Adam Equipment 3106610631 User Manual

AE 402

Indicator

(P.N. 3106610631, Revision B1, October 2010)

Adam Equipment

© Adam Equipment Company 2010

Easy Reference:

Model name of the scale:

Serial number of the unit:

Software revision number

(Displayed when power is first turned on):

Date of Purchase:

Name of the supplier and place:

© Adam Equipment Company 2010

CONTENTS

1.0

INTRODUCTION...................................................................................................................................2

2.0

SPECIFICATIONS ................................................................................................................................3

3.0

INSTALLATION.....................................................................................................................................4

3.1

LOCATING THE SCALES ................................................................................................................ 4

3.2

LIST OF ACCESSORIES ................................................................................................................. 4

3.3

SETTING UP THE SCALES.............................................................................................................5

3.4 CONNECTIONS .................................................................................................................................... 5

3.4.1 CONNECTION OF LOAD CELL .....................................................................................................5

3.4.2 CONNECTION OF RS-232 .............................................................................................................. 6

3.4.3 CONNECTION OF RELAY DRIVERS ............................................................................................. 6

4.0

KEY DESCRIPTIONS ...........................................................................................................................7

5.0

DISPLAYS.............................................................................................................................................8

6.0

OPERATION .........................................................................................................................................9

6.1

ZEROING THE DISPLAY .................................................................................................................9

6.2

TARING ............................................................................................................................................ 9

6.3

WEIGHING A SAMPLE .................................................................................................................. 10

6.4

PARTS COUNTING........................................................................................................................11

6.5

CHECK-WEIGHING ....................................................................................................................... 12

6.6

ACCUMULATED TOTAL................................................................................................................15

6.7

PERCENT WEIGHING ................................................................................................................... 16

6.8

ANIMAL (Dynamic) WEIGHING ..................................................................................................... 18

6.8.1 ANIMAL WEIGHING PROCEDURE..........................................................................................19

7.0

USER PARAMETERS ........................................................................................................................20

7.1

CHECK WEIGHING PARAMETERS..............................................................................................20

7.2

PERCENT WEIGHING and ANIMAL WEIGHING.......................................................................... 21

7.3

RS-232 PARAMETERS..................................................................................................................22

7.4

SCALE PARAMETERS .................................................................................................................. 23

8.0

BATTERY OPERATION .....................................................................................................................25

9.0

RS-232 INTERFACE...........................................................................................................................26

9.1

INPUT COMMANDS FORMAT ...................................................................................................... 29

10.0 RELAY INTERFACE ...........................................................................................................................30

11.0 CALIBRATION .................................................................................................................................... 31

12.0 SERVICE SECTION ...........................................................................................................................32

12.1 USING “1000” TO ENTER THE SERVICE PARAMETERS........................................................... 32

12.2 USING “2006” TO ENTER THE SECURE PARAMETERS ...........................................................33

12.3 PARAMETER DETAILS ................................................................................................................. 34

12.3.1 F1 -CALIBRATION ................................................................................................................ 34

12.3.2 F2–DECIMAL POINT POSITION ..........................................................................................34

12.3.3 F3 – CAPACITY/ WEIGHING UNIT/INCREMENT ................................................................35

12.3.4 F4 –INITIAL ZERO RANGE ..................................................................................................36

12.3.5 F5 -RE-ZERO RANGE...........................................................................................................36

12.3.6 F6 -SUCCESSIVE TARE....................................................................................................... 36

12.3.7 F7 –ADC COUNTS ................................................................................................................ 36

12.3.8 F8 –ZERO MODE .................................................................................................................36

12.3.9 F9 –LOW VOLTAGE DETECTION .......................................................................................37

12.3.10 FA –AZn Auto Zero Range ..............................................................................................37

12.3.11 Fb –FPS User Fucntion Password ................................................................................. 37

13.0 ERROR CODES .................................................................................................................................38

14.0 REPLACEMENT PARTS AND ACCESSORIES ................................................................................39

15.0 SERVICE INFORMATION ..................................................................................................................39

16.0 WARRANTY STATEMENT................................................................................................................ 40

1 | P a g e © Adam Equipment Company 2010

1.0 INTRODUCTION

• The AE 402 indicator provides the user with the electronics necessary to

build an accurate, fast, versatile weighing system.

• Functions are, weighing, check weighing, parts counting, animal

weighing and percent weighing.

• The system includes automatic zero tracking, audible alarm for check-

weighing, semi-automatic tare and an accumulation facility that allows

the individual weights or counts to be stored and the total recalled.

• The scales have a bi-directional RS-232 interface for communicating

with a PC or printer.

• RS-232 outputs include Real time Clock, English, German, French or

Spanish language text and data required for GLP reports.

• The indicator can be used with 1- to 4 load cell platforms.

• Internal rechargeable battery and IP-65 rated enclosure allow for a

fully portable and rigged weighing system.

2 | P a g e © Adam Equipment Company 2010

2.0 SPECIFICATIONS

External resolution ratio 1/1000-1/30000

Non-linear error ±0.016% F.S

Range of signal input of

the transducer

Load cell drive capacity up to 4, 350Ω or 1000Ω load cells

Load cell excitation + 5V DC

Load Cell Connection

Calibration Automatic External

Stabilisation Time 2 seconds typical

0-20mV

6 wire connection, 2 x excitation, 2 x sense, 2 x signal

plus shield.

