Page 1

IronWeld 160/180/200/220

Operating manual

DC Inverter Welder

IronWeld 160/180/200/220

Manufacturer: ADAINSTRUMENTS Address: WWW.ADAINSTRUMENTS.COM

Page 2

IronWeld 160/180/200/220

Table of contents

1.Complete set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. Spesications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5. Features and operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7. Maintenance andservice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13Maintenance and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8. Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9. Exceptions from responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10. Appendix 1- «Certicate of acceptance and sale»

11. Appendix 2- «Warranty card»

2

MEASUREMENT FOUNDATION

Page 3

IronWeld 160/180/200/220

WARNING!

Please, read all instructins before operation. Failure to follow all instructions listed below may result in electric

shock, re and/or serious injury.

1. Complete set

- Hammer/brush

- Mask. When welding, the mask will protect your eyes and face.

- Electrode holder (with 2.5M welding cable)

- Earth clamp (with 1.5M earth cable)

2. Application

Inverter welder is used for welding with covered electrodes (ММА). It is designed wih Advanced Inverter

IGBT Technology. Models of welding inverter allow to perfect manual art-starting performance of welder.

These welders are specially designed for application in daily routine: for repair work when building a house,

for residential care and so on.

The equipment uses electrical arc between electrode and weld material as a heat source for melting of the

electrode and weld material. It is used in the welding of all kinds of elecctrodes: rutile, base contact, electrodes from stainless steel and other. The instrument is protected from overheating and it is used for work

with power 220V.

The main characteristics of this inverter instrument are:

- Small size and light weight. That’s why it’s easy to use it for repair work in eld condition.

- Perfect striking of an arc.

3

MEASUREMENT FOUNDATION

Page 4

IronWeld 160/180/200/220

- Availability of protection protects the instrument from overheating, overvoltage, voltage loss, overcurrent

and so on.

- Convenient connection. External plug makes connections safe, fast and reliable.

3. Safety instructions

WARNING. Welder is under voltage. Disconnect the plug from the power source before making any adjust-

ments, changing accessories, or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally. Only specialists can work with he welder.

- Always follow safety instructions. Wear appropriate protective clothing, shoes and helmet to avoid damages of eyes and skin.

- Always wear protective mask when operate the welder. Or use protective glasses with protective darkening glass.

- Try to avoid from arc ray, sparing and splattering.

- Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of

electric shock. When you operate outside, protect the instrument from rain and sun rays. Use the welder in

the place where there is no rain and direct sun rays.

- The welding fog and gas can make the worker uncomfortable, or hunted, especially in the limited landscape, so do not breathe the fog and gas. Be sure of good ventiation.

- Be sure that the radiation of the arc doesn’t reach other people, that are near to the place of welding.

- Remember, that the temperature of welding surface increases. So ty not to touch to the welding parts. It

can cause burns.

4

MEASUREMENT FOUNDATION

Page 5

IronWeld 160/180/200/220

- It’s forbidden to touch electrode with bare hands. It’s forbidden to wear wet or damaged gloves or protective clothes.

- Don’t touch the parts under voltage.

- It’s forbidden to touch electrode that is in contact with welding surface, ground or other electrode which is

connected to another welder.

- Never weld tanks that contain ammable and explosive materials.

- To avoid accidents when working at height, follow safety regulations.

- Be careful, there must be no bystanders on the working site.

- Welders radiate electromagnetic waves and make noises. So be sure that there are no people with cardiac

stimulator or other equipment that can be inuenced with electromagnetic waves and radio frequencies.

- Before operation check the connection of cables and earth. From time to time check the condition of welding cable. If you use this instrument regularly, check it once per month.

- Only qualied specialists can do servicing.

- If you don’t use welder for a long time, store it in place wih good ventilation.

- Regularly clean welder from dust. Check holding elements. They must be tighten. Check ectromagnetic

system, current adjusting knob and so on.

- Dust in the air and also corrosive substances mustn’t exceed permissible levels.

- It’s necessary to provide access for air for the welder. There must be free space around welder, about 50

cm.

- Ensure that there are no metallic or foreign objects near the welder. They can get into the welder.

- Take out the electrode if you don’t use welder for a long time.

- Don’t place the welder on the vibrating surface.

- Ensure that there are no noises in the place of adjustment of welder.

