Page 1

Adam Equipment

AE-301 INDICATOR

P.N. 700660194 Revision B- November 2011

Software rev 2.4

© Adam Equipment Company November 2011

Page 2

© Adam Equipment Company November 2011

Page 3

CONTENTS

1.0 INTRODUCTION............................................................................................. 3

2.0 SPECIFICATIONS...........................................................................................3

2.1 KEYBOARD AND DISPLAY ........................................................................4

2.2 POWER SUPPLY........................................................................................5

2.3 LOAD CELLS...............................................................................................5

3.0 OPERATIONS................................................................................................. 6

3.1 POWER .......................................................................................................6

3.2 ZERO FUNCTION .......................................................................................6

3.3 TARE FUNCTION........................................................................................6

3.4 UNIT SELECTION....................................................................................... 6

3.5 WEIGHING ..................................................................................................7

3.6 CHECK WEIGHING.....................................................................................7

3.7 ALARM ........................................................................................................8

3.7.1 Over-load alarming ...............................................................................8

3.7.2 Low-load alarming ................................................................................8

3.7.3 Low battery alarming.............................................................................8

4.0 USER PARAMETERS.....................................................................................8

4.1 BLT = BACKLIGHT CONTROL ................................................................... 9

4.2 CHK = CHECKWEIGHING CONTROL........................................................9

4.3 FIL = FILTERING CONTROL ......................................................................9

4.4 SDT = RS-232 CONTROL.........................................................................10

4.5 PAR = SETTING OF PARITY.................................................................... 10

4.6 BPS = SELECTING BAUD RATE.............................................................. 10

5.0 RS-232 INTERFACE..................................................................................... 11

6.0 TECHNICAL PARAMETERS.........................................................................12

6.1 ZERO TRACKING .....................................................................................12

6.2 UNIT SETTING.......................................................................................... 12

6.3 CALIBRATION...........................................................................................13

7.0 TROUBLE-SHOOTING GUIDE.....................................................................14

8.0 SERVICE INFORMATION.............................................................................15

WARRANTY INFORMATION .................................................................................16

© Adam Equipment Company November 2011

1

Page 4

© Adam Equipment Company November 2011

2

Page 5

1.0 INTRODUCTION

The AE 301 Indicators are general purpose weighing indicators for use

cells. The AE 301 MD indicators come with a built-in load cell for

conversion of mechanical scale to digital readout by connection of the

load cell to the base assembly.

The indicators offer:

• Simple operation

• Zero Tracking

• Selectable automatic backlight

• Check-weighing with low and high limits

• RS-232 interface as standard

• Selectable communication mode

• Operation from internal rechargeable battery or mains power

• 4 weighing units (kg, g, ounce & pound)

