1237-04 Installation

S

INSTALLATION

INSPECTING YOUR SHIPMENT

Upon receipt of the equipment:

• Unpack each container and inspect the contents for signs of damage. If the equipment has been damaged in

transit, immediately report the extent of damage to the transportation company and to ADC

Telecommunications, Inc. Order replacement equipment, if necessary.

• Check the packing list to ensure complete and accurate shipment of each listed item. If the shipment is short

or irregular, contact ADC as described in “Appendix B - Product Support” on page 14. If you must store the

equipment for a prolonged period, store the equipment in its original container.

INSTALLING THE HRM-238 SHELF

Install the HRM-238 in a CO equipment bay rack. If the CO rack is 19 inches wide, attach the short side of the

mounting bracket to the HRM-238 shelf and use the long side of the mounting bracket to attach to the CO rack.

If the CO rack is 23 inches wide, reverse the mounting bracket. Attach the long side of the mounting bracket to

the HRM-238 shelf and use the short side of the mounting bracket to attach to the CO rack (Figure 6).

1 Position the HRM-238 shelf in the CO rack. (See “Operational Capabilities” on page 2, and Figure 2 on

page 2, Figure 3 on page 3, or Figure 4 on page 3 for recommended placement.)

2 Align the HRM-238 shelf mounting brackets with the vertical mounting holes on the CO rack (Figure 6).

3 Install the mounting hardware and secure.

Mounting bracket

AB

Figure 6. Shelf with Brackets Positioned for 19-inch Rack

ecurity bracket

Mounting bracket

H0546-B

INSTALLING FRAME GROUND AND BATTERY POWER

Perform the following steps to install the -48 Vdc battery to the HRM-238 shelf and to connect battery common

ground (LGND) and frame ground (FGND). The HRM-238 shelf terminal block TB1 has two connection points

for supplying redundant battery capability. Connect a -48 Vd c battery source to Term in al 1 (-48V_A) to supply

voltage to the HRM-238 shelf (Table 2 on page 6). Connect another -48 Vdc battery source to Terminal 2

(-48V_B) to supply redundant voltage to the HRM-238 shelf. See Table 2 on page 6 for TB1 terminal block

information.

HRM-238 List 1 July 21, 2004 5

Page 14

Installation LTPH-UM-1237-04

)

Table 2. Terminal Block (TB1)

Terminal Description

1 -48V_A

2 -48V_B

3 BATTERY RETURN

4 FGND

1 Remove the fuse(s) in the equipment bay fuse panel for the circuit(s) where the HRM-238 shelf battery

wire(s) will terminate.

2 Connect one end of the frame ground wire to Terminal 4 (FGND) on TB1 of the HRM-238 shelf and attach

the other end of the frame ground wire to the CO ground wire termination point.

3 Connect the -48 Vdc CO battery to the HRM-238 shelf (Figure 7):

a Connect a wire to the HRM-238 shelf TB1 Terminal 1 (-48V_A) for Primary CO batter y.

b Connect a wire to the HRM-238 shelf TB1 Terminal 2 (-48V_B) for Redundant CO battery.

c Connect the battery common wire to HRM-238 shelf TB1 Terminal 3 (BATTERY RETURN) of the

HRM-238 shelf and attach the other end to CO battery ground source(s).

d Connect the wire(s) from the HRM-238 TB1 Terminal 1 and Terminal 2 to the CO -48 Vdc power

termination point(s).

Terminal 1

to -48 Vdc

Terminal 2

to -48 Vdc

Terminal 3 to battery

common (Battery Return)

Terminal 4 to

frame ground (FGND

H0547-B

Figure 7. Connect -48 Vdc and Frame Grounds to TB1

INSTALLING COMMUNICATION WIRING

All wiring and connections for the HRM-238 shelf are on the back. Figure 5 on page 4 shows the shelf backplane

and connectors. Connect the NMA wiring from the HRM-238 shelf to each HiGain or Megabit Modem line unit

that will be managed using the steps beginning on page 7. Then, use the other connectors in “Connect to a LAN

or Interconnect Shelves” on page 9 and “Connect to a Computer, Terminal, or Modem” on page 9 that are

appropriate for your application.