5

MEASUREMENT FOUNDATION

Page 6

IronWeld 160/180/200/220

4. Spesications

Environmental conditions:

a) temperature range

During welding : -10 °C ~ +40 °C

During transportation and storage : -25 °C ~ +55 °C

b) humidity

at +40 °C <50%

at +20 °C <90%

c)

dust, acid and dirt in the air of work area also mustn’t exceed permissible levels (except of emission from weld-

er).

d) height above sea level no more than 1000 m.

e) angle of slope during operation mustn’t exceed 15 °.

f) noise level during operation mustn’t exceed 75 dB

6

MEASUREMENT FOUNDATION

Page 7

IronWeld 160/180/200/220

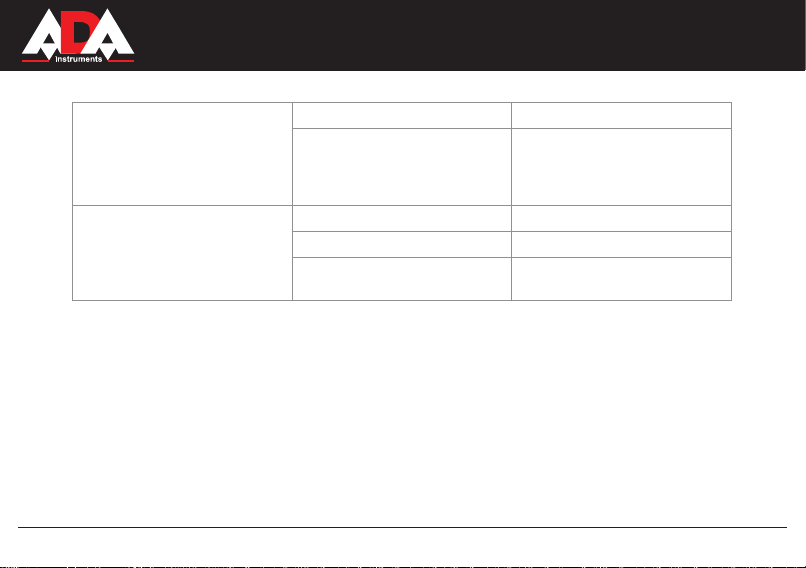

Parameter

Input voltage 230V 230V 230V 230V

Frequency 50/60Hz 50/60Hz 50/60Hz 50/60Hz

Phase Single Single Single Single

Max input power 4.6 KVA 5.3 KVA 6.2 KVA 7.1 KVA

Max No-load voltage 68 V 68 V 68 V 68 V

Current range 10-160 A 10-180 A 10-200 A 10-220 A

Duty cycle 60% 60% 60% 60%

Insulation grade F F F F

Electrode diameter 2.0-4.0 mm 2.0-4.0 mm 2.0-5.0 mm 2.0-5.0 mm

Dimensions (L×W×H) 38х22х30 cm 38х22х30 cm 38х22х30 cm 38х22х30 cm

IronWeld 160 IronWeld 180 IronWeld 200 IronWeld 220

7

Model

MEASUREMENT FOUNDATION

Page 8

IronWeld 160/180/200/220

5. Features and operation

There is power indicator, indicator of thermoprotection and adjusting knob of current strength on the upper

part of the instrument. There are plugs for connection of welding cables with electrode holders and clamp

on the bottom. Power switch is located on the back panel.

1

6

2

3

4

5

1. Power indicator

2. Indicator of thermopro-

tection.

7

3. Adjusting knob of current strength.

4. Plug for connection of

earth clamp.

5. Plug for connection

of cable with electrode

holder.

6. Input of cable connection to the electricity

supply.

7. Power switch.

8

MEASUREMENT FOUNDATION

Page 9

IronWeld 160/180/200/220

WARNING: Indicator of thermoprotection will light after long period of operation. That means that inner tem-

perature exceeds permitted value. In that case stop work and let the instrument cool down. You can continue

operation when the indicator is switched off.

Installing of welder

Do not expose your welder to rain or direct sunlight. You must provide good ventilation. The distunce above

welder must be no less than 50 cm. In case of poor inner ventilation, set the equipment to get rid of smoke

and protect from wind.

Connection of power suply

Connect electric cable to single-phase net of power supply 220V with switch.

It’s forbidden to use voltage 380V. As it can damage the tool and operator.

When connecting welder to the electric network under voltage 220V and with frequency 50 Hz, it’s necessary

to provide protection of the socket. It’s important for connection with automatic switch or 25 A fuse.

WARNING: Use socket with ground connection to connect the tool.

Connection of cables with electrode holders and earth clamp

Connection of welding cable. Connect bayonet plug of welding cable to the output connection on the front

panel with marking «+» and turn clockwise.

Electrode holder is used for electrode clamp

Connection of earth cable. Connect bayonet plug of welding cable to the output connection on the front panel

and turn clockwise. Earth clamp is used for connection of welding material to the chain of welding current.

9

MEASUREMENT FOUNDATION

Page 10

IronWeld 160/180/200/220

Cleanup of welding material befor welding

Metal must be cleaned of rust, oil dust, water, paint and so on. Clean the metal at distance 10-20 mm from

the joint.

Welding

Adjustment before welding.

Adjust current according to the thickness of welding detail and diameter of welding electrode.

Take electrode holder, set the electrode, touch welding material with electrode in order to get arc.

