Page 1

GX-AE series

GX-124AE/GX-224AE/GX-324AE

GX-A series

GX-124A/GX-224A/GX-324A

GX-203A/GX-303A/GX-403A/GX-603A/GX-1003A/GX-1603A

GX-2002A/GX-3002A/GX-4002A/GX-6002A/GX-10002A

GX-6001A/GX-10001A

GF-A series

GF-124A/GF-224A/GF-324A

GF-123A/GF-203A/GF-303A/GF-403A/GF-603A/GF-1003A/GF-1603A

GF-1202A/GF-2002A/GF-3002A/GF-4002A

GF-6002A/GF-10002A/GF-6001A/GF-10001A

GX-AWP series

GX-203AWP/GX-403AWP/GX-603AWP

GX-2003AWP/GX-4002AWP/GX-6002AWP

GX-6001AWP

GF-AWP series

GF-203AWP/GF-403AWP/GF-603AWP

GF-2003AWP/GF-4002AWP/GF-6002AWP

GF-6001AWP

1WMPD4003475D

Page 2

© 2019 A&D Company Ltd. All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, or translated into

any language in any form by any means without the written permission of A&D Company

Ltd.

The contents of this manual and the specifications of the instrument covered by this

manual are subject to change for improvement without notice.

Windows, Word and Excel are registered trademarks of the Microsoft Corporation.

Page 3

Contents

1. Introduction .................................................................................................................... 7

1-1 Features ................................................................................................................................................ 7

1-2 About The Models .................................................................................................................................. 8

1-3 About The GX-AE Series ....................................................................................................................... 8

1-4 Compliance ............................................................................................................................................ 9

1-5 About Communication Manual .............................................................................................................. 9

2. Part Names, Installation And Precautions .................................................................... 10

2-1 Installing The Balance ......................................................................................................................... 14

2-2 Precautions .......................................................................................................................................... 14

2-3 During Use ........................................................................................................................................... 15

2-4 Precautions After Use .......................................................................................................................... 17

2-5 Power Supply ...................................................................................................................................... 17

3. Display Symbols And Key Operation ........................................................................... 18

4. Weighing ...................................................................................................................... 20

4-1 Units .................................................................................................................................................... 20

4-2 Basic Operation ................................................................................................................................... 25

4-3 Counting Mode (PCS) ......................................................................................................................... 27

4-4 Percent Mode (%) ............................................................................................................................... 29

4-5 Animal Weighing Mode (Hold Function) .............................................................................................. 30

5. Impact Shock Detection Function ................................................................................ 30

5-1 Recording Impact History .................................................................................................................... 31

5-2 Output Impact History .......................................................................................................................... 31

6. Response Adjustment / Self Check Function ............................................................... 32

6-1 Response Adjustment ......................................................................................................................... 33

6-2 Self Check Function / Automatic Setting Of Minimum Weighing Value By ECL ................................. 33

6-2-1 With Balance Software Version 1.200 To Version 1.220 .............................................................. 34

6-2-2 With Balance Software Version 1.300 or Later ............................................................................ 35

7. Sensitivity Adjustment .................................................................................................. 37

7-1 Automatic Sensitivity Adjustment (GX-AE/GX-A/GX-AWP Series Only) ............................................. 39

7-1-1 Inputting the set time .................................................................................................................... 40

7-1-2 Clearing the set time .................................................................................................................... 41

7-1-3 Setting the interval time ................................................................................................................ 42

7-2 Sensitivity Adjustment Using The Internal Mass (GX-AE/GX-A/GX-AWP Series Only) ........................ 44

7-3 Calibration Test Using The Internal Mass (GX-AE/GX-A Series 0.0001g Models Only) .................. 45

7-4 Sensitivity Adjustment Using An External Weight ............................................................................... 46

3

Page 4

7-5 Calibration Test Using An External Weight .......................................................................................... 47

7-6 How To Set The Sensitivity Adjustment Weight Value ......................................................................... 48

7-7 Correcting The Internal Mass Value Of The GX-AE/GX-A/GX-AWP Series ................................................................ 49

7-7-1 Correcting The Internal Mass Value Of The GX-AE/GX-A/GX-AWP Series (Auto) ..................... 50

7-7-2 Correcting The Internal Mass Value Of The GX-AE/GX-A/GX-AWP Series (Manual) ................. 51

8. Function Switch And Initialization ................................................................................. 53

8-1 Permit Or Inhibit .................................................................................................................................. 53

8-2 Initializing The Balance ....................................................................................................................... 56

9. Function Table .............................................................................................................. 57

9-1 Setting The Function Table .................................................................................................................. 57

9-2 Details Of The Function Table ............................................................................................................. 59

9-3 Description Of The Class Environment Display .................................................................................. 66

9-4 Description Of The Data Output .......................................................................................................... 67

9-5 Description Of The Data Format ......................................................................................................... 67

9-6 Output Example Of The Data Format .................................................................................................. 67

9-7 Clock And Calendar Function .............................................................................................................. 68

9-8 Comparator Function ........................................................................................................................... 70

9-9 Description Of Application ................................................................................................................... 77

