ADC AD-410 Installation Instructions

AD-410 Installation Manual

Phase 7 / S.A.F.E. System

WARNING: For your safety the

information in this manual must be

followed to minimize the risk of fire or

explosion and to prevent property

damage, personal injury or death.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS:

●

Do not try to light any appliance.

●

Do not touch any electrical switch;

do not use any phone in your

building.

●

Clear the room, building or area of

all occupants.

●

Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

●

If you cannot reach your gas

supplier, call the fire department.

— Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

AVERTISSEMENT: Assurez-vous de

bien suivre les instructions données dans

cette notice pour réduire au minimum le

risque d’incendie ou d’explosion ou pour

éviter tout dommage matériel, toute

blessure ou la mort.

—Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables à proximité de cet

appareil ou de tout autre appareil.

—QUE FAIRE SI VOUS SENTEZ UNE

ODEUR DE GAZ:

●

Ne pas tenter d’allumer d’appareils.

●

Ne touchez à aucun interrupteur. Ne

pas vous servir des téléphones se

trouvant dans le bâtiment.

●

Évacuez la pièce, le bâtiment ou la

zone.

●

Appelez immédiatement votre

fournisseur de gaz depuis un voisin.

Suivez les instructions du fournisseur.

●

Si vous ne pouvez rejoindre le

fournisseur de gaz, appelez le service

des incendies.

—L’installation et l’entretien doivent être

assurés par un installateur ou un

service d’entretien qualifié ou par le

fournisseur de gaz.

American Dryer Corporation

88 Currant Road

Fall River MA 02720-4781 USA

Telephone: +1 (508) 678-9000 / Fax: +1 (508) 678-9447

e-mail: techsupport@amdry.com

www.adclaundry.com

ADC Part No. 113112-10

Retain This Manual in a Safe Place for Future Reference

This product embodies advanced concepts in engineering, design, and safety. If this product is properly

maintained, it will provide many years of safe, efficient, and trouble free operation.

Only qualified technicians should service this equipment.

OBSERVE ALL SAFETY PRECAUTIONS displayed on the equipment or specified in the installation

manual included with the dryer.

The following “FOR YOUR SAFETY” caution must be posted near the dryer in a prominent location.

FOR YOUR SAFETY

Do not store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

We have tried to make this manual as complete as possible and hope you will find it useful. The manufacturer reserves

the right to make changes from time to time, without notice or obligation, in prices, specifications, colors, and material,

and to change or discontinue models. The illustrations included in this manual may not depict your particular dryer

exactly.

POUR VOTRE SÉCURITÉ

Ne pas entreposer ni utiliser d’essence

ni d’autres vapeurs ou liquides

inflammables à proximité de cet

appareil ou de tout autre appareil.

IMPORTANT

For your convenience, log the following information:

DATE OF PURCHASE ________________________________________________ MODEL NO. _____________________

RESELLER’S NAME __________________________________________________________________________________

SERIAL NUMBER(S) __________________________________________________________________________________

____________________________________________________________________________________________________

AD-410 PH7

____________________________________________________________________________________________________

Replacement parts can be obtained from your reseller or the ADC factory. When ordering replacement parts from the

factory, you can FAX your order to ADC at +1 (508) 678-9447 or telephone your order directly to the ADC Parts

Department at +1 (508) 678-9000. Please specify the dryer model number and serial number in addition to the description

and part number, so that your order is processed accurately and promptly.

These instructions are only valid if the following country code is on the appliance… If this code is not present on the

appliance, it is necessary to refer to the technical instructions which will provide the necessary information concerning

the modification of the appliance to the condition of use for the country.

In accordance with EN ISO 3166-1, the names of countries shall be represented by the following codes:

GB United Kingdom

IE Ireland

“IMPORTANT NOTE TO PURCHASER”

Information must be obtained from your local gas supplier on the

instructions to be followed if the user smells gas. These

instructions must be posted in a prominent location near the dryer.

2 American Dryer Corp. 113112-10

!

WARNING

Proposition 65

Use of this product could expose you to

substances from fuel combustion that contain

chemicals known to the State of California

to cause cancer, birth defects and other

reproductive harm.

In the State of Massachusetts, the following installation

instructions apply:

■ Installations and repairs must be performed by a

qualified or licensed contractor, plumber, or

gasfitter qualified or licensed by the State of

Massachusetts.

■ If using a ball valve, it shall be a T-handle type.

■ A flexible gas connector, when used, must not

exceed 3 feet.

IMPORTANT

You must disconnect and lockout the electric supply

and the gas supply or the steam supply before any

covers or guards are removed from the machine to allow

access for cleaning, adjusting, installation, or testing

of any equipment per OSHA standards.

Please observe all safety precautions displayed on the

equipment and/or specified in the installation manual

included with the dryer.

Before installation, check that the local distribution

conditions, nature of gas and pressure, and adjustment

of the appliances are compatible.

CAUTION

Dryer(s) should never be left unattended while in

operation.

When discarding or storing your old clothes dryer,

remove the door.

Lorsque vous entreposez ou mettez votre

sécheuse au rebut, enlevez-en la porte.

“Caution: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper

operation.”

«Attention: Au moment de l’entretien des commandes,

étiquetez tous les fils avant de les débrancher. Des

erreurs de câblage peuvent entraîner un

fonctionnement inadéquat et dangereux.»

WARNING

Children should not be allowed to play on or near the

dryer(s). Children should be supervised if near dryer(s)

in operation.

Under no circumstances should the dryer door

switch(es), lint door/drawer switch(es), or heat safety

circuit(s) ever be disabled.

DO NOT MODIFY THIS APPLIANCE.

The dryer must never be operated with any of the back

guards, outer tops, or service panels removed.

Personal injury or fire could result.

The dryer must never be operated without the lint filter/

screen in place, even if an external lint collection system

is used.

FOR YOUR SAFETY

Do not dry mop heads in the dryer. Do not use dryer in

the presence of dry cleaning fumes.

The dryers must not be installed or stored in an area

where it will be exposed to water and/or weather.

The wiring diagram for the dryer is located behind the

control panel.

Table of Contents ___________________

Safety Precautions ............................................. 4

Specifications ..................................................... 5

Dimensions and

Component Identification / Location ................ 6

Installation Procedures ...................................... 9

Reassembly of Dryer................................................. 9

Location Requirements ..........................................18

Fresh Air Supply Requirements ..............................19

Exhaust Requirements ...........................................19

Compressed Air Supply System ............................. 22

Electrical Information...............................................22

Gas Information ....................................................... 23

Steam Information ................................................... 25

Preoperational Test ................................................. 27

Preparation for Operation / Start-Up ....................... 28

Shutdown Instructions ............................................ 29

Service / Parts Information ............................. 29

Service ..................................................................... 29

Parts ......................................................................... 29

Warranty Information ....................................... 29

Returning Warranty Cards ...................................... 29

Warranty ...................................................................29

Returning Warranty Parts ........................................ 29

Routine Maintenance ....................................... 30

Adjustments............................................................. 31

Lubrication ...............................................................31

Component System Descriptions .................... 31

Burner and Tumbler / Lint Chamber

Manual Reset Hi-Limit Instructions ................. 32

Data Label Information .................................... 33

Procedure for Functional Check

of Replacement Components.......................... 34

S.A.F.E. System ................................................ 34

List of Acronyms _________________________

DSI Direct Spark Ignition

HVAC Heating, Ventilating, and Air-Conditioning

in WC Inches of Water Column

L.E.D. Light Emitting Diode

L.P. Liquid Propane

OSHA Occupational Safety and Health Administration

R.M.A. Return Material Authorization

113112-10 www.adclaundry.com 3

Safety Precautions ___________________

!

