GG

XX

MM

SS

EE

RR

II

EE

SS

G

F

-

M

S

E

R

I

E

S

M

u

l

t

i

-

F

u

n

c

t

i

o

n

B

a

l

a

n

c

e

GX-M series

GF-M series

G

G

G

X

F

F

M

u

M

u

---M

-

M

-

M

i

t

l

i

t

l

INSTRUCTION MANUAL

-

-

F

F

u

u

n

n

S

S

S

c

t

i

c

t

i

E

E

E

o

o

n

n

R

R

B

B

R

a

l

a

a

l

a

I

I

I

n

n

E

E

E

c

e

c

e

S

S

S

GX-8202M / GX-8202MD / GX-10202M / GX-12001M

GX-22001M /GX-32001M / GX-32001MD

GF-8202M / GF-8202MD / GF-10202M / GF-12001M

GF-22001M / GF-32001M / GF-32001MD

1WMPD4003846

© 2020 A&D Company Ltd. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, or translated

into any language in any form by any means without the written permission of A&D

Company Ltd.

The contents of this manual and the specifications of the instrument covered by this

manual are subject to change for improvement without notice.

Windows, Word and Excel are registered trademarks of the Microsoft Corporation.

Contents

1. Introduction .................................................................................................................... 6

1-1 Features ................................................................................................................................................. 6

1-2 About The Models .................................................................................................................................. 7

1-3 Compliance ............................................................................................................................................ 7

1-4 About Communication Manual ............................................................................................................... 8

2. Unpacking The Balance ................................................................................................. 9

2-1 Installing The Balance .......................................................................................................................... 10

3. Precautions ................................................................................................................... 11

3-1 Before Use.............................................................................................................................................11

3-2 During Use............................................................................................................................................ 12

3-3 After Use ............................................................................................................................................... 12

3-4 Power Supply ....................................................................................................................................... 13

4. Display Symbols And Key Operation ........................................................................... 14

4-1 Smart Range Function ......................................................................................................................... 16

5. Weighing Units ............................................................................................................. 17

5-1 Units ..................................................................................................................................................... 17

5-2 Storing Units ......................................................................................................................................... 22

6. Weighing ...................................................................................................................... 24

6-1 Basic Operation .................................................................................................................................... 24

6-2 Counting Mode(PCS) ...................................................................................................................... 26

6-3 Percent Mode (%) ................................................................................................................................ 28

6-4 Animal Weighing Mode(Hold Function) ........................................................................................... 29

7. Impact Detection Function ........................................................................................... 30

7-1 Recording Impact History ..................................................................................................................... 31

7-2 Output Impact History ........................................................................................................................... 31

8. Response Adjustment / Self Check Function ............................................................. 33

8-1 Response Adjustment .......................................................................................................................... 33

8-2 Self-Check-Function / Automatic Setting Of Minimum Weight Value ................................................... 34

9. Calibration .................................................................................................................... 36

9-1 Automatic Self Calibration For The GX-M Series ................................................................................... 37

9-2 One-Touch Calibration For The GX-M Series ...................................................................................... 38

9-3 Calibration Using An External Weight .................................................................................................. 39

9-4 Calibration Test Using An External Weight ........................................................................................... 40

9-5 How to set the External Weight Value .................................................................................................. 41

9-6 Correcting The Internal Mass Value Of The GX-M series .................................................................... 42

9-7 Correcting The Internal Mass Value Of The GX-M series (Auto) .............................................................. 43

10. Function Switch And Initialization ............................................................................... 44

10-1 Permit Or Inhibit ................................................................................................................................. 44

3

10-2 Initializing The Balance....................................................................................................................... 46

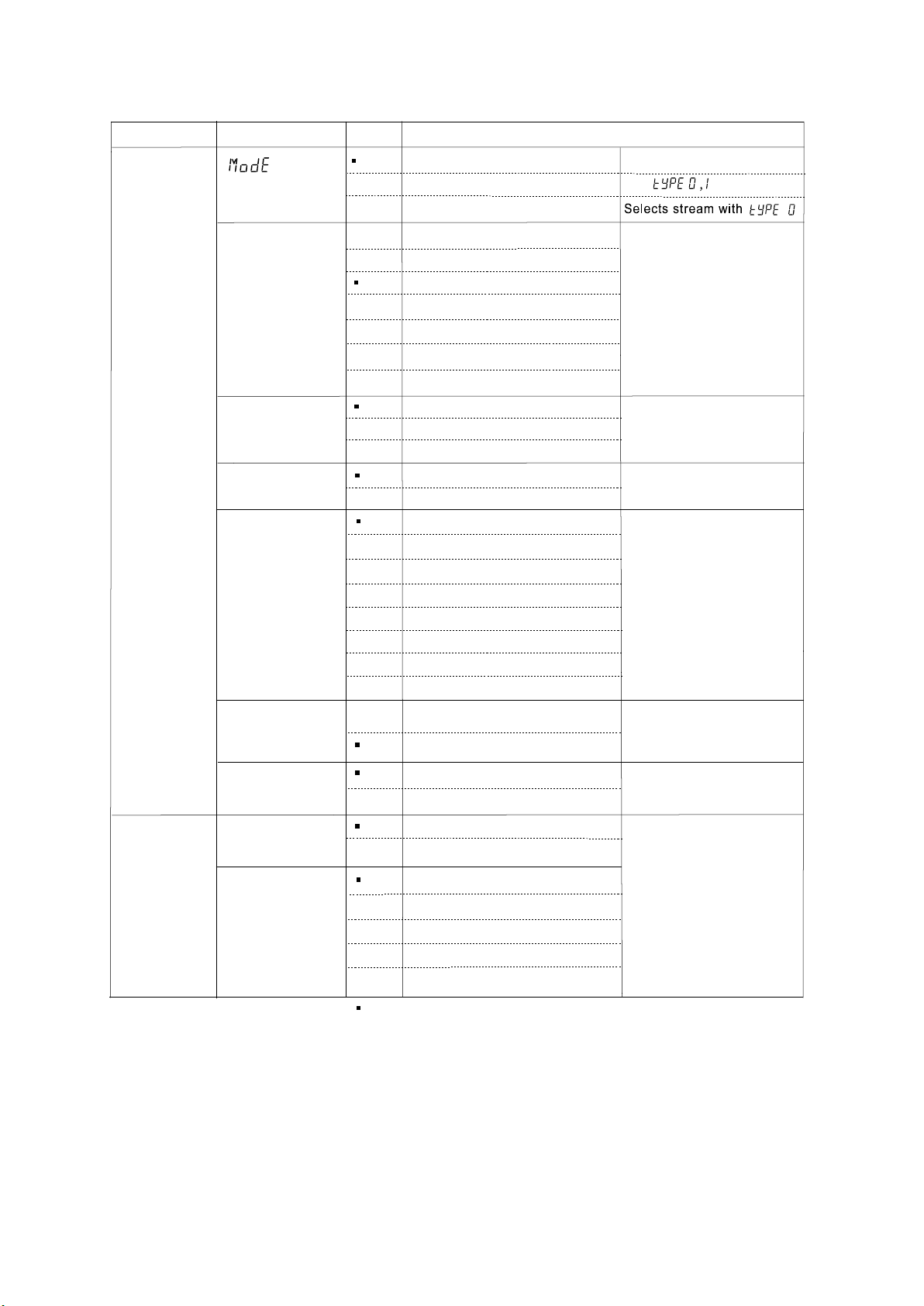

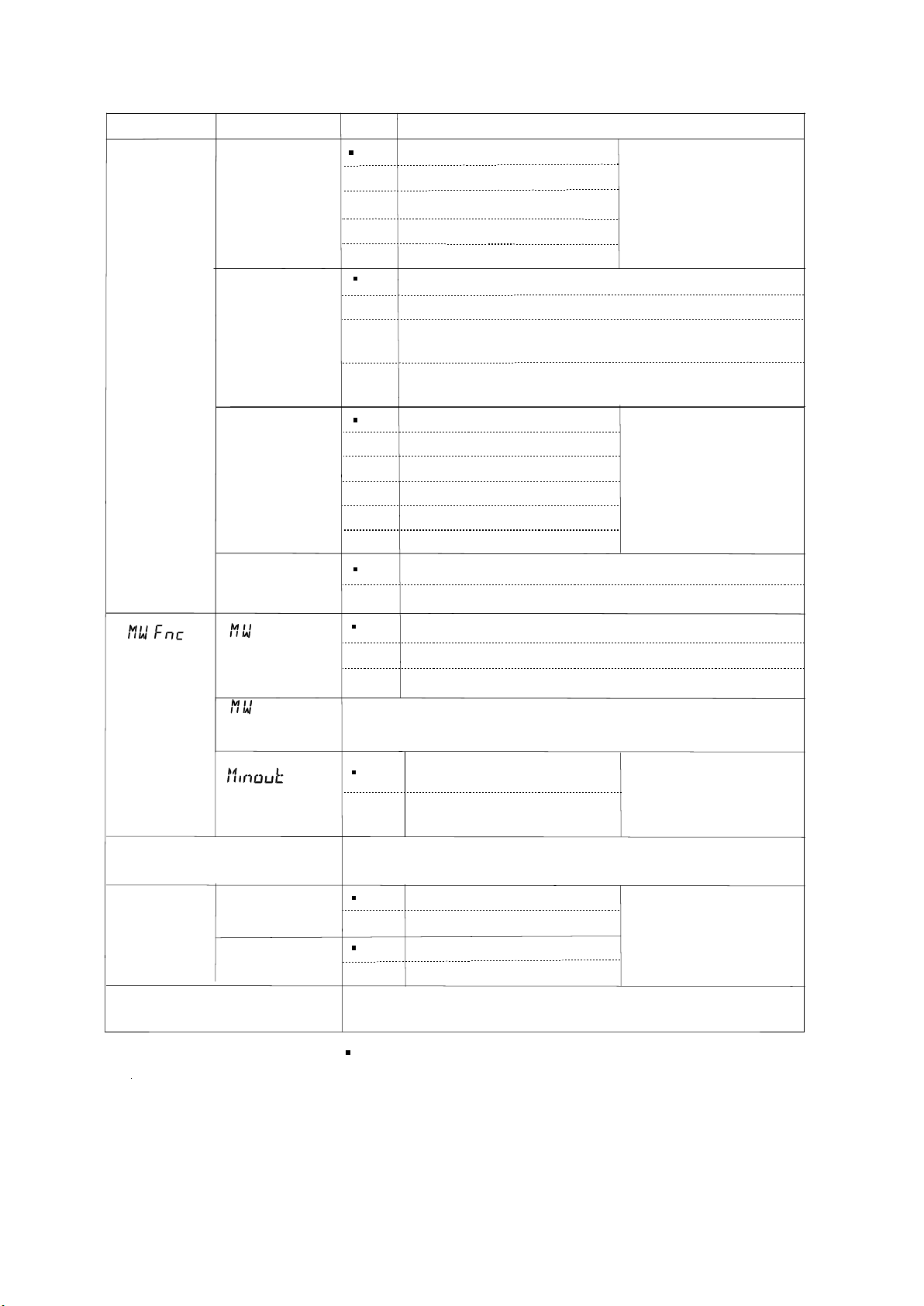

11. Function Table ............................................................................................................ 47

