Page 1

FCC ID: F8I-DVLRCSPCS - User Manual - Part 2

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

4 SPECTRUM TRANSPORT MODULE

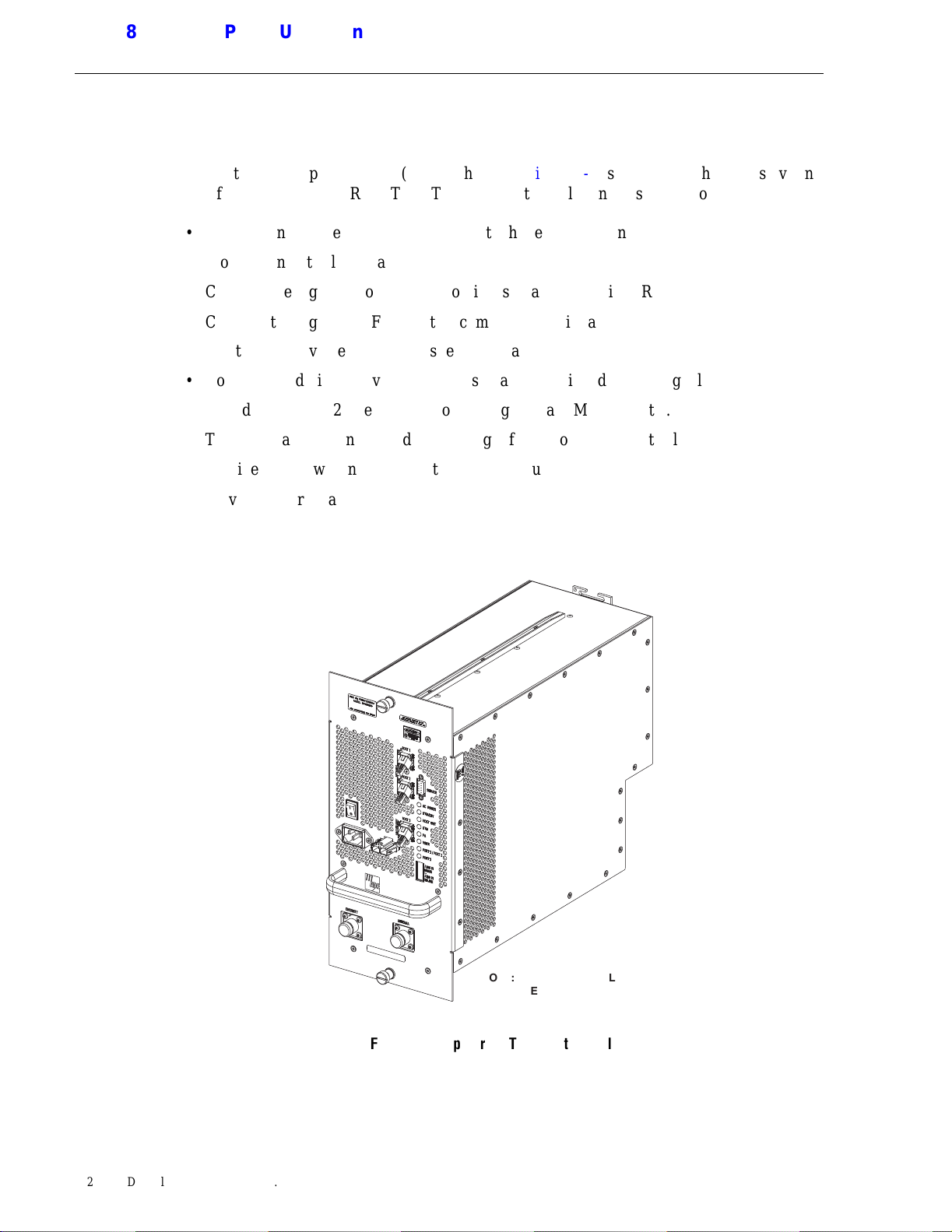

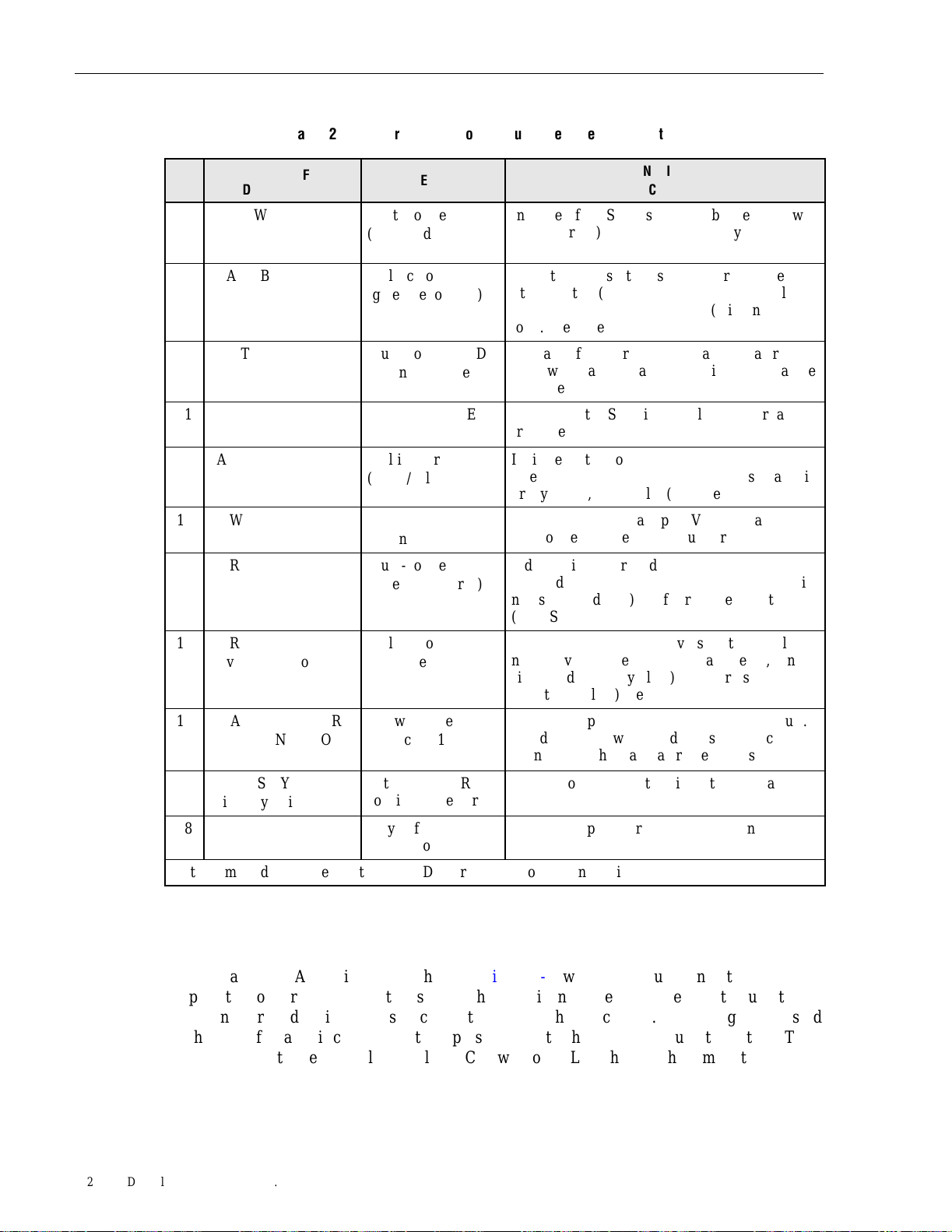

The Spectrum Transport Module (STM), shown in Figure 2-5, serves as the handset servicing

device for the Digivance LRCS. The STM provides the following basic functions:

• Provides an RF interface (antenna ports) to the remote antenna(s).

