Page 1

Adam Equipment

ABK, AFK Scales

(P.N. 3116611364 - Revision A, December 2011)

© Adam Equipment Company 2011

Page 2

Easy Reference:

Model name of the scale:

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

© Adam Equipment Company 2011

Page 3

CONTENTS

1.0

INTRODUCTION .................................................................................................................................. 3

2.0

SPECIFICATIONS................................................................................................................................ 4

3.0

INSTALLATION .................................................................................................................................... 6

3.1

UNPACKING....................................................................................................................................6

3.2

LOCATING....................................................................................................................................... 6

3.3

SETTING UP THE SCALES ............................................................................................................ 8

4.0

KEY DESCRIPTIONS........................................................................................................................... 9

5.0

DISPLAYS .......................................................................................................................................... 11

6.0

OPERATION....................................................................................................................................... 12

6.1

ZEROING THE DISPLAY............................................................................................................... 12

6.2

TARING.......................................................................................................................................... 12

6.3

WEIGHING A SAMPLE.................................................................................................................. 13

6.4

PARTS COUNTING ....................................................................................................................... 14

6.5

CHECK-WEIGHING.......................................................................................................................15

6.6

ACCUMULATED TOTAL ............................................................................................................... 18

6.7

PERCENT WEIGHING................................................................................................................... 19

6.8

ANIMAL (Dynamic) WEIGHING..................................................................................................... 21

6.8.1 ANIMAL WEIGHING PROCEDURE.............................................................................................. 22

7.0

USER PARAMETERS........................................................................................................................ 23

7.1

CHECK WEIGHING PARAMETERS............................................................................................. 23

7.2

PERCENT WEIGHING and ANIMAL WEIGHING.........................................................................24

7.3

RS-232 PARAMETERS ................................................................................................................. 25

7.4

SCALE PARAMETERS.................................................................................................................. 26

8.0

BATTERY OPERATION..................................................................................................................... 28

9.0

RS-232 INTERFACE .......................................................................................................................... 29

9.1

INPUT COMMANDS FORMAT...................................................................................................... 32

10.0 RELAY INTERFACE........................................................................................................................... 33

11.0 CALIBRATION.................................................................................................................................... 35

12.0 SERVICE SECTION........................................................................................................................... 36

12.1 USING “1000” TO ENTER THE SERVICE PARAMETERS..........................................................36

12.2 USING “2006” TO ENTER THE SECURE PARAMETERS........................................................... 37

12.3 PARAMETER DETAILS................................................................................................................. 38

12.3.1 F1 -CALIBRATION....................................................................................................................... 38

12.3.2 F2–DECIMAL POINT POSITION ................................................................................................38

12.3.3 F3 – CAPACITY/ WEIGHING UNIT/INCREMENT...................................................................... 39

12.3.4 F4 –INITIAL ZERO RANGE.........................................................................................................40

12.3.5 F5 -RE-ZERO RANGE................................................................................................................. 40

12.3.6 F6 -SUCCESSIVE TARE.............................................................................................................40

12.3.7 F7 –ADC COUNTS......................................................................................................................40

12.3.8 F8 –ZERO MODE........................................................................................................................40

12.3.9 F9 –LOW VOLTAGE DETECTION..............................................................................................41

12.3.10 FA –AZn Auto Zero Range ........................................................................................................ 41

12.3.11 Fb –FPS User Function Password ............................................................................................41

13.0 ERROR CODES................................................................................................................................. 42

14.0 REPLACEMENT PARTS AND ACCESSORIES................................................................................ 43

15.0 SERVICE INFORMATION.................................................................................................................. 43

16.0 WARRANTY STATEMENT ............................................................................................................... 44

1

| P a g e © Adam Equipment Company 2011

Page 4

2

| P a g e © Adam Equipment Company 2011

Page 5

1.0 INTRODUCTION

• The ABK/AFK scales provides an accurate, fast and versatile

general purpose weighing scales with parts counting, percent

weighing and check-weighing functions.

• The ABK/AFK has LEDs to indicate when a weight is below the

low limit, between the limits or above the high limit next to the

display. These can work in conjunction with an audible alarm for

check weighing as well as LCD showing LO, OK and HI.

• The ABK/AFK is supplied with a RS-232 bi-directional interface

and real time clock (RTC).

• The ABK/AFK has a sealed keypad with colour coded membrane

switches and a large easy to read liquid crystal type display (LCD)

supplied with a backlight.

• Includes automatic zero tracking, semi-automatic tare and

accumulation facility that allows the weight to be stored and

recalled as an accumulated total.

3

| P a g e © Adam Equipment Company 2011

Page 6

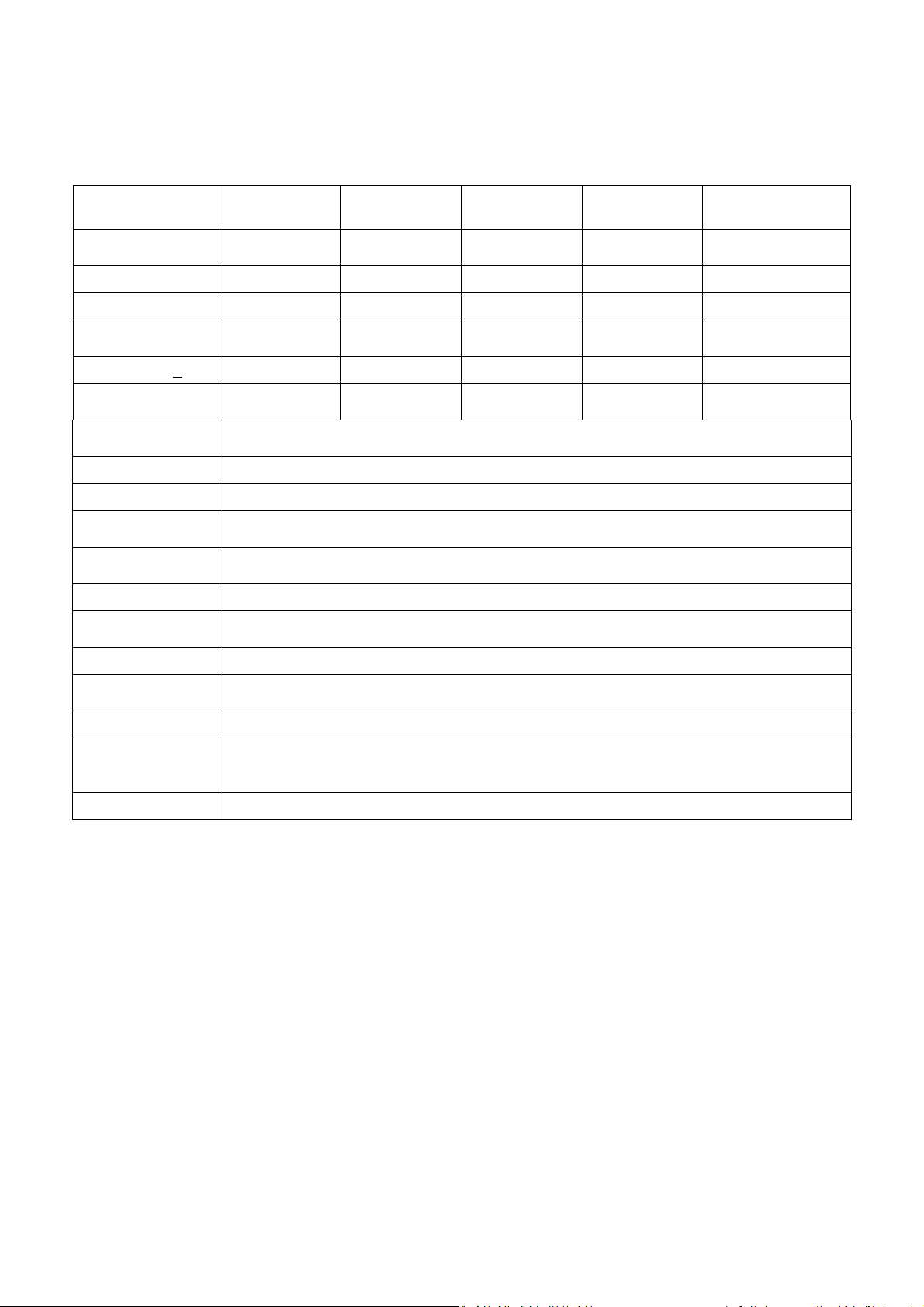

2.0 SPECIFICATIONS

Model #

Maximum

Capacity

Readability 0.2g/0.0005lb 0.5g/0.001lb 1g/0.002lb 2g/0.005lb 5g/0.01lb

Resolution 1:40000 1:32000 1:32000 1:30000 1:24000

Repeatability

(Std Dev)

Linearity + 0.4g/0.001lb 1g/0.002lb

Eccentric Loading

Pan size

w x d

Units of Measure g / Kg / Lb / Lb:oz / Newtons/Ounces for all non approved

Stabilization Time 2-3 Secs

Operating

Temperature

Power Supply

Calibration External

Calibration Mass

Display Backlit Green display 40mm with capacity tracker

Draft Shield

(w x d x h)

Balance Housing 304 Stainless steel housing IP66 rated

Overall

Dimensions

(w x d x h)

Net Weight 7.9kg / 17.4Lb (approx)

ABK 8

ABK 16a

8000g/16lb 16kg/35lb 32kg/70lb 60kg/130lb 120kg/260lb

0.2g/0.0005lb 0.5g/0.001lb 1g/0.002lb 2g/0.005lb 5g/0.01lb

0.4g/0.001lb 1g/0.002lb

User Selectable for non approved only, pre set for approved models

ABK 16

ABK 35a

-10°C to +40°C / +32°F to +104°F

12vDC 800mA External adaptor

300mm x 520mm x 610mm/ 11.8in x 20.5in x 24in (approx)