Power supply

6V 4Ah Rechargeable battery And

AC/DC 12V 800mA adapter power;

Power consumption 0.1VA

Overall dimension 240 x 140 x 104 mm (including bracket)

Balance Housing Indicator: IP 65 rated Stainless Steel

Net weight 2 kg

Operating temperature 0C-40C

Operating humidity ≤85% RH

General Purpose Weighing Scales

Applications

Weighing, Check weighing, Parts counting, Memory

Functions

Accumulation, Animal weighing, Percent weighing

6 digits, 40mm digit height LCD digital display with

Display

backlight

Weighing units Grams, Kilogram, pound, ounce, pound/ounce; Newton;

battery; stable; net weight; zero set; Animal Weighing;

Symbol indication

Hold

RS-232 bi-directional Interface

Interface

3 | P a g e © Adam Equipment Company 2010

3.0 INSTALLATION

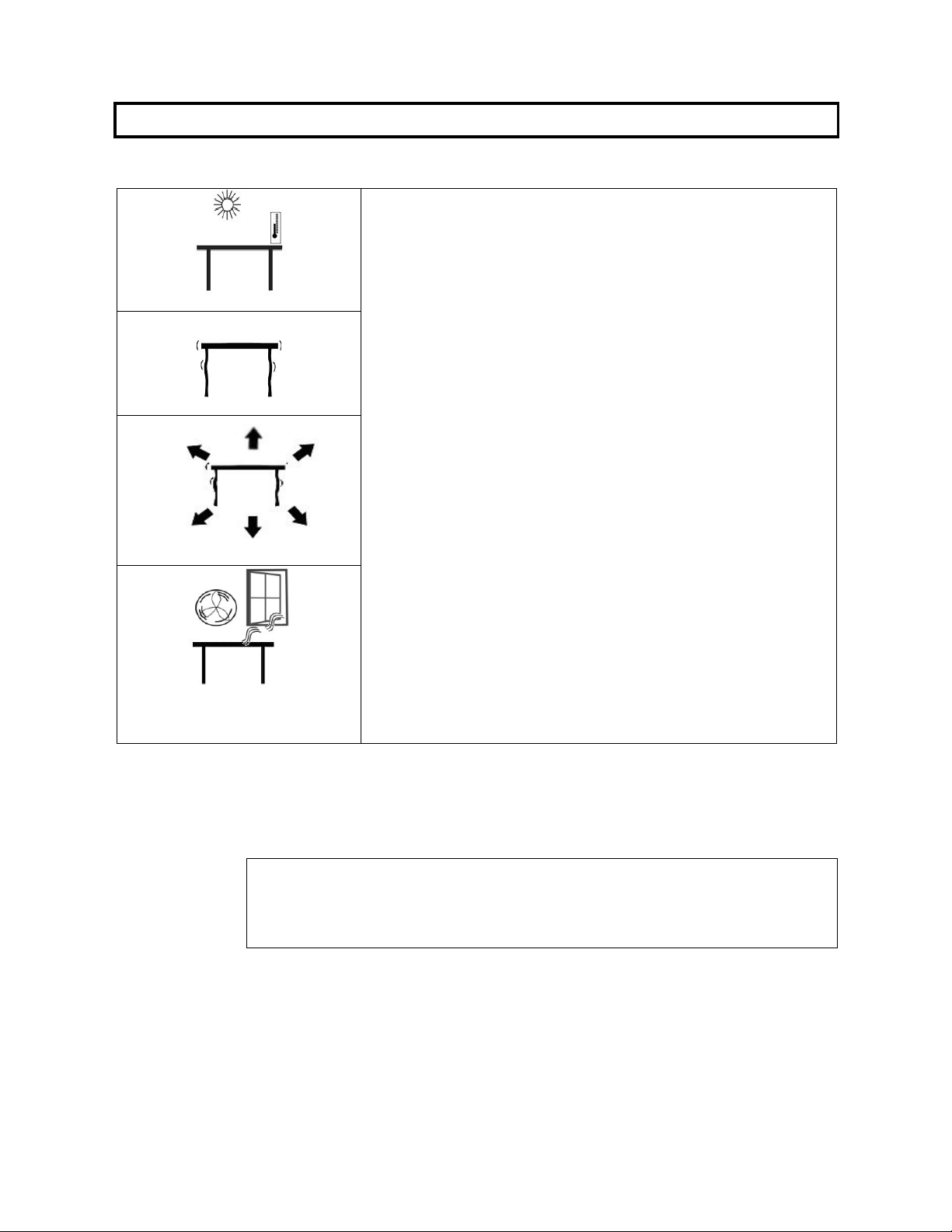

3.1 LOCATING THE SCALES

3.2 LIST OF ACCESSORIES

Your packet contains-

AC adapter

Indicator

Wall mount bracket and mounting hardware

Instruction manual

• The scales should not be placed in a location that

will reduce the accuracy.

• Avoid extremes of temperature. Do not place in

direct sunlight or near air conditioning vents.

• Avoid unsuitable tables. The table or floor must be

rigid and not vibrate.

• Avoid unstable power sources. Do not use near

large users of electricity such as welding equipment

or large motors.

• Do not place near vibrating machinery.

• Avoid air movement such as from fans or opening

doors. Do not place near open windows or airconditioning vents.

• Keep the scales clean. Do not stack material on the

scales when they are not in use.

4 | P a g e © Adam Equipment Company 2010

3.3 SETTING UP THE SCALES

• Attach the power supply module to the connector on the side of the indicator.

Press the [On/Off] key. The software revision number will be displayed

followed by a self-test showing all digits before the zero is displayed along with

the unit of weight that was selected last.