• Provides an optical interface to the HU.

•Converts the digitized forward path optical signal to a digitized RF signal.

•Converts the digitized RF signal to a composite RF signal.

• Digitizes the reverse path composite RF signal.

•Converts the digitized reverse path RF signal to a digitized optical signal.

• Provides an RS-232 interface for connecting a local EMS computer.

• Transports alarm, control, and monitoring information via the optical link.

• Provides AC power input and battery power input.

• Provides external alarm input.

Page 2-12

© 2002, ADC Telecommunications, Inc.

17528-A

NOTE: UNIT SHOWN INCLUDES

DIVERSITY OPTION

Figure 2-5. Spectrum Transport Module

Page 2

4.1 Primary Components

The STM consists of an electronic circuit board assembly, power supply, duplexer, and fan

assembly that are mounted within a powder-coated sheet metal enclosure. The metal enclosure

provides a mounting point for the electronic components and controls RF emissions. Except for

the fan unit, the electronic components are not user replaceable. The STM is designed for use

within the RU cabinet. Except for the LPA interface connector, all controls, connectors,

indicators, and switches are mounted on the STM front panel for easy access. A carrying handle

is provided on the front of the STM to facilitate installation and transport.

4.2 Mounting

The STM mounts on a shelf within the RU cabinet. A runner on the bottom of the STM meshes

with a track on the mounting shelf. The runner and track guide the STM into the installed

position. The electrical interface between the STM and LPA is supported by a D-sub female

connector located on the rear side of the STM. A corresponding D-sub male connector mounted

at the rear of the RU cabinet mounting shelf mates with the STM connector. Captive screws are

provided for securing the STM to the mounting shelf.

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

4.3 Fault Detection and Alarm Reporting

The STM detects and reports various faults including remote unit fault, optical fault, power

fault, temperature fault, power amplifier fault, and external (door open) fault. Various front

panel Light Emitting Diode (LED) indicators turn from green to red or yellow if a fault is

detected. The status of the STM, the alarm state (major or minor), and other alarm information

is summarized and reported over the optical fiber to the HU and also over the service interface.

In addition, the alarm state of the HU is received over the optical fiber and reported to the

service interface. This information may be accessed remotely through the NOC/NEM interface

or locally through the EMS software GUI.

4.4 Antenna Cable Connection

The antenna cable connections between the STM and the antenna are supported through either

one (non-diversity unit) or two (diversity unit) N-type female connectors. On non-diversity

units, a single connector is used for the antenna cable which carries both the forward and

primary reverse path RF signals. On diversity units, a second connector is used for the diversity

antenna cable which carries only the diversity reverse path RF signals. The STM does not

connect directly to the antenna but instead connects to a lightning protector that is mounted on

the bottom of the RU cabinet (see Section 3.5). A coaxial jumper cable is provided (included

with the enclosure) for connecting the STM connector to the lightning protector.

4.5 RF Signal Level Adjustment

The STM is equipped with a digital attenuator for adjusting the signal level of the forward path

RF output signal. The remote forward path attenuator adjusts the level of the output RF signal

at the RU antenna port and will add from 0 to 30 dB of attenuation to the output signal level.

© 2002, ADC Telecommunications, Inc.

Page 2-13

Page 3

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

The attenuator can be set in 1 dB increments. The attenuator is software controlled and is

adjusted through the NOC/NEM interface or the EMS software GUI.

4.6 Optical Connection

Fiber optic connections between the STM and the HU are supported through either two (nondiversity unit) or three (diversity unit) SC-type optical connector ports. On non-diversity units,

one port is used for connecting the forward path optical signal and the other port is used for

connecting the primary reverse path optical signal. On diversity units, a third optical port is used

for connecting the diversity reverse path optical signal.

4.7 Service Interface Connection

The service interface connection between the STM and a local laptop computer loaded with the

EMS software is supported by a single DB-9 female connector. The service interface connector

provides an RS-232 DTE interface. The STM service interface connector supports local

communications with both the STM and the corresponding HU.

4.8 Powering

The STM is powered by 120 or 240 Vac (50 or 60 Hz) power which is supplied through a threeconductor AC power cord. The power cord is provided with the RU cabinet. One end of the cord

is hard-wired to the AC power outlet box and the other end is terminated with a molded-on plug

cap. The power cord connects to a 3-wire AC cord connector mounted on the STM front panel.

A switch on the STM front panel provides AC power On/Off control.

The STM (and the connected LPA) may be powered by a 24 Vdc back-up battery system which

is available as an accessory kit. A connector is provided on the STM front panel for connecting

the wiring harness for the back-up battery system.

4.9 Cooling

Continuous air-flow for cooling is provided by a single fan mounted on the rear side of the STM

housing. An alarm is provided that indicates if a high temperature condition (>50º C/122º F)

occurs. If the temperature falls below 32º F (0º C), the fan automatically shuts off. The fan may

be field replaced if it fails.

