Page 1

Fiber Distribution Terminal

ACE-142S/142V Cabinet

User Manual

ADCP-96-015

Issue 1

July 2004

19603-A

1290491 Rev A

Page 2

ADCP-96-015 • Issue 1 • July 2004 • Preface

COPYRIGHT

© 2004, ADC Telecommunications, Inc.

All Rights Reserved

Printed in the U.S.A.

REVISION HISTORY

ISSUE DATE REASON FOR CHANGE

1 07/2004 Original release.

LIST OF CHANGES

The technical changes incorporat ed into this issue are lis ted below.

PAGE IDENTIFIER DESCRIPTION OF CHANGE

All Original release

TRADEMARK INFORMATION

ADC and ADC Telecommunications are regis tered trademarks of ADC Telecomm unications, Inc.

Telcordia is a registered trademark of Telcordi a Technologies, Inc.

DISCLAIMER OF LIABILITY

Contents herein are current as of the date of publication. ADC reserves the right to change the contents without prior notice. In no

event shall ADC be liable for any damages resulting from loss of data, loss of use, or loss of profits and ADC further

disclaims an y and all liability for indirec t, incidental, special, consequen tial or other similar dam ages. This discl aimer of

liability applies to all products, publications and services during and after the warranty period.

This publ ication may be verified at any time by contacting ADC’s Technical Assistance Cent er at 1-800-366-3891, ex tension 73475

(in U.S. A . or Canada) or 952-9 17-3475 (outside U.S.A. and Canada), or by e-mail to bcg_tac@adc. com .

Page ii

ADC Telecommunications, Inc.

P.O. Box 1101, Minneapolis, Minnesota 55440-1101

In U.S.A. and Canada: 1-800-366-3891

Outside U.S.A. and Canada: (952) 938-8080

Fax: (952) 917-1717

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Content Page

ABOUT THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Related Publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

ADMONISHMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

GENERAL SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

STANDARDS CERTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

LIST OF ACRONYMS AND ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

1 DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 ACE-142S/142V Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Accessories and Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 BEFORE STARTING THE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Unpacking and Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Cabinet Installation Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Tools and Materials Required for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5 Cabinet Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 MOUNTING THE CABINET ON A FIBERGLASS MOUNTING SLEEVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Installation Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Excavation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Placement of the FMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Cable Conduit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Grounding System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Back Fill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.7 Mounting the Cabinet on the FMS-20000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 MOUNTING THE CABINET ON A CONCRETE PAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Installation Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2 Cable Conduit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Base Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.4 Concrete Pad Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5 Grounding System Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6 Mounting the Cabinet on the Concrete Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5 FEEDER CABLE INSTALLATION AND SPLICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Bottom Cover Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Cabinet Grounding Wire Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Feeder Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.4 Feeder Cable and Splitter Input Fiber Splicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 DISTRIBUTION CABLE INSTALLATION AND SPLICING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.1 Distribution Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.2 Bottom Cover Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3 Distribution Cable and Connector Panel Pigtail Splicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 GUIDELINES FOR USING ROUND SPLICE TRAYS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8 PRE-INSTALLED DISTRIBUTION CABLE CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

ADCP-96-015 • Issue 1 • July 2004 • Preface

© 2004, ADC Telecommunications , Inc.

Page iii

Page 4

ADCP-96-015 • Issue 1 • July 2004 • Preface

TABLE OF CONTENTS

TABLE OF CONTENTS

Content Page

9 CONNECTOR PANEL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10 SPLITTER MODULE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

11 ROUTING AND CONNECTING THE SPLITTER OUTPUT FIBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.1 Storing The Splitter Output Fibers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.2 Enabling Service To a Subscriber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

12 MAINTENANCE AND REPAIR PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.1 Painting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.2 Adapter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12.3 Connector Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13 CUSTOMER INFORMATION AND ASSISTANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

_________________________________________________________________________________________________________

Page iv

© 2004, ADC Telecommunications , Inc.

Page 5

ABOUT THIS MANUAL

This publication provides a complete description of the Fiber Distribution Terminal (FDT)

ACE-142 S/142V Cabinet. Also included are procedures for mounting the cabine t, installing and

splicing the feeder and distribution cables, installing additional connector panels and splitter

modules, connecting the splitter output fibers to the distribution fibers, and replacing damaged

components.

RELATED PUBLICATIONS

Listed below are related manuals and their publication numbers. Copies of these publications

can be ordered by contacti ng the ADC T e chnical Assi stance Center at 1-800-366- 389, ext ension

73475 (in U.S.A. or Canada) or 1-952-917-3475 (outside U.S.A. and Canada).

Title ADCP Number

Round Splice Tra y Cable Routing Instructions 90-321

Optical Fiber Systems Cleaning and Mating Instructions 90-159

ADCP-96-015 • Issue 1 • July 2004 • Preface

ADMONISHMENTS

Important safety admonishments are used thr oughout this manual to warn of possible hazards to

persons or equipment. An admonishment identifies a possible hazard and then explains what

may happen if the hazard is not avoided. The admonishments — in the form of Dangers,

Warnings, and Cautions — must be followed at all times. These warnings are flagged by use of

the triangular alert icon (seen below) and are listed in descending order of severity of injury or

damage and likelihood of occurrence.

Danger: Danger is used to indicate the presence of a hazard that will cause severe personal

injury, death, or substantial property damage if the hazard is not avoided.

Warning: Warning is used to indicate the presence of a hazard that can cause s evere personal

injury, death, or substantial property damage if the hazard is not avoided.

Caution: Caution is used to indicate the presence of a hazard that will or can cause minor

personal injury or property damage if the hazard is not avoided.

GENERAL SAFETY PRECAUTIONS

Warning: Wet conditions increase the potential for receiving an electrical shock when

installing or using electrically-powered equipment. To prevent electrical shock, never install or

use electrical equipment in a wet locat ion or during a lightning storm.

© 2004, ADC Telecommunications , Inc.

Page v

Page 6

ADCP-96-015 • Issue A • June 2001 • Preface

Danger: Do not look into the ends of any optical fiber. Exposure to laser radiation may result.

Do not assume the laser power is turned-off or that the fiber is disconnected at the other end.

Danger: Use adequate lifting equipment when moving or installing Fiber Distribution Terminal

cabi n ets . Verify t ha t th e m ax im um l ift w eig ht rat ing of t he e qu ip m ent is su ffic ient t o h and le th e

weight of the cabinet.

Danger: Do not stand under a Fiber Distribution Terminal cabinet as it is being hoisted into

position for mounting. A failure of the lifting equipment or apparatus could result in serious

personal injury.

Warning: Before digging, check with all local utilities for the presence of buried cables or

pipes. Contact with underground cables or pipes, especially electric power cables and gas

service lines, could interrupt local utility service and cause serious personal injury and

extensive property damage.

STANDARDS CERTIFICATION

Telcordia: This equipment complies with the applicable sections of GR-2898-CORE (Issue 2,

December 1999)

LIST OF ACRONYMS AND ABBREVIATIONS

The acronyms and abbreviations used in this manual are detailed in the following list:

AWG American Wire Gauge

C Centigrade

F Fahrenheit

FDT Fiber Distribut ion Terminal

FMS Fiberglass Mounting Sleeve

FTTP Fiber To The Premises

OSP Outsid e Plan t

PMF Pad Mount Frame

Page vi

© 2004, ADC Telecommunications , Inc.

Page 7

1 DESCRIPTION

This section provides a description of the ACE-142S/142V cabinet plus specifications. Also

included is a listing of the various acc es s orie s and kits .

