Page 1

HiGain

HiGain

4E

M

O

D

E

L

HiGain

HDSL2

SETUP

STATUS

USER MANUAL

H

2

T

U

*

C

3

1

9

L

B

K

B

R

G

O

U

L

T

I

N

E

B

R

G

I

N

L

I

N

E

R

S

2

3

2

DCE

H2TU-C-319 List 4E

Product Catalog: H2TU-C-L4E

CLEI Code: VACHYVYG

Page 2

LTPH-UM-1049-02, Issue 2

Revision History of This Manual

Issue Release Date Revisions Made

1 October 5, 2001 Initial release.

2 January 9, 2002 BERT update.

Copyright

January 9, 2002

© 2002 ADC DSL Systems, Inc. All rights reserved.

Trademark Information

ADC is a registered trademark of ADC Telecommunications, Inc. HiGain is a registered trademark of ADC DSL Systems, Inc.

No right, license, or interest to such trademarks is granted hereunder, and you agree that no such right, license, or interest

shall be asserted by you with respect to such trademark. Other product names mentioned in this practice are used for

identification purposes only and may be trademarks or regi stered trademarks of their respect ive companies.

Disclaimer of Liability

Information containe d in this documen t is company private to ADC DSL Systems, Inc., and shal l not be modified , used, copied ,

reproduced or discl osed in whole or in part without the wr itten consent of AD C.

Contents herein are current as o f th e da te of publication. ADC reserves the right to c h an ge th e c onte nts wi tho ut prior no tic e .

In no event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits, and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

ii January 9, 2002 H2TU-C-319 List 4E

Page 3

LTPH-UM-1049-02, Issue 2 Using This Manual

USING THIS MANUAL

The following conventions are used in this manual:

• Monospace type indicates screen text.

• Keys you press are indicated by small icons such as or . Key combinations to be pressed

simultaneously are indicated with a plus sign as follows: + .

Y ENTER

CTRL ESC

• Items you select are in bold.

• Three types of messages, identified by icons, appear in text.

Notes contain information about special circumstances.

Cautions indicate the possibility of personal injury or equipment damage.

The Electrostatic Discharge (ESD) symbol indicate s that a device or as sembly is susc eptible to

damage from electrostatic discharge.

For a list of abbreviations used in this document, refer to “Appendix E - Abbreviations” on page 76.

INSPECTING SHIPMENT

Upon receipt of the equipment:

• Unpack each container and inspect the contents for signs of damage. If the equipment has been damaged in

transit, immediately report the extent of damage to the transportation company and to ADC DSL Systems,

Inc. Order replacement equipment, if necessary.

• Check the packing list to ensure complete and accu rate shipmen t of each listed item. If the shipment is short

or irregular, contact ADC DSL Systems, Inc. as described in “Returns” on page 75. If you must store the

equipment for a prolonged period, store the equipment in its original container.

H2TU-C-319 List 4E January 9, 2002 iii

Page 4

Inspecting Shipment LTPH-UM-1049-02, Issue 2

iv January 9, 2002 H2TU-C-319 List 4E

Page 5

LTPH-UM-1049-02, Issue 2 Table of Contents

TABLE OF CONTENTS

Overview ____________________________________________________________________________ 1

Features..............................................................................................................................................1

Compatibility .....................................................................................................................................2

Applications.......................................................................................................................................2

Front Panel __________________________________________________________________________ 3

Installation___________________________________________________________________________ 8

Verification ........................................................................................................................................9

Verification without an H2TU-R Remote Unit...................................................................9

Verification with an H2TU-R Remote Unit ........................................................................9

Provisioning_________________________________________________________________________ 10

Using the MODE and LBK Pushbuttons.........................................................................................10

Setting Options through MODE and LBK........................................................................10

Resetting to Factory Default Values..................................................................................11

Displaying System Parameter Settings..............................................................................11

Disabling an Alarm............................................................................................................11

Loopback Modes ...............................................................................................................11

Using a Maintenance Terminal................................................................................................ ........12

Connecting to a Maintenance Terminal.............................................................................12

The Logon Screen..............................................................................................................12

Provisioning Tasks......................................... .................................. ...... ..... .....................................14

Setting Date and Time.......................................................................................................14

Setting Circuit ID Numbers...............................................................................................15

Configuring the System.....................................................................................................16

Clearing the History, Alarm, and Event Log Screens .......................................................33

Monitoring System Activity and Performance ____________________________________________ 34

Using the Monitor Screen to View System Activity........................................................................35

Using the Performance Screens to View Performance Data............................................................37

Performance History at the DS1 Interface......................................................................... 38

Performance History at the HDSL2 Interface...................................................................40

Current Statistics Screens for the DS1 Interface...............................................................42

Current Statistics for HDSL2 Interface.............................................................................43

Using the Performance Screens to View Alarm Data......................................................................44

Alarm History at the DS1 Interface...................................................................................44

Alarm History at the HDSL2 Interface..............................................................................46

Using the System Event Log to Track Events .................................................................................48

Using the Report Menu....................................................................................................................50

H2TU-C-319 List 4E January 9, 2002 v

Page 6

Table of Contents LTPH-UM-1049-02, Issue 2

Testing _____________________________________________________________________________ 52

System Alarms................................................................................................................................. 52

Alarm Option for the Digital Loop Carrier Feed.............................................................. 53

Retiring System Alarms.................................................................................................... 53

Remote LOS and AIS Response.......................................................................................54

OCT55 Test Pattern with AMI Line Code...................................................................................... 54

Loopback Operation........................................................................................................................55

Generic Loopback Commands.......................................................................................... 56

Special Loopback Commands........................................................................................... 56

SmartJack Loopback Commands...................................................................................... 57

Manual Loopback Session............................................................................................................... 57

Activating Manual Metallic Test Access ........................................................................................58

in-band Loopback Sessions.............................................................................................................59

General Troubleshooting Tips .......................................................................................... 59

GNLB Test Procedures.................................................................... ...... ..... ...................... 59

A2LB Test Procedures......................................................................................................61

A3LB and A4LB Test Procedures....................................................................................64

SmartJack Test Procedure ................................................................................................. 64

Appendix A - Specifications____________________________________________________________ 65

Power Consumption ................................................ ..... .................................. ...... ........................... 66

Maximum Power Dissipation..........................................................................................................66

Maximum Current Drain................................................................................................................. 66

Loop Attenuation, Insertion Loss, and Reach..................................... .................................. ..... .....67

H2TU-C-319 List 4E Card-Edge Connector................................................................................... 68

Network Management Control Bus.................................................................................. 69

Fuse Alarm........................................................................................................................ 69

System Alarm Output Pin.................................................................................................70

Craft Port.........................................................................................................................................71

Appendix B - Functional Operation _____________________________________________________ 72

Timing .............................................................................................................................................73

Ground Fault Detect........................................................................................................................ 73

Appendix C - Compatibility____________________________________ ________________________ 74

Appendix D - Product Support _________________________________________________________ 75

Technical Support............................................................................................................................ 75

Returns............................................................................................................................................. 75

Appendix E - Abbreviations____________________________________________________________76

Certification and Warranty _____________________________________________ Inside Back Cover

vi January 9, 2002 H2TU-C-319 List 4E

Page 7

LTPH-UM-1049-02, Issue 2 List of Figures

LIST OF FIGURES

1. H2TU-C-319 List 4E Front Panel ...................................................................................................................3

2. Installing the H2TU-C-319 List 4E into a Shelf .............................................................................................8

3. Logon Screen.................................................................................................................................................13

4. Config Menu - Date and Time....................................................................................................................... 14

5. Inventory Screen......................................... .................................. ...... ...........................................................15

6. Config Menu..................................................................................................................................................16

7. Config Menu - Standard Options (defaults shown).......................................................................................17

8. Config Menu - ADC Options (defaults shown) ............................................................................................17

9. Metallic Test Access Block Diagram............................................................................................................28

10. MTA Relays ..................................................................................................................................................29

11. Metallic Test Access TB6 on HMS-358 Backplane......................................................................................29

12. H2TU-C-319 List 4E Block Diagram ...........................................................................................................30

13. Config Menu - Reset to Factory Defaults......................................................................................................32

14. Config Menu - Master Clear..........................................................................................................................33

15. Monitor Screen - Active Loopback with Alarms .......................................................................................... 35

16. H2TU-R DS1 31-Day Performance History .................................................................................................38

17. H2TU-R DS1 25-Hour Performance History................................................................................................38

18. H2TU-C DS1 48-Hour Performance History................................................................................................39

19. H2TU-C HDSL2 31-Day Performance History............................................................................................40

20. H2TU-C HDSL2 48-Hour Performance History ..........................................................................................40

21. H2TU-C HDSL2 25-Hour Performance History ..........................................................................................41

22. H2TU-R DS1 Current Statistics ....................................................................................................................42

23. H2TU-C DS1 Current Statistics ....................................................................................................................42

24. H2TU-C HDSL2 Current Statistics...............................................................................................................43

25. H2TU-C DS1 Alarm History Screen.............................................................................................................44

26. H2TU-R DS1 Alarm History Screen.............................................................................................................45

27. H2TU-C HDSL2 Alarm History Screen .......................................................................................................46

28. System Event Log..........................................................................................................................................48

29. Report Menu - Full Report.......................................... .................................. ...... .......................................... 50

30. H2TU-R LOS and AIS Response Priorities ..................................................................................................54

31. Loopback Summary.......................................................................................................................................55

32. Loopback Modes ...........................................................................................................................................60

33. H2TU-C-319 List 4E Card-Edge Connector.................................................................................................68

34. HMS-358 Backplane H2TU-C-319 List 4E Card Edge Connector Labeling...............................................69

35. RS-232 Craft Port Pinouts.............................................................................................................................71

36. H2TU-C-319 List 4E Block Diagram ...........................................................................................................72

H2TU-C-319 List 4E January 9, 2002 vii

Page 8

List of Tables LTPH-UM-1049-02, Issue 2

LIST OF TABLES

1. Front-Panel Description..................................................................................................................................4

2. Front-Panel Display Messages........................................................................................................................ 5

3. Navigational Keys for the HiGain HDSL2 Maintenance Terminal Screens................................................ 12

4. Logon Screen Menus..................................................................................................................................... 13

5. H2TU-C-319 List 4E Standard Config Menu Options................................................................................. 18