ABK 32

ABK 70a

2g/0.004lb

2g/0.004lb

300 mm x 400mm

+ 6v 4.5Ah battery

Not Applicable

ABK 60

ABK 130a

4g/0.01lb

4g/0.01lb

ABK 120

ABK 260a

10g/0.02lb

10g/0.02lb

4

| P a g e © Adam Equipment Company 2011

Page 7

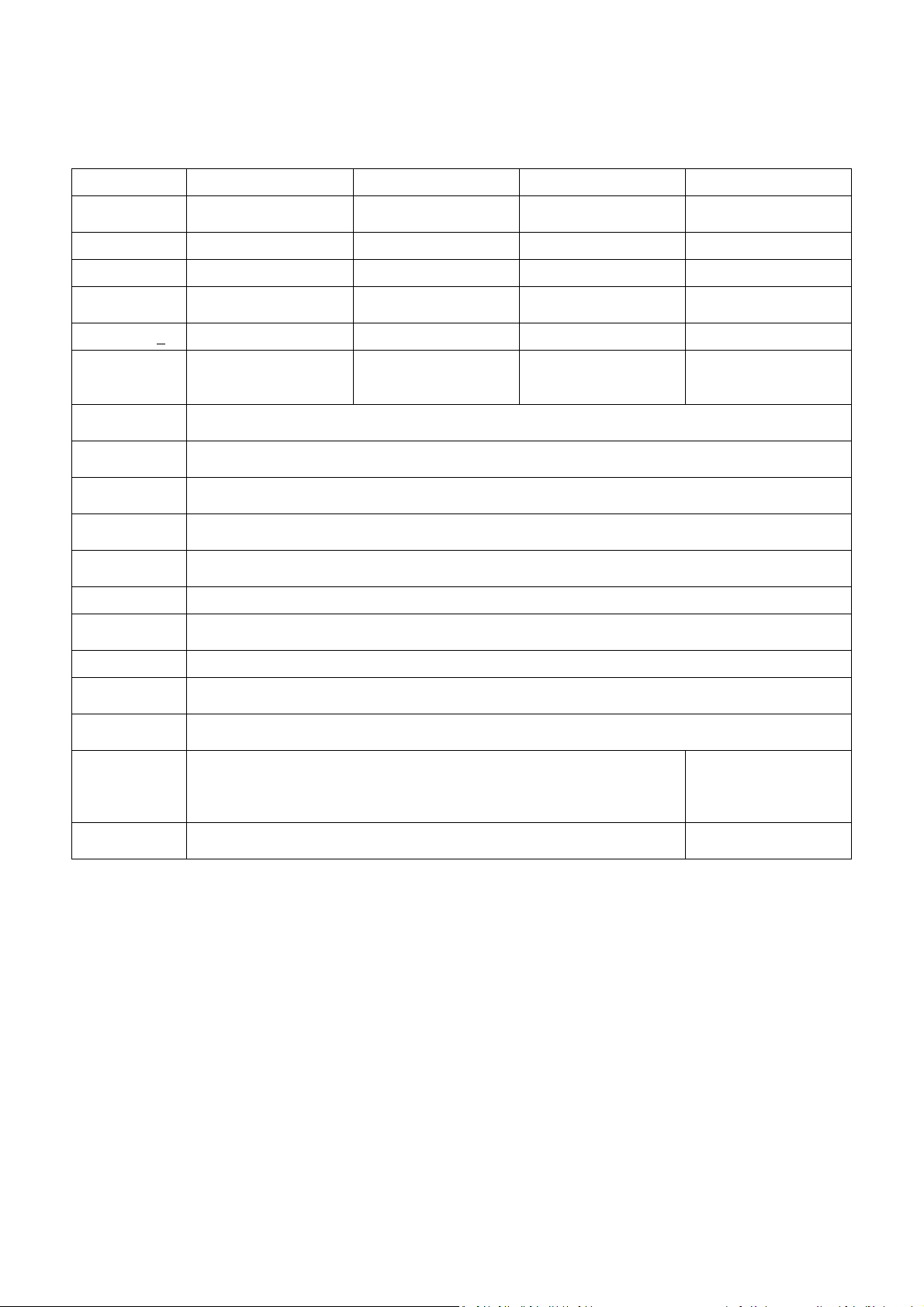

Model # AFK 75/165a AFK 150/330a AFK 300/660a AFK 600/1320a

Maximum

Capacity

Readability 5g/0.01lb 10g/0.02lb 20g/0.05lb 50g/0.1lb

Resolution 1:15000 1:15000 1:15000 1:12000

Repeatability

(Std Dev)

Linearity + 10g/0.02lb 20g/0.04lb 40g/0.1lb 100g/0.2lb

Eccentric

Loading

Pan size

w x d

Units of

Measure

Stabilization

Time

Operating

Temperature

Power Supply

Calibration External

Calibration

Mass

Display Backlit Green display 40mm with capacity tracker

Draft Shield

(w x d x h)

Balance

Housing

Overall

Dimensions

(w x d x h)

Net Weight 12.8kg/28.2lb (approx)

75kg/165lb 150kg/330lb 300kg/660lb 600kg/1320lb

5g/0.01lb 10g/0.02lb 20g/0.05lb 50g/0.1lb

10g/0.02lb 20g/0.04lb 40g/0.1lb 100g/0.3lb

400mm x 500mm

g / Kg / Lb / Lb:oz / Newtons/Ounces for all non approved

2-3 Secs

-10°C to +40°C / +32°F to +104°F

+ 6v 4.5Ah battery

12vDC 800mA External adaptor

User Selectable for non approved only, pre set for approved models

Not Applicable

304 Stainless steel housing IP66 rated

600mm x 940mm x

400mmx 620mm x 790mm/ 15.7in x 24.4in x 31 in (approx)

23.6in x 37in x 32.7in

830mm

(approx)

24.3kg/ 53.6lb

(approx)

5

| P a g e © Adam Equipment Company 2011

Page 8

3.0 INSTALLATION

3.1 UNPACKING

The ABK/AFK scales have already been adjusted to work with a platform and

have been configured for this application. The platform and indicator have

been calibrated as a pair and must be used together .

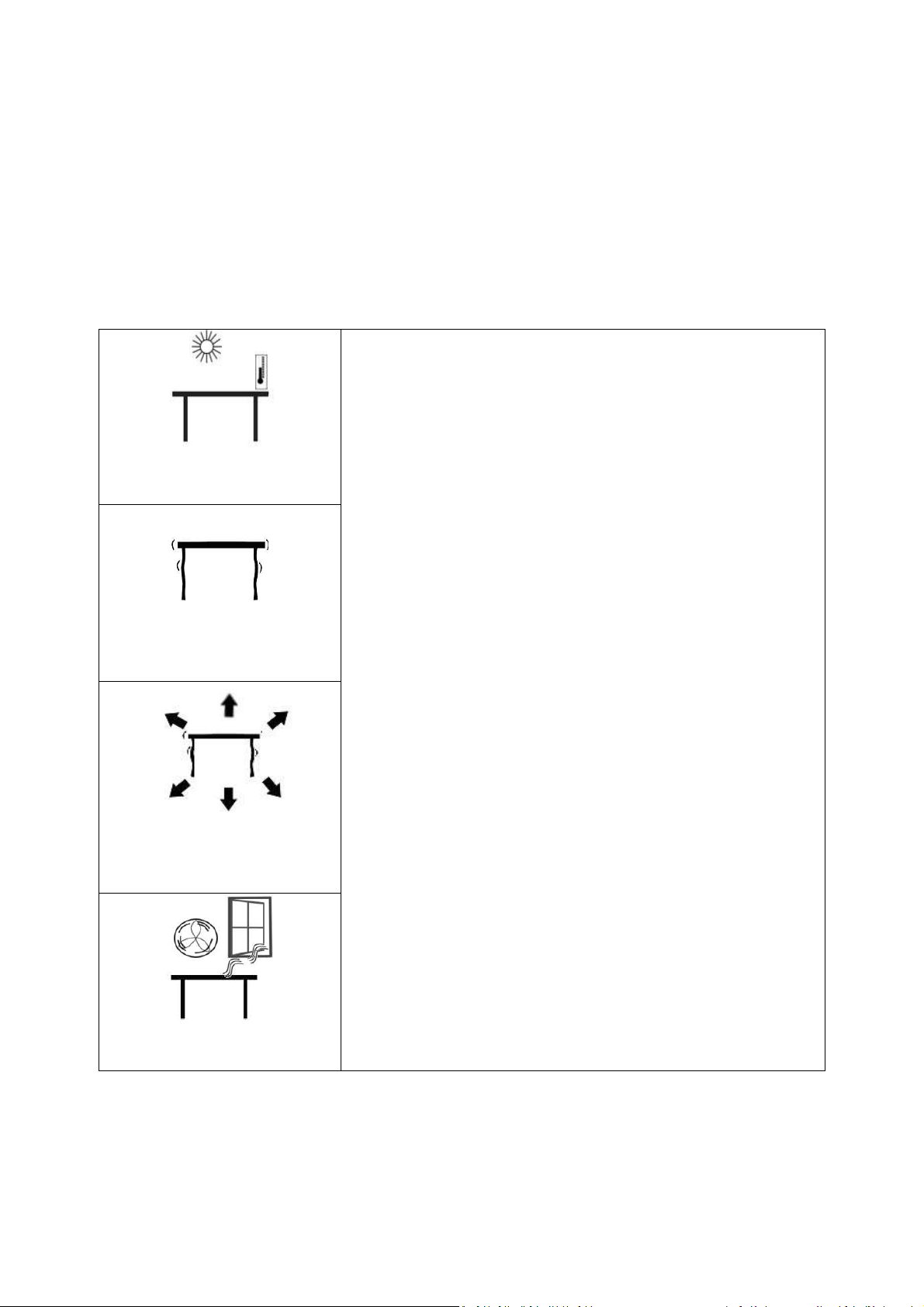

3.2 LOCATING

• The scales should not be placed in a location that

will reduce the accuracy.

• Avoid extremes of temperature. Do not place in

direct sunlight or near air conditioning vents.

• Avoid unsuitable tables. The table or floor must be

rigid and not vibrate.

• Avoid unstable power sources. Do not use near

large users of electricity such as welding equipment

or large motors.

• Do not place near vibrating machinery.

• Avoid high humidity that might cause condensation.

Avoid direct contact with water. Do not spray or

immerse the scales in water.

• Avoid air movement such as from fans or opening

doors. Do not place near open windows or airconditioning vents.

•

Keep the scales clean. Do not stack material on the

scales when they are not in use.