Electrode replacement

Stop welding when the length of electrode decreases up to 1-2 cm. Press the handle of electrode holder.

After that, set new electrode and release handle.

WARNING: Electrode warms till the high temperature. Please, follow safety precautions to avoid burns.

10

MEASUREMENT FOUNDATION

Page 11

IronWeld 160/180/200/220

6. Troubleshooting

TROUBLE REASON SHOOTING

Indicator of thermoprotection

lights

Adjustment of current doesn’t

work

Electrode holder and welding cable heat up to the high

temperature

Overheating protection because

of poor ventilation.

Environment temperature is too

high.

Usage of tool beyond its duty

cycle.

Adjustment of current is broken.

Socket is dirty with oxides. Clean the sockets.

Distance between holder and

cable is big.

Improve the conditions of

ventilation.

Reduce the temperature. The

indicator will switch off.

Replace the adjustment of

current.

Disconnect electrode holder

and clean up cable of the place

of contact.

11

MEASUREMENT FOUNDATION

Page 12

Electrode lights the arc, but it

sticks at once

Ventilator doesn’t work

IronWeld 160/180/200/220

Current strength is too low. Encrease current

Measure voltage in the net. If it

Undervoltage in net.

Malfunction of power switch. Apply service center.

Ventilator is damaged. Replace ventilator.

Difculties (obstacles) in the

work of ventilator.

is not enough, use equipment of

voltage regulation, according to

the power of welder.

Check and shoot trouble.

12

MEASUREMENT FOUNDATION

Page 13

IronWeld 160/180/200/220

7. Maintenance and service

In comparison with standard welder, this tool is improved with up to day electronic components and perfect

technology. That’s why only qualied personnel can maintain this tool. But due to the small quantity of

rapidly wearing parts, it doesn’t require regular after-sales service. Except of cleanup. Only qualied persons

are reliable for such work. In case of problems, the buyer should apply service center.

- Protect the tool from rain, snow and long-term exposure of sunlight (if you operate outdoor).

- If you don’t use welder for a long period of time, store it at temperature from -25°С to +55°С, humidity no

more than 90%.

- Professional worker of service support must clean the welder from dust with dry low-pressure air (air

compressor or another instrument). Clean the details that are covered with oil with cloth. Check if any

hardware has been xed. Clean the tool if there is dust. Usually clean your tool once a year. Do it once a

quarter if there is a lot of dust.

- Check input and output cables. Make sure they are properly xed. Check cables once a month and before

storage.

13

MEASUREMENT FOUNDATION

Page 14

IronWeld 160/180/200/220

Warranty

This product is warranted by the manufacturer to the original purchaser to be free from defects in material and workmanship under normal use for a period of two (2) years from the date of purchase.

During the warranty period, and upon proof of purchase, the product will be repaired or replaced (with the same or similar

model at manufactures option), without charge for either parts of labour.

In case of a defect please contact the dealer where you originally purchased this product. The warranty will not apply to

this product if it has been misused, abused or altered. Without limiting the foregoing, leakage of the battery, bending or

dropping the unit are presumed to be defects resulting from misuse or abuse.

Exceptions from responsibility

The user of this product is expected to follow the instructions given in operators’ manual.

Although all instruments left our warehouse in perfect condition and adjustment the user is expected to carry out periodic

checks of the product’s accuracy and general performance.

The manufacturer, or its representatives, assumes no responsibility of results of a faulty or intentional usage or misuse

including any direct, indirect, consequential damage, and loss of prots.

The manufacturer, or its representatives, assumes no responsibility for consequential damage, and loss of prots by any

disaster (earthquake, storm, ood ...), re, accident, or an act of a third party and/or a usage in other than usual condi-

tions.

The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of prots due to a change of

data, loss of data and interruption of business etc., caused by using the product or an unusable product.

The manufacturer, or its representatives, assumes no responsibility for any damage, and loss of prots caused by usage

other thsn explained in the users’ manual.

The manufacturer, or its representatives, assumes no responsibility for damage caused by wrong movement or action due

to connecting with other products.

14

MEASUREMENT FOUNDATION

Page 15

WARRANTY DOESN’T EXTEND TO FOLLOWING CASES:

1. If the standard or serial product number will be changed, erased, removed or wil be unreadable.

2. Periodic maintenance, repair or changing parts as a result of their normal runout.

3. All adaptations and modications with the purpose of improvement and expansion of normal sphere of

product application, mentioned in the service instruction, without tentative written agreement of the expert

provider.

4. Service by anyone other than an authorized service center.

5. Damage to products or parts caused by misuse, including, without limitation, misapplication or nrgligence

of the terms of service instruction.

6. Power supply units, chargers, accessories, wearing parts.

7. Products, damaged from mishandling, faulty adjustment, maintenance with low-quality and non-standard

materials, presence of any liquids and foreign objects inside the product.