6. H2TU-C-319 List 4E ADC Config Menu Options....................................................................................... 19

7. DS1 and DSX-1 24-hour PM Threshold....................................................................................................... 22

8. Response to H2TU-R DS1 Frame Conversion Options................................................................................ 24

9. Extended SuperFrame Format.......................................................................................................................25

10. SuperFrame Format.......................................................................................................................................25

11. DDS NI and DS0 DP Latching Loopback Sequence.................................................................................... 26

12. HiGain HDSL2 Loopback vs. Latching Sequence ....................................................................................... 26

13. Response of H2TU-C-319 List 4E and H2TU-R to LOS and AIS............................................................... 27

14. Monitor Screen Descriptions......................................................................................................................... 36

15. Error Acronyms Used on the DS1 Performance History Screens.................................................................39

16. Error Acronyms Used on the HDSL2 Performance History Screens........................................................... 41

17. DS1 Alarm Descriptions...............................................................................................................................45

18. HDSL2 Alarm Descriptions..........................................................................................................................47

19. Event Log Entry Messages List.................................................................................................................... 49

20. Report Types.................................................................................................................................................51

21. Front-Panel System Alarms Summary..........................................................................................................52

22. Summary of HiGain HDSL2 Generic Loopback Codes and Activation Methods ....................................... 56

23. Addressable Repeater Loopback Commands (A2LB).................................................................................. 61

24. Addressable Repeater Loopback Commands (A3LB and A4LB)................................................................ 64

25. SmartJack Loopup and Loopdown Commands ............................................................................................ 64

26. H2TU-C-319 List 4E Power Parameters.......................................................................................................66

27. HDSL2 Reach Chart ..................................................................................................................................... 67

viii January 9, 2002 H2TU-C-319 List 4E

Page 9

LTPH-UM-1049-02, Issue 2 Overview

OVERVIEW

The H2TU-C-319 List 4E (H2TU-C) line unit is the Central Office (CO) side of a T1 transmission system. The

HiGain HDSL2 product family is fully compliant with the HDSL2 standard ANSI T1.418. Providing full-rate T1

access using a single copper pair, HDSL2 is a cost-effective solution that offers an open architecture. The open

architecture inherent in HDSL2 guarantees interoperability allowing simple and economic accommodation of

network growth.

HiGain HDSL2 products provide 1.552 Mbps transmission on one unconditioned copper pair over the full Carrier

Service Area (CSA) range. The CSA inc ludes loo ps up to 12,000 feet of 24 AWG wire or 9,0 00 feet o f 2 6 AWG

wire, including bridged taps.

FEATURES

Features specific to the List 4E family of HDSL2 modules include:

• Report menu option for downloading status and performance monitoring data to a file

• Enhanced loopback commands controlled by the SmartJack Loopback (LPBK) option as follows:

– 100 in-band loopdown command

– 100000 (1-in-6) in-band loopu p command

• Connection of the HDSL2 span to Loop 2 on pins K and 9 rather than on Loop 1, pins F and 6

• Sources sealing current when connected to an H2TU-R-402 List 5E or higher

Standard features include:

• HDSL2 transmission features

– Lightning and power cross-protection on HDSL2 interfaces

– Full-duplex HDSL2 transmission on one pair at 1.552 Mbps

– Ultra-low wander (Stratum 1 compliant)

– Grounded loop detection on High-bit-rate Digital Subscriber Line 2 (HDSL2)

• Front-panel provisioning features

– Four character status display

– DS1 splitting and bridge access

– Status Light Emitting Diodes (LEDs)

– RS-232 craft port for connection to a maintenance terminal

– MODE and LBK pushbuttons

• Maintenance screens for inventory, provisioning, and troubleshooting

– DS1 and HDSL2 performance monitoring

– Non-volatile performance monitoring

– Performance Report Messaging (PRM) support for Supplemental PRM (SPRM) and Network PRM

(NPRM) at the H2TU-R

– Payload (PL) and HiGain (HG) loopback source identification

– Margin Alarm (MAL) threshold

H2TU-C-319 List 4E January 9, 2002 1

Page 10

Overview LTPH-UM-1049-02, Issue 2

• Configuration options

– Selectable DS1 pre-equalizer

– Bipolar Violation Transparency (BPVT) options

– Bit Error Rate (BER) alarm

– Power Back Off Network (PBON) and Power Back Off Customer (PBOC) options for confi guring output

levels

– Loss of Signal/Alarm Indication Signal (LOS/AIS) payload alarm option

– Remote provisioning

• Compatible with HMS-358 Soneplex

• Digital Data Service (DDS) latching loopback

• Network Management and Administration (NMA) interface

• Metallic Test Access (MTA)

• Dual DSX-1 port option

DS1 is used throughout this document to refer to either the remote unit’s DS1 interface or the

line unit’s DSX-1 interface.

®

Wideband 3190 shelves only

COMPATIBILITY

The H2TU-C has two unique features, Metallic Test Access and Dual DS1 port options, which are not provided

in standard ADC line units with 3192 mechanics. These featu res require additional access pins which are pr ovided

by a special card-edge connector, shown in F igure 33 on page 68. Only the HMS-358 set of shelves can

accommodate this special connector.

APPLICATIONS

HiGain HDSL2 systems provide a cost-effective, easy-to-deploy method for delivering T1 High Capacity Digital

Service (HCDS) over a single copper pair. HiGain HDSL2 systems support a multitude of network connections

and system models .

• The service is deployed over one unconditioned, non-loaded copper pair.

• Conventional, inline DS1 repeaters are no longer required.

• Cable pair conditioning, pair separation and bridged tap removal are not r e quir ed.

Each loop has no more than 35 dB of loss at 196 kHz, with driving and terminating impedances of 135

general, HiGain HDSL2 systems:

• Operate effectively in the same cable binder g roup with other HDSL2 lines, HDSL, T1, ADSL, SDSL, POTS,

DDS, and other transmission schemes.

• Can be used with customers requiring DS1 service on a temporary or permanent basis.

Ω. In

• Provide a means of quickly deploying service in advance of fiber-optic transmission systems.

