Page 1

Adam Equipment

CBD SERIES

Software revision 3.26

© Adam Equipment Company 2016 1

Page 2

Easy Reference:

Model name of the scale:

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

© Adam Equipment Company 2016 2

Page 3

1.0 CONTENT

P.N. 302666242, Revision B1, November 2016

1.0 CONTENT 3

2.0 INTRODUCTION 4

3.0 TECHNICAL SPECIFICATION 5

3.1 SPECIFICATIONS FOR THE LOCAL SCALE 5

3.2 SPECIFICATIONS FOR THE REMOTE SCALE 5

3.3 COMMON SPECIFICATIONS 5

4.0 INSTALLATION 6

4.1 LOCATING THE SCALES 6

4.2 SETTING UP THE SCALES 7

4.3 REMOTE SCALE SET UP 8

5.0 KEY DESCRIPTIONS 9

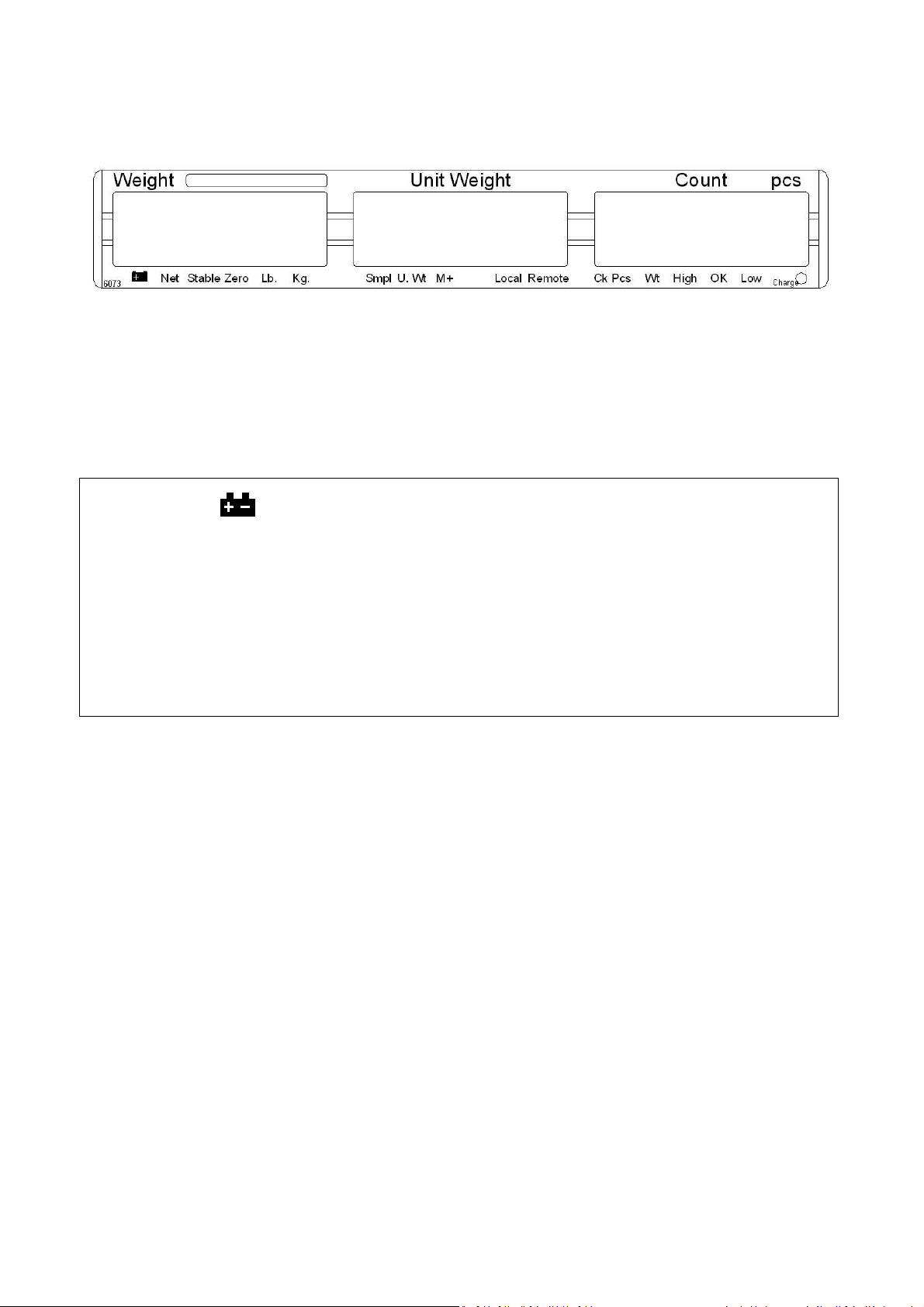

6.0 DISPLAYS 10

6.1 WEIGHT WINDOW 10

6.2 UNIT WEIGHT WINDOW 10

6.3 COUNT WINDOW 11

7.0 OPERATION 11

7.1 ZEROING AND TARING THE DISPLAY 12

7.2 MEMORY FUNCTIONS 13

7.2.1 MANUAL ACCUMULATION 13

7.2.2 AUTOMATIC ACCUMULATED TOTAL 14

7.3 PARTS COUNTING 14

7.3.1 WEIGHING A SAMPLE TO DETERMINE THE UNIT WEIGHT 14

7.3.2 ENTERING A KNOWN UNIT WEIGHT 15

7.3.3 AUTOMATIC UPDATE OF UNIT WEIGHT 15

7.3.4 COUNT PRE-SET OR CHECK-WEIGHING 15

7.4 PLU (Product Look Up) 17

7.4.1 STORING PLU’S MANUALLY 17

7.4.2 ENTERING DESCRIPTION MANUALLY 19

7.4.3 RECALLING PLU’S MANUALLY 20

8.0

8.1 REAL TIME CLOCK 23

9.0

10.0 RS-232 OUTPUT 25

10.1 INPUT COMMANDS FORMAT 26

10.2 STORING DATA VIA RS232 27

10.3 PLU ENTRY USING RS-232 INTERFACE 27

11.0

12.0

13.0

14.0

15.0

PARAMETERS 21

BATTERY OPERATION 24

CALIBRATION 28

ERROR CODES 30

TECHNICAL PARAMETERS 31

REPLACEMENT PARTS AND ACCESSORIES 33

SERVICE INFORMATION 33

© Adam Equipment Company 2016 3

Page 4

2.0 INTRODUCTION

• The CBD series offers a range of an accurate, fast and versatile counting scales that

can use one additional external platform (Remote scale) for weighing or counting of

heavier items.

• These counting scales have the ability to use many stored information (PLU).

• The scale can be operated using either pounds only, kilograms only or can be

switched between pounds and kilograms.

• All have stainless steel weighing platform on a Steel base assembly.

• All the keypads are sealed, colour coded membrane switches and the displays are

large easy to read liquid crystal type displays (LCD). The LCD’s are supplied with a

backlight.

• All units include automatic zero tracking, audible alarm for pre-set weights,

automatic tare, pre-set tare and an accumulation facility that allows the count to

be stored and recalled as accumulated total.

• The scales have an bi-directional RS-232 interface for communicating with a PC or

printer. An optional USB interface is available.

