Page 1

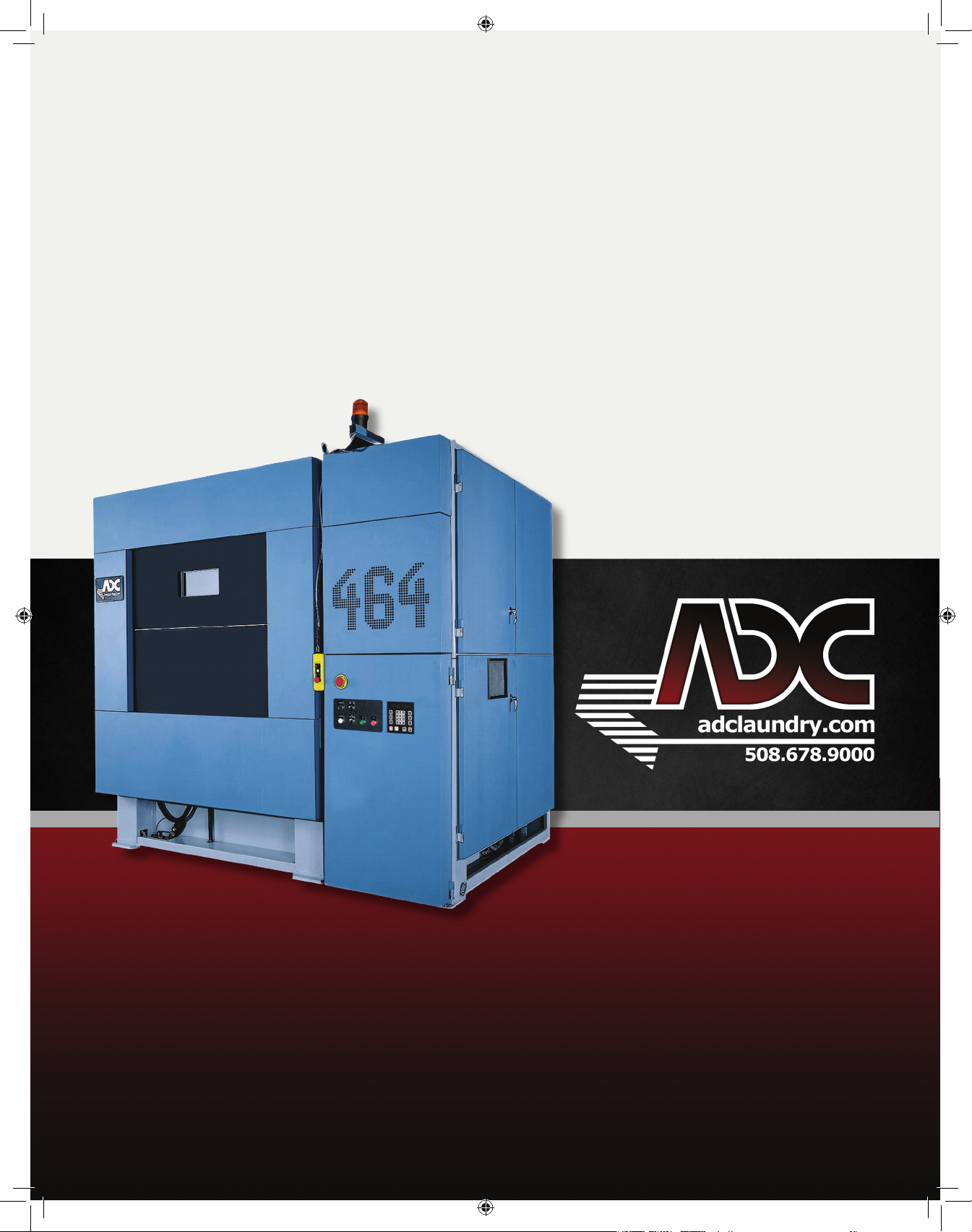

AD-464

88 Currant Road Fall River, MA 02720-4781 • 508.678.9000 • Fax: 508.678.9447 • Email: sales@adclaundry.com

Front Panel

Page 2

our Loads

F

Per Hour

Productivity is the benchmark by which

all large tumblers are measured. The AD464 can dry up to four loads per hour of

terry towels*. With its 175 cu. ft. basket,

2.8 million Btu/hr, and 13,000 cfm, this

performer will show immediate returns

through added productivity.

We manufacture the AD-464 as an “allinclusive” machine. ADC incorporates

as standard every feature necessary

for proper operation. Our competitors

prefer to oer their machines as stripped

down. They add important features,

such as, sprinkler systems**, computer

controls, insulation, rotational sensors,

and even lint collection systems as

expensiveoptions.

The AD-464 is an industrial grade dryer

suited to batch, conventional, and

overhead sling conveyor operations. ADC

oers the laundry manager the highest

possible level of exibility, fast drying,

andsafety.