8. Acts of God and/or actions of third persons.

9. In case of unwarranted repair till the end of warranty period because of damages during the operation of

the product, it’s transportation and storing, warranty doesn’t resume.

For more information you can visit our website WWW.ADAINSTRUMENTS.COM

or write the letter with your questions on info@adainstruments.com

Page 16

WARRANTY CARD

Name and model of the product ________________________________________________

Serial number ________________date of sale_______________________

Name of commercial organization _____________________stamp of commercial organization

During this warranty period the owner of the product has the right for free repair of his instrument in case of manufacturing defects.

Warranty is valid only with original warranty card, fully and clear lled (stamp or mark of thr seller is obligatory).

Technical examination of instruments for fault identication which is under the warranty, is made only in the authorized service center.

In no event shall manufacturer be liable before the client for direct or consewuential damages, loss of prot or any other damage which

occur in the result of the instrument outage.

The product is received in the state of operability, without any visible damages, in full completeness. It is tested in my presence. I have

no complaints to the product quality. I am familiar with the conditions of qarranty service and i agree.

purchaser signature _______________________________

If you have any questions about the warranty service and technical support contact seller of this product

Before operating you should read service instruction!

Page 17

Certicate of acceptance and sale

__________________________________________________________________________

__________________________________________________________________________

___________________________________________________________№_____________

name and model of the instrument

Corresponds to ______________________________________________________________

designation of standard and technical requirements

Data of issue _______________________________________________________________

Stamp of quality control department

Price

Sold ___________________________________ Date of sale ______________________

name of commercial establishment

Page 18

Руководство по эксплуатации

Инверторный сварочный аппарат

IronWeld 160/180/200/220

Производитель: ADAINSTRUMENTS Адрес: WWW.ADAINSTRUMENTS.COM

Page 19

IronWeld 160/180/200/220

Содержание

1. Комплектация . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2. Назначение . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Правила по технике безопасности . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Технические характеристики. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5. Устройство и работа. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6. Неисправности и методы их устранения . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7. Техническое обслу�ивание и правилахранения . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30Техническое обслу�ивание и правила хранения . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8. Гарантия . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

9. Освобо�дение от ответственности . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

10. Прило�ение 1- “Свидетельство о приемке и прода�е”

11. Прило�ение 2- “Гарантийный талон”

19

MEASUREMENT FOUNDATION

Page 20

IronWeld 160/180/200/220

ВНИМАНИЕ!

Перед началом работы пользователь обязан ознакомиться с правилами техники безопасности и условиями

надле�ащей эксплуатации инструмента. Соблюдение приведенных ни�е инструкций позволит избе�ать

нештатных ситуаций или несчастных случаев и создать условия безопасной работы.

1. Комплектация

- Молоток / щетка

- Маска. При сварке , маска защитит ваши глаза и лицо.

- Дер�атель электродов (с 2,5 м сварочного кабеля)

- Заземляющий за�им (с 1,5 м кабеля заземления)

2. Назначение

Инверторный аппарат для сварки штучными покрытыми электродами (ММА) создан с использованием

усовершенствованной технологии IGBT. Модели сварочных инверторов позволяют проводить ручную

дуговую сварку.

Данные сварочные аппараты разработаны специально для использования в повседневной домашней

работе: для ремонтных работ при постройке дома, обустройстве приусадебного участка и т.д.

Аппарат использует электрическую дугу ме�ду электродом и свариваемым материалом в качестве

источника тепла для плавления электрода и свариваемого металла. Аппарат позволяет производить

сварку всеми типами электродов: рутиловыми, базовыми, из нер�авеющей стали и др.

Аппарат имеет защиту от перегрева и предназначен для работы от напря�ения 220 В.

Основными характеристиками данного инверторного аппарата являются:

- Небольшой объем и малый вес, из-за чего аппаратом легко пользоваться для выполнения ремонтных

работ в полевых условиях.

20

MEASUREMENT FOUNDATION

Page 21

IronWeld 160/180/200/220

- Великолепное за�игание дуги и перенос металла.

- Наличие различных средств защиты предохраняет аппарат от перегрева, перенапря�ения, падения

напря�ения, чрезмерного тока и т.д.

- Удобное соединение. Внешние разъемы делают соединения безопасными, быстрыми и наде�ными.

3. Правила по технике безопасности

ВНИМАНИЕ. Сварочный аппарат находится под напря�ением, поэтому пре�де, чем приступить к

его обслу�иванию, следует обесточить его во избе�ание пора�ения электрическим током. Перед

проведением любых работ всегда необходимо отключать источник питания. К работам со сварочным

аппаратом допускаются только специалисты.

- Всегда соблюдайте правила безопасности. Носите защитную оде�ду и специальные средства

защиты, чтобы избе�ать повре�дения глаз и ко�ных покровов.

- Всегда надевайте защитную маску во время работы сварочным аппаратом или используйте очки с

защитным затемненным стеклом.