6

| P a g e © Adam Equipment Company 2011

Page 9

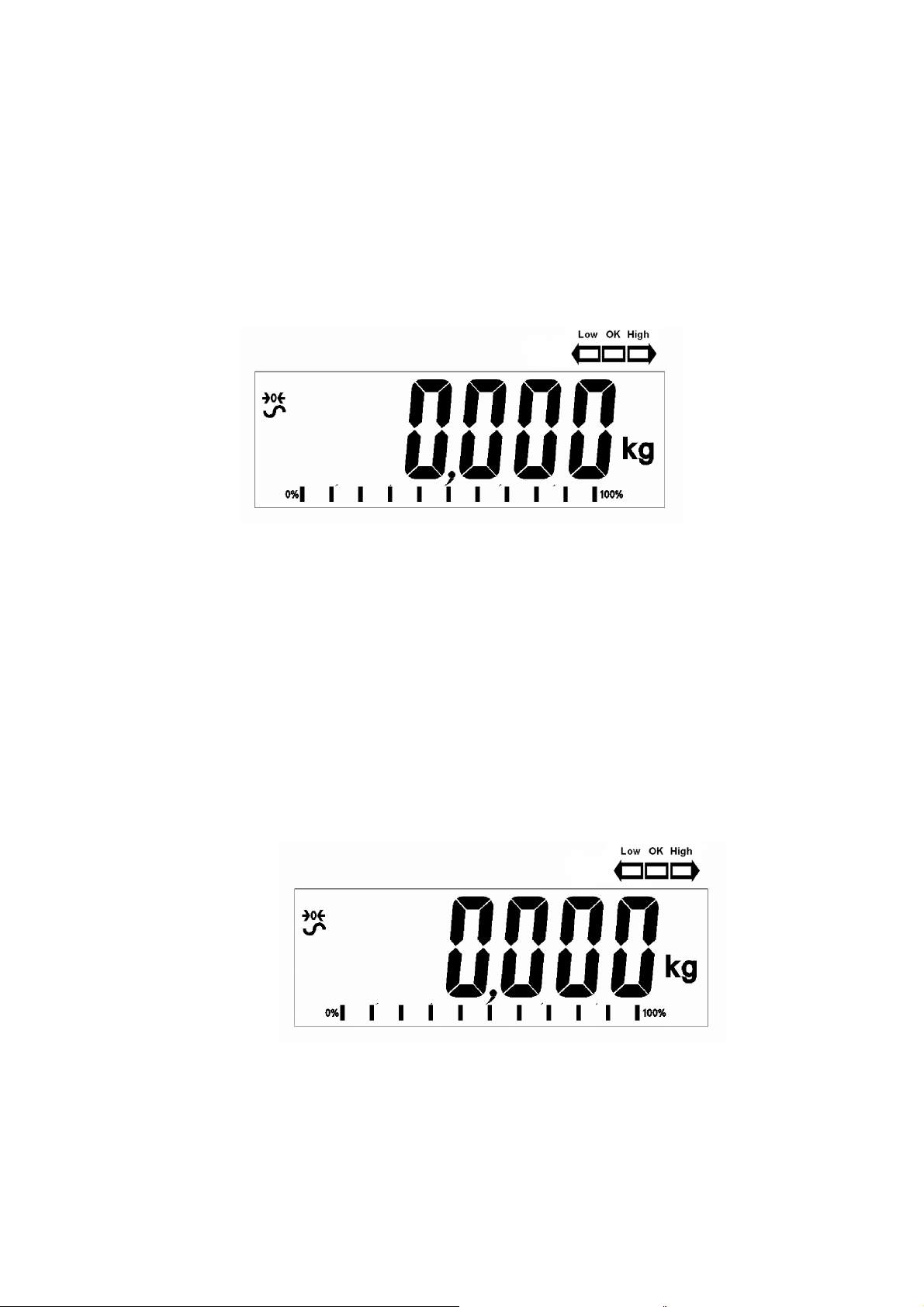

3.3 SETTING UP THE SCALES

• The pillar is attached to the base using a bracket that must be

attached to the base frame first using the 4 bolts supplied. The

pillar is secured to the bracket using 2 sets of screws. The cable

from the base to the indicator module is run through the tube and

taken out through the support at the top. Excess cable can be

stored within the tube.

• The ABK/AFK Series comes with a stainless steel platform

packed separately. Place the platform in the base.

• Level the scale by adjusting the four feet. If the scale rocks re-

adjust the feet.

• Attach the indicator module to the pillar by securing it with the 2

thumb screws provided. Attach the cable from the base to the

connector on the rear of the indicator.

• Attach the power to the indicator. Press the [On/Off] key. The

software revision number will be displayed followed by a self-test

showing all digits before the zero is displayed along with the unit

of weight that was selected last.

8

| P a g e © Adam Equipment Company 2011

Page 10

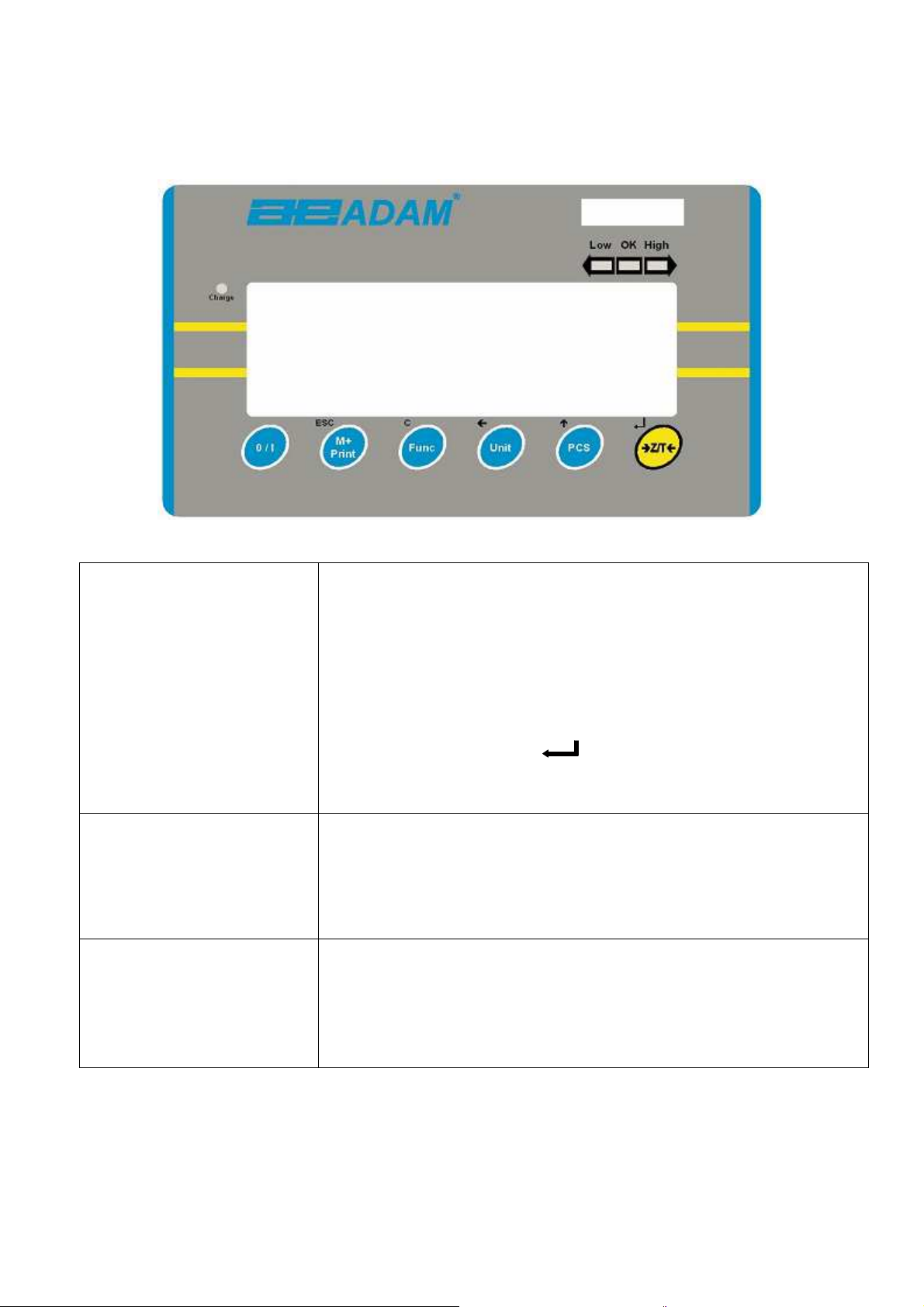

4.0 KEY

[>Z/T<]

DESCRIPTIONS

If near zero, Sets the zero point for all subsequent

weighing. The display shows zero.

Tares the scale. Stores the weight currently on the

scale as tare value, subtracts the tare value from the

gross weight and shows the results

A secondary function, is of “Enter” key used when

setting up the value for the Parameters.

[Pcs/] Selects parts counting. Used to set the sample

quantities while parts counting.

A secondary function, is of incrementing the active

digit when setting a value for Parameters.

[Unit/]

Selects the weighing unit to be displayed from those

which are enabled. See parameter S1 in section 7.4.

A secondary function, is to move the active/flashing

digit to the left when setting values for Parameters.

9

| P a g e © Adam Equipment Company 2011

Page 11

[Func/C]

[Print/M+/Esc]

[O/I]

Selects the Functions of the scale. If the scale is

weighing, it will select parts counting. If it is not in

weighing mode, it will return the user to weighing.

A secondary function (C) is to act as a clear key when

setting values for Parameters.

Sends the results to a PC or a Printer using the RS232 interface. It also adds the value to the

accumulation memory if the accumulation function is

not automatic.

A secondary function (ESC) is to return to normal

operation when the scale is in a Parameter setting

mode.

To switch on and switch off the indicator.

The ABK/AFK will store the weighing unit in use and

the check weighing values currently in memory when

power is off.

