Page 1

FlexWave™ Base Station System

2x1 microBTS

Installation Manual

ADCP-75-246 • Issue 1 • 6/2008

1431641 Rev A

22576-A

Page 2

ADCP-75-246 • Issue 1 • 6/2008 • Preface

COPYRIGHT

© 2008, ADC Telecommunications, Inc.

All Rights Reserved

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 06/2008 Original release

LIST OF CHANGES

The technical changes incorporated into this issue are listed below.

PAGE IDENTIFIER DESCRIPTION OF CHANGE

- Original release

TRADEMARK INFORMATION

ADC and ADC Telecommunications are registered trademarks of ADC Telecommunications, Inc.

FlexWave is a trademark of ADC Telecommunications, Inc.

nanoBTS is a trademark of ip.access Ltd.

TORX is a trademark of Textron, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims any and all liability for indirect, incidental, special, consequential or other similar damages. This disclaimer of

liability applies to all products, publications and services during and after the warranty period.

This publication may be verified at any time by contacting ADC’s Technical Assistance Center at 1-800-366-3891, extension 73475

(in U.S.A. or Canada) or 952-917-3475 (outside U.S.A. and Canada), or by e-mail to connectivity_tac@adc.com.

Page ii

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

Page 3

TABLE OF CONTENTS

Content Page

ABOUT THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

RELATED PUBLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

ADMONISHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

GENERAL SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

STANDARDS CERTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

LIST OF ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

1 INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 MICR0BTS DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1 Primary Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Fault Detection and Alarm Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 IP Backhaul Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.5 Network Listen Antenna Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.6 Base Station Antenna Cable Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.7 Powering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.8 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.9 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.10 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.11 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 ACCESSORY ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Strand Mount Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Lightning Protector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Solar Shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 UNPACKING AND INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 MOUNTING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Before Mounting the microBTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Lift Ring Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.3 Standard Mounting Bracket Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.4 Installing the Enclosure on the Standard Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.5 Strand-Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 INSTALLATION PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 Ground Wire Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Network Listen Antenna Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4 IP Backhaul Cable Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.5 Base Station Antenna Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.6 AC Power Wiring Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.7 Touch-Up Painting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.8 Power-Up and Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.9 microBTS Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 CUSTOMER INFORMATION AND ASSISTANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

ADCP-75-246 • Issue 1 • 6/2008 • Preface

© 2008, ADC Telecommunications, Inc.

Page iii

Page 4

ADCP-75-246 • Issue 1 • 6/2008 • Preface

TABLE OF CONTENTS

Content Page

Blank

Page iv

© 2008, ADC Telecommunications, Inc.

Page 5

ABOUT THIS MANUAL

This publication provides a description of the FlexWave microBTS (Base Transceiver Station).

Also provided are procedures for mounting and installing the microBTS. An overview of the

FlexWave Base Station System (BSS), a description of the system components, the system turnup and test procedures, and the system troubleshooting procedures are provided in other

publications. The microBTS works in conjunction with the Base Station Controller (BSC).

RELATED PUBLICATIONS

Listed below are related manuals and their publication numbers. Copies of these publications

can be ordered by contacting the ADC Technical Assistance Center at 1-800-366-3891,

extension 73476 (in U.S.A. or Canada) or 1-952-917-3476 (outside U.S.A. and Canada).

Title ADCP Number

ADC FlexWave BSS List of User Documentation 75-330

ADC FlexWave V3.1 BSS Overview 75-329

ADCP-75-246 • Issue 1 • 6/2008 • Preface

ADC FlexWave Base Station System Provisioning Guide 75-312

ADC FlexWave V3.1 Base Station System Configuration Guide 75-321

ADC FlexWave V3.1 BSS MIB Definitions 75-319

ADC FlexWave BSS nanoBTS OMC-R User Manual 75-331

ADC FlexWave SR3.1 BSS LCT Operations Guide 75-306

ADC FlexWave BSS BSC Configuration Utilities Guide 75-316

ADMONISHMENTS

Important safety admonishments are used throughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below) and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warn i n g: Warning is used to indicate the presence of a hazard that can cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

© 2008, ADC Telecommunications, Inc.

Page v

Page 6

ADCP-75-246 • Issue 1 • 6/2008 • Preface

GENERAL SAFETY PRECAUTIONS

Warn i n g: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically-powered equipment. To prevent electrical shock, never install or

use electrical equipment in a wet location or during a lightning storm.

STANDARDS CERTIFICATION

1900 MHz microBTS Standards

FCC: The microBTS complies with the applicable sections of Title 47 CFR Part 24.

Caution: Modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

Note: To comply with Maximum Permissible Exposure (MPE) requirements, the maximum

composite output from the antenna cannot exceed 1640 Watts EIRP and the antenna must be

permanently installed in a fixed location that provides at least 6 meters (20 feet) of separation

from all persons.

UL/CUL: The microBTS complies with NEMA Type 6, UL and CUL 50 Standard for

Enclosures for Electrical Equipment.

The microBTS provides the degree of protection specified by IP67 as defined in IEC

(International Electrotechnical Commission) Publication 60529.

This microBTS complies with UL and CUL 60950 and UL 50 as Communication Service

Equipment under the DUZO category.

IC: The microBTS complies with the applicable sections of RSS-133. The term “IC:” before the

radio certification number only signifies that Industry Canada Technical Specifications were met.

1800 MHz microBTS Standards

EU Harmonized Standards: Meets essential requirements of R&TTE 1999/5/EC.

• Article 3.1a – The protection of the health and the safety of the user and any other person,

including the objectives with respect to safety requirements contained in Directive 72/23/

EEC, but with no voltage limit applying.

• Article 3.1b – The protection requirements with respect to electromagnetic compatibility

contained in Directive 89/336/EEC.

• Article 3.2 – In addition, radio equipment shall be so constructed that it effectively uses

the spectrum allocated to terrestrial/space radio communication and orbital resources so as

to avoid harmful interference.

Page vi

© 2008, ADC Telecommunications, Inc.

Page 7

LIST OF ACRONYMS AND ABBREVIATIONS

The acronyms and abbreviations used in this manual are detailed in the following list:

AC Alternating Current

AMR Adaptive Multi-Rate

AW G American Wire Gauge

BSC Base Station Controller

BSS Base Station System

BTS Base Transceiver Station

C Celsius

CUL Canadian Underwriters Laboratories

DC Direct Current

EDGE Enhanced Data rates for GSM Evolution

EMS Element Management System

ESD Electrostatic Discharge

EU European Union

F Fahrenheit

FCC Federal Communications Commission

GFCI Ground Fault Circuit Interrupter

GPRS General Packet Radio Service

GSM Global System for Mobile communications

IEC International Electrotechnical Commission

IC Industry Canada

IP Internet Protocol

LED Light Emitting Diode

LNA Low Noise Amplifier

LPA Linear Power Amplifier

MHz Megahertz

MPE Maximum Permissible Exposure

MTBF Mean Time Between Failure

NEM Network Element Manager

NEMA National Electrical Manufacturers Association

OMC-R Operations and Maintenance Center - Radio

OSP Outside Plant

POE Power Over Ethernet

RF Radio Frequency

RMA Return Material Authorization

RX Receive or Receiver

TAC Technical Assistance Center

TRX Transmit/Receive

UL Underwriters Laboratories

VA Volt Amps

ADCP-75-246 • Issue 1 • 6/2008 • Preface

© 2008, ADC Telecommunications, Inc.

Page vii

Page 8

ADCP-75-246 • Issue 1 • 6/2008 • Preface

VA C Volts Alternating Current

VDC Volts Direct Current

Page viii

© 2008, ADC Telecommunications, Inc.

Page 9

1 INTRODUCTION

The FlexWave 2x1 microBTS is an environmentally hardened outdoor base station solution that

supports GSM/AMR voice traffic and GPRS/EDGE data traffic. An Internet Protocol (IP)

backhaul provides the interface between the microBTS and the Base Station Controller (BSC).

All voice and data traffic and all operation and maintenance functions are transported by the IP

backhaul. A complete FlexWave Operations and Maintenance Center - Radio (OMC-R)

management solution is available that provides total control of the microBTS, BSC, and other

FlexWave system elements.