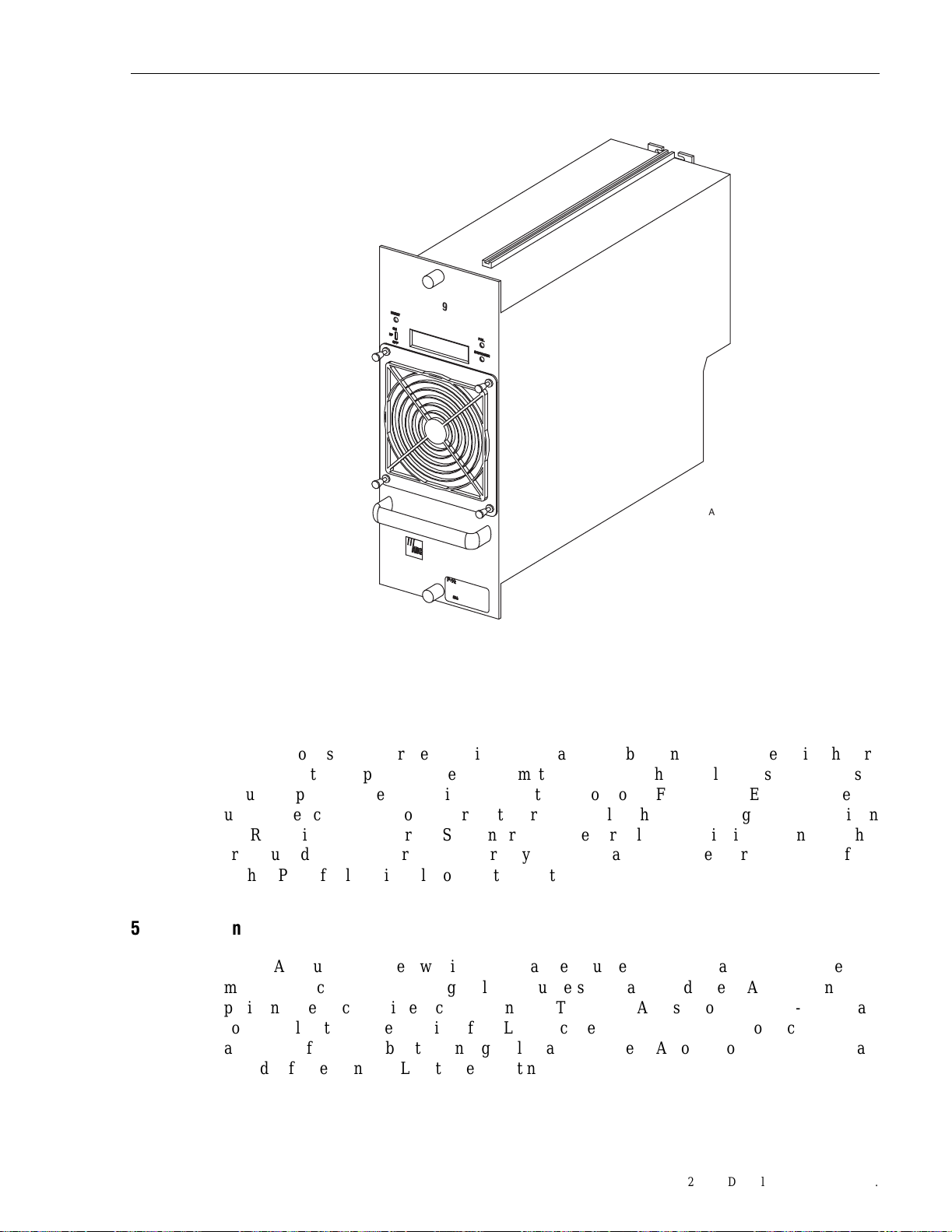

4.10 User Interface

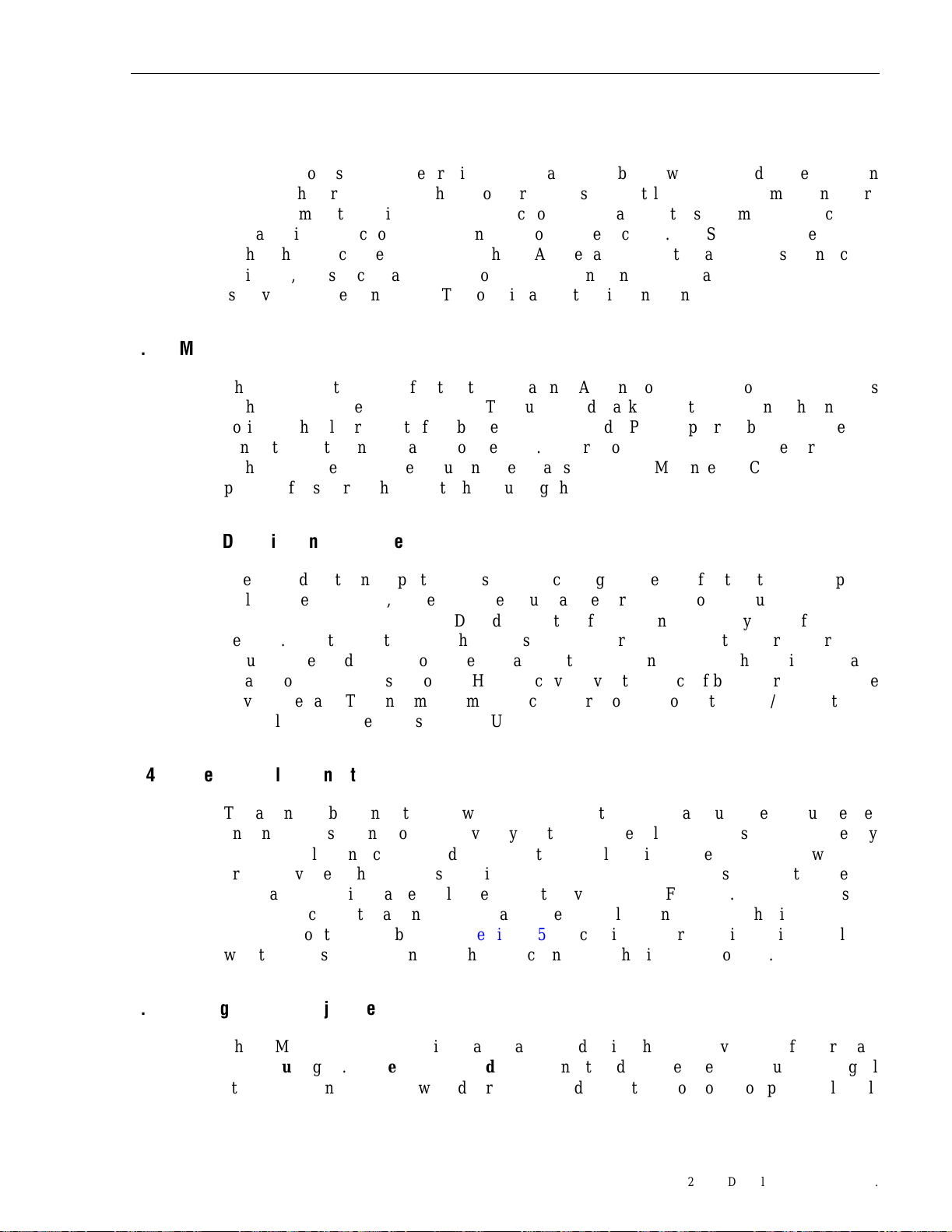

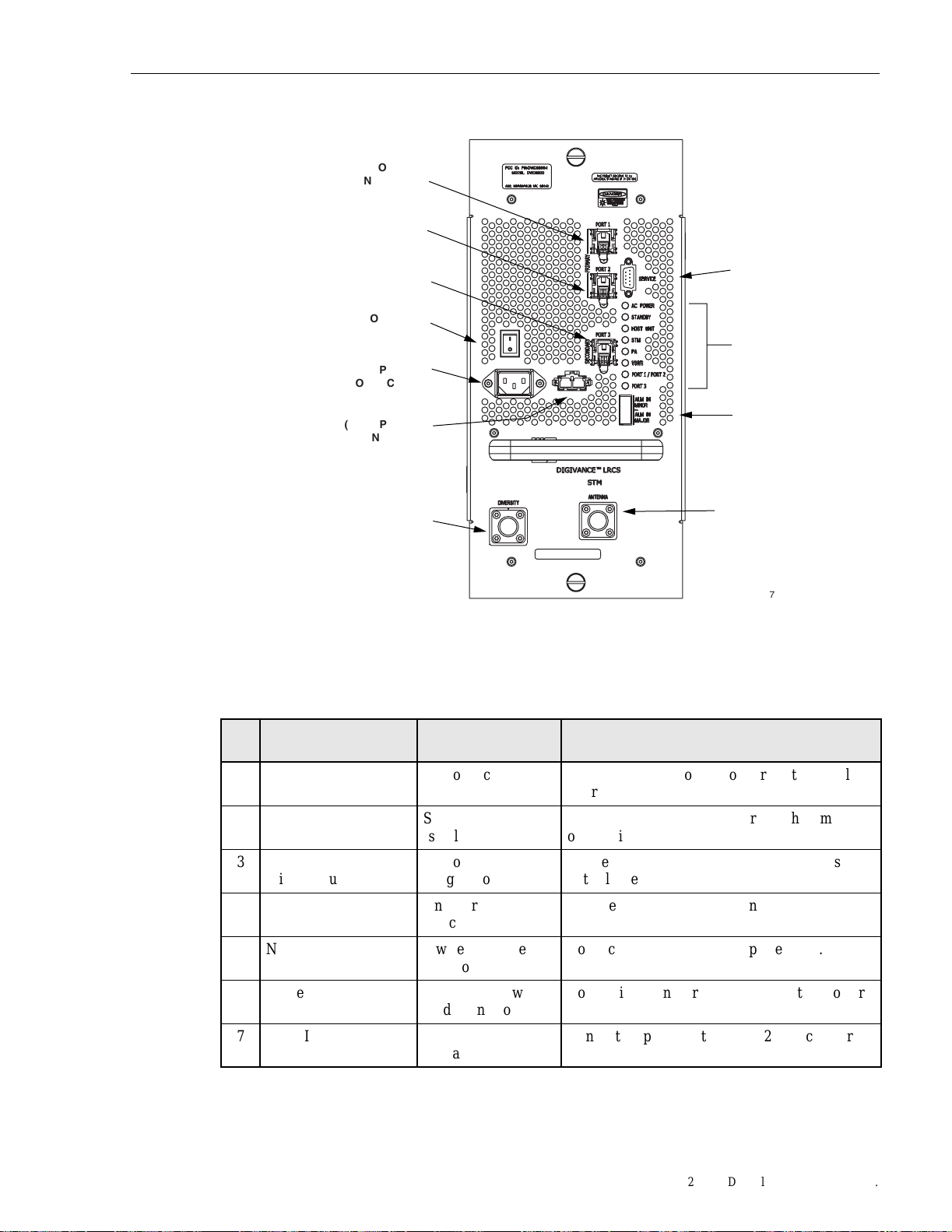

The STM user interface consists of the various connectors, switches, and LEDs that are

provided on the STM front panel. The STM user interface points are indicated in Figure 2-6 and

described in Table 2-3.

Page 2-14

© 2002, ADC Telecommunications, Inc.

Page 4

(1) PORT 1

CONNECTOR

(2) PORT 2

CONNECTOR

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

(3) PORT 3

CONNECTOR

(4) ON/OFF

SWITCH

(5) AC POWER

CONNECTOR

(6) DC POWER

CONNECTOR

(17) DIVERSITY

ANTENNA

CONNECTOR

NOTE: UNIT SHOWN INCLUDES

DIVERSITY OPTION

Figure 2-6. Spectrum Transport Module User Interface

Table 2-3. Spectrum Transport Module User Interface

(7) SERVICE

CONNECTOR

(8-15) LED

INDICATORS

(16) ALARM

CONNECTOR

(18) ANTENNA

CONNECTOR

17527-A

REF

NO

1PORT 1SC

USER INTERFACE

DESIGNATION

DEVICE

connector

(single-mode)

2PORT 2SC

connector

(single-mode)

3PORT 3

(diversity unit only)

41/0 On/Off rocker

SC connector

(single-mode)

switch

5No designation 3-wire AC power

cord connector

6No designation 2- wire DC power

cord connector

7 SERVICE DB-9 connector

(female)

FUNCTIONAL

DESCRIPTION

Connection point for the forward path optical

fiber.

Connection point for the reverse path primary

optical fiber.

Connection point for the reverse path diversity

optical fiber.

Provides AC power on/off control.

Connection point for the AC power cord.

Connection point for the back-up battery power

cord.

Connection point for the RS-232 service interface cable.