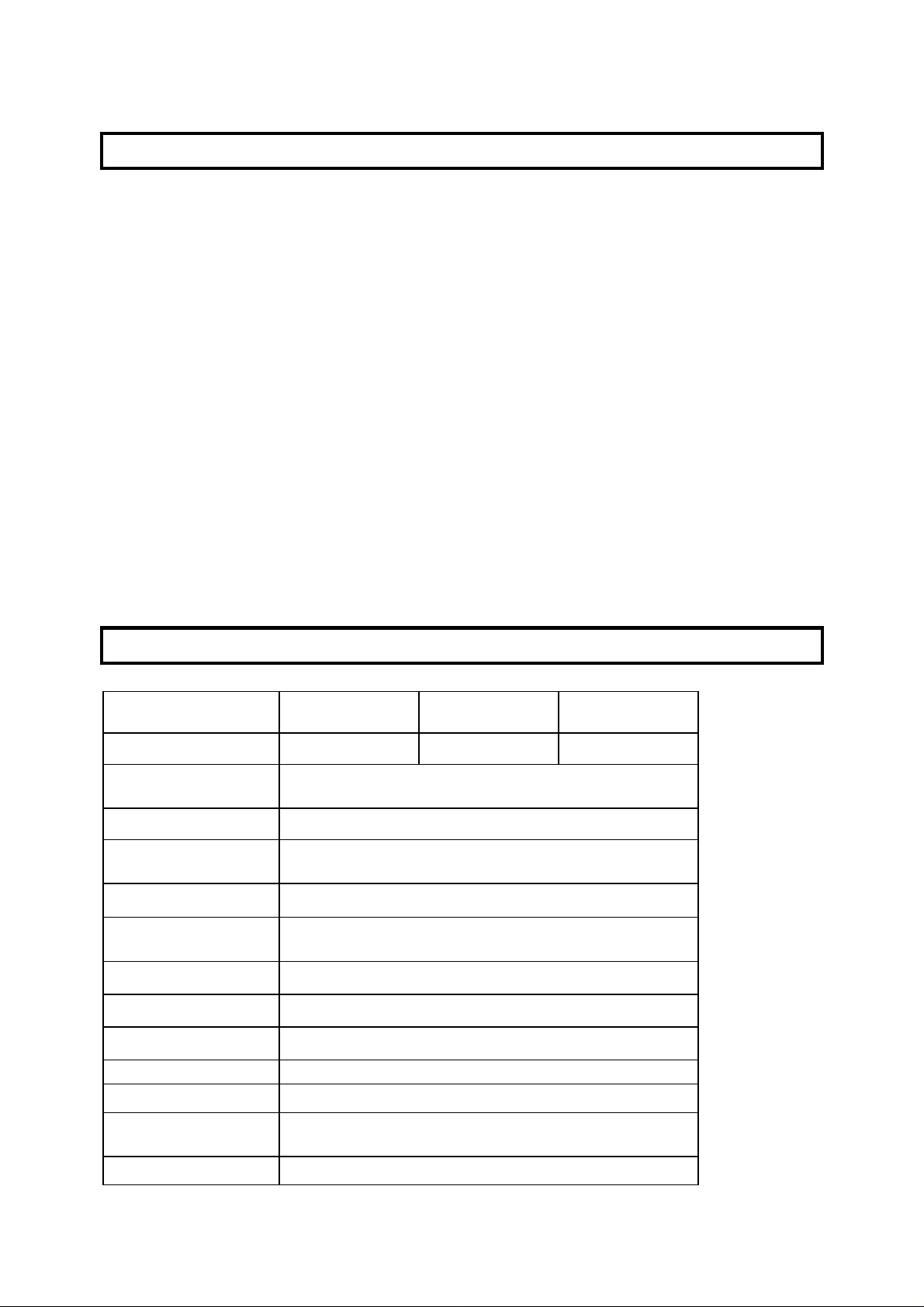

2.0 SPECIFICATIONS

Model

Load cell capacity - 50 kg 100 kg

Internal Counting

resolution

Tare Range Full range

Units of Measure 4 (kg, g, lb, oz)

Stabilisation Time 2-3 seconds

Operating

Temperature

Interface RS-232 bi-directional

Power supply Re-chargeable battery located or mains power

AE 301 AE 301 MD-50 AE 301 MD-100

250,000

0°C to 40°C

Display Large LCD with backlight

Calibration Automatic calibration

Housing ABS Plastic

Dimensions

(w x d x h)