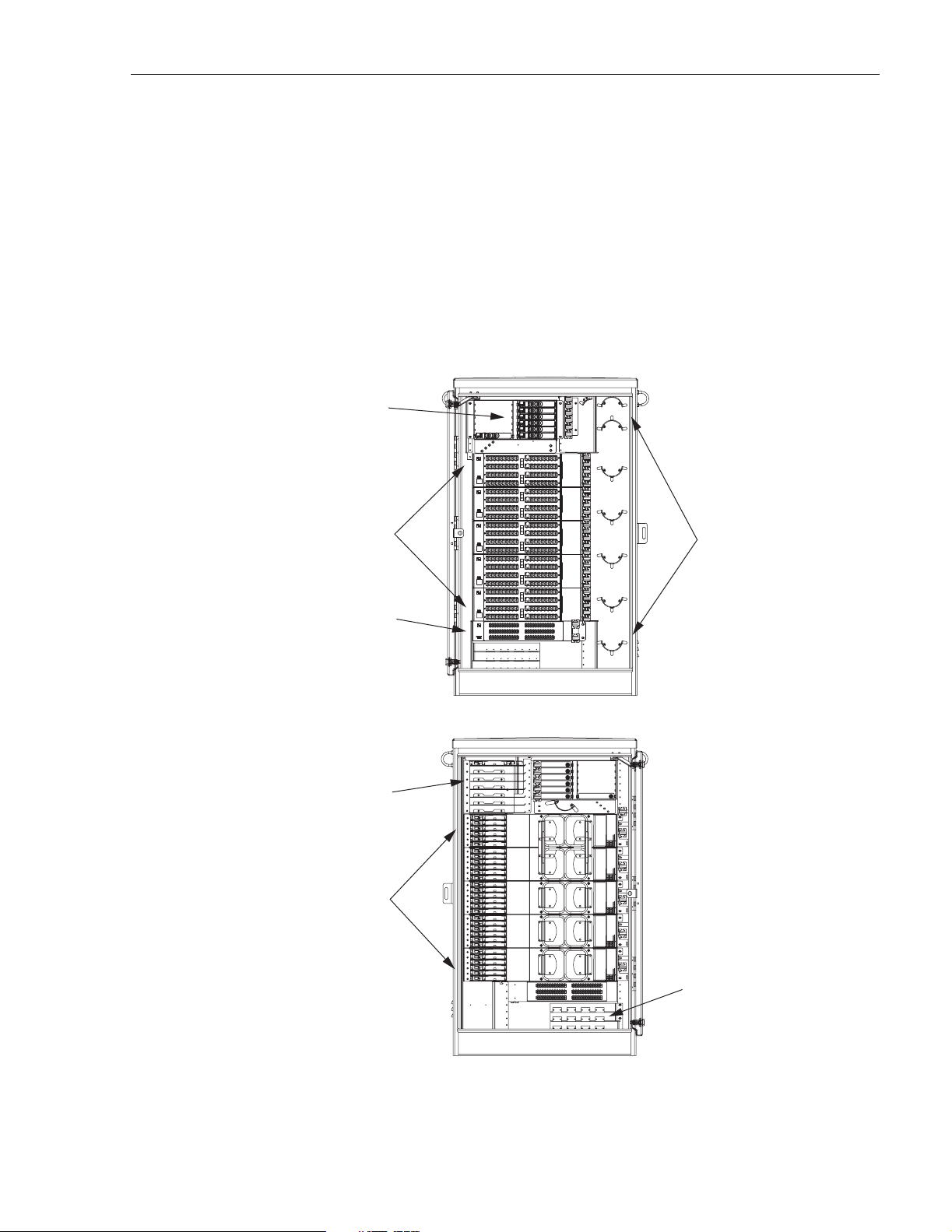

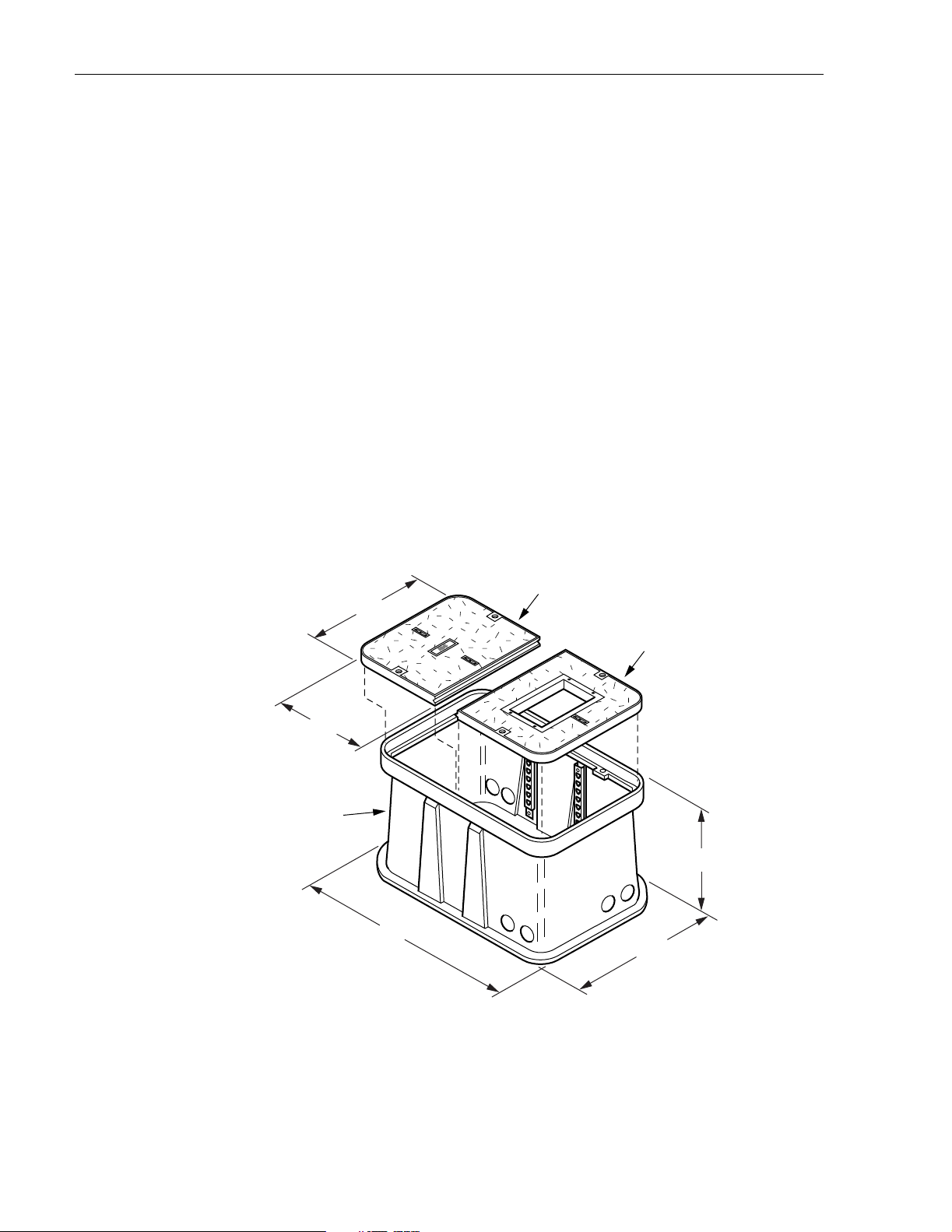

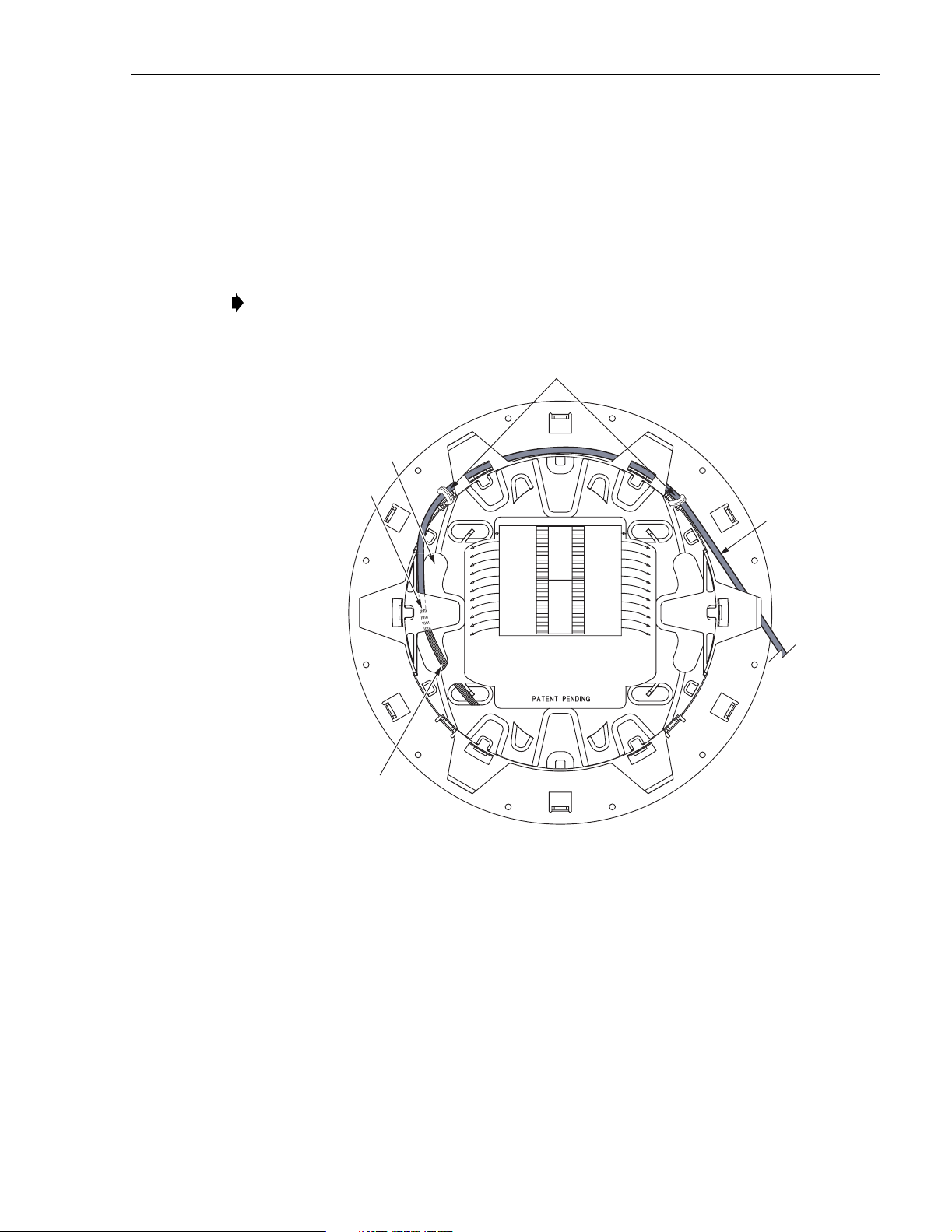

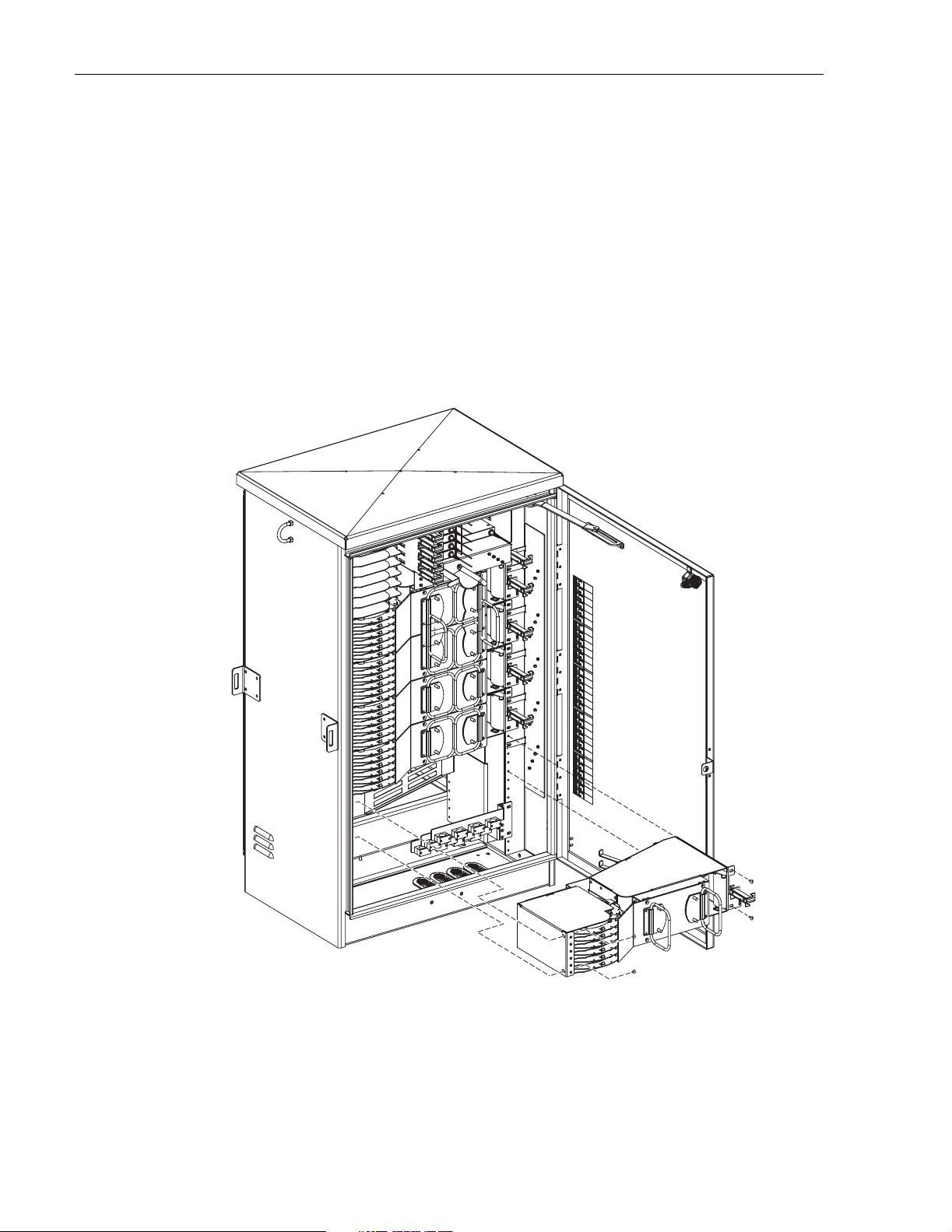

1.1 ACE-142S/142V Cabinet

The ACE-142S/142V cabinet is a secure, above-ground, outdoor fiber optic distribution cabinet

that is designed to hold the splice trays, splitters, connector panels, and connector storage panel

required for various Fiber To The Premises (FTTP) applications. A typical ACE-142S/142V

cabinet (with split ter modules and connector panels installed) is shown in Figure 1.

SPLITTER

MODULES

ADCP-96-015 • Issue 1 • July 2004

CONNECTOR

PANELS

CONNECTOR

STORAGE PANEL

(PARKING LOT)

FEEDER CABLE

SPLICE TRAYS

DISTRIBUTION

CABLE

SPLICE TRAYS

RADIUS LIMITERS

FOR SPLITTER

OUTPUT FIBER

SLACK STORAGE

FRONT

REAR

Figure 1. Typical ACE-142S/142V Cabinet

CABLE

CLAMPS

19620-A

Page 1

© 2004, ADC Telecommunications , Inc.

Page 8

ADCP-96-015 • Issue 1 • July 2004

The outsid e plant (OSP) fe eder and dist ribution cables e nter the cabinet from the botto m rear

side. Clamps are provided for securing each cable to the inside of the cabinet. The bottom of the

cabinet is e nclose d with a t wo-piec e removable m oistu re ba rrier. The cable ent ry/exit hol es ar e

fitted with grommets to resist the entry of dust and moisture. On an optional basis, the cabinet

may be ordered with the distribution cables pre-installed.

The ACE-142S/142V cabinet is constructed of heavy gauge aluminum and is coated with an

almond-colored finish. The cabinet doors are equipped with tamper-resistant latches with hasps

for padlocks , stainless steel hinges, and door catches to prevent accidental closing. Acc ess to the

cabinet requ ires a

the sides of the cabinet to allow use of hoisting equipment. A grounding bus is provided within

the cabinet for grounding the cabinet and cables per local practice.

The ACE-142S/142V cabinet can accommodate up to thirty-seven round splice trays, up to

twelve 1x8 or 1x32 splitter modules, and five 72-position c onnector panels equipped with APC/

SC adapters. Seven splice tray slots are provided for feeder cable splices. Thirty splice tray slots

are provided for distribution cable splices. The ACE-142S/142V cabinet is equipped with two

doors that provide fro nt and rear access to the opti cal components. Th e specifications for the

ACE-142S/142V cab i net are p rovid ed in Table 1.

216B key tool (accessory) to operate the latches. Lifting eyes are attached to

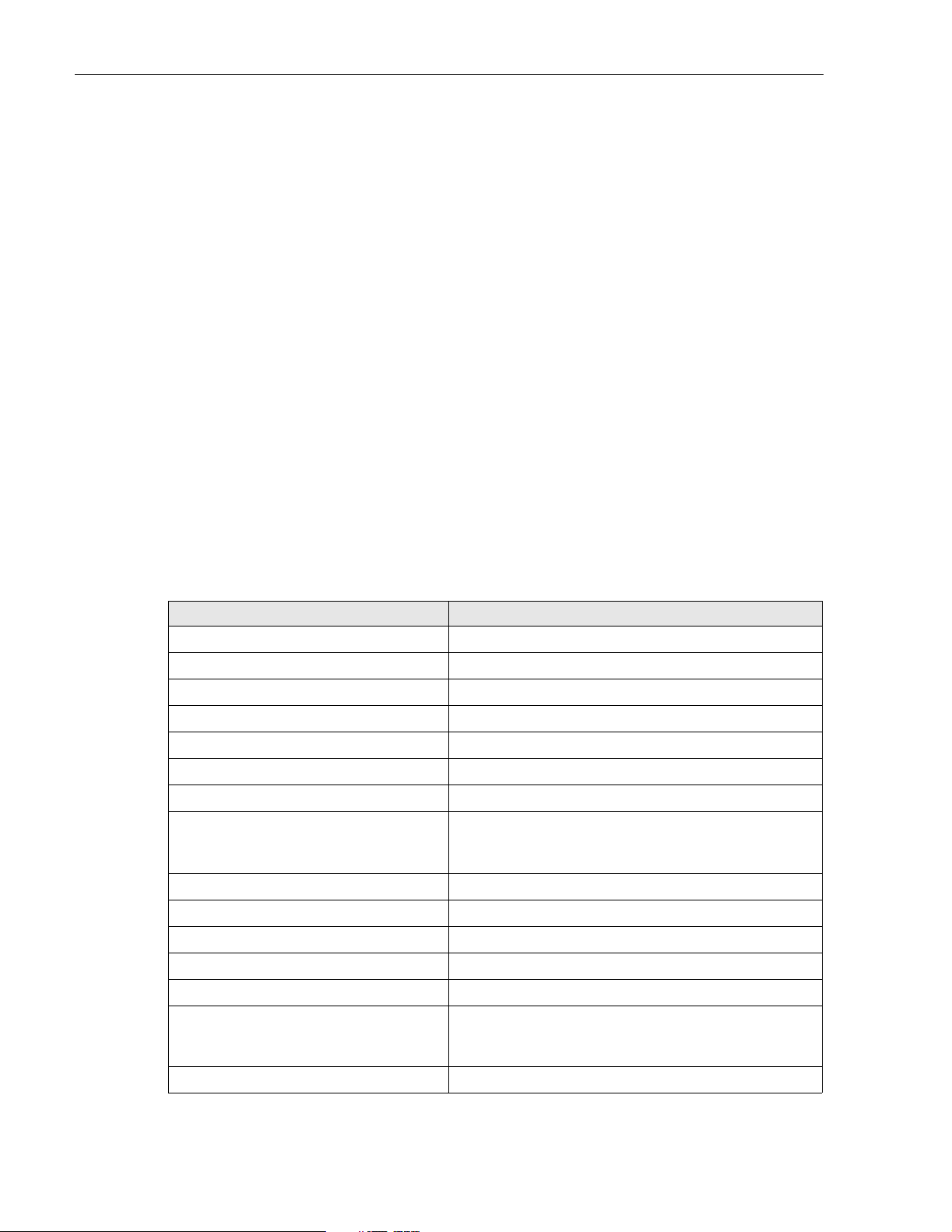

Table 1. ACE-142S/142V Cabinet Specifications

PARAMETER SPECIFICATION

Cabinet

Dimensions (W x D x H) – See Figure 2 27.5 x 19.7 x 47.5 inches (699 x 500.4 x 1206.5 mm)

Weight (fully loaded) 210 lbs (95.3 kg)

Certification (Pending) GR-2898-CORE (Issue 2, December 1999)

Distribution ports 360 (with 5 connector panels installed)

Distribution port connectors APC/SC

Splitter module capacity (1x8 or 1x32) 12

Splice tray capa city (round)

Feeder cable

Distribution cable

Total feeder cable splices 84 (7 splice trays with 12 spli ces per tray)

Total distrib ution cable splices 360 (30 splice trays with 12 splices per tray)

Splitter Modules

Splitter module output pigtails 2 mm with APC/SC connectors

Splitter module input pigtail 2 mm

Test bandpass 1260–1360 nm

7

30

1480–1500 nm

1550–1560 nm

Overall bandpass 1260–1625 nm

Page 2

© 2004, ADC Telecommunications , Inc.