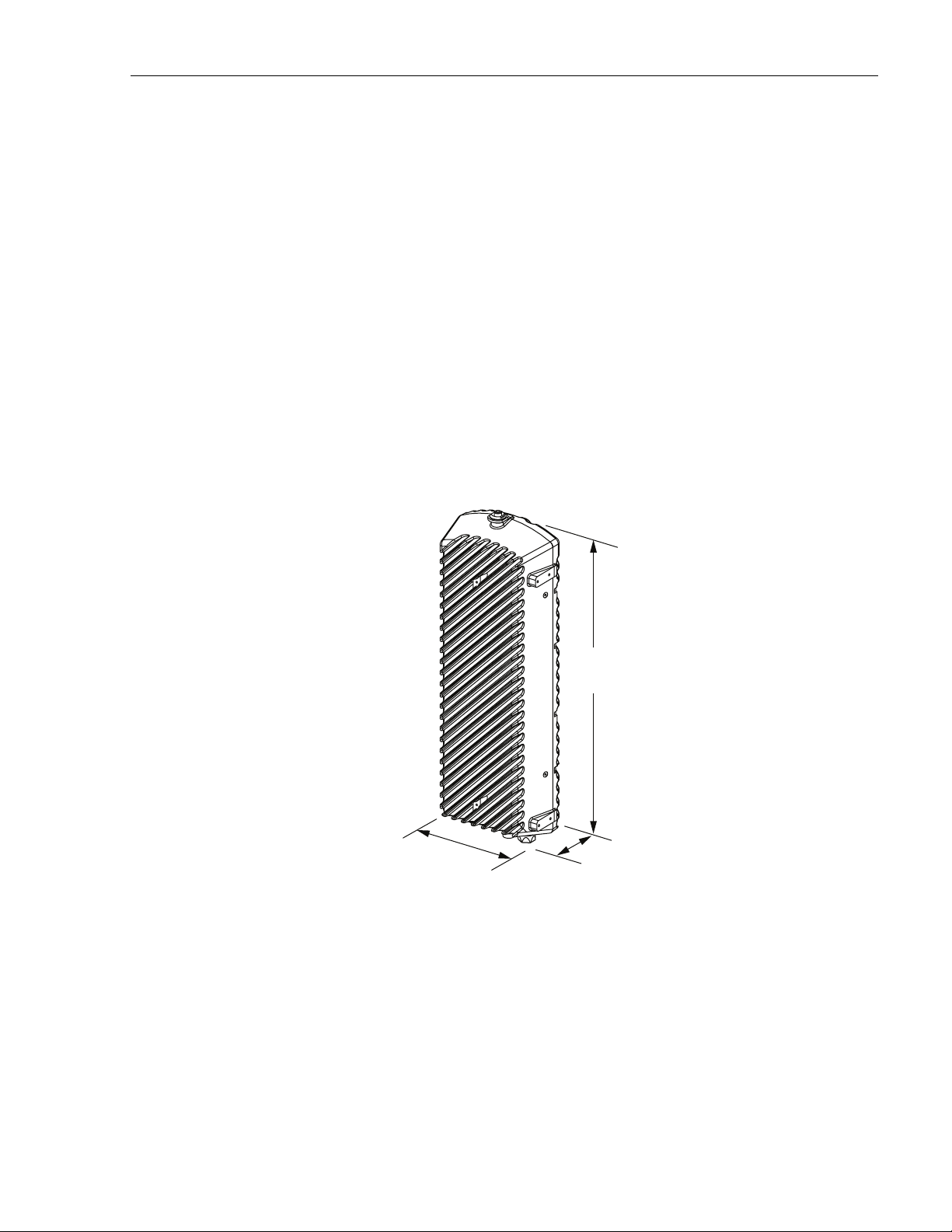

The microBTS, shown in Figure 1, consists of an environmentally-sealed enclosure and various

electronic modules that are housed within the enclosure. Excess heat is dissipated using a

passive cooling system which eliminates the need for external cooling fans. The low profile

design of the enclosure requires minimal real estate for installation. The enclosure may be

mounted from a wall, pole, or overhead cable (strand). A separate base station antenna (not

provided) mounts near the enclosure.

ADCP-75-246 • Issue 1 • 6/2008

2 MICROBTS DESCRIPTION

The 2x1 microBTS, supports or provides the following basic functions:

• Supports GSM/AMR voice traffic and GPRS/EDGE data traffic via two TRX units.

• Supports OMC-R functions including provisioning, alarm management, and performance

management.

• Supports IP backhaul for voice and data traffic and OMC-R communications.

9.7 IN.

(24.6 CM)

29.4 IN.

(74.7 CM)

5.7 IN.

(14.5 CM)

Figure 1. 2x1microBTS

22577-A

© 2008, ADC Telecommunications, Inc.

Page 1

Page 10

ADCP-75-246 • Issue 1 • 6/2008

• Provides Power Over Ethernet (POE) to the IP backhaul device

• Provides an RF interface (antenna port) for the base station remote antenna.

• Provides an RF interface (antenna port) for the Network Listen antenna.

• Accepts AC power input.

• Provides a visual indication of unit status

2.1 Primary Components

The microBTS is a fully integrated base station solution that includes the following: radio

transceivers (2), Linear Power Amplifier (LPA), RX Low Noise Amplifier (LNA), duplexer,

power supply, IP switches, Network Listen unit, processor board, carrier board, and enclosure.

The enclosure houses the electronic assemblies, controls RF emissions, seals out dirt and

moisture, and provides passive cooling. The internal components are not user replaceable or

accessible. The base station antenna cable connector, IP backhaul connector, AC power

connector, and the unit status indicator are located on the bottom of the enclosure. The Network

Listen antenna connector is located on the top of the enclosure.

2.2 Mounting

The microBTS may be mounted on a flat vertical surface (such as the side of a building), on a

utility pole, or from a strand. A combination wall/pole mounting bracket is provided with each

unit. Wall or pole-mount installation consists of securing the bracket to the mounting surface

and then hanging the enclosure from the bracket. The bracket may be attached to a variety of

surfaces such as wood, concrete, or masonry. Various fasteners including hex-head capscrews,

tee-nuts, and concrete anchors are provided. A separate strand-mount kit (accessory item) is

available if it is necessary to mount the microBTS from a cable. The mircroBTS should be

mounted in a restricted access location only.

2.3 Fault Detection and Alarm Reporting

The microBTS detects and reports fault and alarm information. A single bottom-mounted Light

Emitting Diode (LED) indicator turns from off to red if a major fault is detected. The status of

the microBTS, the alarm state, and other fault information is summarized and reported over the

IP backhaul. Fault and alarm information may be accessed using the FlexWave OMC-R

management solution.

2.4 IP Backhaul Connection

The IP backhaul cable connection is through an Ethernet port that consists of a single bottommounted hardened RJ-45 female connector. The IP backhaul cable carries the voice and data

traffic plus all OMC-R provisioning, alarm, and performance monitoring communications

between the microBTS and the BSC. The IP backhaul connection also provides DC power

(POE) to the IP backhaul device with a 15 Watt maximum power output at 48 VDC. The

maximum drop cable length is 300 feet (91.4 m).

2.5 Network Listen Antenna Connection

The Network Listen antenna (depending on the option ordered) connection is through a single

top-mounted NMO (female) RF connector. The Network Listen antenna attaches directly to the

NMO connector.

Page 2

© 2008, ADC Telecommunications, Inc.

Page 11

2.6 Base Station Antenna Cable Connection

The base station antenna cable connection is through one 50-ohm N-type female connector. The

microBTS includes an internal duplexer which allows a single antenna cable to carry both

forward and reverse path RF signals between the base station antenna and the microBTS.

An externally-mounted lightning protector is available as an accessory. The surge/antenna

connector on the lightning protector is an N-type female connector. The microBTS enclosure

must be properly grounded for the lighting protector to function properly.

2.7 Powering

The microBTS is powered by 90 to 265 VAC (nominal 115 or 230 VAC), 47 to 63 Hz power.

The AC power is supplied through a 15-foot three-wire power cable that is provided with the

enclosure. The power cable connects to a mini 3-pin AC power connector mounted on the

bottom of the microBTS enclosure. The power cable is rated for indoor or outdoor use and must

not be placed within electrical conduit as this will impede the cooling of the cable during usage.

The stub end of the power cable must be routed to an external junction box (not provided) for

connection to the AC power source. A circuit breaker rated at 15 Amps (150 VAC) should be

used to provide overcurrent protection for the microBTS power circuit. It is also recommended

that an external AC outlet (not provided) be installed near the microBTS enclosure to power test

equipment and power tools.

ADCP-75-246 • Issue 1 • 6/2008

2.8 Grounding

A grounding terminal (hex socket capscrew and washer) is provided on the bottom of the

enclosure for connecting a grounding cable to the enclosure. A 1.5 meter #6 stranded copper

wire terminated with a ring terminal is provided with the microBTS for linking the enclosure to

an earth ground source.

2.9 Cooling

Passive cooling of the electronic assemblies is provided by conducting excess heat from the

internal electronic components to the aluminum enclosure. The heat is then dissipated to the

outside air by radiation and convection air flow over the enclosure’s external cooling fins. An

alarm is generated if a high temperature condition occurs within the enclosure.

2.10 User Interface

The microBTS user interface consists of the connectors, grounding lug, and LED that are

provided on the exterior of the enclosure. The microBTS user interface points are indicated in

Figure 2 and described in Tab le 1.

© 2008, ADC Telecommunications, Inc.

Page 3

Page 12

ADCP-75-246 • Issue 1 • 6/2008

TOP VIEW BOTTOM VIEW

(1) NETWORK LISTEN

ANTENNA CONNECTOR

NOTE: SHOWN WITH DUST CAPS REMOVED

Figure 2. 2x1 microBTS User Interface

Table 1. 2x1 microBTS User Interface

REF

NO

USER INTERFACE

DESIGNATION

DEVICE

1 No designation NMO female RF

connector

(3) BASE STATION

ANTENNA

CONNECTOR

(5) LED

INDICATOR

(6) AC POWER

CONNECTOR

(2) GROUNDING WIRE

CONNECTION POINT

FUNCTIONAL

DESCRIPTION

Connection point for the Network Listen

antenna.

(4) IP BACKHAUL

CABLE CONNECTOR

22589-A

2 Ground symbol Threaded hole with

3 Antenna symbol N-type female RF

4 Network symbol Sealed RJ-45 female

5 No designation Red LED

6 115/230 VAC

47–63 Hz

6.8 AMP

Page 4

© 2008, ADC Telecommunications, Inc.

hex socket screw

coaxial connector

connector

(off/red)

Sealed 3-wire AC

power connector

Connection point for the grounding wire.

Connection point for the base station antenna

cable.

Connection point for the IP backhaul cable.

Indicates if the microBTS is powered and normal

(off) or if a major fault is detected (red).

Connection point for the AC power cord.

Page 13

2.11 Specifications

The specifications for the 2x1 microBTS are listed in Tab le 2.

PARAMETER SPECIFICATION REMARKS

Physical/Environmental/

Electrical

Enclosure dimensions (L×W×D) 29.4 × 9.7 × 5.7 inches

Mounting Wall, pole, or strand Strand mounting requires an

Weight 40 lbs (18.2 kg) Without shields installed

Weather resistance (see Note 1) NEMA-6, IEC IP67 Indoor or outdoor installation

Operating temperature –30º to +55º C (-22º to +131º F)

Storage temperature –40º to +70º C (-40º to +158º F)

AC power connector Sealed 3-pin AC power

Table 2. 2x1 microBTS Specifications

(747 × 246 × 145 mm)

ADCP-75-246 • Issue 1 • 6/2008

0.94 cu. ft.