© Adam Equipment Company 2016 4

Page 5

3.0 TECHNICAL SPECIFICATION

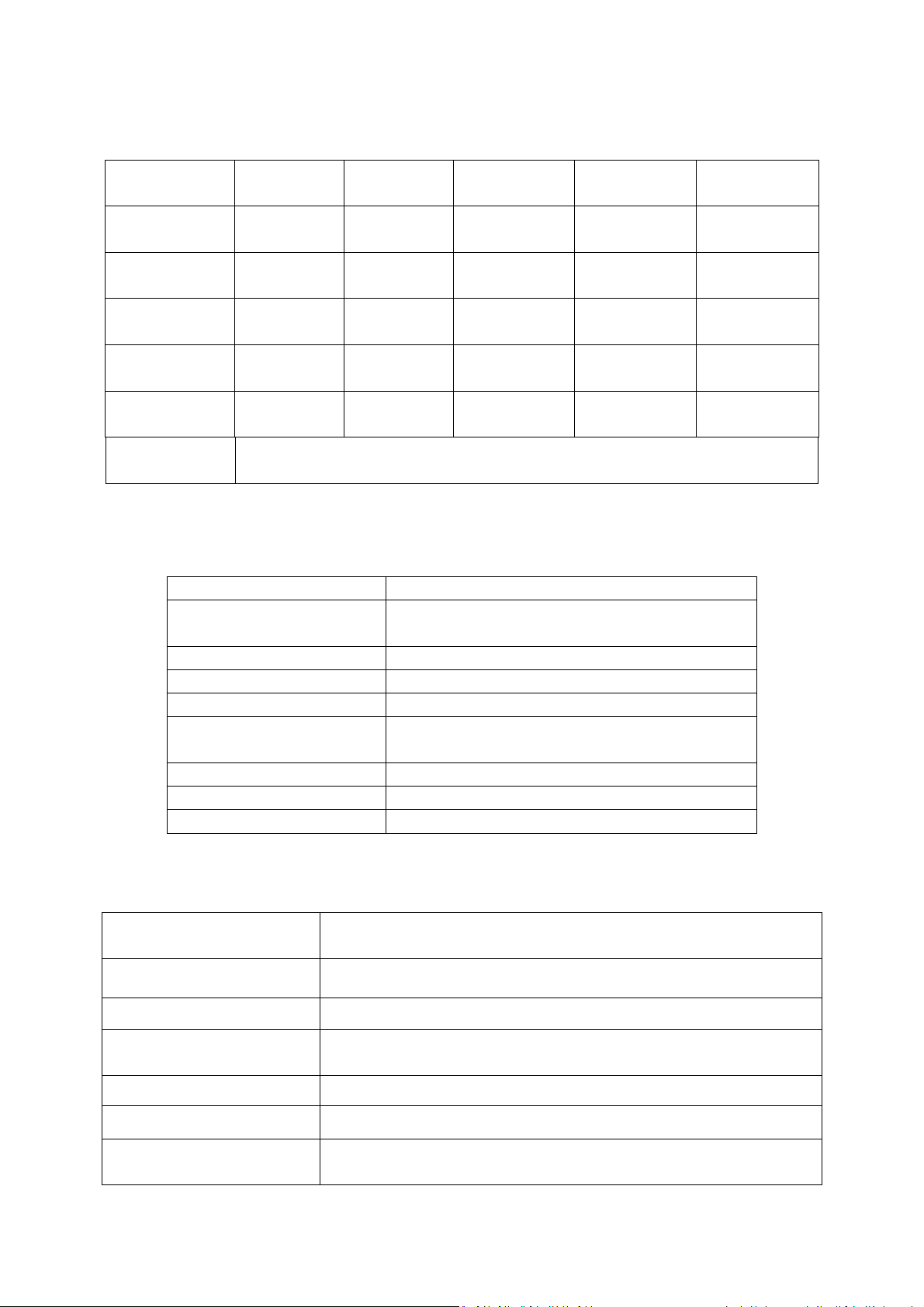

3.1 SPECIFICATIONS FOR THE LOCAL SCALE

Model #

Maximum

Capacity

Readability

Tare Range

Repeatability

(Std Dev)

Linearity ±

Units of

Measure

CBD 4

CBD 8a

4 kg /

8 lb

0.0001 kg /

0.0002 lb

-4 kg /

-8lb

0.0001 kg /

0.0002 lb

0.0002 kg /

0.0005 lb

CBD 8

CBD 16a

8 kg /

0.0002 kg /

0.0005 lb

-8 kg /

-9.9995 lb

0.0002 kg /

0.0005 lb

0.0004 kg /

0.001 lb

16 lb

CBD 16

CBD 35a

16 kg /

35 lb

0.0005 kg /

0.001 lb

-9.9995 kg /

-35 lb

0.0005 kg /

0.001 lb

0.001 kg /

0.002 lb

kg, lb

CBD 32

CBD 70a

32 kg /

70 lb

0.001 kg /

0.002 lb

-32 kg /

-70 lb

0.001 kg /

0.002 lb

0.002 kg /

0.004 lb

CBD 48

CBD 100a

48 kg /

100 lb

0.002 kg /

0.005 lb

-48 kg /

-99.995 lb

0.002kg /

0.005 lb

0.004 kg /

0.01 lb

3.2 SPECIFICATIONS FOR THE REMOTE SCALE

Excitation voltage 5 VDC

Signal range

0-20 mV

(allows 3 mV/ V LC with 5 mV zero offset)

Zero range 0-5 mV

Sensitivity 0.02µV / internal ADC count or better

Internal ADC counts 500,000 typical at 10 mV input

Load

87 ohm – 1200 ohm,

Suitable for 4 X 350 ohm load cells

Connection 4 wire connection to load cells plus shield

Maximum cable length 6 meters

Termination 9 pin D-subminiature plug on scale

3.3 COMMON SPECIFICATIONS

Interface

Stabilisation Time 2 Seconds

Bi-directional RS-232 Interface

Optional USB Serial Interface

Operating Temperature 0°C - 40°C

Power supply

12 VDC 800 mA from external power supply for USA

115/230 VAC 50/60Hz. or

Calibration Automatic external

Display 3 x 6 digits LCD digital display

Housing

Indicator ABS Plastic,

Stainless Steel platform

© Adam Equipment Company 2016 5

Page 6

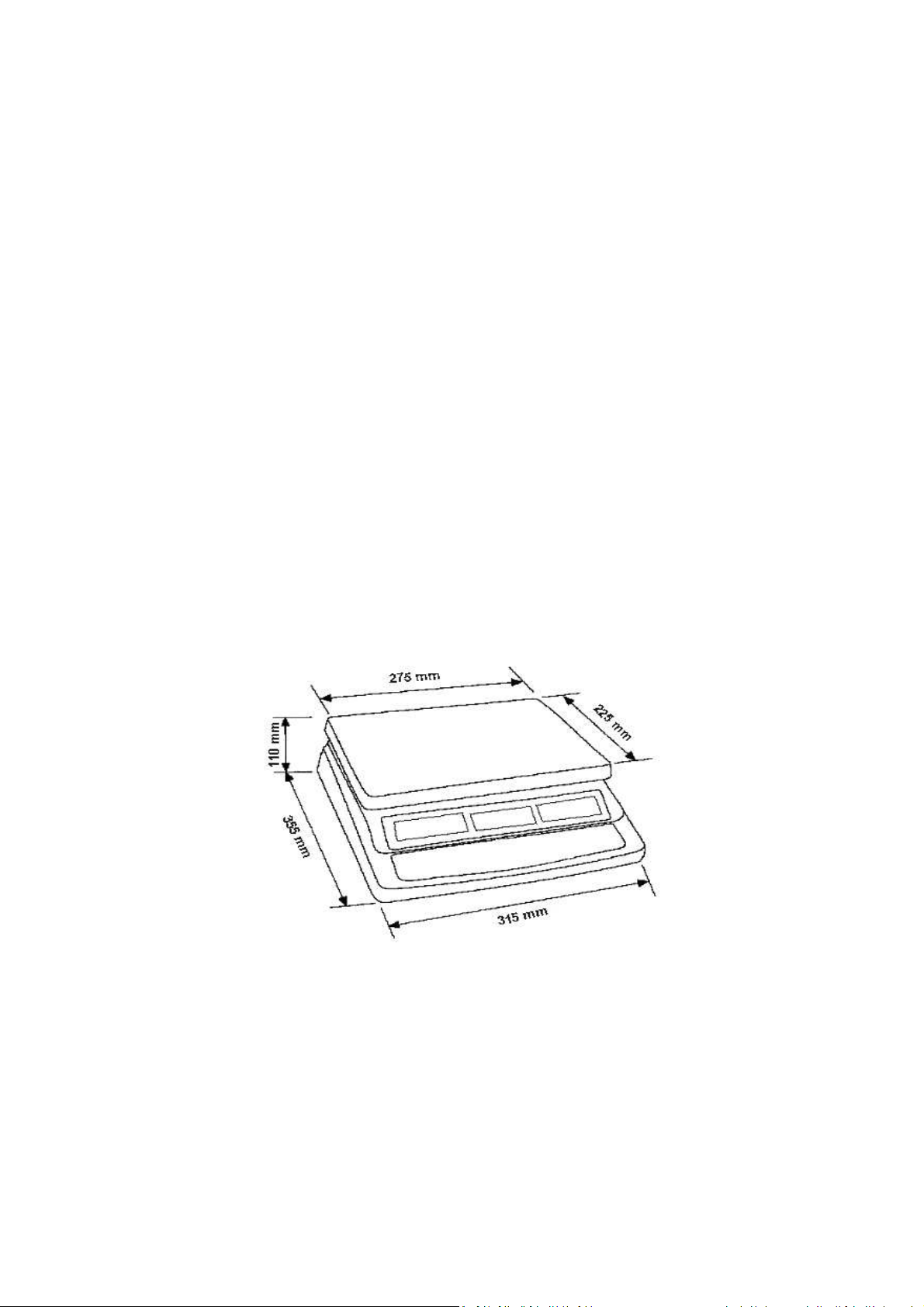

Pan size

Overall dimensions

225 x 275mm

8.9” x 10.8”

315 x 355 x 110mm

12.4” x 14” x 4.3”