WARNING

For your safety, the information in this manual must

be followed to minimize the risk of fire or explosion or

to prevent property damage, personal injury, or loss

of life.

The dryer must never be operated with any of the

back guards, outer tops, or service panels removed.

Personal injury or fire could result.

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

Do not spray aerosols in the vicinity of this appliance while

it is in operation.

Purchaser/user should consult the local gas supplier for

proper instructions to be followed in the event the user

smells gas. The instructions should be posted in a

prominent location.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

Installation and service must be performed by a qualified

installer, service agency, or gas supplier.

Dryer(s) must be exhausted to the outdoors.

Although ADC produces a very versatile dryer, there are some

articles that, due to fabric composition or cleaning method,

should not be dried in it.

!

WARNING

Dry only water washed fabrics. Do not dry articles

spotted or washed in dry cleaning solvents, a

combustible detergent, industrial chemicals, or “all

purpose” cleaner. Explosion could result.

Do not dry rags or articles coated or contaminated

with gasoline, kerosene, oil, paint, or wax. Explosion

could result.

Do not dry mop heads. Contamination by wax or

flammable solvents will create a fire hazard.

Do not use heat for drying articles that contain plastic,

foam, sponge rubber, or similarly textured rubber

materials. Drying in a heated tumbler may damage

plastics or rubber and may be a fire hazard.

The possible presence of residual quantities of aggressive

or decomposed chemicals in the load may produce damage

to the machine and harmful fumes.

A program should be established for the inspection and

cleaning of lint in the heating unit area, exhaust ductwork,

and inside the dryer. The frequency of inspection and

cleaning can best be determined from experience at each

location.

!

WARNING

The collection of lint in the burner area and exhaust

ductwork can create a potential fire hazard.

For personal safety, the dryer must be electrically grounded

in accordance with local codes and/or the National Electrical

Code ANSI/NFPA NO. 70-LATEST EDITION or in Canada,

the Canadian Electrical Codes Parts 1 & 2 CSA C22.1-1990

or LATEST EDITION.

NOTE: Failure to do so will void the warranty.

Under no circumstances should the dryer door switch, lint

drawer switch, or heat safety circuits ever be disabled.

!

WARNING

Personal injury or fire could result.

This dryer is not to be used in the presence of dry cleaning

solvents or fumes.

Remove articles from the dryer as soon as the drying cycle

has been completed.

!

WARNING

Articles left in the dryer after the drying and cooling

cycles have been completed can create a fire hazard.

Do not operate steam dryers with more than 125 psi (8.61

bar) steam pressure. Excessive steam pressure can

damage steam coil and/or harm personnel.

Replace leaking flexible hoses or other steam fixtures

immediately. Do not operate the dryer with leaking flexible

hoses. Personal injury may result.

Read and follow all caution and direction labels attached to

the dryer.

For safety, proper operation, and optimum performance, the

dryer must not be operated with a load less than sixty-six

percent, 270 lb (122.47 kg) of its rated capacity.

!

WARNING

You must disconnect and lockout the electric supply

and the gas supply or the steam supply before any

covers or guards are removed from the machine to

allow access for cleaning, adjusting, installation, or

testing of any equipment per OSHA standards.

IMPORTANT: Dryer must be installed in a location/

environment, which the ambient temperature remains

between 40° F (4.44° C) and 130° F (54.44° C).

CE ONLY

IMPORTANT: This appliance must only be installed and

operated in the country of destination indicated on the

dryer’s data plate. If the appliance is to be installed and

operated in a country other than the one indicated on the

data plate, a data plate amendment must be obtained

from American Dryer Corporation.

IEC335 applies.

4 American Dryer Corp. 113112-10

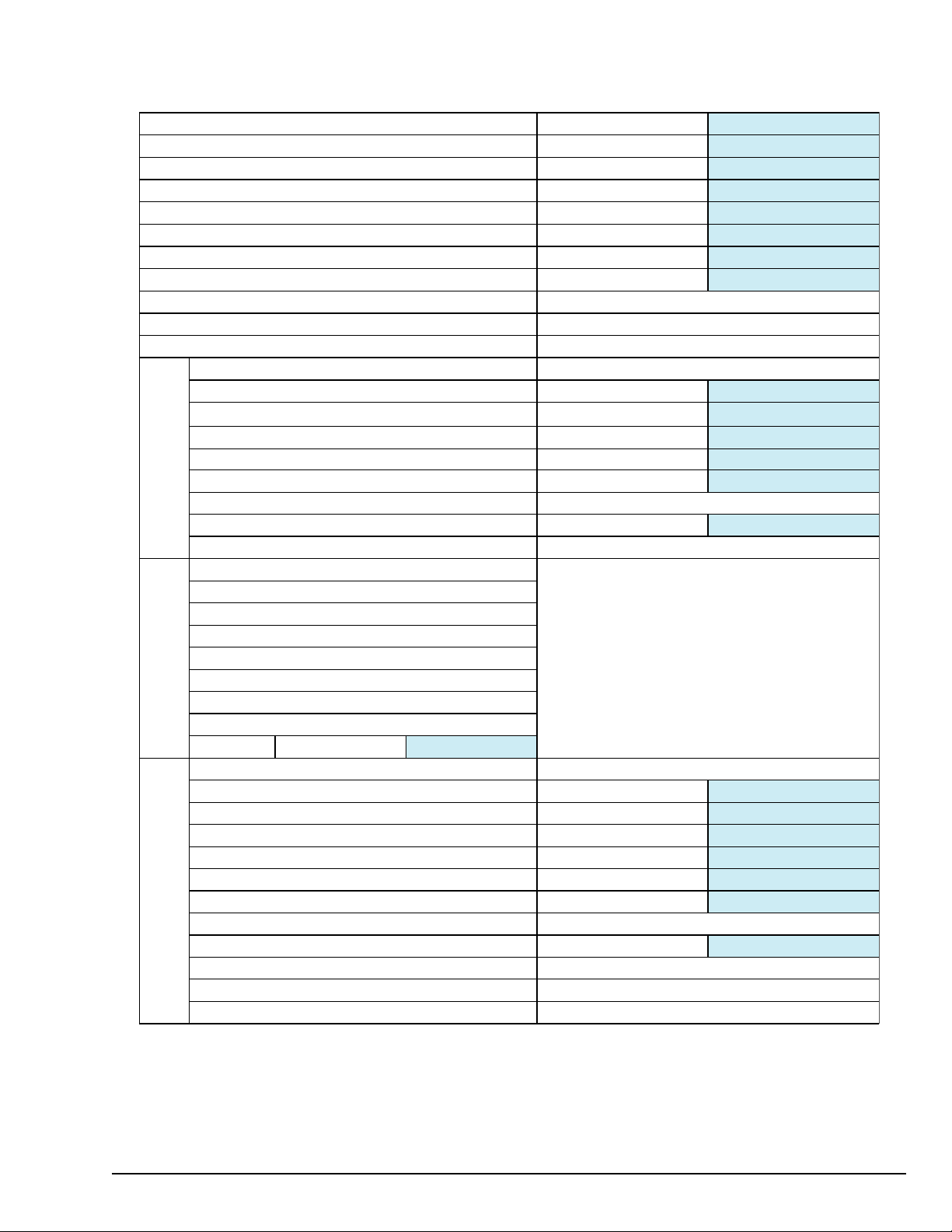

Specifications______________________________________________________________________

MAXIMUM CAPACITY (DRY WEIGHT) 410 lb

TUMBLER DIAMETER 68-3/4”

TUMBLER DEPTH 66-3/8”

TUMBLER VOLUME 143 cu ft

TUMBLER/DRIVE MOTOR 7-1 /2 hp

BLOWER/FAN MOTOR (GAS / STEAM) 15 hp / 25 hp

DOOR OPENING 38” w x 50" h

DOOR SILL HEIGHT 39-3/4”

185.97 kg

174.63 cm

168.61 cm

4049.309 L

5.59 kW

11.2 kW / 18.7 kW

96.52 cm x 127 cm

100.97 cm

WATER CONNECTION 1” F.N.P.T.