2 January 9, 2002 H2TU-C-319 List 4E

Page 11

LTPH-UM-1049-02, Issue 2 Front Panel

FRONT PANEL

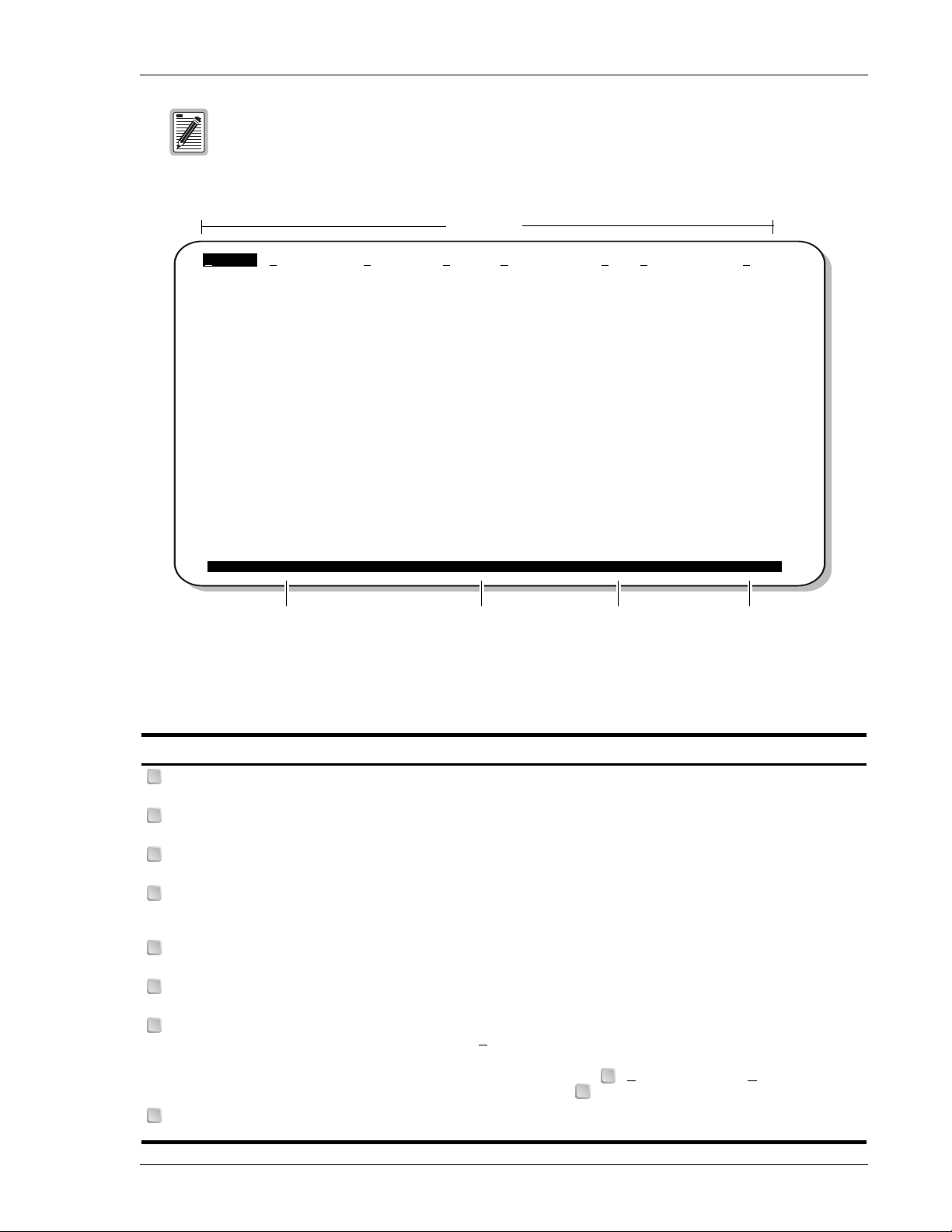

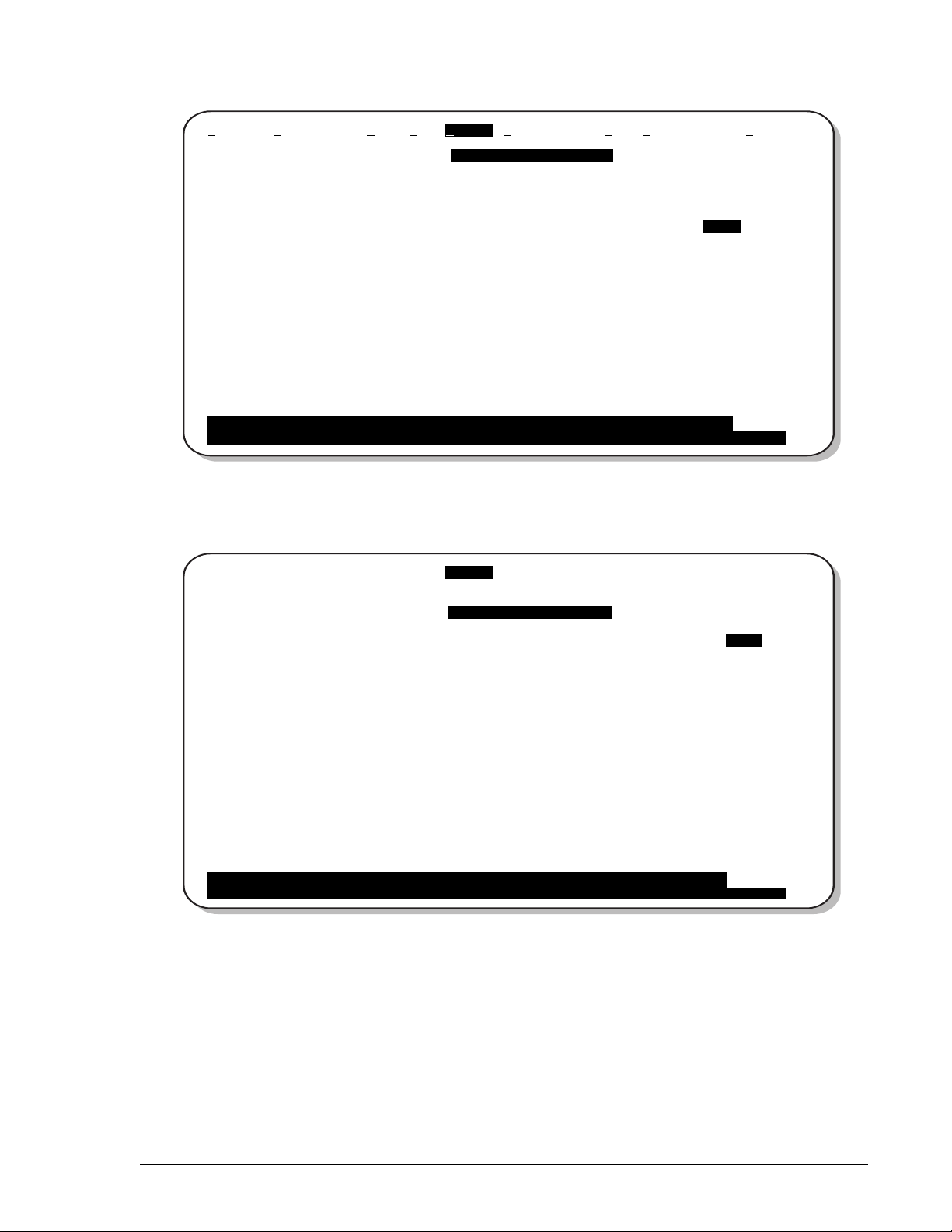

Figure 1 shows the H2TU-C-319 List 4E front panel. Table 1 on page 4 describes the front -panel components. F or

pinout diagrams of the H2TU-C-319 List 4E card-edge connector and craft port, refer to “Appendix A -

Specifications” on page 65.

HiGain

HDSL2

H

List number

Status LED

Card handle

(CLEI code and

ECI bar code label on

outside of handle)

2

T

U

*

C

3

L

1

4E

9

SETUP

M

S

O

E

D

L

E

STATUS

B

R

G

O

U

L

T

I

N

E

B

R

G

I

N

L

I

N

E

Front-panel display

System option pushbuttons

DSX-1 access jacks

Craft port

R

S

2

3

2

DCE

Figure 1. H2TU-C-319 List 4E Front Panel

H2TU-C-319 List 4E January 9, 2002 3

Page 12

Front Panel LTPH-UM-1049-02, Issue 2

Table 1. Front-Panel Description

Front-Panel Feature Function

Front-panel display Displays four-character status, provisioning, and alarm system messages. The front-panel display

illuminates when power is initially applied. To conserve power the display only remains on for

5 minutes. Using the MODE or LBK pushbuttons reactivates the display and restarts the 5-minute

timer. Refer to Table 2 on page 5 for a listing of the four-character messages.

MODE and LBK system

option pushbuttons

Permits user options to be monitored and modified without the need of a maintenance terminal. Used

to initiate all HiGain loopbacks and test states as well as to display DSX-1 line parameters and line

unit identity.

Status LED The status LED can report the following conditions:

Off Line power is off.

Green Normal operation.

Flashing green HDSL2 acquisition.

Red Fuse alarm.

Flashing red System alarm.

Yellow An H2TU-C Customer Remote Loopback (CREM) or a Network Local Loopback (NLOC) is in effect.

Flashing yellow H2TU-C is in an Armed state.

DSX-1 access jacks

BRG Provides non-intrusive bridging jack access to (IN) and from (OUT) the HDSL2 span at the

MUX DSX-1 interface. Allows the two DS1 payloads to be monitored.

LINE Provides splitting jack access to (IN) and from (OUT) the HDSL2 span at the MUX DSX-1 interface.

Breaks the IN and OUT paths to permit test signal insertion and retrieval.

Craft port (RS-232) Provides bidirectional communication between the unit and an external terminal to allow

configuration and performance monitoring through the maintenance terminal screens.

CLEI and ECI bar code label Provides the human-readable Common Language Equipment Identifier (CLEI) code number and the

Equipment Catalog Item (ECI) bar code number.

List number Identifies the list number of the H2TU-C.

4 January 9, 2002 H2TU-C-319 List 4E

Page 13

LTPH-UM-1049-02, Issue 2 Front Panel

Table 2 lists the front-panel display messages. The fou r-character display reports the code o f an alarm, loopback ,

or diagnostic message and, in some cases, is followed by a second four-character message that modifies the first

message with a value or current configuration setting.

Table 2. Front-Panel Display Messages

Message Full Name Description

ALARM MESSAGES

ACO Alarm Cut Off A system alarm has occurred, and has been retired to an ACO

condition by pressing the LBK pushbutton on the H2TU-C front

panel.

ALRM Alarm Condition Exists A system alarm condition is in effect.

DBER DS1 Bit Error Rate A system DS1 BER alarm is in effect and remains in effect until cleared.

HBER HDSL2 Block Error Rate A system HDSL2 Block Error Rate alarm is in effect.

LA Loop Attenuation Indicates that the attenuation on the HDSL2 loop has exceeded the

LAIS Local Alarm Indication Signal Indicates an AIS (all ones) pattern is being received or transmitted

LLOS Local Loss of Signal Indicates that no signal is detected at the DSX-1 input to the

LOSW Loss of Sync Word Indicates that the HDSL2 loop has lost synchronization.

MAL Margin Alarm The margin on HDSL2 loop has dropped below the threshold

MTA Metallic Test Access Indicates the H2TU-C is in a metallic test access state.

PWR FEED GND Power Feed Ground The HDSL2 loop is grounded.

PWR FEED OPEN Power Feed Open Indicates a line power open condition.

PWR FEED SHRT Power Feed Short Indicates a short between the Tip and Ring of the HDSL2 pair.

PRMF Performance Report Messaging - Far

End

PRMN Performance Report Messaging - Near

End

RAIS Remote Alarm Indication Signal Indicates an AIS (all ones) pattern is being received or transmitted

RLOS Remote Loss of Signal Indicates that no signal is detected at the DS1 input to the H2TU-R.

RRAI Remote RAI—Remote Alarm

Indication at the H2TU-R (Net signal

has errors.)

SPN1 Span Number Accompanies the LOSW alarm and identifies the span where the

TRCI Transmit RAI-CI—TX RAI-CI

Indication - Customer Installation at

the H2TU-R (Net signal does not have

errors.)

TUC Transmission Unit Central Office Accompanies the HBER, MAL, and LA alarm and indicates that the

TUR Transmission Unit Remote End Accompanies the HBER, MAL, and LA alarm and indicates that the

maximum threshold value.

at the H2TU-C DS1 input or output ports.

H2TU-C. Causes a system alarm.

(0 to 15 dB) as set by the operator.

H2TU-R PRM-FE BER threshold has been exceeded.

H2TU-R PRM-NE BER threshold has been exceeded.

at the H2TU-R DS1 input or output ports.

Causes a system alarm.

Indicates an RAI alarm (yellow LED) from the CPE with errors from

the line unit or network.

LOSW alarm occurred.

Upon reception of an RAI (yellow LED) from the CPE, the H2TU-R

sends RAI-CI toward the network if the network signal received at the

H2TU-R is clear. If the network signal is impaired (LOS, AIS, or Loss

of Frame [LOF]), then the RAI is automatically passed on to the

network.

alarm has occurred at the H2TU-R remote unit.

alarm has occurred at the H2TU-R remote unit.

Continued

H2TU-C-319 List 4E January 9, 2002 5

Page 14

Front Panel LTPH-UM-1049-02, Issue 2

Table 2. Front-Panel Display Messages (Continued)

Message Full Name Description

LOOPBACK MESSAGES

CLOC Customer Local Loopback Signal from customer is looped back to the customer at the

H2TU-R.

CREM Customer Remote Loopback Signal from customer is looped back to the customer at H2TU-C.

NLOC Network Local Loopback DSX-1 signal is looped back to the network at the H2TU-C.

NREM Network Remote Loopback DSX-1 signal is looped back to the network at the H2TU-R.

SMJK Remote SmartJack Loopback DSX-1 signal is looped back to the network at the H2TU-R

DIAGNOSTIC MESSAGES

A = xx Maximum Loop Attenuation The Attenuation (A) message appears followed by xx, where xx is

ACQ Acquisition The multiplexers of the H2TU-C and H2TU-R (or the H2TU-C and

ARM HiGain System Armed Armed to respond to Intelligent Repeater Loop (ILR) codes.

BAD RT? No Response from H2TU-R The H2TU-C receives no response from the H2TU-R and all HDSL2

FERR Framing Bit Error Occurred Framing bit error occurred at H2TU-C DSX-1 input.