3.4

CONNECTIONS

3.4.1 CONNECTION OF LOAD CELL

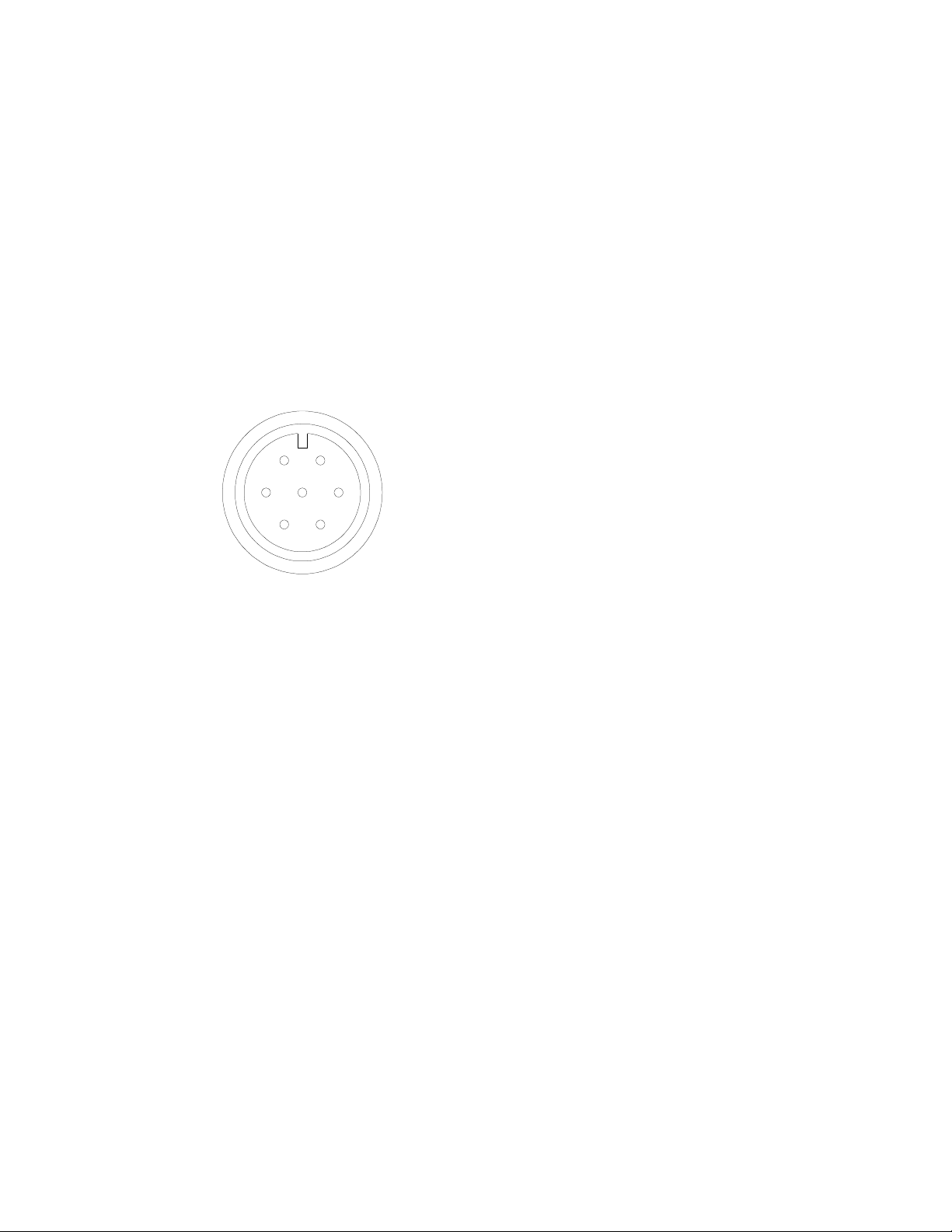

Please see figure 1

6: Pin +IN +Signal

2

1

7: Pin –IN -Signal

3: Pin AGND Shield

5

7

3

4

6

1: Pin +E, +Excitation

2: Pin +S +Sense

4: Pin –E -Excitation

5: Pin -S -Sense

As viewed from the back of the indicator

Note:

For 4 wire load cell, connect the load cell +Excitation and +Sense together at the

connector and -Excitation and -Sense together at the connector.