Page 9

Table 1. ACE-142S/142V Cabinet Specifications, continued

PARAMETER SPECIFICATION

Insertion loss at test bandpass

1x8 standard APC/SC

1x32 standard APC/SC

11.1 dB Maximum (Including connector)

17.8 dB Maximum (Including connector)

Return loss at test ba ndpass

1x8 standard APC/SC

1x32 standard APC/SC

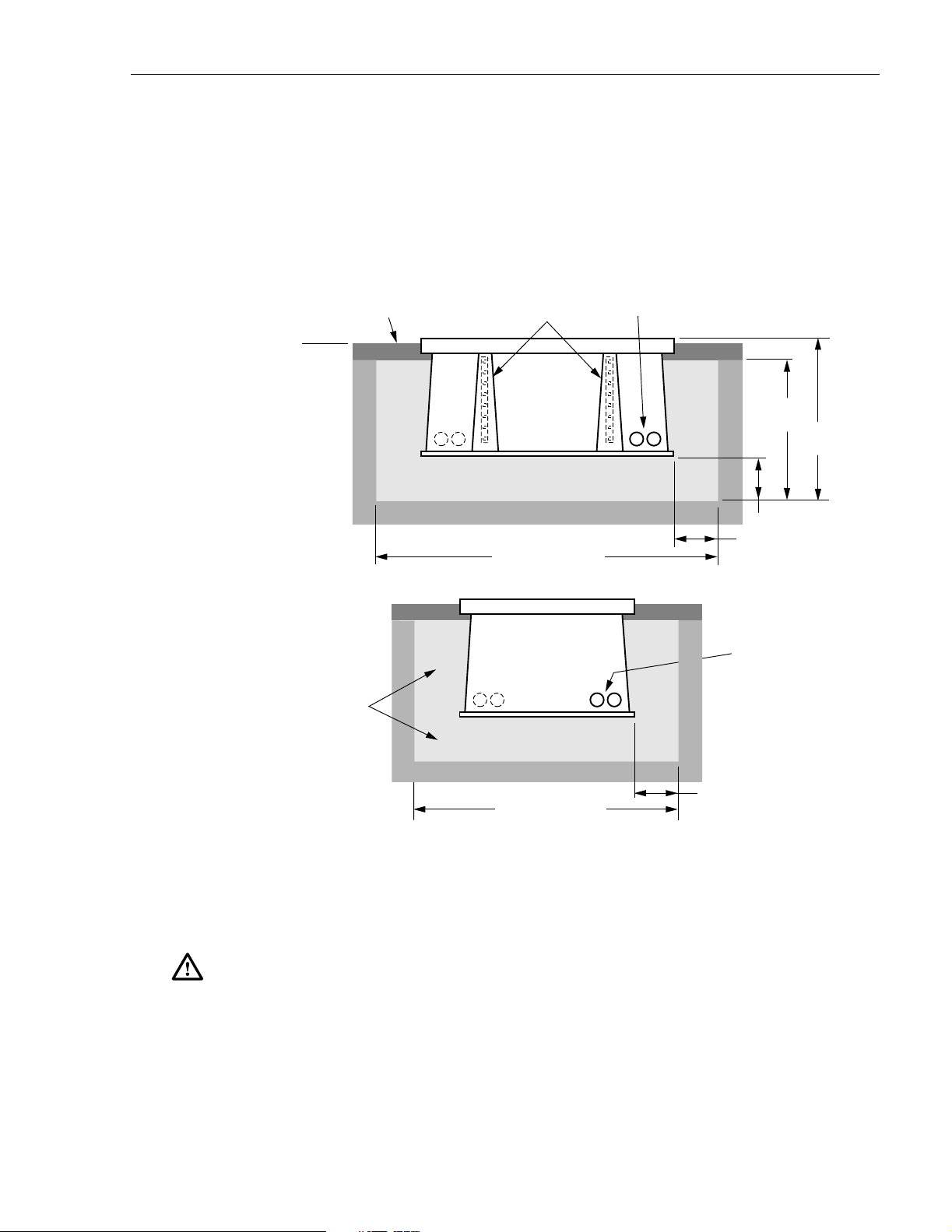

30.8 IN.

(78.2 CM)

>55 dB

>55 dB

ADCP-96-015 • Issue 1 • July 2004

47.5 IN.

(120.7 CM)

27.3 IN.

(69.3 CM)

Figure 2. ACE-142S/142V Cabinet Dimensions

© 2004, ADC Telecommunications , Inc.

19.7 IN.

(50.1 CM)

19606-A

Page 3

Page 10

ADCP-96-015 • Issue 1 • July 2004

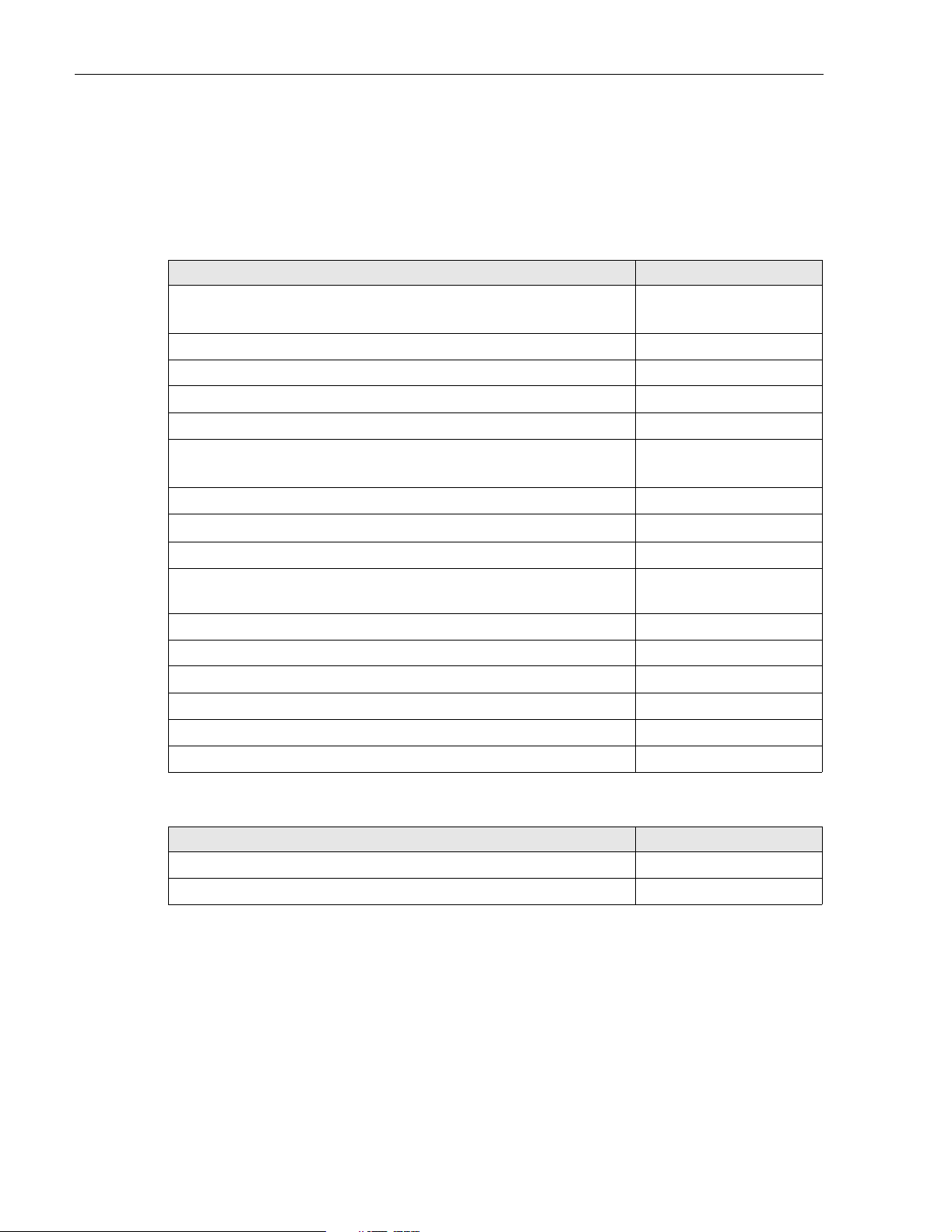

1.2 Accessories and Replacement Parts

Refer to Table 2 and Table 3 for a listing o f the various acces sories and replacem ent parts th at

are available for the ACE-142S/142V cabinet.

Table 2. ACE-142S/142V Cabinet Accessories and Replacement Parts

DESCRIPTION CATALOG NUMBER

Mounting Kits

Fiberglass Mounting Sleeve (se e Figure 3 for dimensions) FMS-20000

FMS sleeve cover FCVR-200CVR

FMS adapter cover FCVR-200ACE 1000

Concrete pad mount frame (PMF) kit ACE-100PMF

Ground spacer ACE-ACCSPCRO6S-102

Cable Hardware Kit s

Blocking kit, loose buffer tube FBK-OSP002

Clamping kit OSP-CLPSST

Grounding kit, loose buffer tube

GND-STPKIT

Cable grommet kit ACE-ACC-CBLGRMT

Miscellaneous

OSP-216BKEY1

216B key tool (required to open cabinet door)

Splice wheel, HS FST-DRS12-HS

Splice wheel, mechanical FST-DRS12 - M T

Touch-up paint - Almond ACE-ACC-PTALMD

Filter replacement kit OSP-FLTRKIT1

Cleaning kit FPC-CLNKIT1

Straight retainer kit FBA-ASCZ-S/R

Table 3. ACE-142S/142V Cabinet Splitter Modules

DESCRIPTION OF SPLITTER MODULE CATALOG NUMBER

1x8, standard, APC/SC FPS-SPK1AOJ

1x32, standard, APC/SC FPS-SPK1JOJ

Page 4

© 2004, ADC Telecommunications , Inc.

Page 11

2 BEFORE STARTING THE INSTALLATION

This section provides general installation considerations, unpacking and inspection procedures,

and lists the tools and materia ls required for cabinet installation.

2.1 Installation Overview

Installation of the ACE-142S/142V cabinet involves the fo llowing main tasks:

Installing a Support Base–The cabinet must be mounted on a suitable support base. The

following two mounting options are available:

• Fiberglass M ounti ng Sl eeve (FM S)–The FMS provides a stable mounting platform plus

storage space under the cabinet for OSP cable slack. The FMS may also be used as a

splicing va ult for the OSP feeder and distribution cables.

• Poured Concrete Pad–Concrete slab with Pad Mounting Frame (PMF). The PMF

provides a stainless-steel frame for mounting the cabinet. The PMF ensures that the

cabinet will be securel y anchor ed to the concrete slab.

ADCP-96-015 • Issue 1 • July 2004

Mounting the Cabinet–After the support base is installed, the cabinet is secured to the support

base.

Feeder and Di stribution Ca ble Installa tion–The cabinet OSP feeder and distribution cables

are routed into the cabinet and spliced.

Connector Panel Installation-Additional connector panels are installed in the cabinet if

needed.

Spli tter in stal la t i o n–Additional splitters are installed in the cabinet if needed.

2.2 Unpacking and Inspection

This section provides instructions for opening the shipping boxes, verifying that all parts have

been recei ved, and verifying that no shipping damag e has occurred.

Use the following pr ocedure to unpack and inspect the cabinet and all accessorie s:

1. Open the shi pping carton(s) and carefully unpack the cabinet and any accessories from the

protective packing material.

2. Open the cabinet doors (requires 216B key tool) and check for broken or missing parts. If

there are damages, contact ADC (see Section 13) for an RMA (Return Material

Authorization) and to reorder if replacement is required.

© 2004, ADC Telecommunications , Inc.

Page 5

Page 12

ADCP-96-015 • Issue 1 • July 2004

2.3 Cabinet Installation Hardware

The cabi net i s s hipp ed with fastener s (see Table 4) for securing the ACE-142S/142V cabinet to

the FM S or the PMF.

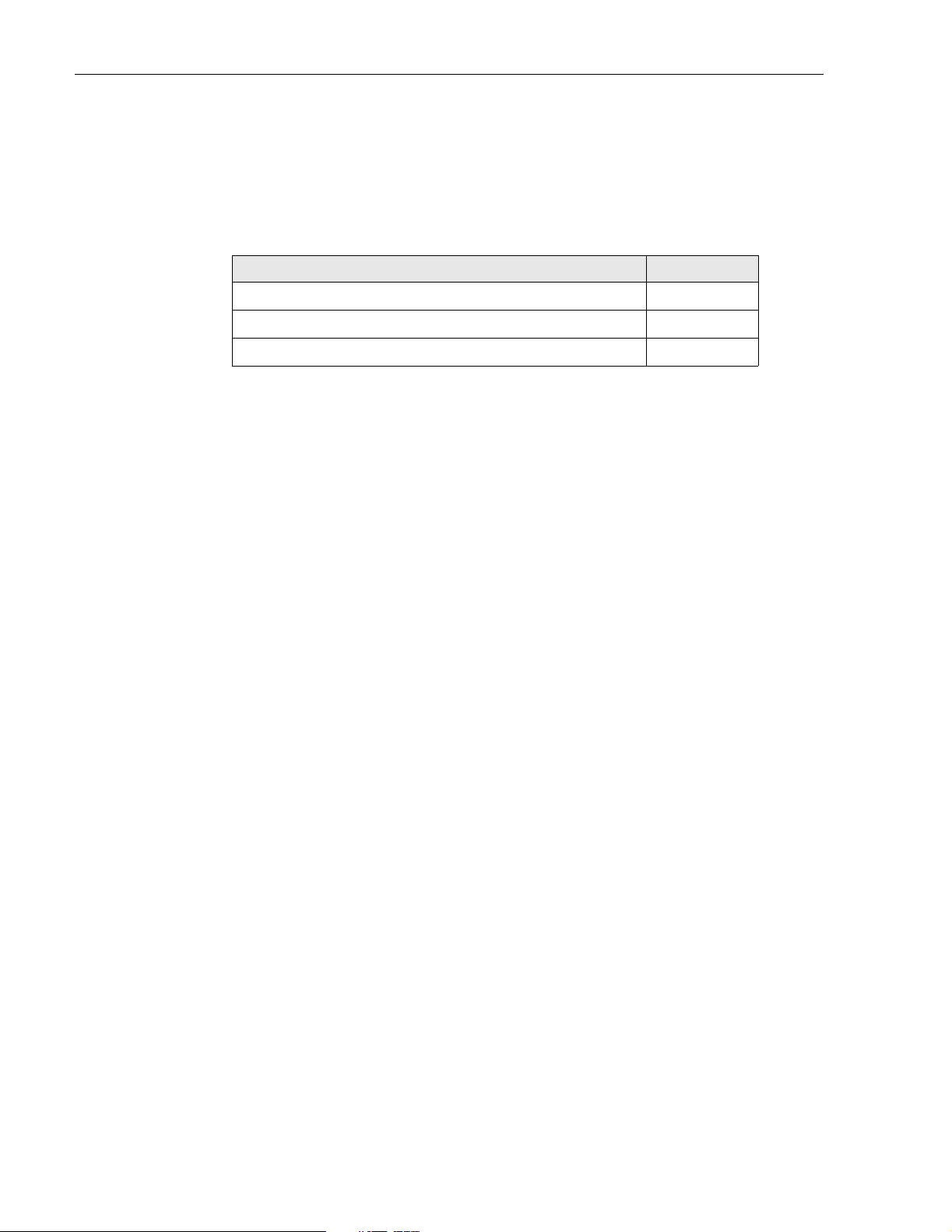

Table 4. Cabinet Installation Fasteners

ITEM QUANTITY

3/8 x 1-inch hex head capscrews 4

3/8-in ch fl at wa sh er s 4

3/8-i n ch lo ck wa sh er s 4

2.4 Tools and Materials Required for Installation

The followin g tools and materials are required for cabinet insta llation:

All Installations

• 9/16-inch w rench

•Hammer

• Wire cutter

• Utility knife

• Screwdriver (flat blade)

• Tape measure

•Pen or marker

• 216B key tool (required to open cabinet door)

• Padlock (optional)

• Grounding system, copper wire, and grounding clamp (per local requirements)

• Splicing equipment for splicing OSP feeder and distribution cables

• Lifting equipment f or hoisting the cabinet into position for mounting

Fiberglass M ounting Sleeve Instal lat ion s

• Fiberglass Mounting Sleeve (FMS), FMS sleeve cover, FMS adapter cover (see Table 2)

• Excavation and earth moving equipment

• Stone aggre gate

• Tamping equipment

•Level

• Hole saw and drill (use to cut holes for cable conduit if pre-drilled holes are not usable)

• Landscaping equipm ent and site restoration supplies

Page 6

© 2004, ADC Telecommunications , Inc.

