Tumble Dryer

AD-25V / AD-30V / AD-50V / AD-758V

EN – Installation/Operator Manual

GB, IE

To avoid errors and damage to the dryer,

please read these instructions carefully

before attempting to install or operate

American Dryer Corporation

88 Currant Road

Fall River MA 02720-4781 USA

Telephone: +1 (508) 678-9000 / Fax: +1 (508) 678-9447

e-mail: techsupport@amdry.com

www.adclaundry.com

ADC Part No. 113686-1

Safety Precautions ______________

Only qualified personnel should install, service,

or adjust this equipment.

The information in this manual must be followed to minimize

the risk of fire or explosion and to prevent property damage,

personal injury, or loss of life.

Do not allow children to play on or in the dryer.

Children must be supervised when near an operating dryer.

The appliance can be used by children aged

from 8 years and above and persons with

reduced physical, sensory and mental

capabilities or lack of experience and

knowledge if they have been given supervision

or instruction concerning use of appliance in a

safe way and understand the hazards involved.

Do not modify this appliance.

Do not bypass or disable any door or drawer switch.

Do not bypass or disable any heat safety circuit.

Do not operate with any guards or service panels removed.

Do not operate if the lint filter is not in place.

Do not use dryer in the presence of dry cleaning fumes.

Do not spray aerosols near the dryer while it is operating.

Dry only water washed fabrics. Do not dry articles spotted or

washed in dry cleaning solvents, combustible detergents,

industrial chemicals, or “all-purpose” cleaner.

Do not dry rags or articles coated or contaminated with gasoline,

kerosene, oil, paint, or wax.

Items that have been spotted or soaked with vegetable or

cooking oil constitute a fire hazard and should not be dried.

Do not dry mop heads. Contaminations from wax or flammable

solvents are a fire hazard.

Do not store or use gasoline or other flammable liquids or vapors

in the vicinity of this appliance.

A qualified technician must be called if any high-limit thermostat

trips to investigate, and resolve, the issue.

Disconnect power before resetting any safety device.

Do not use heat for drying articles that contain plastic, foam,

sponge rubber, or similarly textured rubber materials.

Lint buildup in the burner area, exhaust duct, and around the

machine is a fire hazard and must be cleaned frequently.

You must disconnect and lockout the electric supply and the

gas supply, before removing any guards.

Label all wires prior to disconnection when servicing the dryer.

Every drying cycle finishes with a cool-down period to remove

heat from the dry load. Never stop the dryer before the end of

the drying cycle unless the load is quickly removed and spread

out to allow the heat to dissipate quickly.

Fabric softeners or similar products should only be used as

recommended by the fabric softener manufacturer.

Exhaust duct outlet should be checked periodically for

blockages, and if any found, removed.

Use this dryer only for its intended purpose, drying fabrics.

Purchaser and user should consult the local gas supplier for

proper instructions to be followed in the event the user smells

gas. The instructions should be posted in a prominent location.

What To Do If You Smell Gas:

• Do not try to operate any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Clear the room, building, and area of all occupants.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the fire

department.

Table of Contents ________________________________________________________________________

SAFETY PRECAUTIONS ........................................................................................................................ 2

TECHNICAL SPECIFICATIONS .............................................................................................................. 4

INSTALLATION PROCEDURES ............................................................................................................. 6

LOCATION REQUIREMENTS ................................................................................................................. 6

UNPACKING / SETTING UP ................................................................................................................... 6

DRYER ENCLOSURE REQUIREMENTS .............................................................................................. 6

FRESH (MAKE-UP) AIR SUPPLY REQUIREMENTS ............................................................................ 6

EXHAUST REQUIREMENTS .................................................................................................................. 6

ELECTRICAL INFORMATION (50HZ) .................................................................................................... 8

GAS INFORMATION.............................................................................................................................. 10

GAS TYPE CONVERSION .....................................................................................................................11

BURNER PRESSURE MEASURE AND ADJUST ................................................................................ 12

STEAM INFORMATION......................................................................................................................... 12

WATER INFORMATION ........................................................................................................................ 14

START-UP .............................................................................................................................................. 14

PREOPERATIONAL TEST .................................................................................................................... 14

OPERATING INSTRUCTIONS.............................................................................................................. 14

ROUTINE MAINTENANCE.................................................................................................................... 15

SERVICE / PARTS INFORMATION ...................................................................................................... 15

DATA LABEL INFORMATION ................................................................................................................ 15

WARRANTY INFORMATION ................................................................................................................ 16