- Старайтесь, чтобы искры и брызги не попали на тело.

- Не работайте под водой или в месте с повышенной вла�ностью. Когда сварочный аппарат

используется при работах вне помещений, его следует беречь от до�дя и предохранять от длительного

воздействия солнечных лучей. Сварочный аппарат дол�ен быть установлен в таком месте, где на

него не будет попадать до�дь и солнечные лучи.

- Дым и газ, которые попадают в воздух при сварке, опасны для здоровья. Перед началом работ

убедитесь, что вытя�ка и вентиляция исправно работают.

- Убедитесь, что излучение дуги не попадет на других людей, находящихся поблизости от места сварки.

21

MEASUREMENT FOUNDATION

Page 22

IronWeld 160/180/200/220

- Помните, что при сварке температура обрабатываемой поверхности повышается, поэтому

старайтесь не прикасаться к обрабатываемым деталям во избе�ание о�огов.

- Запрещается касаться электрода голыми руками. Запрещается надевать мокрые или повре�денные

перчатки или защитную оде�ду.

- Не касайтесь деталей, находящихся под напря�ением.

- Запрещается касаться электрода, контактирующего с обрабатываемой поверхностью, землей или

другим электродом, подключенным к другому аппарату.

- Никогда не производите сварку емкостей, в которых могут содер�аться легковоспламеняющиеся

или взрывоопасные материалы.

- При высотных работах во избе�ание несчастного случая соблюдайте правила техники безопасности

работы на высоте.

- Следите за тем, чтобы на рабочей площадке не было посторонних людей.

- Сварочные аппараты излучают электромагнитные волны и создают помехи для радиочастот,

поэтому следите за тем, чтобы в непосредственной близости от аппарата не было людей, которые

используют стимулятор сердца или другие принадле�ности, для которых электромагнитные волны и

радиочастоты создают помехи.

- Перед началом работ всегда проверяйте подключение входных и выходных кабелей и заземление.

Время от времени следует проверять состояние сварочного кабеля. Если аппарат используется

регулярно, его следует проверять не менее одного раза в месяц.

- Техническое обслу�ивание дол�ны выполнять только квалифицированные специалисты.

- Если сварочный аппарат не используется продол�ительное время, его следует хранить в сухом,

хорошо проветриваемом помещении.

- Регулярно следует очищать сварочный аппарат от пыли. Проверьте, не ослаблены ли детали

крепления аппарата, электромагнитную систему, ручки настройки тока и т.д.

22

MEASUREMENT FOUNDATION

Page 23

IronWeld 160/180/200/220

- Наличие в воздухе пыли, а так�е едких и коррозионных веществ не дол�но превышать допустимых норм.

- Необходимо обеспечить доступ воздуха к сварочному аппарату, для этого вокруг него дол�но быть

свободное пространство не менее 50 см.

- Убедитесь, что на месте работы сварочного аппарата нет металлических или инородных предметов

во избе�ание их попадания в аппарат.

- Если аппарат не эксплуатируется, электрод следует вынимать из дер�ателя.

- Не устанавливайте сварочный аппарат на вибрирующую поверхность.

- Убедитесь, что в месте установки сварочного аппарата отсутствуют посторонние помехи.

4. Технические характеристики модели

Условия окружающей среды:

а) диапазон температур

Во время сварки : -10 °C ~ +40 °C

Во время транзита и хранения : -25 °C ~ +55 °C

б) вла�ность

при +40 °C <50%

при +20 °C <90%

в) количество пыли, кислоты и грязи в воздухе в рабочей зоне не мо�ет превышать

значение, указанное в нормативах (за исключением выбросов от сварочного аппарата).

г) высота над уровнем моря не больше 1000 м

д) угол наклона аппарата при работе не дол�ен привышать 15 °.

е) при работе аппарата уровень шума не превышает 75 дБ.