(26.6 L)

accessory mounting kit.

Antenna cable connector 50 ohm N-type (female) 50 ohms input/output impedance

IP backhaul connector Sealed RJ-45 (female) Ethernet port

Power over Ethernet port 48 VDC with 15 Watt maximum

Network Listen antenna connec-

NMO (female)

tor

Lightning suppression (for

antenna cable connector)

20 kA IEC 1000-4-5 8/20 μs

waveform

Provided by external lightning

protector (accessory)

Voltage input 90 to 265 VAC, 47 to 63 Hz

Power consumption (maximum) 600 VA at 120 VAC

Current rating (maximum) 6.8 Amps at 90 VAC Requires 15 Amp circuit for 115

VAC operation

Downlink

System bandwidth 60 MHz

Frequency range for 1800 MHz 1805 – 1880 MHz

Frequency range for 1900 MHz 1930 – 1990 MHz

Out-of-band emissions < –13 dBm per 1 MHz band-

width from 30 MHz to 20 GHz

Passband gain 21 dB In addition to +13 dBm gain set-

ting on each nanoBTS

Composite RF output power

(maximum)

41.5 dBm (14.13 Watts) max at

antenna port

40.5 dBm (11.22 Watts) for

Industry Canada using two-tone

method

Gain variation ± 3 dB over temperature and

unit-to-unit

© 2008, ADC Telecommunications, Inc.

Page 5

Page 14

ADCP-75-246 • Issue 1 • 6/2008

PARAMETER SPECIFICATION REMARKS

Gain flatness

Band flatness

Channel flatness

Uplink

Frequency range for 1800 MHz 1710 – 1785 MHz

Frequency range for 1900 MHz 1850 – 1910 MHz

RX sensitivity (CS-1 M) <-110 dB

RX sensitivity (MCS-1M) < -110 dB

RX sensitivity (MCS-5 M) < -102 dB

Note 1: The microBTS has been tested to assure it meets the dust and water resistance

requirements of IP67 as specified by IEC Publication 60529. These tests were conducted using

closure caps attached to the cable ports. To assure the dust and water resistance level is

maintained, it is the responsibility of the user to select AC power, antenna, and IP backhaul

cable assemblies that have a dust and water resistance level of IP67 or higher. If user is uncertain

of cable manufacturers that meet this requirement, please contact ADC Technical Assistance.

Table 2. 2x1 microBTS Specifications, continued

± 1.5 dB across frequency range

± 1.0 dB across any 1.25 MHz

channel

3 ACCESSORY ITEMS

This section provides a description of the accessory items that are available separately for the

microBTS. The accessory items may or may not be required depending on the application.

3.1 Strand Mount Kit

A strand-mount kit is available if the application requires that the microBTS be mounted from a

horizontal cable system. Mounting pads are provided on the side of the enclosure for securing a

pair of cable-attachment clips. Screws are used to secure the cable-attachment clips to the

enclosure. All fasteners required for installation are provided with the kit.

3.2 Lightning Protector

An external lightning protector is available separately for the microBTS. It is recommended that

a lightning protector be installed at the base station antenna port to reduce the chance of damage

to electronic components should a lightning strike occur. The lighting protector surge/antenna

port is an N-type female connector.

3.3 Solar Shields

A solar shield kit is available if the microBTS must be mounted in full sunlight for extended

periods of time with extremely high ambient temperatures. The solar shields attach to the

exterior of the microBTS enclosure and shade the enclosure from direct exposure to the sun.

The solar shields are constructed of sheet metal and are painted to match the color of the

enclosure. All fasteners and brackets required for installation are provided with the kit.

Page 6

© 2008, ADC Telecommunications, Inc.

Page 15

4 UNPACKING AND INSPECTION

This section provides instructions for opening the shipping boxes, verifying that all parts have

been received, and verifying that no shipping damage has occurred. The basic microBTS

includes the following items:

• microBTS enclosure

• Network Listen antenna

• Fasteners, cables, strapping, and mounting bracket as specified in Table 3, Section 5, and

Tabl e 4, Section 6.

The following accessories may also be shipped with the microBTS:

• Strand mount kit

• Lightning protector

•Shields

Use the following procedure to unpack and inspect the microBTS components:

ADCP-75-246 • Issue 1 • 6/2008

1. Open the shipping cartons and carefully unpack each component from the protective

packing material.

2. Check each component for broken or missing parts. If there are damages, contact ADC

(see Section 7) for an RMA (Return Material Authorization) and to reorder if replacement

is required.

© 2008, ADC Telecommunications, Inc.

Page 7

Page 16

ADCP-75-246 • Issue 1 • 6/2008

5 MOUNTING PROCEDURES

This section provides instructions for mounting the FlexWave microBTS. The microBTS may

be secured to an interior or exterior wall, attached to a utility pole, or attached to a horizontal

cable (strand-mount). Mounting the microBTS from a cable requires an accessory kit not

included with the unit.

5.1 Before Mounting the microBTS

5.1.1 Mounting Considerations

Before mounting the microBTS, verify that the installation site is in conformance with the

system design plan (not documented here). If a system design plan has not been prepared,

consult the Wireless Technical Assistance Center (TAC) for technical assistance (see Section 7).

The site chosen must conform to all local codes and any permits required must be obtained prior

to the start of mounting. The location must be accessible and provide adequate parking for

worker and vehicle safety. The installed unit must not create a visual or physical obstruction to

vehicular or pedestrian traffic or block pole-climbing access.

Note: The microBTS is intended for restricted access locations only.

The microBTS must be located as specified in the system design plan and must have ready

access to the specified AC power source. The site must provide adequate ventilation and must

comply with the unit environmental specifications. A minimum of 18 inches of clearance must

be provided on all sides (except the back) of the enclosure to allow free air circulation. In

addition, the bottom (cable entry end) and either the top, the front, or one of the sides must be

open to free air space. Adequate clearance must be allowed at the bottom of the enclosure to

provide access for attaching cables and for viewing the LED indicator.

5.1.2 Mounting Hardware Provided With the microBTS

The microBTS is shipped with the mounting hardware required for a typical wall-mount or

pole-mount installation. Tab le 3 lists the mounting hardware provided. Additional hardware

may have to be provided by the installer depending on the site requirements.

Table 3. microBTS Mounting Hardware and Fasteners

ITEM QUANTITY

Hoist ring 1

Hoist ring mounting screws 2

Mounting bracket 1

Strapping 2

3/8-inch concrete anchors 4

3/8 x 1-inch cap screws 4

3/8 x 1.5-inch lag screws 4

Page 8

© 2008, ADC Telecommunications, Inc.

Page 17

Table 3. microBTS Mounting Hardware and Fasteners, continued

3/8-inch flat washers 4

3/8-inch lock washers 4

5/16 x1.25-inch cap screw 1

5/16-inch flat washer 1

5/16-inch lock washer 1

5/16-inch nut 1

5.1.3 2x1 microBTS Dimensions

The basic dimensions of the 2x1 microBTS are shown in Figure 3.

ADCP-75-246 • Issue 1 • 6/2008

29.4 IN.

(74.7 CM)

9.7 IN.

(24.6 CM)

Figure 3. 2x1 microBTS Dimensions

5.7 IN.

(14.5 CM)

22636-A

Page 9

© 2008, ADC Telecommunications, Inc.

Page 18

ADCP-75-246 • Issue 1 • 6/2008

5.1.4 Tools and Additional Materials Required For Mounting

The tools and any additional materials required for mounting the 2x1 microBTS are dependent

on the mounting system. The following sections list the tools required for the various mounting

systems.

Wood-Framed Wall Mounting

• 9/16-inch wrench

• 1/2-inch wrench (2)

• Torque wrench with 3/16-inch hex key socket

• Drill

• Pencil or marker

• 4 foot x 2 foot sheet of pressure-treated 3/4-inch plywood

• Fasteners and tools for securing the 3/4-inch plywood to wall

• 3/16-inch standard drill bit

Masonry Wall Mounting

• 9/16-inch wrench

• 1/2-inch wrench (2)

• Torque wrench with 3/16-inch hex key socket

• Drill

• Pencil or marker

• 5/8-inch masonry drill bit

Wooden Utility Pole Mounting

• 9/16-inch wrench

• 1/2-inch wrench (2)

• Torque wrench with 3/16-inch hex key socket

• Drill

• Pencil or marker

• 3/16-inch standard drill bit

Metal Utility Pole Mounting

• Clamp banding tool (BT1HT from Panduit)

• 1/2-inch wrench (2)

• Torque wrench with 3/16-inch hex key socket

Page 10

© 2008, ADC Telecommunications, Inc.