10

| P a g e © Adam Equipment Company 2011

Page 12

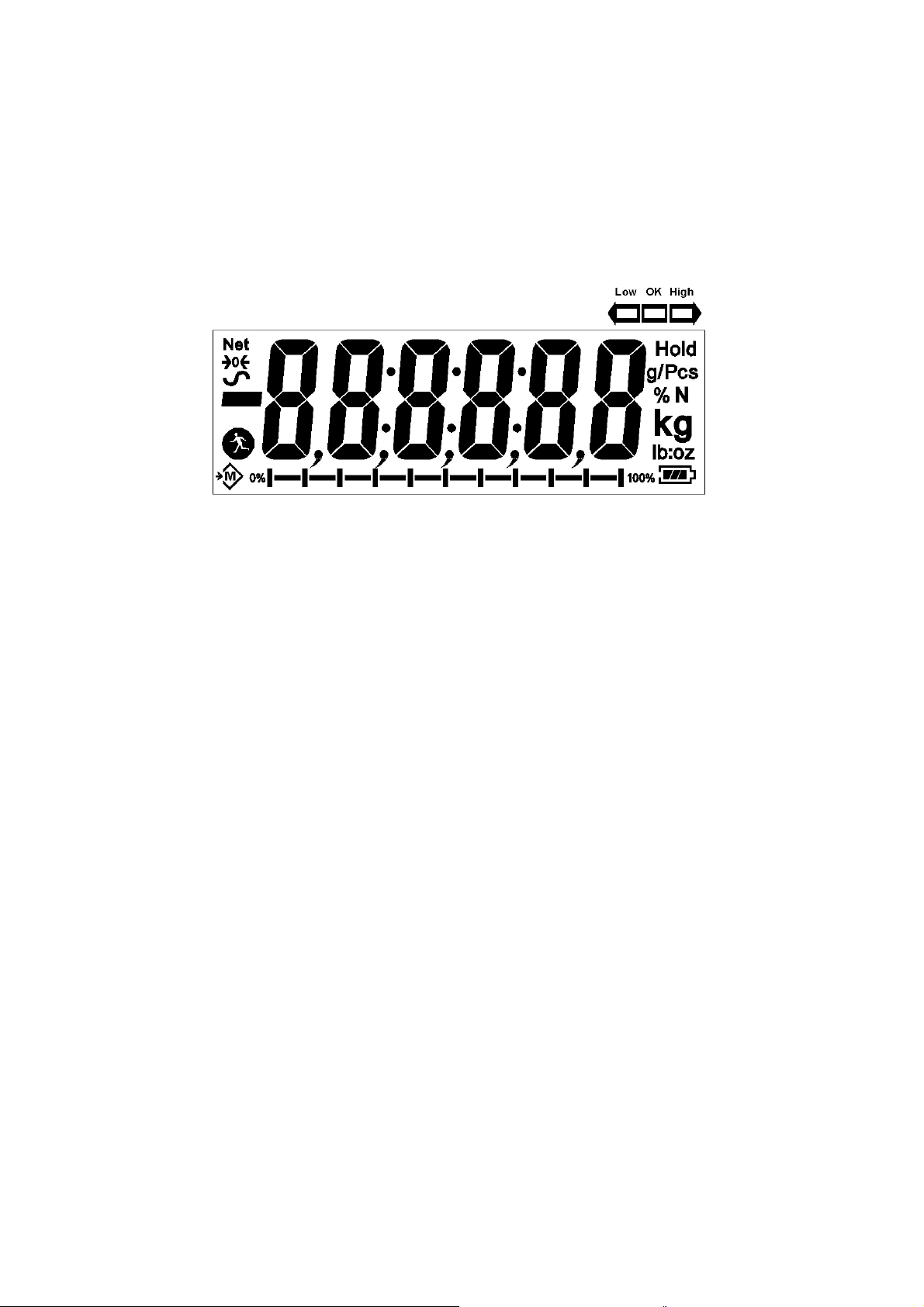

5.0 DISPLAYS

The LCD display will show a value and a unit to the right of the digits.

In addition the LED’s above the display will show when a weight is below or

above check-weighing limits.

Other symbols will show when a weight has been tared (NET) the scale is at

zero and stable, if a value has been stored in memory or when the animal

weighing function has been enabled. A battery symbols will show the state of

charge of the internal battery.

11

| P a g e © Adam Equipment Company 2011

Page 13

6.0 OPERATION

6.1 ZEROING THE DISPLAY

• You can press the [Z/T] key at any time to set the zero point. This

will usually be necessary when the platform is empty. When the

zero point is obtained the display will show an indicator for zero.

• The scale has an automatic re-zeroing function to account for

minor drifting or accumulation of material on the platform.

However you may need to press the [Z/T] key to rezero the scale

if small amounts of weight are shown when the platform is empty.

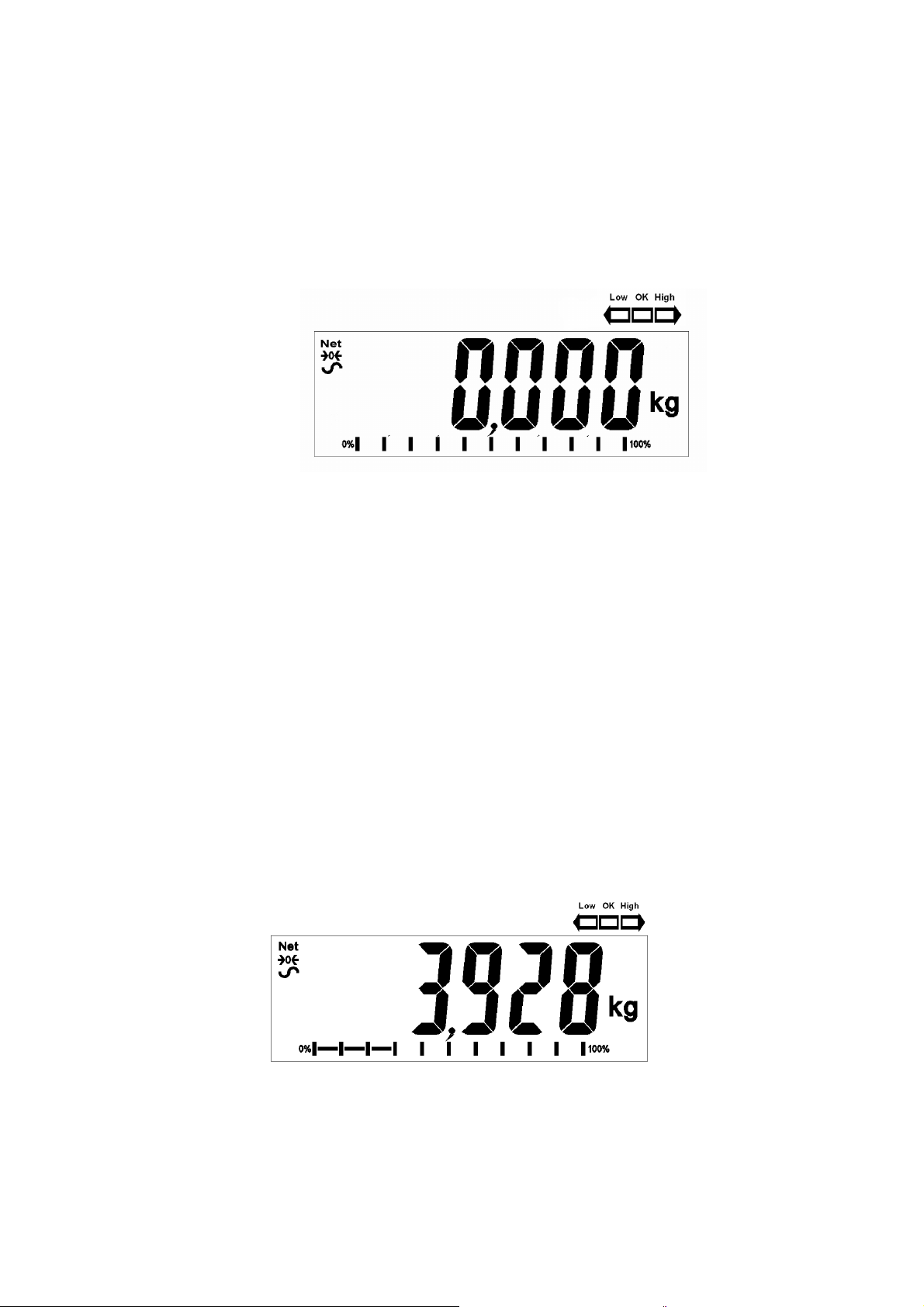

6.2 TARING

• Zero the scale by pressing the [Z/T] key if necessary. The

“ZERO” indicator will be ON.

• Place a container on the platform, a value for its weight will be

displayed.

12

| P a g e © Adam Equipment Company 2011

Page 14

• Press the [Z/T] key to tare the scale. The weight that was

displayed is stored as the tare value and that value is subtracted

from the display, leaving zero on the display. The “NET” indicator

will be ON. As a product is added only the net weight of the

product will be shown. The scale could be tared a second time if

another type of product was to be added to the first one. Again

only the weight that is added after taring will be displayed.

• When the container is removed a negative value will be shown. If

the scale was tared just before removing the container this value

is the gross weight of the container plus all products that was

removed. The “ZERO” indicator will be on to indicate that the

platform is back to the same condition as it was when zero was

last set.

• To delete a Tare value, press [Z/T] when the pan is empty.

6.3 WEIGHING A SAMPLE

To determine the weight of a sample, first tare the empty container if it is to

be used and then place the sample in the container. The display will show

the net weight of the sample and the units of weight currently in use.

13

| P a g e © Adam Equipment Company 2011

Page 15

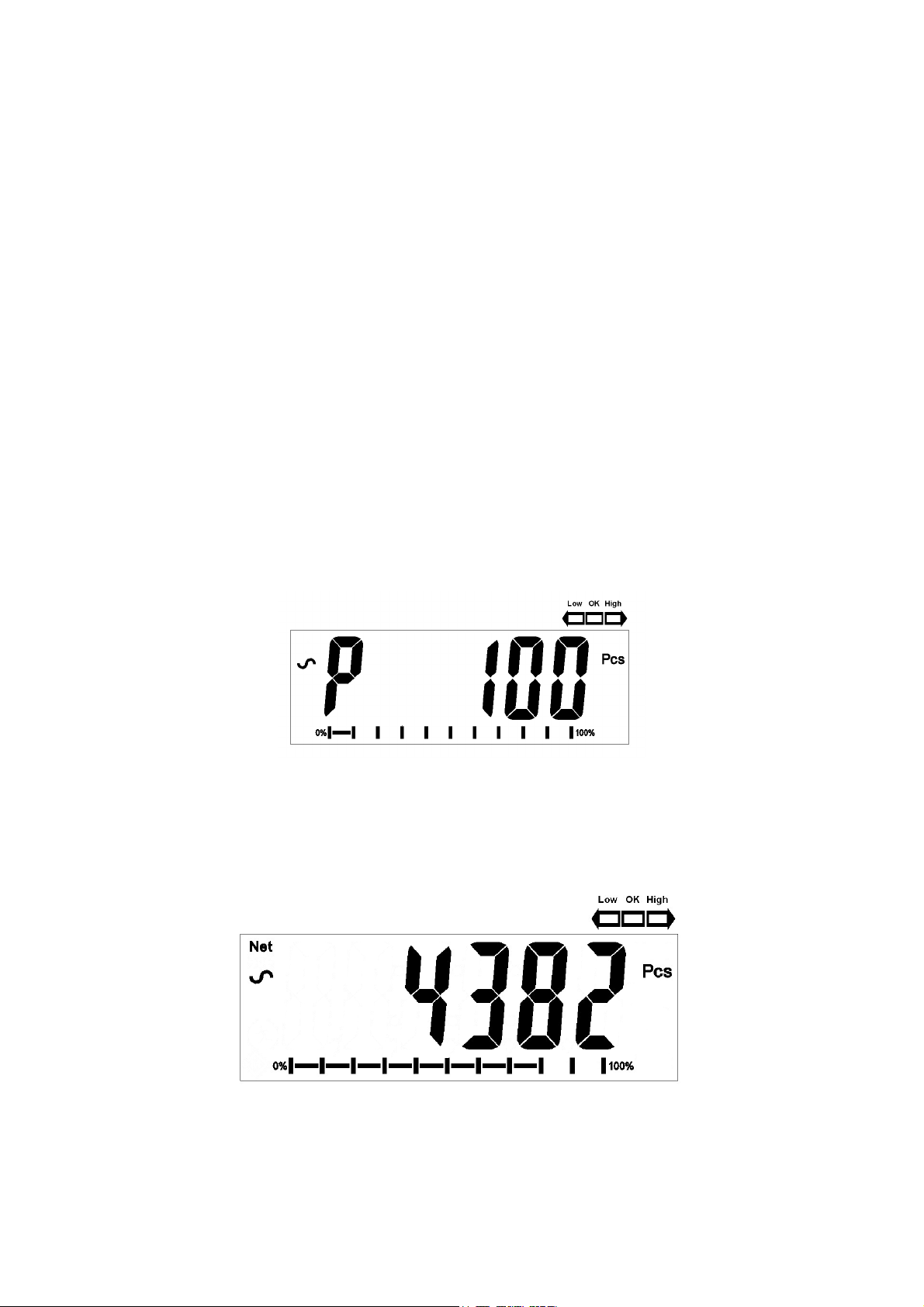

6.4 PARTS COUNTING

If parts counting is enabled, See section 7.4, it is possible to count parts using

a sample of the parts to determine average piece weight.