FLDL Flash Download Flash download of firmware upgrades. Contact Customer Service

HES HDSL2 CRC Error H2TU-C HDSL2 Loop Cyclical Redundancy Check (CRC) error.

LBPV Local Bipolar Violation A bipolar violation has been received at the DSX-1 input to the

M=xx HDSL2 Loop Margin Indicates the power of the received HDSL2 signal relative to noise

MNGD Managed The H2TU-C is under control of the HMU-319 Network management

PWR FEED OFF Power Feed Off HDSL2 span power has been turned off by setting the PWFD option

PWR FEED ON Power Feed On Indicates that the HDSL2 loop is not grounded or shorted.

SIG Signaling The transceivers of the H2TU-C and H2TU-R (or the H2TU-C and

SmartJack module.

the loop attenuation of the longest (maximum loss) span, measured

in dB.

first regenerator) are trying to establish synchronization over the

HDSL2 loop of Span 1.

loop conditions are normal. Therefore, the integrity of the H2TU-R

or the HDSL2 loop is questionable.

for upgrade procedures (see “Appendix D - Product Support” on

page 75).

H2TU-C.

(S/N with respect to 21.5 dB). Any value of 6 dB or greater is

adequate for reliable system operation.

unit. In this state, the front-panel craft port and pushbuttons are

disabled.

to off, or HDSL2 span power has been turned off by use of the A2LB

Intelligent Office Repeater (IOR) Power Down code.

first regenerator) are trying to establish contact with each other over

the HDSL2 loop of Span 1.

Continued

6 January 9, 2002 H2TU-C-319 List 4E

Page 15

LTPH-UM-1049-02, Issue 2 Front Panel

Table 2. Front-Panel Display Messages (Continued)

Message Full Name Description

SYSTEM INFORMATION MESSAGES

(a)

CODE xxxx Line Code: AMI or B8ZS The DS1 line code setting: Alternate Mark Inversion (AMI) or Bipolar

with 8-Zero Substitution (B8ZS).

FRM xxxx Frame: SF, ESF, or UNFR Defines the type of frame pattern being received from the DSX-1:

SuperFrame (SF), Extended SuperFrame (ESF), or Unframed

(UNFR).

LATT xx Loop Attenuation The current loop attenuation threshold setting measured in decibels.

LIST xx H2TU-C List Number The list number of the H2TU-C.

MARG xx Margin The current margin threshold setting measured in decibels.

VER x.xx H2TU-C Software Version Number The software version number (x.xx).

(a) System information messages are displayed in Scroll Mode. To scroll through the messages, press the MODE pushbutton for

3 or more seconds.

H2TU-C-319 List 4E January 9, 2002 7

Page 16

Installation LTPH-UM-1049-02, Issue 2

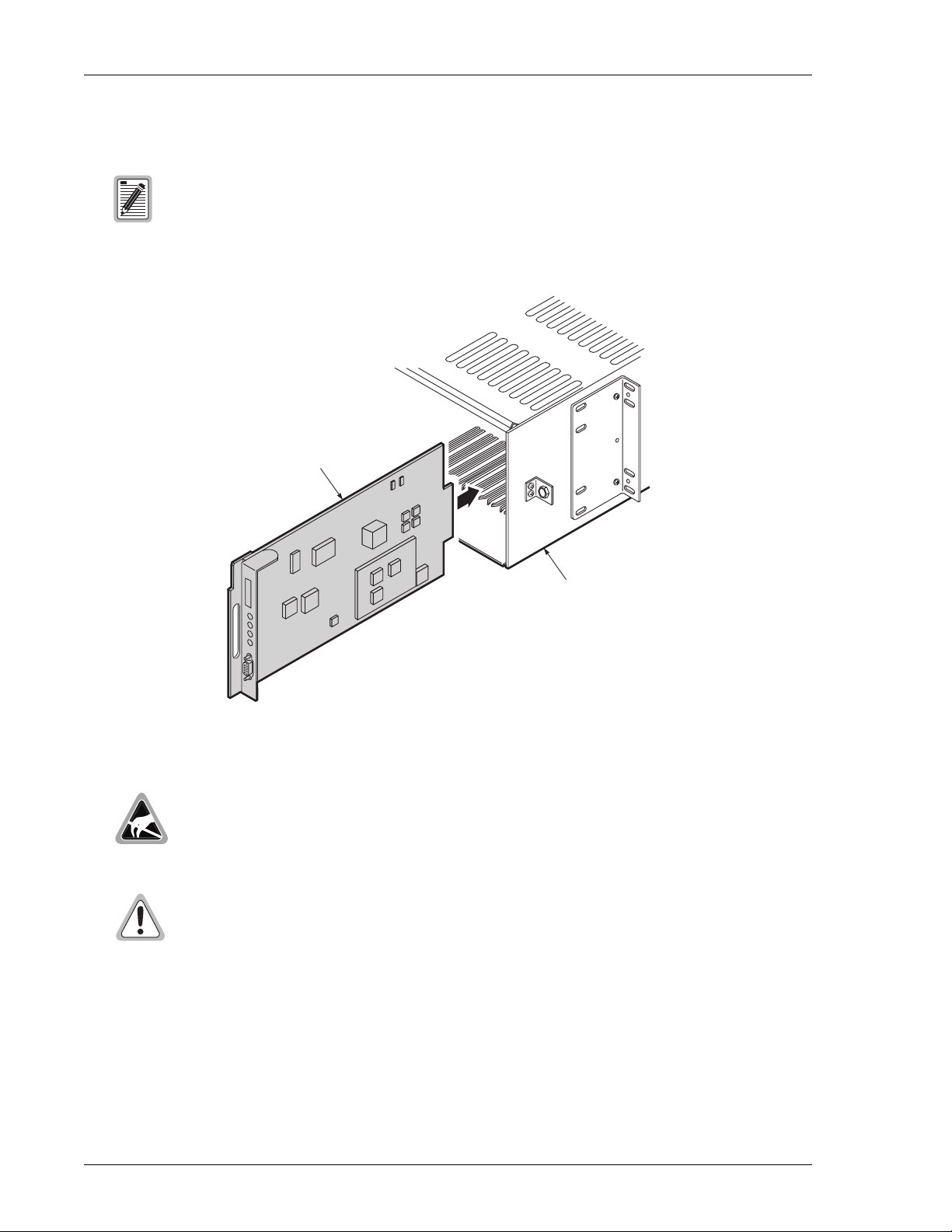

INSTALLATION

Upon receipt of the equipment, ins pect th e con tents for signs of dam age . If the e quipm ent has

been damaged in transit, immediately report the extent of damage to the transportation

company and to ADC.

H2TU-C-319

CO shelf

Figure 2. Installing the H2TU-C-319 List 4E into a Shelf

When installing an H2TU-C in a chassis , be sure to wear an antistatic wrist strap. Avo id touching

components on the circuit board.

To comply with the intrabuilding wiring requirements of GR-1089 CORE, Section 4.5.9, the

shields of the ABAM-type cables that connect the H2TU-C DSX-1 output ports to the

cross-connect panel must be grounded at both ends.

1 Align the H2TU-C with the enclosure slot guides, then push the unit in until it touches the backplane

card-edge connector.

2 Place your thumbs on the H2TU-C front panel and push the H2TU-C firmly into the slot guides until the unit

clicks into the backplane and is properly seated.

8 January 9, 2002 H2TU-C-319 List 4E

Page 17

LTPH-UM-1049-02, Issue 2 Installation

VERIFICATION

Once the H2TU-C is installed, verify that it is operating properly. To do this, monitor the following:

• Status LED

• Status messages reported by the front-panel display (Table 2 on page 5 lists the status messages).

Verification without an H2TU-R Remote Unit

If there is no H2TU-R remote unit installed:

1 Verify that the H2TU-C powers up. The front-panel display illuminates and reports status messages. (See

Table 2 on page 5 lists the messages.)

2 Verify that the H2TU-C attempts to communicate with a remote unit (status LED flashes red). Even if a

remote unit is not present, the following events should occur:

a The front-panel display reports various four-character status messages.

b The H2TU-C again attempts communicatio n with a remote unit until a remote unit is detected.

Verification with an H2TU-R Remote Unit

If an H2TU-R remote unit has been installed:

1 Verify that the H2TU-C powers up. (The front-panel display illuminates and reports various status messages.)

2 Verify that the H2TU-C attempts to communicate with the remote unit (status LED flashes red). One of the

following occurs:

• If the remote unit is successfully identified and the HDSL2 loop synchronizes, the H2TU-C status LED

lights a steady green. The H2TU-C reports normal margin messages o n the front-panel display.

• If the remote unit is not identified, the H2TU-C reports four-character status messages. The H2TU-C

attempts communication again and reports four-character status messages. The H2TU-C repeats this

cycle until a remote unit is detected.

3 Verify that a valid DS1 signal has been applied to the H2TU-C and the H2TU-R.

• If no DS1 signal is being applied to either the H2TU-C or the H2TU-R inputs, then the appropriate DS1

alarms (LLOS or RLOS) display on the front panel and the status LED flashes red.

• If a valid DS1 signal is being supplied to the H2TU-C and H2TU-R, then DS1 alarm indications should

be absent and the status LED should be a steady green.

H2TU-C-319 List 4E January 9, 2002 9

Page 18

Provisioning LTPH -UM-1049-02, Issue 2

PROVISIONING

There are two provisioning methods:

• Use the MODE and LBK pushbuttons on the front panel of the H2TU-C to:

– Set system options

– Reset the H2TU-C to its factory default settings for system options

– Display system option settings (scroll mod e)

– Select system loopbacks

– Select MTA test mode

• Use a maintenance terminal, such as an ASCII terminal or a PC running terminal emulation software,

connected to the H2TU-C craft port or an HMU craft port to access the maintenance screens. Figure 3 on

page 13 shows the maintenance screen. This provides full access to all H2TU-C status, histor y, inventory, and

provisioning screens.

No dip switches or jumpers are required to provision the H2TU-C as it contains a non-volatile

RAM (NVRAM) which stores the system option settings. System option settings are retained if

shelf power is lost or if the H2TU-C is unplugged.

USING THE MODE AND LBK PUSHBUTTONS

Setting Options through MODE and LBK

To provision the H2TU-C through the MODE and LBK pushbuttons on the front panel:

1 Press the MODE pushbutton for 1 second and then release it. The front panel display alternately shows the

first system parameter and its current setting.