Page 19

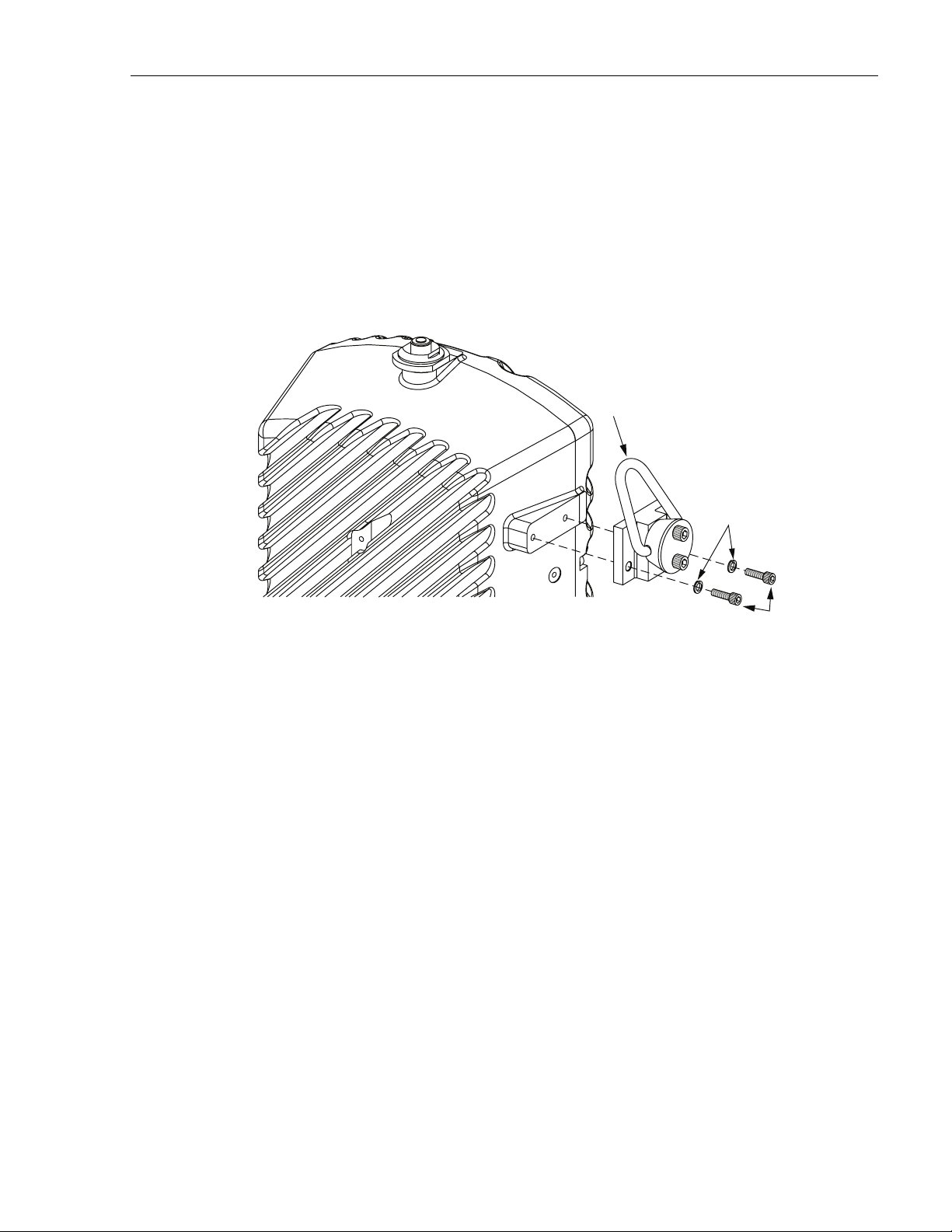

5.2 Lift Ring Installation

A lift ring is provided with the microBTS. Secure the lift ring to the side of the enclosure as

shown in Figure 4 using the two 5/8-inch long 1/4-20 socket head screws and two 1/4-inch split

washers provided. Use a torque wrench with a 3/16-inch hex key socket to tighten the cap screws

to 40 – 45 lbs/force-inches (4.5 to 5.1 Nm) of torque. Do not overtighten. If the threads show

signs of damage, yielding, or stripping when tightening the cap screws, discontinue lift ring

installation and remove the lift ring. Always use appropriate lifting equipment when hoisting the

enclosure into position for mounting. Remove the lift ring after the enclosure has been mounted.

LIFT

RING

ADCP-75-246 • Issue 1 • 6/2008

USE A TORQUE WRENCH

WITH A 3/16-INCH HEX KEY TO

TIGHTEN THE CAP SCREWS TO

40 TO 45 LBS/FORCE-INCHES

(4.5 TO 5.1 Nm) OF TORQUE

SPLIT

WASHERS

NOTE: IF THE THREADS SHOW SIGNS OF DAMAGE, YIELDING, OR STRIPPING

WHEN THE CAP SCREWS ARE TIGHTENED, DISCONTINUE INSTALLATION OF

THE LIFT RING. REMOVE LIFT RING AND DO NOT USE TO LIFT microBTS.

Figure 4. Hoist Ring Installation

5.3 Standard Mounting Bracket Installation

A standard mounting bracket is provided with each enclosure. The standard mounting bracket

may be mounted vertically or horizontally. If mounted horizontally, it is recommended that the

bracket be oriented so the enclosure cooling fins will face upward or to the side with respect to

the ground. The following sections provide instructions for installing the standard mounting

bracket on a wood-framed wall, masonry wall, wooden utility pole, or metal pole. Refer to the

procedure that applies to the installation.

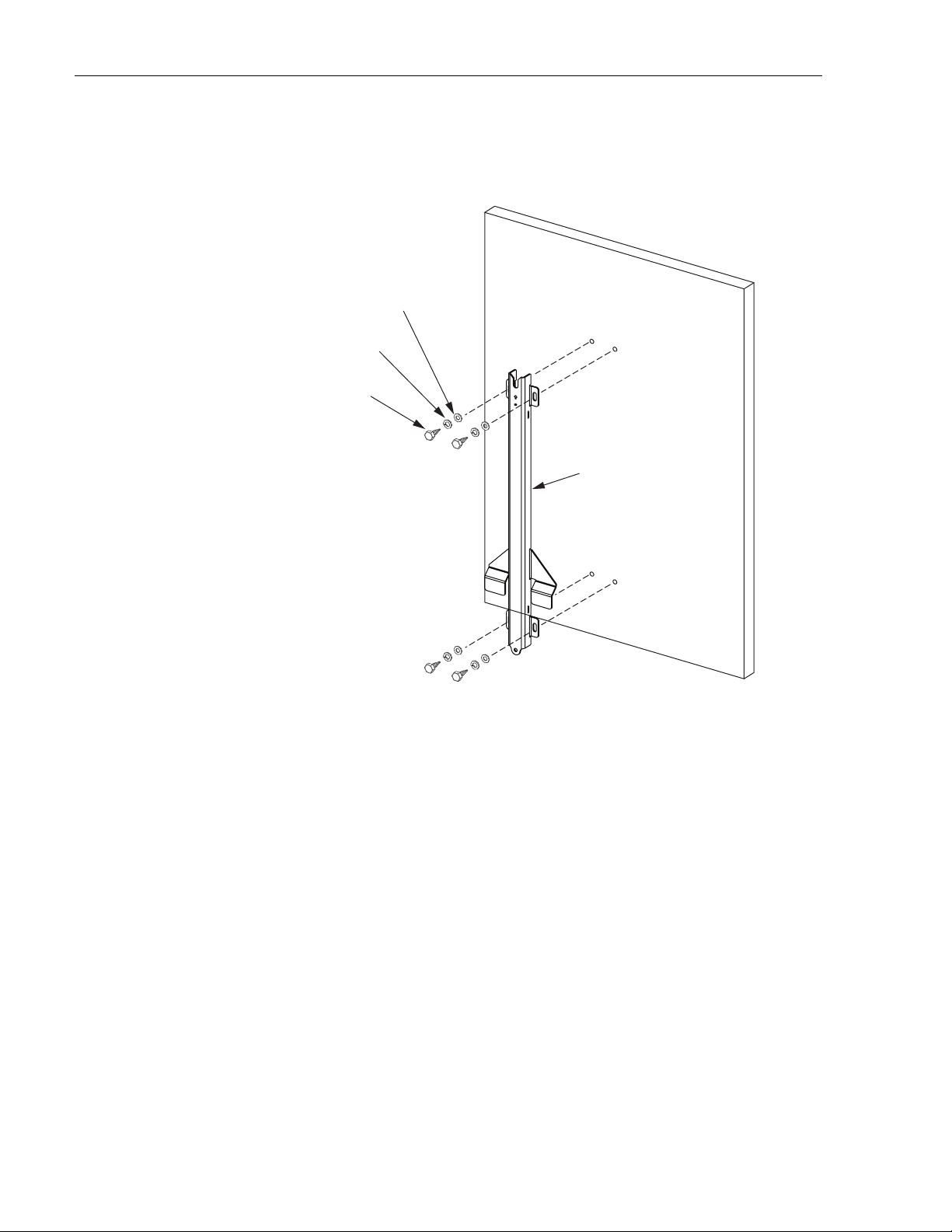

5.3.1 Wood-Framed Wall Mounting

When mounting the enclosure on a wood-framed wall, it is recommended that pressure-treated

plywood with a minimum thickness of 0.75-inch (19.0 cm) be used as a backer board. The

backer must be firmly secured to the interior framing of the wall. Use the following procedure to

install the standard mounting bracket on a wood-framed wall:

1. Mount the plywood backer (not-provided) on the wall and firmly secure it to the wall’s

interior studs.

22637-A

5/8-INCH LONG

1/4-20 CAP SCREWS

2. Hold the enclosure mounting bracket in position for installation on the plywood backer as

shown in Figure 5. The end with the V-notch should be at the top.

© 2008, ADC Telecommunications, Inc.

Page 11

Page 20

ADCP-75-246 • Issue 1 • 6/2008

3/8-INCH FLAT

WASHER (2)

3/8-INCH LOCK

WASHER (2)

3/8 x 1-1/2-INCH

LAG SCREW (2)

NOTE: THE MOUNTING BRACKET IS

SHOWN WITH A VERTICAL ORIENTATION.

THE MOUNTING BRACKET MAY ALSO

BE MOUNTED HORIZONTALLY IF REQUIRED.

3/4-INCH PLYWOOD

BACKER BOARD

(SECURE TO WALL STUDS)

MOUNTING

BRACKET

2263-A

Figure 5. Secure Standard Mounting Bracket To Plywood Backer

3. Mark the location of the mounting bracket’s two mounting holes on the plywood backer.

4. Drill a 3/16-inch hole in the backer board at each of the locations marked in step 3.

5. Locate the two 3/8 x 1-1/2-inch lag screws (provided with the enclosure) and place a 3/8inch lock washer and 3/8-inch flat washer on each screw.

6. Secure the mounting bracket to the plywood using the screws and washers prepared in step

5. Tighten screws until bracket is securely attached to the plywood.

7. Hang the enclosure from the mounting bracket as described in Section 5.4.

Page 12

© 2008, ADC Telecommunications, Inc.