• Before starting, tare the weight of any container that may be used,

leaving the empty container on the scale. Place a known number

of samples in the container, if used. The number should match

the options for parts counting, i.e., 10, 20, 50, 100 or 200 pieces.

• When the scale is showing weight, pressing the [Pcs/] key will

start the parts counting function.

• The scale will show “P 10” asking for a sample size of 10 parts.

Change the sample size to the desired quantity by pressing the

[Pcs/] key. It will cycle through the options: 10, 20, 50, 100,

200 and back to 10.

• Press the [Z/T] key again when the number matches the number

of parts used as the sample. As more weight is added the

display will show the number of parts (Pcs).

Pressing the [Unit/] key will display the unit weight (g/pcs), pressing it

second time will display the net weight (pcs and kg) and the third time, it will

be the count again (pcs).

14

| P a g e © Adam Equipment Company 2011

Page 16

• Press the [Pcs/] key to return to normal weighing. Press the

[Pcs/] key again to start counting a different sample.

6.5 CHECK-WEIGHING

Check-weighing is a procedure to cause lamps to come on (and if enabled,

an alarm to sound) when the weight on the scale meets or exceeds values

stored in memory. The memory holds the last values for a high and a low

limit when the power is turned off. The user can set either one limit or both as

described below.

See Section 7.1 for the procedure to set the limits. The limits can be set when

the scale is in weighing or parts counting modes. After limits have been set

the Check-weighing function is enabled.

When a weight is placed on the scale the LED’s above the display will show if

the weight is above or below the limits and the beeper will sound as

described below, if the beeper is enabled (see section 7.1).

The relay outputs are open collector drivers to control an external relay. The

relays will be active when the corresponding LED is on during checkweighing. The ZERO relay output will be on when the scale is showing the

display is at Zero.

15

| P a g e © Adam Equipment Company 2011

Page 17

sound when the weight is

BOTH LIMITS SET.

BOTH LIMITS SET The display will show OK

when the weight is

between the limits

LOW LIMIT SET

HIGH LIMIT is set to

zero

The display will show LOW

when the weight is less

than the Low Limit. Above

the Low Limit the display

will show OK,

F3 bEP = bP InL .

The beeper will sound

when the weight is

between the limits, i.e. OK

F3 bEP = bP OtL

Beeper will sound if weight

is outside the limits.

F3 bEP = bP InL .

The beeper will be off

when the weight is less

than the Low Limit.

Above the Low Limit the

beeper will be on

F3 bEP = bP OtL

The beeper will be on

HIGH LIMIT SET

LOW LIMIT is set to

zero

LOW IS SET

GREATER THAN

HIGH

The display will show OK

when the weight is less

than the High Limit. Above

the High Limit the display

will show HIGH

This condition is not

allowed.

below the Low Limit

F3 bEP = bP InL .

The beeper will be on

when the weight is less

than the High Limit. Above

the High Limit the beeper

will be off.

F3 bEP = bP OtL

The beeper will be off

when the weight is below

the High Limit, on when it

is above the High limit.

16

| P a g e © Adam Equipment Company 2011

Page 18

NOTE: Weight must be more than 20 scale divisions for check weighing to

operate. Below 20 scale divisions the LED’s will not light and the

beeper will not be on.

The Check-weighing function can be set up during Weighing or Parts Counting

by entering values as Low or/and High Limits keyed in by the user. The limits are

displayed in kg (or Lb) or pcs respectively.

Checkweighing during Parts Counting

To disable the Check-Weighing function enter zero into both limits by

pressing the [Func/C] key when the current limits values are displayed during

the setting procedure, then pressing [Z/T] to store the zero values.

The values set for the check-weighing will remain in memory when the

weighing units or the function changes to parts counting but will not be active.

The will become active again when the weighing unit or parts counting that

was active at the time the limits were set is reactivated.

17

| P a g e © Adam Equipment Company 2011

Page 19

6.6 ACCUMULATED TOTAL

• The scale can be set to accumulate manually by pressing the

[Print/M+/Esc] key or automatically when a weight is removed

from the scale. See the Section 7.3 for details of setting the

Parameter “C3 PRM” and “C4 Aon”. The accumulation function is

available when weighing or when counting parts. However the

memory is cleared if the weighing units or functions are changed.

• When the weight (or count) displayed is stored in memory the

display will show “ACC 1” and then the total in memory for 2

seconds before returning to weighing. The RS-232 interface will

output to a printer or PC.

• Remove the weight, allowing the scale to return to zero and put a

second weight on. When this value is stored, the display will

show “ACC 2”, then the new total and finally the value of the

second weight. Repeat as necessary to add all the values needed

to the memory.

• To view the total in memory press the [Print/M+/Esc] key when

there is no weight on the scale. The display will show the number

of entries and the total.

• To clear the memory (set the value to zero) press the [Func/C]

key during the time the totals are being displayed.

18

| P a g e © Adam Equipment Company 2011

Page 20

6.7 PERCENT WEIGHING

The scale can be set to perform percent weighing. See Section 7.2.

The scale will use a mass on the platform as the 100% reference weight. If

the platform is empty (or the scale is tared) then the user can input a

reference weight using the keypad.

• Press [Func/C]. The first option is “FunC 1”, press the [Func/C] key

again display “FunC 2”.

• Press the [Z/T] key. “P1 PCt” will be displayed.

• Press [Z/T] again to enter percent weighing. The scale will set the

sample mass on the platform as 100% reference weight.

• Remove the sample weight. Then any other weight placed on the scale

will be displayed as a percentage of the original sample. For example,

if 3500g is placed on the scale and percent weighing is selected, the

display will show 100.0%. Remove the 3500g weight and place a 3000g

weight. The display will show 85.7% as 3000g is 85.7% of 3500g.

• The number of decimal points will depend on the weight used in

19

| P a g e © Adam Equipment Company 2011

Page 21

comparison to the capacity of the system. A smaller weight will show

only “100%” while a larger weight might show “100.00%”.

• If the scale was showing zero weight when entering this function, then

the user must manually enter the weight to be set as 100% as

described below.

• Press the [Z/T] key. “P1 PCt” will be displayed.

• Press [Z/T] again to enter percent weighing. The scale will now accept

a value the user enters as the reference weight.

• Enter the value using the [Unit/] key and [Pcs/] key to set the

values of the 100% mass.

• When set press the [Z/T] key to store the value. The display will show

“0.00 %”.

• The weight entered must be greater than 50 scale divisions.

• Press [Unit/] to return to weighing.

NOTE:

The display may jump by large numbers unexpectedly if small weights are

used to set as 100% reference. The scale checks if the weight is too small

and will show Error 7.

20

| P a g e © Adam Equipment Company 2011

Page 22

6.8 ANIMAL (D

YNAMIC)

WEIGHING

The scale can be set to animal (dynamic) weighing for weighing any items

that are unstable or may move. See Section 7.4.

The scale will use a special filter to minimise the effects of any movement

while the moving animal or unstable samples are on the scale.

• Press [Func/C]. The first option is “FunC 1”, press the [Func/C] key

again to display “Func 2”.

• Press the [Z/T] key. “F2 PCt” will be displayed. Press the [Pcs/] key to

advance to the second function, “P2 AnL”, Animal weighing.

• Press [Z/T] to enter animal weighing. The scale will change to animal

weighing and allow weighing of an unstable animal or sample on the

platform.

• To use the Animal Weighing function it is necessary to set the amount

of filtering required for the item to be weighed. More active animals will

require a higher level of filtering to give a stable result. The display will

show “Flt x” where x is a value from 1 to 5. The higher the value the

greater the amount of filter will be. To increment the value shown press

the [Pcs/] key then press the [Z/T] key to accept it.

• The display will flash “Ani “ 2 times then show the current weight, 0.00.

The scale is now ready to weigh.

21

| P a g e © Adam Equipment Company 2011

Page 23

6.8.1ANIMAL WEIGHING PROCEDURE

• With the platform empty the display will show zero weight. Place

containers or blankets onto the platform and press the [Z/T] key to zero

the display. The scale may go into the animal (dynamic) weighing

procedure when the items are placed on the scale but will return to

showing zero when the [Z/T] key is pressed.

• Place the animal or sample to be weighed on the platform.

• The display will show the Animal/Dynamic weighing symbol until a

stable weight is determined. The time it takes for the stable value will

depend upon the setting of the filter parameter in the first step.

• When a stable reading is found, the display will show this value, and the

display will be locked until the [Z/T] key is pressed. The display will

show the “Hold” symbol while the display is locked.

• To weigh a second subject press the [Z/T] key if necessary to zero the

display, and place the next animal on the scale. The scale will detect

the new weight and hold it as before.

• The scale will remain in the animal weighing mode until the [Unit/]

key is pressed. Then it will return to normal weighing.

22

| P a g e © Adam Equipment Company 2011

Page 24

7.0 USER

PARAMETERS

Pressing the [Func/C] key during normal operation allows the user to access

the parameters for customizing the scale. The parameters are split into 4

groups-

1. Check weighing parameters,

2. Percent and Animal Weighing Functions

3. RS-232 parameters and

4. Scale parameters

• When [Func/C] is pressed, display will first show “FunC 1” for Check

weighing parameters.

• Press either the [Func/C] key or the [Pcs/] to advance through the

groups “FunC 1”, “FunC 2” , “FunC 3” and “FunC 4”. Press [Z/T] to enter the

desired group of parameters.

• When in one of the sections press [Print/M+/Esc] to return to the group

“FunC 1”. If you press [Print/M+/Esc] again, the scale will exit the User

Parameter section and return to normal weighing.

7.1 CHECK WEIGHING PARAMETERS

• Press [Z/T] to enter the group.

• Use the [Unit/] key and [Pcs/] key to set the values or just the

[Pcs/] key to select the options.

• Press [Z/T] to confirm the change and then advance to the next

parameter by pressing the [Pcs/] key.

This group of parameters-

- Set low and high limits for check-weighing

- Enables or disables the check weighing alarm

- Enables or disables the negative check weighing

23

| P a g e © Adam Equipment Company 2011

Page 25

Parameter Description Options Default

setting

F1 Lo Set Low limit.

Use the [Unit/] key

and [Pcs/] key to set

000000

the values of the lower

limit.

