Page 1

FlowCon

Fabric Air Diffusers

Flush Rail Installation Guide

204 Hallberg St.

PO BOX507

Delavan, WI.

53115

INSTALLATION INSTRUCTIONS OVERVIEW

STEP ONE: INVENTORY

STEP TWO: SUSPENSION HARDWARE

STEP THREE: INSTALLATION OF FABRIC DIFFUSER

STEP FOUR: START UP

WARRANTY

CLEANING AND REPAIR

STEP ONE: INVENTORY

Before installing fabric diffuser system read all general information in the following

sections. For best results use this manual in conjunction with the mechanical blue

print or diffuser layout if supplied.

Check the shipment carefully. Diffuser systems are shipped in polyethylene bags or

boxes. Larger orders will be shipped in large skidded containers with individual contents in polyethylene bags or folded. All packages will be labeled with diffuser diameter and length.

Make sure contents match the packing list. Note any missing or damaged pieces and

notify your supplier before starting installation. Check length & diameters before installing & contact supplier before installation. (Not responsible for labor costs accrued

from installing incorrect lengths or layouts.)

Page 2

STEP TWO: SUSPENSION HARDWARE

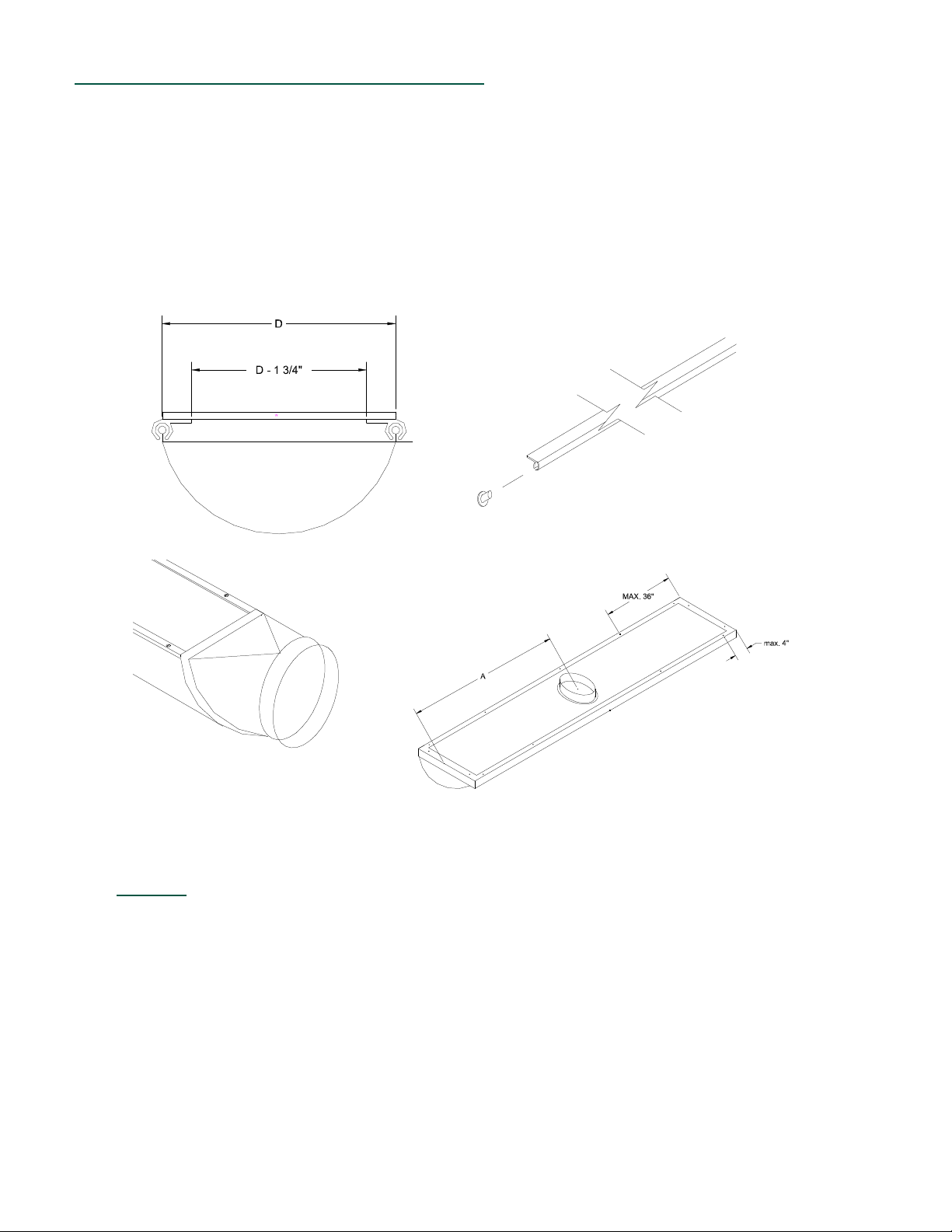

The aluminum flush rail supplied comes in 10 foot sections. Identify rail location and mounting

locations. D-shape systems require side mounting based on 3:00 and 9:00. flush mount rail

must be mounted to a flat surface. Rail can be mounted with rivets or screws to T-Bar or flat

surface of ceiling. If D-shape diffuser is not mounted to a flat surface it will not retain it’s half

round shape. Rails should be mounted the width of the diffuser. The inside distance between

the rails is equal to the diameter minus 1 3/4”. Diffusers can be supplied with air from end or

from top flat area of diffuser. ( See below).

Fittings

When fabric fittings are incorporated in your installation, align rails off centerline of

the system. When elbows are used in the system rail should be installed as indicated

as above. Rail bends and precut rail sections will be provided for suspension of the

elbows. (Note: rail bends may come in two sections, a coupler may be needed to

connect.)

When tee’s or take offs are used Install rail perpendicular to main rail to suspend

branch runs. To insure proper alignment the main of the fabric system can be installed to the rail and the air handler first. Then the cross rails perpendicular to the