2 Press the LBK pushbutton to step through all possible settings of the selected paramete r.

3 After the desir ed s e ttin g ha s been selected, press the MODE pushbutton. This updates the current displayed

parameter to the selected setting, then advances to the next configurable parameter. After the last parameter

has been selected, a CONF NO message appears on the front-panel display.

4 Do one of the following:

• To cancel the session without saving the requested parameter changes, press the MODE pushbutton or

do nothing. After 30 seconds, the display returns to its normal mo de without saving the new changes.

• To accept the requested parameter changes, press the LBK pushbu tton. A CONF YES message displays,

and the display returns to its normal mode after saving the new changes.

10 January 9, 2002 H2TU-C-319 List 4E

Page 19

LTPH-UM-1049-02, Issue 2 Provisioning

Resetting to Factory Default Values

All user options for the H2TU-C, described in Table 5 on page 18 , can be set to the factory default values using

the MODE and LBK pushbuttons. To set the user options to their default values:

1 Press the LBK pushbutton for 6 seconds until the following message appears:

DFLT NO

2 Press the LBK pushbutton until the DFLT NO message is displayed.

The message changes to DFLT YES indicating the factory default values are now in effect and the display

returns to the normal mode.

To terminate the DFLT mode without setting the factory default values, do one of the following:

• Press the MODE pushbutton to return to the normal display mode.

• Wait 30 seconds for the unit to return to the normal display mode.

Displaying System Parameter Settings

To scroll through the current settings of all system parameters, press the MODE pushbutton for 3 or more seconds.

The H2TU-C displays the following parameters:

• H2TU-C software version number

• H2TU-C list number

• Type of frame pattern received from the DSX-1

• Line code of the signal received from the DSX-1

• All user-configured parameter settings

• Loop attenuation threshold setting

• Margin alarm threshold setting

Disabling an Alarm

System alarms can be disabled by pressing the LBK pushbutton on the H2TU-C front panel. This executes an

ACO and returns the H2TU-C to its non-alarm state. For more information, see “Retiring System Alarms” on

page 53.

Loopback Modes

See “Loopback Operation” on page 55 for instructions on using the MODE and LBK pushbuttons to activate

loopbacks.

H2TU-C-319 List 4E January 9, 2002 11

Page 20

Provisioning LTPH -UM-1049-02, Issue 2

USING A MAINTENANCE TERMINAL

Connecting to a Maintenance Terminal

The craft port on the front panel allows you to connect the H2TU-C to a maintenance terminal (ASCII terminal

or PC running a terminal emulation program). Once connected to a maintenance terminal, you can access the

maintenance, provisioning, and performance screens.

To connect to a maintenance terminal:

1 Connect a standard 9-pin terminal cable to the RS-232 craft port, as shown in Figure 1 on page 3, on the

front panel.

2 Connect the other end of the cable to the serial port on the maintenance terminal.

3 Start a terminal emulation program such as Procomm that emulates a VT100 terminal.

4 Con fi gur e the main tenan ce ter mi nal to the following communication settings:

• 9600 baud

• No parity

• 8 data bits

• 1 stop bit

• Hardware flow control to OFF

5 If necessary, press + to refresh the HiGain HDSL2 logon screen.

CTRL R

The Logon Screen

The HiGain HDSL2 maintenance terminal screens allow you to mo nitor, provision, and troubleshoot an H2TU-C

system.

To select a menu from the HiGain HDSL2 logon screen, shown in Figure 3 on page 13, do one of the following:

• Press the underlined letter of the menu.

• Use the arrow keys to select the menu and press .

Table 3 summarizes the navigational keys. They are also listed in the onscreen Help menu. Table 4 on page 13

describes t he Logon screen menus.

(a)

Key

SPACEBAR

ENTER

Return to the parent menu.

ESC

or + Select the submenu or item above the current one, or return to the previous menu.

CTRL E

↑

or + Select the submenu or item below the current one.

CTRL X

↓

→

or + Select the menu or item to the right of the current one.

CTRL D

←

or + Select the menu or item to the left of the current one, or return to the previous menu.

CTRL S

+ Refresh the screen.

CTRL R

(a) Legacy management units require the use of control keys instead of arrow keys.

← →

ENTER

Table 3. Navigational Keys for the HiGain HDSL2 Maintenance Terminal Screens

Function

Cycle through selections.

Activate the current setting or choice, or display a menu.

12 January 9, 2002 H2TU-C-319 List 4E

Page 21

LTPH-UM-1049-02, Issue 2 Provisioning

Most VT100 emulation programs support a print s cree n o ption. For Wind ow s-ba sed prog ra ms ,

such as Procomm or HyperTerminal, see the Help menu for instructions.

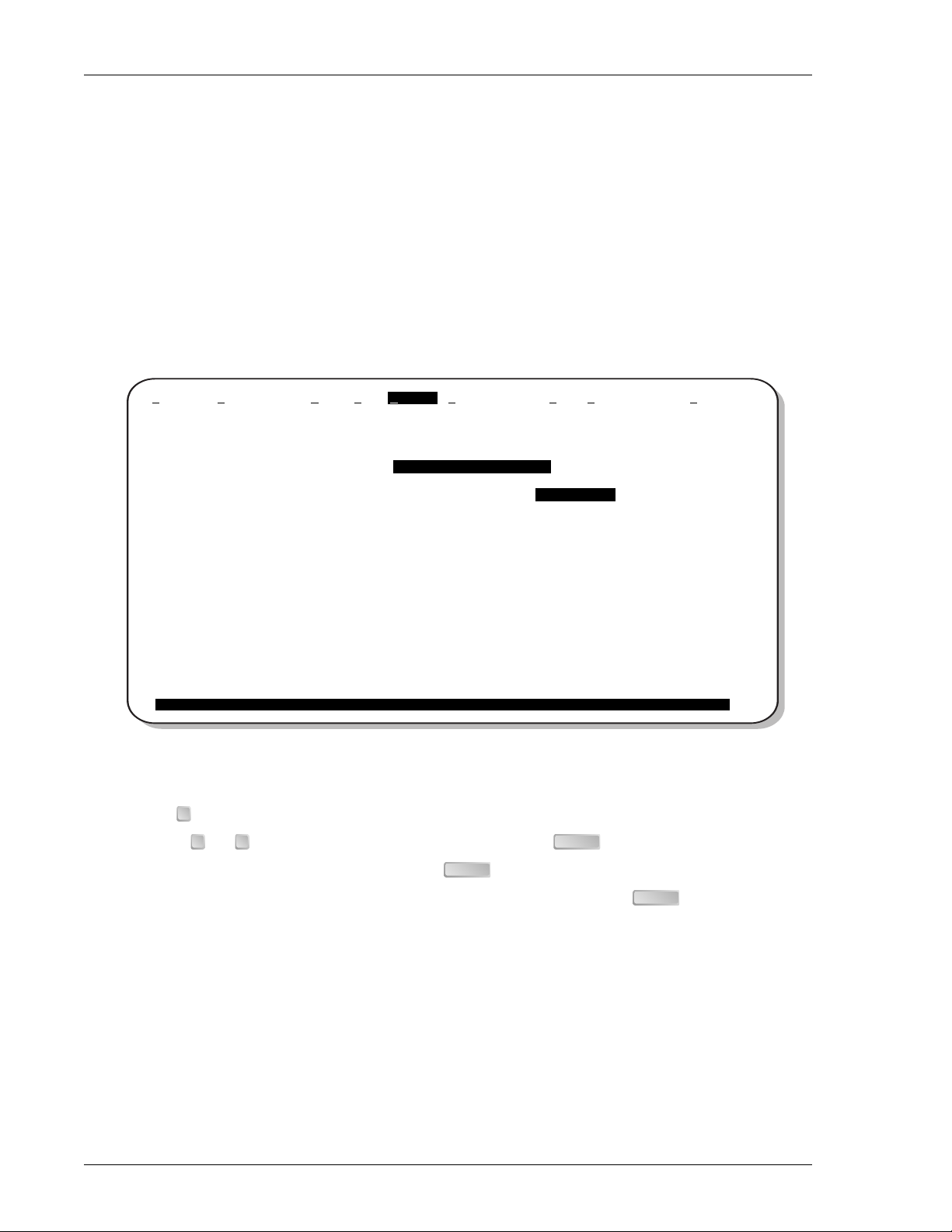

Menu bar

Monitor Performance Event Log Config Inventory Report Rlogon Help

+------------------------------------------+

||

| ADC DSL Systems, Inc. |

| HiGain HDSL2 |

||

| Voice: 800.638.0031 |

| Fax : 714.832.9924 |

||

+------------------------------------------+

ID: xxxx--xxxx--xxxx--xxxx 08/01/2001 06:38:12 H2TU-C System: OK

Circuit ID Date and Time Logon Device System Status

Figure 3. Logon Screen

Table 4. Logon Screen Menus

Press this key: To access this menu: Menu Functions

M

P

E

C

I

O

R

H

Monitor Monitors loopbacks and alarms, and provides a graphical representation of

circuit activity, including ES, UAS, SES, and line code.

Performance Provides performance and alarm histories for current, 24-hour, 48-hour, or

31-day periods for either the DS1 or HDSL2 interface.

Event Log Identifies the 100 most recent system events and reports the date and time of

occurrence.

Config Provides standard configuration options, ADC options, date and time setting,

and a reset option (factory settings). Also provides a master clear option that

clears all performance, alarm, and event log entries.

Inventory Provides product information about the various devices that are in the system

and lists circuit and device identifications.

Report Provides four types of reports: Full Report, Short Report, System Information

Report, and Event Report.

Rlogon/Rlogout Remote logon can be performed from the H2TU-C or H2TU-R. The screen

displays “R

logout” when the H2TU-C or H2TU-R is remotely logged on to the

other unit at the end of the circuit.

To logoff the remote unit, press . “Rlogout” changes to “Rlogon”. The unit is

now locally logged on until is pressed again to reinitiate the remote logon.

Help Provides a glossary of terms used in the maintenance screens, a list of

navigational keys, and ADC contact information.

R

R

H2TU-C-319 List 4E January 9, 2002 13

Page 22

Provisioning LTPH -UM-1049-02, Issue 2

PROVISIONING TASKS

After the H2TU-C is successfully installed, perform these basic provisioning tasks:

• Set date and time (see “Setting Date and Time” on this page).