When set press the

[Z/T] key to store the

value and go to F2 Hi

F2 Hi Set High limit.

Use the [Unit/] key

and [Pcs/] key to set

0000000

the values of the high

limit.

When set press the

[Z/T] key to store the

value and go to F3

bEP

F3 bEP This parameter sets the

Beeper to off or on. If set

to on, the beeper can

further be set to sound

when the weighing result

bP oFF - Off

bP inL - Within limits

bP otL - Outside limits

(>20d)

bP inL

is within or outside the

check-weighing limits.

F4 nCK This parameter enables

negative check weighing

function with ability to do

on

oFF

on

negative tare.

7.2 PERCENT WEIGHING

AND

ANIMAL WEIGHING

See section 6.7 and 6.8 for details of these special weighing modes.

• Press [Z/T] to enter a parameter. Use the [Unit/] key and [Pcs/]

key to set the values or just the [Pcs/] key to select the options.

• Press [Z/T] to confirm the change and then advance to the next

parameter by pressing the [Pcs/] key.

• Press [Print/M+/Esc] to return to the group “FUnC 2”. If you press

24

| P a g e © Adam Equipment Company 2011

Page 26

[Print/M+/Esc] again, the scale will exit the User Parameter section

and return to weighing.

Parameter Description Options Default

setting

P1 PCt

This parameter allows the

user to enter the Percent

None Enabled

always

weighing Function. See

Section 6.7.

P2 AnL Enter the Animal Weighing

mode of operation, See

section 6.8

Set the filter value. Enabled

Always

7.3 RS-232 PARAMETERS

• Press [Z/T] to enter a parameter. Use the [Unit/] key and [Pcs/]

key to set the values or just the [Pcs/] key to select the options.

• Press [Z/T] to confirm the change and then advance to the next

parameter by pressing the [Pcs/] key.

• Press [Print/M+/Esc] to return to [Pcs/] the group “FUnC 3”. If you

press [Print/M+/Esc] again, the scale will exit the User Parameter

section and return to weighing.

This group of parameters can be set by the user for setting the RS-232 active

or not, baud rate, printing mode, accumulation mode, RS-232 language, and

user or scale ID numbers.

Parameter

C1 on Enable or disable

C2 bd

Description Options Default Values

or setting

the RS-232 interface

Baud Rate

Prt on

Prt oFF

600

1200

Prt on

9600

2400

4800

9600

19200

C3 PrM Printing Mode-

Manual, Continuous

or Automatic

mAn,

Cont (not on EC

approved scales)

mAn

AUto

C4 Aon Enable or disable AC on AC on

25

| P a g e © Adam Equipment Company 2011

Page 27

the Accumulation AC oFF

C5 Ln Select Language EnGLi (English)

EnGLi

FrEnCH (French)

GErmAn (German)

SPAn (Spanish)

C6 UId Set User ID To be entered

000000

manually

C7 Sid Set Scale ID To be entered

000000

manually

Scale will perform the following, depending on the Accumulation and Print

Settings:

A

CCUMULATION

SETTINGS

PRINT SETTINGS

AC on

AC Off

AUto

mAn

Cont

Not available on

approved scales

Accumulate and print

automatically

Accumulate and Print only

when [Print/M+/Esc] key

pressed. If [Print/M+/Esc]

is pressed a second time

only print the weight.

Print continuously.

Accumulate when

[Print/M+/Esc] key is

pressed

Print automatically,

Do not accumulate

Print when [Print/M+/Esc] key is

pressed,

Do not accumulate.

Print continuously.

Do not accumulate.

7.4 SCALE PARAMETERS

• Press [Z/T] to view the list of parameters.

• Press [Z/T] to enter a parameter. Use the [Unit/] key and [Pcs/]

key to set the values or just the [Pcs/] key to select the options.

• Press [Z/T] to confirm the change and then advance to the next

parameter by pressing the [Pcs/] key.

• Press [Print/M+/Esc] to return to the group “FUnC 4”. If you press

[Print/M+/Esc] again, the scale will exit the User Parameter section

and return to normal weighing.

26

| P a g e © Adam Equipment Company 2011

Page 28

This group of parameters is used to control the operation of the scale.

Parameter Description Options Default

setting

S1 Un Enable or disable

weighing units, will not

allow to disable all units,

at least one has to be

enabled. Parts counting

can be enabled/disabled

S2 bL Backlight set to always

on, always off or

automatic on whenever

Kg

Grams

lb

oz

lb:oz

N (Newtons)

PCS

EL oFF

EL on

EL AU

Kg

EL AU

a weight is placed or a

key is pressed

S3 AoF Auto Off- Disable or set

time increment to turn

off scale

SLP 0

SLP 1

SLP 5

SLP 0

SLP 10

S4 dt Set Time and Date

format and settings.

Format for date can be

changed when the

display shows mmddyy,

ddmmyy or yymmdd by

pressing the [Pcs/]

key, then enter the date.

S5 diS Display all weights or

only when stable

Enter the time

manually.

Enter the date

format and then the

numeric value

manually.

ALL

StAb

00:00:00

mm:dd:yy

ALL

S6 Fi Filter setting to slow,

normal or fast

SLow

nor

nor

FASt

S7 SPS Password Enter new pass word

Not active

twice,, controls

access to Func 1 to

Func 4

S8 CAL Calibration Calibrate the scale.

See Section 11.0

-

27

| P a g e © Adam Equipment Company 2011

Page 29

8.0 BATTERY

• The scales can be operated from the battery if desired. The

battery life can be up to 70 hours depending on the load cells

used and how the backlight is used.

• When the battery needs charging a symbol on the display will

show less bars in the battery symbol. The battery should be

charged when only the battery outline is on. Once the bars have

been turned off the scale will still operate for a short time after

which it will automatically switch off to protect the battery.

• To charge the battery, simply plug the adaptor into the mains

power. The scale does not need to be turned on.

• The battery should be charged for 12 hours for full capacity.

• Near the display is an LED to indicate the status of battery

charging. When the scale is plugged into the mains power the

internal battery will be charged. If the LED is green the battery

has a full charge. If it is Red the battery is nearly discharged and

yellow indicates the battery is being charged.

OPERATION

28

| P a g e © Adam Equipment Company 2011

Page 30

9.0 RS-232

INTERFACE

The ABK/AFK indicator is supplied with bi-directional RS-232 interface as

standard. The scale when connected to a printer or computer outputs the

weight with the selected weighing unit through the RS-232 interface.

Specifications:

RS-232 output of weighing data

ASCII code

9600 Baud (user selectable)

8 data bits

No Parity

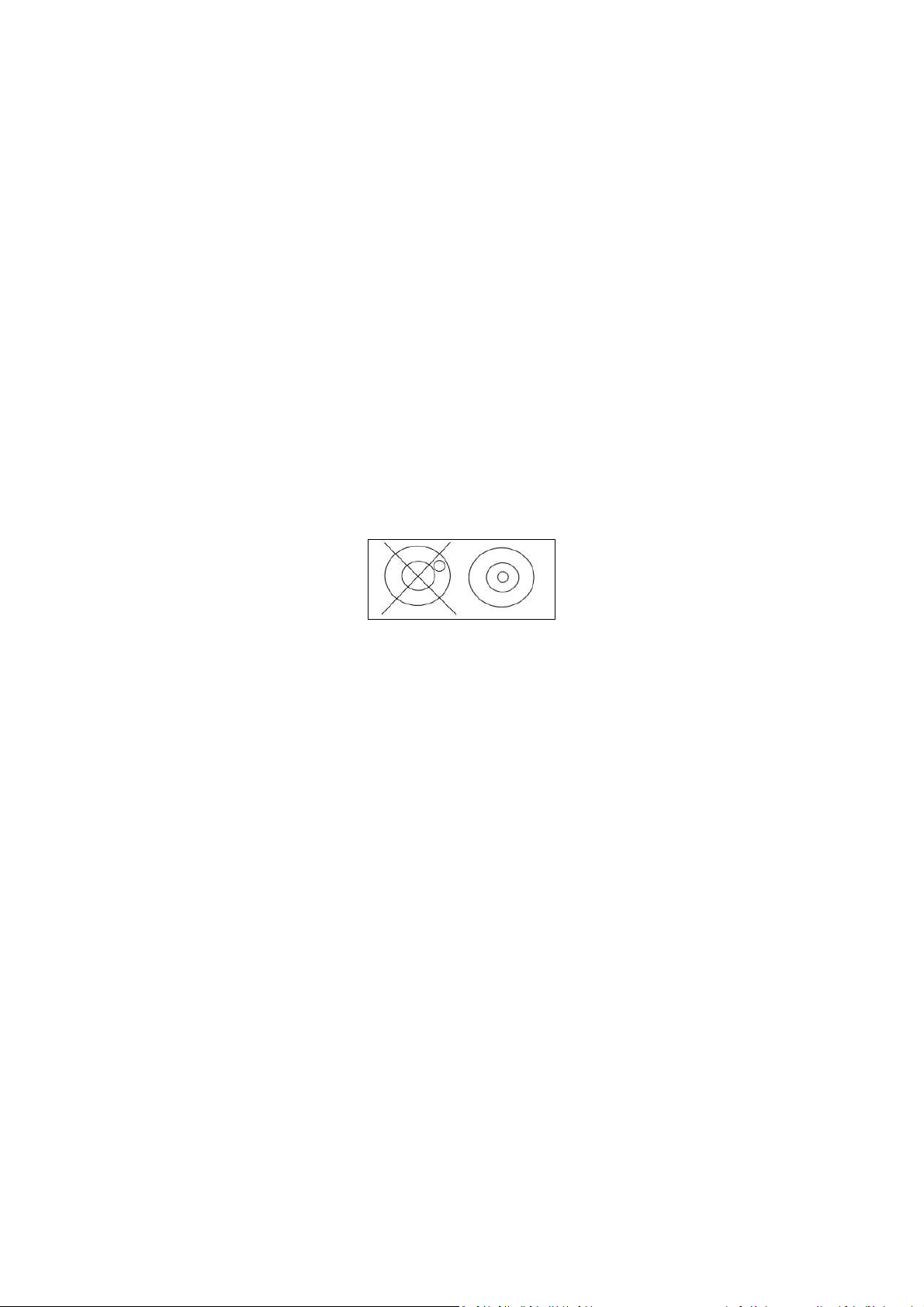

RS-232 serial interface is a plug as figure 2 shows:

12

1: Pin GND, Signal Ground

2: Pin RXD, Received Data

3: Pin TXD, Transmitted Data

3

4

As viewed from the back of the indicator

The scale can be set to print text in English, French, German or Spanish.

See the RS-232 parameters section for details.