5 | P a g e © Adam Equipment Company 2010

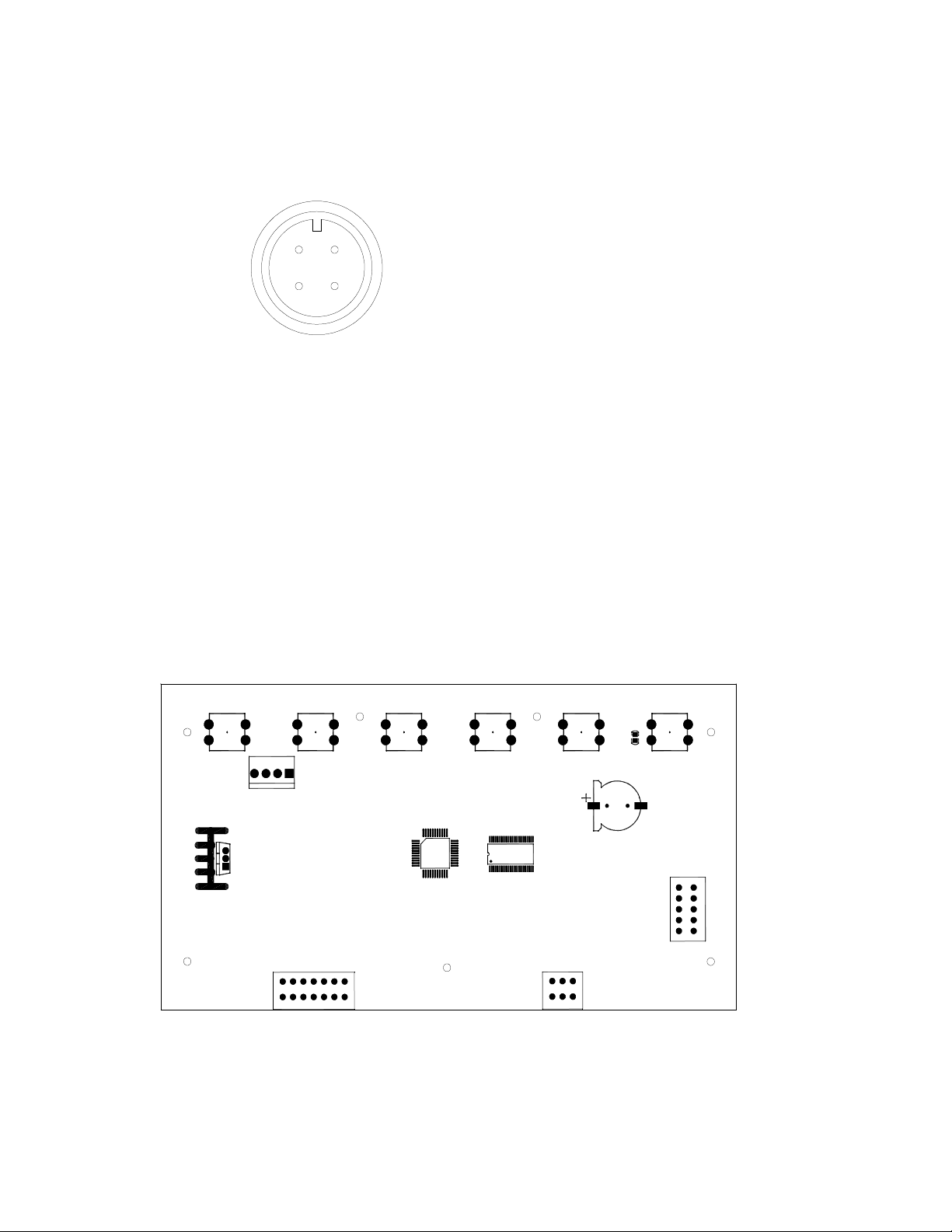

3.4.2 CONNECTION OF RS-232

RS-232 serial interface is a plug as figure 2 shows:

12

1: Pin GND, Signal Ground

2: Pin RXD, Received Data

3: Pin TXD, Transmitted Data

3

4

As viewed from the back of the indicator

See section 9 for details of the RS-232 Interface.

3.4.3 CONNECTION OF RELAY DRIVERS

The output to drive external relays is on the circuit board inside the enclosure. To

gain access you must remove the 6 screws securing the front to the rear of the case.

Pass the wires for the relays through the grommet on the rear panel. The wires will

connect to the PCB using the terminal strip P1.

C18

U4

BT1

Clock Battery

CR1220 type

U1

Relay Output

COM

Common

HI

High

OK

OK

LOW

ZERO

Low

P1

RXT

COM1

Zero

Q5

SEN+

EXE+

Power1

SIG+

SHIE

SIG-

EXE-

SEN-

Power Connector

Battery Vin

+ - no polarity

Load Cell Input

U5

09/01/2009

TXT

AE9721 VER B

LC1

GND

RS-232 Interface

The circuit to control the relays requires an external voltage compatible with the

relays used. For more information see section 10.

6 | P a g e © Adam Equipment Company 2010

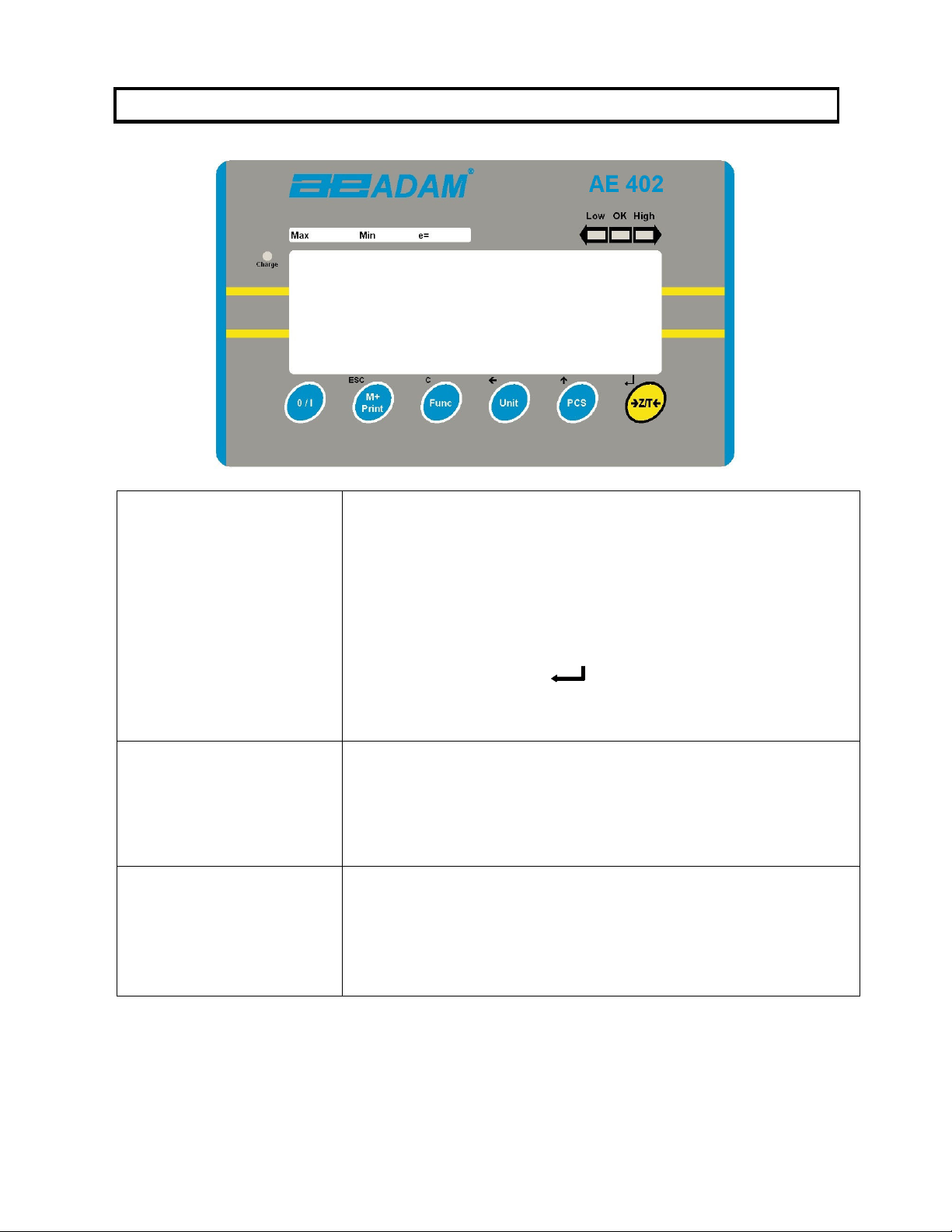

4.0 KEY DESCRIPTIONS

[>Z/T<]

If near zero, Sets the zero point for all subsequent weighing.