Net weight 4.4 kg / 9.7 lb

Applications Counting Scale

Functions

Other Features and Specs

4.0 INSTALLATION

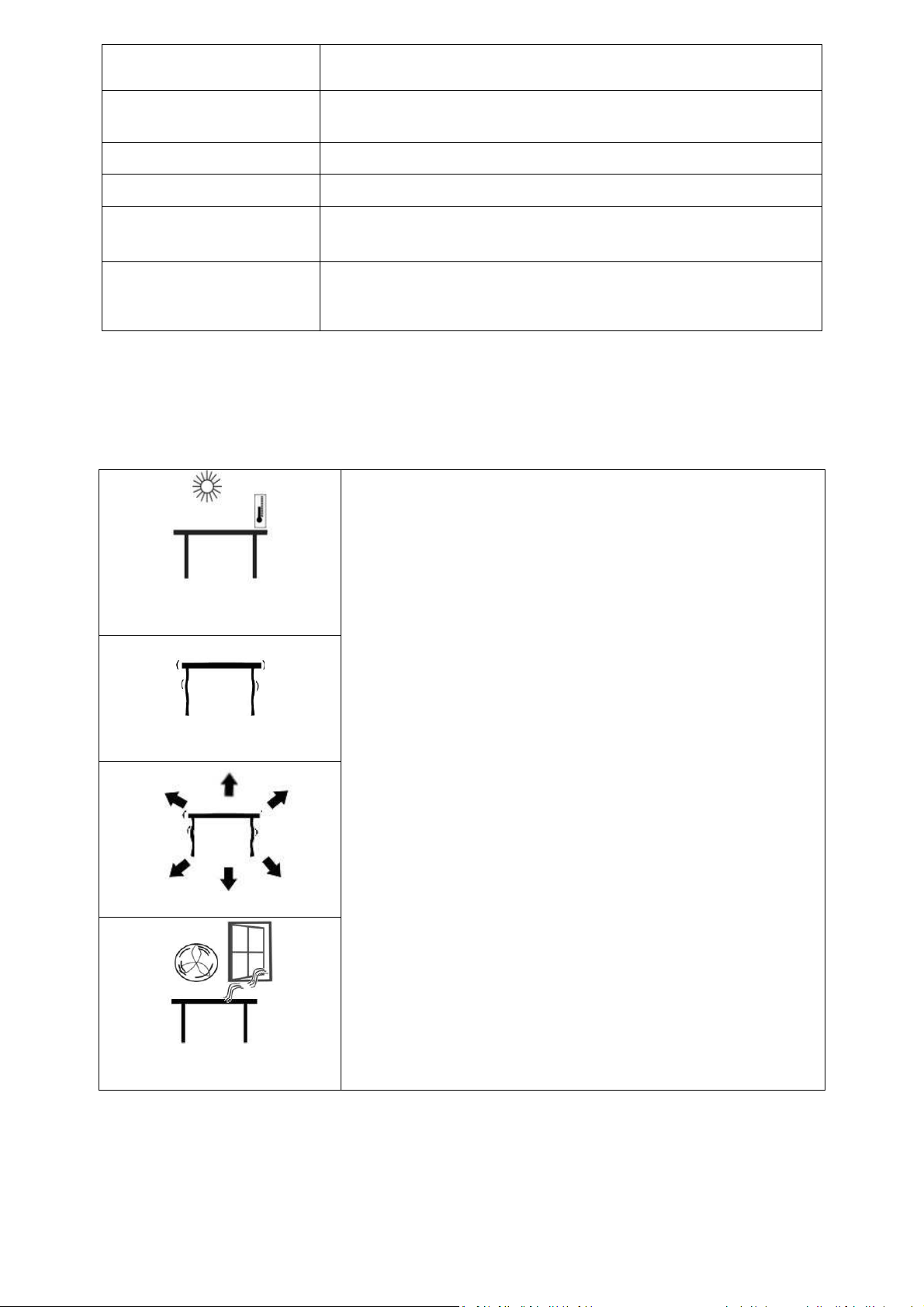

4.1 LOCATING THE SCALES

Weighing, parts counting, accumulating memory, preset count

with alarm, up to 100 PLUs with description, unit & tare weight

Accuracy enhancement for parts counting, internal

rechargeable battery (up to 70 hours operation dependent on

number of load cells used and use of the backlight)

• The scales should not be placed in a location that will

reduce the accuracy.

• Avoid extremes of temperature. Do not place in

direct sunlight or near air conditioning vents.

• Avoid unsuitable tables. The table or floor must be

rigid and not vibrate.

• Avoid unstable power sources. Do not use near large

users of electricity such as welding equipment or

large motors.

• Do not place near vibrating machinery.

• Avoid high humidity that might cause condensation.

Avoid direct contact with water. Do not spray or

immerse the scales in water.

• Avoid air movement such as from fans or opening

doors. Do not place near open windows or airconditioning vents.

• Keep the scales clean. Do not stack material on the

scales when they are not in use.

© Adam Equipment Company 2016 6

Page 7

4.2 SETTING UP THE SCALES

SETTING UP THE LOCAL SCALE

• The CBD Series comes with a stainless steel platform packed separately.

• Place the platform in the locating holes on the top cover.

• Do not press with excessive force as this could damage the load cell inside.

• Level the scale by adjusting the four feet. The scale should be adjusted such that the

bubble in the spirit level is in the centre of the level and the scale is supported by all

four feet.

• AC powered scales, attach the power cable to the connector on the bottom of the

scale base. If using the external plug in power supply module (USA) connect it to the

socket on the side.

• The power switch is located at the right side of the scale base.

• The scale will show the model number in the “Weight” display window (CBD 15,

where 15 denotes the maximum capacity of the scale in Kg) and the current software

revision number in the “Unit Weight” display window.

• Next a self-test is followed. At the end of the self-test, it will display “zero weight and

zero values in all three displays. If the weight display shows a value it was not possible

to set a new zero during power on.

SETTING UP THE REMOTE SCALE

• The CBD Series can be connected to any size of load cell type weighing base via the

Remote scale port on the right side of the scale case. Ensure you have the correct base

for the scale as each is matched for calibration.

• Place the remote scale platform in the position where it is to be used. Level the scale

by adjusting the four feet. If fitted with a spirit level then it should be adjusted such

that the bubble is in the centre.

• Press [Local/Rem] to select the local scale or the remote base for configuration and

operation.

© Adam Equipment Company 2016 7

Page 8

REMOTE SCALE CONNECTION

The cable for the load cell goes to a 9 pin D-subminiature plug connector with the following

connections:

Pin numbers Connection

Pins 1,2 - Excitation (0 V)

Pins 4,5 + Excitation (+5 V)

Pin 7 + Signal

Pin 8 - Signal

(The sense wires connections of a six wire load cell are not used and should be connected to the

respective Excitation pins).

4.3 REMOTE SCALE SET UP

The remote scale should set for a realistic resolution with respect to the input provided by the

load cell/s. See Section 13 for details of configuring the remote scale.

If a single 2 mV / V load cell is fitted and more than 60% of the load cell is used for full capacity

then the high output of >6 mV span makes it possible to set a high resolution.

If this criterion is met then the remote scale can be set to a high resolution with a maximum of

1:30,000, i.e. 300 kg x 0.01 kg.

Where more than one load cell is fitted or the total load cell capacity is not utilised then a

reduced resolution should be selected in the remote scale technical set up. For example, if a

system uses four 2 mV / V 1000 kg load cells for a scale of 1000 kg capacity then the span output

at full scale will be only 2.5 mV.

In this situation the resolution should be reduced to give a good number of ADC counts per

displayed division. ie. Set to 1:5000 or 1000 kg x 0.2 kg.

Setting a high resolution without providing a good input to the remote scale ADC will not give

better accuracy and may make the scale difficult to meet performance specification.

For best performance ensure a minimum of 0.V / d.