29

| P a g e © Adam Equipment Company 2011

Page 31

<cr><lf>

<cr><lf>

Data Format-Normal Output:

<cr><lf>

Date 12/09/2006 <cr><lf>

Time 14:56:27 <cr><lf>

<cr><lf>

Scale ID 123456 <cr><lf> If ID is zero, it is left blank

User ID 234567 <cr><lf>

<cr><lf>

Net Wt 1.234 Kg <cr><lf> Net Wt. (or Gross Wt.)

<cr><lf>

<cr><lf>

<cr><lf>

<cr><lf>

Only weight value along with the weighing unit is printed. If Percent weighing

is used then % is shown in place of weighing units.

Data Format-Parts Counting Output:

Weight, Unit weight and number of parts are printed.

<cr><lf>

Date 12/09/2006 <cr><lf>

Time 14:56:27 <cr><lf>

<cr><lf>

Scale ID 123456 <cr><lf>

User ID 234567 <cr><lf>

<cr><lf>

Net Wt. 1.234 Kg <cr><lf> Net Wt. (or Gross Wt.)

Unit Wt. 123 g <cr><lf> g for metric and lb for pounds

PCS 10 pcs <cr><lf>

<cr><lf>

<cr><lf>

<cr><lf>

<cr><lf>

30

| P a g e © Adam Equipment Company 2011

Page 32

Data Format- Memory Recall Output:

<cr><lf>

Date 12/09/2006 <cr><lf>

Time 14:56:27 <cr><lf>

<cr><lf>

Scale ID 123456 <cr><lf>

User ID 234567 <cr><lf>

<cr><lf>

------------------<cr><lf>

TOTAL

No. 5 <cr><lf>

Wt. 1.234 Kg <cr><lf>

<cr><lf>

PCS 10 pcs <cr><lf>

------------------<cr><lf>

<cr><lf>

Data Format- Continuous Output- Normal weighing:

ST,GROSS 1.234 Kg <cr><lf> ST or US for STable or UnStable,

US,NET 0.000 Kg <cr><lf> NET or GROSS for Net Weight

or Gross wt. and the weighing unit, kg, lb etc.

Data Format- Continuous Output- Parts Counting:

ST Net 1.234 Kg <cr><lf> Net Weight (or Gross wt.)

U.W. 123 g <cr><lf> Kg and g for metric and Lb for pounds

PCS 10 pcs <cr><lf>

<cr><lf>

<cr><lf>

NOTE:

1. The accumulated total will not be sent to the RS-232 when the continuous

print is turned on.

2. The continuous print will only be for the current weight and the display data.

3. In other languages the format is the same but the text will be in the language

selected.

31

| P a g e © Adam Equipment Company 2011

Page 33

Description ENGLISH FRENCH GERMAN SPANISH

Net weight

Weight per unit

counted

Number of items

counted

Number of

weighing added

to subtotals

Total weight and

count printed

Print date

Net Wt. Pds Net Net-Gew Pso Net

Unit Wt. Pds unit Gew/Einh Pso/Unid

Pcs Pcs Stck. Piezas

No. Nb. Anzhl Num.

Total Total Gesamt Total

Date Date Datum Fecha

Print time

Time Heure Zeit Hora

Scale ID number

Scale ID Bal ID Waagen ID Bal ID

User ID Number

User ID Util ID Nutzer ID Usuario ID

9.1 INPUT

COMMANDS FORMAT

The scale can be controlled with the following commands. Press the [Enter] key of

the PC after each command.

T<cr><lf>

Tares the scale to display the net weight. This is the same as

pressing [Z/T].

Z<cr><lf>

Sets the zero point for all subsequent weighing. The display shows

zero.

P<cr><lf>

Prints the results to a PC or printer using the RS-232 interface. It

also adds the value to the accumulation memory if the

accumulation function is not set to automatic.

32

| P a g e © Adam Equipment Company 2011

Page 34

10.0 RELAY

INTERFACE

The indicator is supplied with drivers to control external relays. The drivers

could be used to control a number of different relays depending upon the

users need. The relay drivers are isolated outputs requiring the use of an

external power supply for the relays. Also see section 3.4.3.

Contact Adam Equipment or your supplier for a relay interface that is

compatible with the relay drivers, however other interfaces can be used as

long as the following conditions apply.

CONNECTION OF RELAY DRIVERS

The output to drive external relays is on the circuit board inside the enclosure. To

gain access you must remove the 6 screws securing the front to the rear of the case.

Pass the wires for the relays through the grommet on the rear panel. The wires will

connect to the PCB using the terminal strip P1.

C18

Power1

Q5

SEN+

EXE+

EXE-

SEN-

SIG+

SIG-

SHIE

Load Cell Input

Power Connector

Battery Vin

+ - no polarity

LC1

U5

09/01/2009

AE9721 VER B

TXT

GND

RS-232 Interface

U4

BT1

Clock Battery

CR1220 type

U1

Relay Output

COM

Common

HI

High

OK

OK

LOW

ZERO

Low

P1

RXT

COM1

Zero

The circuit to control the relays requires an external voltage compatible with the

relays used.

33

| P a g e © Adam Equipment Company 2011

Page 35

Connections to the drivers:

Connections are made to the PCB, Connector P1. The connector is a spring

activated type, simply press on the top of the connector and insert the wire.

Do not exceed the safe limits of voltage or current of 24VDC or 15ma per

output.

Depending upon the application it may be necessary to use a small relay to

drive larger relays, or to provide additional protection to prevent

electromagnetic interference (diodes as shown above) to this or other

machinery.

34

| P a g e © Adam Equipment Company 2011

Page 36

11.0 CALIBRATION

The scale can be calibrated using the following procedure. To enter this

procedure it is necessary to use Func 4 accessible using the [Func/C] key as

described in section 7.4 or using the password access as described in

section 12.

The ABK/AFK scales calibrate using either metric or pound weights,

depending on the weighing unit in use before calibration. The display will

show either "kg" or "lb" to identify the weights expected.

PROCEDURE

• Enter the calibration section using Func 4, C8 CAL or using the

password as described in section 12.

• The display will show "unLoAd".

• Remove any weight from platform, when the stable symbol is on

press [Z/T].

• The display will show "Ld" the “0000XX” to show the last calibration

weight used. Place this calibration weight on the scale. Press

the [Z/T] key. If the weight you put on the scale does not match

the value displayed, press the [Func/C] key to clear the vale then

use the [Unit/] key and [Pcs/] key to set the correct value.

When it is correct press [Z/T].

• If the calibration is acceptable the scale will run a self-test during

which the calibration weight should be removed. If an error

message “FAiL L” is shown try calibration again as a disturbance

may have prevented a successful calibration.

After calibration the scale should be checked to verify the calibration is

correct. If necessary repeat calibration, make sure that the scale is stable

before accepting any weight.

35

| P a g e © Adam Equipment Company 2011

Page 37

12.0 SERVICE

SECTION

The scales will allow entry to the parameters if the [Tare] key is pressed

during the power on cycle. The passwords work as above.

In this case the display will show the passcode request screen, “ P - - - - “ . To

continue enter a passcode as described below.

Entering passcode 0000 will allow calibration as shown in section 11.

Entering 1000 will allow access to a limited set of parameters described in

section 12.1.

Entering the passcode 2006 will allow access to all parameters as shown in

section 12.3.

12.1 USING “1000” TO ENTER THE SERVICE PARAMETERS

Press the [Z/T] key during the display counting when turned on,

When “Pn “ is displayed, enter the number 1000 using the [Unit/] and

[Pcs/] keys and then press [Z/T].

The displays will show the first parameters, called “F4 Int”.

To select another parameter press the [Pcs/] key to advance through the

parameters.

Press the [Z/T] key to enter a parameter.

To exit a parameter, press the [Print/M+/Esc] key.

The display will show the parameter number and a name.

When a parameter is entered by pressing the [Z/T] key, the displays will

guide you through the parameter selected and the options available.

36

| P a g e © Adam Equipment Company 2011

Page 38

The parameters available are:

“F4 Int” Initial Zero Range

“F5 rEZ” Re-Zero range

“F6 SCS” Successive Tare Enable

“F7 Cnt” Display the A/D counts

“F8 Zem” Zero Mode

“F9 Lvd” Low voltage detection

“FA AZn” Auto Zero Range

“Fb FPS” User Function Password

The description of the parameters is shown in section 12.3

12.2 USING “2006” TO ENTER THE SECURE PARAMETERS

Press the [Z/T] key during the display counting when turned on,

When “Pn “ is displayed, enter the number 2006 using the [Unit/] and

[Pcs/] keys and then press [Z/T]. The displays will show the first

parameters, called “F1 CAL”.

To select another parameter press the [Pcs/] key to advance through the

parameters.

Press the [Z/T] key to enter a parameter.

To exit a parameter, press the [Print/M+/Esc] key.

The display will show the parameter number and a name.

When a parameter is entered by pressing the [Z/T] key, the displays will

guide you through the parameter selected and the options available.

The parameters available are:

“F1 CAL” To enter the Calibration

“F2 dEC” Decimal Point Position

“F3 CAP” Default Weighing Unit and capacity

“F4 Int” Initial Zero Range

“F5 rEZ” Re-Zero range

“F6 SCS” Successive Tare Enable

“F7 Cnt” Display the A/D counts

“F8 Zem” Zero Mode

“F9 Lvd” Low voltage detection

“FA AZn” Auto Zero Range

“Fb FPS” User Function Password

37

| P a g e © Adam Equipment Company 2011

Page 39

12.3 PARAMETER DETAILS

12.3.1 F1 -CALIBRATION

To enter the calibration parameter, press the [Z/T] key when “F1” is displayed.

The scale will be calibrated using 2 masses of approximately 1/3Maximum

and Maximum. If the scale has been calibrated once the values will be

stored. If this is the first time the scale is calibrated the user must enter the

values for the calibration masses.

NOTE: It is necessary to set the decimal point location and the capacity

before calibration is possible.

The display will instruct you to remove any weight from the scale, “UnloAd”.

Press [Z/T].

The display will tell you to add the first weight to the scale: “Ld 1” “ 10 kg” If

necessary change the value shown to match the weight to be used. Press

[CE] to clear the old value and then enter the new value. All values entered

are in whole numbers only.

Add the weight shown, wait for stability then press the [Z/T] key.

The display will tell you to add the second weight to the scale: “Ld 2 “ “ 30

kg”

Either add the weight shown, wait for stability then press the [Z/T] key or

press the [Print/M+/Esc] key to accept the single point calibration and return

to weighing.

The display will show “PASS” if the calibration is OK.

Remove the weight.

12.3.2 F2–DECIMAL POINT POSITION

To set the value for the decimal point location. The options are 0, 0.0,

0.00, 0.000, 0.0000

To enter this parameter, press the [Z/T] key when “F2 dEC” is shown.

The display will show the current setting.

Press the [Pcs/] key to change the value. Select from 0, 0.0, 0.00, 0.000,

0.0000

Press [Z/T] to accept the displayed value.