Page 21

ADCP-75-246 • Issue 1 • 6/2008

5.3.2 Masonry Wall Mounting

When mounting the enclosure on a masonry surface, locate the mounting anchors as close as

possible to the center of any bricks or blocks, especially the upper anchors. Use the following

procedure to install the standard mounting bracket on a masonry wall:

1. Hold the enclosure mounting bracket in position for installation on the masonry wall as

shown in Figure 6. The end with the V-notch should be at the top.

2. Using a pencil, mark the location of the mounting bracket’s two mounting holes on the

wall.

3. Drill holes in the wall (at the locations marked in step 2) that are the correct diameter for

the type of anchors being used. The recommended hole size for the ADC-provided

concrete anchors is 5/8-inch (15.9 mm).

4. Set the anchors in the wall.

3/8-INCH FLAT

WASHER (2)

3/8-INCH LOCK

WASHER (2)

3/8 x 1-INCH

HEX BOLT (2)

CONCRETE

ANCHOR

CONCRETE

WAL L

NOTE: THE MOUNTING BRACKET IS

SHOWN WITH A VERTICAL ORIENTATION.

THE MOUNTING BRACKET MAY ALSO

BE MOUNTED HORIZONTALLY IF REQUIRED.

MOUNTING

BRACKET

3/8-INCH

CONCRETE

ANCHOR (2)

Figure 6. Secure Standard Mounting Bracket to a Masonry Wall

© 2008, ADC Telecommunications, Inc.

22633-A

Page 13

Page 22

ADCP-75-246 • Issue 1 • 6/2008

5. Locate the two 3/8 x 1-inch cap screws (provided with enclosure) and place a 3/8-inch

lock washer and 3/8-inch flat washer on each screw.

6. Place the mounting bracket in position for mounting on the wall and then thread the 3/8 x

1-inch cap screws (with installed washers) into the two anchors. Tighten cap screws until

secure.

7. Hang the enclosure from the mounting bracket as shown in Section 5.4.

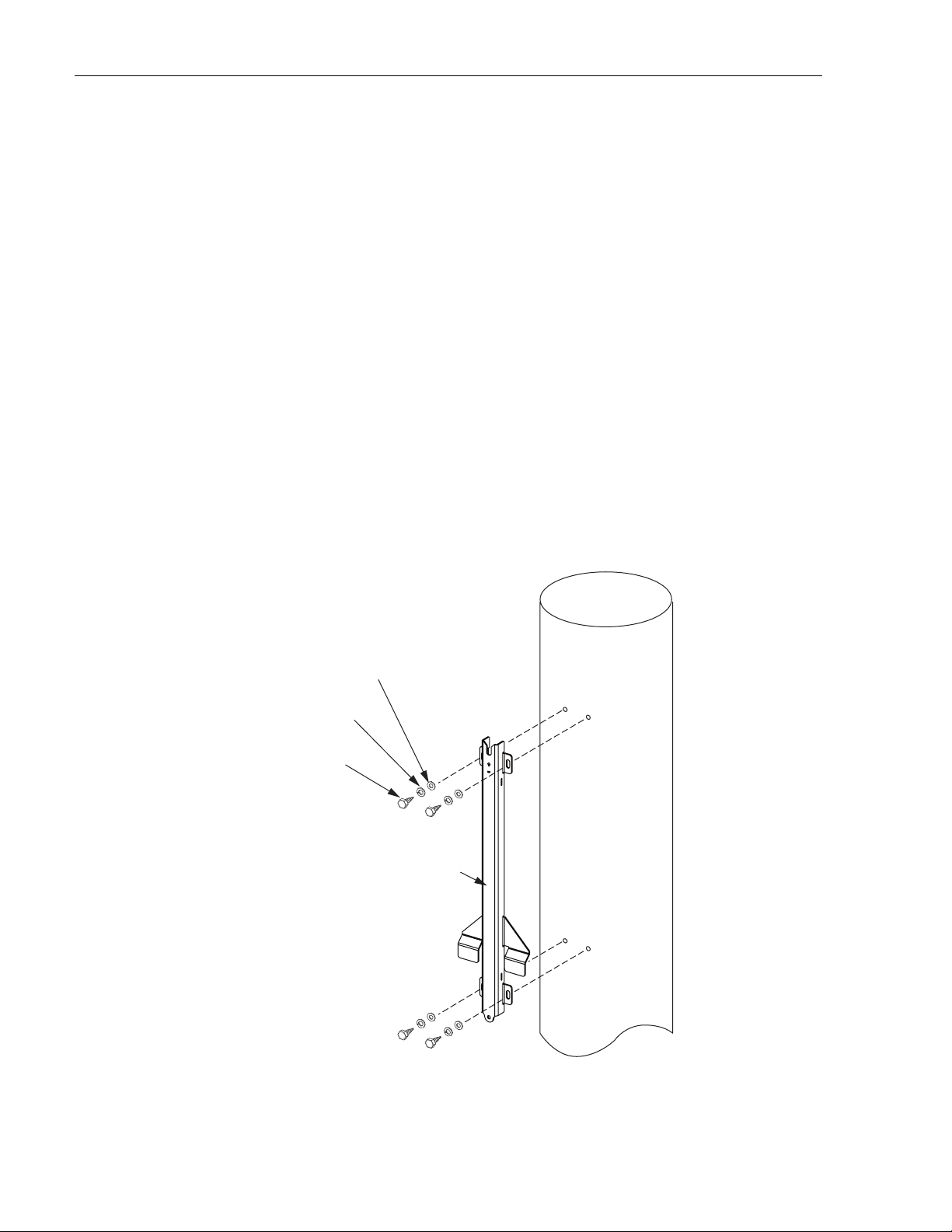

5.3.3 Wooden Utility Pole Mounting

When mounting the enclosure from a wooden utility pole, make sure the pole is sound and has

not been damaged or weakened by decay. Use the following procedure to install the standard

mounting bracket on a wooden utility pole:

1. Hold the enclosure mounting bracket in position for installation on the wooden pole as

shown in Figure 7. The end with the V-notch should be at the top.

2. Using a pencil, mark the location of the mounting bracket’s two mounting holes on the

pole.

3. Mark the location of the mounting bracket’s two mounting holes on the wooden pole.

3/8-INCH FLAT

WASHER (4)

3/8-INCH LOCK

WASHER (4)

3/8 x 1-1/2-INCH

LAG SCREW (4)

MOUNTING

BRACKET

Page 14

© 2008, ADC Telecommunications, Inc.

22634-A

Figure 7. Secure Standard Mounting Bracket to a Wooden Pole

Page 23

ADCP-75-246 • Issue 1 • 6/2008

4. Drill a 3/16-inch hole in the utility pole at each of the locations marked in step 3.

5. Locate the two 3/8 x 1-1/2-inch lag screws (provided with the enclosure) and place a 3/8inch lock washer and 3/8-inch flat washer on each screw.

6. Secure the mounting bracket to the pole using the screws and washers prepared in step 5.

Tighten screws until bracket is securely attached to the plywood.

7. Hang the enclosure from the mounting bracket as shown in Section 5.4.

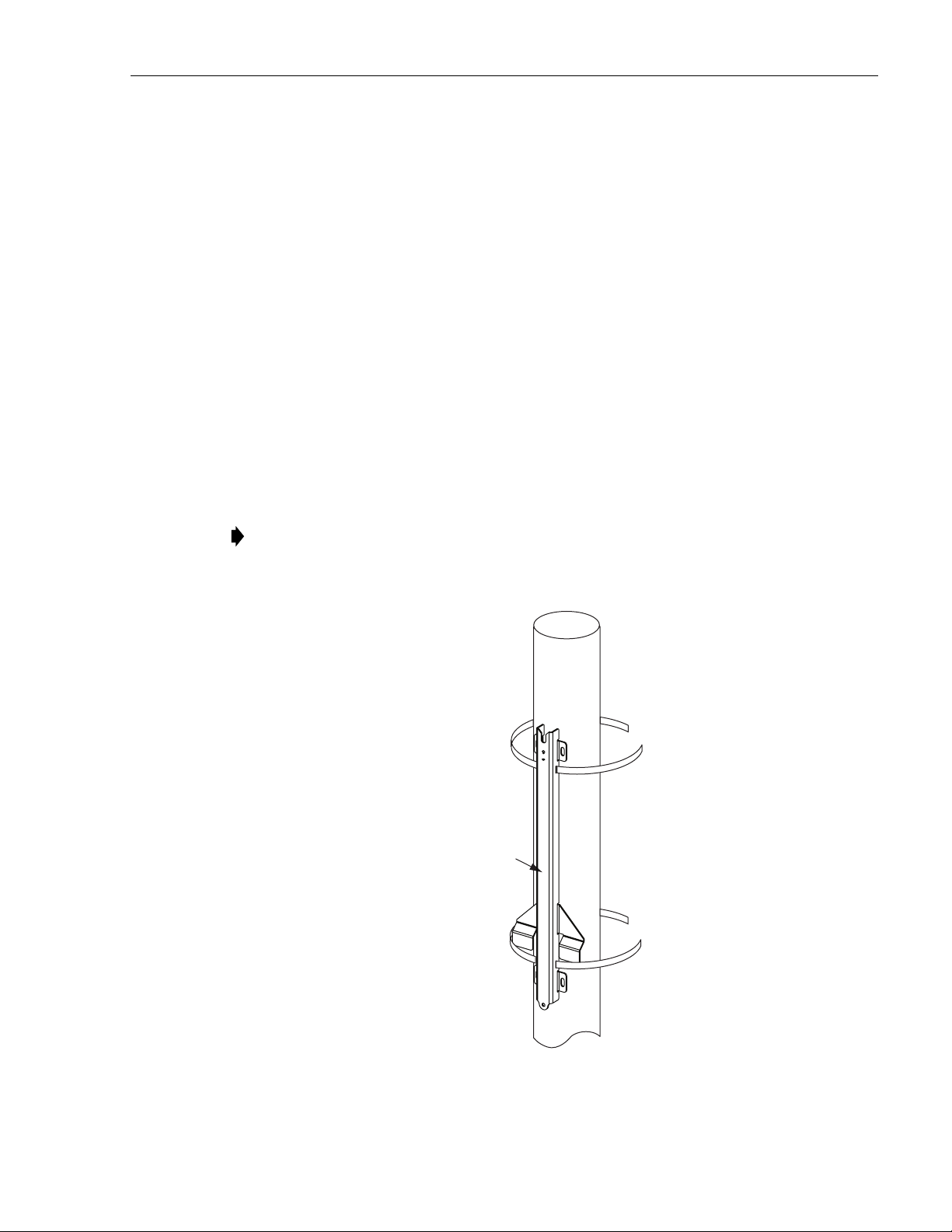

5.3.4 Metal Utility Pole Mounting

Stainless steel strapping is provided for securing the mounting bracket to a cylindrical object

(such as a metal utility pole) that cannot be pierced with a screw or bolt. A special tool (Panduit

BT1HT) is required to properly secure and tension the strapping. Use the following procedure

to install the mounting bracket on a metal utility pole:

1. Insert the two sections of stainless steel metal strapping (provided with the enclosure)

through the slots in the mounting bracket and place in position for mounting as shown in

Figure 8. The end with the V-notch should be at the top.