The display shows zero.

Tares the scale. Stores the weight currently on the scale as

tare value, subtracts the tare value from the gross weight

and shows the results

A secondary function, is of “Enter” key used when

setting up the value for the Parameters.

[Pcs/] Selects parts counting. Used to set the sample quantities

while parts counting.

A secondary function, is of incrementing the active digit

when setting a value for Parameters.

[Unit/]

Selects the weighing unit to be displayed from those which

are enabled. See parameter S1 in section 7.4.

A secondary function, is to move the active/flashing digit

to the left when setting values for Parameters.

7 | P a g e © Adam Equipment Company 2010

[Func/C]

[Print/M+/Esc]

[O/I]

5.0 DISPLAYS

Selects the Functions of the scale. If the scale is weighing, it

will select parts counting. If it is not in weighing mode, it will

return the user to weighing.

A secondary function (C) is to act as a clear key when setting

values for Parameters.

Sends the results to a PC or a Printer using the RS-232

interface. It also adds the value to the accumulation

memory if the accumulation function is not automatic.

A secondary function (ESC) is to return to normal operation

when the scale is in a Parameter setting mode.

To switch on and switch off the indicator.

The AE402 will store the weighing unit in use and the check

weighing values currently in memory when power is off.

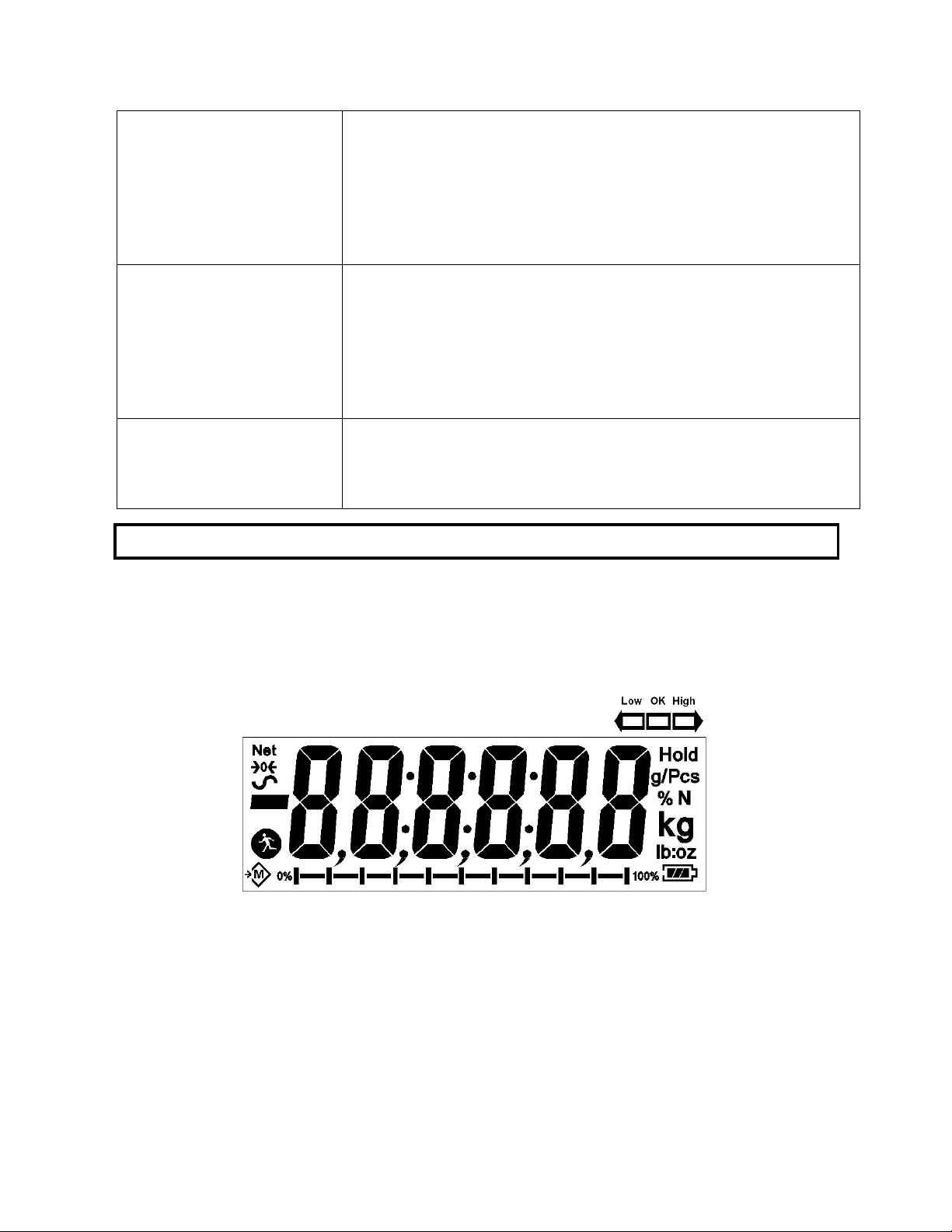

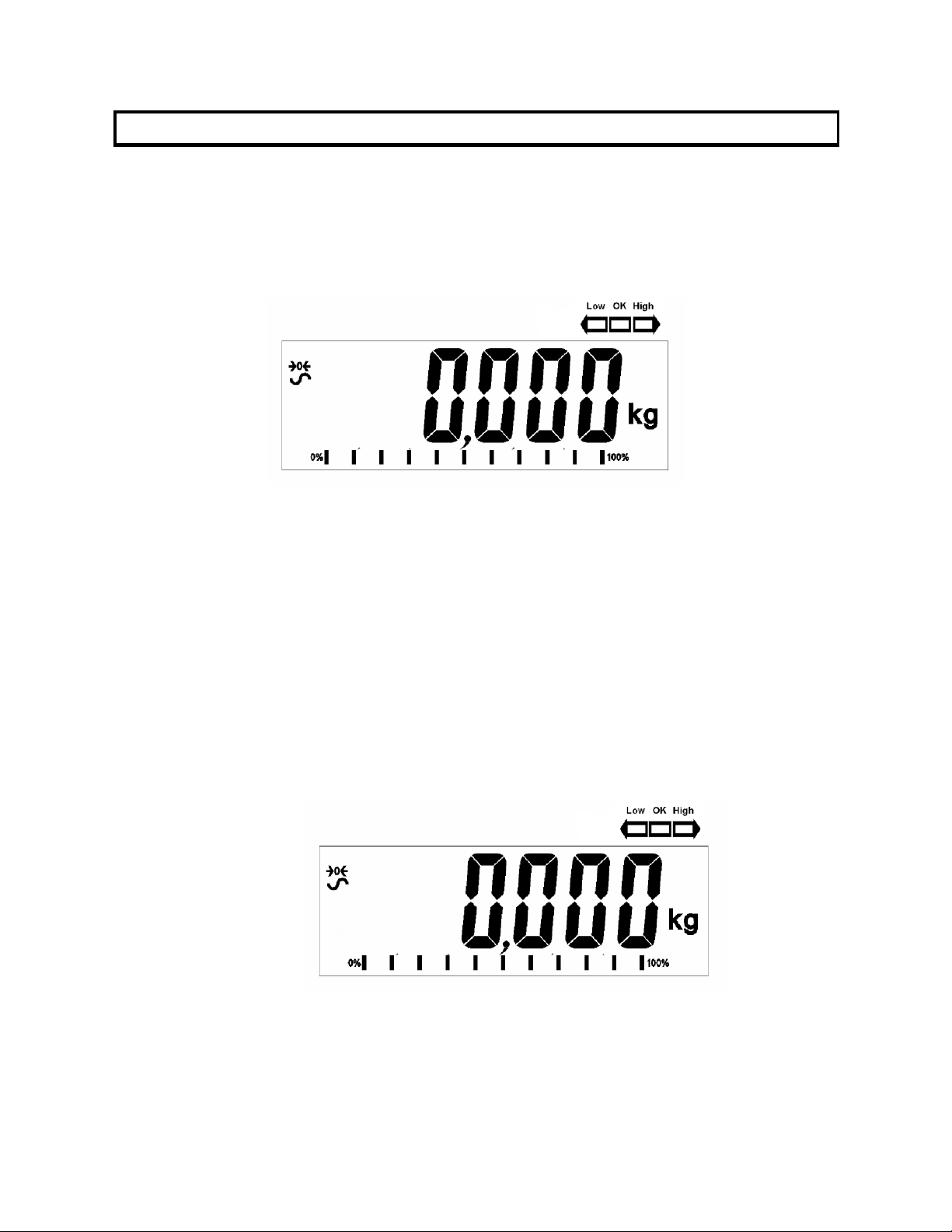

The LCD display will show a value and a unit to the right of the digits.

In addition the LED’s above the display will show when a weight is below or above

check-weighing limits.

Other symbols will show when a weight has been tared (NET) the scale is at zero and

stable, if a value has been stored in memory or when the animal weighing function

has been enabled. A battery symbols will show the state of charge of the internal

battery.

8 | P a g e © Adam Equipment Company 2010

6.0 OPERATION

6.1 ZEROING THE DISPLAY

• You can press the [Z/T] key at any time to set the zero point. This will

usually be necessary when the platform is empty. When the zero point

is obtained the display will show an indicator for zero.

• The scale has an automatic re-zeroing function to account for minor

drifting or accumulation of material on the platform. However you may

need to press the [Z/T] key to rezero the scale if small amounts of

weight are shown when the platform is empty.