11-1 Setting The Function Table ................................................................................................................. 47

11-2 Details Of The Function Table ............................................................................................................ 49

11-3 Description Of The Class "Environment, Display" .............................................................................. 56

11-4 Description Of The Data Output ......................................................................................................... 57

11-5 Description Of The Data Format ......................................................................................................... 57

11-6 Output Example Of The Data Format ................................................................................................. 57

11-7 Clock And Calendar Function ............................................................................................................. 58

11-8 Comparator Function .......................................................................................................................... 60

11-9 Adding the Comparison Results ......................................................................................................... 66

11-10 Main Display Comparison Function .................................................................................................. 67

11-11 Description Of Application ................................................................................................................. 68

11-12 Outputting the function setting information ....................................................................................... 69

12. ID Number And GLP Report ....................................................................................... 72

12-1 Main Objective .................................................................................................................................... 72

12-2 Setting The ID Number ....................................................................................................................... 72

12-3 GLP Report ......................................................................................................................................... 74

13. Data Memory .............................................................................................................. 78

13-1 Data Memory For Weighing Data ....................................................................................................... 78

13-2 Data Memory For Calibration And Calibration Test ............................................................................ 82

13-3 Data Memory for Unit Mass in the Counting Mode ............................................................................ 85

13-4 Data Memory for Comparator Settings ............................................................................................... 88

13-5 Data Memory for Tare Value ............................................................................................................... 91

13-6 Data Memory: Quick Selection Mode ................................................................................................. 94

13-7 Data Memory: Confirmation and Storage Mode ................................................................................. 95

14. Statistical Calculation Mode ........................................................................................ 97

14-1 How To Use The Statistical Calculation .............................................................................................. 97

14-2 Statistical Calculation Mode (Example Of Use) ................................................................................ 102

15. Flow Measurement ................................................................................................... 104

15-1 How To Use Flow Measurement ...................................................................................................... 104

16. Gross Net Tare Function ........................................................................................... 108

16-1 Preparation Of Gross Net Tare Function .......................................................................................... 108

16-2 Example Of Using The Gross Net Tare Function ............................................................................. 110

17. Minimum Weighing W ar ning Function ...................................................................... 111

17-1 Comparing the minimum weighing value .......................................................................................... 111

17-2 Entering and outputting the minimum weighing value...................................................................... 112

18. Underhook ................................................................................................................ 117

19. Programmable-Unit .................................................................................................. 118

20. Density Measurement ............................................................................................... 119

4

21. Password Lock Function .......................................................................................... 124

21-1 Enable Password Lock Function ...................................................................................................... 125

21-2 How To Input The Password At The St art Of Weighing .................................................................... 126

21-3 How To Logout.................................................................................................................................. 127

21-4 Registering Password (Changing) ................................................................................................... 128

21-5 Changing Password ......................................................................................................................... 129

21-6 How To Delete The Password(U5ER 01~10) ................................................................................. 130

21-7 Missing Password ............................................................................................................................ 130

22. Repeatability Check Function (GX-M series only) ................................................. 131

23. Interface Specification(Standard) ........................................................................ 132

24. Maintenance ............................................................................................................ 132

24-1 Treatment Of The Balance. .............................................................................................................. 132

25. Troubleshooting ....................................................................................................... 133

25-1 Checking The Balance Performance And Environment ................................................................... 133

25-2 Error Codes ...................................................................................................................................... 134

25-3 Other Display .................................................................................................................................... 137

25-4 Asking For Repair ............................................................................................................................. 137

26. Connection With Periphecal Device ......................................................................... 138

26-1 Command ......................................................................................................................................... 138

26-2 Key Lock Function ............................................................................................................................ 138

27. How To Check The Software Version Of The Balance ............................................. 138

28. Specifications ........................................................................................................... 139

29. External Dimention ................................................................................................... 141

29-1 Options And Peripheral Instruments ................................................................................................ 142

5

1. Introduction

This manual describes how the GX-M/GF-M series balance works and how to get the most out of it in

terms of performance. Read this manual thoroughly before using the balance and keep it at hand for

future reference.

Depending on the softw are version of your balance, there are cases that behave differently.

For confirmation of the software version of the balance, refer to "27. How To Check The Software

Versi on Of The Balance".

1-1 Features

□ The balance has a self-ch eck function that inspects the balance itself using e l ec t r oni cally

controlled load (ECL) and evaluates performance. Read t his manual thoroughly before using the

balance and keep it at hand for fut ur e reference.

□ The balance can detect i m pact applied to its mass sensor and display the level of that impact .

ISD (Impact Shock Detection).

□ Continuous change of the balance can be calculated as flow rate, displayed and output. FRD :( Flow

Rate Display).

□ The b alance is equipped with a dat a memory function, which can r ecord weighing value,

calibration result, and mult iple unit mass (mass per sample in counting mode) (Up to 200 items

are stored for weighing value).

□ The GX-M series has automatic self c al ibration using the internal mass, adapting to temperat ur e

changes, setting time and interval time.

□ Good laboratory practice (GLP) / Good manufacturing practice (GMP) data can be output using

the RS-232C serial interfa ce.

□ A built-in clock and calendar that can add the time and date to the output data.

(Setting changes due to the clock can be limited only for an administrator. (Password Lock

Function))

□ Comparator Indicators, displaying the comparison results with

the setting, 5-step comparison is also possible.)

□ Capa city Indicator, displaying the weight value in percentage relative to the weighing capacity.

□ Hold Function, provided for weighing a moving object such as an animal.

□ Underhook, for me asuring density and weighing magnetic materials.

□ Password lock function can limit users for the balance to be used or changes due to the func tion

settings by setting a password.

□ Key lock func tio n all ows t he ba lan ce to only operate using commands from an external equipment

by disabling key operation s on the balance.

□ The balance is equipped with an RS-232C serial interface and a USB interface to communicate

with a computer. Windows computer using the Windows communication tools software (WinCT)

make building a system very easy. The latest Win-CT software can be downloaded from the A&D

website.

Windows is the registered trademark of the Microsoft Corporation.

□ A breeze break is included wit h t he m odel featuring a minimum display of 0.01g.

HI OK LO .(Depending on

6

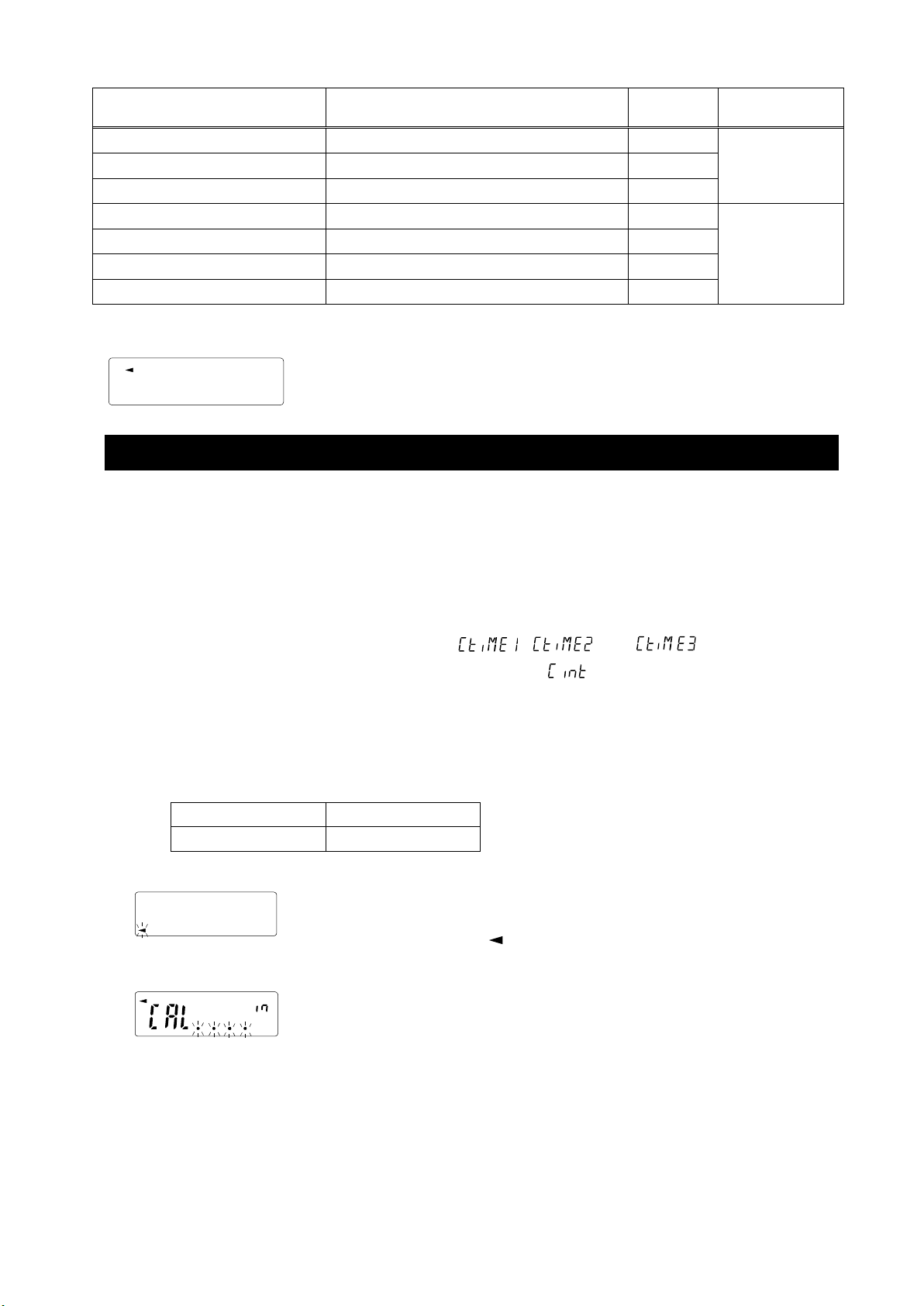

1-2 About The Models

Model

Minimum

Applicable model

Internal mass type

General type

GX-8202M / GX-8202MD

GX-10202M

GF-8202M / GF-8202MD

GF-10202M

GX-12001M / GX-22001M

GX-32001M / GX-32001MD

GF-12001M / GF-22001M

GF-32001M / GF-32001MD

There are many models in the GX-M series and GF-M series with differences in the models being the

minimum display and weighing capacity. In this manual, they are listed collectively by the minimum

display as shown in the ta ble below.