© Adam Equipment Company 2016 8

Page 9

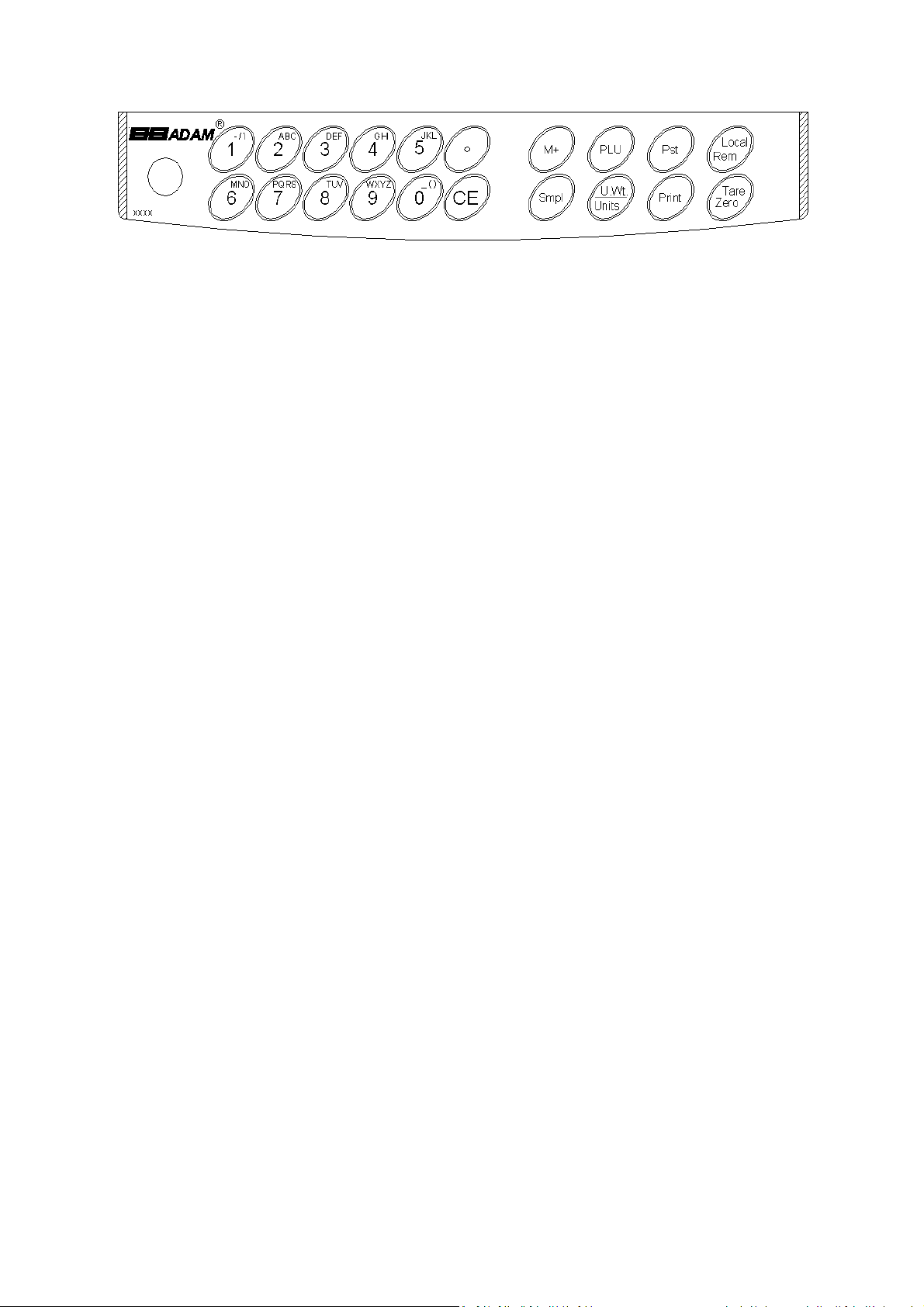

5.0 KEY DESCRIPTIONS

[0-9, •]

These keys are used to manually enter a value for tare weights, unit weight and sample size. A

secondary function is to enter alpha-numeric characters for PLU descriptions etc.

[CE]

Pressing this key clears the unit weight or an erroneous entry. It also clears the memory

accumulation when the total is displayed.

[M+]

This key is used to add the current count to the accumulator. It also recalls the memory when

pressed with no load on the scale. Up to 99 values or full capacity of the weight display can be

added. Also prints the displayed values when Auto print is switched off.

[Smpl]

This is used to enter the number of items of a sample.

[PLU]

To store and recall the Product Look Up sample information.

[U. Wt./Units]

This key is used to enter the weight of a sample manually. It will also change the weighing units

when other units are enabled.

[PST]

To set the upper limit for the number of items counted. When this upper limit is exceeded the

scale will sound the beeper. A secondary function is to use it access the menus for user settings.

[Print]

It is used to print the weighing data.

[Local Rem]

This key is used to select the local or remote scale.

[Tare/Zero]

This key has a combined Zero and Tare function.

If the net weight is below ±2% of maximum then it acts as a Zero key. This sets the zero point for

all subsequent weighing by setting the display to zero.

It also tares the scale by storing the current weight in the memory as a tare value, subtracting the

tare value from the total weight and displaying the results as a net weight.

© Adam Equipment Company 2016 9

Page 10

6.0 DISPLAYS

The scales have three display windows- Weight, Unit Weight and Count.

6.1 WEIGHT WINDOW

This consists of a 6 digit display to indicate the weight on the scale.

An arrow above the symbols will indicate the following:

Low battery,

Net Weight Display, "Net"

Stability indicator, “Stable”

Zero indicator, “Zero”

Unit in use indicator, “Lb” or “Kg”

6.6

6.2 UNIT WEIGHT WINDOW

This display will show the unit weight of a sample. This value is either entered by the user

manually or computed by the scale. The unit of measure is either gram on all scales with

kilogram selected as weighing unit or in pounds.

When the scale has determined that there is insufficient number of samples to accurately

determine the count, an arrow will be shown above "Smpl".

When the unit weight is not large enough to determine an accurate count, the arrow will

show at "U.Wt".

When a value has been entered into the memory, the arrow above "M+" will be on.

In both the cases the scale continues to operate and the indicators are to alert the user of a

potential problem.

© Adam Equipment Company 2016 10

Page 11

6.3 COUNT WINDOW

This display will show the number of items on the scale or the value of the accumulated count.

See the OPERATION section.

An arrow above the symbols will indicate the following:

Checkweighing is active during counting, "Ck Pcs"

Checkweighing is active during weighing, “Ck Wt”

Checkweighing is active, result is above the High Limit, “High”

Checkweighing is active, result is between the Low and High Limit, “OK”

Checkweighing is active, result is below the Low Limit, “Low”

Just under the “Count” display is an LED to indicate the status of the battery charging. When the

scale is plugged into the main power the internal battery will be charged. If the LED is green, the

battery has a full charge. If it is red, the battery requires further charging and yellow indicates the

battery is being charged.

7.0 OPERATION

The basic weighing functions are same for both the local and remote scales. However the

number of weighing divisions may be less on the remote scale dependant on the total capacity

of the load cell/s used.

Each scale (local or remote) has the ability to count parts based on the current unit weight.

This is best obtained by weighing and counting a sample on the local scale which may have the

best sensitivity. Then the scale can be switched to the remote where large quantities can be

counted.

Each scale has a separate tare value that can be entered through the keypad or by placing a

weight on the platform and pressing the [Tare/Zero] key. The tare value for each scale is

retained as the user switches between the remote and local scales.

Either scale can be used to determine a unit weight.

When the scale is switched from local to remote, a clear display will be shown to identify the

change and the scales will count based on the tare and unit weight currently in use for the

scale selected. Display for the change is:

“c h A n g E” ”L o c A L“ and “c h A n g E” ”r e m o t E “

The display will be based on the 7 segment interpretations, some of the letters are shown

later.

© Adam Equipment Company 2016 11

Page 12

The switch from local scale to remote scale should be possible at any time by pressing the

[Local/Rem] key.

NOTE: For frequently used items, counting is made easier by using PLU numbers (Product Look

Up). Up to 100 PLU’s can be stored and recalled. Place the item on the pan and enter the

appropriate PLU number using the keypad. The scale will display the Total Weight, Unit weight

and the Count of the item in the respective windows. See section 7.4.

7.1 ZEROING AND TARING THE DISPLAY

The Tare and Zero function are combined into one key. When the gross weight is within ±2% of

the zero, set at power on for either scale then a new zero is set. If the gross weight is greater

than ±2% then the tare function is performed.

ZEROING

You can press the [Tare/Zero] key at any time to set the zero point from which all other weighing

and counting is measured. When the zero point is obtained the Weight display will show the

indicator at “Zero”.

The scale has an automatic re-zeroing function to account for minor drifting or accumulation of

material on the platform. However you may need to press the [Tare/Zero] to re-zero the scale if

small amounts of weight are still shown even when the platform is empty.

TARING

Preset tare values can be used with both the local and remote scale. If a new tare value is to be

used, there are two methods for entering a tare value. The first method uses the weight on the

platform and the second uses a value to be entered by the user.

FIRST METHOD OF ENTERING A TARE VALUE:

• Zero the scale by pressing the [Tare/Zero] key, if necessary. The arrow indicator over

“Zero” will be on.

• Place a container on the platform, a value for its weight will be displayed.

• Press the [Tare/Zero] key to tare the scale. The weight that was displayed is stored as the

tare value and that value is subtracted from the display, leaving zero on the display. The

arrow over "Net" will be on. As product is added only the net weight of the product will be

shown. The scale could be tared a second time if another type of product was to be added

to the first one. Again only the weight that is added after taring will be displayed.

© Adam Equipment Company 2016 12

Page 13

• When the container is removed a negative value will be shown. If the scale was tared just

before removing the container this value is the gross weight of the container plus all

products those were removed. The zero indicator will also be ON because the platform is

back to the same condition as it was when the [Tare/Zero] key was last pressed.

SECOND METHOD OF ENTERING A TARE VALUE:

• This method allows you to enter a value for the tare weight from the keypad. This is

useful if all containers are the same or if the container is already full but the net weight is

required and the weight of the container is known.

• Remove all weights from the platform, press the [Tare/Zero] key to zero the display.

• Enter the value for the Tare weight including decimal point using the keypad, press

[Tare/Zero] to store the tare value. The weight will show a negative value equal to the

tare.

• Place the container on the platform.

• The display will then show the weight of the container minus the tare weight. When the

full container is placed on the platform the tare value will be subtracted from the gross

weight displaying only the net weight of the contents.