Net Weight 1.35 kg

© Adam Equipment Company November 2011

260 x 155 x 105 mm

3

Page 6

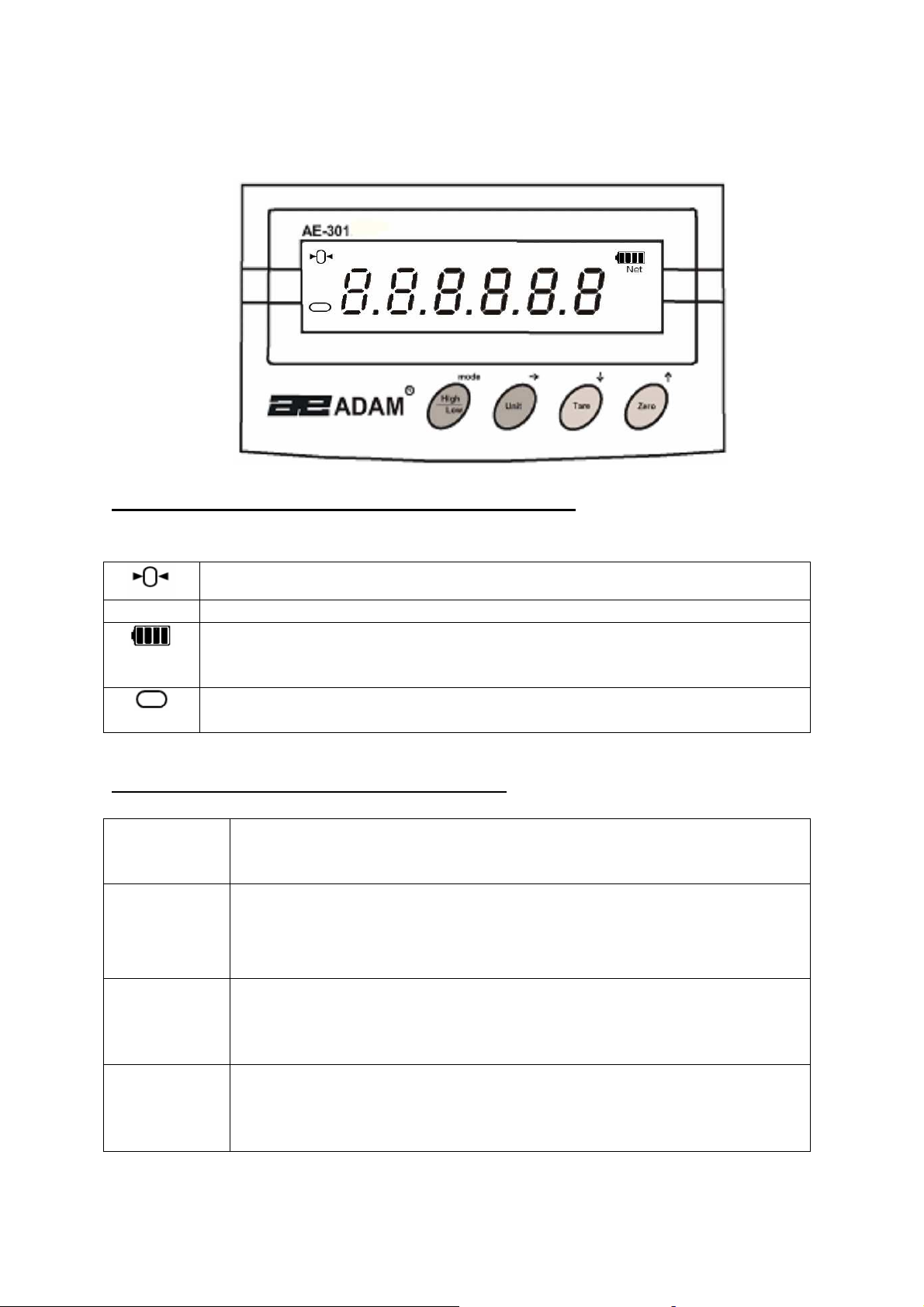

2.1 KEYBOARD AND DISPLAY

The AE-301 indicator has the following symbols:

The scale is at zero

Net A weight has been tared, the display is showing the net weight

The battery symbol showing the state of charge. While the battery is

being re-charged this symbol will show four bars

The weight is stable.

The keys perform the following functions:

[High/Low/

Mode]

[Unit/]

This key is used during setting of the user functions.

It is also used during setting of the High and Low Limits for checkweighing facility and for setting the alarm function.

This key is used to change the weighing units while the indicator is

in the weighing mode.

It is also used for advancing the digit while the indicator is in the

setting mode.

This key is used to deduct the weight of the container from the

[Tare/]

[Zero/ ]

© Adam Equipment Company November 2011

gross weight and thus to display the net weight only.

It is also used to decrease the digit while the scale is in the setting

mode.

This key is used to reset the zero position for accurate weighing

while the scale is in the weighing mode.

It is also used to the increment digit during the setting mode.