DRYERS PER 20’/40’ CONTAINER 1 / 3

DRYERS PER 48’/53’ TRUCK 3 / 4

VOLTAGE AVAILABLE 208-575v 3ø 3,4w 50/60 Hz

APPROX. NET WEIGHT 6,300 lb

APPROX. SHIPPING WEIGHT 6,800 lb

AIRFLOW 9,200 cfm

HEAT INPUT 1,400,000 Btu/hr

GASELECTRICSTEAM

EXHAUST CONNECTION (DIAMETER) 28”

2,857.63 kg

3,084.43 kg

260.52 cmm

352,794 kcal/hr

71.12 cm

COMPRESSED AIR CONNECTION 3/8” F.N.P.T.

COMPRESSED AIR VOLUME (1-WAY / 2-WAY) 5-1/2 cfh / 7 cfh

0.16 cmh / 0.2 cmh

INLET PIPE CONNECTION 1-1/2” F.N.P.T.

VOLTAGE AVAILABLE

APPROX. NET WEIGHT

APPROX. SHIPPING WEIGHT

AIRFLOW

EXHAUST CONNECTION (DIAMETER)

N / A

COMPRESSED AIR CONNECTION

COMPRESSED AIR VOLUME (1-WAY / 2-WAY)

OVEN SIZE

kW Btu/hr

kcal/hr

VOLTAGE AVAILABLE 208-575v 3ø 3,4w 50/60 Hz

APPROX. NET WEIGHT 6,800 lb

APPROX. SHIPPING WEIGHT 7,300 lb

AIRFLOW 10,300 cfm

STEAM CONSUMPTION 1,257 lb/hr

OPERATING STEAM PRESSURE 125 psi max

EXHAUST CONNECTION (DIAMETER) 28”

3,084.43 kg

3,311.22 kg

291.66 cmm

570.17 kg/hr

8.62 bar

71.12 cm

COMPRESSED AIR CONNECTION 3/8” F.N.P.T.

COMPRESSED AIR VOLUME (1-WAY / 2-WAY) 5-1/2 cfh / 7 cfh

0.16 cmh / 0.2 cmh

BOILER HORSEPOWER (NORMAL LOAD) 42 Bhp

SUPPLY CONNECTION 2” M.N.P.T.

RETURN CONNECTION 1-1/4 ” M.N.P.T.

Shaded areas are stated in metric equivalents 9/18/09

NOTE: Dryers must be provided with a clean, dry, regulated 80 psi +/- 10 psi (5.51 bar +/- 0.68 bar) air supply (equivalent

volume = 11 cfh [0.31 cmh]).

NOTE: ADC reserves the right to make changes in specifications at any time without notice or obligation.