Page 13

Concrete Pad Installations

• Pad Mount Frame kit for ACE-142

• Excavation and earth moving equipment

• Concrete finishing equipment

• Approximately 10 cu. ft. concrete

• Sand or gravel

• Tamping equipment

• 2 x 6 inch framing lumber

• 1 x 4 inch woo den stakes (4)

• Nails and construct ion screws

• Utility wire (to secure PMF during installation)

•Saw

• Drill with screwdriver bits

• Square

ADCP-96-015 • Issue 1 • July 2004

•Level

• Landscaping equipm ent and site restoration supplies

2.5 Cabinet Mounting

The next two sections provides instructions for mounting the cabinet on either a fiberglass

mounting sleeve or concrete pad. Use whichever procedure is appropriate for the inst allation.

© 2004, ADC Telecommunications , Inc.

Page 7

Page 14

ADCP-96-015 • Issue 1 • July 2004

3 MOUNTING THE CABINET ON A FIBERGLASS MOUNTING SLEEVE

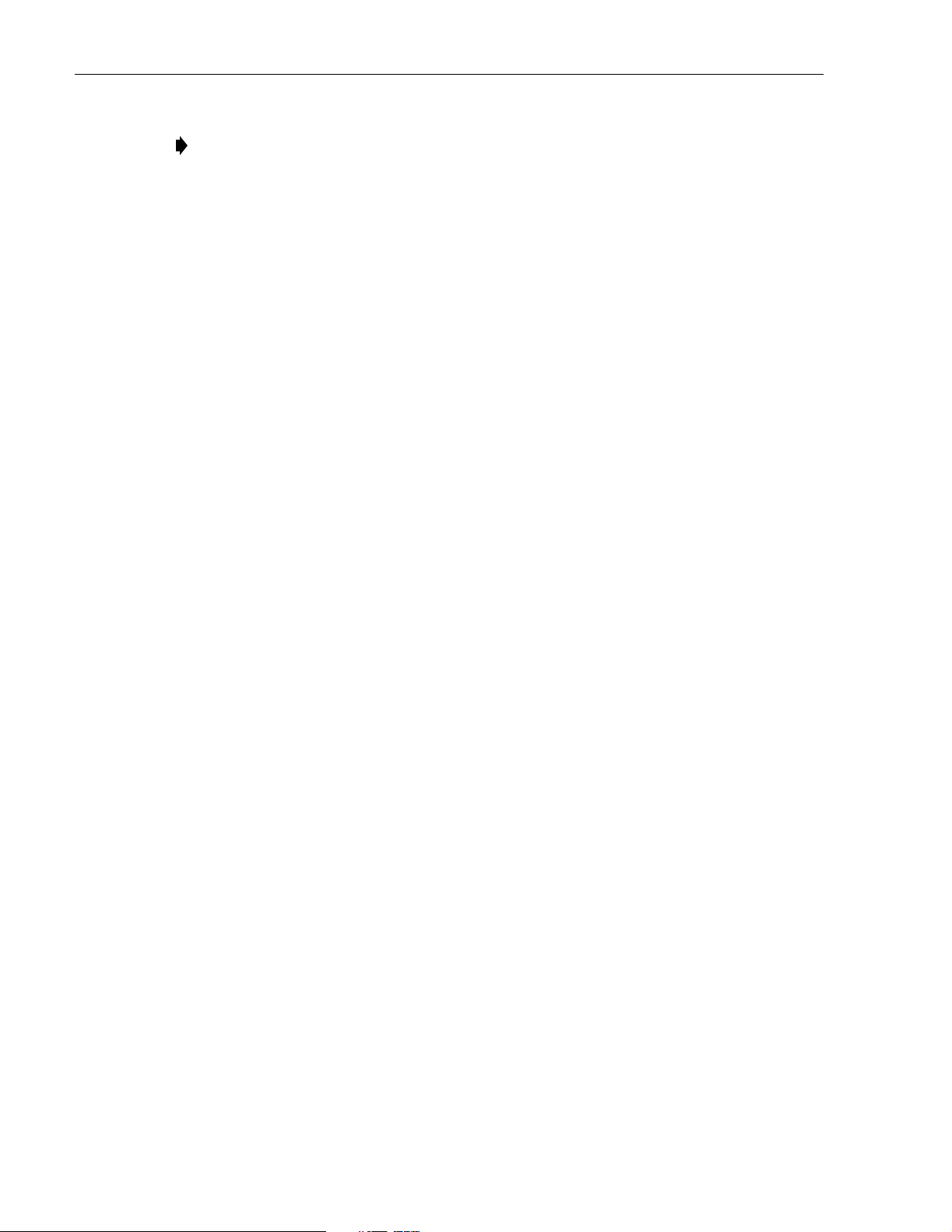

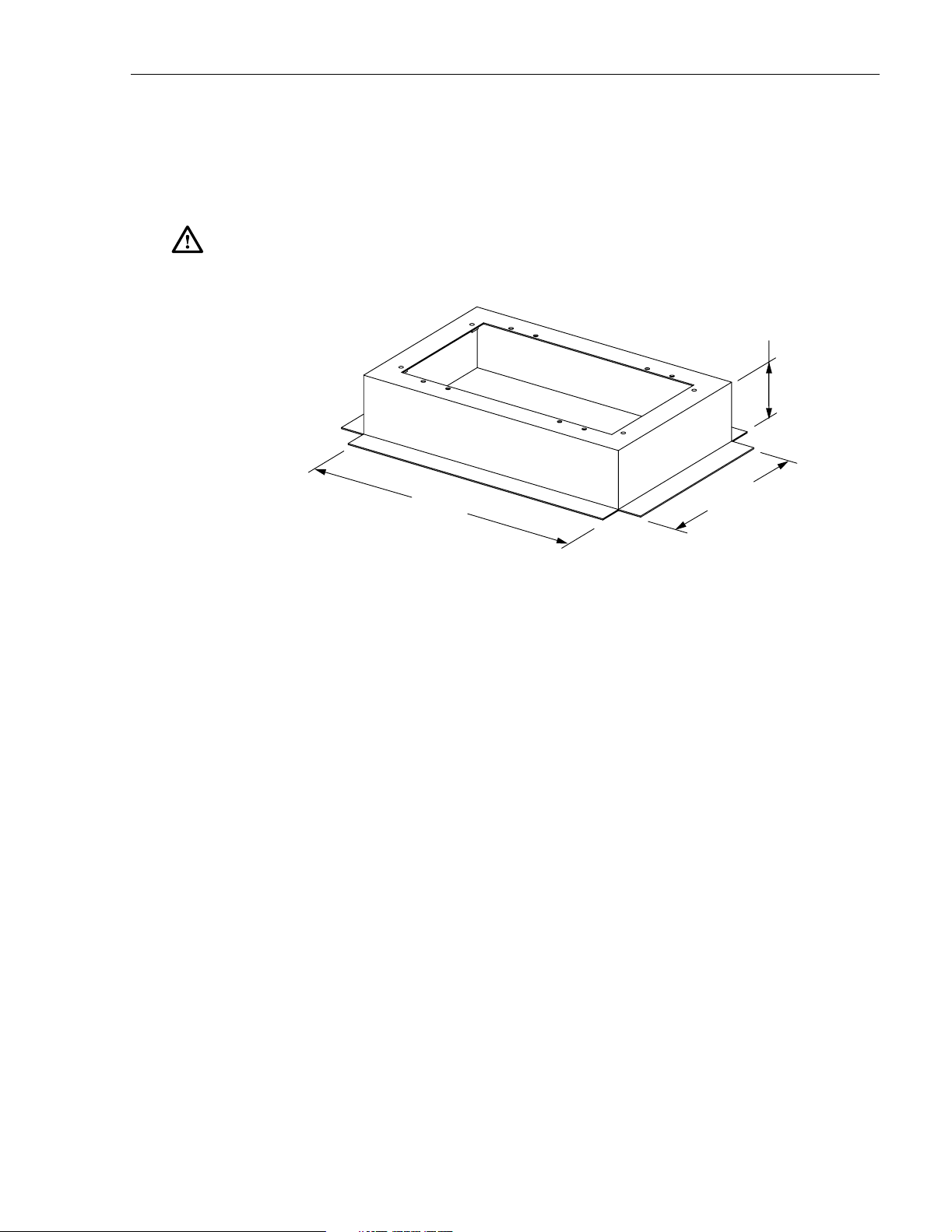

The FMS-20000, shown in Figure3, is a fiberglass and polymer concrete sleeve that may be

used to support the cabinet at ground level. The FMS may also be used as a splicing vault. Four

vertical racks are molded into the sides of the FMS to accommodate removable rungs (not

provided). The rungs provide support for splice cases or OSP cable storage.

3.1 Installation Recommendations

The site chosen for the installation must conform to all local codes and any permits required

must be obtained prior to the start of installation. The location must be accessible and provide

adequate parking for worker and vehicle safety.

The installed cabinet must not create a visual or physical obstruction to vehicular or pedestrian

traffic. Ensure that there is sufficient space on all sides to facilitate cabinet installation.

Depending on the landscaping requirements, the top surface of the mounting sleeve may be

located from 0 to 4 inches (10.2 cm) above the surrounding grade.

29.81 IN.

FIBERGLASS

MOUNTING

SLEEVE (FMS)

FMS COVER

38.5 IN.

FMS ADAPTER

COVER

30.0 IN.

68.0 IN.

47.0 IN.

19161-B

Page 8

© 2004, ADC Telecommunications , Inc.

Figure 3. Fiberglass Mounting Sleeve (FMS-20000)

Page 15

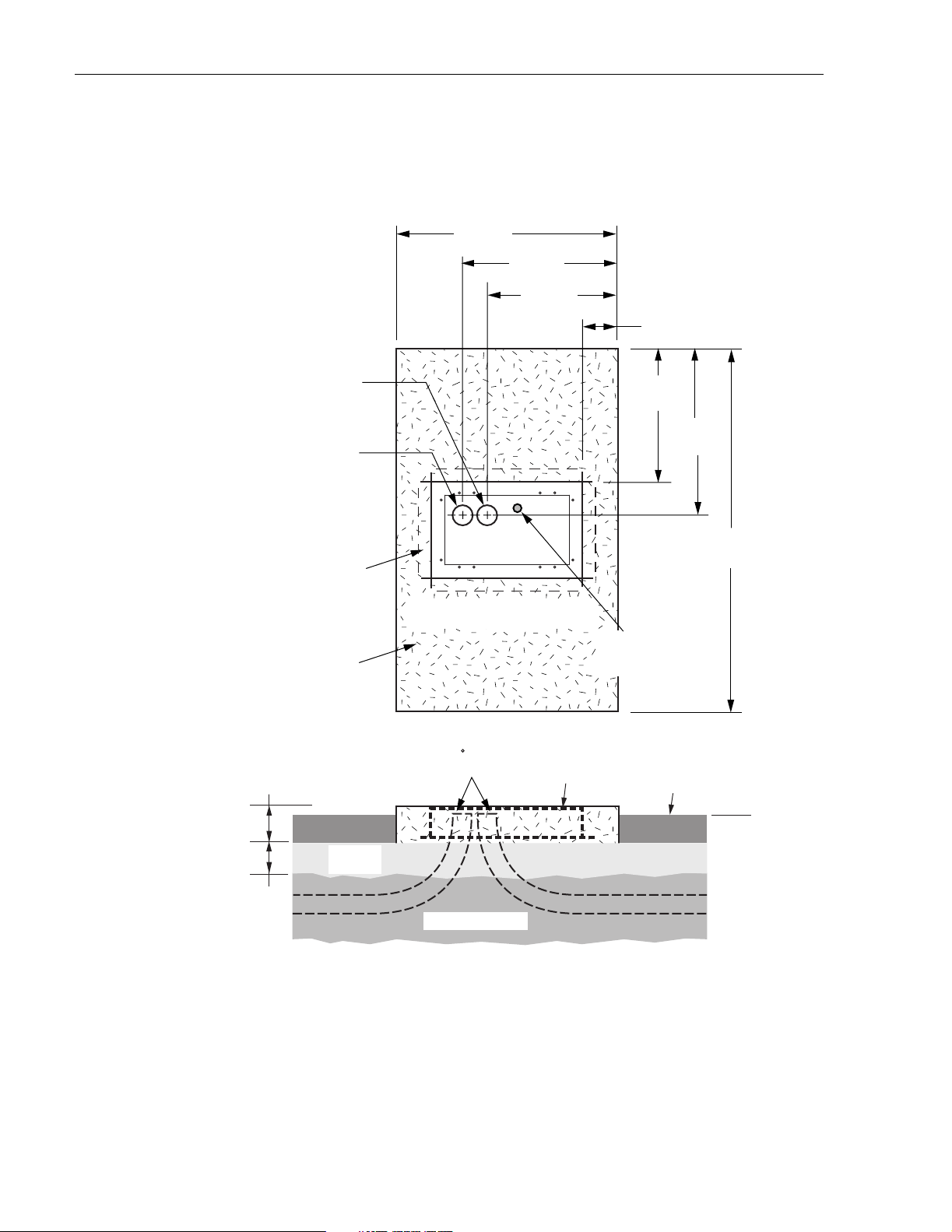

3.2 Excavation

The excavation must be large enough to provide a fill base that will maintain stability for the

FMS and the cabinet mounted on it. There must be room for 12 inches (30.5 cm) of fill below

and on each side of the FMS. The excavation dimensions for the FMS 20000 are shown in

Figure 4. Excavate a rectangular hole for the FMS.

ADCP-96-015 • Issue 1 • July 2004

TOPSOIL OR

DECORATIVE ROCK

GRADE

TAMP AGGREGATE AS

HOLE IS FILLED

VERTICAL RACKS

FOR MANHOLE

CABLE SUPPORT BARS.

SIDE VIEW

STONE

AGGREGATE FILL

COMPACTED SOIL

92 IN (234 CM)

END VIEW

STONE

AGGREGATE FILL

CONDUIT

ENTRANCE

HOLES

38 IN

(96.5 IN)

42 IN

(106.7 CM)

12 IN

(30.5 CM)

CONDUIT

ENTRANCE

HOLES

3.3 Placement of the FMS

Danger: Use adequate lifti ng equi pme nt wh en ins tal li ng the FMS. Do not s tan d in th e hole w hil e

placing the FMS in position. An unexpected shift of the FMS could result in personal injury.

Use the following procedures to place the FMS into the excavation.

1. Fill the bottom of the hole with stone aggregate, tamping it as it is filled to build a 12 inch

(30.5 cm) layer with a level surface. The stone aggregate will provide a stable base to

support the FMS.

COMPACTED SOIL

71 IN (180 CM)

(30.5 CM)

Figure 4. Excavation Recommendations for FMS-20000

© 2004, ADC Telecommunications , Inc.

12 IN

19090-B

Page 9

Page 16

ADCP-96-015 • Issue 1 • July 2004

Note: Use crushed rock 3/8-inch or less in size mixed with stone dust (per local practice)

to fill the hole. The name of the material may differ in different geographical areas.

Possible names are Class 5, stone dust, aughts (0s) and ones (1s), or stone aggregate

2. Use appropriate lifting equipment to place the FMS into the center of the hole. Lifting

loops are provided on eit her side of the FMS for attaching a sling or chain.

3. Use a carpenter’s level to verify that the FMS is level. If it is necessary to add or remove

fill for leveling, tamp any added fill to maintain the base stability.