6 July 21, 2004 HRM-238 List 1

Page 15

LTPH-UM-1237-04 Installation

Connect NMA Wiring

From the 50-pin Amphenol connector P1 and/or P6 (Figure 8), wire directly to the NMA pin 46 on the 220-type

shelf backplane for each line unit being managed. Route wires from the P1 and P6 connectors to the NMA

220-type mechanics shelves as shown in Figure 2 on page 2. Refer to Table 3 for P1 and P6 NMA connector

information.

50-pin Amphenol

connector (P6)

50-pin Amphenol

connector (P1)

H0548-A

Figure 8. Connect NMA Wiring

1 Remove the plastic cover from the 50-pin Amphenol connector P1 and/or P6.

2 Install a 50-pin female plug into the connector. Separate the wires for each of the 50 pins.

For 220 type mechanics:

3 Wire wrap the corresponding NMA wire from the plug to the NMA pin 46 on the shelf for each line unit being

managed. The wire leads from the Amphenol plug can be up to 20 feet maximum.

For 3190 type mechanics:

4 Wire wrap the corresponding NMA wire from the plug to the NMA pin 7 on the shelf for each line unit being

managed. The wire leads from the Amphenol plug can be up to 20 feet maximum.

For DDM+ type mechanics:

5 Wire wrap or soldier (depending on chassis manufacturer) the corresponding NMA wire from the plug to the

NMA pin 104 on the shelf for each line unit being managed. The wire leads from the Amphenol plug can be

up to 20 feet maximum.

HRM-238 List 1 July 21, 2004 7

Page 16

Installation LTPH-UM-1237-04

Table 3. P1 and P6 NMA Connectors

Pin Description Pin Description

26 NMA_1 1 NMA_2

27 NMA_3 2 NMA_4

28 NMA_5 3 NMA_6

29 NMA_7 4 NMA_8

30 NMA_9 5 NMA_10

31 NMA_11 6 NMA_12

32 NMA_13 7 NMA_14

33 NMA_15 8 NMA_16

34 NMA_17 9 NMA_18

35 NMA_19 10 NMA_20

36 NMA_21 11 NMA_22

37 NMA_23 12 NMA_24

38 NMA_25 13 NMA_26

39 NMA_27 14 NMA_28

40 F_ALAM 15 ERR_ALM

41 LOS_ALM 16 GND

42 GND 17 GND

43 GND 18 GND

44 GND 19 GND

45 GND 20 GND

46 GND 21 GND

47 GND 22 GND

48 GND 23 GND

49 N/C 24 N/C

50 N/C 25 N/C

8 July 21, 2004 HRM-238 List 1

Page 17

LTPH-UM-1237-04 Installation

Connect to a LAN or Interconnect Shelves

Use the BNC connector (Figure 9) when required for access using a LAN or for interconnecting multiple shelves.

Consult the appropriate user manual for the HMU-319 management unit and for the software used in the

application. See Table 4 for information on BNC connector J1 and J3.

H0549-A

BNC connector (J1)BNC connector (J3)

Figure 9. Using BNC Connector

Table 4. BNC Connector J1 and J3

Shield LAN-, CDS

Center LAN+

Connect to a Computer, Terminal, or Modem

The AUX and OS connectors (Figure 10) are DB-25, configured as Data Terminal Equipment (DTE). There is

one AUX and one OS connector for each of the two management unit slots. Use these connectors for a direct

connection (straight-through) with devices configured Data Communication Equipment (DCE) such as modems,

X.25 Packet Assembler/Disassemblers (PADs), or LAN terminal servers.

AUX port DB-25

connector (P5)

OS port DB-25

connector (P4)

AUX port DB-25

connector (P3)

Figure 10. AUX or OS Connectors

OS port DB-25

connector (P2)

H0550-A

HRM-238 List 1 July 21, 2004 9

Page 18

Installation LTPH-UM-1237-04

Use a null modem connector for cross-over cabling when attaching a device that is not configured as DCE (such

as terminals or computers running terminal emulation software) to these connectors. Table 5 shows the pinouts

for the two AUX ports (one port for each management unit). Table 6 shows the pinouts for the two OS ports (one

port for each management unit).