4

Page 7

2.2 POWER SUPPLY

• Power can be supplied using an internal re-chargeable

battery provided within the indicator case, or from mains

power.

•

If the battery is low on charge the symbol on the LCD will

show just one bar meaning the battery needs to be recharged immediately. While the battery is being re-charged,

this symbol will show four bars.

• With the internal re-chargeable acid battery, the battery life is

approximately 60 hours. The battery life will vary depending

on the use of the backlight

2.3 LOAD CELLS

• To connect the AE 301 indicator to a new base it is

necessary to connect the load cells properly. Then set the

parameters for the weighing system.

• User should ensure the load cells are correct for the purpose

and the signal from the load cell is correct.

• Note that it may not be possible to measure the voltage

signal from the load cell with all DVM. Some DVM will

measure the Excitation and signal voltage while others will

not. Try measuring the excitation voltage to determine if your

voltmeter will work.

CONNECTING TO LOAD CELLS

The AE 301 is supplied with a connector to connect an external

load cell.

The load cell can be connected in either a 4 or 6-wired

configuration. The standard connection is 4 wired.

Pin 1 Excitation +

Pin 2 Excitation –

Pin 3 Signal +

Pin 4 Signal –

© Adam Equipment Company November 2011

5

Page 8

3.0 OPERATIONS

3.1 POWER

• Attach the mains adaptor to the power supply and plug the

connector into the socket on the Indicator The indicator will

charge the internal battery whenever it is connected to the

220VAC power supply.

• Push the ON/OFF switch at the back right hand side of the

indicator to the ON position to power up.

• Push the ON/OFF switch at the back right hand side of the

indicator to the OFF position to power down.

3.2 ZERO FUNCTION

• For accurate weighing, zero the display by pressing the key

[Zero] with nothing on the platform of the scale.

• The zero indicator 0 will be on.

3.3 TARE FUNCTION

• When the scale has a container on it press the [Tare] key.

• The Tare indicator Net will be shown.

• The display will show zero. If it does not show zero, press

the [Zero] key.

• To clear the tare, remove the container and press the [Tare]

key again. Press [Zero] to switch off the Tare indicator.

3.4 UNIT SELECTION

• The indicator can be set for different units by pressing the

[Unit] key. The options are kilogram, gram, pound and

ounce. They can be enabled as needed (see section 6.2).

Kilogram is always on.

© Adam Equipment Company November 2011

6

Page 9

3.5 WEIGHING

• Place the sample on the scale platform. The weight will be

displayed in the selected Unit.

• Wait until the stable indicator is displayed for accurate

weighing.

3.6 CHECK WEIGHING

Check-weighing is a procedure to sound an alarm when the weight of

the sample on the scale meets or exceeds the pre-set Low and High

values stored in the memory.

To set the High and Low values, follow the procedure given below-

•

Press the [High/Low] key. The display will show “000.00 HI”

with the first digit flashing for setting the High value. To set

your limit, use the [Unit] key to advance the flashing digit, the

[Tare] key to decrease the value of the flashing digit and the

[Zero] key to increase the value of the flashing digit .

• The display will now show “000.00 LOW” with the first digit

flashing for setting the Low value. To set your limit, use the

[Unit] key to advance the flashing digit, the [Tare] key to

decrease the value of the flashing digit and the [Zero] key to

increase the value of the flashing digit . Press [Mode] again

to confirm the value and the display will return to normal

weighing mode.

• Once the check weighing Limits are set and the alarm

function is active, a beep will sound slowly when the sample

weight is below the Low Limit. The beep will sound quickly if

the weight is above the High Limit. If the sample weight is in

between the Limits, the beep does not sound.

© Adam Equipment Company November 2011

7

Page 10

3.7 ALARM

3.7.1 Over-load alarming

• When the sample weight on the scale is over the maximum

capacity the beep will sound and the display will show “Err“.

• Remove the weight immediately to avoid any damage to the scale.

3.7.2 Low-load alarming

• If the top pan is not placed on the scale the beep will sound.

• Place the top pan on the scale before starting to weigh.

3.7.3 Low battery alarming

• When appears on the LCD, re-charge the battery.