3.4 Cable Conduit Installation

Select the conduit entrance hole(s) for the OSP feeder and distribution cables. Refer to Figure 4

for the location of the holes. If necessary, additional conduit entrance holes may be cut using a

power drill and hole saw. Place and route the conduit into the entrance hole(s). If preferred, the

FMS may be installed without conduit . OSP cables may be routed into the FMS at any point tha t

is convenient. Cut the cable entrance hole to match the size of the cable.

3.5 Grounding System Installation

Install a grounding system (not provi ded ) that meets all loc al electr ical codes. C heck local codes

for grounding system installation, use of clamps, wire size, and any other grounding

requirements. Typically, #6 AWG copper wire is used for the grounding wire. Install the

grounding syste m inside the FMS where it will not interfere with the conduit or cables. Connect

the grounding wire to the grounding system. Leave sufficient slack in the grounding wire to

allow it to be routed into the cabinet after the cabinet is mounted on the sleeve.

3.6 Back Fill

If installing conduit, hand shovel stone aggregate under the conduit to avoid damage from the

power tamper. Complete the back fill as follows:

1. Add stone aggregate evenly around the FMS and tamp. Fill to approximately 6 inches

(15.2 cm) from the top of the excavation.

2. Complete the back-fill with crushed rock or topsoil depending on the landscaping

requirements. The top surface of the mounting sleeve may be located from 0 to 4 inches

(10.2 cm) above the surrounding grade (see Figure 4).

3.7 Mounting the Cabinet on the FMS-20000

The following sections provide instructions for mounting the ACE-142S/142V cabinet on the

FMS-20000. With the ACE-142S cabinet, the distribution cables must be installed after the

cabinet is mounted. With the ACE-142V cabinet, the distribution cables are pre-installed in the

cabinet by the factory. If mounting an ACE-142S cabinet, refer to Section 3.7.1 for the cabinet

mounting procedure. If mounting an ACE-142V cabinet with pre-installed distribution cables,

refer to Section 3.7.2 for t he cabinet mounting proce dur e. Use the 216B key tool to un-latch and

latch the cabinet doors as need ed during the mounting process.

Page 10

© 2004, ADC Telecommunications , Inc.

Page 17

ADCP-96-015 • Issue 1 • July 2004

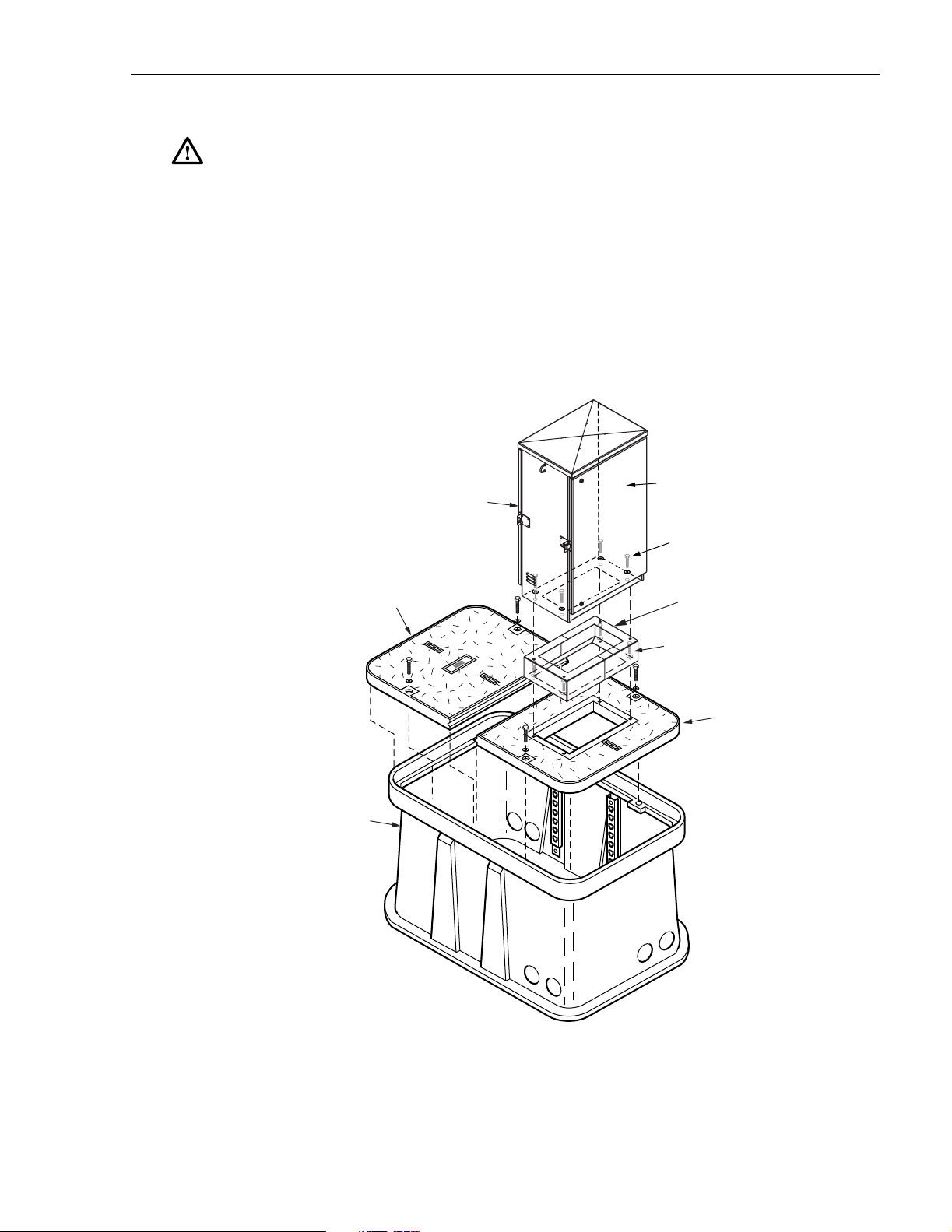

Warning: Use appropriate lifting equipment when moving or installing the cabinet. Do not

stand under a cabinet as it is being hoisted into position for mounting. A failure of the lifting

equipment could result in serious personal injury.

3.7.1 Mounting the ACE-142S Cabinet on the FMS-20000

Use the following procedure to mount an ACE-142 cabinet on the FMS-20000:

1. Install the FMS adapter cover onto the FMS and secu re using the t wo capscrews and flat

washers provided with the cover as shown in Figure 5. Tighten each capscrews securely.

ACE-142S

CABINET

FRONT

(REAR)

FMS SLEEVE

FMS-20000

COVER

HEX BOLTS, FLAT

WASHERS, AND

NUTS (4 PLACES)

GROUND SPACER

(ACCESSORY)

CAPSCREWS, LOCK

WASHERS, AND FLAT

WASHERS (4 PLACES)

FMS ADAPTER

COVER

19607-B

Figure 5. Mounting the ACE-142S Cabinet on the FMS-20000

© 2004, ADC Telecommunications , Inc.

Page 11

Page 18

ADCP-96-015 • Issue 1 • July 2004

2. If a ground spacer (accessory) will not be installed, proceed to step 7. If a ground spacer

will be installed, align the ends of the left ground spacer section with the ends of the right

ground spacer section and then press the two sections together.

3. Place the assembl ed ground spacer in position for mounting on the adapter cov er.

4. Align the mounting holes in the ground spacer with the mounting holes in the adapter

cover.

5. Secure the ground spacer to the adapter cover using the f our capscrews, four lock washers,

and four flat washers provided with the cabinet. Tighten all capscrews securely.

6. Open the rear door of the cabinet and remove the back section of the cabinet bottom cover

as described in Section 5.1. Then return to step 7 of this procedure to finish mounting the

cabinet.

7. Using appropriate lifting equipment, hold the cabinet in position for mounting onto the

ground spacer or adapter cover.

8. Lo wer the cabinet onto the groun d spa cer or adapter cover and align the mounting hole s in

the bottom of the cabinet with the holes in the spacer or cover.

9. If the installation includes a ground spacer, secure the cabinet to the spacer using the four

hex bolts, four flat washers and four nuts provided with the spacer. If the installation does

not include a ground spacer, secure the cabinet to the adapter cover using the four hex

bolts, lock flat washers, and four flat washers provided with the cabinet. Tighten all

fasteners secur ely.

10. If the FMS will be used as a splicing vault for the OSP feeder and distribution cables,

install the requi red spli ce en clo su re.

11. Install the FMS sleeve cover onto the FMS and secure using the two capscrews and

washers provided with the cover. Tighten both capscrews securely.

3.7.2 Mounting The ACE-142V Cabinet on the FMS-20000

Use the following pr ocedure to mount the ACE-142V cabinet on the FMS-20000:

1. Mount the FMS adapter cover on the FMS and secure using the two capscrews and flat

washers provided with the cover as shown in Figure 6. Tighten each cap screw securely.

2. If a ground spacer (accessory) will not be installed, proceed to step 7. If a ground spacer

will be installed, align the ends of the left ground spacer section with the ends of the right

ground spacer section and then press the two sections together.

3. Place the assembl ed ground spacer in position for mounting on the adapter cov er.

4. Align the mounting holes in the ground spacer with the mounting holes in the adapter

cover.

5. Secure the ground spacer to the adapter cover using the f our capscrews, four lock washers,

and four flat washers provided with the cabinet. Tighten all capscrews securely.

6. Open the rear door of the cabinet and remove the back section of the cabinet bottom cover

as described in Section 5.1. Then return to step 7 of this procedure to finish mounting the

cabinet.

Page 12

© 2004, ADC Telecommunications , Inc.

Page 19

ACE-142V

CABINET

ADCP-96-015 • Issue 1 • July 2004

FMS SLEEVE

FMS-20000

COVER

FRONT SIDE

REAR SIDE

HEX BOLTS, FLAT

WASHERS, AND

NUTS (4 PLACES)

GROUND SPACER

(ACCESSORY)

CAPSCREWS, LOCK

WASHERS, AND FLAT

WASHERS (4 PLACES)

FMS ADAPTER

COVER

19814-A

Figure 6. Mounting The ACE-142V Cabinet on the FMS-20000

7. Using appropriate lifting equipment, hold the cabinet in position over the FMS-20000 so

the cabinet is suspended over the rectangular opening in the top of the ground spacer or

adapter cover.

8. Carefully route the distribution cables through the rectangular opening in the ground

spacer or adapter cover and into the FMS-20000.

Note: The cables are coiled on spools for shipment. On each spool is a label that lis ts each

fiber subunit within the cabl e and the connect or panels wh ere each subunit is term inated.

After the cable is unspooled, label each cable with the corresponding fiber subunit and

connector panel designa tions. In additi on, tag or label the stub end of each cabl e so that the

cable can be identif ie d after being routed to the splice enclosure.

9. Lo cate the ends of the c onduit sect ions that were installed in the bottom of the FMS-20000.

© 2004, ADC Telecommunications , Inc.

Page 13

Page 20

ADCP-96-015 • Issue 1 • July 2004

10. Feed each distribution cable into the appropriate conduit section and route to the splice

enclosure (not provided). An y excess cable slack may be stored in the bottom of the FMS.

Note: A separate splice enclosure (not provided) is required for splicing the cabinet OSP

distribution cables to the system OSP distribution cables. If preferred, the splice enclosure

for the distribution cables may be mounted within the FMS-20000.

11. Lo wer the cabinet onto the groun d spa cer or adapter cover and align the mounting hole s in

the bottom of the cabinet with the holes in the cover.

12. If the installation includes a ground spacer, secure the cabinet to the spacer using the four

hex bolts, four flat washers and four nuts provided with the spacer. If the installation does

not include a ground spacer, secure the cabinet to the adapter cover using the four

capscrews, four lock washe rs , a nd fou r fl at w as hers p r ovide d with t he cabinet. Tighten al l

fasteners secur ely.

13. Install the FMS sleeve cover onto the FMS and secure using the two capscrews and

washers provided with the cover. Tighten both capscrews securely.

Page 14

© 2004, ADC Telecommunications , Inc.

Page 21

4 MOUNTING THE CABINET ON A CONCRETE PAD

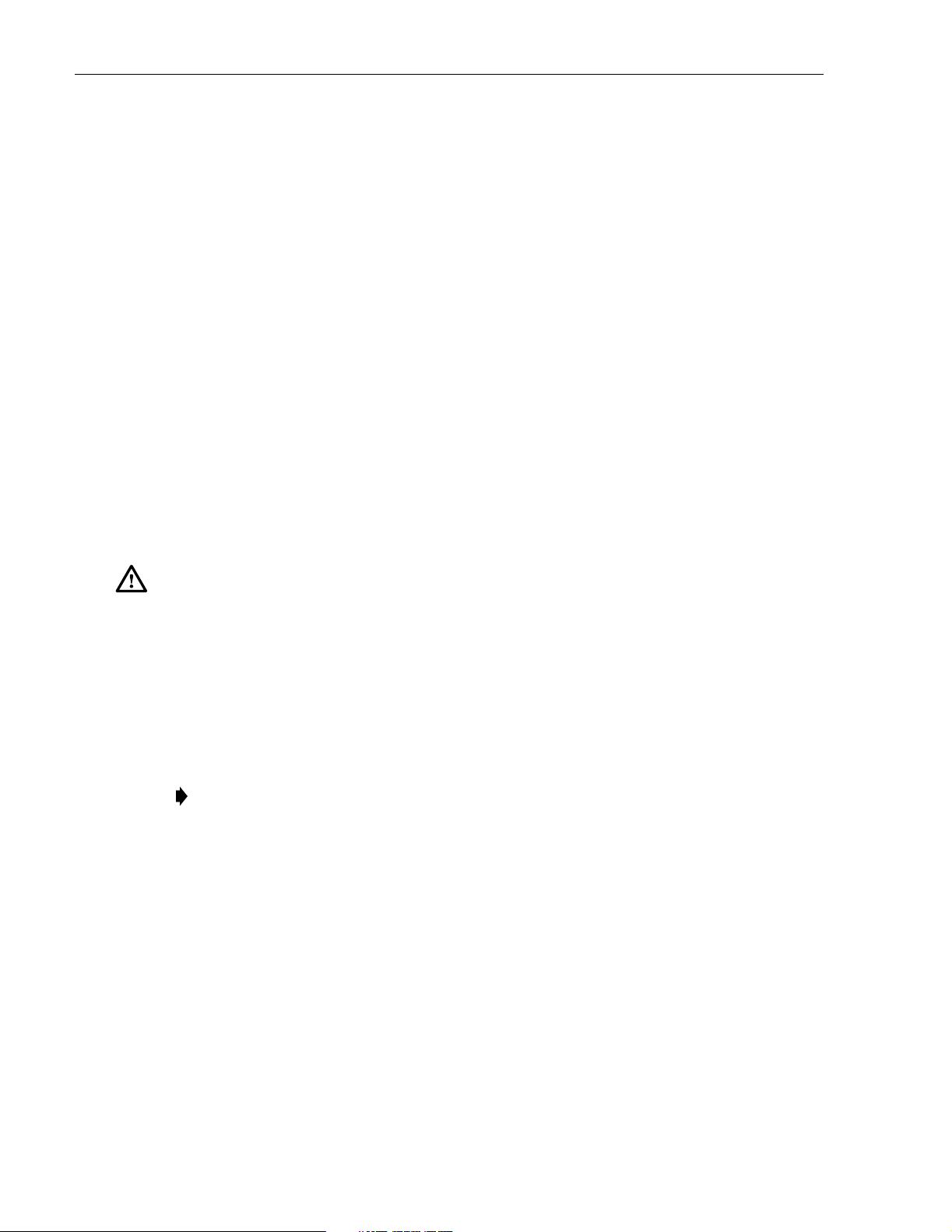

The Pad Mount Frame (PMF), shown in Figure 7, is a stainless steel frame that provides a

mounting base for the cabinet when installed in a concrete pad foundation.