© 2002, ADC Telecommunications, Inc.

Page 2-15

Page 5

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

Table 2-3. Spectrum Transport Module User Interface, continued

REF

NO

USER INTERFACE

DESIGNATION

DEVICE

8AC POWER Multi-colored LED

(green/red)

9 STANDBY Multi-colored LED

(green/yellow/red)

10 HOST UNIT Multi-colored LED

(green/yellow/red)

11 STM Multi-colored LED

(green/yellow/red)

12 PA Multi-colored LED

(green/yellow/red)

13 VSWR Multi-colored LED

(green/yellow/red)

14 PORT 1/PORT 2 Multi-colored LED

(green/yellow/red)

FUNCTIONAL

DESCRIPTION

Indicates if the STM is powered by the AC power

source (green) or the back-up battery system

(red). See Note.

Indicates if the system is in the Normal state (off)

Standby state (blinking green), Test state (blinking red), or Program Load state (blinking yellow). See Note.

Indicates if no alarms (green), a minor alarm

(yellow), or a major alarm (red) is detected at the

HU. See Note.

Indicates if the STM is normal (green) or faulty

(red). See Note.

Indicates if the power amplifier is normal

(green), over temperature (yellow), has a fan failure (yellow), or is faulty (red). See Note.

Indicates if the forward path VSWR is above

(red) or below (green) the fault threshold.

Indicates if the forward path optical signal

received from the HU is normal (green), if no signal is detected (red), or if errors are detected

(red). See Note.

15 PORT 3

(diversity unit only)

16 ALARM IN MINOR

ALARM IN MAJOR

17 DIVERSITY

(diversity unit only)

18 ANTENNA N-type female RF

Note: A more detailed description of LED operation is provided in Section 5.