23

MEASUREMENT FOUNDATION

Page 24

IronWeld 160/180/200/220

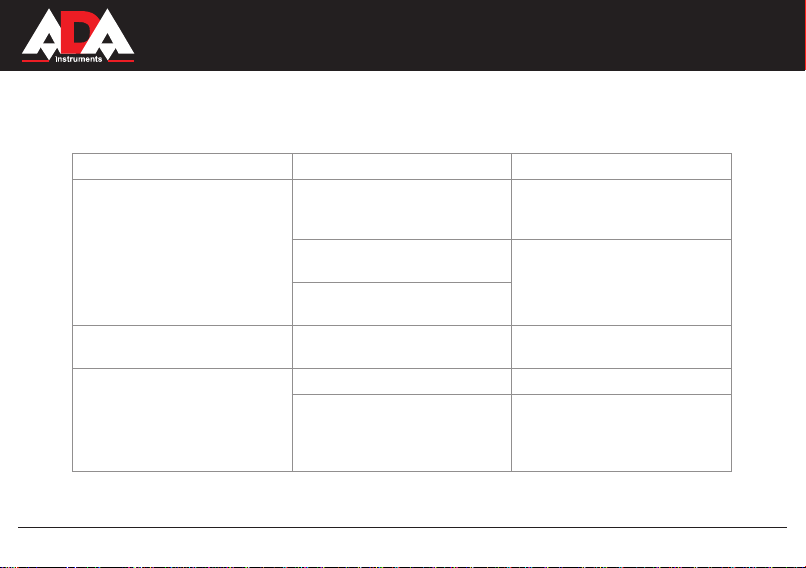

Параметр

Входное напря�ение 230V 230V 230V 230V

Частота 50/60Hz 50/60Hz 50/60Hz 50/60Hz

Фаза одна одна одна одна

Максимальная

потребляемая мощность

Максимальное

напря�ение холостого

хода

Диапазон тока 10-160 A 10-180 A 10-200 A 10-220 A

Рабочий цикл 60% 60% 60% 60%

Класс нагревостойкости

изоляции

Диаметр электрода 2.0-4.0 мм 2.0-4.0 мм 2.0-5.0 мм 2.0-5.0 мм

Размеры (ДхШхВ) 38х22х30 см 38х22х30 см 38х22х30 см 38х22х30 см

IronWeld 160 IronWeld 180 IronWeld 200 IronWeld 220

4.6 кВА 5.3 кВА 6.2 кВА 7.1 кВА

68 В 68 В 68 В 68 В

F F F F

24

Модель

MEASUREMENT FOUNDATION

Page 25

IronWeld 160/180/200/220

5. Устройство и работа

В верхней части аппарата размещены индикатор питания, индикатор срабатывания термозащиты

и ручка регулировки силы сварочного тока. В ни�ней части аппарата размещены разъемы для

подключения сварочных кабелей с электрододер�ателем и за�имом массы. На задней панели

аппарата установлен выключатель питания.

1

6

2

3

4

5

1. Индикатор питания

2. Индикатор

термозащиты

7

3. Регулятор сварочного

тока

4. Разъем подключения

кабеля за�има

заземления

5. Разъем

подключения кабеля

электрододер�ателя

6. Ввод кабеля

подключения к

электросети

7. Выключатель питания

25

MEASUREMENT FOUNDATION

Page 26

IronWeld 160/180/200/220

ВНИМАНИЕ. Индикатор термозащиты загорится после долгого периода работы, что означает, что

внутренняя температура превышает допустимое значение, в таком случае следует остановить

работу аппарата на некоторое время и дать ему остыть. Работу мо�но продол�ить после того, как

индикатор защиты погаснет.

Размещение сварочного аппарата

Сварочный аппарат дол�ен быть установлен в таком месте, где он не подвергается

воздействию солнечного света и до�дя. Для обеспечения достаточной вентиляции расстояние над

сварочным аппаратом дол�но быть не менее 50 см. Если внутренней вентиляции не достаточно,

следует установить оборудование для устранения дыма и предохранения от ветра.

Подсоединение источника питания

Подсоедините электрокабель к однофазной сети электропитания 220 В с выключателем.

Напря�ение 380 В запрещено использовать, так как оно мо�ет серьезно повредить аппарат и иметь

серьезные последствия для оператора.

При подключении сварочного аппарата к электрической сети переменного тока напря�ением

220 В и частотой 50 Гц необходимо обеспечить защиту розетки для подключения автоматическим

выключателем или плавкой вставкой с током срабатывания равным 25 А.

ВНИМАНИЕ. Для подключения аппарата используйте розетку с заземлением.

Подключение кабелей электрододержателя и зажима заземления.

Подсоединение сварочного кабеля. Подсоедините байонетный разъем сварочного кабеля к

выходному соединению на передней панели с маркировкой «+» и поверните по часовой стрелке.

26

MEASUREMENT FOUNDATION

Page 27

IronWeld 160/180/200/220

Электрододержатель используется для зажима электрода.

Подсоединение кабеля заземления. Подсоедините байонетный разъем кабеля заземления к

выходному разъему на передней панели и поверните по часовой стрелке. За�им заземления

используется для подключения свариваемого материала в цепь сварочного тока.

Зачистка свариваемого материала перед выполнением сварки.

Металл на расстоянии 10-20 мм от шва дол�ны быть очищены от р�авчины, маслянистой пыли,

воды, краски и т.д.

Сварка

Регулировка перед проведением сварки.

Отрегулируйте сварочный ток. Сварочный ток подбирают исходя из толщины обрабатываемой детали

и диаметра сварочного электрода.

Возьмите электрододер�атель, установите электрод, коснитесь электродом свариваемого материала

для возбу�дения дуги.