113112-10 www.adclaundry.com 5

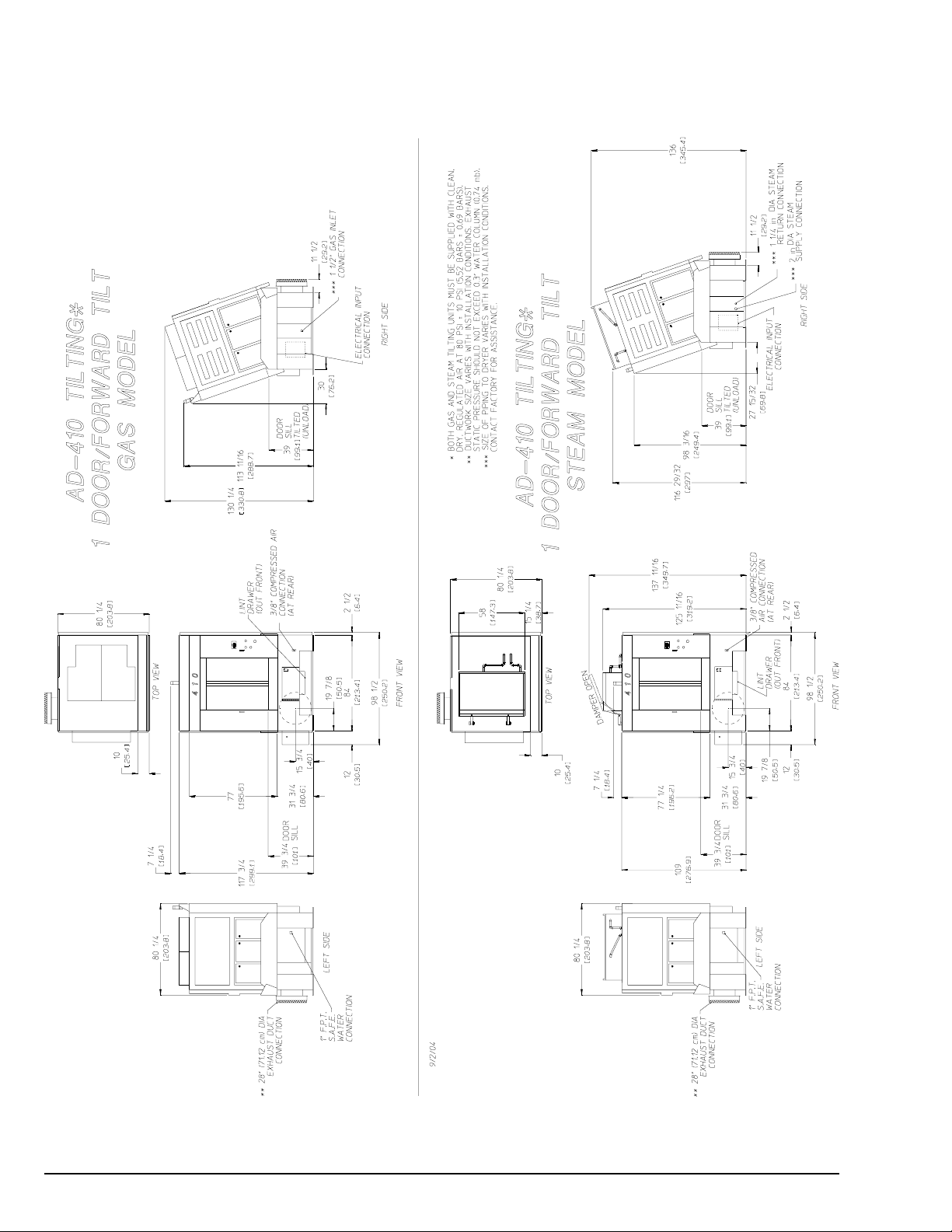

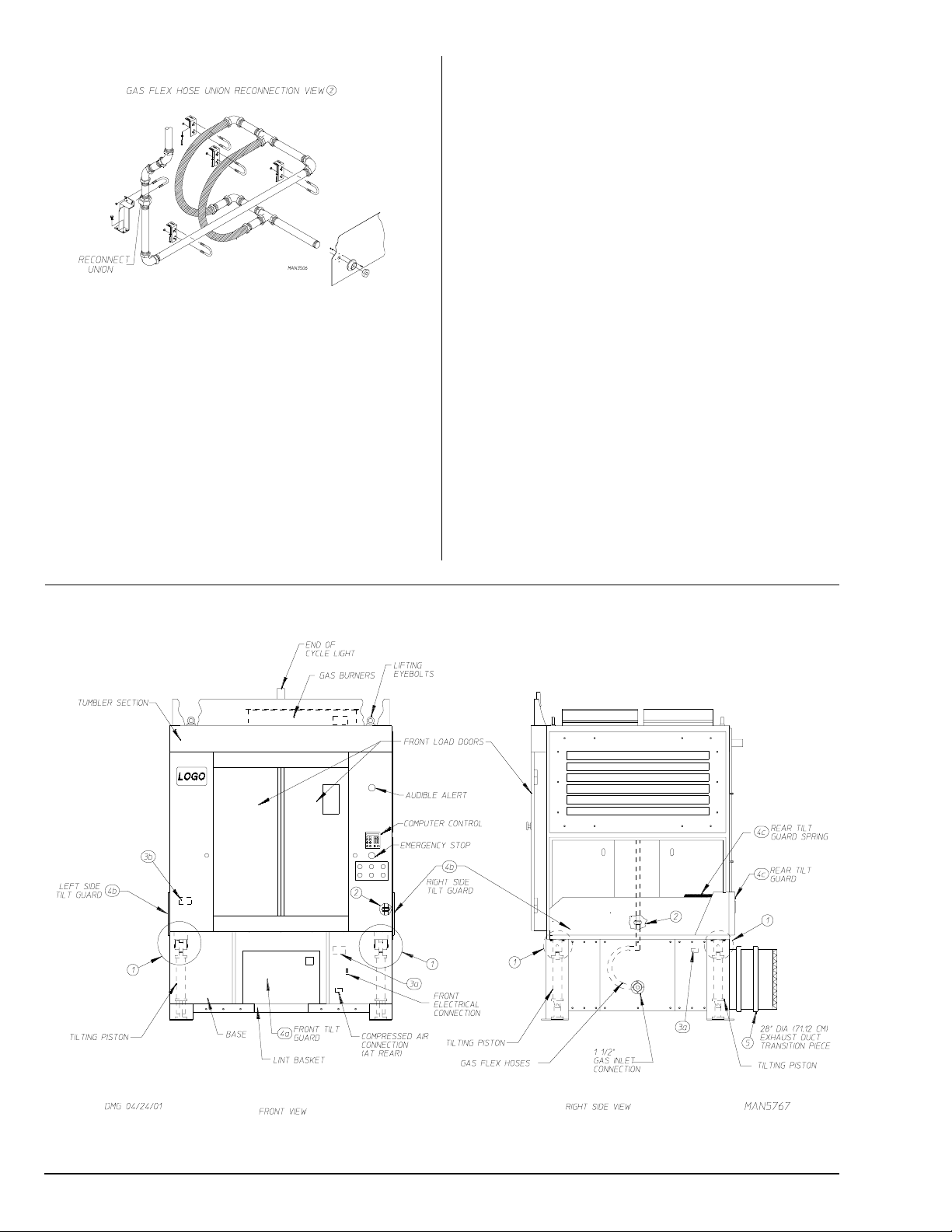

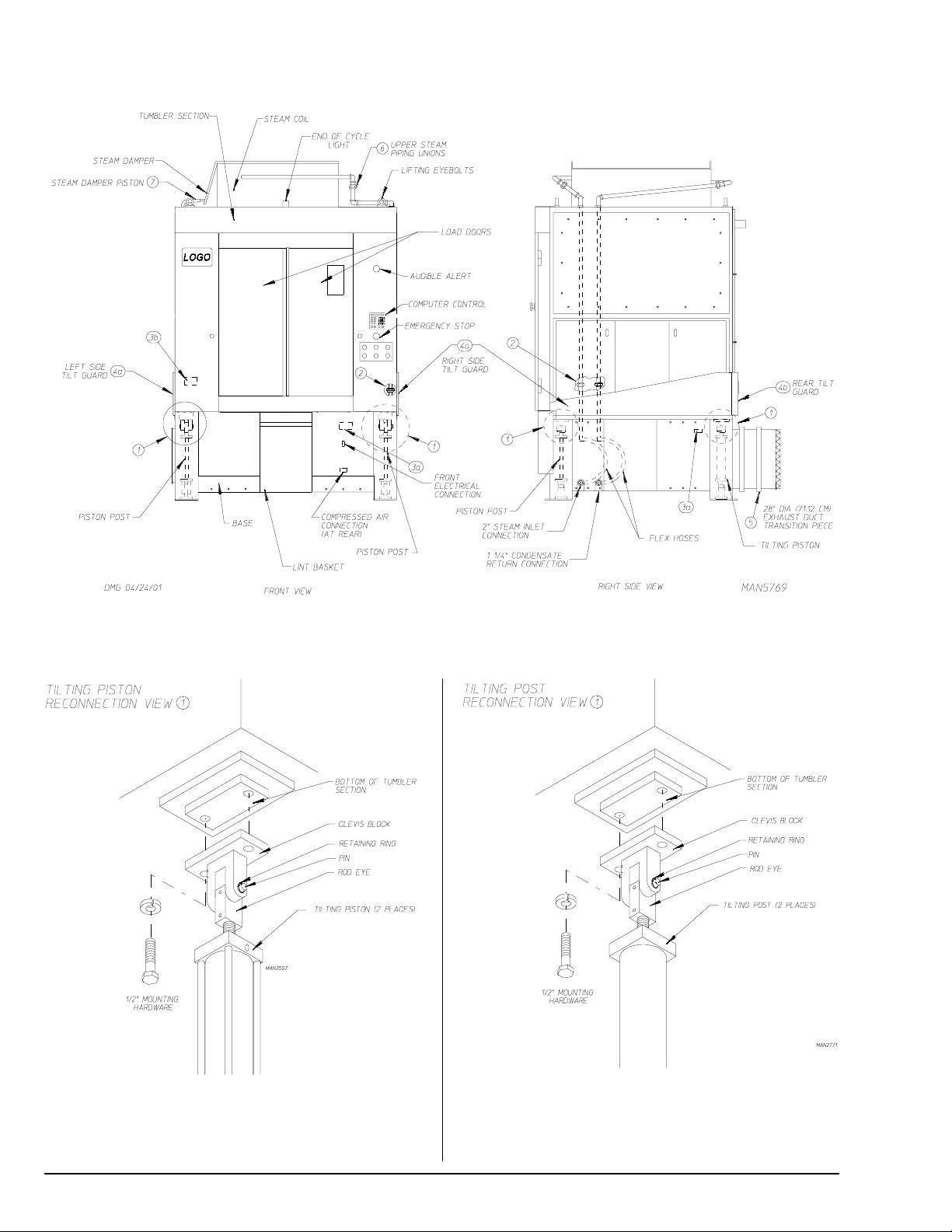

Dimensions and Component Identification / Location ____________________________

NOTE: ADC reserves the right to make changes in specifications at any time without notice or obligation.