2 American Dryer Corp. 113686-1

This Page Is

Intentionally Left Blank

113686-1 www.adclaundry.com 3

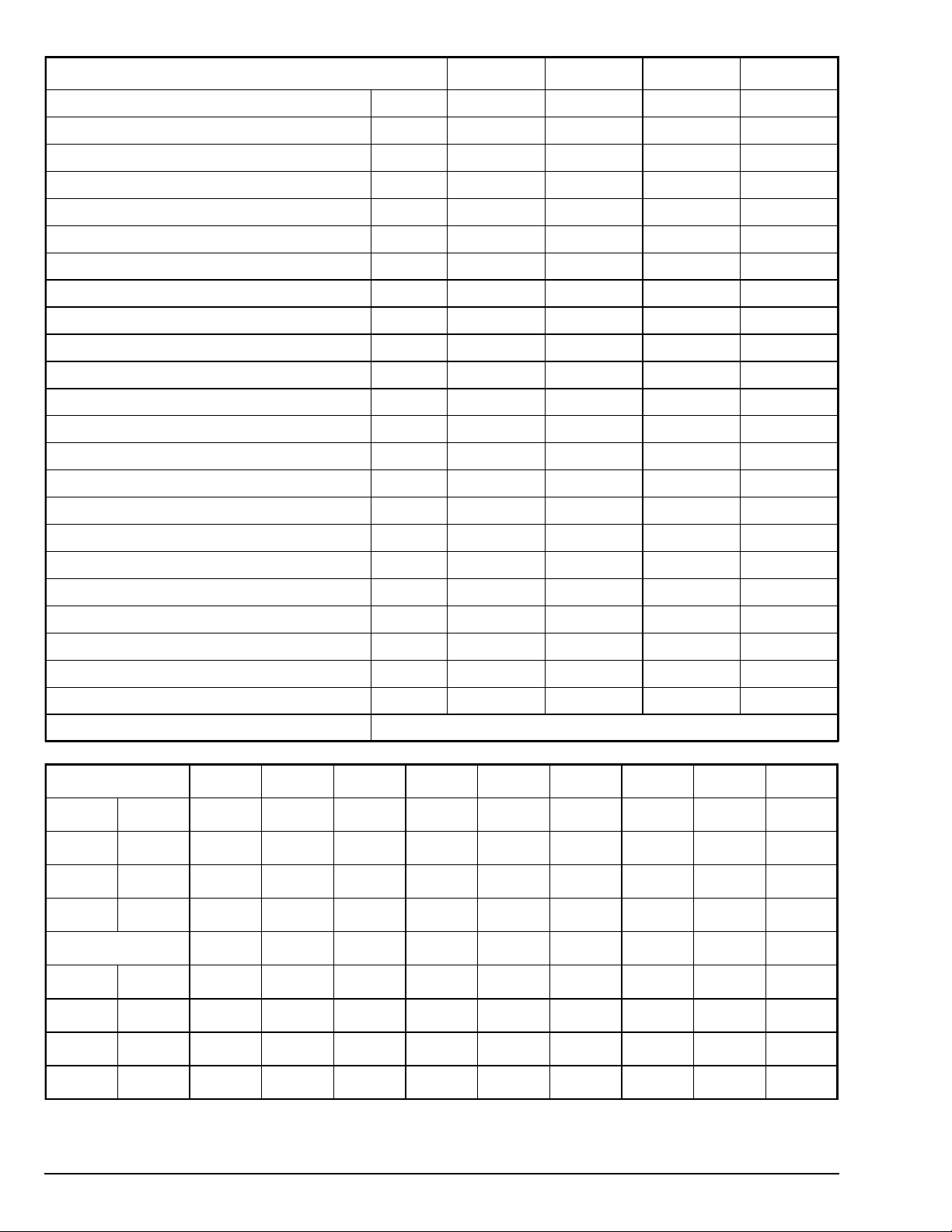

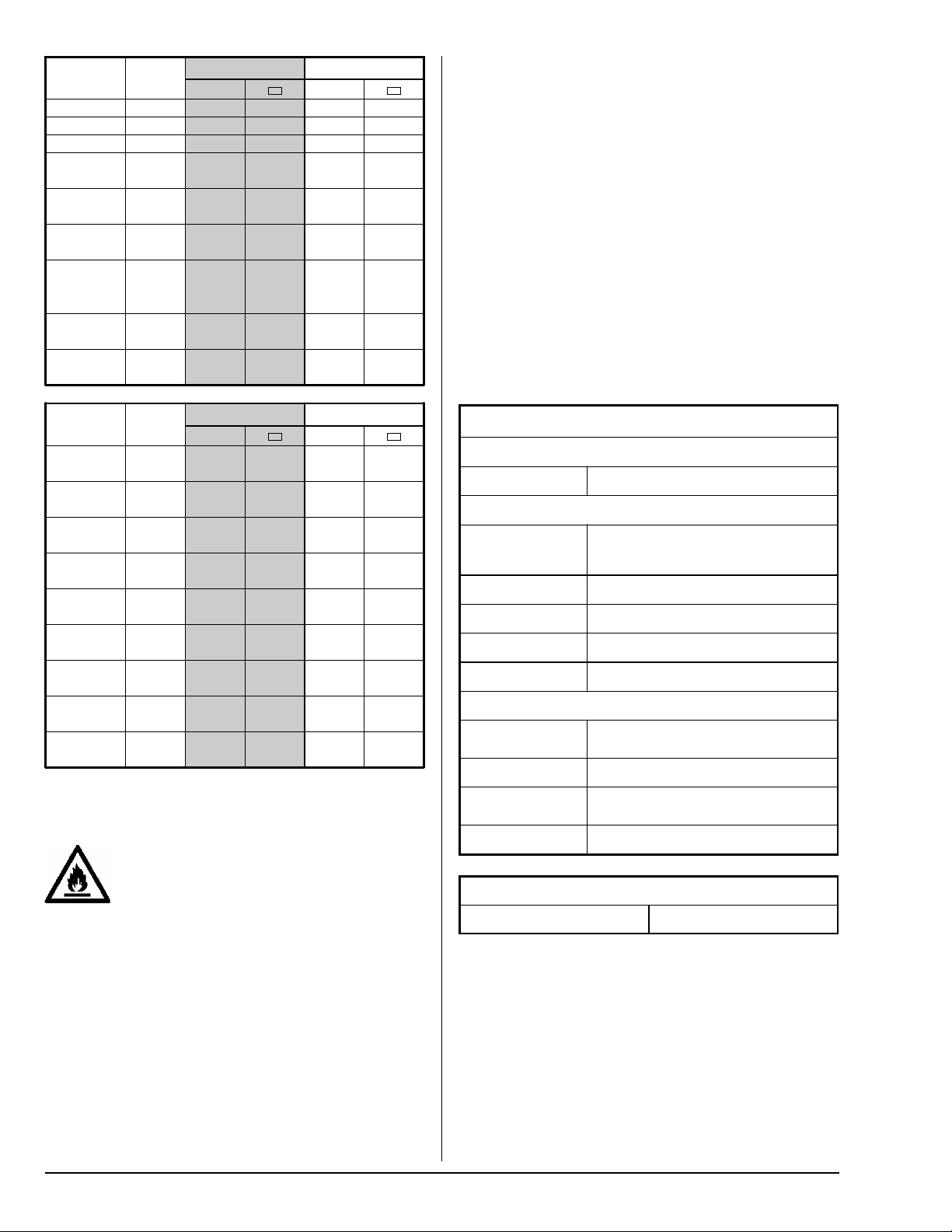

Technical Specifications AD-25V AD-30V AD-50V AD-758V

Maximum Capacity (Dry Weight) kg

Tumbler Volume liters

Tumbler (Diameter x Depth) cm

Door Opening (Diameter) cm

Airflow (50Hz) (Gas-Electric / Steam) cmm

Heat Rate (Gas) kW

Heat Rate (Steam) – Normal Load Bhp

Steam Consumption kg/hr

Airborne Sound Level dB(A)