5 LINEAR POWER AMPLIFIER

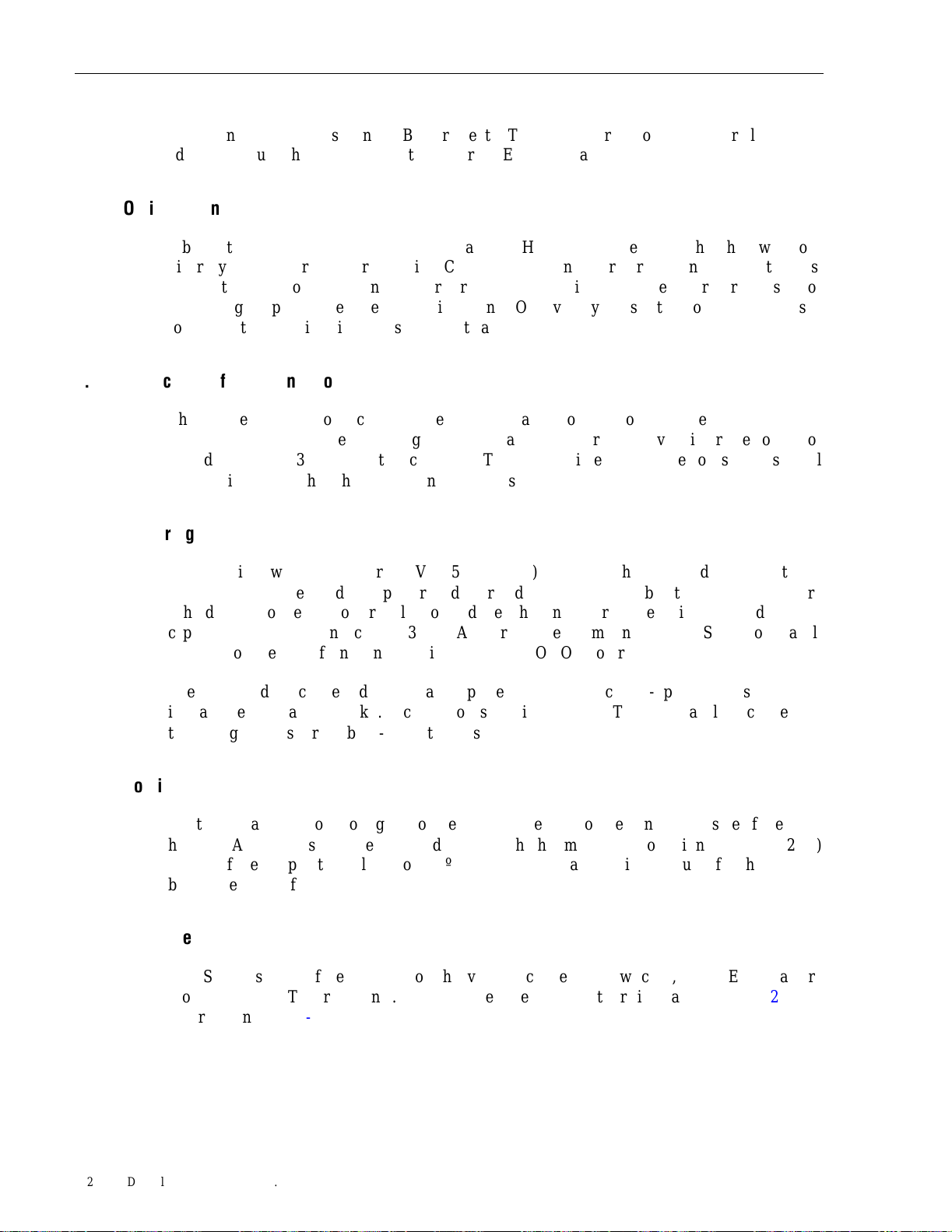

The Linear Power Amplifier (LPA), shown in Figure 2-7, works is conjunction with the STM to

amplify the forward path RF output signal. The STM is interfaced with the LPA through the Dsub connectors and wiring harness located at the rear of the RU cabinet. The RF signal is passed

to the LPA for amplification and then passed back to the STM for output via the STM’s

ANTENNA port. The STM also supplies DC power to the LPA through the same interface.

Multi-colored LED

(green/yellow)

Screw-type terminal

connector (14–26

AWG)

N-type female RF

coaxial connector

coaxial connector

Indicates if the diversity reverse path optical signal received by the HU is normal (green), if no

signal is detected (yellow), or if errors are

detected (yellow). See Note.

Connection point for two external alarm inputs.

The door-open switch lead wires are typically

connected to the major alarm terminals.

Connection point for the diversity antenna.

Connection point for the primary antenna.

Page 2-16

© 2002, ADC Telecommunications, Inc.

Page 6

LPA 1940

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

5.1 Primary Components

The LPA consists of several electronic circuit board assemblies and two fan assemblies that are

mounted within a powder-coated sheet metal enclosure. The metal enclosure provides a

mounting point for the electronic components and controls RF emissions. Except for the fan

units, the electronic components are not user replaceable. The LPA is designed for use within

the RU cabinet. Except for the STM interface connector, all controls, indicators, and switches

are mounted on the LPA front panel for easy access. A carrying handle is provided on the front

of the LPA to facilitate installation and transport.

5.2 Mounting

17546-A

Figure 2-7. Linear Power Amplifier

The LPA mounts on a shelf within the RU cabinet. Runners on the top and bottom of the LPA

mesh with tracks on the mounting shelf. The runners and tracks guide the LPA into the installed

position. The electrical interface between the STM and LPA is supported by a D-sub female

connector located on the rear side of the LPA. A corresponding D-sub male connector mounted

at the rear of the RU cabinet mounting shelf mates with the LPA connector. Captive screws are

provided for securing the LPA to the mounting shelf.

Page 2-17

© 2002, ADC Telecommunications, Inc.

Page 7

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

5.3 Fault Detection and Alarm Reporting

The LPA in conjunction with the STM detects and reports various faults including power

amplifier fault, output power fault, temperature fault, and fan fault. Various Light Emitting

Diode (LED) indicators, located on the front panels of both the STM and LPA, turn from green

to red or yellow if an LPA fault is detected. In addition, a digital display located on the LPA

front panel provides various fault messages. The status of the LPA, the alarm state (major or

minor), and other more detailed information is summarized and reported (by the STM) over the

optical fiber to the HU and also to the service interface. This detailed information may be

accessed remotely through the NOC/NEM interface or locally through the EMU software GUI.

5.4 Powering

The LPA is powered by various DC voltages which are supplied by the STM over the electrical

interface provided by the D-sub connectors and wiring harness mounted within the RU cabinet.

5.5 Cooling

Continuous air-flow for cooling is provided by a pair of fans mounted at the front and the rear

side of the LPA housing. The front fan pulls cool air into the module and the rear fan exhausts

heated air out of the module. An alarm is provided that indicates if a high temperature condition

(>50º C/122º F) occurs or if a fan failure occurs. Either fan may be field replaced if it fails.

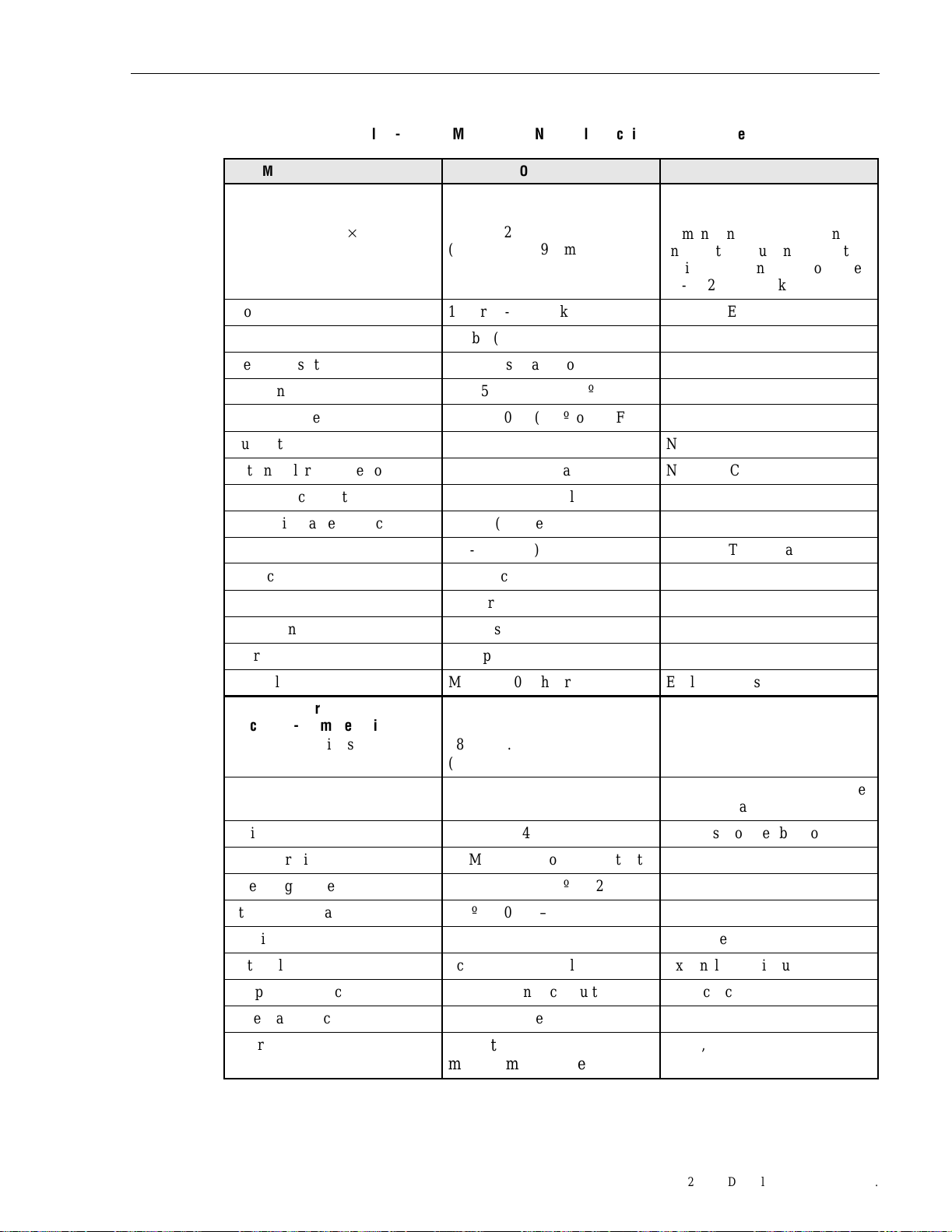

5.6 User Interface

The LPA user interface consists of the various LEDs, message displays, and switches that are

provided on the LPA front panel. The LPA user interface points are described in Table 2-4 and

indicated in Figure 2-8.