• During re-charging, the symbol will show four bars.

• If this symbol appears, re-charge the battery immediately to avoid

any damage to the battery.

4.0 USER PARAMETERS

The following parameters can be set by the user by entering the function

setting mode. Press the [Tare] key while switching on the indicator. The

first parameter will be displayed along with the settings done previously.

• The available parameters can be cycled through by pressing

the [Mode] key.

• Not all parameters may be enabled. Some parameters may

be set during the initial configuration and the user is not

given access to them. In this case those will not be seen

when the [Mode] key is pressed. To use any of the

parameters see the corresponding section of the manual.

• Switch off and switch on again to return to weighing when

settings are complete.

© Adam Equipment Company November 2011

8

Page 11

Parameters

Description

1.

2.

3.

4.

5.

6.

BLT

CHK

FIL

SDT

PAT

BPS

Enable / disable the backlight

Enable / disable the check-weighing facility

Enable / disable the ADC filter rate

Sets the RS-232 output function.

Options are 1, 2, 3 and 4.

Sets the following parity options-

8 n 1 7 E 1 -

7 0 1 -

Changes the baud rate for RS-232 transmission

speed. Options are 1200, 2400, 4800 and 9600.

8 data bits, no parity

7 data bits, even parity

7 data bits, odd parity

4.1 BLT = BACKLIGHT CONTROL

• When “BLT” is displayed press the [Unit] key to change

setting

“BLT= 0FF“ Backlight is disabled.

“BLT= On” Backlight is enabled.

• Press the [Mode] key to store the setting and move on.

4.2 CHK = CHECK WEIGHING CONTROL

• When “CHK” is displayed press the [Unit] key to change

setting

“CHK= 0FF“ Check weighing is disabled.

“CHK= On” Check weighing is enabled.

• Press the [Mode] key to store the setting and move on.

4.3 FIL = FILTERING CONTROL

• When “FIL” is displayed press the [Unit] key to change

setting.

“FIL= 0FF“ Filtering function is disabled.

“FIL= On” Filtering function is enabled.

• Press the [Mode] key to store the setting and move on.

© Adam Equipment Company November 2011

9

Page 12

4.4 SDT = RS-232 CONTROL

• When this function is displayed with the current setting, press

the [Unit] key to change to the other settings.

1 Continuous output

2 Outputs under command from PC

3 Outputs weight when the scale is stable

4 Outputs complete data to printer when scale is stable

• Press the [Mode] key to store the desired setting and move

to the next function.

4.5 PAR = SETTING OF PARITY

• When this function is displayed with the current setting, press

the [Unit] key to change to the other settings.

8 n 1 - 8 data bits, no parity (default setting)

7 E 1 - 7 data bits, even parity

7 0 1 - 7 data bits, odd parity

• Press the [Mode] key to store the desired setting and move

to the next function.

4.6 BPS = SELECTING BAUD RATE

• When this function is displayed with the current setting, press

the [Unit] key to change to the other settings. The options

are 1200, 2400, 4800 and 9600.

• Press the [Mode] key to store the desired setting.

• To return to weighing, switch the indicator off and then on

again.

© Adam Equipment Company November 2011

10

Page 13

5.0 RS-232 INTERFACE

The BFW series of indicators come with a standard RS-232 interface.

U

The standard Interface parameters are:

RS-232 output of weighing data

ASCII code

Selectable Baud

Selectable data bits

U

Connection details are:

Connector: 9 pin d-subminiature socket

Pin 3 Output

Pin 2 Input

Pin 5 Signal Ground

Selectable Parity

U

Normal OutputU: (For SDT 1, 2 and 3)

SN ± xx.xxx LL UU S stands for stable,

N for no error G/W for gross weight,

LL for OK, HI or LO (during check weighing)

UU for the chosen unit( kg, g, lb, oz)

Complete Data Output: (For SDT 4)

When the SDT is set to 4 (see section 4.4), it will send 6 lines of data to

the printer in the following format

<SOH><cr><If>

G±sp spXX.XXXsp sp <kg><cr><If>

T±sp spXX.XXXsp sp <kg><cr><If>

N±sp spXX.XXXsp sp <kg><cr><If>

<cr><If>

<cr><If>

<EOT>

First line is blank

Gross weight printed

Tare weight printed

Net weight printed

Blank line

Blank line

End of Transmission

Input commands format:

The indicator can be used from a PC with the following commands. The commands

must be sent in upper case letters, i.e. “T” not “t” and press the Enter button.