6 American Dryer Corp. 113112-10

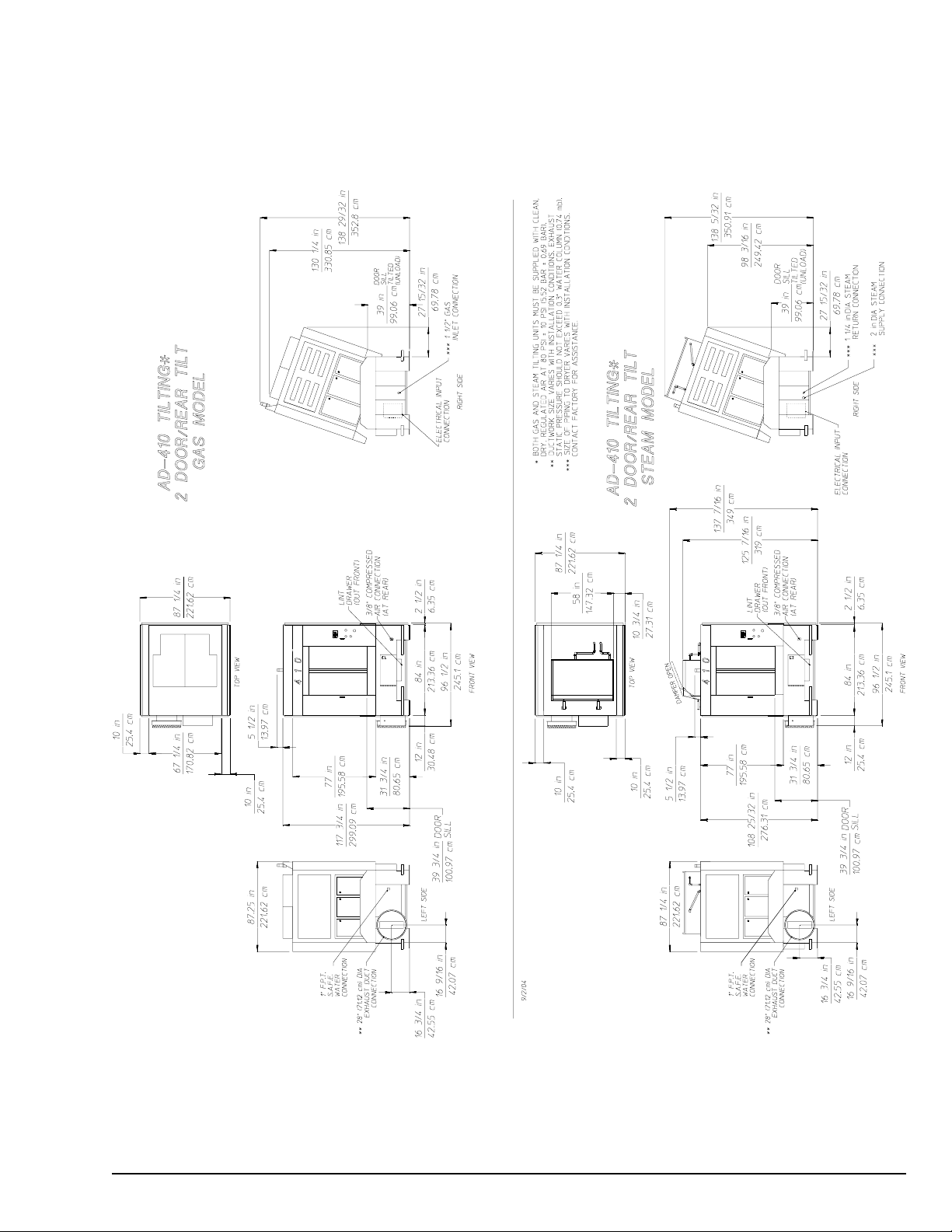

Dimensions and Component Identification / Location ____________________________

NOTE: ADC reserves the right to make changes in specifications at any time without notice or obligation.

113112-10 www.adclaundry.com 7

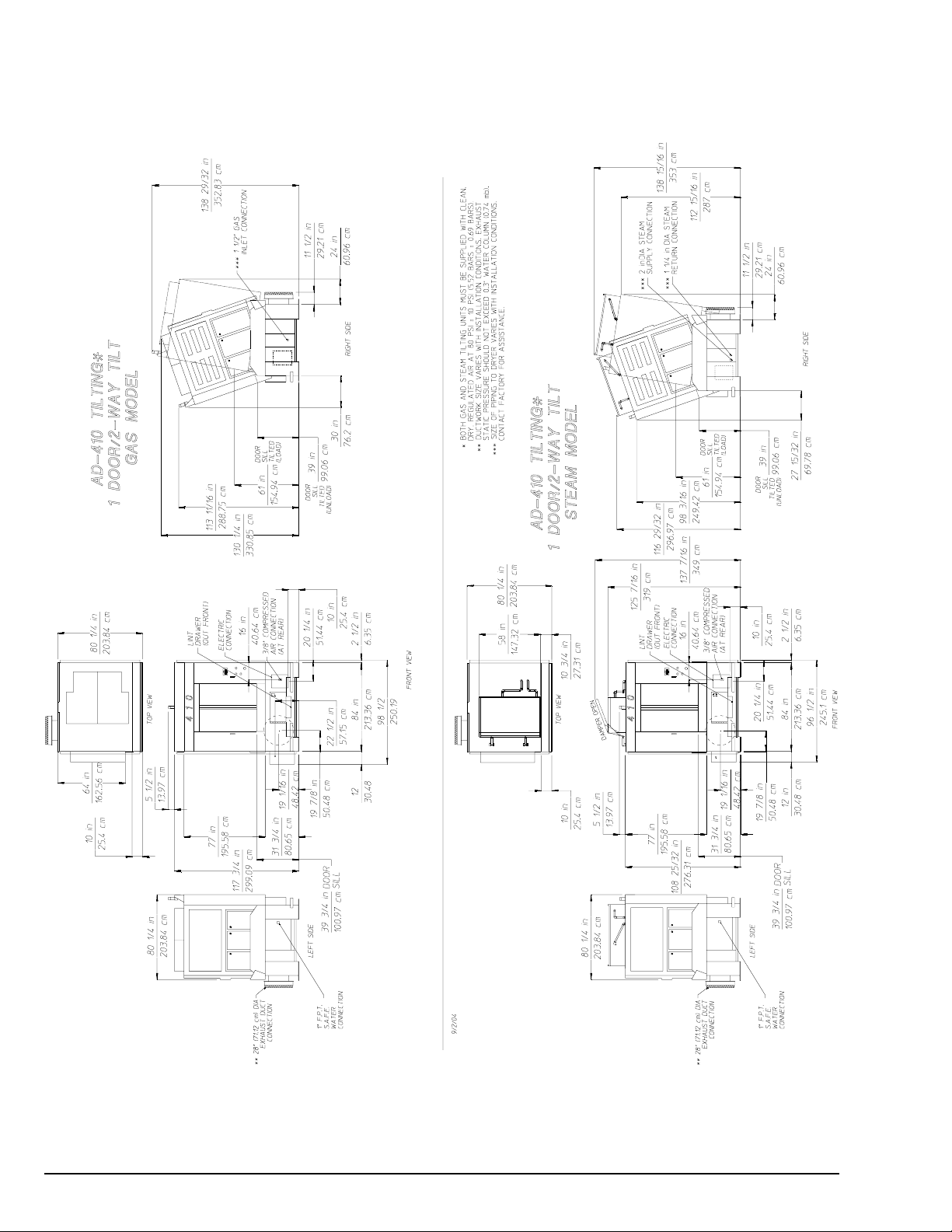

Dimensions and Component Identification / Location ____________________________

NOTE: ADC reserves the right to make changes in specifications at any time without notice or obligation.

8 American Dryer Corp. 113112-10

Installation Procedures ______________

Installation should be performed by competent technicians

in accordance with local and state codes. In the absence of

these codes, the installation must conform to applicable

American National Standards: ANSI Z223.1-LATEST

EDITION (National Fuel Gas Code) or ANSI/NFPA NO. 70LATEST EDITION (National Electrical Code) or in Canada,

the installation must conform to applicable Canadian

Standards: CAN/CGA-B149.1-M91 (Natural Gas) or CAN/

CGA-B149.2-M91 (L.P. Gas) or LATEST EDITION (for General

Installation and Gas Plumbing) or Canadian Electrical

Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION (for

Electrical Connections).