Note: Two sections of stainless steel metal strapping are provided with the enclosure. If

additional strapping is required, use 5/8-inch wide 304 AISI stainless steel strapping with

a minimum tensile strength of 700 lbs force.

MOUNTING

BRACKET

22635-A

Figure 8. Secure Standard Mounting Bracket To a Metal Pole

© 2008, ADC Telecommunications, Inc.

Page 15

Page 24

ADCP-75-246 • Issue 1 • 6/2008

2. Wrap the top section of strapping around the pole and secure using Panduit tool # BT1HT.

Adjust the tool tension setting to #7. Follow the instructions provided with the tool by the

tool manufacturer (see MS Strapping Tool Operation Instructions PA24808A01).

3. Repeat step 2 for the bottom section of strapping.

4. Hang the enclosure from the mounting bracket as shown in Section 5.4.

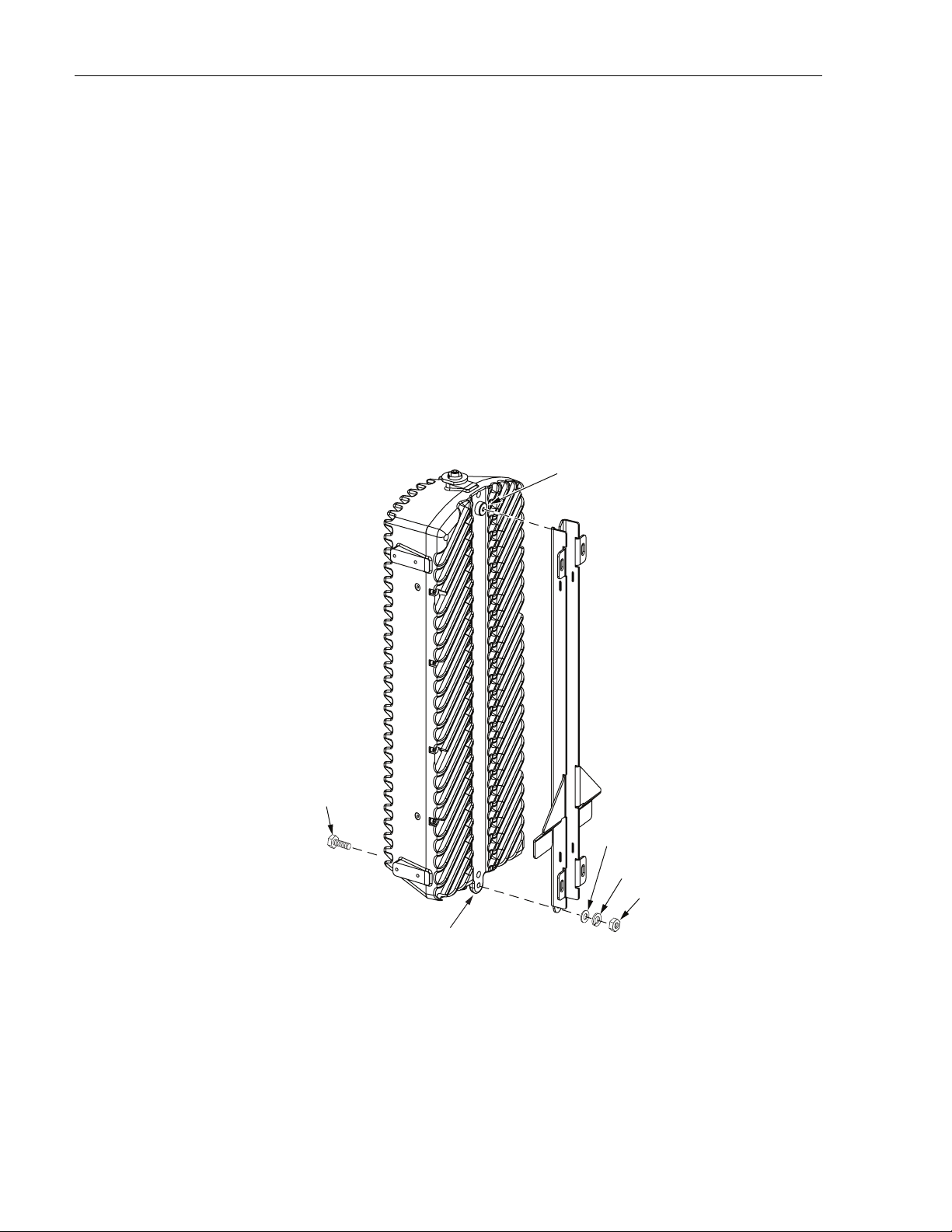

5.4 Installing the Enclosure on the Standard Mounting Bracket

Use the following procedure to install the microBTS on the standard mounting bracket.

1. Hang the enclosure from the mounting bracket as shown in Figure 9. The shoulder screw

in the rear side of the enclosure fits into the notch at the top of the mounting bracket.

SHOULDER

SCREW

2. Insert a 5/16 x 1-1/4-inch hex bolt through the hole in the mounting tab located at the

bottom of the enclosure.

3. Place a 5/16-inch flat washer and 5/16-inch flat washer on the hex bolt.

4. Thread a 5/16-inch nut onto the hex bolt and tighten securely.

Page 16

© 2008, ADC Telecommunications, Inc.

5/16 x 1-1/4-INCH

HEX BOLT

5/16 INCH

FLAT WASHER

5/16 INCH

LOCK WASHER

5/16 INCH NUT

22632-A

MOUNTING TAB

Figure 9. Secure Enclosure To Mounting Bracket

Page 25

5.5 Strand-Mount Installation

An accessory kit is available for mounting the microBTS enclosure from an overhead wire or

strand. The strand-mount kit can accommodate wire cable that ranges in size from 0.25 to 0.625

inches in diameter. A minimum break strength of 4400 lbs. is recommended. Stainless steel

cable is preferred.

An installation drawing is provided with each strand-mount kit. Follow the instructions

provided on the drawing when installing the strand-mount kit. For all strand-mount

installations, form a drip-loop in the cables entering the enclosure.

ADCP-75-246 • Issue 1 • 6/2008

© 2008, ADC Telecommunications, Inc.

Page 17

Page 26

ADCP-75-246 • Issue 1 • 6/2008

6 INSTALLATION PROCEDURES

This section provides procedures for installing the Network Listen antenna; connecting the

grounding, base station antenna, IP backhaul, and AC power cables; and installing the shields.

Installation of the microBTS may proceed separately from the installation of the corresponding

BSC. When the installation of the microBTS is completed, refer to the appropriate manuals (see

Related Publications section) for the system turn-up and test procedures.

Danger: Wet conditions increase the potential for receiving an electrical shock when installing

or using electrically-powered equipment. To prevent electrical shock, never install or use

electrical equipment in a wet location or during a lightning storm.

6.1 Installation Overview

Installation of the microBTS consists of the following basic steps:

Note: To insure that all connectors and ports remain dust-free during installation,

leave all dust caps and dust protectors in place until directed to remove them.

Note: If the microBTS will be horizontally mounted, provide drip loops for all cables that

connect to the enclosure.

1. Connecting a grounding cable to the microBTS grounding point.

2. Installing the Network Listen antenna.

3. Connecting the IP backhaul cable.

4. Connecting the base station antenna coaxial cable to the microBTS antenna port.

5. Installing the AC power cable and connecting it to the microBTS power port.

6. Installing the shields.

6.1.1 Installation Hardware Provided with microBTS Enclosure

The installation hardware that is provided with the microBTS is listed in Tab le 4.

Table 4. microBTS Installation Hardware

ITEM QUANTITY

M8 x 10 hex socket capscrew (for grounding cable) 1

M8 washer (for grounding screw) 1

Grounding cable (1.5 m) 1

AC Power Cable (15 feet) 1

Network Listen antenna 1

Page 18

© 2008, ADC Telecommunications, Inc.

Page 27

ADCP-75-246 • Issue 1 • 6/2008

6.1.2 Tools and Materials Required

The following tools are required in order to complete the procedures in this instruction:

• #6 metric socket key or 7/32-inch hex key wrench

• Wire cutters

• Wire stripper

• Compression pliers for splicing grounding cable

• Tools for installing exterior AC circuit

• Tool kit for attaching N-type connectors to coaxial cable

The following materials are required in order to complete the installation procedures:

• #6 AWG (4 mm) copper wire and splice

• Connector for attaching #6 grounding wire to approved earth ground source

• Junction box, conduit, fasteners, connectors, and wire to install a 120/240 Volt, 15 Amp,

exterior AC circuit.

