ADC AD-758V Spec Sheet

ADC AD-758V

75-lb Capacity OPL Dryer

Standard Features:

• 75-lb. capacity

• 21.50 cu. ft. basket volume

• 175,000 Btu/hr heat input, 1,000 cfm airflow

• Radial airflow

• Steel door with gasketless glass

• 8" diameter vent connection

• Easy-to-clean lint drawer

• Available in gas, steam and electric heat

Optional Features:

• Stainless steel front, cabinet & basket

• Reversing basket

• S.A.F.E. (Sensor Activated Fire Extinguishing System)

OPL

AD-758V OPL Dryer

Why Purchase ADC AD-758V?

Engineer-Driven Design That is Built to Last

Our dryers showcase ADC’s engineer-driven approach to design. Bearings are permanently lubricated on the motor and

drive system. There are no chains used at ADC; rather, we use V-belts and pulleys for smooth, quiet, and trouble-free

operation. Our dryer cabinets are electrostatically powder-painted inside and out, then baked at 420-degrees fahrenheit

before final assembly—ensuring the hardest surface and the longest-lasting finish in the industry.

Rugged Steel Door with Gasketless Door Glass

Our dryer doors are one solid piece of steel with gasketless glass. This eliminates the issue of glass falling out, due to wear

and tear on rubber gaskets that some manufacturers use to secure their glass. The security and durability that gasketless

glass provides is essential to a successful laundromat operation.

Easy-to-Read, Multilingual Controls

We were the first to bring computer-operated dryers to the market and today we continue to be a leader in applying

technology to dryer operation. Our years of experience along with our accessible design, easy-to-read LED screens and

our user-friendly multilingual interface positions ADC as the pioneer in the laundry industry.