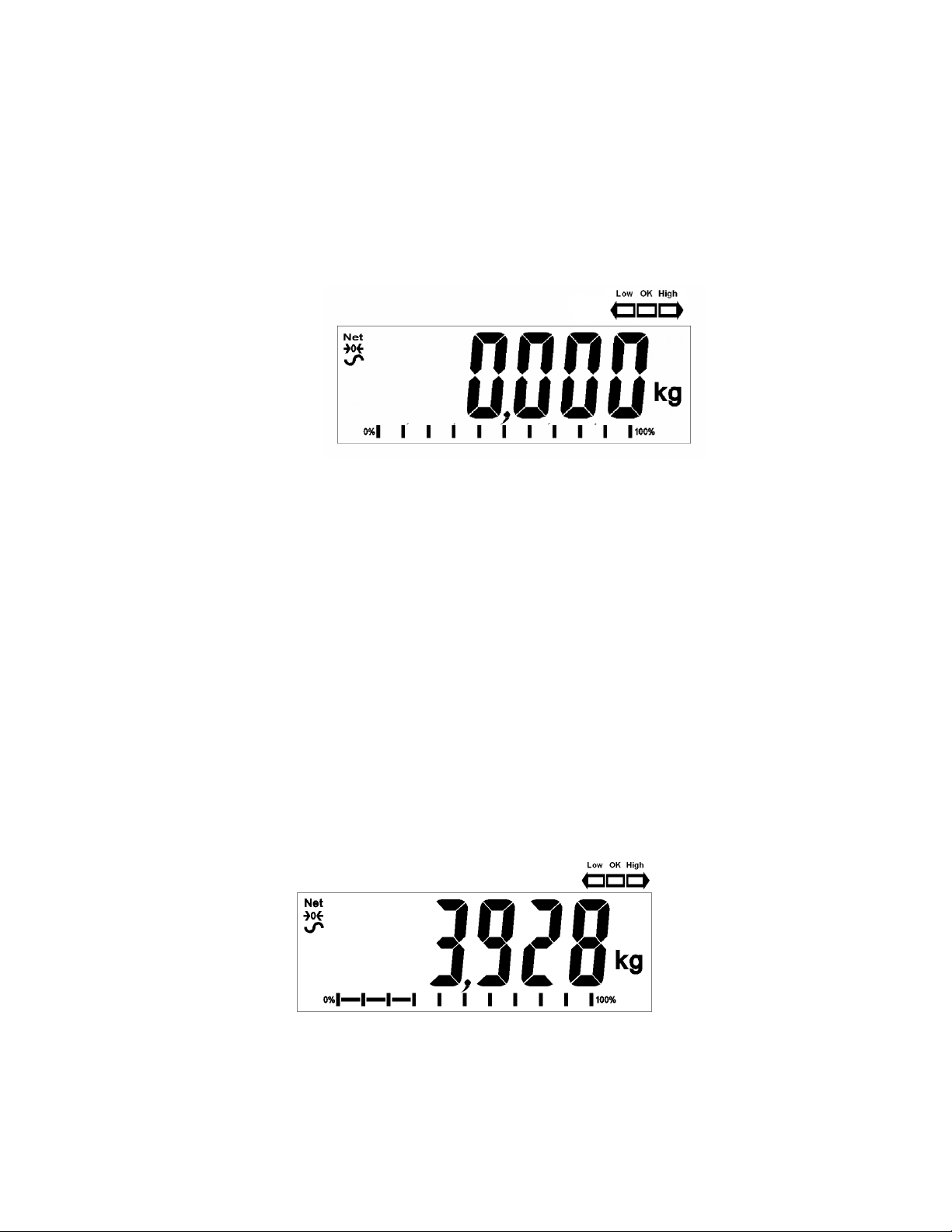

6.2 TARING

• Zero the scale by pressing the [Z/T] key if necessary. The “ZERO”

indicator will be ON.

• Place a container on the platform, a value for its weight will be

displayed.

9 | P a g e © Adam Equipment Company 2010

• Press the [Z/T] key to tare the scale. The weight that was displayed is

stored as the tare value and that value is subtracted from the display,

leaving zero on the display. The “NET indicator will be ON. As a product

is added only the net weight of the product will be shown. The scale

could be tared a second time if another type of product was to be

added to the first one. Again only the weight that is added after taring

will be displayed.

• When the container is removed a negative value will be shown. If the

scale was tared just before removing the container this value is the

gross weight of the container plus all products that was removed. The

“ZERO” indicator will be on to indicate that the platform is back to the

same condition as it was when zero was last set.

• To delete a Tare value, press [Z/T] when the pan is empty.

6.3 WEIGHING A SAMPLE

To determine the weight of a sample, first tare the empty container if it is to be used

and then place the sample in the container. The display will show the net weight of

the sample and the units of weight currently in use.

10 | P a g e © Adam Equipment Company 2010

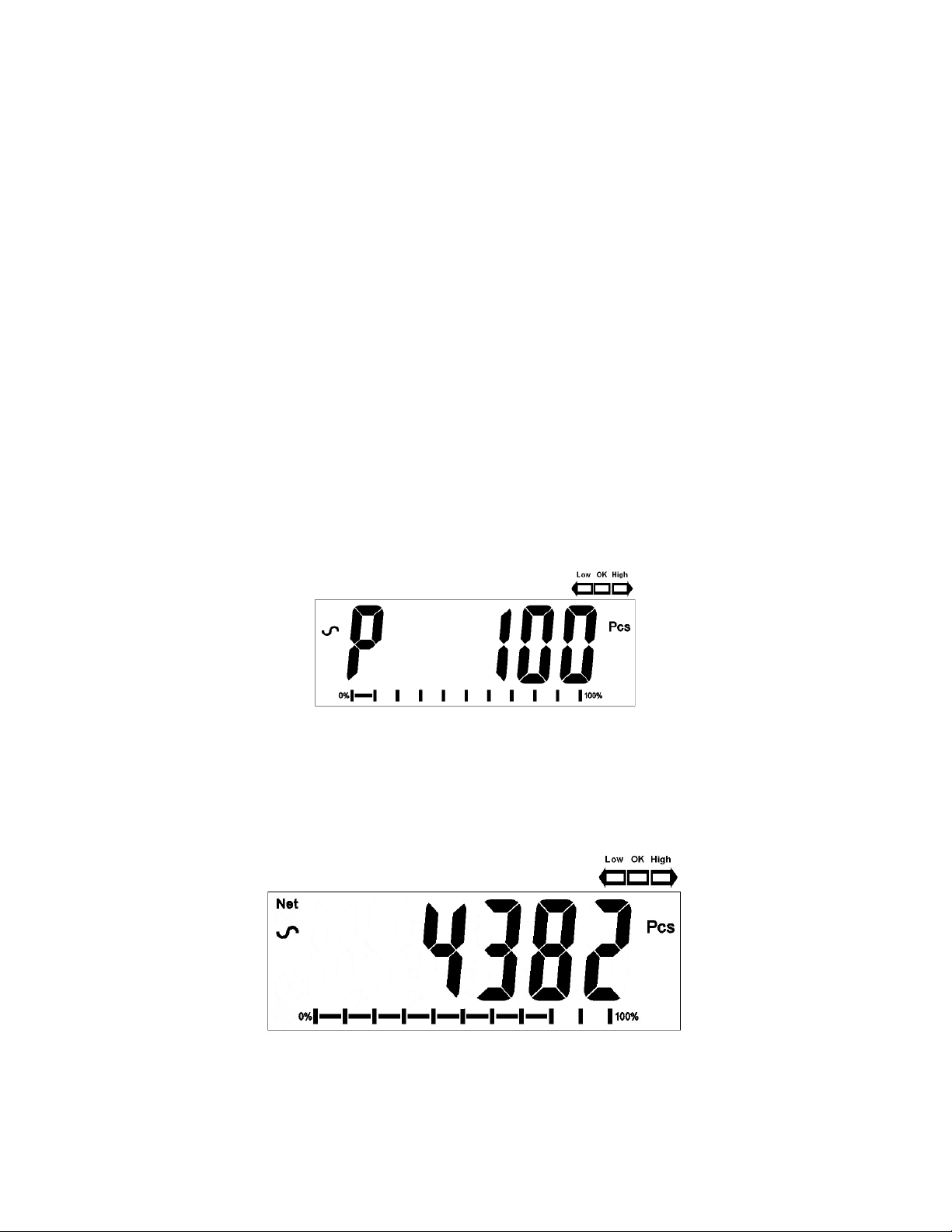

6.4 PARTS COUNTING

If parts counting is enabled, See section 7.4, it is possible to count parts using a

sample of the parts to determine average piece weight.