• If the value input is not consistent with the increment of the scale, the scale will round the

tare value to the nearest value possible. For example, if a tare value of 103g is entered into

the 60Kg scale with 5g readability, then the display will show -105g.

• The tare value for each scale is held in memory so that they are not lost when the active

scale changes.

7.2 MEMORY FUNCTIONS

The [M+] key will add the results of a weighing into memory, regardless of whether the local or

remote scale is being used for the weighing.

7.2.1 Manual accumulation

The values (weight and count) shown on the display can be added to the values in the

accumulator by pressing the [M+] key. The "Weight" display will show the total weight, the

"Count" display will show the total accumulated count and the "Unit Weight" display shows

the number of times items have been added to the accumulation memory. The values will be

displayed for 2 seconds before returning to normal.

The scale must return to zero or a negative number before another sample can be added to

the memory.

More products can then be added and the [M+] key pressed again. This can continue for up to

99 entries or until the capacity of the “Weight” display is exceeded.

© Adam Equipment Company 2016 13

Page 14

To observe the total value stored, press the [M+] key when the scale is at zero. The total will

be displayed for 2 seconds.

To clear the memory, first press [M+] to recall the total from the memory and then press [CE]

to clear all values from the memory.

7.2.2 Automatic accumulated total

The scale can be set to automatically accumulate total when a weight is placed on the scale. This

eliminates the need to press the [M+] key to store values into the memory. However the [M+]

key is still active and can be pressed to store the values immediately. In this case, the values will

not be stored when the scale returns to zero.

See Section 8 for enabling Automatic Accumulation.

7.3 PARTS COUNTING

The basic function of parts counting is same for both the scales. In order to do parts counting it is

necessary to know the average weight of the items to be counted. This can be done either by

weighing a known number of the items and letting the scale determine the average unit weight or

by manually inputting a known unit weight using the keypad.

Either of the scales can be used to determine the sample unit weight or for the manual entry

which can be used to count using either of the scales.

It is possible to increase the accuracy of the unit weight at any time during the counting process

by entering the count displayed and then pressing the [Smpl] key. You must ensure that the

quantity displayed matches the quantity on the scale before pressing the key. The unit weight can

be adjusted based on a larger sample quantity. This will give greater accuracy when counting

larger sample sizes.

7.3.1 Weighing a sample to determine the Unit Weight

To determine the average weight of the items to be counted place a known quantity of the items

on the scale and then enter the quantity being weighed. The scale will then divide the total

weight by the number of samples and display the average unit weight.

• Zero the scale by pressing the [Zero] key if necessary. If a container is to be used, place the

container on the scale and tare as discussed earlier.

• Place a known quantity of items on the scale. After the “Weight” display is stable enter the

quantity of items using the numeric keys followed by pressing the [Smpl] key. The number

of units will be displayed on the "Count" display and the computed average weight will be

shown on the "Unit Weight" display.

• As more items are added to the scale, the weight and the count will increase.

• If the scale is not stable, the calculation will not be completed.

© Adam Equipment Company 2016 14

Page 15

• If the weight is below zero, the “Count” display will show negative count.

7.3.2 Entering a known Unit Weight

If the unit weight is already known then it can be entered using the keypad.

Enter the value of the unit weight using the numeric keys followed by pressing the [U. Wt.]

key within few seconds while the display is flashing. If no action is initiated within a few

seconds, the "Unit Weight” display will revert to the previous value, otherwise it will show the

new value that has been entered.

The sample is then added to the scale and the weight will be displayed as well as the quantity

based upon the unit weight. When weighing in kilograms the unit weight is shown in grams.

When weighing in pounds the unit weight is shown in pounds.

After the unit weight has been determined or entered, the scale can be used for parts

counting. The scale may be tared to account for the net weight as discussed in an earlier

section.

After the scale is tared, the items to be counted are added and the "Count" display will show

the number of items computed using the weight and the unit weight.

It is possible to increase the accuracy of the unit weight at any time during the counting

process by manually entering the sample quantity and then pressing the [Smpl] key. You must

ensure that the quantity displayed matches the quantity on the scale before pressing the key.

The unit weight will be adjusted based upon a larger sample quantity. This will give greater

accuracy when counting larger sample sizes.

7.3.3 Automatic update of unit weight

The scales will automatically update the unit weight when a sample less than the initial sample

count is added. A beep will be heard when the value is updated. It is wise to check the quantity is

correct when the unit weight has been updated automatically.

To lock the unit weight and prevent Auto-update, press [U.Wt.].

This feature is turned off as soon as the number of items added exceeds the count used as a

sample.

7.3.4 Count pre-set or check-weighing

Check-weighing (or Count Pre-setting) is a procedure to cause an alarm to sound when the net

weight (or the number of items) on the scale meets or exceeds a number stored in memory. The

value to be stored is entered from the keyboard.

SETTING OF PRESET LIMITS

It is possible to set a high and low limit for either counting or weighing (using net weight). When

the [Pst] key is pressed the user can select either counting or weighing and then set the lower and

upper limit.

© Adam Equipment Company 2016 15

Page 16

For example:

ACTION DISPLAYS

Press [Pst] “CHECk ” “ nEt “ “ “ if currently in the weighing mode

Press [U.Wt/Units] “CHECk ” “ CoUnt “ “ “ to toggle from weighing to counting

“Hi cnt” “0.3 2 3 4” “ ” The current high count limit is displayed,

Press [Print]

Press [Print]

Press [Print] Return to weighing with limits set.

Clearing of either or both the limits is allowed. Both limits cleared will disable the Preset

altogether.

If Preset Weight was selected the first display would show “Hi WEG” and “Lo WEG”.

The beeper will work as described in the Beeper Parameter.

press [CE] to clear and change if needed.

If using net weight the display will show “Hi WEG”

“lo cnt” “0.0 2 3 4” “ ” The current low count limit is displayed, press

[CE] to clear and change if needed.

If using net weight the display will show “Lo WEG”

© Adam Equipment Company 2016 16

Page 17

7.4 PLU (Product Look Up)

Product Look-Up (PLU) numbers are used to store information about the commonly used items.

The Tare Weight, Description of the product and Unit Weights for a particular item are recalled by

entering the PLU number for ease of operation.

The scale is capable of storing values for the Tare weight, Description and Unit Weight for a

maximum of up to 100 PLU numbers.

Tare Weight value is required for calculating the Net Weight where a container is used during

weighing. Descriptions are used for sending data over RS-232 for viewing or printing and Unit

Weight is used for parts counting.

These data should be entered against a particular PLU before the weighing process starts so that

the desired PLU’s can be recalled during the weighing process. The data can be stored and

recalled manually or by sending data over RS-232 Interface.

7.4.1 Storing plu’s manually

ACTIONS

Press [Tare/Zero] if

required.

Note:

Enter or determine the Tare Weight when a container is to be used (see section 7.2 of this User

Manual). If a Tare value is used, the scale will be in the NET mode.

Enter or determine the Unit Weight as described in section 7.3.1 and 7.3.2 of this User Manual.

The Tare and Unit Weight to be stored can be either taken from a weighing in process or by

manual entry of data.

Weight Unit weight Count

“0.0000” “ 0“ “ 0“ The scale is zeroed.

DISPLAYS

REMARKS

© Adam Equipment Company 2016 17

Page 18

Please find below an example for setting up “PLU 27” with Description as “M4 Nut” and Unit

weight of “0.015”.

ACTIONS

Press [PLU] “PLU ” “ - -“ “ “

DISPLAYS

Weight Unit weight Count

REMARKS

-

-

Press [2], [7] “PLU ” “ 27” “ “

The current description will

be shown with the first

Press [Pst] “PLU 27” “x x x x x x” “x x x ”

character flashing. The

flashing digit can be

changed as stated in the

Note below.

Pressing the [CE] key

when the first character

is flashing will clear all

“PLU 27 ” “ “ “ “

-

the descriptions.

Continue to enter

characters until

description is complete.

Press [Print] to save the

PLU.

“PLU 27 ” “M 4 Nut“ “Brass “

“STOrE” “PLU “ “ 27 “

12 characters in total

spreading over both the

displays (UNIT WEIGHT and

COUNT).

The display will show the

PLU is saved then return to

normal weighing mode.

Note:

Use the [.] key to go back to the previous digit or the [M+] key to advance to the next character.

A flashing character can be used for entering a space by pressing the [0] key for slightly longer

duration.

Tare value will only be stored with PLU data if the scale is in the NET mode. If the container is less

then the manual zero range which is set in "Technical parameters" (default is 2% of capacity) then

the scale will be Zeroed and no tare value will be stored. To avoid this, use a larger container,

reduce the zero range or use the digital tare method.

© Adam Equipment Company 2016 18

Page 19

7.4.2 Entering description manually

The description can be up to 12 characters long and can be a mix of numbers, symbols or letters.

During the procedure to set the description the numeric keypad will work in a similar way to a

mobile telephone. Pressing a number briefly will show the number and holding it down will scroll

through all the characters.