REF

NO

1 RESET Momentary contact

2RF ON OFF 2-position switch Placing the switch in the OFF position puts the

3FAIL LED indicator

4 SHUTDOWN LED indicator (red) Indicates the LPA is in service (off) or shutdown

USER INTERFACE

DESIGNATION

Table 2-4. Linear Power Amplifier User Interface

DEVICE

Momentarily pressing the switch push button

push button switch

(yellow)

clears all alarms and restarts the amplifier

LPA in a standby state with RF output disabled.

Placing the switch in the ON position puts the

LPA in the normal state with RF output enabled.

Indicates the LPA is normal (off) or faulty

(yellow).

(red).

FUNCTIONAL

DESCRIPTION

5No designation Digital display Provides status and alarm messages. See Note.

Note: A more detailed description of the digital display messages is provided in Section 5.

Page 2-18

© 2002, ADC Telecommunications, Inc.

Page 8

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

(1) RESET

SWITCH

(2) RF ON/OFF

SWITCH

LPA 1940

(3) FAIL

LED

(4) SHUTDOWN

LED

(5) DIGITAL

DISPLAY

17545-A

Figure 2-8. Linear Power Amplifier User Interface

6 DIGIVANCE ELEMENT MANAGEMENT SYSTEM

The Digivance Element Management System (EMS) is a network management tool that provides

control and monitoring functions for the Digivance LRCS system. The EMS is used to provision

and configure new systems for operation, set system operating parameters, get system alarm and

status messages, and upgrade the system software. The EMS supports both local control by an

on-site service technician and remote control by a Network Operations Center (NOC).

6.1 Primary Components

The EMS, shown in Figure2-9, consists of a PC-type desk-top computer (not provided) that is

loaded with the EMS software. The EMS software is stored on a CD-ROM that is shipped with

the HU. The EMS software must be installed on the EMS computer along with the Java 2

Version 1.3.1 Runtime Environment software which is also provided. Installation consists of

inserting the CD-ROM into the computer’s CD-ROM drive and then running the software install

programs. This places the Java 2 Runtime Environment and EMS software files in assigned

folders on the computer’s hard drive.

© 2002, ADC Telecommunications, Inc.

Page 2-19

Page 9

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

OR

PLUS

16803-A

The EMS software may also be installed on a PC-type lap-top computer (not provided). A laptop version of the EMS computer can be used as a portable network management tool for

service and maintenance purposes. A laptop EMS can be connected temporarily to a system to

enter the initial configuration data or to trouble-shoot problems and then removed when the task

is completed. Permanent control and monitoring functions would be provided by the desk-top

EMS computer.

6.2 Service Interface Connection

The service interface connection between the EMS computer and the HU or RU requires that

the EMS computer be equipped with a DB-9 connector that is configured to provide an RS-232

DCE interface. A straight-through RS-232 interface cable (accessory item) equipped with a

male DB-9 connector on one end and a PC-compatible connector on the other end is required to

link the EMS computer to the HU. When multiple HUs are networked together, the EMS

computer may be connected to the service connector on any one of the networked HUs.

CD-ROM WITH EMS

SOFTWARE

Figure 2-9. Alarm Network Unit

6.3 NOC Interface Connection

The NOC interface connection between the EMS computer and the NOC requires that the EMS

computer be equipped with a connector that is configured to provide an RS-232 ASCII

interface. The link between the EMS computer and the NOC would generally be supported by a

data network or dial-up modem. Cables and equipment (not provided) to support the RS-232

interface connection between the EMS computer and the data network or dial-up modem are

required.

Page 2-20

© 2002, ADC Telecommunications, Inc.

Page 10

6.4 EMS Software User Interface

The EMS software provides two user interfaces: the Graphical User Interface (GUI) and the

Network Operation Center-Network Element Manager (NOC/NEM) interface. Both interfaces

provide essentially the same functionality except only the GUI can upgrade the LRCS system

with new system software. In addition, only the NOC/NEM interface can record and playback

alarm data.

The GUI is presented at the EMS computer or on a laptop computer. The GUI is used for local

control and monitoring operations. The GUI consists of a series of displays and screens, such as

the one shown in Figure 2-10, that provide the user with alarm and status information and that

allow the user to set various operating parameters.

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

Figure 2-10. EMS Graphical User Interface Host/Remote Display

The NOC/NEM interface is a command line interface that is presented at an NOC terminal. The

NOC/NEM interface is used for remote control and monitoring operations. The NOC/NEM

interface consists of ASCII text strings that are input as SET or GET commands which are

followed by the action or information required. A text string response is received from the

specified LRCS system or systems to confirm the requested action or to report the requested

information. Examples of several typical NOC-NEM interface commands and the responses

received are shown in Figure 2-11. The NOC/NEM interface requires only a VT100 terminal/

emulator or a PC-type computer that is loaded with a communication software such as

Procomm Plus. While primarily intended for use at the NOC, the NOC/NEM interface

commands may also be input from the EMS computer.

Page 2-21

© 2002, ADC Telecommunications, Inc.

Page 11

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

7 SPECIFICATIONS

Refer to Table 2-5 for the Digivance 1900 MHz LRCS system nominal specifications. All

specifications apply after a five minute warm-up period.

PARAMETER SPECIFICATION REMARKS

Optical - Host and Remote Unit

Fiber type 9/125, single-mode

Number of fibers required

Non-diversity with WDM

Diversity with WDM

Non-diversity without WDM

Diversity without WDM

Forward path wavelength 1550 nm

Reverse path wavelength 1310 nm

Diversity path wavelength 1310 nm

Figure 2-11. NOC/NEM Interface Typical Commands

Table 2-5. 1900 MHz System Nominal Specifications

1

2

2

3

The wavelength division multiplexer (WDM) is an accessory

item.

Optical transmit power output

Host Unit

Remote Unit

Optical budget 25 dB

Optical Receive Input –15 dBm

Optical connectors Industry standard SC Host, remote, and WDM

Page 2-22

© 2002, ADC Telecommunications, Inc.

0 dBm

+2 dBm

For optical BER of 10

–6

Page 12

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

Table 2-5. 1900 MHz System Nominal Specifications, continued

PARAMETER SPECIFICATION REMARKS

RF Forward Path - 1900 MHz

System bandwidth

20 MHz AD band, 25 MHz

DBE,BEF, and EFC bands

Frequency range

AD

DBE

BEF

EFC

1930 to 1950 MHz

1945 to 1970 MHz

1950 to 1975 MHz

1965 to 1990 MHz

Out-of-band emission s

Primary

–13 dBm per 1 MHz bandwidth

from 10 kHz to 20 GHz

Secondary (see Note 1)

–98 dBm per 100 kHz from 824

to 849 MHz and from 1850 to

1910 MHz

Gain of forward path

(Host input to Remote primary

antenna port)

83.5 dB at band center, room

temperature, and 0 dB attenuation setting

Includes power amplifier.