• Set circuit ID numbers (see “Setting Circuit ID Numbers” on page 15).

• Make any configuration changes (see “Configuring the System” on page 16).

• Clear history, alarm, and event log screens to remove miscellaneous data during startup (see “Clearing the

History, Alarm, and Event Log Screens” on page 33).

Setting Date and Time

Monitor Performance Event Log Config Inventory Report Rlogon Help

ID: xxxx--xxxx--xxxx--xxxx 08/01/2001 06:38:12 H2TU-C System: OK

+-----------------------+

| Standard Options -> |

| ADC Options -> |

| Test Mode -> |

| Date and Time -> |

+---------------------------------+

| Date (mm/dd/yyyy) : 08/01/2001 |

| Time (hh:mm[:ss]) : 06:40:11 |

+---------------------------------+

Figure 4. Config Menu - Date and Time

1 Press to select the Config menu.

2 Use the and arrow keys to select Date and Time, then press .

C

↑ ↓

ENTER

3 Type the date in the format indicated, then press .

4 Type the time in the format indicated (entering seconds is optional), then press .

14 January 9, 2002 H2TU-C-319 List 4E

ENTER

ENTER

Page 23

LTPH-UM-1049-02, Issue 2 Provisioning

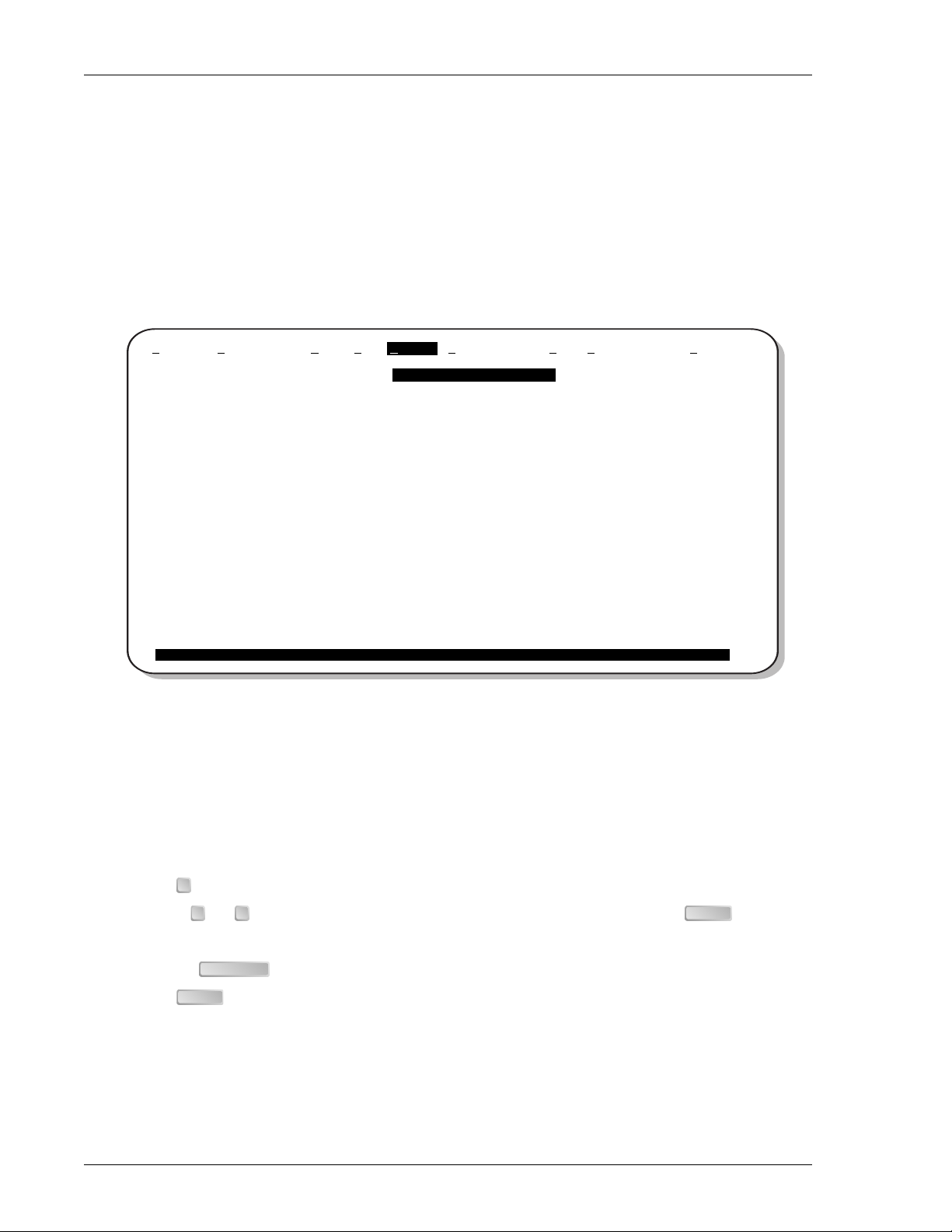

Setting Circuit ID Numbers

The Inventory menu provides product information on all units in the system and allows setting of the circuit and

unit identification numbers.

Monitor Performance Event Log Config Inventory Report Rlogon Help

-------------------------- Product Information ---------------------------Unit : H2TU-C H2TU-R

Product : H2TU-C-319 H2TU-R-402

List : 4E 6E

Sw Ver. : 3.00 3.00

Build # : 10 25

Checksum : 0x604A 0x9616

H2 Xcvr : L1-HB2 1.31 L1-RA2 1.31

Serial # : 01232456789 0123456789

CLEI : VACHYVYGAA XXXXXXXXXX

Mfg. Date: 6-1-2001 6-1-2001

-------------------- Circuit and Unit Identifications ---------------------

Circuit ID : xxxx--xxxx--xxxx--xxxx

H2TU-R ID : xxxx--xxxx--xxxx--xxxx

Circuit Notes:

ID: xxxx--xxxx--xxxx--xxxx 08/01/2001 06:42:07 H2TU-C System: OK

Figure 5. Inventory Screen

1 Press to select the Inventory menu.

2 Type the Circuit ID number, then press .

3 Type the ID numbers of all other devices listed in the system, pressing after each entry.

I

ENTER

ENTER

H2TU-C-319 List 4E January 9, 2002 15

Page 24

Provisioning LTPH -UM-1049-02, Issue 2

Configuring the System

The Config menu (see Figure 6 below) allows you to make the following changes:

• Standard options (see “Making Changes to Standard and ADC Options” on page 16).

• ADC options (see “Making Changes to Standard and ADC Options” on page 16).

• Date and time (see “Setting Date and Time” on page 14).

• Master clear (see “Clearing the History, Alarm, and Event Log Screens” on page 33).

• Reset to factory default configuration (see “Resetting to Factory Defaults” on page 32 ).

Monitor Performance Event Log Config Inventory Report Rlogon Help

ID: xxxx--xxxx--xxxx--xxxx 08/01/2001 06:38:12 H2TU-C System: OK

+-----------------------+

| Standard Options -> |

| ADC Options -> |

| Test Mode -> |

| Date and Time -> |

| Master Clear |

| Set Factory Defaults |

+-----------------------+

Figure 6. Config Menu

Making Changes to Standard and ADC Options

Figure 7 and Figure 8 on page 17 show the Standard and ADC configuration options. Standard o ptions are tho se

supported by HiGain HDSL2 units when conn ected to units fro m other vend ors. ADC options are an extended set

of options that are only available when using HiGain u nits exclusively. For a descri ption of each option and a list

of possible option settings, refer to Table 5 on page 18 and Table 6 on page 19. To make changes to these options:

1 Press to select the Config menu.

2 Use the and arrow keys to select Standard Options or ADC Options, then press .

C

↑ ↓

ENTER

3 Use the arrow keys to select an option.

4 Press the to cycle through the available settings for that option.

5 Press to activate your choice.

16 January 9, 2002 H2TU-C-319 List 4E

SPACEBAR

ENTER

Page 25

LTPH-UM-1049-02, Issue 2 Provisioning

Monitor Performance Event Log Config Inventory Report Rlogon Help

+-----------------------------------------------------+

| Loopback Timeout (LBTO) : 120 min |

| Loop Attenuation Threshold (LATT) [0-40] : 32 dB |

| Margin Threshold (MARG) [0-15]: 5 dB |

| DS1 Frame Formatting (FRMG) : AUTO |

| DS1 Line coding (DS1) : B8ZS |

| H2TU-C Equalization (EQL) : 0 ft |

| H2TU-R Line Buildout (RLBO) : -7.5 dB |

| Alarm Pattern (ALMP) : AIS |

| H2TU-R TLOS Loopback (TLOS) : DIS |

| Power Back Off Network (PBON) : DEF |

| Power Back Off Customer (PBOC) : DEF |

+-----------------------------------------------------+

Use <Spacebar> to cycle through option settings and <Enter> to activate

ID: xxxx--xxxx--xxxx--xxxx 08/01/2001 06:43:31 H2TU-C System: OK

+-----------------------+

| Standard Options -> |

Figure 7. Con fig Menu - Standard Options (defaults sh ow n)

Monitor Performance Event Log Config Inventory Report Rlogon Help

+-----------------------+

| Standard Options -> |

| ADC Options -> |

+-------------------------------------------------+

| Line Power Feed (PWRF) : ON |

| Remote Provisioning (RTPV) : ENA |

| Bipolar Violation Transparency (BPVT) : DIS |

| DS1 BER (DBER) : DIS |

| HDSL2 BER Threshold (HBER) : 1E-6 |

| Special Loopback Mode (SPLB) : GNLB |

| Smartjack Loopback (LPBK) : ENA |

| Minor Alarm (ALM) : DIS |

| Network AIS Pattern (NAIS) : CI |

| Performance Report Messaging (PRM) : S+N |

| SF-RAI to SF-RAI-CI toward NET (RACI) : ENA |

| ESF-RAI to SF-RAI Overwrite (ROVR) : ENA |

| H2TU-R DS1 Frame Conversion (CONV) : ACON |

| Fractional T1 Mode (FT1) : DIS |

| Active DS1 Port (ADS1) : MUX |

+-------------------------------------------------+

Use <Spacebar> to cycle through option settings and <Enter> to activate

ID: xxxx--xxxx--xxxx--xxxx 08/01/2001 06:43:31 H2TU-C System: OK

Figure 8. Config Menu - ADC Options ( defaults shown)

H2TU-C-319 List 4E January 9, 2002 17

Page 26

Provisioning LTPH -UM-1049-02, Issue 2

Table 5 describes the Standard Config scr een options and lists their front-panel dis play codes. Table 6 on page 19

describes the ADC Config screen options and lists their front-panel d isplay codes. Selections in bold typeface are

the factory default settings.

