Page 1

Page 2

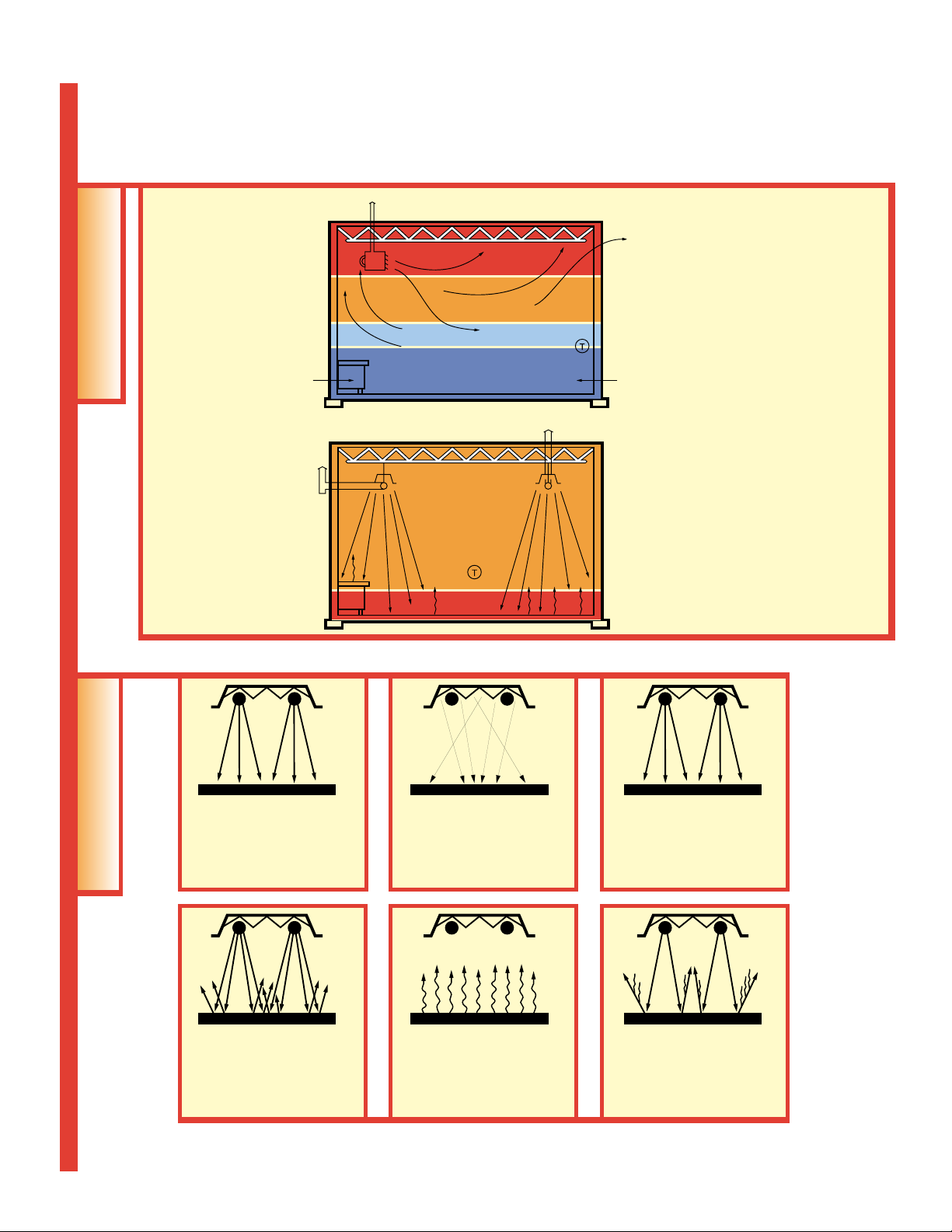

“ Sun-Heat” radiant system directs the heat down where it belongs…

fuel savings of 30% to 50%

Compare conventional warm air to infra-red radiant heat.

Warm Air

Radiant Heat

The balance of the radiant

heat is reflected from the

heating surface to be

absorbed by surrounding

cool surfaces.

A part of the secondary ray

energy, now of longer wave

length, is absorbed by

moisture and particles in the

air, which helps to raise the

temperature.

As a secondary effect, the

room temperature is raised

by convective transfer from

the heated surface.

Infra-red rays travel in

divergent straight lines from

heat source to all surfaces

and objects without heating

the air they pass through.

In addition to those rays

which travel directly from the

heat source, other rays are

re-directed downward by a

mirror surfaced reflector.

90°

70°

60°

75°

65°

70°

No air movement, but

same comfort level, with

lower thermostat setting.

No stacking effect; greatly reduces static pressure

at the roof line, reducing costly infiltration.

With the comfort of warm floors, building

is heated from floor up instead of from

roof down.

Low stack temperature 300°

Reradiation from concrete mass

results in even temperature

throughout the building.

Negative pressure at

the perimeter of building

allows for infiltration.

High temperature or static pressure at the roof

line increases heat transfer through roof.

The higher the bay area, the higher the static

pressure.

Because of air movement in the building

space, thermostat must be set higher to

achieve comfort level.

Cold floors in most cases are 10° less than

thermostat setting.

Listed by CSA for vented or unvented application.

20% to 25% stack loss

120oand higher.

Discharged air rises to roof line.

What is infra-red and how does it work?

A portion of the ray’s energy

is absorbed by cooler receiving

surfaces.Conduction carries

some of the heat deeper into

the heated material creating

a heat reservoir.

Page 3

GAS BURNER

• Burner and controls CSA listed for United States and Canada

• Hot Surface ignition and electronic safety– No Pilot

• 60,000, 80,000, 100,000, 125,000, 150,000, 175,000,

200,000 Btu/hr input sizes (natural or propane gas)

• Combustion Air inlet collar

• Sight glass for monitoring burner operation

• Combustion air proving differential switch

• Electrical & gas controls separated from combustion

air stream

• Burner Housing 18 GA. galvanized steel

• Electrical–120 volt/60/1 ph

• CSA listed for Vented or Unvented applications

•(1)year limited warranty

TUBE SYSTEM

• Combustion chamber–10' x 4" OD, 16 gauge aluminized

steel with flared burner mounting flange

• Heat exchanger– as required, remaining system comes

in 10' or 5' 16 gauge aluminized steel

• Flared fitting pipe connector with draw bolts at each joint

for solid compression type fitting–no gaskets or draw bands

• 20' to 70' systems–Straight systems or optional “L” or “U”

shaped systems using 90 deg elbows. (see schedule for

tube lengths available)

• 10 year limited warranty

REFLECTORS

• High polished parabolic reflectors standard

• 8' or 4' lengths

• Reflector shield and tube system supported by heavy gauge

wire hangers placed approx. 7' apart

Sun-Heat Standard System Features

FLARED PIPE FORMS

Male-Female Type Connection

Compression Fitting

No Clamps or Draw Bands

OPTIONAL FEATURES

• Outside combustion air inlet hood with flexible 4" diameter duct

• 90 deg elbows for “L” or “U” shaped configurations

• Diffuser “V” reflector for low mounting applications

• Vent cap adapter (4" dia steel to 4" dia class “B” vent pipe

• Line voltage thermostat

• 24 volt relay to convert line voltage thermostat to

24 volt thermostat

• Burner “ON” running light

Page 4

Loading...

Loading...