display

0.01g model 0.01g

0.1g model 0.1g

□ For the GX-M series, a w eight for sensitivity adjustment is built in. It is possible to use functions

such as calibration and aut o cali br at i on using the internal mass.

□ For the GF-M series, sensitivity adjustment w eights are not built-in. When calibrating, it is

necessary to prepare an external weight.

1-3 Compliance

Compliance with FCC Rules

Please note that this equipment generates, uses and can radiate radio frequency energy. This

equipment has been tested and has been found to comply with the limits of a Class A computing

device pursuant to Subpart J of Part 15 of FCC rules. These rules are designed to provide

reasonable protection against interference when equipment is operated in a commercial

environment. If this unit is operated in a residential area, it may cause some interference and under

these circumstances the user would be required to take, at his own expense, whatever measures

are necessary to eliminate the interference.

(FCC = Federal Communi c at io ns C ommission in the U.S.A.)

7

1-4 About Communication Manual

About the contents of the communication, download "Communication manual" from our website

(https://www.aandd.jp/) and refer to it.

8

2. Unpacking The Balance

AX-TB248

Serial

Breeze beak provided for

Grounding

terminal

AC adapter plug

. The connection is tight

dustproof.

RS-232C terminals

(D-sub9 pin)

T er minal cov er

) to keep

waterproof and dustproof.

AC adapter jack

Draft gate

when cleaning.

Position of placing

AC adapter labels

Weighing pan

Bubble sprit level

Display

Keys

USB (mini-B)

Leveling foot

Pan support

A clear display cover

Handling hole

AC adapter plug

local voltage and receptacle type.

USB cable

The balance i s a prec isio n instru ment.

Unpack the balan ce careful ly. Keep the

packing materi al to be used for

transporting th e balance in the future.

The packing contents depend on the

balance mod el. See the ill ustratio ns to

confirm tha t every thing is contai ned.

Note

Cover the termin al or

connect the waterpro of

RS-232C cable

(AX-KO2737-500JA

Note

Please confirm that the AC

adapter type is correct for your

AC adapter labels

GX-8202M, GX-8202MD, GX-10202M,

GF-8202M, GF-8202MD, GF-10202M.

9

number

Remove the gate

Note

Insert t he plu g int o th e jack

firmly

to keep waterproof and

(approx. 1.8m)

2-1 Installing The Balance

3. Precautions

Bubble sprit level

Leveling foot

Grounding

T o AC adapter

Good No good

Install the balance as follows:

1 Refer to "

" for installing the balance.

2 Install the pan support, weighing pan and draft gate.

Refer to the previous page.

3 Adjust the leveling feet to level the balance.

Confirm it using the bubble spirit level.

4 Confirm that the AC adapter type is corre ct for the

local voltage and power receptacle type.

5 Connect the AC adapter to the balance firmly. Earth

the balance. Warm up the balance for at least 30

minutes with nothing on the weighing pan.

(Earth)

10

3.Precautions

To get the optimum performance from the balance and acquire accurate weighing data,

note the following:

3-1 Before Use

The maximum resolution of the precision balance is one million counts. Therefore, there are

tendencies to be influenced by temperature change, air pressure change, vibration and

drafts where the balance is placed.

Install the balance in an environment where the temperature and humidity are not

excessive. The best operating temperature is about 20°C / 68°F at about 50% relative

humidity.

Install the balance where it is not exposed to direct sunlight and it is not affected by heaters

or air conditioners.

Install the balance where it is free of dust.

Install the balance away from equipment that produces magnetic fields.

Install the balance in a stable place avoiding vibration and shock. Corners of rooms on the

first fl oor ar e best , as they ar e les s pr one to vi brat io n.

The w eighi ng tab le s houl d b e soli d a nd fr ee fr om vi br ati on, dr aft s an d as lev el as pos sibl e.

Level the balance by adjusting the leveling feet and confirm it using the bubble spirit level.

Ensure a stable power source when using the AC adapter.

Connect the AC adapter and warm up the balance for at least 30 minutes.

Cali brat e t he bal an ce per io dic ally for acc ura te wei gh ing .

When the balance is installed for the first time or has been moved, warm up the balance for

at least 6 hours to allow the balance to reach equilibrium with the ambient temperature, and

then perform calibration before use.

The meaning of IP-65 is "No ingress of dust. Projected against water jets".

If a powerful water jet is used or the balance is immersed in water, it may cause a damage

that is due to ingress of water.

Confirm that "the plug is inserted firmly into the jack" and "the terminal is covered using the

waterproof cover or the waterproof RS-232C cable (AX-KO2737-500JA)", when using the

balance.

Use the waterproof option cable AX-KO2737-500JA, when the RS-232C interface is used

with IP-65.

AX-KO2466-200, a st andard RS-232C cable, is not waterproof or dustproof.

Confirm that the weighing pan does not touch to rim.

Do not install the balance where flammable or corrosive gas is present.

11

3-2 During Use

Material case

Charged

Magnetic

40

20

Draft

Weighing Pan

Grounding

Shock

Discharge static electricity from the weighing material. When

weighing sample (plastics, insulator, etc.) could have a static

charge, the weighing value is influenced. Ground the balance, and

Eliminate the static electricity by AD-1683 as an accessory.

Or try to keep the ambient humidity above 45%RH at the room.

Or use the metal shield case.

Or wipe a charged material (plastic sample etc.) with the wet cloth.

This balance uses a strong magnet as part of the balance

assembly, so please use caution when weighing magnetic

materials such as iron. If there is a problem, use the underhook on

the bottom of the balance to suspend the material away f rom the

influence of the magnet.

sample

material

Eliminate any temperature difference between the samp le and the

environment. When a sample is warmer (coole r) than the amb ient

temperature, the sample will be lighter (heavier) than the true

°C

°C

weight. This error is due to a rising (falling) draft around the

sample.

Make each weighing gently and quickly to avoid errors due to

changes in the environmental conditions.

Do not drop things upon the weighing pan, or place a sample on

the pan that is beyond the balance weighing capacity. Place the

sample in the center of the weighing pan.

Do not use a sharp instrument such as a pencil to p ress the ke ys.

Use your fing er only .

Press the RE-ZERO key before each weighing to prevent

possible err ors.

Cali brat e t he bal an ce per io dic ally so as to el i minat e p ossi ble err ors .

Take into consideration the affect of air buoyancy on a sample

when more accuracy is required.

Prevent foreign matter, such as powder, liquid and metal, from invading the area around

the weighing pan.

3-3 After Use

Use t he "b reez e br eak " for a pr eci sio n weig hi ng.

Avoid mechanical shock to the balance.

Do not disassemble the balance. Contact the local A&D dealer if the balance needs service

or repair.

Do not use organic solvents to clean the balance. Clean the balance with a lint free cloth

that is moistened with warm water and a mild detergent.

12

Do not allow the balance to be immersed in wa ter. Even thou gh the ba lance comp lie s with

IP code, the balance will not withstand being completely immersed in water.

The weighing pan, pan support and draft gate can be removed to clean the ba lance. Clean

by spl as hi ng w it h w a ter .

3-4 Power Supply

Do not remove the AC adapter while the internal mass is in motion, for example, right

after the AC adapter is connected, or during calibration using the internal mass.

If the AC adapter is removed under the conditions described above, the internal mass

will be left unsecured, that may cause mechanical damage when the balance is

moved.

Before removing the AC adapter, press the ON:OFF key and confirm that zero is

displayed.

When the AC adapter is connected, the balance is in the standby mode if the standby

indicator is on. This is a normal state and does not harm the balance. For accurate

weighing, keep the AC adapter connected to the balance and AC power unless the

balance is not to be used for a long period of time.