Caution: Mounting the cabinet directly on a concrete pad may cause chemical corrosive action

to the cabinet. Use only the Pad Mount Frame (PMF) as a mounting base for the cabinet. Do

not use caulking compounds as a sealer between the cabinet and the PMF.

ADCP-96-015 • Issue 1 • July 2004

5.5 IN.

(14.0 CM)

4.1 Installation Recommendations

The site chosen for the installation must conform to all local codes and any permits required

must be obtained prior to the start of installation. The location must be accessible and provide

adequate parking for worker and vehicle safety. Situate the concrete pad along the trench that

was used for routing the OSP fibe r cables for the system.

The installed cabinet must not create a visual or physical obstruction to vehicular or pedestrian

traffic. Ensure that there is sufficient space on all sides to facilitate cabinet installation.

Depending on the landscaping requirements, the top surface of the concrete pad may be located

from 0 to 3 inches (7.6 cm) above the surrounding grade.

4.2 Cable Conduit Installation

Install the cable conduit from below as shown in Figure 8 and position it so that the top of each

upward bend will be located within the PMF opening at the indicated point. When installed, the

top of the conduit should be lo cate d 1 to 2 inches (2.54 to 5.08 cm) below the top of the finished

concrete pad. Install the conduit before pouring the pad.

25.8 IN.

(65.5 CM)

Figure 7. Pad Mount Frame Dimensions

16.4 IN.

(41.7 CM)

19065-C

4.3 Base Installation

Prepare a base f or the concrete pad that meets all local code requir ements. The base must have a

footing of 4 to 6 inches (10.2 to 15.2 cm) of sand or gravel (per local practice) on firmly

compacted soil. Refer to the construction diagram (see Figure 8) for details.

© 2004, ADC Telecommunications , Inc.

Page 15

Page 22

ADCP-96-015 • Issue 1 • July 2004

DISTRIBUTION CABLES

4 IN DUCT FOR

(LOCATE 1 - 2 INCHES

BELOW TOP OF PAD)

44.0 IN.

(111.8 CM)

30.6 IN.

(77.7 CM)

26.1 IN.

(66.4 CM)

9.0 IN.

(22.9 CM)

28.0 IN.

(71.1 CM)

4 IN DUCT FOR

FEEDER CABLES

(LOCATE 1 - 2 INCHES

BELOW TOP OF PAD)

PAD MOUNT FRAME

CAST IN PLACE

REINFORCED

CONCRETE PAD

6 IN.

(15.2 CM)

SAND OR

GRAVEL

4 IN. MIN.

(10.2 CM)

FRONT

DO NOT POUR CONCRETE INSIDE

THE PAD MOUNT FRAME

90 BEND

IN DUCT

COMPACTED SOIL

TOP OF PMF SHOULD

BE FLUSH WITH TOP

OF CONCRETE

33.0 IN.

(83.8 CM)

72.0 IN.

(182.9 CM)

GROUNDING ROD

(LOCATE 1 - 2 INCHES

BELOW TOP OF PAD)

TOPSOIL OR

DECORATIVE ROCK

GRADE

Page 16

© 2004, ADC Telecommunications , Inc.

19616-A

Figure 8. Constructing the Concrete Pad for the ACE-142S/142V Cabinet

Page 23

4.4 Concrete Pad Construction

Use the following procedure to construct the concrete pad:

1. Build a wood form for the concre te pad using 2 x 6 framing lumber as shown in Figure 9.

2. Locate the PM F as shown in the co nst ructio n diagra m (se e Figure 8). When installed, the

top surface of the PMF must be flush and level with the top of the concrete pad.

Note: Use temporary top framing to keep the top surface of the PMF flush and level with

the top of the concrete pad (see Figure 9).

3. Place reinfor cing material inside the form but outside of the PMF.

DIMENSIONS SHOW FINISHED

SIZE OF CONCRETE PAD

(182.9 CM)

ADCP-96-015 • Issue 1 • July 2004

44 IN.

(111.8 CM)

72 IN.

LEVELING

STAKES

(4 PLACES)

FRONT

PAD MOUNT

FRAME (PMF)

TEMPORARY

SUPPORT WIRES

(4 PLACES)

2 x 6 FRAMING

FOR FORM

19615-A

Figure 9. ACE-142S Cabinet Concrete Pad Framing

4. Verify that the PMF and form are level. Depending on the landscaping requirements, the

top surface of the concrete pad may be 0 to 3 inches (0 to 7.6 cm) above the final grade. The

weld nuts ar e c ov e red wi th pl ugs whic h mus t b e le ft in pla ce until t he e ncl osure is mo unte d.

5. Pour the c oncrete to form the pad but do not pour concret e into the center area of the PMF.

Note: Allow some concrete to flow under the flanges on the bottom of the PMF so the

PMF will be locked in place when the concrete hardens. However, do not allow concrete to

fill the center of the PMF. If necessary, partially fill the center of the PMF with sand or

gravel to pr event an inflow of concrete.

6. Remove the top framing and the temporary support wires when the concrete is ready to be

finished.

7. Allo w concrete to cure before proceeding with the installation.

© 2004, ADC Telecommunications , Inc.

Page 17

Page 24

ADCP-96-015 • Issue 1 • July 2004

4.5 Grounding System Installation

Install a grounding system (not provi ded ) that meets all loc al electr ical codes. C heck local codes

for grounding system installation, use of clamps, wire size, and any other grounding

requirements. Typically, #6 AWG copper wire is used for the ground wire. If the grounding

system includes a ground rod, install the rod (see Figure 8) within the PMF opening at the

indicated point. When installed, the top of the rod should be located 1 to 2 inches (2.54 to 5.08

cm) below the top of the finished concrete pad. Connect the grounding wire to the grounding

system. Leave sufficient slack in the grounding wire to allow it to be routed into the cabinet

after the cabinet is mounte d on the pad.

4.6 Mounting the Cabinet on the Concrete Pad

The following sections provide instructions for mounting the ACE-142S/142V cabinet on the

concrete pad. With the ACE-142S cabinet, the distribution cables must be installed after the

cabinet is mounted. With the ACE-142V cabinet, the distribution cables are pre-installed in the

cabinet by the factory. If mounting an ACE-142S cabinet, refer to Section 4.6.1 for the cabinet

mounting procedure. If mounting an ACE-142V cabinet with pre-installed distribution cables,

refer to Section 4.6.2 for t he cabinet mounting proce dur e. Use the 216B key tool to un-latch and

latch the cabinet doors as need ed during the mounting process.

Warning: Use appropriate lifting equipment when moving or installing the cabinet. Do not

stand under the cabinet as it is being hoisted into position for instal lation. A failure of the lifting

equipment could result in serious personal injury.

4.6.1 Mounting the ACE-142S Cabinet on a Concrete Pad

Use the following pr ocedures to mount the ACE-142S cabinet on the concrete pad.

1. Remove the plastic plugs that are in stalled in the threaded co rner holes of the PMF and

clean off an y concrete that may have adhered to the top of the PMF.

Note: Make sure all remnants of concrete are removed from the PMF prior to mounting

the cabinet. It is not necessary to use shims to level or align the cabinet as long as the top

surface of the PMF is clean and free of any installation debris.

2. If a ground spacer will not be installed, proceed to step 7. If a ground spacer (acces sory)

will be installed, align the ends of the left ground spacer section with the ends of the right

ground spacer section and then press the two sections together.

3. Place the assembled ground spacer in position for mounting on the PMF as shown in

Figure 10.

4. Align the mounting holes in the ground spacer with the mounting holes in the PMF.

5. Secure the ground spacer to the PMF using the four capscrews, four lock washers, and

four flat washers pro vided with the cabinet. Ti ghten all capscrews securely.

6. Open the rear door of the cabinet and remove the back section of the cabinet bottom cover

as described in Section 5.1. Then return to step 7 of this procedure to finish mounting the

cabinet.

Page 18

© 2004, ADC Telecommunications , Inc.

Page 25

ACE-142S

CABINET

(FRONT)

HEX BOLTS, FLAT

WASHERS, AND

NUTS (4 PLACES)

CAPSCREWS, LOCK

WASHERS, AND FLAT

WASHERS (4 PLACES)

ADCP-96-015 • Issue 1 • July 2004

GROUND

SPACER

(ACCESSORY)

CONCRETE

PAD

19617-B

CABLE

CONDUIT

PAD MOUNTING

FRAME (PMF)

Figure 10. Mounting the ACE-142S Cabinet on the Concrete Pad

7. Using appropriate lifting equipment, hold the cabinet in position for mounting over the

ground spacer or PMF.

8. Lower the cabinet onto the ground spacer or PMF and align the mounting holes in the

cabinet base with the threaded holes in the spacer or PMF.

9. If the installation includes a ground spacer, secure the cabinet to the spacer using the four

hex bolts, four flat washers and four nuts provided with the spacer. If the installation does

not include a gro und spacer, secure the cabi net to the PMF using the four hex bol ts, lock

flat washers, and four flat washers provided with the cabinet. Tighten all fasteners securely.

4.6.2 Mounting the ACE-142V Cabinet on a Concrete Pad

Use the following pr ocedures to mount the ACE-142V cabinet on the concrete pad.

1. Remove the plastic plugs that are in stalled in the threaded co rner holes of the PMF and

clean off an y concrete that may have adhered to the top of the PMF.

© 2004, ADC Telecommunications , Inc.

Page 19

Page 26

ADCP-96-015 • Issue 1 • July 2004

Note: Make sure all remnants of concrete are removed from the PMF prior to mounting

the cabinet. It is not necessary to use shims to level or align the cabinet as long as the top

surface of the PMF is clean and free of any installation debris.

2. If a ground spacer will not be installed, proceed to step 7. If a ground spacer (access ory)

will be installed, align the ends of the left ground spacer section with the ends of the right

ground spacer section and then press the two sections together.

3. Place the assembled ground spacer in position for mounting on the PMF as shown in

Figure 11.

ACE-142S

CABINET

(FRONT)

HEX BOLTS, FLAT

WASHERS, AND

NUTS (4 PLACES)

GROUND

CAPSCREWS, LOCK

WASHERS, AND FLAT

WASHERS (4 PLACES)

CONCRETE

PAD

PAD MOUNTING

FRAME (PMF)

CABLE

CONDUIT

SPACER

(ACCESSORY)

19816-A

Figure 11. Mounting the ACE-142V Cabinet on the Concrete Pad

4. Align the mounting holes in the ground spacer with the mounting holes in the PMF.

5. Secure the ground spacer to the PMF using the four capscrews, four lock washers, and

four flat washers pro vided with the cabinet. Ti ghten all capscrews securely.

Page 20

© 2004, ADC Telecommunications , Inc.

Page 27

ADCP-96-015 • Issue 1 • July 2004

6. Open the rear door of the cabinet and remove the back section of the cabinet bottom cover

as described in Section 5.1. Then return to step 7 of this procedure to finish mounting the

cabinet.

7. Using appropriate lifting equipment, hold the cabinet in position over the pad (see

Figure 11) so the cabinet is suspended over the rectangular opening in the top of the

ground spacer or PMF.

8. Feed each distribution cable into the appropriate conduit section and route to the splice

enclosure (not provided).

Note: The cables are coiled on spools for shipment. On each spool is a label that lis ts each

fiber subunit within the cabl e and the connect or panels wh ere each subunit is term inated.

After the cable is unspooled, label each cable with the corresponding fiber subunit and

connector panel designa tions. In additi on, tag or label the stub end of each cabl e so that the

cable can be identif ie d after being routed to the splice enclosure.

Note: A separate splice enclosure (not provided) is required for splicing the cabinet OSP

distribution cables to the system OSP distribution cables.

9. Lower the cabinet onto the ground spacer or PMF and align the mounting holes in the

cabinet base with the threaded holes in the spacer or PMF.

10. If the installation includes a ground spacer, secure the cabinet to the spacer using the four

hex bolts, four flat washers and four nuts provided with the spacer. If the installation does

not include a gro und spacer, secure the cabi net to the PMF using the four hex bol ts, lock

flat washers, and four flat washers provided with the cabinet. Tighten all fasteners securely.

© 2004, ADC Telecommunications , Inc.

Page 21

Page 28

ADCP-96-015 • Issue 1 • July 2004

5 FEEDER CABLE INSTALLATION AND SPLICING

This section describes how to install the OSP feeder cables in the ACE-142S/142V cabinet and

how to use the feeder cable spl i ce tray s .

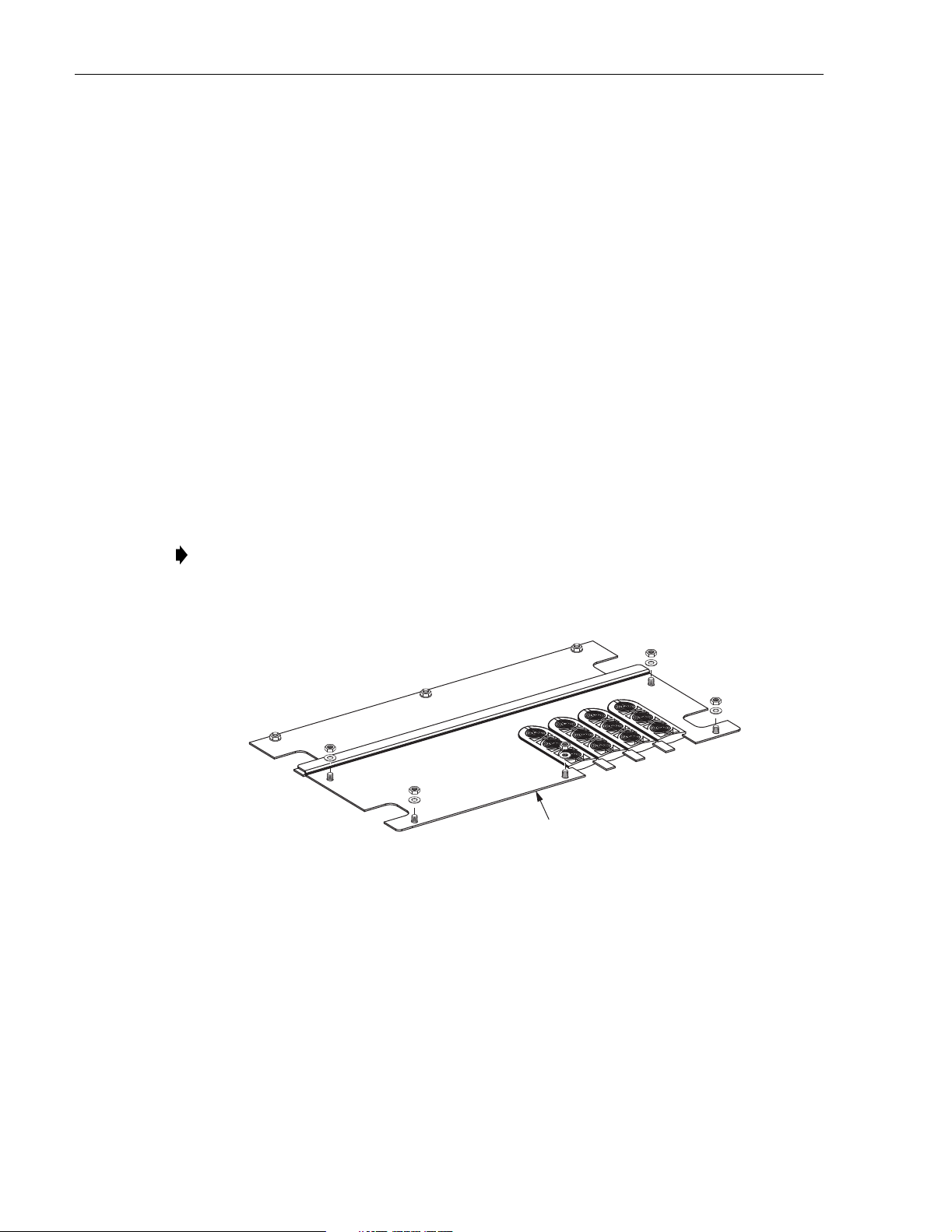

5.1 Bottom Cover Removal

The ACE-142S/142V cabinet is equipped with a two-piece bottom cover that prevents moisture

and dirt from entering the cabinet through the bottom. The cable-entry section of the bottom

cover m ust be removed to allow i nstallation of the OSP c ables. If the bottom cover was removed

previously, skip this section and proceed to Section 5.2. Use the following procedure to remove

the cable-entry section of the cabinet bottom cover from the cabinet:

1. Open the rear door of the cabine t.

2. Remove the five lock nuts and five flat washers that secure the cable-entry section of the

bottom cover to the cabinet as shown in Figure 12. Save the nuts and washers for reuse.