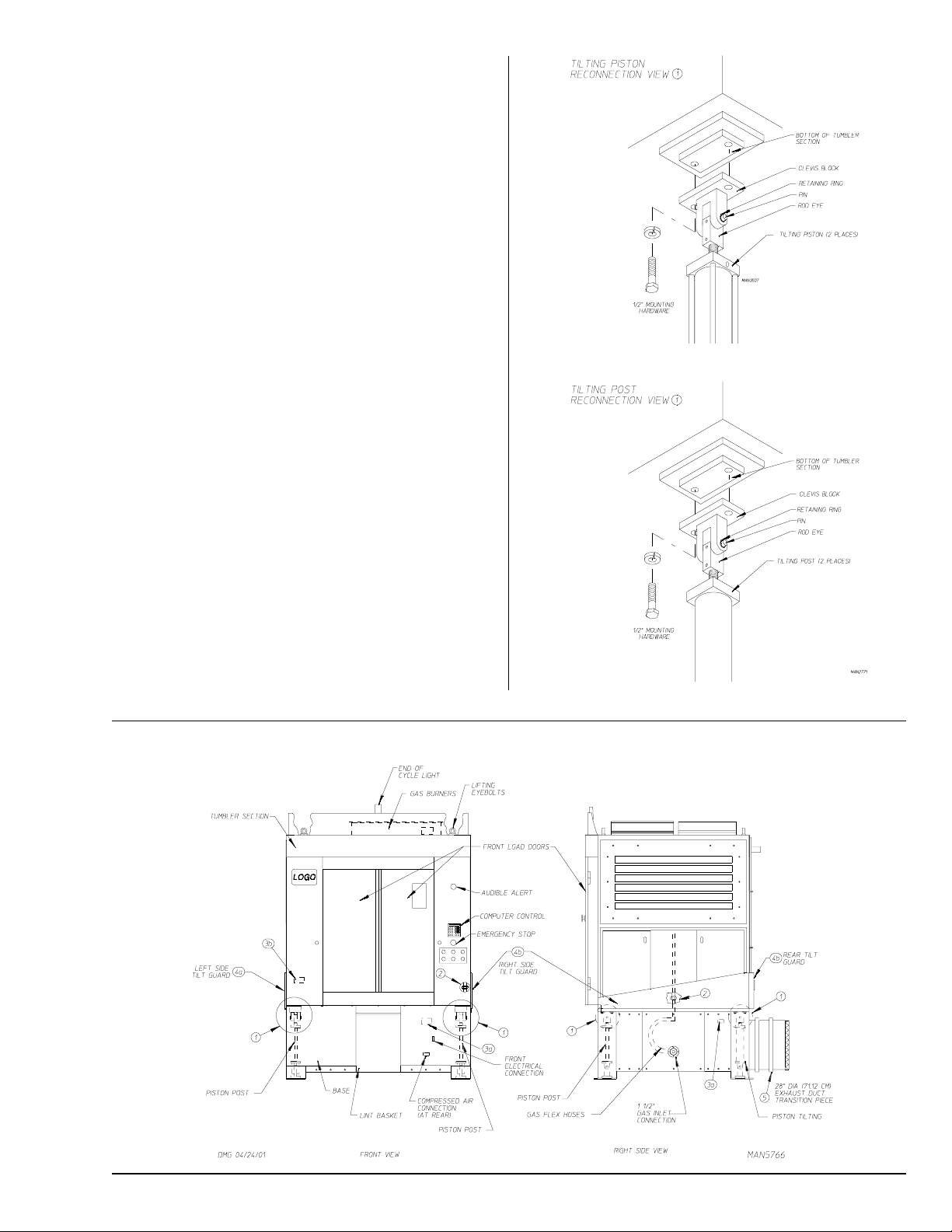

Reassembly of Dryer _________________

IMPORTANT: Always keep the tumbler section of the

dryer in an upright position when moving it.

The dryer may be shipped 1 of 2 ways: as a complete unit

fully assembled and ready for hookup or with the tumbler

section separated from the base. If the dryer is shipped in

2 pieces, the tumbler section will have to be lifted onto the

base. Use cables through the eyebolts on top of the tumbler

section, or use a forklift for the lifting process.

The tilting dryer is made in many loading and unloading

options. Please refer to the reassembly instructions on the

following pages for your particular style of dryer.

If a steam dryer is shipped in 2 pieces, the steam coil may

have been removed from the top of the tumbler section and

shipped with the base. If this is the case, lift the steam coil

onto the top of the tumbler section with the steam pipe

connections facing towards the right side of the dryer and

bolt the coil to the top of the dryer with the 1/4” hardware

supplied. There are 3 panels that cover the front, right side,

and rear of the steam coil. Fasten these in proportion also.

Reconnect the steam and condensate pipe unions to the

coil. These pipes run down to the flex hoses in the base.