38

| P a g e © Adam Equipment Company 2011

Page 40

12.3.3 F3 – CAPACITY/ WEIGHING UNIT/INCREMENT

To enter this parameter, press the [Z/T] key when “F3 CAP” is shown.

The display will show the current capacity and default weighing unit.

Enter the numeric values using the [Unit/] and [Pcs/] keys. The scale

will check the number of division’s n = maximum/increment is less than

30,000 divisions. (3000 divisions for EC approved versions).

To select the weighing unit press the [Unit/] until the default weighing unit

is flashing, either kilogram (kg) or pounds (lb).

Press [Z/T] to accept the displayed value.

On non-approved versions the display then lets you select the increment, “InC

2”

For example 100kg x 0.01kg the increment is 10grams, but the last digit

increments by 1.

The display will show the current increment value as used with the current

decimal point position.

Press the [Pcs/] key to change the value. Select from 1, 2, 5, 10, 20 or 50

Not all increments may be available for the capacity you selected.

For EC Approved versions the scale will determine the increment that

maintains the number of divisions to be 3000 or less.

Press [Z/T] to accept the displayed value.

Press [Print/M+/Esc] to return to weighing.

39

| P a g e © Adam Equipment Company 2011

Page 41

12.3.4 F4 –INITIAL ZERO RANGE

To enter this parameter, press the [Z/T] key when “F4 int” is shown.

The display will show the current initial zero range.

Press the [Pcs/] key to change the value and press [Z/T] to accept the

value.

Press [Print/M+/esc] to return to weighing.

12.3.5 F5 -RE-ZERO RANGE

To enter this parameter, press the [Z/T] key when “F5 rEZ” is shown.

The display will show the current re-zero range.

Press the [Pcs/] key to change the value.

Press [Z/T] to accept the value.

Press [Print/M+/esc] to return to weighing.

12.3.6 F6 -SUCCESSIVE TARE

To enter this parameter, press the [Z/T] key when “F6 SCS” is shown.

The display will show if the successive tare is on or off.

Press the [Pcs/] key to change the value.

Press [Z/T] to accept the displayed value.

Press [Print/M+/Esc] to return to weighing.

12.3.7 F7 –ADC COUNTS

To enter this parameter, press the [Z/T] key when “F7 Cnt” is shown.

This parameter allows you to view the A/D counts from the internal A/D

converter. This can be an aid to service.

Press the [Z/T] key to return to the PARAMETER menu.

Press the [Print/M+/Esc] key to return to weighing.

Typical value at zero is 30,000-90,000 (approx.).

Typical value at full capacity is 500,000 (approx.).

12.3.8 F8 –ZERO MODE

To enter this parameter, press the [Z/T] key when “F8 ZEm” is shown.

Select the Zero mode desired. In all but special cases Zero Mode 1 is used.

The other 2 zero modes are for unique locations in the world and effect the

+/- range of the zero.

Press the [Pcs/] key to change the value.

Press [Z/T] to accept the displayed value.

Press [Print/M+/Esc] to return to weighing.

40

| P a g e © Adam Equipment Company 2011

Page 42

12.3.9 F9 –LOW VOLTAGE DETECTION

This parameter allows detection of low voltage when the battery wears down.

To enter this parameter, press the [Z/T] key when “F9 LVd” is shown.

The display will show if the LVD Mode is set to on or oFF.

Press the [Pcs/] key to change the value.

Press [Z/T] to accept the displayed value.

Press [Print/M+/Esc] to return to weighing.

12.3.10 FA –AZn Auto Zero Range

This parameter sets the auto zero range from 0 (Off) to 4d.

Calibration and parameter counting function to be active. To enter this

parameter, press the [Z/T] key when “FA AZn” is shown.

The display will show if the current Auto Zero range.

Press the [Pcs/] key to change the value.

Press [Z/T] to accept the displayed value.

Press [Print/M+/Esc] to return to weighing.

12.3.11 Fb –FPS User Function Password

This parameter set a password to control access to the user functions as

described in Section 7. If the password is set to 0000 the control is disable

and the user has free access to the functions.

To enter this parameter, press the [Z/T] key when “Fb FPS” is shown.

The display will show “P1 - - - -“ Enter the new password code followed by [Z/T]

to accept.

The display will then show “P2 - - - -“ Enter the new password code again

followed by [Z/T] to accept. The same code number must be entered both

times for the password to be set.

Press the [Unit/] and [Pcs/] keys to enter the values.

Press [Print/M+/Esc] to return to weighing.

41

| P a g e © Adam Equipment Company 2011

Page 43

13.0 ERROR

CODES

ERROR

DESCRIPTION SUGGESTIONS

CODES

- -oL - - Over-range Remove weight from the scale.

If the problem persists contact your dealer or Adam

Equipment for assistance.

Err 1 Time Setting

Error

Enter time using correct format and reasonable

values. Format: hh:mm:ss

Err 2 Date Setting

Error

Enter date using correct format and reasonable

values. Format: yy:mm:dd

Err 4 Zero Setting

Error

The scale was outside the normal zero setting

range either when it was turned on or when the

[Zero] key was pressed.

Remove weight from the scale and try re-zeroing

again.

Use the [Z/T] key to set the display to zero value.

If the problem persists contact your dealer or Adam

Equipment for assistance.

Err 6 A/D out of range The values from the A/D converter are outside the

normal range.

Remove the weight from the scale if overloaded.

Make sure the pan is attached.

Indicates the load cell or the electronics may be

faulty.

If the problem persists contact your dealer or Adam

Equipment for assistance.

Err 9 Check weigh

limits error

Shown if the low limit is set higher than the current

high limit. Reset High limit or different low limit.

FAIL Calibration

error.

Improper calibration (should be within + 10% of the

factory calibration). The old calibration data will be

retained until the calibration process is complete.

If the problem persists contact your dealer or Adam

Equipment for assistance.

42

| P a g e © Adam Equipment Company 2011

Page 44

A. Details of your company

14.0 REPLACEMENT

PARTS AND ACCESSORIES

If you need to order any spare parts and accessories, contact your supplier or Adam

Equipment. A partial list of such items is as follows-

• Power Supply Module

• Replacement Battery

15.0 SERVICE

INFORMATION

• Printer, etc.

This manual covers the details of operation. If you have a problem with the scale that is not

directly addressed by this manual then contact your supplier for assistance. In order to

provide further assistance, the supplier will need the following information which should be

kept ready:

-Name of your company:

-Contact person’s name:

-Contact telephone, e-mail,

fax or any other methods:

B. Details of the unit purchased

(This part of information should always be available for any future correspondence. We

suggest you to fill in this form as soon as the unit is received and keep a print-out in your

record for ready reference.)

Model name of the scale:

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

C. Brief description of the problem

Include any recent history of the unit. For example:

-Has it been working since it’s delivered

-Has it been in contact with water

-Damaged from a fire

-Electrical Storms in the area

-Dropped on the floor, etc.

43

| P a g e © Adam Equipment Company 2011

Page 45

16.0 WARRANTY

Adam Equipment offers Limited Warranty (Parts and Labour) for the components

failed due to defects in materials or workmanship. Warranty starts from the date of

delivery.

During the warranty period, should any repairs be necessary, the purchaser must

inform its supplier or Adam Equipment Company. The company or its authorised

Technician reserves the right to repair or replace the components at any of its

workshops depending on the severity of the problems. However, any freight involved

in sending the faulty units or parts to the service centre should be borne by the

purchaser.

The warranty will cease to operate if the equipment is not returned in the original

packaging and with correct documentation for a claim to be processed. All claims are

at the sole discretion of Adam Equipment.

STATEMENT

This warranty does not cover equipment where defects or poor performance is due to

misuse, accidental damage, exposure to radioactive or corrosive materials,

negligence, faulty installation, unauthorised modifications or attempted repair or

failure to observe the requirements and recommendations as given in this User

Manual. Additionally rechargeable batteries (where supplied) are not covered under

warranty.

Repairs carried out under the warranty does not extend the warranty period.

Components removed during the warranty repairs become the company property.

The statutory right of the purchaser is not affected by this warranty. The terms of this

warranty is governed by the UK law. For complete details on Warranty Information,

see the terms and conditions of sale available on our web-site.

44

| P a g e © Adam Equipment Company 2011

Page 46

45

| P a g e © Adam Equipment Company 2011

Page 47

This product has been manufactured in accordance with the

llowing the provisions of the

Adam Equipment Co. Ltd.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

in a

commercial environment. The equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

nt in a residential

area is likely to cause harmful interference in which case the user will be required to correct

Shielded interconnect cables must be employed with this equipment to insure compliance

with the pertin

Changes or modifications not expressly approved by Adam Equipment could void the user's

Any Electrical or Electronic Equipment (EEE) component or assemb

ly of parts intended to be

incorporated into EEE devices as defined by European Directive 2002/95/EEC must be

harmful

002/95/EC or amending legislation.

Battery disposal in Landfill Sites is more regulated since July 2002 by regulation 9 of the

Landfill (England and Wales) Regulations 2002 and Hazardous Waste Regulations 2005.

Waste Electrical and Electronic Equipment

Manufacturer’s Declaration of Conformity

harmonized European standards, fo

below stated directives:

Electro Magnetic Compatibility Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

Bond Avenue, Denbigh East

Milton Keynes, MK1 1SW

United Kingdom

FCC COMPLIANCE

reasonable protection against harmful interference when the equipment is operated

harmful interference to radio communications. Operation of this equipme

the interference at his own expense.

ent RF emission limits governing this device.

authority to operate the equipment.

WEEE COMPLIANCE

recycled or disposed using techniques that do not introduce hazardous substances

to our health or the environment as listed in Directive 2

Battery recycling has become topical and the

(WEEE) Regulations are set to impose targets for recycling.

© Adam Equipment Company 2011

Page 48

certified global company with more than 35

ADAM EQUIPMENT is an ISO 9001:2008

years experience in the production and sale of electronic weighing equipment.

For a complete listing of all Adam scales and balances visit our website at:

www.adamequipment.com

© Copyright by Adam Equipment Co. Ltd. All rights reserved. No part of this

publication may be reprinted or translated in any form or by any means

without the prior permission of Adam Equipment.

Adam Equipment reserves the right to make changes to the technology,

features, specifications and design of the equipment without notice.

All information contained within this publication is to the best of our

knowledge timely, complete and accurate when issued. However, we are not

responsible for misinterpretations which may result from the reading of this

material.

The latest version of this publication can be found on our Website.

Head Office:

Adam Equipment Co. Ltd.

Bond Avenue,

Milton Keynes,

MK1 1 SW

Tel: +44 (0)1908 274545

Fax: +44 (0)1908 641339

sales@adamequipment.co.uk

For regional office worldwide visit www.adamequipment.com

© Adam Equipment Company 2011

Loading...

Loading...