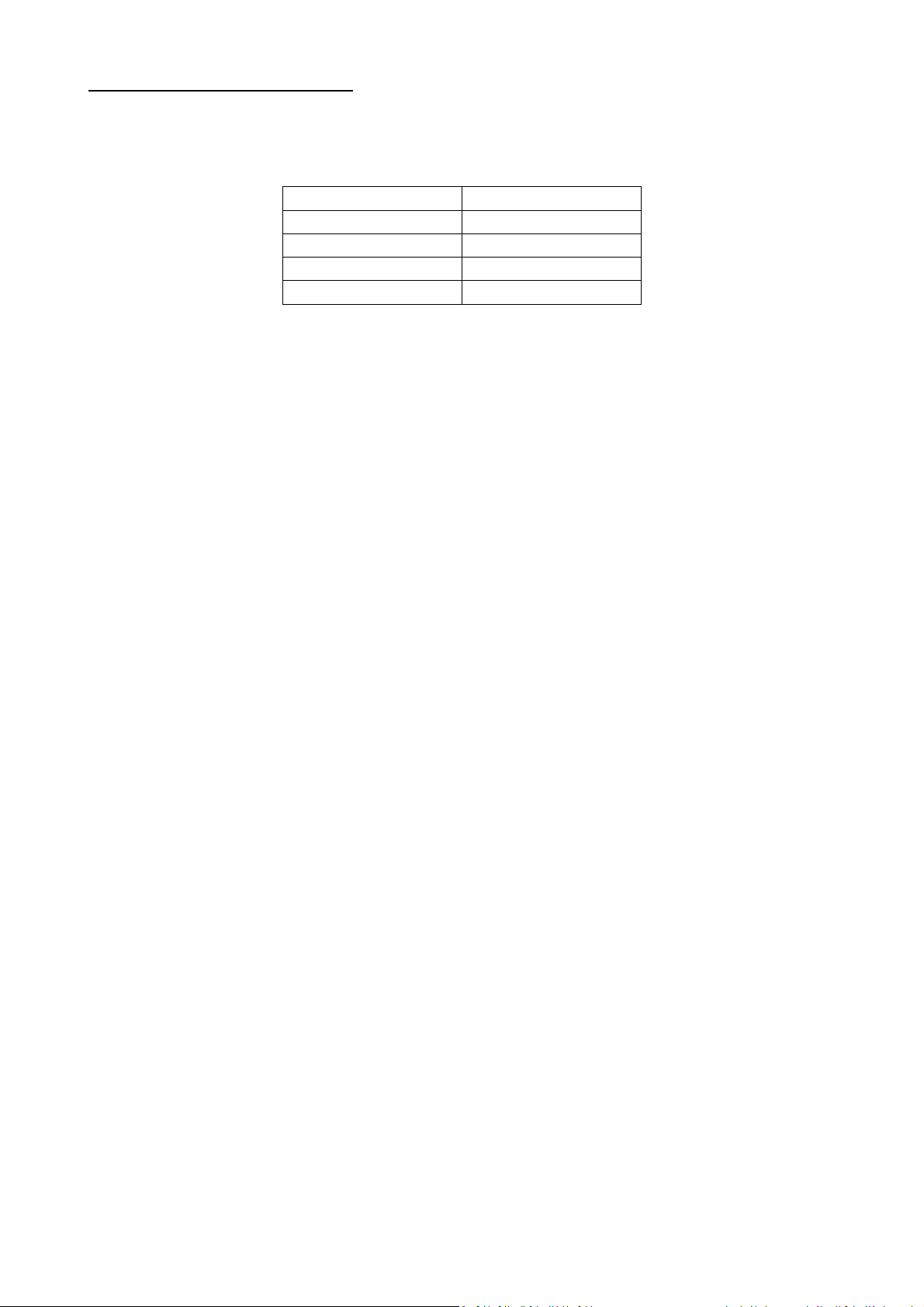

The numbers and characters are:

1 - / \

2 A B C

3 D E F

4 G H I

5 J K L

6 M N O

7 P Q R S

8 T U V

9 W X Y Z

0 [ ] Where _ is a Space (Not underscore)

The limitations of the 7 segment display sometimes make it difficult to display some letters. The

characters and the displayed symbols are:

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z - / \ ( )

The characters will be stored as text so the output of the RS-232 interface will look correct.

The numbers 1 2 3 4 5 6 7 8 9 0 will be 1 2 3 4 5 6 7 8 9 0.

Note that this method is only used where alpha-numeric data is permitted. This is used for the

Description field and the User ID number, Scale ID number in the parameters section.

© Adam Equipment Company 2016 19

Page 20

7.4.3 RECALLING PLU’S MANUALLY

To recall the PLU values the user should first select either local or remote scale as the tare value

stored will be specific to the scale selected.

Then press the [PLU] key, enter the PLU number (00 – 99) then press the [PLU] key again to recall

the data.

The display will show the results of the recall for 1 second then return to weighing with the data

in place.

For example:

Press [PLU]

Press [2], [7] “PLU ” “ 27” “ “

ACTIONS DISPLAYS

“PLU ”

“ - -“ “ “

Press [PLU] “PLU 27 ” “M 4 Nut“ “Brass “

After 1 second, it will return to normal

weighing with the Tare and Unit Weight

previously entered.

“ x x x x“ “ x x x x ” “ x x“

If the [PLU] key is held down after the numeric entry, it will show the description as long as the

key is pressed.

In this example the display “PLU 27 ” “M 4 Nut“ “Brass “ shows the description for 1 second,

if no data is stored then it will show

“nO ” “ PLU “ “SAVE “.

If the tare value is outside the range permitted for the selected scale (For example, if the local

scale is selected whereas the tare value applies to the remote scale, this would exceed the

capacity of the local scale) the “Weight” display would show zero tare weight.

If the tare value stored does not match the increment of the selected scale (For example, storing -

1.446 for a scale with d=0.05) then round the tare weight depending on the scale resolution (For

example, in this case, -1.45 would be used as the tare value).

If a PLU number is recalled that does not have any information stored against it, the scale will

continue to work with Tare and Unit weight unchanged.

NOTE: PLU’s can be stored and recalled using RS-232 Interface (see section 10.1 and 10.2 of this

user Manual).

© Adam Equipment Company 2016 20

Page 21

8.0 PARAMETERS

The following parameters set up the scale as required by the user. For the Technical parameters

and configuring the remote platform refer to Section 13.

Enter the User Parameters section by pressing the [Pst] key during the self-test when the power is

turned on or press and hold the [Pst] key for 3 seconds during normal operation. This will allow

the user to set the way he wants the scale to work by choosing specific values from some options.

• Press the [U.Wt./Units] key to scroll through the main parameters. To enter any

parameter, press the [Print] key.

• Press [U.Wt./Units] to scroll through the sub-parameters. To see the earlier setting, press

the [Print] key. To change and scroll through the other available settings, press

[U.Wt./Units]. To choose the desired setting and thereby go back to the sub-parameter,

press the [Print] key.

• To return to the parameter, press the [Tare/Zero] key.

PARAMETER

SUBPARAMETER

F1 oFF bEEP

EL “LitE"” “"oFF"”

DISPLAYS AND SETTINGS

“bEEP"“ "oFF"” Beeper is set to off

“bEEP"” "on In "” Beeper is set to on between limits

“bEEP” “"on oUt” ” Beeper is set to on outside limits (>0)

Backlight is set to off

“LitE"” "on"” Set to on at all times

Set to work automatically when a

“LitE"” "AUt"

weight is placed on the scale or a key

is pressed.

© Adam Equipment Company 2016 21

Page 22

Un I t

“UnI t” ” KG/ Lb” kg/ lb both are enabled

”UnI t” “KiLo” kg only is enabled

”UnI t” “Lb” lb only is enabled

F2 Prt P Mo dE Print Au Off Prints only when the Auto-

Accumulation is set to

off.

Au on Prints only when the Auto-

Accumulation is set to on.

P Cont Sets the RS-232 interface to print

continuously and the accumulation

function is disabled.

SEr r E

Sets the RS-232 to print continuously

the weight only.

P bAU d b 600

b 1200

b 2400

b 4800

b 9600

Sets the required baud

rate (speed for the RS-232

communications).

Default rate is 4800.

b 19200

PAritY

8 n 1

7 E 1

7 o 1

8 data bits, no parity

7 data bits, even parity

7 data bits, odd parity

F3 U id “USE id”

“ Abc234”

“ “

Shows the current user ID (if any).

Enter a new User ID as described in the Description under the PLU

section. The ID can be alpha-numeric but is limited to 6 characters.

F4 S id “SC id”

“ Abc678”

“ “

Shows the current scale ID (if any).

Enter a new Scale ID as described in the Description under the PLU

section. The ID can be alpha-numeric but is limited to 6 characters.

tECH Allows access to the Technical parameters using a password. Not

normally accessed by user. See Section 13.

© Adam Equipment Company 2016 22

Page 23

8.1 REAL TIME CLOCK

The Real Time Clock (RTC) is used only for the RS-232 output. See Section 10. The Date and Time

can be set as required. The scale will keep the clock running even when the power is off.