13

S

t

a

b

i

l

i

z

a

t

i

o

n

i

n

d

i

c

a

t

or

Processing indicator

Response indicators

Standby indicator

Comparator indicators

Interval output mode

standby indicator

Number of statistical data

(Statistical calculation mode)

Displays the weight data relative to the

weighing capacity, in percentage, in the

weighing mode (Capacity indicator)

NET G PT

Preset tare mark

Gross mark

Net mark

USB connecting mark

Unit display

gross zero mark

Shock indicators

Animal weighing mark

Disiplay the measured value,

stored data, setting item name

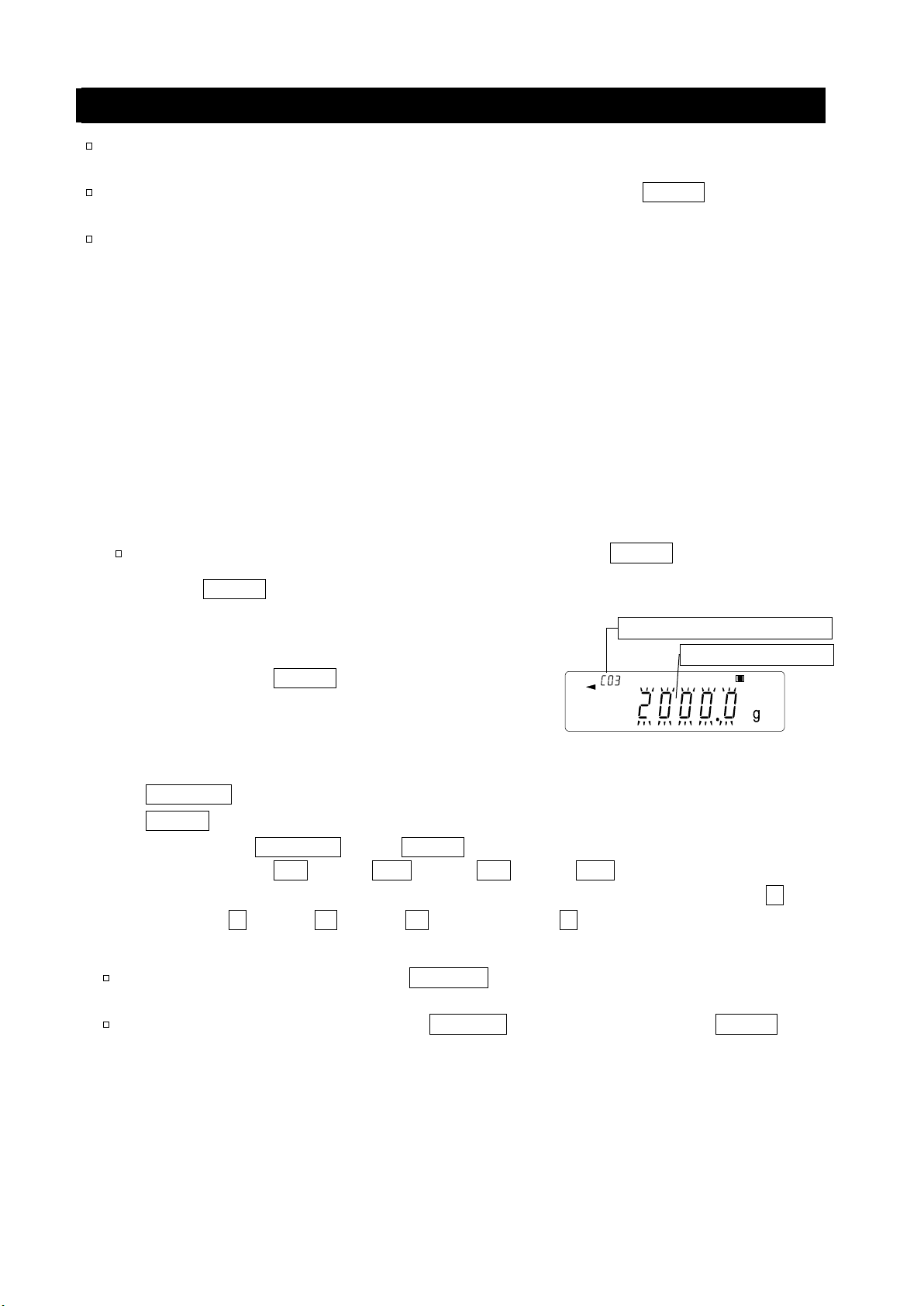

4.Display Symbols And Key Operation

Blinking display contents

Processing indicator

Interal output mode

active indicator

Data number being displayed

Auto calibration notice

Blinking

Display symbols

14

Key operation

(for 2 seconds)

key during

operation will interrupt op er at ion and t ur n the display OFF. *

In the weighing mode, turns the minimum

Check Function". (GX -M s eries only)

erforms calibration of the balance using

ther items of the calibration

Stores the weighing data in memory or

sonal computer

depending on the function table settings.

Enters mode to change the unit mass

Outputs "Title block" and "End

Enters mode for reading density

Press and hold the key.

Press the key.

(Press and release the key immediately.)

Key operation af fe cts how the balance funct ions. The basic key oper at ions are:

“Press and release the key immediat ely” or “Press the key”

= normal key operation during me asur ement

“Press and hold the key”

(for 2 seconds)

Key When pressed

Turns the display ON:OFF . The standby indicator is displayed when the display is

turned off. The w ei ghing mode is enabled when t he display is turned on.

When password function is enable, password input display will be displayed. Refer to

"21-2 How to Input The Password At The S tart Of Weighing"

This ON:OFF key is available anytime. Pressing the ON:OFF

weighing value on and off.

In the counting or percent mode, enters the

sample storing mode.

Switches the weighing units stored in the

function table.

P

the internal mass. (GX-M series only)

Refer to "5. Weighing ".

When pressed and held

・Enters the function t able mode.

Please r efer to "1 1. Function Table".

・Run the repeatability check functi on.

Please refer to "22.Repeatability

Enters mode of the Self-Check

Function.

Displays o

menu.

outputs to a printer or per

(Factory setting = output)

Sets the display to zero.

* When the "Gross net tare function" is selected, the display is turned off by pressi ng and holding (for 2

seconds).

Please refer to "16.Gross Net Tare Function".

registration number in cou nt ing mode.

By changing the function table:

・

block" for GLP,GMP report.

・ Displays the data memory menu.

・

number in flow measurement.

15

(after RE-ZERO key is pressed

)

GX-32001MD

GF-32001MD

GX-8202MD

GF-8202MD

4-1 Smart Range Function

The GX-8202MD, GF-8202MD, GX-32001MD and GF-32001MD are equipped with two ranges of

"precision range" of a higher resolution and "standard range" of normal resolution.

The range is switched automatically depending on the value displayed.

Placing a heavy container on the weighing pan and pressing the RE-ZERO key allows the

balance to weigh in the pr ecision range. (Smart range fu nc t i on)

The range can be fixed to the standard range, by pressing the SAMPLE key.

Note

Once the range is switched to the standard range, it will not switch to the precision range

automatically even when the displayed value becomes within the precision range value. Press

the RE-ZERO or SAMPLE key to use the precision range again.

Example

GX-32001MD and GF-32001MD, precision range = 6.2 kg x 0.1g,

standard range = 32.2 kg x 1 g.

Step 1 Press the RE-ZERO key.

The balance will start weighing, using the

precision range.

Step 2 Place a container on the weighin g pan.

When the weighing value exceeds the

precision range, the range will be

switched to the standard range.

Step 3 Press the RE-ZERO key.

The balance will be switched to the precision

range.

Step 4 Place a sample on the pan.

When the weighing value is within the

precision range, the balance will perform a

weighing using the precision rang e.

Precision range/standard range value

Precision range

Weighing Pan

Precision range

Tare (Container)

Standard range

Precision range

Sample

Precision range

Standard range

g Up to 6200.9 g

g Up to 2200.09 g

16

6201 g to 32208 g

2200.1 g to 8200.8 g

5.Weighing Units

Function table

(Storing mode)

Conversion factor

1 g =

Gram

g

1 g

Counting mode

PCS

Percent mode

%

Ounce (Avoir)

OZ

28.349523125 g

Pound

Lb

453.59237 g

1 oz=28.349523125 g

Troy Ounce

OZt

31.1034768 g

Metric Carat

ct

0.2 g

Momme

mom

3.75 g

Pennyweight

dwt

1.55517384 g

Grain (UK)

GN

0.06479891 g

Tael (HK general, Singapore)

37.7994 g

Tael (HK jewelry)

37.429 g

Tael (Taiwan)

37.5 g

Tael (China)

31.25 g

Tola (India)

tol

11.6638038 g

Messghal

MES

4.6875 g

is used to

show the density.

Programmable-unit (Multi-unit)

MLT

p C 5 p C

5

t o 1

t o 1

g

OZ

L

PC

Pct OZ

Lb

OZt

ct

mom

dwt

GN

TL

MES

DS

Percent mode

Density mode (To use this mode, it must be stored in the function table as described on

page 15. For details about this mode, refer to "19. DENSITY MEASUREMENT".

To select this mode, press the MODE key until the processing indictor

blinks with the unit "g" displayed. "DS" appears only when the density

value is displayed.)

Programmable-unit (No unit displayed. For

details, refer to "18. PROGRAMMABLE-UNIT".)

Counting mode

tol

MLT

kg

“19.Programmable-Unit”.)

“20. Density Measurement”.

page 47.

5-1 Units

With the GX-M /GF-M series balance, the following weighing units and weighing modes ar e available :

A unit or mod e can be se lected and stored in the function table as desc r i bed on page 47.

If a weighing mode (or unit of weight) has been turned off, that mode or unit will be missing in the

sequence. Tael has four varieties, one of which ca n be selected and installed at the factory.

To select a unit or mode for weighing, press the MODE key.

For details about the units and modes, see the table below:

Name (unit, mode) Abbrev. Display

kilogram

kg 1000 g

Pound/Ounce L OZ l0 1Lb=16 oz,

TL

Density mode

(See note below)

DS

17

Note: The blinki ng processing i ndicator with “g” indicates that the dens i ty mode is selected.

GX-8202M

GF-8202M

GX-10202M

GF-10202M

minimum

display

The tables below indicate the weighing capacity and the minimum display for each unit,

depending on the balance model.