Смена электрода

Когда длинна электрода уменьшится до 1-2 см прекратите процесс сварки и на�мите на ручку

электрододер�ателя. После этого вставьте новый электрод и отпустите ручку.

ВНИМАНИЕ. Электрод нагревается до высокой температуры, соблюдайте меры безопасности во

избе�ание о�огов.

27

MEASUREMENT FOUNDATION

Page 28

IronWeld 160/180/200/220

6. Неисправности и методы их устранения

НЕИСПРАВНОСТЬ ПРИЧИНА УСТРАНЕНИЕ

Горит индикатор термозащиты

Регулятор сварочного тока не

работает

Дер�атель электрода и

сварочный кабель

нагреваются до высокой

температуры

Плохая вентиляция привела

к срабатыванию защиты от

перегрева

Температура окру�ающей

среды слишком высока

Использование сверх рабочего

цикла

Регулятор сломан Замените регулятор

Разъем загрязнен окислами Очистите разъемы

Большое сопротивление

ме�ду

электрододер�ателем и

кабелем

Улучшите условия вентиляции

аппарата

При пони�ении температуры

индикатор автоматически

погаснет

Отсоедините

электрододер�атель и

зачистите

кабель место контакта

28

MEASUREMENT FOUNDATION

Page 29

IronWeld 160/180/200/220

Электрод за�игает дугу, но

сразу �е прилипает

Вентилятор не включается

Установлен недостаточный

сварочный ток.

Недостаточное напря�ение

в сети

Неисправность выключателя

питания

Повре�ден вентилятор Замените вентилятор

Препятствие в работе

вентилятора

29

Увеличьте сварочный ток

Замерьте напря�ение в сети,

если оно ни�е допустимого,

используйте устройства

стабилизации сетевого

напря�ения рассчитанные

на мощность сварочного

аппарата

Обратитесь в сервисный центр

Проверьте и устраните

неисправность

MEASUREMENT FOUNDATION

Page 30

IronWeld 160/180/200/220

7. Техническое обслуживание и правила хранения

В отличие от стандартного сварочного аппарата, данный сварочный аппарат является усовершенствованным, в котором используются современные электронные компоненты и совершенная технология. Поэтому проведение технического обслу�ивания такого аппарата следует проводить только

квалифицированному персоналу. Однако, в силу того, что в данном аппарате присутствует очень

малое количество быстро изнашиваемых деталей, он не требует проведения регулярного сервисного обслу�ивания, за исключением очистки. Отвечать за выполнение данной работы могут только

квалифицированные работники. Настоятельно рекомендуется покупателям в случае возникновения

проблем, которые они неспособны решить собственными силами обращаться в Сервисный центр

для получения технической поддер�ки.

- Защищайте аппарат от до�дя, снега и длительного воздействия солнечного света при использовании на улице.

- Если сварочный аппарат не используется долгое время, его следует хранить при температуре от

-25°С до +55°С и относительная вла�ность не мо�ет быть более 90%.

- Профессиональный работник сервисной слу�бы дол�ен регулярно очищать сварочный аппарат

от пыли с�атым сухим воздухом (воздушный компрессор или другое подобное устройство). Детали

склонные к замасливанию дол�ны очищаться тряпкой и одновременно проводить осмотр на наличие

неплотно закрепленных деталей внутри аппарата. В случае обнару�ения скопления пыли необходима немедленная очистка. В нормальных условиях очистку необходимо проводить только один раз в

год. В случае чрезмерного пылеобразования очистку следует проводить раз в квартал.

- Необходимо регулярно проверять входные и выходные кабели сварочного аппарата, для того, чтобы гарантировать их правильное и прочное соединение. Проверку необходимо проводить один раз в

месяц и ка�дый раз перед тем как убирать аппарат на хранение.

30

MEASUREMENT FOUNDATION

Page 31

IronWeld 160/180/200/220

Гарантия

Производитель предоставляет гарантию на продукцию покупателю в случае дефектов материала или

качества его изготовления во время использования оборудования с соблюдением инструкции пользователя

на срок до 2 лет со дня покупки. Во время гарантийного срока, при предъявлении доказательства покупки,

прибор будет починен или заменен на такую �е или аналогичную модель бесплатно. Гарантийные

обязательства так�е распространяются и на запасные части. В случае дефекта, по�алуйста, свя�итесь с

дилером, у которого вы приобрели прибор. Гарантия не распространяется на продукт, если повре�дения

возникли в результате деформации, неправильного использования или ненадле�ащего обращения. Все

вышеизло�енные безо всяких ограничений причины, а так�е утечка батареи, искривление прибора являются

дефектами, которые возникли в результате неправильного использования или плохого обращения.

Освобождение от ответственности

Пользователю данного продукта необходимо следовать инструкциям, которые приведены в руководстве

по эксплуатации. Да�е, несмотря на то, что все прборы проверены производителем, пользователь дол�ен

проверять точность прибора и его работу.