Table 5. AUX P3 and P5 Connectors

Pin Description I/O Pin Description I/O

1 N/C 14 N/C

2 AUX_TX O 15 N/C

3 AUX_RX I 16 N/C

4 N/C 17 N/C

5 N/C 18 N/C

6 AUX_DSR- I 19 N/C

7 LGND I 20 AUX_DTR- O

8 N/C 21 N/C

9 N/C 22 N/C

10 N/C 23 N/C

11 N/C 24 N/C

12 N/C 25 N/C

13 N/C

Table 6. OS Port P2 and P4

Pin Description I/O Pin Description I/O

1 N/C 14 N/C

2 OS_TX O 15 OS_TCLK I

3OS_RX I 16N/C

4 OS_RTS- O 17 OS_RCLK I

5 OS_CTS- I 18 N/C

6OS_DSR- I 19N/C

7 LGND I 20 OS_DTR- O

8 N/C 21 N/C

9 N/C 22 N/C

10 N/C 23 N/C

11 N/C 24 OS_TCLK I

12 N/C 25 N/C

13 N/C

For further details about connecting to the AUX or OS connectors, consult the appropriate user

manual for the management unit and applicab le so ftwa r e.

10 July 21, 2004 HRM-238 List 1

Page 19

LTPH-UM-1237-04 Installation

IDENTIFYING ALARMS

Alarm relay contacts for each management unit are on J13 and J14 (Figure 11). Install wiring between these pins

and an alarm monitoring device per local practice. Table 7 describes the alarm J13 and J14 pinouts.

H0651-A

Alarm relay pins (J13)Alarm relay pins (J14)

Figure 11. Alarm Relay Wire-Wrap Pins

Table 7. Alarm J13 and J14 Pinouts

Pin Description Pin Description

1 CRIT_AUD_NC_A 13 MIN_AUD_NC_A

2 CRIT_AUD_COM_A 14 MIN_AUD_COM_A

3 CRIT_AUD_NO_A 15 MIN_AUD_NO_A

4 CRIT_VIS_NC_A 16 MIN_VIS_NC_A

5 CRIT_VIS_COM_A 17 MIN_VIS_COM_A

6 CRIT_VIS_NC_A 18 MIN_VIS_NO_A

7 MAJ_AUD_NC_A 19 SYS_ID_NC_A

8 MAJ_AUD_COM_A 20 SYS_ID_COM_A

9 MAJ_AUD_NO_A 21 SYS_ID_NO_A

10 MAJ_VIS_NC_A 22 EXT_ACO_A

11 MAJ_VIS_COM_A 23 LGND

12 MAJ_VIS_NO_A

TURNING UP THE SYSTEM

Perform the following procedures prior to installing the management unit(s) into the shelf.

Insert Fuse

Insert an appropriately sized fuse(s) into the equipment bay fuse panel for the circuit(s) where the HRM-238 shelf

battery wire(s) were terminated. Refer to the appropriate management unit user manual fo r power consumption,

power dissipation, and current drain.

HRM-238 List 1 July 21, 2004 11

Page 20

Installation LTPH-UM-1237-04

Verify Cabling

Verify the following:

1Verify a minimum of -42 Vdc and a maximum of -56 Vdc between the following:

a -48 Vdc battery screw Terminal 1 and the battery common Terminal 3 (BATTERY RETURN)

b -48 Vdc battery screw Terminal 2 (when used) and the battery common Terminal 3 (BATTERY

RETURN)

2 Visually verify that all connections are securely terminated.

Secure Cabling

Tie the cable connectors to the back of the HRM-238 shelf using the tie wraps and mounting screws.

INSTALLING THE MANAGEMENT UNIT(S)

1 Install the management unit(s) into the HRM-238 shelf per procedures in the appropriate HMU-319 user

manual.

2 Loosen the security bracket screw, push down the security bracket, and re-tighten the screw (Figure 6 on

page 5).