GX/GF-M

Unit Capacity Capacity

Gram g 8200 10200 0.01

Kiloram kg 8.20 10.2

Once(Avoir) oz 289 360

Pound Lb 18.1 22.5

0.00001

0.0005

0.00005

Pound/Once L oz 18L 1.2oz 22L 7.7oz 0.01

Troy Once Ozt 264 328

Metric Carat ct 41000 51000

Momme mom 2187 2720

Pennyweight dwt 5273 6559

Grain(UK) GN 126545 157410

0.0005

0.05

0.005

0.01

0.2

teal(HK general, Singapore) TL 217 270

Teal(HK jewely) TL 219 273

Teal(Taiwan) TL 219 272

Teal(China) TL 262 326

Tola(India) Tol 703 875

Messghal Mes 1749 2176

0.0005

0.0005

0.0005

0.0005

0.001

0.005

18

GX/GF-M

GX-12001M

GF-12001M

GX-22001M

GF-22001M

GX-32001M

GF-32001M

Minimum

display

Unit Capacity Capacity Capacity

Gram g 12200 22200 32200 0.1

Kiloram kg 12.2 22.20

Once(Avoir) oz 430 783

Pound Lb 26.9 48.9

32.20

1136

71.0

0.0001

0.005

0.0005

Pound/Once L oz 26L 14.3oz 48L 15oz 70L 15.8oz 0.01

Troy Once Ozt 392 714

Metric Carat ct 61000 111000

Momme mom 3253 5920

Pennyweight dwt 7845 14275

Grain(UK) GN 188275 342598

Teal(HK general, Singapore) TL 323 587

Teal(HK jewely) TL 326 593

Teal(Taiwan) TL 325 592

1035

161000

8587

20705

496922

852

860

859

0.005

0.5

0.05

0.1

2

0.005

0.005

0.005

Teal(China) TL 390 710

Tola(India) Tol 1046 1903

Messghal Mes 2603 4736

1030

2761

6869

0.005

0.01

0.05

19

GX/GF-M

GX-8202MD

GF-8202MD

Standard range

Precision range

Minimum

display

Minimum

display

Unit Capacity

Capacity

Gram g 8200 0.1 2200 0.01

Kiloram kg 8.20 0.0001 2.20 0.0001

Once(Avoir) oz 289 0.005 77.6 0.0005

Pound Lb 18.1 0.0005 4.85 0.00005

Pound/Once L oz 18L 1.2oz 0.01 4L 13.6oz 0.001

Troy Once Ozt 264 0.005 70.7 0.0005

Metric Carat ct 41000 0.5 11000 0.05

Momme mom 2187 0.05 587 0.005

Pennyweight dwt 5273 0.1 1415 0.01

Grain(UK) GN 126545 2 33951 0.2

teal(HK general, Singapore) TL 217 0.005 58.2 0.0005

Teal(HK jewely) TL 219 0.005 58.8 0.0005

Teal(Taiwan) TL 219 0.005 58.7 0.0005

Teal(China) TL 262 0.005 70.4 0.0005

Tola(India) Tol 703 0.01 189 0.001

Messghal Mes 1749 0.05 469 0.005

20

GX/GF-M

GX-32001MD

GF-32001MD

Standard range

Precision range

Minimum

display

Minimum

display

mo

m

Unit

Capacity

Capacity

Gram g 32200 1 6200 0.1

Kiloram kg 32.2 0.001 6.20

Once(Avoir) oz 1136 0.05 219

Pound Lb 71.0 0.005 13.7

0.0001

0.005

0.0005

Pound/Once L oz 70L 15oz 0.1 13L 10.6oz 0.01

Troy Once Ozt 1035 0.05 199

Metric Carat ct 161000 5 31000

Momme

8587 0.5 1653

Pennyweight dwt 20705 1 3987

0.005

0.5

0.05

0.1

Grain(UK) GN 496922 - 95681 teal(HK general, Singapore) TL 852 0.05 164

Teal(HK jewely) TL 860 0.05 165.6

Teal(Taiwan) TL 859 0.05 165.3

Teal(China) TL 1030 0.05 198.4

Tola(India) Tol 2761 0.1 532

Messghal Mes 6869 0.5 1323

0.005

0.005

0.005

0.005

0.01

0.05

21

5-2 Storing Units

Press

several times

Select

Specify

Store

Displays the units

sequentially.

The units or modes can be selected and stored in the function table. The sequence of displaying the

units or modes can be arrange d t o fit t he frequency of use.

The units stored are ma intained in non-volatil e memory, even if the AC adapter is rem oved.

Select a unit or mode and arr ange the sequence of display as follows:

1. Press and hold the SAMPLE key (for 2 seconds) until

ba5fnc of the function table is displayed, then release

the key.

2. Press the SAMPLE key several times to display

1Unit .

3. Press the PRINT key to enter the unit selection

mode.

4. Specify a unit or mode in the order to be displayed using

SAMPLE key To sequentially display the units.

5. Press the PRINT key to store the units or modes. T he

6. Press the CAL key to exit the function table. Then the

7. To select other unit or mode for w eighing, press the MODE key.

the following keys.

RE-ZERO key To specify a unit or mode. The

stabilization indicator

appears when the displayed unit or

mode is specified.

If the key is pressed in units already

selected, the stability mar k d isa ppears.

balance displays end and then displays the next menu

of the function table.

balance returns to the weighing mode with the selected unit.

22

Specify

Select

Store

Specify

Pr

es

s

severa

l

t

i

me

s

Pr

es

s

a

nd

ho

l

d

(for 2 seconds)

Unit setting example

The example below sets the units in the order with g (gram) as the first unit followed by pcs

(counting mode).

1. Press and hold the SAMPLE key (for 2 seconds) until

ba5fnc of the function table is displayed, then

release the key.

2. Press the SAMPLE key several times to display

1Unit .

3. Press the PRINT key to enter the unit selection

mode.

4. Press the RE-ZERO key to specify the unit of g

The stabilization indicator appears when the

unit is specified.

5. Press the SAMPLE key to display 1Unit pC5 .

6. Press the RE-ZERO key to specify the unit of pcs.

The stabilization indicator appears when the

unit is specified.

7. Press the PRINT key to store the units.

The balance displays end and then displays the next

menu item of the function table.

8. Press the CAL key to exit the function table. Then

the balance returns to the weighing mode with g, the

unit selected first.

9. Press the MODE key to switch between g and pcs

(g→pcs).

23

6.Weighing

Weighing

pan

Container

(Display off)

Weighi

n

g

pan

Co

n

tai

n

e

r

Sample

R

e

move

th

e

sa

mp

le

6-1 Basic Operation

1. Press MODE key, and then select t he appropriates units

In this case, select " ".

2. Place a container on the weighing pan, if necessary.

Press the RE-ZERO key to cancel the weight (tare).

The balance displays 0.00 g. (The decimal point position

depends on the balance mo del.)

3. Place a sample on the pan or in the container. Wait for the stabilization

indicator

to be display ed. Read t he value.

Remove the sample and c ontainer from the pa n.

Note

□

Press the SAMPLE key to turn on or off the minimum weighing value.

□ The weighing data can be stored in memory. For details, refer to “13.

Data Memory”.

When the ON:OFF key is pressed w it h a container placed

□

on the weighing pan and weigh in g is st ar t ed, the balance

automatically cancels t he weight (tare) and display s 0.00 g.

24

About the operation at when power is turned on

Power on zero

range

GX-8202M,

GF-8202M

Approx.±160g

GX-8202MD,

GF-8202MD

Approx.±160g

GX-10202M,

GF-10202M

Approx.±200g

GX-12001M,

GF-12001M

Approx.±200g

GX-22001M,

GF-22001M

Approx.±400g

GX-32001M,

GF-32001M

Approx.±600g

GX-32001MD,

GF-32001MD

Approx.±600g

The balance will decide the r eference zero point when the pow er i s turned on (AC adapter is

connected).

Depending on the load co ndition at that time, it will automati c ally judge whether to perform z er o or tare

operation. The condition for determining whic h is u sed is "power on zero range" , and w hen power on

zero range is exceeded, the tare subtraction operat ion is performed.

About re-zero operation

By pressing the RE-ZERO key, the dis pl ay can be changed to zero.

Re-zero with the RE-ZERO key will automatically determine whether zero or tare operation is

performed.

The condition for determin ing which is used is "zero range", and when zero range is exceeded, the tare

subtraction operation is p er formed.

About measurement range

For the balance, the range t hat can be w eighed is determined by model.

The total amount (net amount + tare quantity) up to the maximum display of each model is displayed,

and when the maximum display is exceeded, E is displayed to indicate that the weighing range is

exceeded.

When in excess in negative, -E is displayed.

Model

Approx.±1kg

Approx.±3kg

Zero range -E displ ay range

Approx.-1kg or less

Approx.-3kg or less

25

6-2 Counting Mode(PCS)

lo

Weighing pan

Container

Sample

(25 pieces)

(The couting result)

place

This is the mode to determine the number of objects in a sample based on the standard sample unit

mass. Unit mass means the mass of one sample. The smaller the variables in each sa mp le un it ma ss

is, the more accurate the counting will be. This series balance is equipped with the Automatic

Counting Accuracy Improv em ent ( ACAI) function to improve t he counting accuracy.

Note

* For counting, use samples that have a unit mass at least ten times greater than that of the

minimum display in grams.

* If the sample unit m ass variable is too large, it may cause a counting error.

* To improve the counting performance, use the ACAI function frequently or divide the samples

into several groups an d count each group.

Selecting the counting mode

1. Press the MODE key to select pC5 ( pC5 = unit)

Storing a sample unit mass

2. Press the SAMPLE key to enter the sample unit mass

storing mode.

3. To select the number of samples, press the SAMPLE key

several times. It may be set t o 5, 10, 25, 50 or 100.

Note

A great er number of samples will yield more accurate counting result.

Place a container on the weighing pan, if necessary .

Press the RE-ZERO key to cancel the weight (tare). The number

specified in step 3 appear s.

25 0 is displayed if 25 is selected in "3".

4. Place the number of samples specified on the pan. In this example, 25

pieces.

5. When PRINT key pressed, unit mass is stored and changes the

count display. (Ex: when the number is 25, 25 pC5 is displayed.

Note

* If the balance judges that the mass of the samples is too light to

acquire accurate weighing, it displays an error requiring the addition

of more samples to the specified number and press the PRINT..

key. When the unit mass is stored correctly, the balance proceeds to

the counting mode.

* I f the balance judges that the mass of the samples is too light and

* Registered unit mass is remembered even when the power is turned off.

Number mode(counting)

6. Counting is possible.

is not adequate to be used as the unit mass, it displays

26

.

Processing mark

Counting Mode Using The ACAI Function

Press and hold

+1

The ACAI is a function that improves the accuracy of the unit mass automatically by increasing the

number of samples as the counting process.

ACAI: Automatic Counting Accuracy Improvement

After registering un it ma ss of "5", proceed to the following "7".

7. If a few more sam ples are added, the processing indic ator turns on. To

prevent an error, add three or more . The processing indicator does not

turn on if overloaded. Try to add the same number of samples as

displayed.