• N-type male connector

6.2 Ground Wire Installation

A hexagon socket-head capscrew is provided on the underside of the cabinet for attaching a #6

copper grounding wire to the enclosure. A 1.5 meter long #6 AWG copper wire terminated with

a ring terminal is provided for connecting the enclosure to an approved grounding source. Use

the following procedure to install the grounding wire:

Caution: For proper and safe equipment operation, an approved earth ground connection must

be provided. The recommended minimum wire size is #6 AWG copper wire.

1. Locate the 1.5 m #6 AWG (4 mm) copper grounding wire provided with the microBTS

enclosure.

2. Locate the grounding point provided on the underside of the enclosure as shown in

Figure 10.

3. Remove the socket-head capscrew and flat washer from the enclosure using a #6 metric

key or a 7/32-inch hex key wrench.

4. Secure the ring terminal end of the grounding wire to the enclosure using the screw and

washer removed in step 3. Tighten securely.

5. Route the free end of the grounding wire to an approved earth ground source.

6. Cut the ground wire to length and connect it to the earth ground source as specified by

local code or practice.

© 2008, ADC Telecommunications, Inc.

Page 19

Page 28

ADCP-75-246 • Issue 1 • 6/2008

UG

FLAT

WASHER

SOCKET

SCREW

Figure 10. Connecting Grounding Cable to Enclosure

6.3 Network Listen Antenna Installation

The microBTS is shipped with either a Network Listen antenna. Install the antenna by threading

it onto the NMO connector located on the top of the microBTS as shown in Figure 11. Tighten

antenna by hand until secure.

GROUND

L

22642-A

NETWORK LISTEN

ANTENNA

Page 20

© 2008, ADC Telecommunications, Inc.

22650-A

Figure 11. Network Listen Antenna Installation

Page 29

6.4 IP Backhaul Cable Installation

A backhaul cable must be routed from the backhaul device to the microBTS enclosure. The

backhaul cable must be terminated with a hardened RJ-45 male connector for connection to the

microBTS backhaul port. The maximum cable length is 300 feet (91.4 m).

Use the following procedure to install the backhaul cable:

1. Remove the dust cap from the RJ-45 connector located at the bottom of the enclosure as

shown in Figure 12.

2. Route the backhaul cable from the backhaul device to the underside of the enclosure.

3. Align the plug end of the RJ-45 cable connector with the RJ-45 port receptacle and then

insert the cable plug into the port receptacle.

4. Slide the connector nut up to the port until it engages the connector locking mechanism.

5. Tighten the connector nut in a clockwise direction (if necessary, use a wrench or pliers to

grip the connector nut) until it snaps past the detent position and locks into place.

Note: It may be necessary to apply 30 to 50 lbs/force-inches (3.4 to 5.6 Nm) of torque to

the connector nut in order to turn it past the detent position.

ADCP-75-246 • Issue 1 • 6/2008

BOTTOM VIEW

RJ-45 BACKHAUL

CONNECTOR PORT

RJ-45

PLUG

CONNECTOR

NUT

BACKHAUL

CABLE

22639-A

Figure 12. IP Backhaul Cable Installation

Page 21

© 2008, ADC Telecommunications, Inc.

Page 30

ADCP-75-246 • Issue 1 • 6/2008

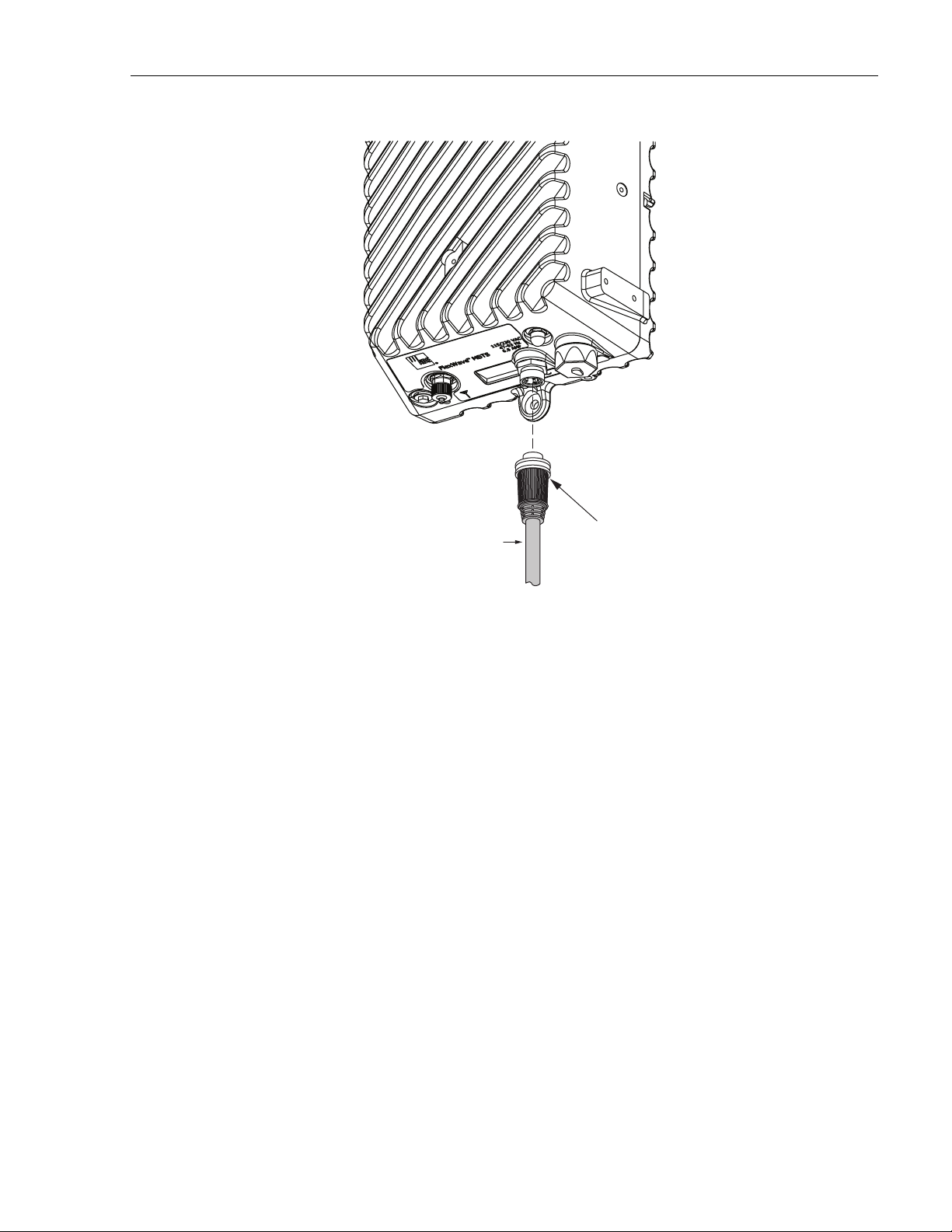

6.5 Base Station Antenna Cable Installation

A coaxial antenna cable must be routed from the base station antenna to the microBTS

enclosure. The cable must be terminated with an N-type male connector for connection to the

microBTS antenna port or the lightning protector (accessory).

Note: To comply with Maximum Permissible Exposure (MPE) requirements, the

maximum composite output from the antenna cannot exceed 1640 Watts EIRP and the

antenna must be permanently installed in a fixed location that provides at least 6 meters

(20 feet) of separation from all persons.

Use the following procedure to install the antenna cable(s):

1. Remove the dust cap from the N-type female connector located on the underside of the

enclosure as shown in Figure 13.

2. If specified, connect a lightning protector (accessory) to the antenna port.

3. Route the coaxial antenna cable from the base station antenna to the underside of the

enclosure.

4. Cut the antenna cable to the required length and terminate with an N-type male connector.

5. Connect the antenna cable to the lightning protector or to the antenna port.

BOTTOM VIEW

LIGHTNING

ANTENNA PORT

(N-TYPE FEMALE)

PROTECTOR

(ACCESSORY)

SURGE PORT

CONNECTOR

Page 22

© 2008, ADC Telecommunications, Inc.

ANTENNA

CABLE

22640-A

Figure 13. Connecting Base Station Antenna Cable to Antenna Port

Page 31

6.6 AC Power Wiring Installation

A 15-foot connectorized 3-wire cable (also available in lengths of 40, 60, or 100 feet) is provided

for the AC power connections. The connectorized end of the cable connects to the AC power port

located on the bottom of the enclosure. The stub end of the cable must be routed to an external

junction box (not provided) for permanent connection to the AC power system wiring.

Note: It is recommended that an AC outlet be installed near the enclosure for powering

tools and test equipment. This outlet must include a GFCI device for protection.

The AC power source must supply 120 or 240 VAC, 50 or 60 Hz, single-phase power through a

15 Amp circuit breaker. The AC power cable provides three wire leads for line, neutral, and

ground connections. The power cable is rated for indoor or outdoor use and must not be placed

within electrical conduit as this will impede the cooling of the cable during usage. The electrical

junction box and any conduit, wire, and fittings required must be provided by the installer.

Note: All electrical work must comply with local codes and requirements. A locally

licensed electrical contractor is best qualified to perform this work. For additional

information, consult with the ADC Technical Assistance Center.

ADCP-75-246 • Issue 1 • 6/2008

Danger: Use extreme caution when working with high voltage AC power. Ensure all power is

disconnected before working on power circuits.

Use the following procedure to install the AC power wiring:

1. Locate the AC power cable that is provided separately with the enclosure.

2. Route the power cable between the AC power port, located on the underside of the

enclosure and the nearest AC power junction box as shown in Figure 14. It may be

necessary to install a new junction box if an existing junction box is not available.

microBTS

ENCLOSURE

AC POWER

CABLE

AC POWER

JUNCTION BOX

AC POWER

WIRES ROUTED

TO CIRCUIT

BREAKER PANEL

22087-A

Figure 14. Typical AC Power Cable Routing

© 2008, ADC Telecommunications, Inc.