Tumbler (Drive) Motor (Non Reversing / Reversing) kW

Blower (Fan) Motor (Non Reversing / Reversing) kW

Net Weight (Approximate) (Gas-Electric / Steam) kg

Shipping Weight (Approximate) (Gas-Electric / Steam) kg

Cabinet Width (A) cm

Cabinet Depth (B) cm

Cabinet Height (C) (+8 cm for Electric) cm

Door Sill Height (D) cm

11.3 13.6 22.7 34.0

262 354 518 609

83.2 x 48.3 83.2 x 65.1 83.2 x 95.3 92.1 x 91.4

54.6 54.6 54.6 79.7

10.9 / 10.9 10.9 / 10.9 17.7 / 17.7 23.6 / 28.3

22.9 27.8 44.0 51.3

2.9 3.0 4.1 7.2

44.8 47.2 64.4 124.7

<70 <70 <70 <70

0.37 / 0.37 0.37 / 0.37 0.56 / 0.37 0.75 / 0.37

— / 0.37 — / 0.37 — / 0.37 — / 0.75

185 / 197 235 / 262 295 / 310 327 / 370

202 / 215 250 / 278 318 / 332 351 / 394

87.0 87.0 87.0 97.2

72.7 93.7 123.2 119.4

182.9 182.9 182.9 190.8

84.2 84.2 84.2 71.1

Exhaust Connection (Diameter) (E) cm

Gas Connection (F) ISO 7/1

Water Connection (G) ISO 7/1

Steam Supply Connection (H) FNPT

Steam Return Connection (I) FNPT

Air Connection – Pneumatic Damper - Steam (J) FNPT

Electric Connection (Gas / Steam Heat) (K)

E1 E2 F1 F2 G1 G2 G3 G4 H1

25V cm

30V cm

50V cm

758V cm

25V cm

30V cm

15.9 26.7 35.6 160.0 29.5 157.5 10.2 157.5 19.4

15.9 26.7 32.7 159.7 26.0 157.5 10.2 157.5 36.0

15.9 26.7 30.5 160.7 23.5 157.5 10.2 157.5 32.5

20.3 47.6 36.2 164.5 30.5 162.6 10.8 162.6 37.6

H2 I1 I2 J1 J2 K1 K2 K3 L

175.6 27.9 163.0 17.8 13.3 19.1 158.8 7.0 142.2

177.2 48.6 164.5 17.8 13.3 19.1 158.8 7.0 163.2

20.3 20.3 20.3 20.3

Rc 1/2Rc 1/2Rc 1/2Rc 3/4

R 3/4 R 3/4 R 3/4 R 3/4

1111

1111

1/8 1/8 1/8 1/8

50V cm

758V cm

177.2 44.8 164.5 17.8 13.3 19.1 158.8 7.0 192.4

180.5 51.8 171.5 17.8 13.3 19.1 163.8 7.0 215.9

NOTE: The manufacturer reserves the right to make changes in specifications at any time, without notice or obligation.

4 American Dryer Corp. 113686-1

113686-1 www.adclaundry.com 5

Installation Procedures __________________

Location Requirements

The temperature of the installation location must remain

between 4° C and 55° C.

The dryer must not be installed or stored in an area where it

will be exposed to water and/or weather.

The dryer should be located where a minimum amount of

exhaust ducting will be necessary.

The dryer must be installed on a sound level floor capable of

supporting its weight. Any carpeting must be removed.

Install a lockable door to prevent the public from accessing the

rear of the dryer.

The appliance must not be installed behind a lockable door, a

sliding door or a door with a hinge on the opposite side to that

of the tumble dryer, in such a way that a full opening of the

tumble dryer door is restricted.

Unpacking / Setting Up

Dryer must be handled in an upright position at all times.

Remove protective shipping material (i.e. plastic wrap and

optional shipping box) from the dryer.

Remove the pallet. Remove the 4 bolts securing the base of

the dryer to the pallet (one in each corner of the cabinet base).

Remove the back guard for access to the 2 rear bolts. Remove

the lint door or drawer to reach the 2 front bolts.

If the dryer is to be slid into its final position, ensure that all four

leveling legs (one in each corner) are extended slightly so the

dryer will slide on these legs (not the cabinet frame).

Once the dryer is in position, adjust the leveling legs so it is

level side-to-side. To increase bearing life and improve

efficiency, the dryer should be tilted slightly to the rear.