8. The balance re-calculates the u nit mass while the proc essing i ndicato r is blink ing . D o not touch

the balance or samples on the pan until the processing indicator turns off.

9. Counting accuracy is improved when the processing indicator turns off.

10. Each time the above operation is perf o rm ed, a more accurate unit mass will be obtained. There

is no definite upper limit of ACAI range for the number of samples exceeding 100. Try to add the

same number of samples as displayed.

11. Remove all the samples used in ACAI and proceed with the counting operation using the

improved unit mass.

Note ACAI will not function on the unit mass entered using the keys, or digital input mode.

Storing the unit mass

By using the data me m or y function, 50 instances of storing a

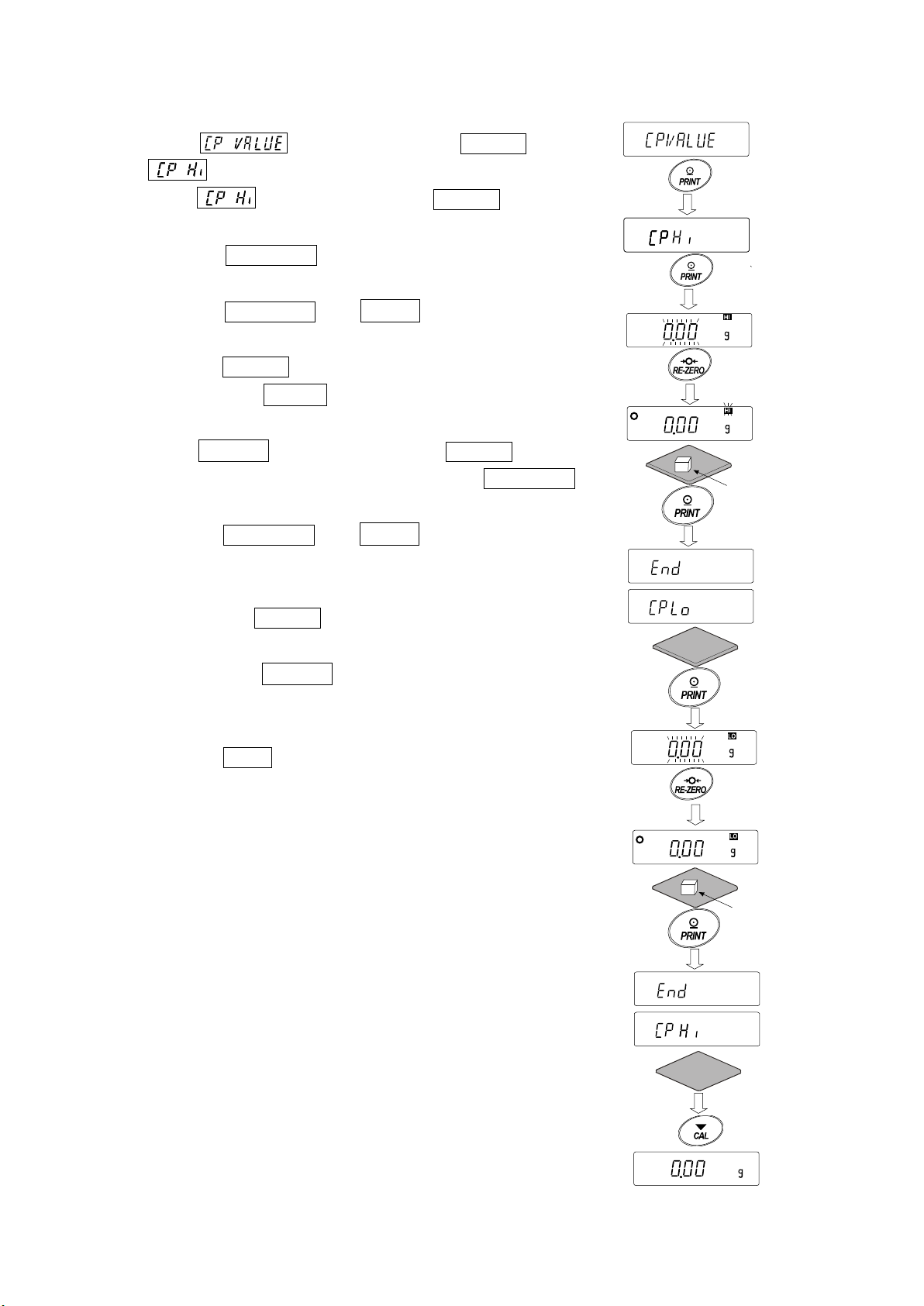

sample unit mass can be st or ed.

1. Set the function s et t ing item "Data memory function ( ) " to "Stores unit mass in counting ( ) " .Refer to "11.Function Table".

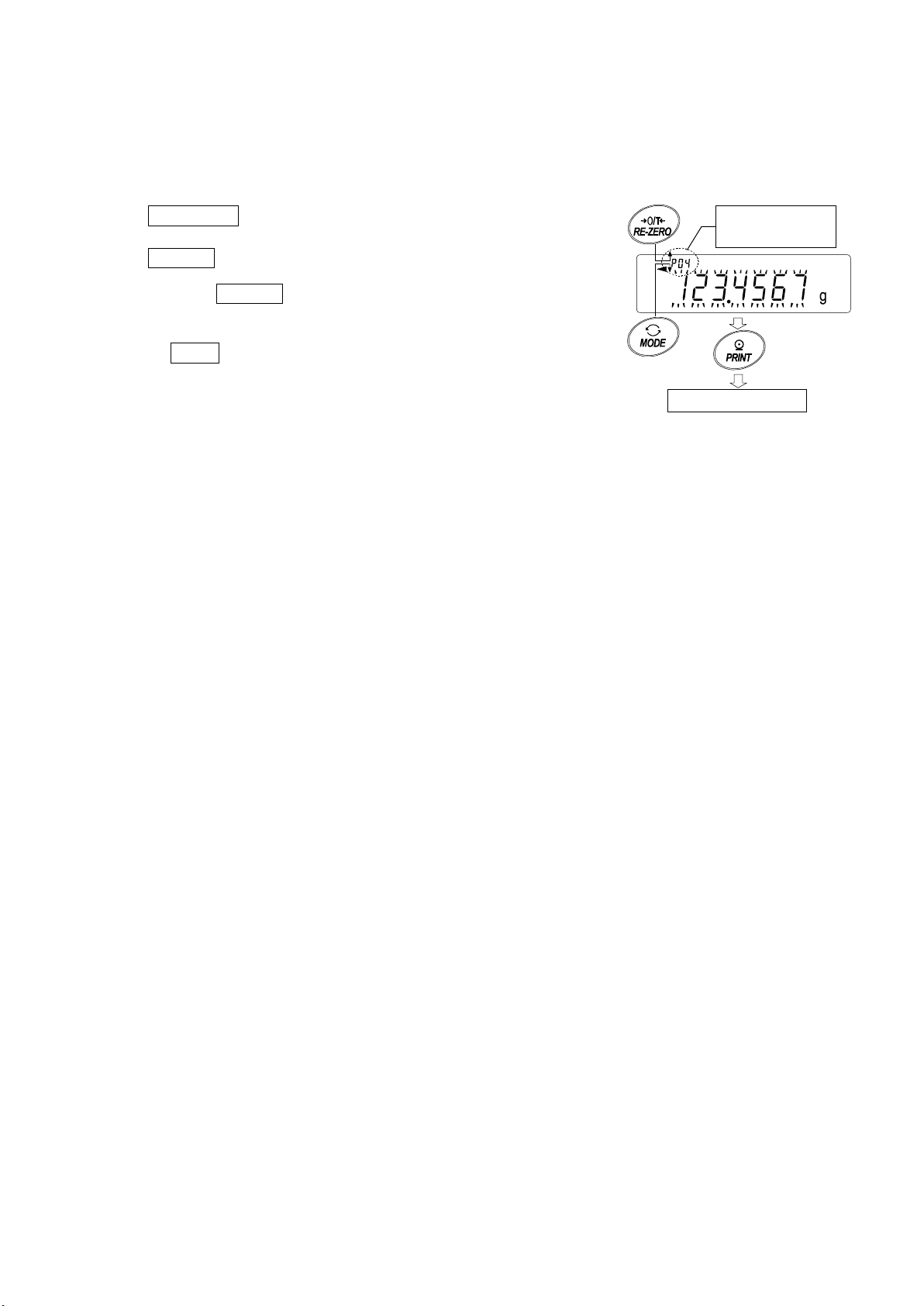

2. The displayed

number.

3. Press and hold the PRINT key (for 2 seconds) to switch to the

mode to change the unit mass r egistration number.

RE-ZERO key ············ Changes the registrat ion number(+)

MODE key ··············· Changes the registration number (-)

PRINT key ··············· Decides on the displayed registration number.

CAL key ··················· Cancel the displayed registration num ber.

4. Multiple unit masses can be stored by registering them with different unit mass registration numbers.

Note

*

p **: The unit weight registr at ion number is entered.

* Unit weight can be read by ″ UN:mm ″ command.

(mm corresponds to P01 to P50 with 01 t o 50.)

* The read unit mass can output by ″ ?UW ″ command and can be changed by ″ UW ″

command.

" p ** " is the selected unit mass registration

(for 2 seconds)

-

1

Note

* ACAI cannot be used for the read unit mass.

27

6-3 Percent Mode (%)

Model

100% mass

Decimal point position

Minimum display 0.01g

1.00g ~ 9.99g

1%

10.00g ~ 99.99g

0.1%

100.00g ~

0.01%

Minimum display 0.1g

10.0g ~ 99.9g

1%

100.0g ~ 999.9g

0.1%

1000.0g ~

0.01%

place

Display % of weighing object

Weighing

pa

n

C

on

t

ainer

Sample

(100%)

The percent mode displays the weighting value in percentage compared to a 100%

reference mass and is used for target weighing or checking the sample variance.

Selecting The Percent Mode

1. Press the MODE key to select the unit % (Percent mode).

Storing The 100% Reference Mass

2. Press the SAMPLE key to enter the 100% reference

mass storing mode.

Even in the storing mode, pressing the MODE key will

switch to the next mode.