12 July 21, 2004 HRM-238 List 1

Page 21

LTPH-UM-1237-04 Appendix A - Specifications

APPENDIX A - SPECIFICATIONS

Power

Maximum power 10.0 Watts

CO Supply -48 Vdc nominal (-42.5 Vdc to -56.5 Vdc)

Fuse Size 0.5A

Physical

Material Steel

Finish Zinc plated

Capacity 2 management modules (HMU-319 or MMU-319)

Mounting 19- or 23-inch rack

Dimensions

Height 1.75 in. (4.39 cm)

Width 17 in. (43.18 cm), without mounting brackets

18.37 in. (46.65 cm), mounting brackets set for 19-inch rack

22.37 in. (56.82 cm), mounting brackets set for 23-inch rack

Depth (including the wire-wrap

terminals)

Weight 2.5 lb. (1.13 kg)

Operational Environment

Temperature -40ºC to +65ºC

Humidity 5 to 95% (non-condensing)

Altitude 200 ft below sea level to 13,000 ft above sea level

Storage Environment

12 in. (30.48 cm)

(-60m below sea level to 4,000m above sea level)

Temperature -40ºC to +70ºC

Humidity 5 to 95% (non-condensing)

HRM-238 List 1 July 21, 2004 13

Page 22

Appendix B - Product Support LTPH-UM-1237-04

APPENDIX B - PRODUCT SUPPORT

ADC Customer Service Group provides expert pre-sales and post-sales support and training for all its products.

Technical support is available 24 hours a day, 7 days a week by contacting the ADC Technical Assistance Center.

Sales Assistance

800.366.3891

Systems Integration

800.366.3891

ADC Technical Assistance Center

800.366.3891

Email: wsd_support@adc.com

Online Technical Support • www.adc.com/Knowledge_Base/index.jsp

Online Technical Publications • www.adc.com/documentationlibrary/technicalpublications

• Quotation Proposals

• Ordering and Delivery

• General Product Information

• Complete Solutions (from concept to installation)

• Network Design and Integration Testing

• System Turn-Up and Testing

• Network Monitoring (upstream or downstream)

• Power Monitoring and Remote Surveillance

• Service/Maintenance Agreements

• Systems Operation

• Technical Information

• System/Network Configuration

• Product Specification and Application

• Training (product-specific)

• Installation and Operation Assistance

• Troubleshooting and Repair/Field Assistance

Product Return Department

800.366.3891

Email: repair.return@adc.com

All telephone numbers with an 800 prefix are toll-free in the USA and Canada.

• ADC Return Material Authorization (RMA) number and instructions must

be obtained before returning products.

14 July 21, 2004 HRM-238 List 1

Page 23

LTPH-UM-1237-04 Appendix C - Abbreviations

APPENDIX C - ABBREVIATIONS

B

BNC: Bayonet-Lockingl Connector

C

CO: Central Office

D

DCE: Data Communication Equipment

DTE: Data Terminal Equipment

H

HCS: HiGain Card Shelf

HMU: HiGain Management Unit

HRM: HiGain Retrofit Management

L

LAN: Local Area Network

N

NMA: Network Management Agent

P

PADs: Packet Assembler/Disassemblers

HRM-238 List 1 July 21, 2004 15

Page 24

Appendix C - Abbreviations LTPH-UM-1237-04

16 July 21, 2004 HRM-238 List 1

Page 25

CERTIFICATION AND WARRANTY

FCC COMPLIANCE

This equipment does not have any clocking source, and is deemed to be a passive device per FCC guidelines.

When used in conjunction with any clocking devices, this combined system may radiate radio frequency energy

that can cause harmful interference to radio communications. Operation of such a system in a residential area is

likely to cause harmful interference, in which case the user will be required to correct the interference at his own.

LIMITED WARRANTY

Product warranty is determined by your service agreement. Refer to the ADC Warranty/So ftw are Handbook for

additional information or contact your sales representative or Cust omer Service for details.

MODIFICATIONS

Any changes or modifications made to this device that are not expressly approved by ADC Telecommunicaitons,

Inc. voids the user's warranty.

All wiring external to the products should follow the provisions of the current edition of the National Electr ical

Code.

Page 26

World Headquarters

ADC Telecommunications, Inc.

PO Box 1101

Minneapolis, Minnesota USA 55440-1101

Technical Assistance

Tel: 800.366.3891

DOCUMENT: LTPH-UM-1237-04

´,•9¶1S¨

1299251

Loading...

Loading...