Производитель или его представители не несут ответственности за прямые или косвенные убытки,

упущенную выгоду или иной ущерб, возникший в результате неправильного обращения с прибором.

Производитель или его представители не несут ответственности за косвенные убытки, упущенную выгоду,

возникшие в результате катастроф (землетрясение, шторм, наводнение и т.д.), по�ара, несчастных

случаев, действия третьих лиц и/или использование прибора в необычных условиях.

Производитель или его представители не несут ответственности за косвенные убытки, упущенную выгоду,

возникшие в результате изменения данных, потери данных и временной приостановки бизнеса и т.д.,

вызванных применением прибора. Производитель или его представители не несут ответственности за

косвенные убытки, упущенную выгоду, возникшие в результате использования прибора не по инструкции.

31

MEASUREMENT FOUNDATION

Page 32

ГАРАНТИЙНЫЕ ОБЯЗАТЕЛЬСТВА НЕ РАСПРОСТРАНЯЮТСЯ НА СЛЕДУЮЩИЕ СЛУЧАИ:

1.Если будет изменен, стерт, удален или будет неразборчив типовой или серийный номер на изделии;

2.Периодическое обслу�ивание и ремонт или замену запчастей в связи с их нормальным износом;

3.Любые адаптации и изменения с целью усовершенствования и расширения обычной сферы применения

изделия, указанной в инструкции по эксплуатации, без предварительного письменного соглашения специалиста

поставщика;

4.Ремонт, произведенный не уполномоченным на то сервисным центром;

5.Ущерб в результате неправильной эксплуатации, включая, но не ограничиваясь этим, следующее:

использовнаие изделия не по назначению или не в соответствии с инструкцией по эксплуатации на прибор;

6.На элементы питания, зарядные устройства, комплектующие, быстроизнашивающиеся и запасные части;

7. Изделия, повре�денные в результате небре�ного отношения, неправильной регулировки, ненадле�ащего

технического обслу�ивания с применением некачественных и нестандартных расходных материалов,

попадания �идкостей и посторонних предметов внутрь.

8.Воздействие факторов непреодолимой силы и/или действие третьих лиц;

9.В случае негарантийного ремонта прибора до окончания гарантийного срока, произошедшего по причине

полученных повре�дений в ходе эксплуатации, транспортировки или хранения, и не возобновляется.

Для получения дополнительной информации Вы мо�ете посетить наш Интернет сайт WWW.ADAINSTRUMENTS.COM

или написать письмо с интерисующими Вас вопросами на электронный адрес info@adainstruments.com

Page 33

ГАРАНТИЙНЫЙ ТАЛОН

Наименование изделия и модель _______________________________________________

Серийный номер ___________________Дата прода�и_________________

Наименование торговой организации ___________________Штамп торговой организации мп.

Гарантийный срок эксплуатации приборов составляет 24 месяца со дня прода�и.

В течении гарантийного срока владелец имеет право на бесплатный ремонт изделия по неисправностям,

являющимся следствием производственных дефектов.

Гарантийные обязательства действительны только по предъявлении оригинального талона, заполненного

полностью и четко (наличие печати и штампа с наименованием и формой собственности продавца

обязательно).

Техническое освидетельствование приборов (дефектация) на предмет установления гарантийного случая

производится только в авторизованной мастерской.

Производитель не несет ответственности перед клиентом за прямые или косвенные убытки, упущенную

выгоду или иной ущерб, возникшие в результате выхода из строя приобретенного оборудования.

Правовой основой настоящих гарантийных обязательств является действующее законодательство, в

частности, Федеральный закон РФ «О защите прав потребителя» и Гра�данский кодекс РФ ч.II ст. 454-491.

Товар получен в исправном состоянии, без видимых повре�дений, в полной комплектности, проверен в моем

присутствии, претензий по качеству товара не имею. С условиями гарантийного обслу�ивания ознакомлен

и согласен.

Подпись получателя_________________________________

Перед началом эксплуатации внимательно ознакомьтесь с инструкцией по эксплуатации!

По вопросам гарантийного обслу�ивания и технической поддер�ки обращаться к продавцу данного товара

Page 34

СВИДЕТЕЛЬСТВО О ПРИЕМКЕ И ПРОДАЖЕ

______________________________________________________________________________________________

______________________________________________________________________________________________

_____________________________________________________________________________№_______________

НАИМЕНОВАНИЕ И ТИП ПРИБОРА

Соответствует __________________________________________________________________________________

обозначение стандарта и технических условий

Дата выпуска ___________________________________________________________________________________

Штамп ОТК (клеймо приемщика)

Цена

Продан(а) ___________________________________________________Дата прода�и ______________________

Page 35

Page 36

MEASUREMENT FOUNDATION

WWW.ADAINSTRUMENTS.COM

ADA

Loading...

Loading...