Page 1

Mark 10

Page 2

ADAMS

INTERburner

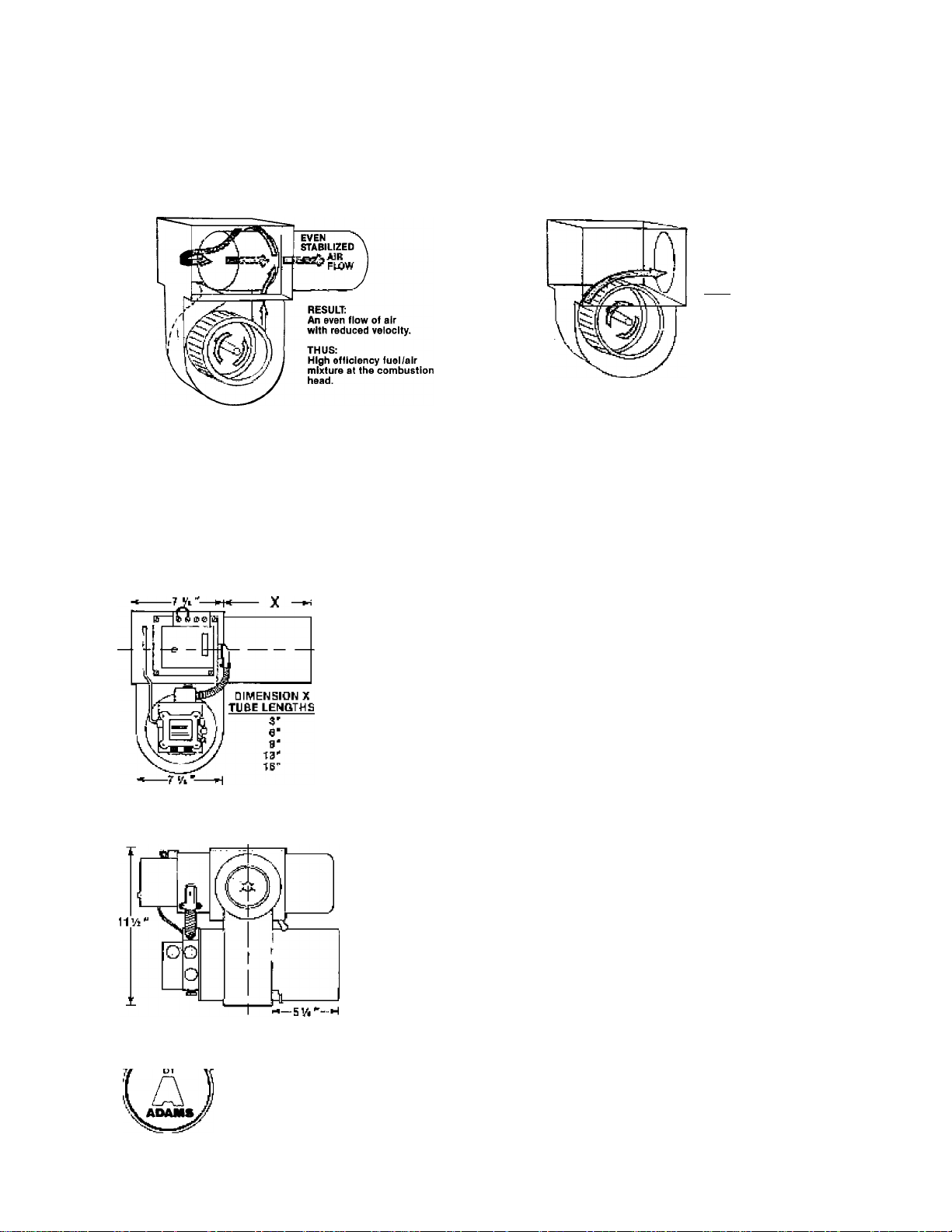

INTERburner Turbo Reversed (TRA)