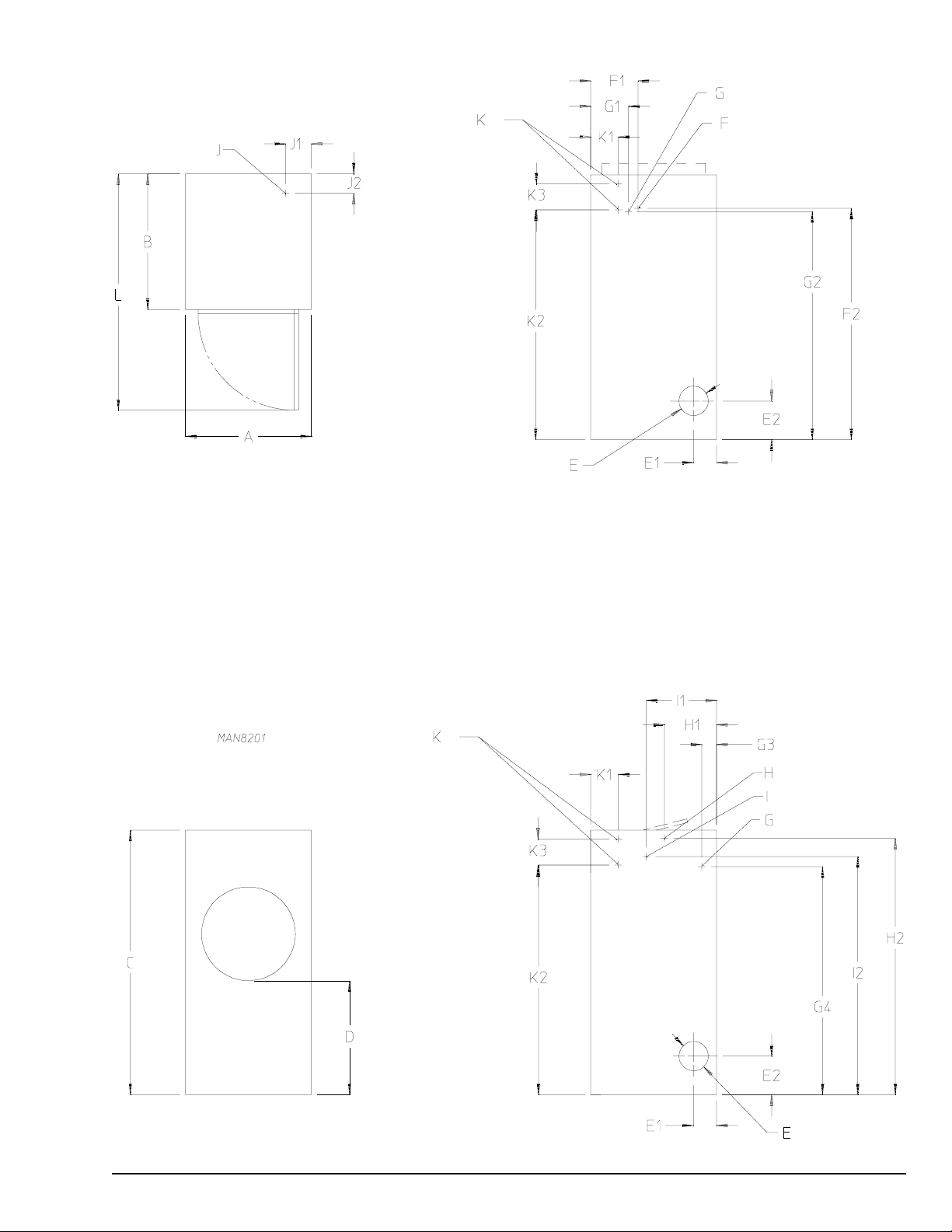

Dryer Enclosure Requirements

Clearance to combustible material

A Minimum 30 cm (46 cm recommended)

B Minimum 30 cm (61 cm recommended)

C Minimum 5 cm

D Minimum 10 cm

E Maximum 10 cm

Clearance to nearest obstacle

F Open Door:

AD-25V, AD-30V, AD-50V: 76 cm, AD-758V: 102 cm

G 2.5 cm (To allow control door to open)

H 2.5 cm

I 1.5 mm

J 1.5 mm

Fresh (Make-Up) Air Supply

Requirements

The dryer draws in air, heats it, passes it through

the tumbler, and exhausts it outside.

Adequate ventilation has to be provided to avoid the back flow

of gases into the room from appliances burning fuels, including

open fires.

Insufficient fresh air supply could diminish dryer performance.

Make-up air must be free of dry cleaning solvent fumes.

Locate fresh air openings away from exhaust vent discharge.

Locate the openings behind the dryer to avoid room drafts.

2

An unrestricted opening to the outdoors of 500 cm

AD-25V, 610 cm2 for each AD-30V, 970 cm2 for each AD-50V

and 1,130 cm2 for each AD-758V is required (Based on 22 cm

per kW).

Separate make-up air openings are not required. Common

openings, located evenly between the dryers, are acceptable.

The size of the make-up air opening must be increased by

33% to compensate for the use of registers or louvers.

for each

Exhaust Requirements

Single (independent) dryer venting is recommended.

Dryers must be exhausted to the outdoors.

The dryer shall not be exhausted into any gas vent, chimney,

wall, ceiling, or concealed space of a building.

Exhaust ductwork should be designed and installed by a

qualified professional. Improperly sized ducting will result in

slow drying and possible dryer malfunction.

Exhaust back pressure should be a minimum of 0 mb and a

maximum of 0.75 mb (1.75 mb for 758V).

The design of the flue system shall be such that any condensate

formed when operating the appliance from cold shall either be

retained and subsequently re-evaporated or discharged.

Use metal ducting or other noncombustible material.

Avoid 90° turns; use gentle (30° or 45°) bends instead.

Elbow radius should be at least 1.5 times the duct diameter.

Avoid using screws or other fasteners that project into the

exhaust airflow and collect lint.

There must be 5 cm of clearance if the duct passes through

any wall, ceiling, or roof made of combustible materials.

Protect the end of the exhaust duct from the weather outside.

2

6 American Dryer Corp. 113686-1

Single Dryer Venting (50Hz)

Multiple Dryer Venting

25V, 30V 50V 758V

A (mm) 203 203 203

B (mm) 870 870 972

Multiple Dryer Venting - Through an End Wall

C (mm) 203 254 254

D (mm) 254 356 305

E (mm) 305 406 356

F (mm) 356 457 406

L1+L2 (m) 12.2 19.7 6.0

Multiple Dryer Venting - Through Roof or Rear Wall

AD-25V AD-30V AD-50V AD-758V

A (m) 30 30 9.5 12

B (mm) 203 203 203 203

Multiple Dryer (Common) Venting (50Hz)

If separate exhaust ducts are not possible then ducts from

multiple dryers may be channeled into a "common main duct."

No more than four dryers should be commonly vented.

The individual ducts should enter the bottom or side of the main duct at an angle of not more than 45° in the direction of airflow. The

main duct diameter should increase before each individual duct is added.

G (mm) 203 305 254

H (mm) 305 406 356

I (mm) 356 457 406

J (mm) 406 508 457

L1+L2+L3 (m) 12.3 26.1 7.9

Multiple Dryer Venting – Through End Wall (3x 90° Turns)

113686-1 www.adclaundry.com 7

Multiple Dryer Venting – Through Roof or Rear Wall (5x 90° Turns)

Electrical Information (50Hz) ___

Electric installation must be performed by qualified

personnel in accordance with national and local

safety regulations.