Gain flatness

Band flatness

Channel flatness

±1.5 dB across freq. range

±1 dB variation across any 1.25

MHz channel

Gain variation ± 3 dB over temp and unit-to-

unit

Out-of-band rejection –40 dB at >

±17.5 MHz from

881.5 MHz

Propagation delay 2.2 µs Excludes fiber delay

Configurable propagation delay

Range

Step size

Up to 63 µs

1µs ± 100 ns

Plus standard propagation delay

Spurious

In-band self generated

Free dynamic range

–13 dBm at remote output

60 dB at 30 kHz bandwidth

Transmit peak-to-average 10 dB

Two-tone Intermodulation –55 dBc at remote output Two tones at 5 Watts each

CDMA Intermodulation

885 kHz to 1.25 MHz

1.25 to 1.98 MHz

1.98 to 2.25 MHz

Nominal composite RF input

signal level

–45 dBc per 30 kHz

–8 dBm per 30 kHz

–55 dBc per 30 kHz

–40 dBm at 0 dB attenuation

–10 dBm at max. attenuation

Absolute level

An input signal level of –40 dBm

provides maximum output power

Configurable input level

Range

Step size

30 dB

1 ± 0.5 dB ±10% of attenuation

monotonic

Page 2-23

© 2002, ADC Telecommunications, Inc.

Page 13

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

Table 2-5. 1900 MHz System Nominal Specifications, continued

PARAMETER SPECIFICATION REMARKS

Composite RF Output power 43.5 dBm (22.4 Watts) at remote

Configurable RF Output

Range

Step size

Transmit path insertion loss 2.5 dB

RF Reverse Path - 1900 MHz

System bandwidth 20 MHz AD band, 25 MHz

Frequency range

AD

DBE

BEF

EFC

antenna port with –40 dBm input

30 dB at remote unit

1 ±0.5 dB ±10% of attenuation

monotonic

DBE,BEF, and EFC bands

1850 to 1870 MHz

1865 to 1890 MHz

1870 to 1895 MHz

1885 to 1910 MHz

40 Watts at power amplifier output

In band spurs (caused by an individual out-of-band signal)

–75 dBc (1 MHz to 20 GHz

and > 10 MHz out-of-band)

–120 dBc (1930 to 1990 MHz)

–120 dBc (869 to 894 MHz) Required for dual band

Propagation delay 2.2 µs Excludes fiber delay

Configurable propagation delay

Range

Step size

Gain flatness

Band flatness

Channel flatness

Up to 60 µs

1µs

1.5 dB across frequency range

±1 dB variation across any 1.25

MHz channel

Plus standard propagation delay

Gain of reverse path

Overall gain

30 dB at band center at room

ALC not invoked

temperature

Gain variation

3 dB over temperature

Out-of-band rejection –40 dB at >

±17.5 MHz from

ALC not invoked

ALC not invoked

836.6 MHz

Spurious (in-band self gener-

–110 dBm referred to input AL C not invoked

ated)

Intermodulation –62 dBc two tones at –50 dBm

System noise figure 8 dB ALC not invoked

Configurable RF output

Range

Step size

30 dB

1 ±0.5 dB ±10% of attenuation

monotonic

Blocking dynamic range 7 0 dB

Level limiting ALC threshold –40 dBm instantaneous

Level limiting ALC range 30 dB

Page 2-24

© 2002, ADC Telecommunications, Inc.

Page 14

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

Table 2-5. 1900 MHz System Nominal Specifications, continued

PARAMETER SPECIFICATION REMARKS

Physical/Environmental/

Electrical - Host Unit

Dimensions (H×W×D) 3.5 × 17.2 × 15.3 inches

(89

×

437

×

389 mm)

Dimension for width does not

include the mounting brackets

which can be installed for either

19- or 23-inch racks.

Mounting 19- or 23-inch rack EIA or WECO

Weight 18 lbs. (8.2 kg)

Weather resistance Indoor installation only

Operating temperature 0º to 50º C (32º to 122º F)

Storage temperature –40º to 70º C (–40º to 158ºF)

Humidity 10% to 90% No condensation

External alarm connector Screw-type terminals NO and NC relay contacts

DC power connector Screw-type terminal strip

RF coaxial cable connectors N-type (female)

Service connector DB-9 (female) RS-232 DTE interface

CAN connectors RJ-45 jack

Power input ± 24 or ± 48 Vdc

Power consumption 55 watts

Current rating 1 Amp at –48 Vdc

Reliability at 25ºC MTBF 80,000 hours Excluding fans

Physical/Environmental/

Electrical - Remote Unit

Cabinet dimensions (H×W×D) 28.4 × 17.4 × 24.9 inches

(721

×

442

×

632 mm)

Mounting Wall or pole Pole mounting requires the pole

mount kit. (accessory)

Weight 120 lbs (54.4 kg) Includes modules but not battery

Weather resistance NEMA-3R, removable dust filter

Operating temperature –30º to 50º C (–22º to 122º F)

Storage temperature –40º to 70º C (–40º to 158ºF)

Humidity 10% to 90% No condensation

External alarm connector Screw-type terminals External alarm inputs

AC power connection 3/4- or 1/2-inch conduit Per local code or practice.

Antenna cable connector N-type (female)

Fiber optic cable size

0.375 to 0.875 inch (10 to 22

mm) diameter cable

9/125, single-mode

© 2002, ADC Telecommunications, Inc.

Page 2-25

Page 15

ADCP-75-126 • Issue B • April 2002 • Section 2: Description

Table 2-5. 1900 MHz System Nominal Specifications, continued

PARAMETER SPECIFICATION REMARKS

Lightning protection 20 kA IEC 1000-4-5 8/20 µs

Service connector DB-9 (female) RS-232 DTE interface

Battery backup operation 1 hour

waveform

Power input 120 or 240 VAC, 50 or 60 Hz Operation on 240 VAC requires

removal of the 120 VAC outlet.

Power consumption 1200 watts

Current rating 9 Amps at 120 Vac

Reliability at 25ºC MTBF 50,000 hours Excluding fans, battery, and air

filter

Note 1: Required for co-located sites such as dual band. Otherwise, the emissions from one unit

can limit the sensitivity of the other.

Page 2-26

© 2002, ADC Telecommunications, Inc.

Page 16

SECTION 3: HOST UNIT INSTALLATION

Content Page

1 BEFORE STARTING INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

1.1 Tools and Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

1.2 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

2 OSP FIBER CABLE INSTALLATION GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3 WDM MOUNTING PROCEDURE (OPTIONAL ACCESSORY) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

4 HU MOUNTING PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

5 CHASSIS GROUND CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

6 COAXIAL CABLE CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

7 OPTICAL CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

7.1 Optical Connections Without WDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

7.2 Optical Connections With WDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

8 CONTROLLER AREA NETWORK CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

9 SERVICE INTERFACE CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

10 EXTERNAL ALARM SYSTEM CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

11 DC POWER CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

_________________________________________________________________________________________________________

ADCP-75-126 • Issue B • April 2002 • Section 3: Host Unit Installation

1 BEFORE STARTING INSTALLATION

This section provides the installation procedures for the HU, the WDM mounting shelf

(accessory item), and the WDM (accessory item). Installation of the RU cabinet and RU

electronic modules may proceed separately from installation of the HU. The installation

procedures for the single band remote cabinet are provided in the Digivance Long-Range

Coverage Solution Single Band Remote Cabinet Mounting Instructions (ADCP-75-117) which

are shipped with the cabinet. The installation procedures for the STM and LPA electronic

modules are provided in the Digivance Long-Range Coverage Solution Remote Unit

Installation Instructions which are shipped with the STM. When all units of the Digivance

LRCS have been installed, refer to Section 4 of this manual for the system turn-up and test

procedures.