main can be installed to suspend the branch runs. Fittings will have quick connect

joints such as zippers to ease the installation and maintenance of the system.

Page 3

STEP THREE: INSTALLATION OF FABRIC DIFFUSER

When handling a diffuser prior and during installation, please keep anything that comes in contact with the diffuser

clean. If a diffuser is to be laid out on the floor, make sure floor is clean or something is laid down to protect diffuser

from dirt or debris on the ground that could catch on air jets and damage diffuser during installation.

1.) Slide the cord down through the rail.

2.) Pull diffuser down the rail until fully extended.

3.) Pull open end of diffuser and slip over metal collar or metal duct (about 6-12”).

4.) install worm gear band around diffuser to secure it to metal duct.

Note: Worm gear bands are perforated and self taping screws can be used to help secure band and

keep from slipping. ( screws not included).

5.) Finish rail installation by trimming off end end with angle piece. Anchor end piece to rail with screws and

anchors provided. Note: Angle end piece should be 2” wider then diffuser.

D -SHAPE W

14"

18"

22"

26"

30"

34"

16"

20"

24"

28"

32"

36"

Quarter Round

Quarter round requires two flush rails mounted on perpendicular surfaces. The tracks

can be concealed by the diffuser. Locate concealed rail so the outer edge is 1/2”

smaller than the radius.

W

STEP FOUR: START UP

Turn on air handler and inflate diffuser. If the diffuser system flutters after installation, check to see if

air handler is operating at its designed air volume and static pressure. Fluttering can cause damage to

fabric shortening life of system.

WARRANTY INFORMATION

Diffuser systems are subject to a five year limited warranty. The warranty covers workmanship and materials on all components of the system. Only replacement costs and credits are covered. Cash payments are not available. The warranty covers freight costs, but does not cover installation costs. The

warranty excludes damage caused by improper installation, failure to specify all system requirements

and air handling equipment not performing as specified.

The effective start date of the warranty is the product ship date.

Loading...

Loading...