The dryer must be electrically earthed (grounded) in accordance

with national and local codes.

Individual earth circuit must be provided to each dryer.

Failure to properly earth the dryer will void the warranty.

An external means of power removal (disconnect device) must

be provided.

Each dryer should be connected to a properly sized, and

independently protected, branch circuit.

The electric supply must match exactly what is specified on

the dryer's rating plate (data badge).

Electrical Connections

The electrical input connections are made into the rear of the

dryer (refer to the Technical Specifications page).

A strain relief must be used where wires enter the dryer.

Gas and Steam Heated Dryers

Single-Phase Connection

8 American Dryer Corp. 113686-1

Three-Phase Connection

Electric Heated Dryers

Single-Phase Connection

Electrical Specifications (50Hz) – Gas and Steam Models

Electric Service 25V 30V 50V 758V

Non-Reversing

220-240V 1 ~ 10 10 10 13

220-240V 3 ~ 6 6 6 10

380-416V 3 ~ 6666

Reversing

220-240V 3 ~ 10 10 10 13

380-416V 3 ~ 6666

Electrical Specifications (50Hz) – Electric Models

AD-25V

220V 1~ 15

220V 3~ 20

230V 3~ 22

240V 3~

380V 3~

380V 3N~

400V 3~

400V 3N~

416V 3~

416V 3N~

Oven

(kW)

Non-Reversing Reversing

Amps —— Amps ——

68 100 N/A N/A

56 80 59 80

59 80 62 80

24

27

13

15

17

20

23

22

25

20

24

27

61 80 64 80

69 100 – –

26 40 – –

29 40 – –

30 40 – –

37 50 – –

41 63 43 63

37 50 – –

41 63 43 63

32 50 – –

39 50 – –

43 63 44 63

Three-Phase Connection

AD-30V

220V 1~

230V 1~

240V 1~

220V 3~

230V 3~

240V 3~

380V 3~

380V 3N~

400V 3~

400V 3N~

416V 3~

416V 3N~

Oven

(kW)

17

20

18.5

22

20

24

17

20

26

18.5

22

28

20

24

30

17

20

26

18.5

22

28

20

24

30

Non-Reversing Reversing

Amps —— Amps ——

81 125

95 125

84 125

99 125

88 125

105 150

49 63 51 80

56 80 59 80

72 100 75 100

50 63 53 80

59 80 61 80

74 100 76 100

53 80 56 80

62 80 65 100

76 100 80 100

28 40 29 40

33 50 34 50

42 63 43 63

29 40 30 40

34 50 35 50

43 63 44 63

30 40 31 40

36 50 37 50

44 63 45 63

N/A N/A

N/A N/A

N/A N/A

113686-1 www.adclaundry.com 9

AD-758V

Oven

(kW)

Non-Reversing Reversing

Amps —— Amps ——

220V 1~

20

100 125

N/A N/A

26

127 160

230V 1~

22

104 160

N/A N/A

28 130 200

240V 1~

24

108 106

N/A N/A

30

133 200

220V 3~

20

61 80 60 80

26 77 100 76 100

230V 3~

22

63 80 63 80

28

78 100 78 100

240V 3~

24

66 100 66 100

30

80 100 80 100

380V 3~

380V 3N~

20

39 50 35 50

26 48 63 44 63

400V 3~

400V 3N~

22

40 50 36 50

28

48 63 45 63

416V 3~

416V 3N~

24 41 63 38 50

30

50 63 46 63

AD-50V

Oven

(kW)

Non-Reversing Reversing

Amps —— Amps ——

220V 1~ 17

83 125 N/A N/A

230V 1~ 18.5

85 125 N/A N/A

240V 1~ 20 88 125 N/A N/A

220V 3~

20

56 80 59 80

26

74 100 75 100

230V 3~

22

60 80 62 80

28

75 100 77 100

240V 3~

24

61 80 65 100

30

76 100 79 100

380V 3~

380V 3N~

20

36 50 34 50

26

45 63 43 63

30

48 63 49 63

400V 3~

400V 3N~

22

37 50 35 50

28 45 63 44 63

416V 3~

416V 3N~

24

38 50 37 50

30

46 63 45 63

AU / NZ Approved Gas Types

NG LPG

Approved Gas Types

1

st

Family

I

1ab

(8) DK, SE

2

nd

Family

I2H (20)

AT, BG, CH, CZ, DK, EE, ES, FI,

GB, GR, HR, IE, IT, LT, LV, NO, PT,

RO, SE, SI, SK, TR

I

2E

(20) DE, LU, PL

I

2E+

(20/25) BE

I

2Er

(20/25) FR

I2L (25) NL

3

rd

Family

I

3+

(28-30/37)

BE, CH, CY, CZ, EE, ES, FR, GB,

GR, IE, IT, LT, PT, LV, SK

I

3P

(37) CZ, PL, SI, SK, TR

I

3B/P

(30)

CZ, CY, DK, EE, FI, HU, IS, LT, LV,

MT, NL, NO, SE, SI, SK, TR

I

3B/P

(50) AT, DE, NL, HU

If the gas connection is made with a flexible hose, it must be

suitable for the appliance category in accordance with national

safety regulations of the country of destination.

Mount a shutoff valve upstream from the dryer.

Test all connections for leaks.

The burner will attempt to light for maximum of 8-seconds (2

retries).

The dryer must be restrained to prevent straining the gas supply

connection (fastening holes are provided in the top of the dryer

for this purpose). The length and design of the restraint should

be suitable to prevent strain on the gas line if the dryer is moved.

If the dryer is to be moved then the following steps must be

taken:

• Disconnect electrical power to the dryer.

• Close all external gas supply shutoff valves.

• Disconnect the gas supply line.

• Remove the restraint from the dryer.

Before installation, check that the local distribution conditions,

nature of gas and pressure, and the adjustment of the

appliances are compatible.