Your local ADC independent authorized distributor

www.adclaundry.com

ADC AD-758V

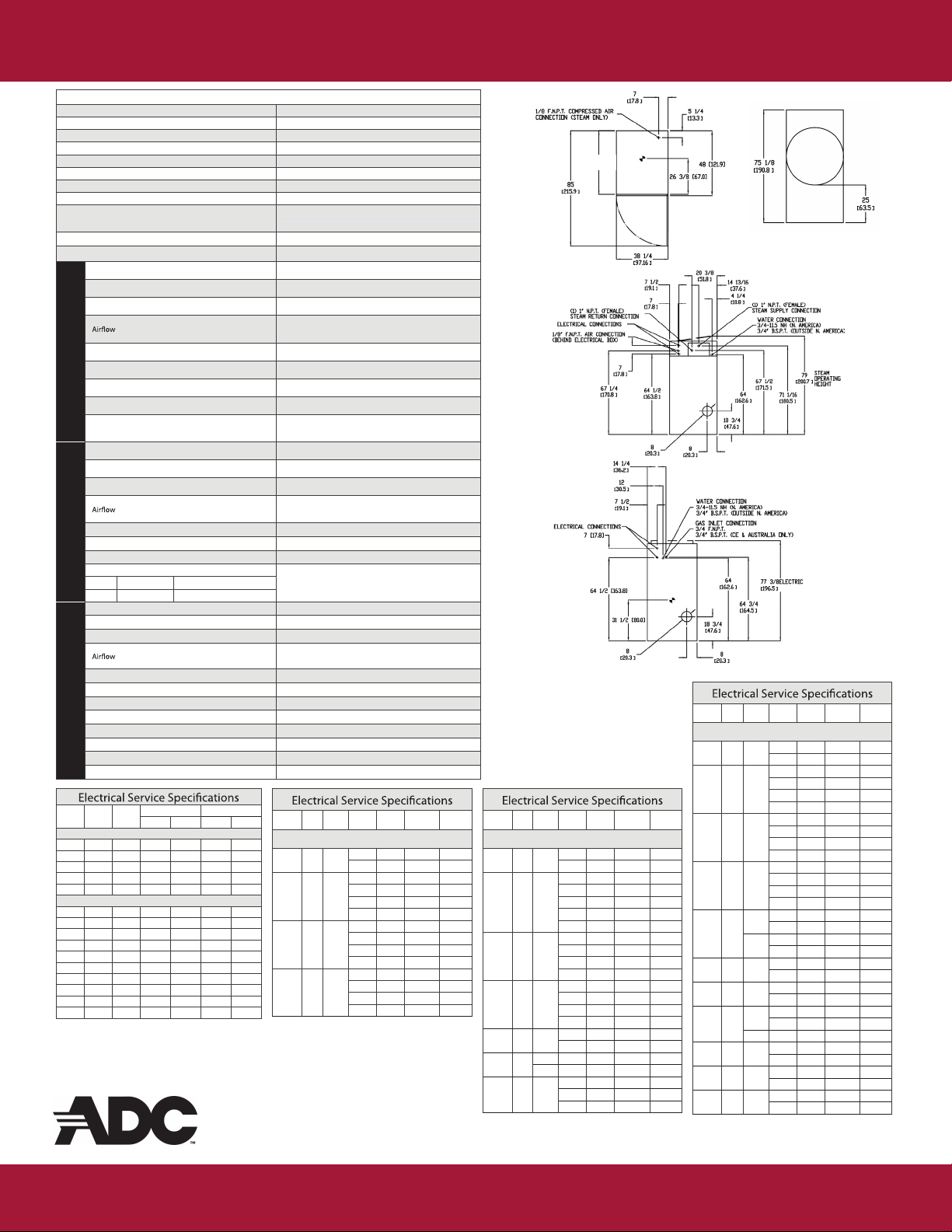

Tumbler Capacity (Dry Weight) 75 lbs. (34.02 kg)

AD-758V Specifications

Tumbler Diameter

Tumbler Depth

Tumbler Volume 21.50 cu ft (608.81 L)

Tumbler/Drive Motor 1 hp / 1/2 hp (0.75kW/0.37 kW)*

Blower/Fan Motor --/1 hp* (--/0.75 kW)

Door Opening (Diameter)

Door Sill Height

S.A.F.E. Water Connection

Dryers per 20'/40' Container

Dryers per 48'/53' Truck

Voltage Available

Approximate Net Weight

Approximate Shipping Weight

Heat Input 175,000 Btu/hr (44,099 kcal/hr)

Exhaust Connection (Diameter)

Compressed Air Connection N / A

Compressed Air Volume N / A

Inlet Pipe Connection

Voltage Available 208-575V 1, 3ø 2,3,4w 50/60 Hz

Approximate Net Weight 721 lb (327.04 kg)

Approximate Shipping Weight 773 lb (350.63 kg)

Exhaust Connection (Diameter)

Compressed Air Connection

Compressed Air Volume N / A

kW Btu/hr kcal/hr

30 102.400 25,800

Voltage Available 120-575V 1, 3ø 2,3,4w 50/60 Hz

Approximate Net Weight 816 lb (370.13 kg)

Approximate Shipping Weight 868 lb (393.72 kg)

Steam Consumption 275 lb/hr (124.7 kg/hr)

Operating Steam Pressure 125 psi max (8.62 bar, 862 kPa)

Exhaust Connection (Diameter)

Steam* Electric Gas

Compressed Air Connection**

Compressed Air Volume ** 0.75 cfh (0.02 cmh)

Boiler HP (Normal Load) 7.2 Bhp

Standard Supply Connections †

Standard Return Connections †

SERVICE

PHASE

VOLTAGE SERVICE

120 1ø 2 13.0 -- 20 -208 1ø 2 7.6 -- 15 -220 1ø 2 7.3 8.6 15 15

230 1ø 2 -- 8.0 -- 15

240 1ø 2 7.0 8.0 15 15

208 3ø 3 4.7 -- 15

220 3ø 3 4.8 4.8 15 15

230 3ø 3 -- 4.7 -- 15

240 3ø 3 4.9 5.4 15 15

380 3ø 4 or 3 2.9 3.1 15 15

400 3ø 4 or 3 -- 3.2 15 15

416 3ø 4 or 3 -- 3.1 15 15

440 3ø 4* 2.6 -- 15 -460 3ø 3 2.8 -- 15 -480 3ø 3 2.8 -- 15 --

Oven Size

APPROX AMP DRAW CIRCUIT BREAKER

WIRE

60 Hz 50 Hz 60 Hz 50 Hz

GAS & STEAM

GAS & STEAM

North America

Outside North America

36-1/4" (92.08 cm)