Setting up the clock

• Press the [CE] key when the display is counting down after power is turned on. The initial

displays show the current date and time.

“ rtC “ “11,14,06” “16,41,35”

• Press the [Tare] key to accept the values shown without change or press the [U.Wt./Units]

key to change the time. The displays display will show the current time, “ timE “ “ H-m-S

” “16,41,35”

• Continue without changing the time or Enter the new time using the numeric keys using a

24 hour clock format, 3:41PM is “154100”.

• Press the [Print] key to accept the time. The display will show the current date format.

Press the [U. Wt./Units] key to change the date format. Available formats are:

“Y-m-d” year, month, day

“m-d-Y” month, day, year

“d-m-Y” day, month, year

The Unit Weight display will show the current format, “Y-m-d” for example.

• Press the [Tare] key to accept the chosen format, the Count display will show the current

settings. Enter the date in this format.

• Press the [CE] key to clear the current setting then enter the new values.

• Press the [Tare] key to accept the date.

An error code will be shown if the time (Err 1) or the date (Err 2) is not the permissible values.

For example, 34th day of a month is an invalid entry.

Pressing the [Zero] key will escape for the date and time settings with the current values

unchanged. It is possible to change only the time by setting a new time, then pressing the [Zero]

key when the date settings are shown.

© Adam Equipment Company 2016 23

Page 24

9.0 BATTERY OPERATION

The scales can be operated from the battery. The battery life is approximately 70 hours if only the

basic unit is used and the backlight is not used. If the backlight and a second platform is used the

battery life will be reduced.

When the battery needs charging the arrow above the low battery symbol under the “Weight”

display will turn on. The battery should be charged as soon as the arrow above the symbol is on.

The scale will still operate for about 10 hours after which it will automatically switch off to protect

the battery.

To charge the battery simply plug into the mains power. The scale need not to be turned on.

The battery should be charged for 12 hours for full capacity.

Just under the “Count” display is an LED to indicate the status of battery charging. When the

scale is plugged into the main power the internal battery will be charged. If the LED is green the

battery has a full charge. If it is red, the battery is nearly discharged and yellow indicates the

battery is nearly charged.

© Adam Equipment Company 2016 24

Page 25

10.0 RS-232 OUTPUT

Specifications:

RS-232 output of weighing, data default settings

ASCII code

4800 Baud (600-9600 selectable)

8 data bits (8 data bits no parity, 7 data bits even and odd parity selectable)

RS-232 Connector style:

9 pin D-subminiature socket

Pin 2 Input

Pin 3 Output

Pin 5 Signal Ground

USB Connector style:

Type B USB connector

Software drivers for allowing a PC to operate with the USB interface is available for the Adam

Equipment web site.

The RS-232 and USB interfaces are the same for input and output.

Sample of output:

Using M+ function Using PRINT function

DATE 01/27/2011

TIME 12:38:49

LOCAL SCALE

SID: ABS123

UID: 123ABC

NAME: Text

4 S. No.

1.234 kg TARE

12.456 kg NET

1.1234 g U.W.

11 PCS

TOTAL

- - - - - - - - - - - -

49.824 kg TW

44 TPC

4 No.

DATE 01/27/2011

TIME 12:39:58

LOCAL SCALE

SID: ABS123

UID: 123ABC

NAME: Text

1.234 kg TARE

12.456 kg NET

1.1234 g U.W.

11 PCS

© Adam Equipment Company 2016 25

Page 26

10.1 INPUT COMMANDS FORMAT

The scale can be controlled with the following commands.

Input Commands:

• The scale has a number of commands to either cause an action or to enter data into

memory. The commands are all upper case and are summarised below.

• All commands are terminated by a carriage return (Enter button on PC keyboard) with the

line feed optional.

• If an illegal command is received or a command cannot be carried out then send the

command back with the addition of ER in front of it. For example if the command is

NN<cr><lf> send back ER NN<cr><lf>.

Basic Commands:

PLUxx

T

T123.456

Z

P

M+

MR

MC

U123.456

S123

SL

SR

Immediate Printing Commands:

Command Output from scale

\L Scale: Local or Remote

\I ID number same as PUID below

\S Scale number same as PSID below

\N Net weight

\G Gross Weight

\T Tare weight

\U Unit weight

\P Count

\C Total Count

\W Total Weight

\M Number of items stored in memory

\B A blank line printed

Select PLU from scale memory to be used

Tare current weight value

preset tare value is 123.456

Zero the display

Print using selected format

Store current results into memory and print

Recall memory values to scale display

Clear memory

Store unit weight of 123.456

(grams if in kilograms or pounds if currently in pounds)

Enter sample size of 123 parts.

Same as pressing [Smpl] key.

Select local scale to be used

Select remote scale to be used

© Adam Equipment Company 2016 26

Page 27

10.2 STORING DATA VIA RS232

To store data the commands are:

SUIDxxxxxx <CR> Store user ID data

SSIDxxxxxx <CR> Store scale ID data

SPLUxx,xxxxxxxxxxxx <CR> Store text data for PLUxx

When PLU text data is stored the Scale stores current unit weight and current tare value along

with the PLU number.

For the SPLU command the data is: PLU number (2 characters), (Comma) description (max 12

characters).

If the fields are less than the maximum all characters need not be used.

10.3 PLU ENTRY USING RS-232 INTERFACE

This method enables the user to send the data from a PC program as well as from the keypad. The

most common PLUs can be stored and recalled from the scale memory. Other PLU data can be

stored on a PC, then the Description (text data), Unit Weight and Tare Weight data can be sent

from the PC for the PLUxx (where xx can be any desired number up to 99). This can then be used

or over-written during operation.

OPERATION:

• Send Tare Weight data to set any tare value to be stored with PLU.

i.e. “T 1.45” <CR>. If no tare is needed then you may send “T 0” to delete any present tare

data.

• Send the Unit Weight to be stored with PLU. i.e. “U0.015” <CR>

• Send PLU text data to be stored with current Tare and U/W values.

i.e. “SPLU27, M4 Nut Brass” <CR>

Any information stored for the Tare Weight, Description and the Unit weight will be stored in the

scale and can be recalled for use in the future.

© Adam Equipment Company 2016 27

Page 28

11.0 CALIBRATION

ACTION DISPLAYS

Press the [Tare/Zero] key during the self-test at

power on. The scale will ask to enter the password.

Default Password is 0000.

Enter “0” four times.

Password can be changed in technical parameters.

Press [Print].

Select the scale to be set up by using the

[Local/Remote] key.

Press the [Print] key to enter the technical section.

Use the [U.Wt.] to select the weighing unit to be

used for setting the calibration for the scale. The

arrow in the “Weight” window will indicate the unit

selected.

Press the [Print] key to continue.

You will enter the first parameter -Calibration.

Display will ask to unload any weight on the platform.

Press the [Print] key to continue.

“ Pi n”

“ Pi n” “ - - - -”

“tECH” “ LocAL” “ “

“tECH” “rEmo tE” “ “

“tECH” “ Uni t” “ “

“nO L o Ad”

Load the calibration weight onto the scale

If the mass is different than the value shown press

the [CE] key then enter the calibration weight to be

“LoAd ” “ 0010” “ KiLoS”

used.

Then press [Print].

The Calibration is complete, the scale will run the

self-test during which the weight should be removed.

If calibration is not possible an error message will be

shown

“- - - -” “ - - - -” “ - - - - ”

“SPAn” “ PASS” “ ”

“SPAn” “ FAiL” “ LoW ” or “HiGH

If The Calibration is being done while in the TECH parameters (section 13) the linearity is set at the

same time as calibration by performing the calibration in 2 steps,

© Adam Equipment Company 2016 28

Page 29

Display will ask to unload any weight on the

platform.

Press the [Print] key to continue.

“nO L o Ad”

Load the first calibration weight onto the scale

If the mass is different than the value shown press

the [CE] key then enter the calibration weight to

be used.

Then press [Print] to continue or press [Zero] to

complete with only one mass being used.

Load the second calibration weight onto the scale

If the mass is different than the value shown press

the [CE] key then enter the calibration weight to

be used.

Then press [Print].

The Calibration is complete, the scale will run the

self-test during which the weight should be

removed.

“LoAd 1 ” “ 0010” “ KiLoS”

“LoAd 2” “ 0030” “ KiLoS”

“- - - -” “ - - - -” “ - - - - ”

“SPAn” “ PASS” “ ”

If calibration is not possible an error

message will be shown

“SPAn” “ FAiL” “ LoW ” or “HiGH

© Adam Equipment Company 2016 29

Page 30

12.0 ERROR CODES

During the initial power-on testing or during the operation, the scale may show an error message.

The meaning of the error messages are described below.

If an error message is shown, repeat the procedure that caused the message, such as turning the

balance on, calibration or any other functions. If the error message is still shown then contact

your dealer for further support.

ERROR CODE DESCRIPTION POSSIBLE CAUSES

Err 4 Initial Zero is greater than the

permissible value (typically 4% of

maximum capacity) when power

is turned on or when the [Zero]

key is pressed,

Err 5 Keyboard error. Improper operation of the scale.