This appliance must only be installed in the country that is

indicated on the rating plate (data badge). If the appliance is to

be installed in a country other than the one indicated, a new

rating plate must be obtained from the manufacturer.

Refer to the Technical Specifications section for minimum gas

supply pipe size (do not reduce). Piping should conform to local

and national requirements. In AU/NZ, refer to AS/NZS 5601.1

for guidance on gas supply pipe size for this appliance

installation.

10 American Dryer Corp. 113686-1

Gas Information _________________

Gas installation should be performed by qualified

personnel in accordance with national and local

safety regulations.

Gas Specifications

Gas Characteristics

Gas Type

(Category)

Gas

Symbol

H

MJ/m

To w ns Ga s

)

(I

1ab

Natural

/ I2E)

(I

2H

Natural

)

(I

2L

** Natural

)

(I

2E+

** Butane or

** Propane (I

Mix Butane &

Propane (I

3B/P

Propane

)

(I

3P

* Consult factory for elevations over 610m for correct burner injector size(s).

** Gas valve's internal regulator is disabled.

G110

G120

G20 37.78 17-25 9.0

G25 32.49 20-30 12.0

G20 37.78 20 –

G25 32.49 25 –

G30 125.81 28-30 –

)

3+

G31 95.65 37 –

G30 125.81 30/50 20.0

)

G31 95.65 37 25.0

15.87

17.77

Supply

s

Pressure

3

(mbar) mbar m3/H mm m3/H mm m3/H mm m3/H mm

6-15 3.5

Burner

Pressure

* ADG-25V * ADG-30V * ADG-50V * ADG-758V

2 Injectors 2 Injectors 3 Injectors 4 Injectors

Gas

Rate

Size

5.20 5.410 6.31 5.791 – –––

2.21 3.048 2.69 3.264 4.13 3.264 4.96 3.264

2.66 3.048 3.24 3.264 4.98 3.264 5.97 3.264

2.21

2.438

2.66 3.24 4.98 5.97

0.70

1.702

0.88 1.08 1.65 1.98

0.70 1.778 0.85 1.994 1.30 1.994 1.56 1.930

0.88 1.778 1.08 1.994 1.65 1.994 1.98 1.930

Injecto r

Gas

Rate

2.69

0.85

Inje cto r

Size

2.705

1.930

Gas

Rate

4.13

1.30

Injecto r

Size

2.794

1.930

Gas

Rate

4.96

1.56

Inje cto r

Size

2.705

1.854

AU and NZ Gas Specifications

Gas Characteristics

Supply

Gas Type

Pressure

kPa kPa m

NG 1.7 - 3.2 0.87

LPG 2.75 2.50 0.70 1.702 0.85 2.057 1.30 2.057 1.56 1.854

* Consult factory for elevations over 610m for correct burner injector size(s).

Burner

Pressure

Gas Type Conversion

This appliance must only operate with

the gas type indicated on the dryer's

rating plate. If the appliance is

converted for use with a gas type other than the one indicated,

a new rating plate must be obtained from the manufacturer.

Burner conversion must be performed by qualified personnel

in accordance with national and local safety regulations.

The required conversion kit will depend on the gas type and

the country the dryer is installed in.

Parts Required for Conversion:

1. Rating Plate (Data Badge)

2. Injector (refer to Gas Specification Chart)

* ADG-25V * ADG-30V * ADG-50V * ADG-758V

2 Injectors 2 Injectors 3 Injectors 4 Injectors

Gas

Rate

3

/H mm m3/H mm m3/H mm m3/H mm

Inje cto r

Size

Gas

Rate

Inje cto r

Size

Gas

Rate

Inje cto r

Size

Gas

Rate

2.21 3.048 2.69 3.454 4.13 3.454 4.96 3.264

3. Gas valve conversion kit:

Gas Valve Conversion Kit

Converting To Gas Valve Kit

I

/ I

2E+

3+

I

/ I

3B/P

3P

NG (AU / NZ)

I

/ I2H / I

ab

2E(LL)

/ I

2L

NG (AU / NZ)

* Disables gas valve's regulator. Adjust the gas supply pressure to the value

shown in the Gas Specification Chart.

* 140411

140413

140418

Inje cto r

Size

113686-1 www.adclaundry.com 11

Conversion Instructions

(Refer to figure)

1. Discontinue electrical power to the dryer.

2. Close shutoff valve in the dryer’s gas supply line.

3. Disconnect gas valve wiring (label wires first).

4. Disconnect the union (A) between the external shutoff and

the gas valve (B).

5. Remove screws (C) and remove the gas valve (B) with

manifold (D) assembly from the dryer.

6. Replace the main burner injector (E) with the correct injector

(see Gas Specification Chart).

7. Instructions on how to convert the gas valve is included

with the gas valve conversion kit (see chart).

8. Reverse step 4 to install the gas valve (B) with manifold

(D) assembly.

9. Open shutoff valve in the dryer’s gas supply line.

10. Test all connections for leaks.

11. Connect gas valve wires.

12. Continue electric power.

13. Provide proper gas pressure to the injector (see chart):

Gas supply pressure for categories I

regulated in the dryer's gas supply line.

All other gas categories require adjustment of the gas

valve's internal regulator; instructions below.

14. Replace the original rating plate with the rating plate.

and I3+ must be

2E+

Burner Pressure Measure and Adjust

(Refer to figure)

1. Discontinue electrical power to the dryer.

2. Turn the gas valve's switch (H) to "OFF" position.

3. Back out the miniature screw inside the outlet pressure

tap ("out P") (G).

4. Attach a manometer to pressure tap (G).

5. Turn the gas valve's switch (H) to the "ON" position.

6. Continue electrical power to the dryer.

7. Run a "heat" cycle and wait for burner ignition.

8. Gas manifold pressure can now be measured.

9. If the gas pressure does not need adjustment then

disconnect electric power and go to step 10, otherwise:

9.1. Disconnect electrical power to the dryer.

9.2. Regulator screw is under the regulator cap (F).

9.3. Remove the regulator cap (F) and turn the plastic

adjustment screw to alter the pressure (clockwise to

increase, or counterclockwise to decrease).