36" (91.44 cm)

31-3/8" (79.69 cm)

28" (71.12 cm)

3/4"-11.5 NH (North America)

3/4" B.S.P.T. (Outside North America)

9 / 20

24 / 26

120-575V 1, 3ø 2,3,4w 50/60 Hz

721 lb (327.04 kg)

773 lb (350.63 kg)

60 Hz 1,000 cfm (28.32 cmm)

50 Hz 833 cfm (23.60 cmm)

8" (20.32 cm)

3/4" F.N.P.T.

3/4" F.B.S.P.T. (CE and Australia Only)

60 Hz 1,000 cfm (28.32 cmm)

50 Hz 833 cfm (23.60 cmm)

8" (20.32 cm)

N / A

60 Hz 1,200 cfm (33.98 cmm)

50 Hz 1,000 cfm (28.32 cmm)

8" (20.32 cm)

1/8" F.N.P.T.

(1) 1-1/4" N.P.T.

(1) 1" N.P.T.

SERVICE WIRE APPROX CIRCUIT

VOLTAGE

PHASE

SERVICE

Hz kW

Single-Phase Heat Single-Phase Motor

208 1ø 2

220 1ø 2

230 1ø 2

240 1ø 2

60 24 123 175

60 30 152 200

60 20 98 125

60 26 125 175

50 20 100 50

50 26 127 175

60 22 97 125

60 28 123 175

50 22 104 150

50 28 130 175

60 24 107 150

60 30 132 175

50 24 108 150

50 30 133 175

AMP DRAW BREAKER

36

[91.44]

Specifications in parentheses are metric equivalents.

*Reversing dryers use 3-phase (3ø) motors.

**Air-operated steam damper system requires a

clean, dry, and regulated 80 psi +/- 10 psi (5.51 bar

+/- 0.69 bar) air supply.

† Optional steam coil connections differ. Refer to

installation manual.

9/23/16

SERVICE

VOLTAGE

WIRE

PHASE

Hz kW

SERVICE AMP DRAW BREAKER

APPROX CIRCUIT

Three-Phase Heat Single-Phase Motor

208 3ø 3

220 3ø 3

230 3ø 3

240 3ø 3

380 3ø 4

400 3ø

416 3ø 4 50 24 41 60

60 24 74 100

60 30 91 125

60 20 60 80

60 30 86 25

60 26 76 100

50 20 61 80

50 26 77 100

60 22 56 80

60 28 71 100

50 22 63 80

50 28 78 100

60 24 65 90

60 30 79 100

50 24 66 90

50 30 80 125

50 20 39 50

50 26 48 70

4 50 22 40 60

4 50 28 48 70

60 30 49 70

50 30 50 70

88 Currant Road, Fall River, MA 02720-4781 • 508.678.9000

PLAN VIEW

REAR VIEW STEAM ONLY

REAR VIEW (GAS & ELECTRIC)

SERVICE

VOLTAGE

WIRE

PHASE

Hz kW

SERVICE AMP DRAW BREAKER

Three-Phase Heat Three-Phase Motor

208 3ø 3

220 3ø 3

230 3ø 3

240 3ø 3

380 3ø

400 3ø 4 or 3

416 3ø 4 or 3

440 3ø

460 3ø 3

480 3ø 3

575 3ø 3

60 24 71 90

60 30 88 125

60 20 57 80

60 26 73 100

50 20 57 80

50 26 73 100

60 22 0 0

60 28 0 0

50 22 60 80

50 28 75 100

60 24 63 80

60 30 77 100

50 24 63 80

50 30 78 100

60 20 33 50

3

60 26 42 60

50 20 33 50

4 or 3

50 26 43 60

50 22 35 50

50 28 44 60

50 24 36 50

50 30 45 60

60 20 29 40

3

60 26 37 50

4 or 3 50 26 37 50

60 22 30 40

60 28 38 50

60 24 32 50

60 30 39 50

60 24 0 0

60 30 0 0

FRONT VIEW

APPROX CIRCUIT

QY160021 1/17

www.adclaundry.com

Loading...

Loading...