Before beginning the installation, review the system design plan with the system engineer.

Make sure each equipment installation site is identified and located and all cable runs are

mapped out.

1.1 Tools and Materials

The following tools are required to complete the procedures in this section:

•Box cutter

• Pencil or scribe

•Medium size flat-bladed screwdriver

• Phillips screwdriver (#2)

© 2002, ADC Telecommunications, Inc.

Page 3-1

Page 17

ADCP-75-126 • Issue B • April 2002 • Section 3: Host Unit Installation

•TORX screwdriver (T20 bit)

• Pliers

•Wire cutters

•Wire stripper

• Tool kit for attaching N-type male connectors to coaxial cable

• Multimeter

•Optical power meter

• Laser light source

The following materials are required to complete the procedures in this section:

• #18 AWG (1.0 mm) insulated stranded copper wire (for chassis grounding wire)

• #18 AWG (1.0 mm) red and black insulated copper wire (for DC power wires)

• Category 3 or 5 cable (for external alarm system wires)

•#6 ring terminal (1) for #18 wire (for chassis ground wire connection)

•#6 fork terminals (2) for #18 wire (for DC power wiring connection)

• Single-mode patch cord(s) with SC connectors (1, 2 or 3 depending on the application)

•High performance, flexible, low-loss 50-ohm coaxial cable

• N-type male connectors

•Wire ties

1.2 Unpacking and Inspection

This section provides instructions for opening the shipping boxes, verifying that all parts have

been received, and verifying that no shipping damage has occurred. Use the following

procedure to unpack and inspect the HU and any accessories:

1. Open the shipping cartons and carefully unpack each component from the protective

packing material.

2. Check each component for broken or missing parts. If there are damages, contact ADC

(see section 6 at the end of this manual) for an RMA (Return Material Authorization) and

to reorder if replacement is required.

2 OSP FIBER CABLE INSTALLATION GUIDELINES

The outside plant (OSP) fiber optic cables should be routed between the HU and RU and

terminated before the equipment is installed. A diagram of a typical OSP cable routing is shown

in Figure 3-1. At the HU, the OSP cable should be terminated at a fiber distribution panel and

spliced to pigtails. Jumper patch cords may then be used to link the HU optical ports to the OSP

cable terminations. Whenever possible, a guideway such as the FiberGuide system should be

provided to protect the fiber optic patch cords from damage and to prevent excessive bending.

The procedures for connecting the OSP cable optical fibers to the HU is provided in Section 7.

Page 3-2

© 2002, ADC Telecommunications, Inc.

Page 18

PATCH

CORD

REMOTE SITE

ADCP-75-126 • Issue B • April 2002 • Section 3: Host Unit Installation

HOST SITE

HOST UNIT

SPLICE

FIBER DISTRIBUTION PANEL

X

PIGTAIL

OUTSIDE PLANT

CABLE

STM

REMOTE UNIT

CABINET

INDOOR/OUTDOOR

CABLE WITH

PIGTAIL LEADS

SPLICE

ENCLOSURE

X

16889-A

Figure 3-1. Typical OSP Cable Routing

At the RU, the OSP fiber optic cable should be spliced to a connectorized outdoor-rated cable

(consisting of individual jacketed pigtails) which is routed into the RU cabinet. The individual

pigtails can then be connected directly to the STM optical ports. A connector is provided on the

bottom of the RU cabinet to seal the cable entry point and provide strain relief. The procedure

for routing the fiber cable into the RU cabinet and for connecting the pigtail leads to the STM is

provided in the Digivance LRCS Single Band SMR Remote Unit Installation Instructions

(ADCP-75-122).

When all splices and terminations are completed, test each fiber for optical loss as described in

Section 5 of this document. The optical loss budget for 9/125, single-mode fiber is 25 dB

minimum for an optical BER of 10

-6

. The power level of the received optical signal should not

exceed –15 dBm to avoid overdriving the optical receiver. If necessary, use an in-line optical

attenuator to adjust the signal level.

Page 3-3

© 2002, ADC Telecommunications, Inc.

Page 19

ADCP-75-126 • Issue B • April 2002 • Section 3: Host Unit Installation

3 WDM MOUNTING PROCEDURE (OPTIONAL ACCESSORY)

A bi-directional wavelength division multiplexer (WDM) is available as an accessory item for

non-diversity versions of the Digivance LRCS. If the application does not require the use of a

WDM, skip this section and proceed to Section 4.

The version of the WDM that is used with the HU consists of one or two WDM modules and a

WDM mounting shelf. Each WDM module can support two HU’s and each WDM mounting

shelf can hold two WDM modules. A fully loaded WDM mounting shelf can therefore support

four HU’s.

When multiple HU’s require connection to a WDM, the WDM mounting shelf and the HU’s

should be mounted in the equipment rack as shown in Figure 3-2. This configuration allows the

pigtail leads from the two WDM modules to be connected directly to the optical ports on any

one of the four HU’s.

POWERWORX

FUSE PANEL

WDM MOUNTING

SHELF

(WITHOUT MODULES)

HOST UNITS

16886-A

Figure 3-2. Typical WDM and HU Configuration

The WDM mounting shelf may be mounted in either a 19-inch or 23-inch EIA or WECO

equipment rack. Four #12-24 screws are provided for securing the mounting shelf to the rack.

Use the following procedure to install the WDM mounting shelf in the equipment rack and to

mount the WDM modules in the WDM mounting shelf:

1. The WDM mounting shelf is shipped with the mounting brackets installed for 19-inch EIA

rack installations. If installing the mounting shelf in a 19-inch EIA rack, proceed to step 5.

If installing the mounting shelf in a 19-inch WECO rack, a 23-inch EIA rack, or a 23-inch

WECO rack, proceed to step 2.

Page 3-4

© 2002, ADC Telecommunications, Inc.

Page 20

ADCP-75-126 • Issue B • April 2002 • Section 3: Host Unit Installation

2. Remove both mounting brackets from the mounting shelf (requires Phillips screwdriver)

and save screws for reuse.

3. Locate the extra mounting brackets that are provided with the mounting shelf and select

the brackets that correspond to the rack type. Each mounting shelf includes extra brackets

for installing the mounting shelf in the rack types specified in step 1.

4. Install the replacement mounting brackets as shown in Figure 3-3. Use the screws

removed in step 2 to attach the new brackets to the mounting shelf.

16885-A

Figure 3-3. Installing the Replacement Mounting Brackets

5. Position the WDM mounting shelf in the designated mounting space in the rack (per

system design plan) and then secure the mounting brackets to the rack using the four #1224 machine screws provided as shown in Figure3-4.

6. Install each WDM module in the mounting shelf (see Figure 3-4). A rail on the side of the

module fits into a guide within the mounting.

7. Secure each WDM module to the mounting shelf by twisting the handle on each quarterturn fastener 90º.

8. Carefully store the pigtail leads from each WDM module. The routing and connection

procedures for the pigtails are provided in Section 7.

© 2002, ADC Telecommunications, Inc.

Page 3-5

Loading...

Loading...