9.4. Continue electrical power to the dryer.

9.5. Run a "heat" cycle and wait for burner ignition.

9.6. Gas manifold pressure can now be measured.

9.7. If the manifold pressure needs further adjustment then

return to "Step 9.1."

9.8. Disconnect electrical power to the dryer.

9.9. Replace the regulator cap (F).

10. Turn the gas valve's switch (H) to "OFF" position.

11. Remove manometer and tighten pressure tap screw (G).

12. Turn the gas valve's switch (H) to "ON" position.

13. Continue electrical power to the dryer.

Steam Information ______________

Steam installation should be performed by

qualified personnel in accordance with national

and local safety regulations.

Care must be taken when leveling a steam dryer to promote

good steam coil drainage. Return lines should be level or

pitched down slightly for good drainage.

The steam supply to the coil must be from the top of a welldripped steam main. If the supply run-out to the dryer exceeds

6 meters then it should be dripped just before the control valve

with a proper trap and dirt pocket.

The normal pH level for copper-type steam coils must be

maintained between 8.5 and 9.5. For steel-type steam coils

the pH level must be between 9.5 to 10.5. These limits are

required to limit the acid attack of the steam coils.

Properly sized steam supply, and return, lines are required to

avoid poor performance.

Clean, dry steam must be provided to the dryer.

The steam supply connection into the main supply line must

be made with a minimum 25 cm riser. This will prevent any

condensate from draining towards the dryer.

The steam supply line to the dryer must include a 30 cm riser

along with a drip trap and check valve. This will prevent any

condensate from entering the steam coil.

Flexible hoses or couplings must be used. The dryer vibrates

slightly when operating which could cause steam connections

to crack if they are hard piped.

Horizontal sections of steam supply piping should be pitched

back towards the steam supply header (minimum slope of 1

cm for every meter) to allow any condensation to flow back

into the header. Install a bypass trap in any low point to eliminate

wet steam.

Failure to comply with the above requirements can result in

water hammer, premature component failure, and will void the

warranty.

12 American Dryer Corp. 113686-1

Steam Supply Requirements

Maximum Pressure 862 kPa

Minimum Pressure 689 kPa

Shutoff valves for each dryer should be installed in the supply

line, return line, and drip trap return line. This will allow the

dryer to be isolated from the steam supply if the dryer will be

serviced.

The supply and return lines should be insulated to save energy

and provide safety to maintenance personnel.

Pneumatic Steam Damper Arrangement

(Refer to figure)

A clean and dry compressed air supply (A) (5.5 bar ± 0.7 bar )

is required for dryers with a pneumatic piston (B) and damper

(C) arrangement.

The air connection is made to the steam damper solenoid valve

(D), which is located at the rear inner top area of the dryer just

in front of the rear electric service relay box (E).

Damper operation was calibrated prior to shipping. Airflow to

the piston (B) can be regulated by adjusting the flow control

valve (F). Turn the knob (G) clockwise to reduce airflow. Turn

the knob (G) counterclockwise to increase airflow.

1. Steam Coil

2. Vacuum Breaker

3. Solenoid Valve (for steam coil without damper)

4. Flexible Hose or Coupling

5. Riser

6. Strainer

7. Manual Shutoff Valve

113686-1 www.adclaundry.com 13

8. Drop

9. Dirt Leg

10. Drip Trap

11. Check Valve

12. Inverted Bucket Steam Trap

13. Return Main

14. Supply Main

Steam Damper System Operation

(Refer to the figure)

The steam damper arrangement allows the coil to be charged

continuously (eliminates repeated expansion and contraction).

During the heat cycle the damper (C) is in the open position.

Air (H) is heated as it passes through the hot coil (J) and into

the tumbler during the drying process.

During the cooldown cycle the damper (C) is in the closed

position. Air (H) will bypass the hot coil (J) and the cool air will

enter the tumbler during the cooldown phase.

Cooldown Cycle

Damper position

Heat Cycle

Damper position

Start-Up ___________________________________

Check:

• Gas dryers – All shutoff valves should be open.

• All back panels (guards) should be in position.

• Service doors should be securely closed.

• Lint door or drawer should be fully closed.

• The tumbler (drum) should rotate freely.

Tumbler Coating

The tumbler has a protective coating that should be wiped clean

with water and mild detergent solution (nonflammable).

Alternatively, tumble a load of old garments that are wetted

with water and mild detergent solution (nonflammable).

Preoperational Test

A performance check is needed after the dryer is fully installed

and before the dryer is ready for use.

Start the dryer (refer to the Operating Instructions below).

Gas heat – Check for flame ignition (may need more than one

attempt to purge air from the gas supply pipe).

Electric heat – Check the contactor(s) are cycling the electric

oven (heater) properly.

Steam heat – Check the damper (or steam solenoid valve, if

equipped) is functioning properly. Dampers should not bind or

slam during operation. If the damper motion is not smooth

and quiet then the flow control must be adjusted.

Water Information _______________

(If dryer is equipped with F.S.S.)

Water installation should be performed by qualified

personnel in accordance with national and local safety

regulations.

If the water system activates then you must have the dryer

inspected by a qualified agency. Do not operate the dryer.

Electric power to the dryer must be on at all times in order for

the fire suppression system (F.S.S.) to function.

The water connection is made into the rear of the dryer (refer

to the Technical Specifications page).

Use a new hose to connect to the water supply.

A flexible supply line, with coupling, must be used to avoid

damaging the water solenoid valve.

Water supply pipe size should be at least 1/2-inch (nominal)

(21.3 mm) and the supply pressure should be 275 ± 137 kPa.

Protect water lines from freezing if they will be exposed to

freezing-cold temperatures.

Safety Related Circuits

The dryer should stop when the main door is opened.

The dryer should stop when the lint door is opened.

If any failed test cannot be corrected, or if other concerns are

detected, contact your local service organization or dealer.

Ready for Use

If all tests are acceptable then the machine is ready for use.

Installer must instruct the end user on how to operate the dryer

before leaving.