Page 23

Page 32

ADCP-75-246 • Issue 1 • 6/2008

3. Secure the cable between the AC power port and the AC power junction box per local

practice. Leave sufficient slack in the cable to allow it to be easily connected and

disconnected from the AC power port.

Note: The power cable is rated for indoor or outdoor use and must not be placed within

electrical conduit as this will impede the cooling of the cable during usage. The cable run

distance to the AC power source must not exceed 100 feet.

4. Install any AC power supply wires that may be required between the AC junction box and

the AC circuit breaker box.

Note: It is recommended that an AC outlet be installed near the enclosure for powering

tools and test equipment. This outlet must include a GFCI device for protection.

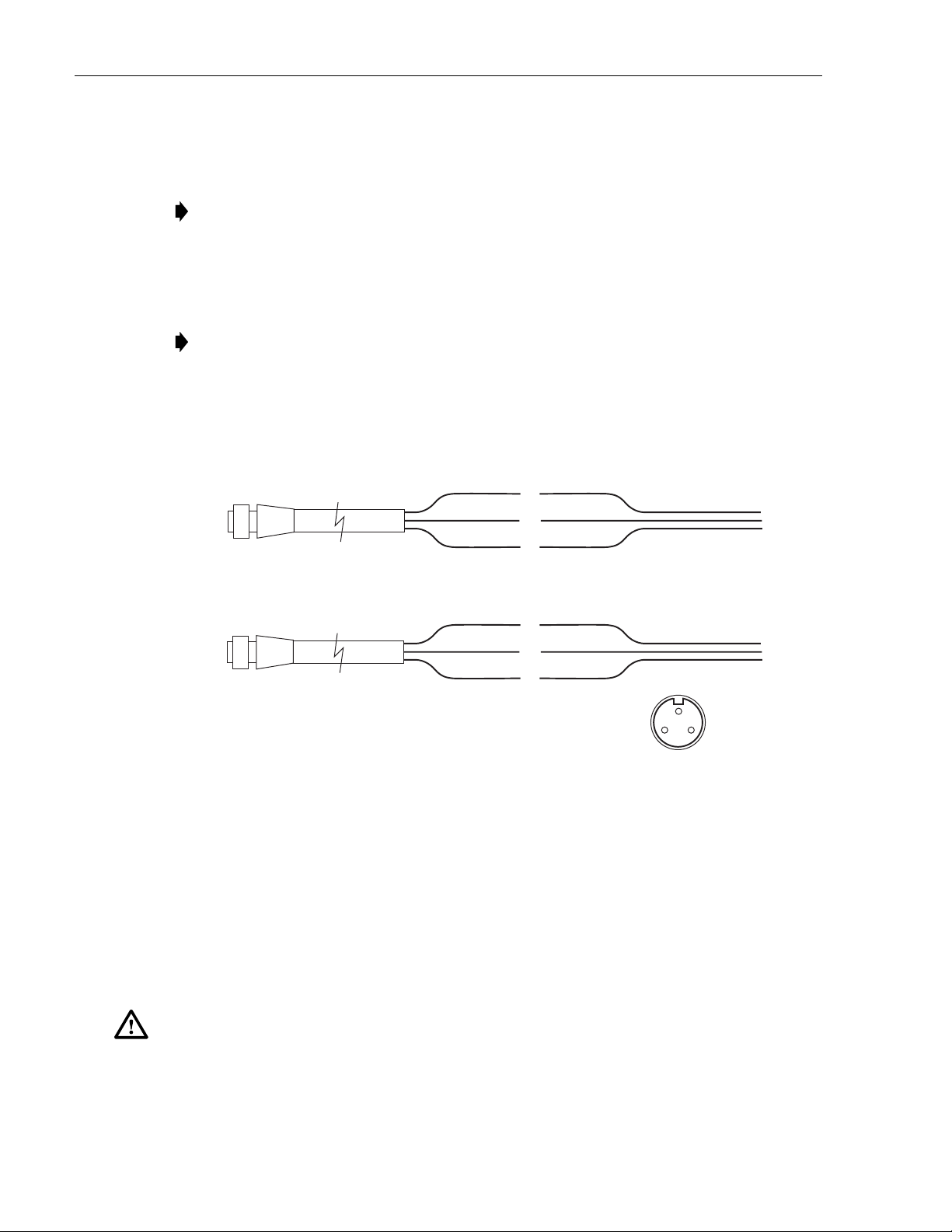

5. Connect the AC power cable wires to the AC power supply wires. Refer to Figure 15 to

identify the color code and wire designations.

120 VAC CONNECTIONS

AC POWER CORD

PROVIDED WITH ENCLOSURE

AC POWER CORD

PROVIDED WITH ENCLOSURE

CONNECTOR PIN DESIGNATIONS

PIN 1 - GREEN/YELLOW

PIN 2 - WHITE

PIN 3 - BLACK

BLACK

GREEN/YELLOW

WHITE

240 VAC CONNECTIONS

BLACK

GREEN/YELLOW

WHITE

LINE

GROUND

NEUTRAL

LINE 1

GROUND

LINE 2

END VIEW OF

CONNECTOR

120 VAC POWER

WIRING

240 VAC POWER

WIRING

20778-A

1

2

3

Figure 15. AC Power Cable Connections

6. At the AC circuit breaker box, connect the AC power supply load wires to a 15 Amp

circuit breaker.

7. Place the circuit breaker in the ON position and then test the connectorized end of the AC

power cable for proper voltage levels and correct polarity.

8. When testing is complete, place the circuit breaker in the OFF position.

9. Remove the dust cap from the AC power port located on the bottom of the enclosure as

shown in Figure 16.

Danger: While trying to connect the AC power cable to the remote unit AC power port, it is

possible for the line terminal on the cable connector to contact the ground pin on the power

port. If the AC cable is energized, this will result in a direct short to ground for the AC power. To

avoid possible personal injury and equipment damage, always turn the AC power off before

connecting the AC power cable to the AC power port.

Page 24

© 2008, ADC Telecommunications, Inc.

Page 33

BOTTOM VIEW

ADCP-75-246 • Issue 1 • 6/2008

10. Connect the power cable connector to the AC power port.

11. Tighten coupling nut until the green band at the top of the connector body is visible.

6.7 Touch-Up Painting

A brush-in-cap type bottle of paint (ACE-ACC-PTLAMD) is available for touching-up nicks

and scratches in the factory coat of paint. Lightly sand the area to be painted and then clean it

thoroughly to remove and dirt, dust, or foreign matter. Shake the paint bottle until thoroughly

mixed and then apply a light coat of paint to the damaged area using the small brush attached to

the cap. Wait until the paint is dry and apply a second coat if necessary. When finished painting,

replace the paint bottle cap and tighten securely.

6.8 Power-Up and Testing

GREEN BAND WILL BE

POWER

CABLE

VISIBLE WHEN COUPLING

NUT IS TIGHTENED

22641-A

Figure 16. Connecting AC Power Cable to Enclosure

When the installation is complete, refer to the applicable publications for the system turn-up and

test procedures. To verify that the microBTS is ready to be placed into service, place the AC

breaker in the closed (on) position and observe the LED indicator light on the bottom of the

enclosure. The LED indicator should turn red immediately following power-up. The LED will

continue to stay red for up to 30 minutes following the initial power-up during which time the

microBTS will synchronize with an external clock source. When the microBTS timing has been

synchronized, the LED will turn off.

© 2008, ADC Telecommunications, Inc.

Page 25

Page 34

ADCP-75-246 • Issue 1 • 6/2008

6.9 microBTS Replacement

The microBTS enclosure contains no user-replaceable or field-serviceable components. Failure

of any internal component will require replacement of the entire unit. The enclosure mounting

hardware, the various cables, and any attached antenna systems may be reused with the

replacement unit. Opening the microBTS enclosure for any reason may cause the product

warranty to be null and void.

Page 26

© 2008, ADC Telecommunications, Inc.

Page 35

7 CUSTOMER INFORMATION AND ASSISTANCE

PHONE:

U.S.A. or CANADA

Sales: 1-800-366-3891

Extension 73000

Tec hnical Assistance: 1-800-366-3891

Connectivity Extension: 73475

Wireless Extension: 73476

EUROPE

Sales Administration: +32-2-712-65 00

Tec hnical Assistance: +32-2-712-65 42

EUROPEAN TOLL FREE NUMBERS

Germany: 0180 2232923

UK: 0800 960236

Spain: 900 983291

France: 0800 914032

Italy: 0800 782374

ASIA/PACIFIC

Sales Administration: +65-6294-9948

Tec hnical Assistance: +65-6393-0739

ELSEWHERE

Sales Admini

Tec hnical Assistance: +1-952-917-3475

WRITE:

stration: +1-952-917-3000

ADCP-75-246 • Issue 1 • 6/2008

13944-Q

ADC Telecommunications (S’PORE) PTE, LTD;

100 Beach Road, #18-01, Shaw Towers.

Singapore 189702.

ADC Telecommunications, INC

PO Box 1101,

Minneapolis, MN 55440-1101, USA

ADC European Customer Service, INC

Belgicastraat 2,

1930 Zaventem, Belguim

PRODUCT INFORMATION AND TECHNICAL ASSISTANCE:

connectivity.tac@adc.com

wireless.tac@adc.com

euro.tac@adc.com

asiapacific.tac@adc.com

REPRINTS:

PDF copies of manuals are available

for downloading at the following link:

www.adc.com/manuals

Contents herein are current as of the date of publication. ADC reserves the right to change the contents

without prior notice. In no event shall ADC be liable for any damages resulting from loss of data,

loss of use, or loss of profits and ADC further disclaims any and all liability for indirect, incidental,

special, consequential or other similar damages. This disclaimer of liability applies to all products,

publications and services during and after the warranty period.

ADCP Number:

ADCP-75-246

© 2008, ADC Telecommunications, Inc.

Page 27

Page 36

Website: www.adc.com

Loading...

Loading...