The AD-464 is constructed and can be

shipped in two (2) or four (4) modules,

easily integrated at the installation

site using simple, military spec, quickconnectplugs.

* Test results may vary by location. In-house test results are

available upon request

** Sprinkler system standard on ADC steam model.

Page 3

he Control

T

Module

he Basket/Drive System

T

Module & Blower Motor

The AD-464 controls

are composed of two

(2) basic sections:

the drying controls

and the load/unload

controls. At the heart

of the drying controls

is an industrial grade

highly reliable, easyto-program computer.

The computer or PLC

(programmable logic

controller) maintains a

complete array of selfdiagnostics throughout

the dryer to assure that

Front Control Panel

operator to access a “system program” mode

which determines functions such as load/

unload positioning and spin/dwell times. The

“pre programmed cycle” mode is the one in

which actual programming of parameters to six

(6) dierent drying cycles can be entered, either

in the manual timed mode or our patented

automatic, percentage dryness mode.

all components are

operating properly. The

computer allows the

A true 460-lb. capacity is assured by the 175

cu. ft. basket, which is stabilized front to back

by eight (8) retaining wheels. The AD-464

dryer’s standard basket is stainless steel and

is machined to assure that the heavy-gauge

basket rings are true in diameter and atness.

The basket is rotated by 11-inch diameter drive

wheels mounted on 2-inch steel shafts which are

powered by a 7-1/2 hp totally enclosed motor.

The entire basket module, both sets of doors,

all control panels, burner chamber, and exhaust

duct come fully insulated as standard to ensure

maximum heat eciency and noise suppression.

The load/unload functions are handled by

front and rear panel controls. An optional front

pendant is available. They are designed to enable

to operator to load or unload the dryer from

the front or rear safely and easily. In general, the

AD-464 PLC oversees the proper running of all

functions, such as, drying cycles, load/unload, lint

collection and air recirculation. As a benet to

the service technician, all computer and electrical

wiring is neatly arranged within the main control

module for easy access.

The AD-464 PLC has our unique “anti-wrinkle”

feature already programmed into each cycle.

With “anti-wrinkle,” the dryer is programmed

to tumble without heat should the attendant

not be aware that the cycle is nished. As a

result, the load is nished without wrinkles, and

the possibility of spontaneous combustion is

greatlyreduced.

An impressive drying time and nish is achieved

by coupling a 25 hp totally enclosed blower

motor which moves 13,000 cfm of air with our

energy-saving air recirculation system. As soon

as a pilot ame is established, the pneumatic air

reclaimer goes to work and stays in operation

during the entire heating cycle. Our system

achieves a 17% rate of hot air reclamation,

thereby drastically reducing energy costs.

Specications subject to change without notice

Page 4

he ADG-464

T

Burner

A

utomatic

Fan Cleaning

The ADG-464 gas burner delivers an

ecient 2.8 million Btu/hr. It is controlled

via the PLC by a burner control module

that ensures that all safety checks have

been adequately satised. Once the spark

ignition system establishes a pilot ame,

the heat reclaimer is activated, and the

gas valves begin operating to maintain

the ame. As a safety precaution, we

have designed our gas valve system

to prevent sudden surges of gas into

the burner. When ready, the rst of two

(2) motorized valves open. Once fully

opened, the second does the same.

tandard

S

Lint Drawers

Of utmost importance to any dryer,

but especially to one of the highcapacity class, is the extraction of lint.

Only ADC incorporates an automatic

compressed air fan cleaning system.

Some dryers require that their fans

be cleaned on a daily basis; others

require multiple cleanings per day. ADC

lters the exhaust air prior to the fan,

eliminating almost all debris that would

collect on the fan. At the end of each

cycle, a powerful blast of compressed

air removes any tiny particles that might

collect and throw the fan out of balance

or reduce airow through the dryer and

cause ineciency or possibly a re.

he ADS-464

T

Steam-Heated Dryer

For the industrial steam laundry

operation, we oer the ADS-464 which

incorporates the exclusive ADC airoperated steam damper system. This

system greatly extends the life of

the rugged coil since it is constantly

charged with steam. To protect against

lint buildup at the coil, it is protected

with its own lint screen. This damper

system also provides the dryer with

an instant source of heat, as well as

cool down. Our recirculation package

is standard on the ADS-464; thus,

maximum heat utilization is assured.

Standard on the AD-464 for lint

removal are two lint drawers located

directly under the basket and accessed

from the left side of the dryer (when

viewed from the front of the dryer).

88 Currant Road, Fall River, MA 02720-4781 • (508) 678-9000 • Fax (508) 678-9447 • www.adclaundry.com

Proud of our past. Excited for our future.

PN-450175

Loading...

Loading...