Table 5. H2TU-C-319 List 4E Standard Config Menu Options

Standard Config

Menu Options

Loopback Timeout LBTO NONE Disables automatic time-out cancellation of all loopbacks.

Loop Attenuation

Threshold

Margin Threshold MARG 0 to 15 dB Determines the minimum allowable margin below which a system alarm can

DS1 Frame

Formatting

DS1 Line Coding DS1 B8ZS Places both the H2TU-C and H2TU-R into their B8ZS modes.

H2TU-C Equalization

See “H2TU-C

Equalization (EQL)

Option.” on page 22.

H2TU-R Line

Buildout

Alarm Pattern

See “Alarm Pattern

(ALMP) Option.” on

page 22.

H2TU-R TLOS

Loopback

Power Back Off

Network

Front-Panel

Display

Code

LATT 0 through

FRMG AUTO Configures the line unit to operate in an auto-framing (AUTO) mode.

EQL 0 ft Sets the Equalizer to DSX-1 for 0 to 132 feet.

RLBO 0 dB Sets the DS1 RLBO level toward the Customer Interface (CI).

ALMP AIS Enables the HiGain HDSL2 system to output an AIS payload at its DS1 ports

TLOS ENA Enables a logic loopback at the H2TU-R when an LOS occurs at its DS1 input,

PBON DEF Configures the power output levels of the H2TU-C network unit towards the

Selection Description

20 Sets automatic cancellation of all loopbacks to 20 minutes after initiation.

60 Sets automatic cancellation of all loopbacks to 60 minutes after initiation.

120 Sets automatic cancellation of all loopbacks to 120 minutes after initiation.

40 dB

32 dB Default value. Zero disables the alarm.

5 dB Default value.

UNFR Configures the same as AUTO except unframed payloads do not cause the

AMI Places both the H2TU-C and H2TU-R into their AMI modes.

133 ft Sets the Equalizer to DSX-1 for 133 to 265 feet.

266 ft Sets the Equalizer to DSX-1 for 266 to 398 feet.

399 ft Sets the Equalizer to DSX-1 for 399 to 532 feet.

533 ft Sets the Equalizer to DSX-1 for 533 to 655 feet.

-7.5 dB Sets the DS1 RLBO level toward the CI to -7.5 dB.

-15 dB Sets the DS1 RLBO level toward the CI to -15 dB.

LOS Enables the HiGain HDSL2 system to output an LOS condition at its DS1 ports

DIS Disables TLOS logic loopback.

ENH Configures the power output levels of the H2TU-C network unit towards the

Determines the maximum loop attenuation before an alarm is declared. Zero

disables the alarm. The loop attenuation threshold can only be set through the

maintenance screens.

occur. Zero disables the alarm.

The Margin Alarm Threshold can only be set through the maintenance

screens.

It detects and locks to both SF or ESF DS1 frame patterns. Line and path

performance parameters are maintained and displayed. Unframed payloads

will cause the ES-P and SES-P counters to increment.

ES-P and SES-P counters to increment.

for LOSW and LOS DS1. For priority resolution, see Figure 30 on page 54 for

LOS/AIS response priorities.

for LOSW and LOS DS1.

if enabled at the H2TU-R. For priority resolution, see Figure 30 on page 54.

customer to comply with the Default template as defined in Section 6.1.4.2 of

ANSIT1.E1.4.

customer to comply with the Enhanced template as defined in Section 6.1.4.2

of ANSIT1.E1.4.

Continued

18 January 9, 2002 H2TU-C-319 List 4E

Page 27

LTPH-UM-1049-02, Issue 2 Provisioning

Table 5. H2TU-C-319 List 4E Standard Config Menu Options (Continued)

Standard Config

Menu Options

Power Back Off

Customer

Front-Panel

Display

Selection Description

Code

PBOC DEF Configures the power output levels of the H2TU-R network unit towards the

network to comply with the Default template as defined in Section 6.1.4.2 of

ANSIT1.E1.4.

ENH Configures the power output levels of the H2TU-R network unit towards the

network to comply with the Enhanced template as defined in Section 6.1.4.2

of ANSIT1.E1.4.

Table 6. H2TU-C-319 List 4E ADC Config Menu Options

ADC Config Menu

Options

Line Power Feed PWRF OFF Disables powering to the HDSL2 pair.

Remote Provisioning RTPV ENA Enables remote provisioning.

Bipolar Violation

Transparency

See “Bipolar

Violation

Transparency

(BPVT) Option” on

page 22.

DS1 BER Threshold

See “DS1 BER

(DBER) Option” on

page 22.

HDSL2 BER

Threshold

See “HDSL2 BER

Threshold (HBER)

Option” on page 22

and “System Alarm

Output Pin” on

page 70.

Special Loopback

Mode

SmartJack Loopback LPBK ENA Enables the HiGain HDSL2 system to recognize all in-band SmartJack

Front-Panel

Display

Selection Description

Code

ON Keeps the HDSL2 line voltage at nominal -185 Vdc.

DIS Disables remote provisioning.

BPVT ENA Enables BPVs and HDSL2 CRC errors at the DS1 input to be converted into

DS1 BPVs at the DS1 output at the distant end. This makes HiGain HDSL2

transparent to BPVs.

DIS Disables BPV Transparency.

DBER ENA Enables the fixed 24-hour DS1 BER threshold.

DIS Prevents the generation of a system alarm due to DS1 BER.

HBER 1E-6 System alarm relay contact closes and the Status LED flashes red when the

Block Error Rate (BER) exceeds 10

1E-7 System alarm relay contact closes and the Status LED flashes red when BER

exceeds 10

-7

.

-6

.

NONE Prevents generation of a system alarm due to BER.

SPLB GNLB Configures the HiGain HDSL2 system to respond to the generic in-band

loopback codes.

A2LB Configures the HiGain HDSL2 system to respond to the in-band loopback

codes of the Teltrend addressable repeater.

A3LB Configures the HiGain HDSL2 system to respond to the in-band loopback

codes of the Wescom addressable repeater.

A4LB Configures the HiGain HDSL2 system to respond to the in-band loopback

codes of the Wescom Mod 1 addressable repeater.

loopback commands.

DIS Configures the HiGain HDSL2 system to ignore all in-band SmartJack

loopback commands.

Continued

H2TU-C-319 List 4E January 9, 2002 19

Page 28

Provisioning LTPH -UM-1049-02, Issue 2

Table 6. H2TU-C-319 List 4E ADC Confi g Menu Options (Continued)

ADC Config Menu

Options

Front-Panel

Display

Code

Selection Description

Minor Alarm ALM ENA Enables the generation of the output alarm on pin H when a system alarm

condition occurs.

DIS Disables the generation of the output alarm on pin H when a system alarm

condition occurs.

Network AIS Signal NAIS CI If ALMP is set to AIS, this option specifies which pattern is sent to the network

when a remote LOS or AIS occurs. When configured for CI, an AIS-CI pattern

is sent to the network.

AIS When configured for AIS, an AIS pattern is sent to the network.

Performance Report

Messaging

PRM SPRM The H2TU-R generates Supplemental PRM (SPRM) every second if no PRM

is received from the CPE within 5 seconds of a reset or if an LOS/AIS/LOF

condition occurs. TL1 commands and responses are enabled.

NPRM The H2TU-R generates Network PRM (NPRM) if no PRM is present from the

CPE. If the CPE is sending PRMs, NPRM is generated every second in addition

to the existing PRM. TL1 commands and response are enabled.

S + N The H2TU-R generates an NPRM which is tagged onto an SPRM every

second. The H2TU-R generates SPRM if no PRM is present from the CPE. If

the CPE is sending PRM, the PRM is converted to an SPRM. TL1 commands

and responses are enabled.

OFF ESF Datalink (DL) is completely transparent. No PRMs are generated. There

are no TL1 responses unless the system is first armed by a TL1 command,

which enables performance monitoring.

SF RAI to SF RAI-CI

Toward Network

See “SF RAI to SF

RAI-CI Toward

RACI ENA Allows a DS1 SF-RAI (yellow alarm) signal received by the H2TU-R to be

converted to an SF-RAI-CI signal toward the network.

DIS Prevents conversion of the DS1 SF-RAI to SF RAI-CI. It does not prevent SF

RAI-CI to ESF RAI-CI from occurring when FCON is active.

Network (RACI)

Option” on page 23.

ESF RAI to SF RAI

Overwrite

ROVR ENA If the CONV option is set to FCON or ACON, an ESF DS1 payload from the

network with an embedded RAI pattern is converted to an SF-RAI pattern

toward the CI at the H2TU-R.

See “ESF RAI to SF

DIS Prevents conversion to an SF-RAI pattern.

RAI Overwrite

(ROVR) Option” on

page 23.

H2TU-R DS1 Frame

Conversion

See “H2TU-R DS1

CONV ACON Auto (ACON) detection of framing and potential frame conversion at the

remote.

OFF Framing determined by the DS1 frame formatting option.

Frame Conversion

(CONV) Option” on

page 23.

FCON Auto detection of framing and forced frame format conversion (FCON) at the

H2TU-R.

Fractional T1 Mode

See “Fractional T1

(FT1) Option” on

page 26.

FT1 ENA Enables system response to DDS latching loopback commands for fractional

T1 applications and enables CPE disconnect or trouble indication. See

Figure 30 on page 54 for LOS/AIS response priorities.

DIS Disables system response to DDS latching loopback commands for fractional

T1 applications and CPE disconnect or trouble indications.

Continued

20 January 9, 2002 H2TU-C-319 List 4E

Page 29

LTPH-UM-1049-02, Issue 2 Provisioning

Table 6. H2TU-C-319 List 4E ADC Config Menu Option s (Continued)

ADC Config Menu

Options

Active DS1 Port

See “Dual DSX-1

Port Option” on

page 31.

Front-Panel

Display

Selection Description

Code

ADS1 MUX The MUX mode selects the DSX-1 (MUX) port as the active source for the DS1

Signal to transmit to the HSDL Line Port #1.