N Sends the net weight to the RS-232 interface.

G Sends the gross weight to the RS-232 interface

T Sends the tare weight to the RS-232 interface.

Z Zero the indicator to display the net weight. This is the same

as pressing [Tare] or [Zero].

Lxx.xxx Sets the lower limit. Same as pressing the [High/Low].

Hxx.xxx Sets the upper limit. Same as pressing the [High/Low].

C0 Disable check weighing.

C1 Enable check weighing.

© Adam Equipment Company November 2011

11

Page 14

6.0 TECHNICAL PARAMETERS

To enter this section, press and hold the [Mode] and the [Tare] key

while you turn on the indicator. The display will show the revision

number and then the first parameter Zero Tracking as “ZEO”

6.1 ZERO TRACKING

• When ZEO is displayed, press [Unit] to change to the other

setting.

“ZEO= 0FF“ Zero tracking function is disabled.

“ZEO= On” Zer0 tracking function is enabled.

• Press the [Mode] key to store the desired setting and move

to the next function.

6.2 UNIT SETTING

The user will be able to enable the weighing units to be used - grams,

pounds or ounce. Kilogram is the default weighing unit.

• When g is displayed, press the [Unit] key to change to the

other setting.

“g= 0FF“ Gram unit is disabled.

“g= On” Gram unit is enabled.

• Press the [Mode] key to store the desired setting and move

to the next unit setting.

© Adam Equipment Company November 2011

12

Page 15

6.3 CALIBRATION

The next section is the Calibration section.

A weight value and. “WEl” will be displayed.

• When WEI is displayed, press the [Unit] key to scroll through the

options for selecting the calibration mass.

• To select the desired mass press the [Mode] key.

• The raw ADC count will be displayed along with “CAI”.

• To set the zero calibration, press the [Mode] key again.

• The scale will display “0 LOD”, place the calibration mass

selected onto the top pan, the display will show the raw ADC

counts of the selected calibration mass, then press [Mode] again.

• The display shows PASS and then returns to normal weighing

• Remove the weight and continue to use.

© Adam Equipment Company November 2011

13

Page 16

7.0 TROUBLE-SHOOTING GUIDE

PROBLEMS POSSIBLE CAUSES

Display is blank On/Off switch on rear panel is off

Indicator not turned on

Battery not charged

No countdown of display on power

up

Error message displayed - Err Overload

Display is unstable Drafts or air currents

Weight value incorrect Calibration error, Recalibrate

Cannot use Full Capacity Overload stops hitting platform

Not Linear Overload stops hitting too soon

Off Center Loading error

Battery will not charge Incorrect power adaptor being used

Battery not charged

Power supply not plugged in or

incorrect type

Power supply faulty

Display turned off

Load cell damaged

Load cell connections not secure

Obstruction under weighing platform

Vibrations through the floor

Temperature changed dramatically

Power supply faulty

Unit calibrated with inaccurate weight

Obstruction around platform

support or hitting bottom of load cell

Parameters set incorrectly

Load cell Damaged

Load cell damaged

Overload stops not set correctly

Load cell damaged

Charging circuit failure

Battery failure

Main voltage not present or too low

© Adam Equipment Company November 2011

14

Page 17

A. Details of your company

8.0 SERVICE INFORMATION

This manual covers the details of operation. If you have a problem with

the indicator that is not directly addressed by this manual then contact

your supplier for assistance. In order to provide further assistance, the

supplier will need the following information which should be kept ready:

-Name of your company:

-Contact person’s name:

-Contact telephone, e-mail,

fax or any other methods:

B. Details of the unit purchased

(This part of information should always be available for any future correspondence.