Reassembly Instructions for Gas Dryer Shipped in 2 Pieces

1 Door / Forward Tilt – Gas Model

113112-10 www.adclaundry.com 9

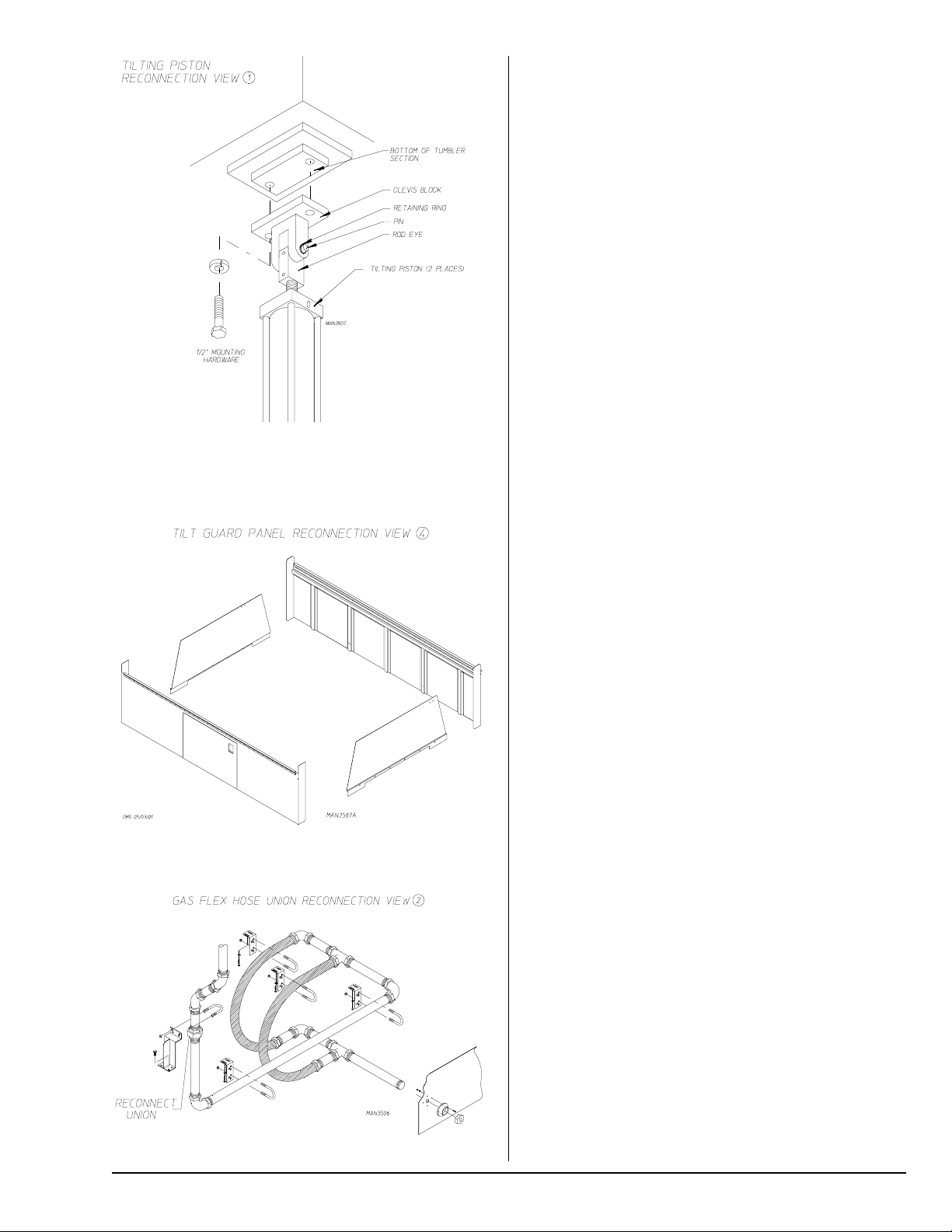

1 Door / Forward Tilt – Gas Model

Reassembly Instructions

for 1 Door / Forward Tilt Gas Dryers

Lift the tumbler section onto the base.

Forward tilt dryers have 2 tilting pistons in the rear of the

base. On the top of each piston is a clevis block. Use the

four 1/2” x 1-1/8” long hex head bolts with lock washers to

secure each piston clevis block to the bottom of the tumbler

section. (Refer to [top] View 1 on the previous page.)

The flexible gas hose union is disconnected when the dryer

is shipped in 2 pieces. The flexible gas hoses are located

in the right side of the base. Insert the flexible hoses with

the union half up through the hole on the bottom of the

tumbler section and retighten the union. The flex hoses

must not be kinked. (Refer to View 2 above.)

There are 2 electrical reconnections:

A plug and cable is located in the right side of the base.

This must be lifted up and reconnected into the mating

socket located at the bottom of the right tumbler section.

The tumbler section power cable must be lifted up from the

base and reconnected into the junction box next to the

tumbler drive motor in the left side of the tumbler section.

Make sure both reconnected cables have enough slack in

them to allow the dryer to tilt freely in both directions.

Reattach the tilt guard panels:

Use 1/4” self-tapping screws to secure the right side and

left side tilt guards.

Use 1/4” self-tapping screws to secure the rear tilt guards

on the rear of the base. Also, secure both outside edges of

the rear tilt guard to each side guard using sheet metal

screws.

Secure the 28-inch (71.12 cm) diameter exhaust duct

transition piece to the dryer’s rectangular exhaust duct with

the 1/4-20 self-tapping screws supplied with the dryer. The

exhaust duct exits from the rear of the base.

On dryers equipped with an automatic (piston operated)

load door, reconnect the 2 poly-flo air lines that run from the

base up to the door pistons.

Reassembly Instructions for Gas Dryer Shipped in 2 Pieces

1 Door / 2-Way Tilt – Gas Model

NOTE: ADC reserves the right to make changes in specifications at any time without notice or obligation.

10 American Dryer Corp. 113112-10

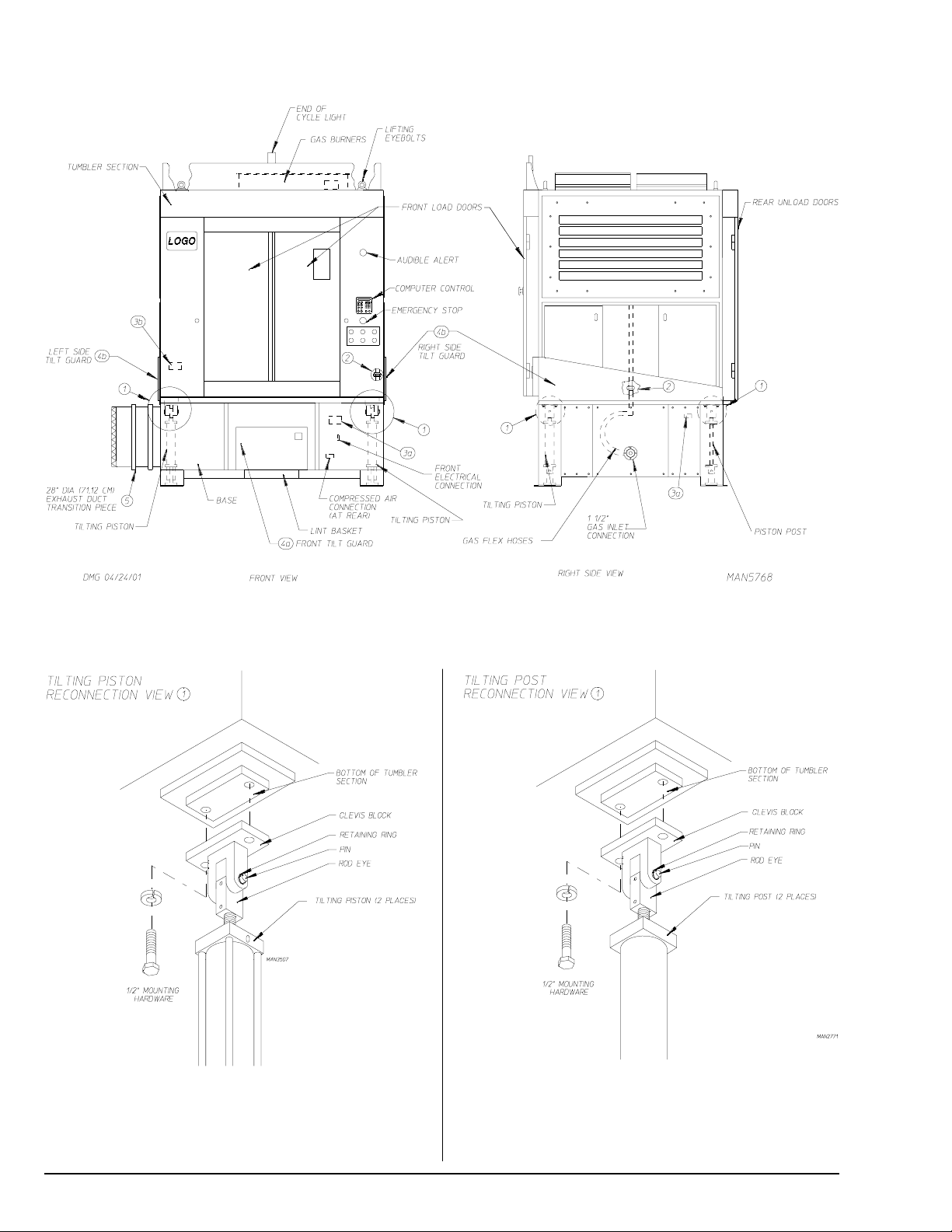

Reassembly Instructions

for 1 Door / 2-Way Tilt Gas Dryers

Lift the tumbler section onto the base.

2-Way tilt dryers have 4 tilting pistons in the base, 1 on each

corner. On the top of each piston is a clevis block to the

bottom of the tumbler section. (Refer to [top] View 1 on the

left.)