An AIS signal is sent to the auxiliary Port #2. Equalizer settings apply to the

MUX DSX-1 port. The AUX equalizer is set to 0.

AUX The AUX mode selects the auxiliary DSX-1 Port #2 as the active source for

DS1 signal to transmit to the HDSL Line Port.

In this case, the MUX port is used as a monitor or splitting device for electrical

test access. Equalizer settings apply to the AUX DSX-1 port. The MUX

equalizer is set to 0.

CTHR Activates the Cut-through mode. This mode electrically connects the MUX

port to the AUX port and the H2TU-C operates as a cut-through card.

This is used when one tributary from the Wideband 3190 MUX card is required

to appear at the DSX-1 interface to the local central office. Equalizer settings

apply to the MUX DSX-1 port. The AUX Equalizer is set to 0.

H2TU-C-319 List 4E January 9, 2002 21

Page 30

Provisioning LTPH -UM-1049-02, Issue 2

HDSL2 BER Threshold (HBER) Option. The HBER option permits the monitoring of loop integrity and

reporting of alarms when excessive errors are detected. The PM primitive used for this purpose is the CRC

checksum performed on the HDSL2 f rame for bo th directions of transmission. It is, therefore, called a block er ror

rate rather than the bit error rate associated with the DS1 interface. The CRC errors and counts are displayed on

the Monitor screen for both the H2TU-C and H2TU-R. The HBER option allows an alarm to be generated if the

total number of CRCs at either the H2TU-C or H2TU-R exceeds the selected BER threshold during the last

1-minute interval .

• HBER option = 1E-6. Alarm is generated if CRC > 93

• HBER option = 1E-7. Alarm is generated if CRC > 9

Once initiated, the HBER count clears when the CRC count drops below the selected threshold. Selecting NONE

inhibits this alarm.

H2TU-C Equalization (EQL) Option. Equalization is the configuration of sys tem transmission characteristics

within specified limits. An adaptive equalizer inserts a frequency-shaped loss that corresponds to an equivalent

addition of an appropriate cable length. By simulating the additional cable loss necessary for correct operation,

the equalizer compensates for a range of variation in transmission path characteristics.

Alarm Pattern (ALMP) Option. To improve HiGain HDSL2 compatibility with the switch-to-protect features

used in Digital Loop Carrier (DLC) feeder applications, the H2TU-C has an Alarm Pattern (ALMP) option that

allows you to select either an AIS or LOS DS1 output payload for the following alarms:

• LOSW on any loop

• LOS DS1

Bipolar Violation Transparency (BPVT) Option. The H2TU-C improves compatibility with Digital Loop

Carrier (DLC) feeder applications because of its ability to transmit DS1 BPV occurrences between its DS1

interfaces. This feature is required to support protection sw itching in DLC applications. Each DLC terminal must

be able to monitor the integrity of its Receive DS1 payload and then switch to the protect line when the integrity

of the path drops below specific user s elected limits . An essential req uiremen t of this feature is the need for each

DLC terminal to detect BPVs in its DS1 input. Standard HDSL systems correct DS1 BPVs at the input and

therefore prevent them from being detected by the DLC terminals to which they are connected. The H2TU-C and

its associated remote units remove this limitation and become BPV transparen t by det ecting and counting input

BPVs at each end and then by replicating them at the DS1 output port of the distant end.

The BPV count is converted into BPVs at the distant end during the following second at a rate of 1 BPV every

-3

128 DS1 bits up to a maximum of 12000 (BER = 7.7 x 10

-3

exceeds the maximum 10

BER required by mo st DLC systems.

). This maximum rate is more than adequate since it

DS1 BER (DBER) Option. The DS1 BER alarm occurs when any of the DS1 or DSX-1 performance

monitoring parameters listed in Table 7 exceed the counts shown for the 24-hour period between 12:00:00 AM

-6

through 11:59:59 PM . These thr eshol ds corr espond to a 10

BER. All PM counters clear to zero at 12:00:00 AM

or when Master Clear is selected. See “Clearing the History, Alarm, and Event Log Screens” on page 33.

Table 7. DS1 and DSX-1 24-hour PM Threshold

Parameter Threshold Count

CV-L (BPV) 133,400

ES-L, ES-P, PRM, PDVS-L 648

SES-L, SES-P 100

UAS-P, UAS-L 10

22 January 9, 2002 H2TU-C-319 List 4E

Page 31

LTPH-UM-1049-02, Issue 2 Provisioning

SF RAI to SF RAI-CI Toward Network (RACI) Option. In general, the Remote Alarm Indication Customer Installation (RAI-CI) signal is a RAI signal which contains a signature indicating that an LOF or AIS

failure has occurred within the customer’s network.

RAI-CI is transmitted toward the network when these two conditions are si multan e ously true at the point from

which RAI-CI is originated (at the H2TU-R, toward the network):

• RAI is received from the CI

• No LOF, LOS, or AIS failure is detected in the signal received from the network.

Since RAI-CI meets the definition of RAI, it may be detected and used exactly as an RAI.

For ESF, the RAI-CI signal is a repetitive pattern with a period of 1.08 seconds. RAI-CI is formed by sequentially

interleaving 0.99 seconds of the unscheduled message 00000000 111 111 11 (ri g ht-t o-l ef t) , whi ch repr esents RAI

in the DL, with 90 milliseconds of the message 00111110 11111111 (right-to-left) to flag the signal as RAI-CI.

For SF, the SF-RAI-CI signal is transmitted in-band by setting each of the 24 channel time slots to 1000 1011

(left-to-right). In addition to the criteria specified above, the generation of SF-RAI-CI has to be held for 1 second

to examine the DS0 channels for the presence of a frame with an all-zeroes pattern. If present, the generation of

SF-RAI-CI is suspended for the duration of the all-zeroes pattern.

In all SF environments, the H2TU-R automatically converts a CPE DS1 payload with an embedded RAI signal

into an RAI-CI pattern toward the network if the RACI option is enabled (default). Such a conversion affects the

payload as described above. Disable RACI to avoid this payload-affecting conversion.

The SF RAI to SF RAI-CI option is only applicable in an all SF framing environme nt. If SF to ESF

conversion is active (the CONV o ption is se t to eith er ACON o r FCON), th e SF RAI is conv erted

into ESF RAI in the FDL, regardless of the RACI setting.

ESF RAI to SF RAI Overwrite (ROVR) Option. If the ESF RAI to SF RAI Overwrite (ROVR) option is

enabled, it allows a network ESF RAI or ESF RAI-CI pattern to be converted into a CPE SF RAI or SF RAI-CI

pattern, and overwrites the payload bits with the specific alarm patterns.

If the ROVR option is disabled, it prevents conversion of a network ESF payload with an embedded RAI pattern

and preserves the integrity of the CPE payload as it was originally tran sm itted.

Power Back Off (PBOC and PBON) Option. Power Back Of Network (PBON) and Power Back Off

Customer (PBOC) allow the HDSL circuit to support two tr ansmit power templates: default (DEF/higher level)

and enhanced (ENH/lower level). These are defined in Section 6.1.4. 2 of the ANSI T1E1.4 HDSL2 standard. Each

HDSL2 receiver detects the level it is receiving during the s tart-up, pre-activation s equence. It then compares this

level to the level it should be receiving according to the PBON and PBOC option settings (DEF or ENH). If the

received level is outside the template limits, the receiver sends a message to the upstream HDSL2 transmitter

requesting the proper level. These levels are adjusted only during the start-up routine or if the PBON or PBOC

option settings are changed during no rmal operation. Since the ENH template levels are up to 15 dBm below those

of the DEF template, the ENH setting can be used to red uce cros stalk lev els into adjacen t circuits. (For examp l e,

if crosstalk noise is being induced by the H2TU-R, set the PBO C option to its lower (ENH) level settin g.

Conversely, if the HDSL2 signal at the H2TU-R is being affected by crosstalk noise induced from adjacent pairs,

set the PBOC option to its higher (DEF) level setting.

Changing these Power Back Off option settings on a live circuit causes the HDSL2 loop to

momentarily drop and then reacquire sy nchronization. This setting can also af fect the operating

margins.

H2TU-R DS1 Frame Conversion (CONV) Option. Frame format conversion is only applicable to the

remote H2TU-R, but selectable by the H2TU-C or H2TU-R. This option enables the network to be ESF, which is

H2TU-C-319 List 4E January 9, 2002 23

Page 32

Provisioning LTPH -UM-1049-02, Issue 2

used to embed SPRM or NPRM into the datalink toward the network. During conversion, frame bit errors are

regenerated to ensure transparency.

The HDSL2 system attempts to find ESF or SF framing or determines that no framing exists. The DS1 framing is

then synchronized with the HDSL2 frame. If the framing is lost, the system generates an Out-of-Frame (OOF)

defect which results in UAS-P. As a result, the system reverts to frame search mode.

This option has the following settings:

• OFF: No frame conversion takes place. All framing issues are determined by the FRMG option settings of

AUTO and UNFR.

• ACON: This is the automatic conversion setting. If the system detects ESF from the network and SF fro m the

CPE, it automatically converts the CPE SF to ESF toward the network as well as the n e twork ESF to SF

toward the CPE.

Upon power-on-reset, after loopdown, or after changing the frame conversion option, the framing needs to

be re-established before a complete conversion takes place. If there is a failure condition (LOS, AIS, or LOF)

during steady state, the previous co nversion st ate is maintained to en sure continuity when the system retu rns

from the failure condition.

If SF is received from the network, the H2TU-R forces an ESF toward the network for about 1.5 seconds.

This signals to the far-end PM-NIU at the network boundary that frame convers ion is requested. If the far-end

PM-NIU is capable of conversion, it changes the framing to ESF. If not, then the H2TU-R reverts to SF and

does not apply any conversion.

If an ESF is received from the CPE, it is passed on to the network, and the network’s inbound framing is

passed on to the CPE.

• FCON: This is the forced conversion setting. Table 8 below lists the HiGain HDSL2 responses to both the

ACON and FCON settings for the CONV option. The responses are identical, except in cases 3 and 4. In these

cases, the FCON reply is attempting to force the network ( or the far-end PM-NIU) to send ESF. It also alerts

the CPE with an AIS alarm pattern while forcing the ESF to the network. Continuity is maintained as for