We suggest you to fill in this form as soon as the unit is received and keep a printout in your record for ready reference.)

Model name of the product:

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

C. Brief description of the problem

Include any recent history of the unit. For example:

-Has it been working since it’s delivered

-Has it been in contact with water

-Damaged from a fire

-Electrical Storms in the area

-Dropped on the floor, etc.

© Adam Equipment Company November 2011

15

Page 18

WARRANTY

Adam Equipment offers Limited Warranty (Parts and Labour) for the components failed due to

defects in materials or workmanship. Warranty starts from the date of delivery.

During the warranty period, should any repairs be necessary, the purchaser must inform its

supplier or Adam Equipment Company. The company or its authorised Technician reserves the

right to repair or replace the components at any of its workshops depending on the severity of

the problems. However, any freight involved in sending the faulty units or parts to the service

centre should be borne by the purchaser.

The warranty will cease to operate if the equipment is not returned in the original packaging

and with correct documentation for a claim to be processed. All claims are at the sole discretion

of Adam Equipment.

This warranty does not cover equipment where defects or poor performance is due to misuse,

accidental damage, exposure to radioactive or corrosive materials, negligence, faulty

installation, unauthorised modifications or attempted repair or failure to observe the

requirements and recommendations as given in this User Manual. Additionally rechargeable

batteries (where supplied) are not covered under warranty.

INFORMATION

Repairs carried out under the warranty does not extend the warranty period. Components

removed during the warranty repairs become the company property.

The statutory right of the purchaser is not affected by this warranty. The terms of this warranty

is governed by the UK law. For complete details on Warranty Information, see the terms and

conditions of sale available on our web-site.

© Adam Equipment Company November 2011

16

Page 19

Manufacturer’s Declaration of Conformity

This product has been manufactured in accordance with the harmonised European

standards, following the provisions of the below stated directives:

Electro Magnetic Compatibility Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

Adam Equipment Co. Ltd.

Bond Avenue, Denbigh East

Milton Keynes, MK1 1SW

United Kingdom

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. The equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Shielded interconnect cables must be employed with this equipment to insure compliance with the

pertinent RF emission limits governing this device.

Changes or modifications not expressly approved by Adam Equipment could void the user's authority to

operate the equipment.

WEEE COMPLIANCE

Any Electrical or Electronic Equipment (EEE) component or assembly of parts intended to be

incorporated into EEE devices as defined by European Directive 2002/95/EEC must be recycled or

disposed using techniques that do not introduce hazardous substances harmful to our health or the

environment as listed in Directive 2002/95/EC or amending legislation. Battery disposal in Landfill Sites is

more regulated since July 2002 by regulation 9 of the Landfill (England and Wales) Regulations 2002 and

Hazardous Waste Regulations 2005. Battery recycling has become topical and the Waste Electrical and

Electronic Equipment (WEEE) Regulations are set to impose targets for recycling.

© Adam Equipment Company November 2011

Page 20

ADAM EQUIPMENT

35 years experience in the production and sale of electronic weighing equipment.

Adam products are predominantly designed for the Laboratory, Educational, Medical,

retail and Industrial Segments. The product range can be described as follows:

-Analytical and Precision Balances

-Compact and Portable Balances

-High Capacity Balances

-Moisture analysers / balances

-Mechanical Scales

-Counting Scales

-Digital Weighing/Check-weighing Scales

-High performance Platform Scales

-Crane scales

-Medical Scales

-Retail Scales for Price computing

For a complete listing of all Adam products visit our website at

is an ISO 9001:2008 certified global company with more than

www.adamequipment.com

© Copyright by Adam Equipment Co. Ltd. All rights reserved. No part of this publication may be

reprinted or translated in any form or by any means without the prior permission of Adam

Equipment.

Adam Equipment reserves the right to make changes to the technology, features, specifications

and design of the equipment without notice.

All information contained within this publication is to the best of our knowledge timely, complete

and accurate when issued. However, we are not responsible for misinterpretations which may

result from the reading of this material.

The latest version of this publication can be found on our Website.

www.adamequipment.com

© Adam Equipment Company November 2011

Loading...

Loading...