Air Flow Pattern

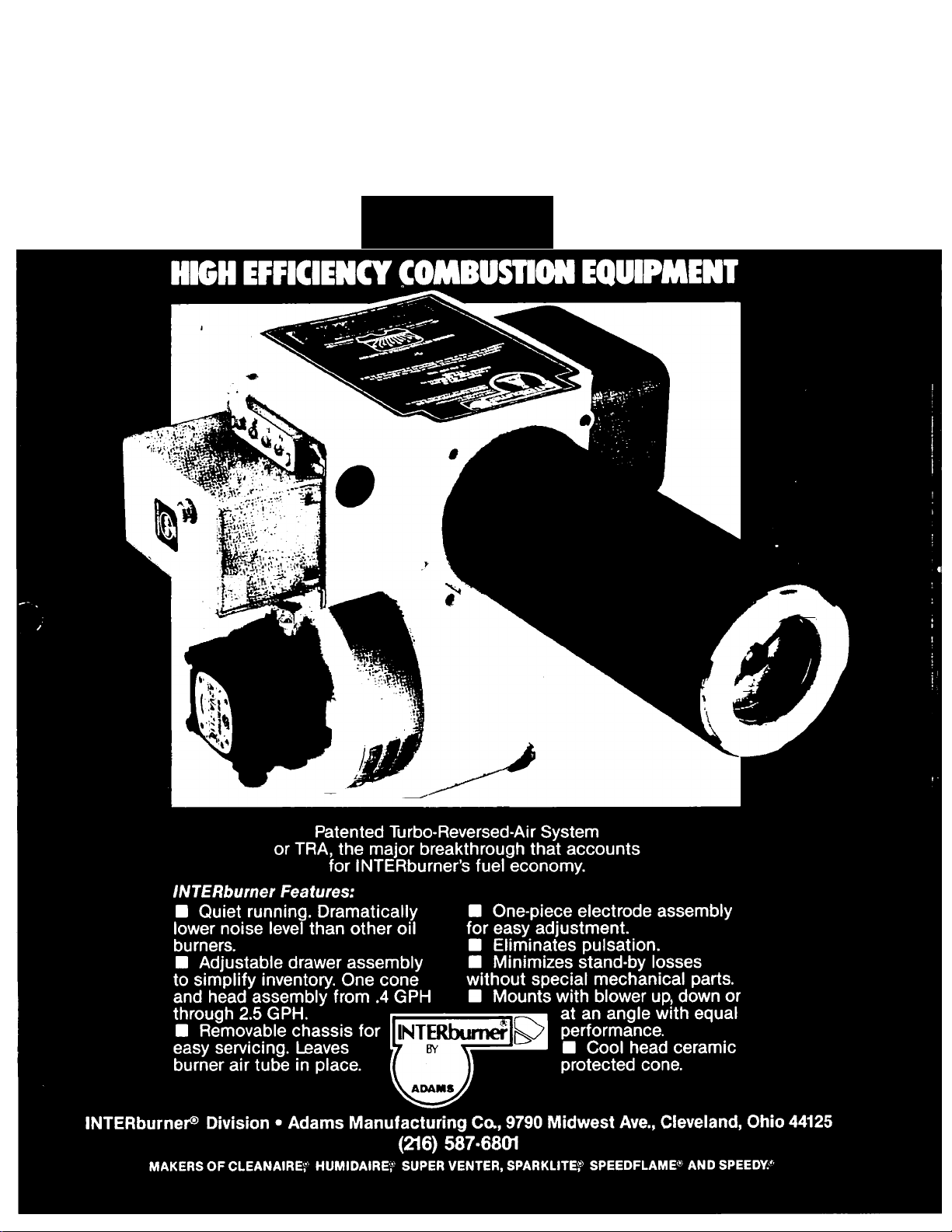

Patented Turbo-Reversed-Air System or

TRA, the major breakthrough that ac

counts for INTERburner’s fuel economy.

Inside each INTERburner, TRA stabilizes

dynamic pressure while maintaining high

static pressure. It creates the most uniform

airflow at the combustion head and gives

DIMENSIONS

T

4"

T

Î

Conventional Oil Burner

Air Flow Pattern

UNEVENAin \

di^hi^utiqnX

PAnEFlH , 1

HIOH vVusilTY^

rmw /

RESULT

An UOD^Vn How Cl ulr

wllh hl^h vticcliv con.

TIHUS:

PIMicmt Id Ob Lam a

luaUiilr mljtiurfi a!

\ha ccHnbuslJnii head.

precise control for the most effective

mixing of combustion air with the oil on

the combustion head ... accomplishing

efficiency levels never before achieved.

INTERburner’s flame burns hotter and

cleaner... requiring less fuel to heat

your home.

flJMciani

SPECIFICATIONS

CAPACITIES

0.40 to 2.50G/P/H, 56,000 to 350,000 B.T.U./Hr. Input.

Other models available to 7 G/P/H.

FUEL

No. 1 or No. 2 Heating Oil.

POWER REQUIREMENTS

115 Volts, 60 Hertz, Single Phase.

MOTOR

3450 R.P.M., 1/7 H.R 115 V., NEMA “M” Flange.

IGNITION TRANSFORMER

10,000 Volts.

CONTROLS

24 Volt Primary Cad Cell Control. Intermittent or

Interrupted Ignition.

FUEL PUMP

3450 R.P.M., 100 RS.I., Singie or 2 Stage with or

without Integral Solenoid Valve.

MOUNTING

Universal Flange and Gasket. Burner Stand Kit —

Burner can be mounted in inverted position.

NOZZLE SIZE

Selection Chart on each burner cover.

Distributed by:

Form IB-86

lllNTERbumef^

lA/ ■ I ■! I .III. ■

Accept only the best.

Insist on INTERburner?

INTERburner® Division • Adams Manufacturing Co., 9790 Midwest Ave., Cieveland, Ohio 44125

(216) 587-6801

Printed in U.S.A.

Loading...

Loading...