3. Lift up the cable-entry section of the bottom cover and push it toward the front of the

cabinet so it will be out of the way when the OSP cables are installed.

Note: Be careful not to da mage the gaskets tha t are attac hed to the underside of the bottom

cover. If the dis tribution ca bles are pr e-ins talled, the grom ments ma y be left in place over

the cables wh en the co ver i s removed.

Figure 12. Bottom Cover Cable-Entry Section Removal

5.2 Cabinet Grounding Wire Connection

Prior to mounting the cabinet, a grounding system should have been installed and a grounding

wire should have been connected to the grounding system (see Section 3.5 or Section 4.5). Use

the follo wing procedure to attached the grounding wire to the cabinet grounding lug:

19608-A

REMOVE BACK SECTION

OF BOTTOM COVER

1. Locate the grounding wire that w as installed prior to mounting the cabinet and pull several

feet of slack up and into the cab in et .

Page 22

© 2004, ADC Telecommunications , Inc.

Page 29

ADCP-96-015 • Issue 1 • July 2004

2. Attach the grounding wire to the grounding lug as shown in Figure 13. The grounding lug

can be used for #6 – #14 AWG wire. Tighten the grounding lug set screw securely.

3. Lea ve suffic ient slack so the grounding wire can be repositioned as needed when the cable

entry section of the bottom co ver is re-installed.

NOTE: SHOWN WITH BOTH

THE FRONT AND REAR

SECTIONS OF THE BOTTOM

COVER (MOISTURE BARRIER)

REMOVED.

5.3 Feeder Cable Installation

The OSP feeder cable enters/exits the ACE-142S/142V cabinet from the bottom. At the entry/

exit point to the cabinet, the feeder cable is secured with a clamp. Beyond the clamp, the outer

sheath of the cable is removed to expose the optical fibers. The feeder cable is typically a 12- to

24-fiber cable with stranded or ribbon type fiber construction. Moisture blocking and/or

grounding kits should be installed (as required by local practice) to protect the exposed optical

fibers. From t he clamp ing point , the opti cal fibers are routed to sp lice tra ys for splic ing to th e

splitter input fibers.

CABINET GROUNDING LUG

(#6 - #14 AWG WIRE)

Figure 13. Grounding Wire Connection To Cabinet

GROUNDING

STUDS FOR

OSP CABLES

WITH METALIC

ELEMENTS

19610-A

Note: If additional splitter modules will be installed in the cabinet as part of the initial

installation, complete splitter installation before proceeding with feeder cable installation.

Refer to Section 10 for the splitter module installation procedure.

Use the following procedure to install the feeder cable:

1. Route the OSP feeder cable into the cabinet from the bottom. If the cabinet is mounted on

a concrete pad, use the duct on the right side.

2. Pull the cable up through the cabinet and strip off 156 inches (396 cm) of the outside cable

sheath to expose the f iber subunits.

3. Install moisture-blocking and/or grounding kits as required by local practice. Follow the

installati on instructions provided with each kit.

© 2004, ADC Telecommunications , Inc.

Page 23

Page 30

ADCP-96-015 • Issue 1 • July 2004

Note: A blocking kit is recommended when installing ribbon cable. The blocking kit

includes plastic tubes that protect the fiber ribbons and prevent damage. If a grounding kit

is required, strip the cable sheath to the recommended length and install the grounding

clamp prior to se curi ng the cab le to the cab inet .

4. Three cable clamping positions are provided for securing feeder cables as shown in

Figure 14. Select one of the clamping positions as the attachment point for the cable.

Note: Use the middle cable clamp position first and the top clamp position second when

installing the feeder cables. The bottom clamp position is an extra. The bracket for the top

row of clamps may be removed if necessary to facilitate cable installation.

19740-A

CLAMPS FOR

ATTACHING THE

FEEDER CABLES

(3 PLACES)

Figure 14. Feeder Cable Clamping Positions

5. Back out the two 2-inch long 6-32 screws that secure the two clamps and cover plate to the

cabinet.

6. Assemble the clamps (and grommet if required) on the cable as shown in Figure 15 an d

then secure the cable to cabinet at the clamping position selected in step 4.

7. If a grounding kit was installed on the cable, attach the cable grounding lead to one of the

grounding studs locate d within the cabinet (see Figure 13).

8. From the cable clamping location, route the first fiber subunit up the right side of the

cabinet as shown in Figure 16.

Page 24

© 2004, ADC Telecommunications , Inc.

Page 31

CABLE

USE GROMMET

FOR SMALLER

DIAMETER CABLES

COVER

PLATE

ADCP-96-015 • Issue 1 • July 2004

FEEDER CABLE

SPLICE TRAYS

CLAMPS

Figure 15. Cable Clamp Assembly for Feeder Cable

SECURE FEEDER CABLE

AND SPLITTER INPUT FIBERS

TOGETHER AT THIS POINT

19623-A

SCREWS

SPLITTER INPUT

FIBER ROUTING

CENTER PANEL

TIE POINT

SECURE FEEDER CABLE

TO PANEL ON RIGHT

SIDE OF CABINET

19625-A

Figure 16. Feeder Cable Fibers Routed To Splice Trays

© 2004, ADC Telecommunications , Inc.

CABLE

CLAMP

Page 25

Page 32

ADCP-96-015 • Issue 1 • July 2004

9. Secure the fiber subunit to the panel on the right side of the cabinet using the tie points

provided.

10. From the right side of the cabinet, route the fiber subunit to the center panel located just

below the spli tter modules and secure using the tie point provided.

11. From the center panel, route the fiber subunit to the splice wheel used for the splitter

module input fibe rs following the same path as the splitter module input fibers.

12. Repeat steps 1–11 fo r each fee der cable subunit and each additional feede r cable.

5.4 Feeder Cable and Splitter Input Fiber Splicing

The OSP feeder cable fibers must be spliced to the splitter input fibers. Up to twelve splitter

modules may be mounted in the cabinet so that a maximum of twelve feeder splices may be

required. Round splice trays are used for splicing and seven splice tray mounting slots are

provided. Each splice tray can hold up to 12 splices. Use the following procedure to install the

feeder cable fibers and splitter input fibe rs in each splice tray in preparation for splicing:

1. The input fibers from each splitter are routed to a splice tray located on the top left side of

the cabinet. Locate the splice tray that was used for the splitter input fibers and remove

that tray from the cabinet.

2. Uncoil the spli tter input fibers from the splice tray.

Note: The splitter input fibers are temporarily coiled around the splice tray for storage.

3. Secure the splitter input fibers and the feeder cable fiber subunit together at the point

where the two com e toget her before enteri ng the splice tray (s ee Figure 16). Adjust slack

as necessary to prevent binding.

4. Check the routing of the splitter input fibers and adjust as needed to relieve tension or

remove excess slack.

5. Starting at the common tie point within the cabinet, measure and mark the f iber cut lengths

for the splitter input fibers and the feeder cable fiber subunits as shown in Figure 17.

CUT LENGTH* 68 TO 146 IN

(173 TO 371 CM)

BREAKOUT

LENGTH 37 IN

(94 CM)

BREAKOUT

LENGTH 48 IN

(122 CM)

SPLITTER INPUT FIBER

FEEDER CABLE

FIBER SUBUNIT

*THE CUT LENGTH MUST BE

THE SAME FOR BOTH FIBERS

COMMON TIE

POINT IN CABINET

19220-A

Figure 17. Cut Length and Breakout Length for Feeder Cable and Splitter Input Fiber

Page 26

© 2004, ADC Telecommunications , Inc.

Page 33

ADCP-96-015 • Issue 1 • July 2004

6. Cut both the splitter input fibers and the feeder cable fiber subunit at the cut length mark.

Make sure that the splitter input fibers and the feeder cable fiber subunit are of equal

length and the overall length is within the range specified.

7. Starting at th e cut end, measure b ackward and ma rk the break-out len gths for the feede r

cable fibers and the splitter input fibers.

8. Starting at the breakout mark, remove the protective jackets to expose the feeder cable

fibers (may be stranded or ribbon fibers) and the splitter input fibers.

9. Instal l the splitter input fibers and the feeder cable fibers in the splice tray and complete all

splices per local practice. Refer to Section 7 for information on how to use the round

splice trays and then retu rn to Step 10 to continue this procedure.

10. After splici ng is comp leted, the splice tray cover replac ed, and the excess slack roll ed up,

insert the splice tray into the designated mounting slot.

11. Repeat this procedure for each feeder cable fiber sub unit.

12. Designation labels, shown in Figure 18 and Figure 19, are provided on the front door of

the cabinet for recording splitter module information. For each splitter, indicate the splice

tray number, feeder cable fiber number, splitter module number, and service information.

FRONT DOOR REAR DOOR

SPLITTER

MODULES

12

11

10

9

8

7

6

5

SPLITTER MODULE LABEL

4

3

2

1

19629-A

Figure 18. Splitter Module Designation Label - Type 1

© 2004, ADC Telecommunications , Inc.

Page 27

Page 34

ADCP-96-015 • Issue 1 • July 2004

FRONT DOOR REAR DOOR

6

5

4

3

2

1

SPLITTER

MODULES

12

11

10

9

8

7

SPLITTER MODULE LABEL

Figure 19. Splitter Module Designation Label - Type 2

19739-A

Page 28

© 2004, ADC Telecommunications , Inc.

Page 35

6 DISTRIBUTION CABLE INSTALLATION AND SPLICING

This section desc ribes how to ins ta ll the OSP distribu tion cables in the ACE-142S/142V cabinet

and how to use the distribution cable splice trays. If the cabinet is equipped with pre-installed

distribution cables, refer to Section 6.2 for the bottom cover installation proc edure.

6.1 Distribution Cable Installation

The OSP distribution cables enter the ACE-142S/142V cabinet from the bottom. At the entry/

exit point to the cabinet, each distribution cable is secured with a clamp. Beyond the clamp, the

outer sheath of the cable is removed to expose the optical fibers. Moisture blocking, grounding,

and fanout kits must be installed (as required by local practice) to protect the exposed optical

fibers. The OSP distribution cable fiber count may be any multiple of 72 (depending on the

number of conne ctor panels) with stranded or ribbon type fiber construction. From the clamping

point, the optical fibers are routed to the splice tr ays for splicing to t he connector panel pigtails.

Use the following pr ocedure to install the distribution cable:

1. Route the OSP distribution cable into the cabinet from the bottom. If the cabinet is

mounted on a concrete pad, use the duct on the left side.

ADCP-96-015 • Issue 1 • July 2004

2. Pull the cable up through the cabinet and strip off 156 inches (396 cm) of the outside cable

sheath to expose the f iber subunits.

3. Install moisture-blocking, fanout, and grounding kits as required by local practice. Follow

the installation instructions provided with each kit.

Caution: A fanout kit is required when installing ribbon cable. The fanout kit includes plastic

tubes that protect the fiber ribbons and prevent damage.

4. Nine cable clamping positions are provided near the center of the cabinet as shown in

Figure 20. Select one of the clamping positions as the attachment point for the cable.

Note: Use the middle cable clamp positions first and the top clamp positions second when

installing the distribution cables. The bottom clamp positions are extra. The bracket for the

top row of clamps may be removed if necessary to facilitate cable installation.

19741-A

CLAMPS FOR

ATTACHING THE

DISTRIBUTION CABLES

(9 PLACES)

Figure 20. Distribution Cable Clamping Positions

© 2004, ADC Telecommunications , Inc.

Page 29

Page 36

ADCP-96-015 • Issue 1 • July 2004

5. Back out the two 2-inch long 6-32 screws that secure the two clamps and cover plate to the

cabinet.

6. Assemble the clamps (and grommet if required) on the cable as shown in Figure 21 an d

then secure the cable to cabinet at the clamping position selected in step 4.

CABLE

USE GROMMET

FOR SMALLER

DIAMETER CABLES

COVER

PLATE

CLAMPS

19623-A

SCREWS

Figure 21. Cable Clamp Assembly for Distribution Cable

7. If a grounding kit was installed on the cable, attach the cable grounding lead to one of the

grounding studs locate d within the cabinet (see Figure 13).

8. Repeat steps 1 through 7 for each additional distribution cable.

9. From the cable clamping location, route the fi rst six distrib ut ion cable f i ber subunit s up the

right side of the cabin et as shown in Figure 22.

10. Secure the subunits to the panel on the right side of the cabinet using the tie points

provided.

11. Use a Phillips screwdriver to remove the four screws that secure the handle assembly to

the back of connector panel #1 (top panel) as shown in Figure 23. Save each screw for

reuse.

12. Remove the handle assembly from the back of connector panel #1.

13. Route the first six fiber subunits across the back of connector panel #1 to splice trays 1–6

located on the left side of the cabinet.

Note: The splice trays are numbered 1 through 30 starting with the top splice tray in

connector panel #1. Route all distribution cable fibers to the splice trays starting with the

top tray and working towards the bottom tray.

14. Secure each fiber subunit to the back of the connector panel using the tie points indicated

in Figure 22.

15. Use the same basic procedure specified in steps 8 through 14 for routing the remaining

distribution cable fiber subunits to the remaining distribution cable splice trays. Repea t the

routing process until every fiber subunit is routed to a splice tray.

Page 30

© 2004, ADC Telecommunications , Inc.

Page 37

DISTRIBUTION CABLE

SPLICE TRAYS 1 - 6

DISTRIBUTION CABLE

SPLICE TRAYS 7 - 12

ADCP-96-015 • Issue 1 • July 2004

DISTRIBUTION CABLE

TIE OFF COLUMNS

(CONNECTOR PANEL #1)

DISTRIBUTION CABLE

SPLICE TRAYS 13 - 18

DISTRIBUTION CABLE

SPLICE TRAYS 19 - 24

DISTRIBUTION CABLE

SPLICE TRAYS 25 - 30

SECURE DISTRIBUTION

CABLE TO PANEL ON

RIGHT SIDE OF CABINET

CABLE

CLAMPS

19633-A

Figure 22. Distribution Cable Fibers Routed to Splice Trays

REAR HANDLE

ASSEMBLY

Figure 23. Rear Handle Assembly Removal and Installation

© 2004, ADC Telecommunications , Inc.