3. Place a container on the weighing pan, if necessary. Press the RE-ZERO

key to cancel the weight (tare). The balanc e di splays 100 0 % .

4. Place the sample to be set as the 100% reference mass on the pan or in

the container.

5. Press the PRINT key to store the reference mass.

The balance displays 100.00 %. (The decimal point

position depends on the refer ence value. The reference

mass stored, even if the AC adapt er is r emoved, is

maintained in non-volat ile memor y. )

Note

□

If the balance judges that the mass of the sample is too light to be

used as a reference, it display s

□ The displayed percentage is based on the 100% re f er ence mass.

□ Registered value s are s t ored even when the power is turned off.

6. Remove the sample

Reading the percentage

7. Please a sample to be co m pared to the reference mass on the pan.

The displayed percentage is based on the 100% reference m ass.

lo .

28

6-4 Animal Weighing Mode(Hold Function)

This is the mode to weigh a mov i ng object such as an animal, even w hen t he display of the weighing

data fluctuates. The hold f unct ion allows the average weight of the animal to be displayed. To use

the hold function, set the funct ion in the function table. Refer to " 11. Function Table" and "11-3.

Description Of The Class " Environment, Display" for details.

29

7. Impact Detection Function

Impact level

Shock indicator

Buzzer

Contents

0

Safe

1

Caution

2

Caution:Consider impact mit igation

3

Warning:Do not apply greater impact

4

Danger:Sensor may be damaged

The GX-M / GF-M series has a function to detect impact to the mass sensor section and to display

the impact level.

By lowering the impact level at the time of loading, it is possible not only to alleviate variation in the

weighing value but also to r educ e t he r isk of failure of the mass sen sor section.

Especially when incorporating the balance in a production line, etc. and weighing by means such as

an automated system, impact to the sensor may be applied greater than expected.

When designing automatic systems and the like, it is recommended that you minimize the impact

level as much as possible while checking the shock indicat or.

Impact level display is from level 0 to level 4, 5level.

No

SHOCK

SHOCK

SHOCK

SHOCK

No

No

No

One

beep

Two

beep

Note

□ Impact on the weighing sensor may be applied to the weighing pan at time of loading, or it may be

applied from the table on which the balance is inst alled.

The impact detection f unction also works for impac t applied from the table.

30

7-1 Recording Impact History

Press and Hold

Press

Output

(for 2 seconds)

Impacts of impact level 3 or higher are stored on the balance with data and time included (maximum

50 data instanc es) .

When the password lock function is on (LOcK 1 or Lock2 ), the login user inf ormation is added when

outputting the impact history.

Note

□ If 50 data instances is exceeded, the data with the lowest impact level is over w r itten.

□ The stored impact history cannot be deleted.

□ Impact data where the balance is not energized (during transport, etc.) is not stored.

7-2 Output Impact History

The stored impact history can be output by sending a specified command to the balance or performing

a key operation.

Output by command

The stored impact data will be output al l at once by sending a ?SA command to the balanc e.

Output by key oper a t ion

1. Press the ON:OFF key to turn off the display.

2. With the display off, press the ON:OFF key

while holding down the MODE key.

3. is displayed, and t he st or ed impact

data is output all at once.

31

Impact history output example

Output

Login user

Function table LOcK

, --,

No login user

,00, ADMIN

Administrator

,01~10,USER

User

1

, --,GUEST

Guest

Date, time, impact level, login and log in user information are output toget her on one line.

The login user information varies by the setting of the login user and the setting of Function table

LOcK when receiving impact.

0, 1, 2

1

2

Output example

2018/05/29,11:08:18,SHOCK LV,3, --,

2018/05/29,11:12:27,SHOCK LV,4,00,ADMIN

2018/05/29,11:13:38,SHOCK LV,3,01,USER

2018/05/29,11:17:04,SHOCK LV,4, -- ,GUEST

32

8. Response Adjustment / Self Check Function

setting

FAST

Cond 0

Slow response, Stable value

MID.

Cond 1

SLOW

Cond 2

Display

Cond (Condition)

5pd (Display refresh rat e)

5t-b (Stability bad width)

FAST

0 2 2

MID.

1 0 1

SLOW

2 0 1

Response

indicator

Press and H

old

R

el

e

ase

and

press again

Each pressing switches

the indicators

After a while

(for 2 seconds)

This function stabilizes the weight value, reducing the influence on weighing that is caused by drafts and/or

vibration at the place where the balance is installed. This function adjusts by automatically analyzing the

environment or by hand-operation. The function has three stages as follows : Changing the weighing speed

changes the display refresh rate.

Display

Function

8-1 Response Adjustment

Response adjustment can be changed by the following met hod.

1. Press and hold the MODE key (for 2 seconds) until

RESPONSE is displayed, and then release the key .

2. Pr ess t he MODE key to select a weighing speed.

Response characterist ic

Fast response, Sensitive value

Either FAST , MID or SLOW can be selected.

3. After a few seconds of inactivity the balance displays end .

4. Then, it returns to the weighing mode and displays the

updated response indicator .

The response indicator remains displayed for a while.

Note

When setting the Response adjustment, "Condition Cond" and

"Display refresh rate 5pd" in the 11.Function T able "Environment

display ba5fnc" are changed as below.

When using a combination other than the above, please set individually as shown in "11. Function Table".

Note

If RESPONSE is displayed and you leave without pressing the MODE key,

the "Self-check function" is activated. Please refer to "8-2. Self-Check-Function /

Automatic Setting Of Min i mu m Weight Value ".

For the setting method, refer to "11.Function Table".

33

8-2 Self-Check-Function / Automatic Setting Of Minimum

4. Display shows a check result after check. When ther e is n o er r or in t he balance, display shows

ECL

Weight Value

The self-check func tion can easi ly check abou t whether proper performances are satisfied for the balance by

checking and displaying repeatability in addition to malfunction check.

In addition, it can also display and store minimum weighing value (reference value) using data of the

repeatability.

Refer to “Balance information” on the A&D web site <http://www.aandd.co.jp/> for details of the minimum

weighing value.

Setting procedure (Together refer to setting flow chart on next page.)

1. Press and hold the MODE key (for 2 seconds) in weighing mode.

2. Release the key after displaying RESPONSE .

3. Display shows and self-chec k function is started. After few seconds, display shows“ECL”. Press the MODE key while is di splayed to observe changes in the weighing value of the repeatability using electronic control load (ECL).

in blinking. When display shows in blinking, there is a possibility that

serious malfunctions occurs in the balance. In such case, t he balance requires repa ir.

SAMPLE key…

PRINT key……Outputs c ur rently displayed contents

MODE key……

Use the following keys while the minimum weighing value (reference value) is displayed to perform

each operation.

5. Outputting data of the minimum weighing value at once

Press and hold the PRINT key (for 2 sec onds) to display Out . After outputting at once,

is displayed.

Switches a display among check result, repeatability and minimum weighing

value (reference value).

At repeatability display, display shows “OK” if it is satisfied for cat al og spec.

However, if it is not satisfied for catalog spec, display requests an

improvement in an environment for the balance installed by blinking “Env”

Switches an allowable measurement error of the minimum weighing value

(reference value).

6. Storin g as minimum weighing value ( r eference value) of “17. Minimum Weighing Warning Function”

Press and hold the SAMPLE key (for 2 seconds) to dislay MW 5Et . Minimum weighing value

(reference value) is store d. Af t er st or ing, display shows and returns to weighin g m ode.

7. When not storing

Press the CAL key to return to weighing mode after disp laying .

34

8. To return to check result display

ECL

4.82

1

Weighing value change in

repeatability

ECL

Press and hold (for 2 seconds)

Release

FAiL

Few seconds later

[

[

REF

REF

OK

4.8

12.3

Env

REF

REF

REF

Normal

Improve the

when

is set to

the balance automatically

Go

Press and ho l d (for 2 seconds )

Batch

Press and hold (for 2 seconds)

Store

minimum weighing value

GX-10202M

Press the SAMPLE key to return to check result display in Step 4.

* Refer to “17. Minimum Weig hing W arning Functio n” for warni ng f unc tion of minimum weighing value.

Setting flow chart

①

Output

Output

Output

Check result]

Repair is required

performance

0_1 %

MW 9.60

0.00

5D

②

③

Check result]

1 %

MW 0.96

Normal

④

0_1 %

MW 54.60

5D

environment installed

MW 5.46

1 %

0.0057 g

output

⑤

Out

End

⑥

⑦

⑧

MW 5ET

MW-CP

set it to

1

(except near zero) and enables comparing

function of the minimum weighing value.

0,

End

0.00

35

9.Calibration

Since the balance's resolu tion is high, weighing values may change due to gravity and daily

environmental cha nges. It is necessary to perform c ali br at i on ( sensitivity adjustment) w ith the

weight in order to keep the weigh in g values from changing even if grav it y or the environment

changes.

It is recommended that you calibrate if the balanc e is installed for the first t ime or relocated, or

when the weighing values change significantly in daily inspection, etc.

Adjustment means to adju st the weighing value of the balance using the reference weight or

internal mass. Calibrati on is to weigh with the reference weight and compare how much the result

deviates from the referen ce value. (Adjustment is not performed in calibration.)

Calibration (Sensitivity adjustment)

Auto calibration·········································· Automatically adjust the balance using the internal

mass depending on the temperature change of the

operating environment or the set time and interval

time.(GX-M series)

Calibration using the inter nal mass ················ Using the internal mass, adjust the balance with a

single touch.

Calibration using an external weight··············· Using an external mass, adjust the balance with an

external mass.

Calibration test(Sensitivity calibration)

Calibration test with an external weight ··········· Output the result of checking the accuracy of

weighing using your own w eight .

* No adjustment is ma de.

Caution

□ Do not allow vibration or drafts to affect the balance during ca li br at ion.

□ To output the data for GLP/GMP using the RS-232C interface, set "GLP/GMP output (info)" of

"Data output (dout)". Refer to "11. Funct ion Table". The time and date can be added to the

GLP/GMP report. If the time or date is not correct, adjust them. Refer to "11-7 Clock and Calendar

Function".

□ The calibration and calibration test data can be stored in memory. To store them, set "Data memory

(data)" .