Err 6 A/D count is not correct when

turning the scale on.

FAIL HiGH or

Calibration error Improper calibration.

FAIL LoW

Weight on the pan when turning the

scale on.

Excessive weight on the pan when

zeroing the scale.

Improper calibration of the scale.

Damaged load cell.

Damaged Electronics.

Platform is not installed.

Load cell may be damaged.

Electronics may be damaged.

If the problem persists contact your

dealer or Adam Equipment for

assistance.

© Adam Equipment Company 2016 30

Page 31

13.0 TECHNICAL PARAMETERS

The technical parameters accessed via the “tECH” prompt at the end of user parameters and are

password controlled to prevent unauthorised access. These parameters set the metrology for the

scales. Each scale is set independently. The parameters will set capacity, division, decimal point

position, initial zero range, auto and manual zero range as well as factory calibration.

ACTION DISPLAYS

When “tEch” is displayed, press the [Print]

key. The scale will ask you to enter the

password.

Default Password is 0000.

Enter “0” four times.

2006 will override any other user password.

Press [Print].

Select the scale to be set up by using the

[Local/Rem] key.

Press the [Print] to enter the technical

section for that scale.

Use the [U.Wt./Units] to select the weighing

unit to be used for setting up the

parameters for the scale. The arrow in the

“Weight” window will indicate the unit

selected.

Press the [Print] key to continue.

Press the [U.Wt./Units] key to scroll through

the menus for the chosen scale. User [Print]

to select and set parameters and the

[Tare/Zero] to escape as without changing

data as with the user parameter section.

“ Pi n”

“ Pi n” “ ----”

“t ECH” “ Lo c A L” “ “

“t ECH” “r E mo t E” “ “

“t ECH” “ Uni t” “ “

“Cn t”

Both scales have the same menus except

that the capacity of the local scale is fixed

and cannot be entered.

© Adam Equipment Company 2016 31

Page 32

Press the [U.Wt/Unit] to go to next menu.

Press [Print] to enter.

Use [U.Wt/Unit] to select the decimal point

position and press [Print].

To change the remote scale cap press CE to

clear and then enter new value followed by

[Print].

Press [U.Wt/Unit] to go to next menu. Press

[Print] to enter.

Use [U.Wt/Unit] to select the division which

you would like the display to increment in,

followed by [Print].

Press the [U.Wt/Unit] to go to next menu,

use [Print] key to enter.

Use [U.Wt/Unit] to increment the values

then [Print].

Press the [U.Wt/Unit] to go to next menu,

use [Print] key to enter.

Use [U.Wt/Unit] to increment the values

then [Print].

Press the [U.Wt/Unit] to go to next menu,

use [Print] key to enter.

Use [U.Wt/Unit] to increment the values

then [Print].

Press the [U.Wt/Unit] to go to next menu,

use [Print] key to enter.

Enter the new PIN number and press [Print].

Confirm the new PIN number and press

[Print].

Press [U.Wt./Units] to continue use [Print]

key to enter.

Escape the parameters with the [Zero/Tare]

“CAP”. Scale capacity setting.

“dESC” “ 0.00”

“LOAd” “0060”

“inC 5”

“AZt” Autozero tracking range.

Select from 0.5d, 1d, 2d, 4,d

“0 Auto” Zero auto range at power on.

Select from 0%, to 10%

“0 manl” Zero manual range.

Select from 0%, to 10%

“Pin” Password number for “tEch”.

“Pin1”

“Pin2”

“donE”

“CAL” Enter calibration section where the local

or remote scale is selected. See section 11.

© Adam Equipment Company 2016 32

Page 33

14.0 REPLACEMENT PARTS AND ACESSORIES

If you need to order any spare parts and accessories, contact your supplier or Adam Equipment. A

partial list of such items is as follows-

• Power Supply Module

• Main Power cord

• Replacement Battery

• In use cover

• Printer, etc.

• Stainless Steel Pan

15.0 SERVICE INFORMATION

This manual covers the details of operation. If you have a problem with the scale that is not

directly addressed by this manual then contact your supplier for assistance. In order to provide

further assistance, the supplier will need the following information which should be kept ready:

A. Details of your company

-Name of your company:

-Contact person’s name:

-Contact telephone, e-mail,

fax or any other methods:

B. Details of the unit purchased

(This part of information should always be available for any future

correspondence. We suggest you to fill in this form as soon as the unit is received

and keep a print-out in your record for ready reference.)

Model name of the scale:

CBD____

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

C. Brief description of the problem

Include any recent history of the unit. For example:

-Has it been working since it’s delivered

-Has it been in contact with water

-Damaged from a fire

-Electrical Storms in the area

-Dropped on the floor, etc.

© Adam Equipment Company 2016 33

Page 34

WARRANTY INFORMATON

Adam Equipment offers Limited Warranty (Parts and Labour) for any components

that fail due to defects in materials or workmanship. Warranty starts from the date

of delivery.

During the warranty period, should any repairs be necessary, the purchaser must

inform its supplier or Adam Equipment. The company or its authorised technician

reserves the right to repair or replace the components at the purchaser’s site or any

of its workshops depending on the severity of the problems at no additional cost.

However, any freight involved in sending the faulty units or parts to the service centre

will be borne by the purchaser.

The warranty will cease to operate if the equipment is not returned in the original

packaging and with correct documentation for a claim to be processed. All claims are

at the sole discretion of Adam Equipment.

This warranty does not cover equipment where defects or poor performance is due

to misuse, accidental damage, exposure to radioactive or corrosive materials,

negligence, faulty installation, unauthorised modifications or attempted repair or

failure to observe the requirements and recommendations as given in this User

Manual.

This product may include a rechargeable battery that is designed to be removed and

replaced by the user. Adam Equipment warrants that it will provide a replacement

battery if the battery manifests a defect in materials or workmanship during the

initial period of use of the product in which the battery is installed.

As with all batteries, the maximum capacity of any battery included in the product

will decrease with time or use, and battery cycle life will vary depending on product

model, configuration, features, use, and power management settings. A decrease in

maximum battery capacity or battery cycle life is not a defect in materials or

workmanship, and is not covered by this Limited Warranty.

Repair carried out under the warranty does not extend the warranty period.

Components removed during the warranty repairs become the company property.

The statutory rights of the purchaser are not affected by this warranty. In the event

of dispute then the terms of this warranty are governed by UK law. For complete

details on Warranty Information, see the terms and conditions of sale available on

our web-site.

www.adamequipment.com

© Adam Equipment Company 2016 34

Page 35

WEEE 2012/19/EU

This device may not be disposed of in domestic waste. This also applies to countries outside

the EU, per their specific requirements. Disposal of batteries (if fitted) must conform to local

laws and restrictions.

Cet appareil ne peut être éliminé avec les déchets ménagers. L’élimination de la batterie doit

être effectuée conformément aux lois et restrictions locales.

Dieses Gerät nicht mit dem Hausmüll entsorgt.

Dispositivo no puede ser desechado junto con los residuos domésticos

Dispositivo non può essere smaltito nei rifiuti domestici.

FCC / IC CLASS A DIGITAL DEVICE EMC VERIFICATION STATEMENT

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC rules and Canadian ICES-003/NMB-003 regulation. These

limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

CALIFORNIA PROPOSITION 65 - MANDATORY STATEMENT

WARNING: This product includes a sealed lead-acid battery which contains chemicals known to

the State of California to cause cancer and birth defects or other reproductive harm.

Adam Equipment products have been tested with, and are always supplied

with mains power adaptors which meet all legal requirements for the

intended country or region of operation, including electrical safety,

interference and energy efficiency. As we often update adaptor products to

meet changing legislation it is not possible to refer to the exact model in this

manual. Please contact us if you need specifications or safety information for

your particular item. Do not attempt to connect or use an adaptor not

supplied by us.

© Adam Equipment Company 2016 35

Page 36

ADAM EQUIPMENT is an ISO 9001:2008 certified global company with more than 40 years’ experience in the

production and sale of electronic weighing equipment.

Adam products are predominantly designed for the Laboratory, Educational, Health and Fitness, Retail and

Industrial Segments. The product range can be described as follows:

-Analytical and Precision Laboratory Balances

-Compact and Portable Balances

-High Capacity Balances

-Moisture analysers / balances

-Mechanical Scales

-Counting Scales

-Digital Weighing/Check-weighing Scales

-High performance Platform Scales

-Crane scales

-Mechanical and Digital Electronic Health and Fitness Scales

-Retail Scales for Price computing

© Copyright by Adam Equipment Co. All rights reserved. No part of this publication may be reprinted or translated in

any form or by any means without the prior permission of Adam Equipment.

Adam Equipment reserves the right to make changes to the technology, features, specifications and design of the

equipment without notice.

All information contained within this publication is to the best of our knowledge timely, complete and accurate when

issued. However, we are not responsible for misinterpretations which may result from the reading of this material.

36

Loading...

Loading...