19614-A

Page 31

Page 38

ADCP-96-015 • Issue 1 • July 2004

6.2 Bottom Cover Installation

The cable-entry section of the bottom cover must be replaced following installation of the

grounding wire, feeder cable(s), and distribution cable(s). Use the following procedure to

replace the cable-entry section of the bottom cover:

1. Locate the b otto m cover (ca ble-entry secti on) that was rem oved fr o m th e cabi n et i n step 2

of Section 5.1.

2. Determine which grommets will be use d for sealing the cable entry/exit points and remove

those grommets from their mounting slots in the bottom cover.

3. Using a utility knife, cut through the slit that runs lengthwise down the center of each

grommet as shown in Figure 24.

4. Remove enough cable cutout sections from each grommet to accommodate the size and

number of cables that will pass thr ough the grommet.

REMOVE CABLE

CUTOUT SECTIONS

BOTTOM

COVER

CUT SLIT

GROUNDING

WIRE

DETAIL DRAWIING

OF GROMMET

Figure 24. Bottom Cover Installation

GROMMET

FEEDER

CABLE

DISTRIBUTION

CABLES

19609-A

5. Install the grommets on the cables.

Note: More than one cable may have to pass though the same grommet.

6. Insert the grommets into their respective mounting slots in the bottom cover.

Page 32

© 2004, ADC Telecommunications , Inc.

Page 39

7. Slide the bottom cover down to the bottom of the cabinet.

8. Align the five holes in the bottom cover with the f ive studs around the edge of the cabinet.

9. Install a flat washer and lock nut (removed in step 1 of Section 5.1) on each stud and

tighten securely.

6.3 Distribution Cable and Connector Panel Pigtail Splicing

The distribution cable must be spliced to the connector panel pigtails. Up to five 72-port

connector panels may be mounted in the cabinet which requires a maximum of 360 distribution

splices. Round splice trays are used for splicing and six splice tray mounting slots are provided

per panel. This equates to a maximum of 30 spice tra ys when fi v e connec tor panels are inst al led.

Each splice t ray can hold up to 12 splices. Use the fol lowing procedure to install the distr ibution

cable fibers and the connector panel pigtails in the splice tray in preparation for splicing:

1. Locate splice tr ay #1 (on the lef t side) and remove that tray from the cabinet.

Note: The pigtails from each connector panel are grouped into six 12-fiber subunits. Each

pigtail subunit is routed to a spli ce tray locat ed on the left s ide of the cabin et. The splic e

trays are numbered consecutively 1 through 30 starting with at the top. The subunit, port,

fiber, and splice tray designations for each connector panel are shown in Table 5.

ADCP-96-015 • Issue 1 • July 2004

2. Uncoil the connector panel pigtail subunit from the splic e tray.

Note: Each connector panel pigtail subunit is temporarily coiled around a splice tray for

storage.

3. Starting at the last column (left side) of tie points on the rear side of the connector panel,

measure and mark the fiber cut lengths for the distribution cable fiber subunits and the

connector panel fiber subunits as sho wn in Figure 25.

CUT LENGTH* 68 TO 146 IN

(173 TO 371 CM)

BREAKOUT

LENGTH 37 IN

(94 CM)

BREAKOUT

LENGTH 48 IN

(122 CM)

*THE CUT LENGTH MUST BE

THE SAME FOR BOTH FIBERS

Figure 25. Cut Length and Breakout Length for Distribution Cable and Connector Panel Fibers

DISTRIBUTION CABLE

FIBER SUBUNIT

CONNECTOR PANEL

FIBER SUBUNIT

COMMON

TIE POINT IN CABINET

19276-A

4. Cut both the distribution cable fiber subunit and the connector panel pigtail subunit at the

cut length mark. Make sure that the distribution cable fiber subunit and the connector

panel pigtail subunit are of equal length and the overall length is within the range

specified.

© 2004, ADC Telecommunications , Inc.

Page 33

Page 40

ADCP-96-015 • Issue 1 • July 2004

Table 5. Connector Panel Sub Unit, Port, Fiber, and Splice Tray Designations

SUB

UNIT

1

2

3

SUB

PORT FIBER SPLICE TRAY

1 1 (Blue) Tray 1 if Panel 1

UNIT

PORT FIBER SPLICE TRAY

37 1 (Blue) Tray 4 if Panel 1

2 2 (Orange) 38 2 (Orange)

3 3 (Green) 39 3 (Green)

4 4 (Brown) 40 4 (Brown)

Tray 7 if Panel 2

Tray 13 if P ane l 3

5 5 (S late) 41 5 (Sla te)

6 6 (White) 42 6 (White)

7 7 (Red) 43 7 (Red)

Tray 19 if P ane l 4

Tray 25 if P ane l 5

4

8 8 (Black) 44 8 (Black)

9 9 (Yellow) 45 9 (Yellow)

10 10 (Violet) 46 10 (Violet)

11 11 (Rose) 47 11 (Rose)

12 12 (Aqua) 48 12 (Aqua)

13 1 (Blue) Tray 2 if Panel 1

49 1 (Blue) Tray 5 if Panel 1

14 2 (Orange) 50 2 (Orange)

15 3 (Green) 51 3 (Green)

16 4 (Brown) 52 4 (Brown)

Tray 8 if Panel 2

Tray 14 if P ane l 3

17 5 (Sla te) 53 5 (Slate)

18 6 (White) 54 6 (White)

19 7 (Red) 55 7 (Red)

Tray 20 if P ane l 4

Tray 26 if P ane l 5

5

20 8 (Black) 56 8 (Black)

21 9 (Yellow) 57 9 (Yellow)

22 10 (Violet) 58 10 (Violet)

23 11 (Rose) 59 11 (Rose)

24 12 (Aqua) 60 12 (Aqua)

25 1 (Blue) Tray 3 if Panel 1

61 1 (Blue) Tray 6 if Panel 1

26 2 (Orange) 62 2 (Orange)

27 3 (Green) 63 3 (Green)

28 4 (Brown) 64 4 (Brown)

Tray 9 if Panel 2

Tray 15 if P ane l 3

29 5 (Sla te) 65 5 (Slate)

30 6 (White) 66 6 (White)

31 7 (Red) 67 7 (Red)

Tray 21 if P ane l 4

Tray 27 if P ane l 5

6

32 8 (Black) 68 8 (Black)

33 9 (Yellow) 69 9 (Yellow)

34 10 (Violet) 70 10 (Violet)

35 11 (Rose) 71 11 (Rose)

36 12 (Aqua) 72 12 (Aqua)

Tray 10 if Panel 2

Tray 16 if Panel 3

Tray 22 if Panel 4

Tray 28 if Panel 5

Tray 11 if Panel 2

Tray 17 if Panel 3

Tray 23 if Panel 4

Tray 29 if Panel 5

Tray 12 if Panel 2

Tray 18 if Panel 3

Tray 24 if Panel 4

Tray 30 if Panel 5

Page 34

© 2004, ADC Telecommunications , Inc.

Page 41

ADCP-96-015 • Issue 1 • July 2004

5. Starting at the cut end, measure backward and mark the break-out lengths for the

distribution cable fibers and the connecto r panel fibers.

6. Starting at the breakout mark, remove the protective jackets to expose the distribution

cable fibers (may be stranded or ribbon fibers) and the connector panel pigtail fibers.

7. Install the connector panel pigtail subunit and the distribution cable fiber subunit in the

splice tray and complete all splices per local practice. Refer to Section 7 for details and

then return to Step 8 to continue this proce dure.

8. After splicin g is compl eted, the splice tray cover replac ed, and the excess slac k rolled up,

insert the splice tray into the designated mounting slot.

9. Repeat this procedure for each connector panel pigtail sub unit.

10. When all splices have been completed, re-install the rear handle assembly on the back of

each connector panel (see Figure 23).

11. Connector panel designation labels, shown in Figure 26 and Figure 27, are provided on the

front door of the cabinet for recording subscriber information. For each connector panel,

indicate the subscriber address and service information and the fiber and cable number if

not specified. Splice tray designation labels, shown in Figure 28, are provided on the rear

door of the cabinet for recording distribution cable information. For each splice tray,

indicate the distribution cable and subunit numb er.

FRONT DOOR REAR DOOR

1234

1-LEFT

2-LEFT

3-LEFT

4-LEFT

5-LEFT

1-RIGHT

2-RIGHT

3-RIGHT

4-RIGHT

5-RIGHT

SPL TRAY 1

FBR 1

19 20 21 22

SPL TRAY 2

PANEL

FBR 7

1

37 38 39 40

SPL TRAY 4

FBR 1

55 56 57 58

SPL TRAY 5

FBR 7

SPL TRAY 1

FBR 2

SPL TRAY 2

FBR 8

SPL TRAY 4

FBR 2

SPL TRAY 5

FBR 8

SPL TRAY 1

FBR 3

SPL TRAY 2

FBR 9

SPL TRAY 4

FBR 3

SPL TRAY 5

FBR 9

SPL TRAY 1

FBR 4

SPL TRAY 2

FBR 10

SPL TRAY 4

FBR 4

SPL TRAY 5

FBR 10

LABEL FOR LEFT SIDE

OF CONNECTOR PANEL #1

19634-A

Figure 26. Connector Panel Designation Label - Type 1

© 2004, ADC Telecommunications , Inc.

Page 35

Page 42

ADCP-96-015 • Issue 1 • July 2004

FRONT DOOR REAR DOOR

6

5

4

3

2

1

1

2

3

4

5

FBR FBR FBR FBR FBR FBR

CABLE CABLE CABLE CABLE CABLE CABL

19

FBR FBR FBR FBR FBR FBR

CABLE CABLE CABLE CABLE CABLE CABLE

PANEL

37

1

FIBERS

1-72

FBR FBR FBR FBR FBR FBR

CABLE CABLE CABLE CABLE CABLE CABLE

55

FBR FBR FBR FBR FBR FBR

CABLE CABLE CABLE CABLE CABLE CABLE

21

20

39

38

57

56

LABEL FOR

CONNECTOR PANEL #1

22

40

58

Figure 27. Connector Panel Designation Label - Type 2

LABEL FOR DISTRIBUTION

CABLE SPLICE TRAYS

SPLICE TRAY 1

PANEL 1

FRONT DOOR

FIBERS 1-12

SPLICE TRAY 2

PANEL 1

FIBERS 13-24

SPLICE TRAY 3

PANEL 1

FIBERS 25-36

SPLICE TRAY 4

PANEL 1

FIBERS 37-48

SPLICE TRAY 5

PANEL 1

23

41

59

24

42

60

19738-A

REAR DOOR

Page 36

© 2004, ADC Telecommunications , Inc.

19635-A

Figure 28. Splice Tray Designation Labels

Page 43

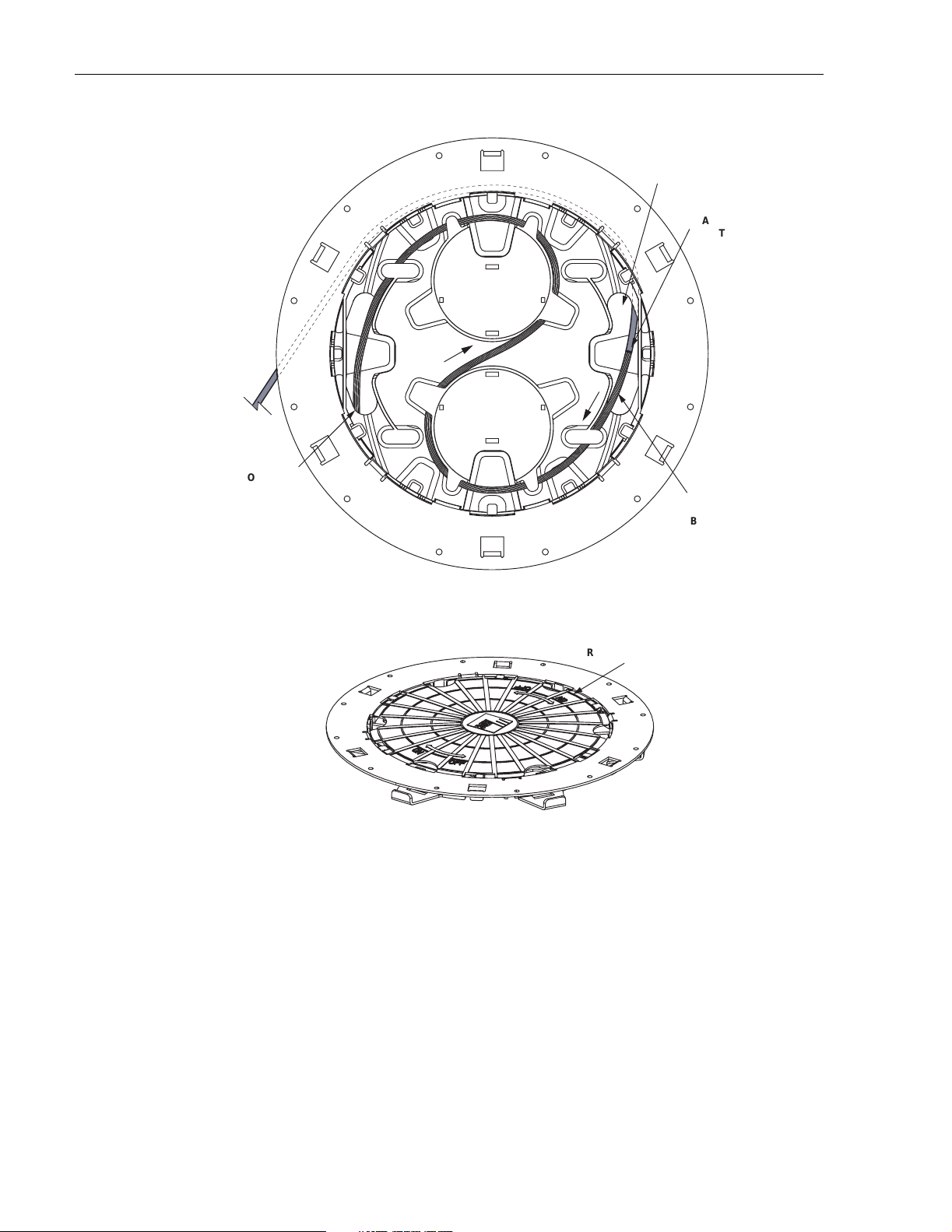

7 GUIDELINES FOR USING ROUND SPLICE TRAYS

This section provides guidelines for using the round splice trays that are provided with the

ACE-142S/142V cabinet. Use the following procedure for installing the fibers in the tray:

1. Remove the top and bottom covers from the splice tray.

2. Secure subunit A to the splice tray at the points shown in Figure 29.

Note: If installing the feeder cable, subunit A is the feeder cable subunit. If installing the

distribution cable, subunit A is the connector panel pigtail subunit.

TRANSITION POINT

FROM TOP TO BOTTOM

FIBER

BREAKOUT

POINT

SUBUNIT A

TIE POINTS

ADCP-96-015 • Issue 1 • July 2004

NOTE 1: FOLLOW SUBUNIT A