Caution when using your external weight

□ The accuracy of the weight used in calibration af fects the accuracy of t he balance after calibrat io n.

□ Select the mass to be used for calibration and calibration tests from the table below.

36

Model Usable calibration weight

Factory

setting

Adjustable

range

GX-8202M,

GF-8202M

2kg to 8kg (1kg interval)

5kg

GX-8202MD,

GF-8202MD

2kg to 8kg (1kg interval)

5kg

GX-10202M,

GF-10202M

2kg to 10kg (1kg interval)

10kg

GX-12001M,

GF-12001M

5kg,

10kg

10kg

GX-22001M,

GF-22001M

5kg,

10kg,

20kg

20kg

GX-32001M,

GF-32001M

5kg,

10kg,

20kg, 30kg

20kg

GX-32001MD,

GF-32001MD

5kg,

10kg,

20kg, 30kg

20kg

CFnc 0

CFnc 1

CFnc 3

CFnc

0.01g models

0.1g models

More than 20g

More than 200g

-99.99g to

+99.99g

-999.9g to

+999.9g

Display

This indicator means "I n pr ocess of measuring calibrat ion d ata".

Do not allow vibration or drafts to affect the balance while the in dicat or i s

displayed.

9-1 Automatic Self Calibration For The GX-M Series

This function automatically calibrates the balance using the internal weight due to a temperature

change in the ambient environment, time set or interval time. It can function even when the balance’s

display is in off. If GLP output in function table is selected, the balance outputs the sensitivity

adjustment report or st ore th e dat a in memo ry after calibratio n.

In the auto calibration mode, either the temperature change (

interval time (

For the setting time, the three function setting of , and can be set.

) can be set with the functi on setting

.

), the setting time (

), or the

Interval time can be set from 0.5h to 24h with function setting .

Caution

If something is on the weighing pan , the balan ce judg es that i t is in use an d doe s not perfo rm automatic

self calibration.

The criteria that the balance judges is in use are as follows.

To maintain the calibrated state, keep the weighing pan clear while not in use.

Indicates that the balance det ects a change in ambient t emp er at ur e and

automatic self calibration will start. If the balance is not used for a few

minutes with this indicator ( ) blinking, the balance performs automatic self

calibration. The blinking duration depends on the environment.

Indicates that the balance is measuring calibration data. Do not allow

vibration or drafts to affect t he bala nce while this indicator is disp lay ed. After

calibration, the balance returns to indicate the previous display.

Note The balance can be used while the indicator blin ks. But, it is recommended that to

maintain the accuracy, stop using the balance and confirm that ther e is nothing on the pan

and allow the balance to perform self calibration.

Depending on the setting of "10.Function Switch And Initializat i on" , " change prohibited" or

"changeable (usable) " can be selected.

37

9-2 One-Touch Calibration For The GX-M Series

This function calibrates the balance using the internal mass.

1. Connect the AC adapter and warm up the balance for at least 30 minutes with nothing on the

weighing pan.

2. Press the CAL key. The balance displays Calin and performs calibration using the internal

mass. Do not allow vibration or drafts to affect the balance.

3. The balance displays end after ca librat ion. If the " GLP out put ( info)" parameter of the function table

is set to "1" or "2", the balance displays glp and outputs the "sensitivity adjustment report" using

the RS-232C interface or store t he dat a in memo ry. Refer to "12-3. GLP Report" and "Data memory

(data)" of the function table for details.

4. The balance will automatically retur n to the weighing mode after cali bration.

About the internal mass

The value of the internal mass may change due to factors such as the operating environment and aging.

Correct the internal mass value as necessary. Refer to "9-6. Correcting The Internal Mass Value Of The

GX-M series", "9-7. Correcting The Internal Mass Value Of The GX-M series (Auto)".

Since the internal mass is about 850g, the possibility of error may increase as the weighing value

incereases.

To maintain the weighing accuracy, perform the calibration using an external weight periodically, as

described below "9-3.

Calibration Using An External Weight".

38

9-3 Calibration Using An External Weight

(Displayed only when

dout, data2

)

Whe

n s

etti

ng

the external weight

Refer to

"9-

5.H

ow t

o s

et

the

external weight value

"

When exte

rna

l w

eigh

t i

s n

ot changed

GLP o

utput

Press and Ho

l

d

(for

2

se

co

nds)

Release

Displayed only on GX-M s

er

i

es

)

Press and Hold

(for 2 seconds)

This function calibrates th e balance using an external wei ght .

1. Connect the AC adapter and w arm up the balance

for at least 30 minutes with nothing on the

weighing pan.

2. Press and hold the CAL key (for 2 seconds) until

1Calout is displayed, then release the key.

3. Make sure that nothing is on the weighing pan and

press the PRINT key to weigh the zero point.

Do not apply vibration, etc.

4. Place the external weight on the weighing pan an d

press the PRINT key. Do not apply vibration etc.

5. Remove the external weight from the weighing pan.

6. After calibration, if GLP output is set, " sensitivity

adjustment report" is output or stored in data

memory.

7. The display automatically returns to weighing

display.

8. Place the external weight again and check

that the set value is ± 2 digits. If it is out of

range, pay attention to the surrounding

environment and start from "1".

39

(

Di

sp

l

ayed only when

dout, data2

)

When setting the external weight

When external weight is

not changed

Refer to "9-5. How to set

the external weight value."

GLP output

External

weight

Release

(Displayed only on GX-M series)

Press and Hold

(for 2 seconds)

Press and Hold

(for 2 seconds)

9-4 Calibration Test Using An External Weight

This function tests the weighing accuracy using an e xt er nal

weight and outputs the result. This is available only when the GLP

output parameter is set to "(

not perform calibration)

1. Connect the AC adapter and warm up the

balance for at least 30 minutes w ith nothing on

the weighing pan.

2. Press and hold the CAL key (for 2 seconds)

until CCout is displayed and release the key .

3. Make sure that nothing is on the weighing pan and

press the PRINT key and weigh the zero point.

Do not apply vibration etc.

4. The weighin g value of zero point is displayed f or

several seconds. Place the external weight on

the weighing pan and press t he PRINT key.

Weigh the external weight.

Do not apply vibration, etc.

5. Weighing value of the external weight is

displayed for several seco nds.

6. Remove the external weight from the weighing

pan.

7. The sensitivity calibration status is output or

stored in the data memory.

8. It automatically returns to the weighing display.

doutinfo1). (Calibration test does

40

9-5 How to set the External Weight Value

Select

Ex: Updated the external weight

3000.12g

20

0

0

.

0

0

3

0

0

0

.

0

0

3

0

00

.1

2

When calibrating the balance or performing a calibration test, the external weight you have on hand

can be set. (Refer to "Usable c al ibrat ion weight" on Page 37.)

After Cal 0 is displayed, the external weight value can be set as shown in "9-3.Calibration Using

An External weight". Or, after CC 0 is displayed, the external weight value can be set as shown in

"9-4.Calibration Test Using An External Weight".

1. After displayed Cal 0 , or after displayed CC 0 , press

the SAMPLE key.

2. Press the RE-ZERO key at all digits blinking to change the

weight to be used.

Calibration Calibration test

3. Specify t he calibration weight value as follow s.

SAMPLE key ··············· Switches the display condition to: "All of the

···································· segments blinking" (calibration weight

···································· selection m ode) or "The last four digits

···································· blinking"(value adjustment mode).

RE-ZERO key ········· Changes the external weight value (all of the

MODE key

······················ In the adjustment range setting, the value

PRINT key ·············· Register s t he changed external weight value.

Registered values are stored even when the

CAL key ················· Suspends setting. (Returns to Cal 0

·································· or CC 0 .)

······················ segments blinking) or changes the

······················ adjustment range (last four digits blinking).

······················ becomes -9999 digits after +9999 digits.

power is turned off.

the external weight

41

Internal setting switch (Factory setting

1

)

Internal mass correcting switch (Factory setting

0

)

9-6 Correcting The Internal Mass Value Of The GX-M series

Hold

With pressing

and holding

End

Internal mass value can be c or rec t ed w it h function setting .

There is one correction method, as follows.

Auto ········ This is a method of correct ing the i nternal mass weight value based on an external weight.

Note

□ Correction of interna l mass value can not be executed at factory setting.

Refer to " 9. Function Switch And Initialization" or t he following setting method, and enable

changi ng of the function setting and cor rec tion the internal mass value.

Setting procedure

1. Press the ON:OFF key to turn off the display.

2. Hold down the PRINT and SAMPLE keys, and press the ON:OFF key

to display p5 .

3. Press the PRINT key and set the "internal mass correction switch"

and "function setting switch" to "1 " with the next key.

SAMPLE key Select the switc h (blinking digit).

RE-ZERO key Change the value of the blinking switch.

4. Press the PRINT key to register and display the weighing display.

42

9-7 Correcting The Internal Mass Value Of The GX-M series (Auto)

Model

Available mass

Factory setting

Adjustable range

GX-8202M

2kg to 8kg (1kg

interval

)

5kg

GX-8202MD

2kg to 8kg (1kg

interval

)

5kg

GX-10202M

2kg to 10kg (1 kg

interval

)

10kg

GX-12001M

5kg,

10kg 10kg

GX-22001M

5kg,

10kg,

20kg

20kg

GX-32001M

5kg,

10kg,

20kg, 30k g

20kg

GX-32001MD

5kg,

10kg,

20kg, 30k g

20kg

During

calibration

with

external

mass

Replace

(for 2 seconds)

Press

several

times

Press and

Calibrate referring to "9-3. Cal ibration Using An External weight ".

This is method of correcting the internal mass weight value based on an external weight.

After calibration with the external mass, the bala nce automatically loads and unloads

the internal mass and corrects the internal mass value.

The available masses are as shown in the table below. The corrected mass

value is maintained in non-volatile m emory even if the AC adapter is remov ed

Place

Setting procedure

1. The internal mass value cannot be corrected at f actory settings. Refer to "9-6.Correcting The Internal Mass Value Of The GX-M series" and enable changi ng of t he function setting and correction the internal mass value.

2. I n w eigh ing mode, press and hold the SAMPLE key to

display .

3. Press the SAMPLE key several times until appears.