• Before starting, tare the weight of any container that may be used,

leaving the empty container on the scale. Place a known number of

samples in the container, if used. The number should match the

options for parts counting, i.e., 10, 20, 50, 100 or 200 pieces.

• When the scale is showing weight, pressing the [Pcs/] key will start

the parts counting function.

• The scale will show “P 10” asking for a sample size of 10 parts. Change

the sample size to the desired quantity by pressing the [Pcs/] key. It

will cycle through the options: 10, 20, 50, 100, 200 and back to 10.

• Press the [Z/T] key again when the number matches the number of

parts used as the sample. As more weight is added the display will

show the number of parts (Pcs).

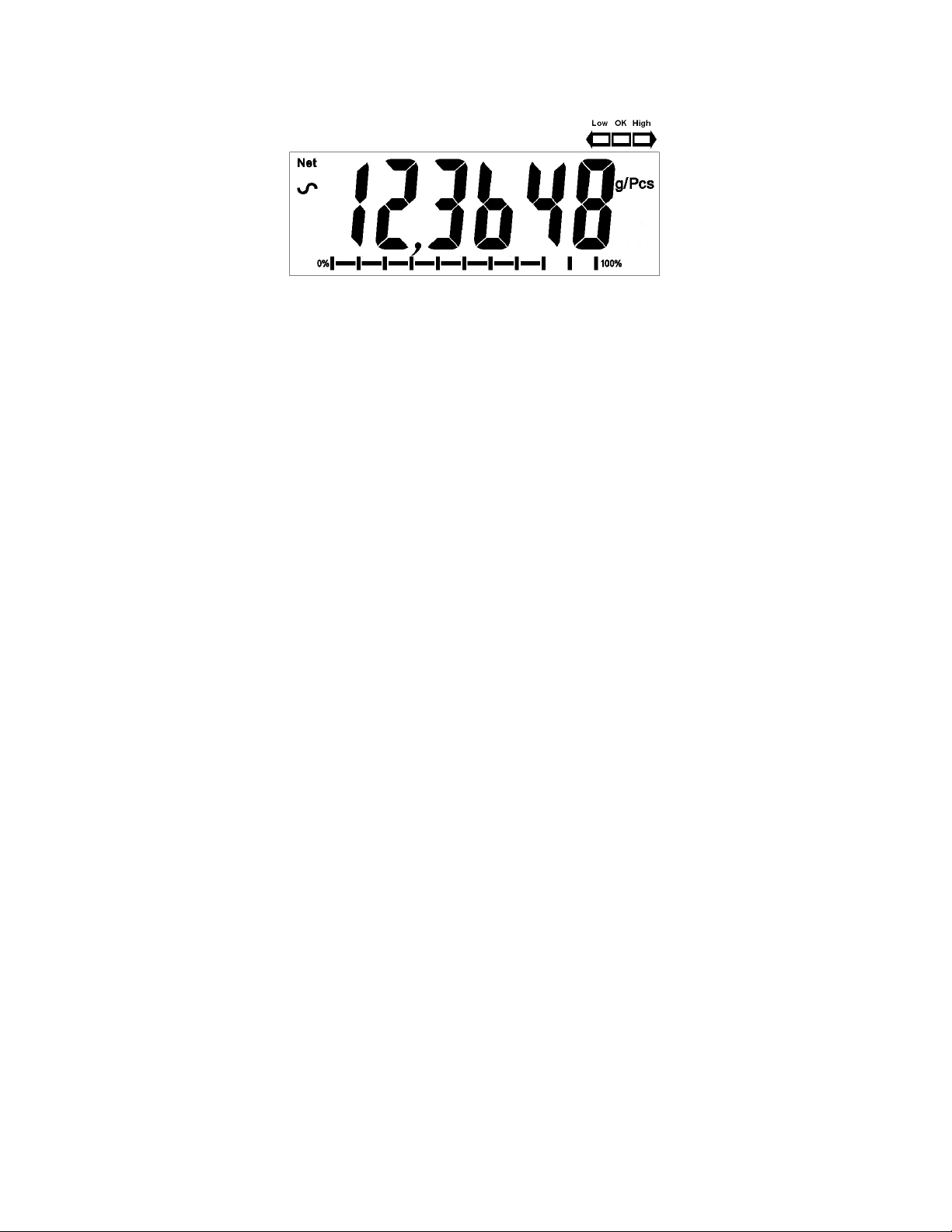

• Pressing the [Unit/] key will display the unit weight (g/pcs), pressing

it second time will display the net weight (pcs and kg) and the third

time, it will be the count again (pcs).

11 | P a g e © Adam Equipment Company 2010

• Press the [Pcs/] key to return to normal weighing. Press the [Pcs/]

key again to start counting a different sample.

6.5 CHECK-WEIGHING

Check-weighing is a procedure to cause lamps to come on (and if enabled, an alarm

to sound) when the weight on the scale meets or exceeds values stored in memory.

The memory holds the last values for a high and a low limit when the power is

turned off. The user can set either one limit or both as described below.

See Section 7.1 for the procedure to set the limits. The limits can be set when the

scale is in weighing or parts counting modes. After limits have been set the Checkweighing function is enabled.

When a weight is placed on the scale the LED’s above the display will show if the

weight is above or below the limits and the beeper will sound as described below, if

the beeper is enabled (see section 7.1).

The relay outputs are open collector drivers to control an external relay. The relays

will be active when the corresponding LED is on during check-weighing. The ZERO

relay output will be on when the scale is showing the display is at Zero.

12 | P a g e © Adam Equipment Company 2010

Loading...

Loading...