The flexible gas hose union is disconnected when the dryer

is shipped in 2 pieces. The flexible gas hoses are located

in the right side of the base. Insert the flexible hoses with

the union half up through the hole on the bottom of the

tumbler section and retighten the union. The flex hoses

must not be kinked. (Refer to [bottom] View 2 on the left.)

There are 2 electrical connections:

A plug and cable is located in the right side of the base.

This must be lifted up and reconnected into the mating

socket located at the bottom of the right tumbler section.

The drive motor wires must be lifted up from the base and

reconnected into the junction box next to the tumbler drive

motor in the left side of the tumbler section.

Make sure both reconnected cables have enough slack in

them to allow the dryer to tilt freely in both directions.

1 Door / 2-Way Tilt – Gas Model

Reattach the tilt guard panels:

Use 1/4-20 x 3/8” hex head bolts with lock washers to bolt

the top of the front and rear tilt guard up into the bottom of

the tumbler section.

Use 1/4” self-tapping screws to secure the right side and

left side tilt guards.

Secure the 28-inch (71.12 cm) diameter exhaust duct

transition piece to the dryer’s rectangular exhaust duct with

the 1/4-20 self-tapping screws supplied with the dryer. The

exhaust duct exits from the rear of the base.

On dryers equipped with an automatic (piston operated)

load door, reconnect the 2 poly-flo air lines that run from the

base up to the door pistons.

113112-10 www.adclaundry.com 11

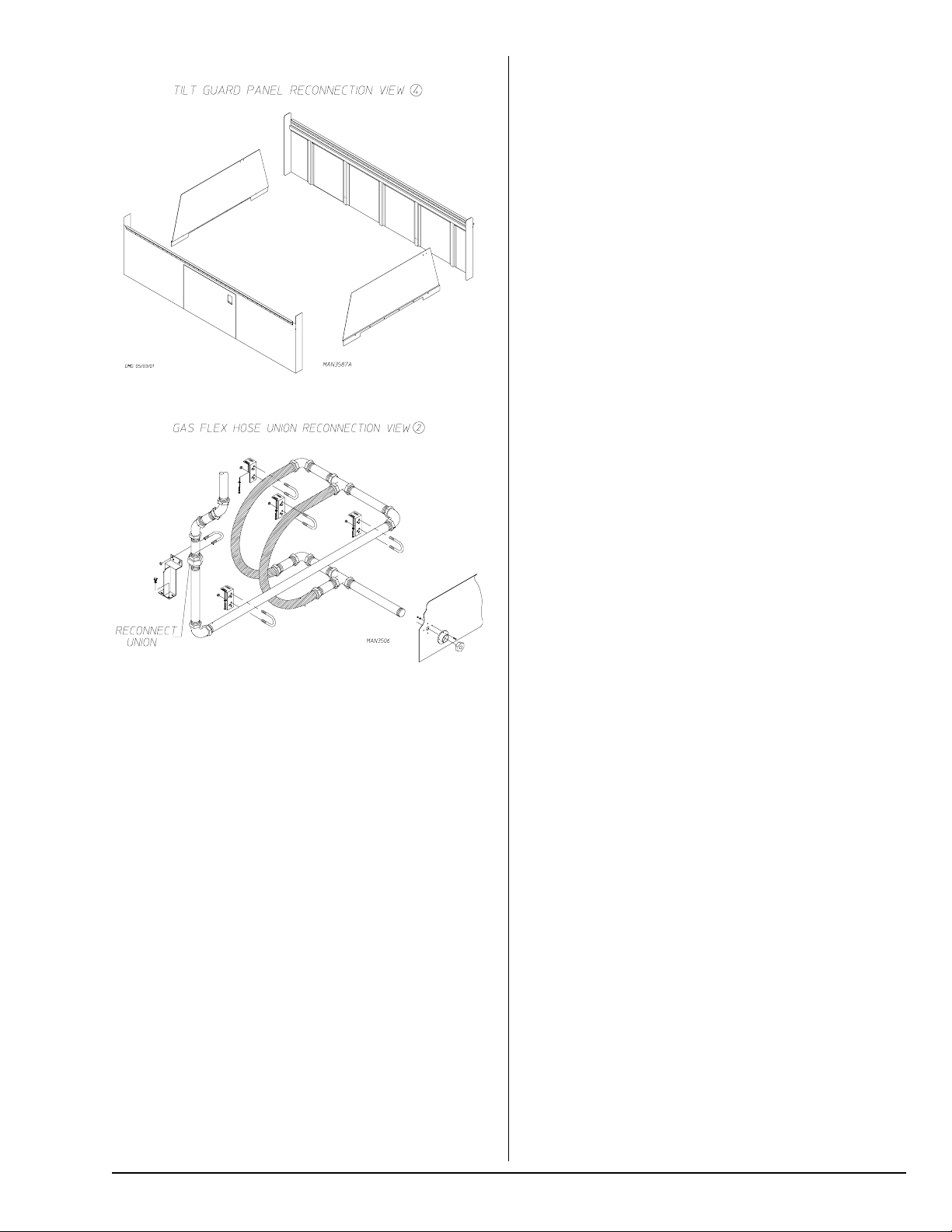

Reassembly Instructions for Gas Dryer Shipped in 2 Pieces

2 Door / Rear Tilt (Pass Thru) – Gas Model

NOTE: ADC reserves the right to make changes in specifications at any time without notice or obligation.

12 American Dryer Corp. 113112-10

2 Door / Rear Tilt (Pass Thru) – Gas Model

Reattach the tilt guard panels:

Use 1/4-20 x 3/8” hex head bolts with lock washers to bolt

the top of the front and rear tilt guard up into the bottom of

the tumbler section.

Use 1/4” self-tapping screws to secure the right side and

left side tilt guards.

Secure the 28-inch (71.12 cm) diameter exhaust duct

transition piece to the dryer’s rectangular exhaust duct with

the 1/4-20 self-tapping screws supplied with the dryer. The

exhaust duct exits from the left side of the base.

On dryers equipped with 2 automatic (piston operated) load

and unload doors, reconnect the poly-flo air lines that run

from the base up to each set of door pistons.

NOTES _____________________________________________________

____________________________________________________________

____________________________________________________________

Reassembly Instructions for 2 Door /

Rear Tilt (Pass Thru) Gas Dryers

Lift the tumbler section onto the base.

Rear tilt dryers have 2 tilting pistons. The 2 pistons are in

the front corners of the base and there are 2 piston posts in

the rear corners of the base. On the top of both tilting pistons

and both piston posts are clevis blocks. Use the four 1/2” x

1-1/8” long hex head bolts with lock washers to secure each

clevis block to the bottom of the tumbler section. (Refer to

[bottom] View 1 on the previous page.)

The flexible gas hoses are located in the right side of the

base. Insert the flexible hoses with the union half up through

the hole on the bottom of the tumbler section and retighten

the union. The flex hoses must not be kinked. (Refer to

View 2 above.)

There are 2 electrical reconnections:

A plug and cable is located in the right side of the base.

This must be lifted up and reconnected into the mating

socket located at the bottom of the right tumbler section.

The tumbler section power cable must be lifted up from the

base and reconnected into the junction box next to the

tumbler drive motor in the left side of the tumbler drive

section.

Make sure both reconnected cables have enough slack in

them to allow the dryer to tilt freely in both directions.

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

113112-10 www.adclaundry.com 13

Reassembly Instructions for Steam Dryer Shipped in 2 Pieces

1 Door / Forward Tilt – Steam Model

NOTE: ADC reserves the right to make changes in specifications at any time without notice or obligation.

14 American Dryer Corp. 113112-10

Loading...

Loading...