Operating Instructions

Coin Models

The display will show “Ready, Insert

the dryer is ready for use.

Insert the required coin(s). The display will show “Select

Temperature” when the “amount-to-start” has been satisfied.

Select the desired cycle by pressing “HI,” “MED,” or “LO.”

The dryer will start and display the cycle and remaining time.

Press “

Non-Coin Models

The display will show “Ready” when the dryer is ready for use.

Press the letter on the keypad to select the desired cycle.

The dryer will start and display the cycle and remaining time.

Press “

Press the “

resume the current cycle, or select a different cycle to restart.

” to pause the dryer. Select desired cycle to restart.

” to stop the dryer.

” key again to clear the dry cycle, press “ ” to

amount

to Start” when

14 American Dryer Corp. 113686-1

Routine Maintenance _____________________

A schedule should be established for the periodic inspection,

cleaning, and lint removal. The frequency of cleaning can best

be determined from experience at each location. Ideal drying

performance depends on sufficient airflow. Lint accumulation

can restrict airflow and is also a fire hazard.

Avoid using harsh chemicals when cleaning the dryer.

Suggested Cleaning Schedule

(Based on approximately 6-8 hours of daily operation)

To avoid electric shock and contacting

moving parts, discontinue electrical

supply any time a panel (without an

interlock switch) or guard is removed.

Every Three or Four Loads

Clean the lint screen – located behind the lint door (lower front

panel). The 50V and 758V have a lint drawer that slides out for

cleaning. Replace the lint screen if it is torn or damaged.

Weekly

Clean lint accumulation from the lint chamber, thermostat and

operating temperature sensor (located just below the drum).

Steam dryers: carefully clean steam coil fins (which are easily

damaged). We suggest using a vacuum cleaner with brush

attachment. Straighten bent fins with a fin comb.

Data Label Information ___________________

When contacting ADC, certain information is required to ensure

proper service/parts information from ADC. This information is

on the data label affixed to the right side panel area at the rear

of the dryer. When contacting ADC, please have the model

number and serial number available.

1. MODEL – Dryer model number.

2. SERIAL NUMBER – Unique identification number.

3. GAS TYPE – Gas type the dryer is constructed for.

4. HEAT INPUT – Rate of combustion

5. ORIFICE SIZE – Injector opening (in mm).

6. ELECTRIC SERVICE – Electric supply type.

7. GAS PRESSURE – Supply and regulated pressure.

CE Rating Plate

90 Days

Clean any lint accumulation in and around the dryer.

Particular attention must be given to the removal of lint from

the burner area - located behind the upper front panel (control

door) and the area near the drive and fan motors.

Caution: Avoid touching the igniter and flame-sensor probes.

6 Months

Remove lint accumulation in the fresh-air intake openings and

in the exhaust ductwork.

Remove lint that may interfere with any back-draft damper.

Check all back-draft dampers for proper operation.

Service / Parts Information ______________

Service must be performed by a qualified technician. If service

is required, contact the reseller who sold you the equipment. If

the reseller cannot be reached then contact our Service

Department for a reseller in your area.

Replacement parts can be obtained from your reseller or the

ADC factory. When ordering replacement parts from the factory,

you can FAX your order to ADC at +1 (508) 678-9447 or

telephone our Parts Department at +1 (508) 678-9000. Please

be prepared to provide the dryer model number, serial number,

description of the part, and the part number (if known).

This dryer is equipped with a manually resettable high-limit

thermostat in the lint compartment area.

The wiring diagram for the dryer is located behind the control

panel.

AGA Rating Plate

113686-1 www.adclaundry.com 15

Warranty Information _____________________

For any warranty-related issues, please contact our Warranty

Department at +1 (508) 678-9000.

If you need a copy of the warranty covering your dryer please

contact the reseller who sold you the equipment. If the reseller

cannot be contacted then call our Warranty Department.

Before calling, please have the dryer model and serial number

(from rating plate) and the installation date of the dryer.

The rating plate can be found behind the control panel on some

dryers and inside the back guard on other dryers.

All warranty claims or inquiries should be addressed to our

Warranty Parts Department. To expedite warranty claim, please

follow these procedures:

Do not ship any part to us without proper authorization (Return

Material Authorization or R.M.A.) from the factory. An R.M.A. is

only valid for 30 days.

Ship the failed component, a copy of the R.M.A., and any other

supporting documentation.

Label or tag each part with the model and serial number (from

the rating plate) of the dryer it was removed from. Warranty

tags (Part No. 450064) are available (no charge) from ADC.

Describe the nature of the failure (be specific).

Provide the date that the dryer was installed.

Provide the date when the component failed.

Specify if the part is being returned for a credit, replacement,

or refund. If a part is marked for a credit or a refund, please

provide the invoice number of the replacement part purchase.

You must clearly note your company’s complete name and

address on the outside of the package.

All returns should be shipped to the factory with adequate

insurance and “proof-of-delivery” from the shipping company.

No replacements, credits, or refunds will be issued for

components damaged during transit. All returns must be

properly packaged to prevent such damage, and any claims

are the responsibility of the shipper.

Shipping charges are your responsibility. Any C.O.D. or “Collect”

shipments will be refused.

You will be notified if your warranty claim cannot be processed

due to insufficient or missing information. We must receive this

information within 30 days otherwise the claim will be rejected

and the part will be discarded.

For your convenience, log the following information:

This product embodies advanced concepts in engineering,

design, and safety. If this product is properly maintained, it will

provide many years of safe, efficient, and trouble-free operation.

We have tried to make this manual as complete as possible

and hope that you will find it useful. The manufacturer reserves

the right to make changes from time to time and without notice

or obligation. The illustrations included in this manual may not

depict your particular dryer exactly.

NOTES ______________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

Date of Purchase: ________________________________

Model Number: __________________________________

Reseller's Name: _________________________________

Serial Number: ___________________________________

_______________________________________________

_______________________________________________

ADC Part No. 113686 1 - 12/18/15

_____________________________________________________________

_____________________________________________________________

_____________________________________________________________

Loading...

Loading...