9-10 Output The Function Table Information ............................................................................................. 78

10. ID Number And GLP Report ....................................................................................... 80

10-1 Main Objective ................................................................................................................................... 80

10-2 Setting The ID Number ...................................................................................................................... 80

10-3 GLP Report ........................................................................................................................................ 81

11. Data Memory .............................................................................................................. 8 6

11-1 Data Memory For Weighing Data ...................................................................................................... 86

11-2 Data Memory For Sensitivity Adjustment And Calibration Test ......................................................... 90

12. Statistical Calculation Mode ....................................................................................... 93

12-1 How To Use The Statistical Calculation ............................................................................................. 93

12-2 Statistical Calculation Mode (Example Of Use) ................................................................................. 98

13. Flow Measurement .................................................................................................. 100

13-1 How To Use Flow Measurement ..................................................................................................... 100

14. Gross Net Tare Function .......................................................................................... 104

14-1 Preparations For Gross Net Tare Function...................................................................................... 104

14-2 Usage Example Of The Gross Net Tare Function ........................................................................... 106

15. Minimum Weighing Warning Function ...................................................................... 107

4

Page 5

15-1 Minimum Weighing Value Comparison ........................................................................................... 108

15-2 Input And Output Of The Minimum Weighing Value ........................................................................ 108

15-2-1 Procedure To Set In The Function Table (With Balance Software Version 1.200 To 1.220)

15-2-2 Procedure To Set In The Weighing Display (With Balance Software Version 1.200 To 1.220)

15-2-3 Procedure To Set In The Function Table (With Balance Software Version 1.300 Or Later)

15-2-4 P

15-2-5 Procedure To Output The Settings In Batch (Balance Software Version 1.300 Or Later)

15-3 Setting Measurement Tolerance Of Minimum Weighing Value ........................................................ 114

15-4 Data Output When Less Than Minimum Weighing Value ................................................................ 115

rocedure To Set In The Weighing Mode (Balance Software Version 1.300 Or Later)

................... 108

............... 109

.................... 109

......................... 112

.............................. 112

16. Underhook ............................................................................................................... 116

17. Programmable Unit .................................................................................................. 117

18. Density (Specific Gravity) Measurement .................................................................. 119

19. Password Lock Function .......................................................................................... 124

19-1 Balance Software Version 1.200 ..................................................................................................... 124

19-2 Balance Software Version 1.211 Or Later ....................................................................................... 125

19-3 Enabling Password Lock Function .................................................................................................. 126

19-4 Entering The Password At The Start Of Weighing .......................................................................... 127

19-5 Logging Out ..................................................................................................................................... 128

19-6 Registering (Changing) Password .................................................................................................. 129

19-7 Changing Password ........................................................................................................................ 130

19-8 Deleting Password (U5ER 01 to 10) .................................................................................................. 131

19-9 If Password Is Lost Or Forgotten .................................................................................................... 131

20. Repeatability Check Function

(GX-AE/GX-A/GX-AWP Series Only)

...................................................... 132

21. Interface Specification (Standard) ............................................................................ 133

22. Maintenance ............................................................................................................ 133

22-1 Treatment Of The Balance .............................................................................................................. 133

23. Troubleshooting ....................................................................................................... 134

23-1 Checking The Balance Performance And Environment .................................................................. 134

23-2 Error Codes ..................................................................................................................................... 135

23-3 Other Display ................................................................................................................................... 138

23-4 Asking For Repair ............................................................................................................................ 138

24. Connection With Peripheral Device ......................................................................... 138

24-1 Command ........................................................................................................................................ 138

24-2 Key Lock Function ........................................................................................................................... 138

25. How To Check The Software Version Of The Balance ................................................ 138

26. Specifications ........................................................................................................... 139

5

Page 6

26-1 Common Specifications ................................................................................................................... 139

26-1-1 Function .................................................................................................................................... 139

26-1-2 Size/Weight .............................................................................................................................. 139

26-2 Individual Specifications .................................................................................................................. 140

26-2-1 0.0001g Models ........................................................................................................................ 140

26-2-2 0.001g Models .......................................................................................................................... 141

26-2-3 0.01g Models ............................................................................................................................ 142

26-2-4 0.1g Model ................................................................................................................................ 143

27. External Dimensions ................................................................................................ 144

27-1 Options And Peripheral Instruments................................................................................................ 147

6

Page 7

1. Introduction

This manual describes how the GX-AE/GX-A/GF-A/GX-AWP/GF-AWP series balance works and how

to get the most out of it in terms of performance. Read this manual thoroughly before using the balance

and keep it at hand for future reference.

Behavior may differ depending on the software version of your balance.

For confirmation of the software version of the balance, refer to "25. How To Check The Software

Version Of The Balance".

1-1 Features

□ The balance has a self-check function that inspects the balance itself using electronically

controlled load (ECL) and evaluates performance.

□ The balance can detect impact applied to its mass sensor and display the level of that impact. ISD

(Impact Shock Detection).

□ Continuous change of the balance can be calculated as flow rate, displayed and output.

FRD (Flow Rate Display)

□ The balance is equipped with a data memory function, which can record weighing value, sensitivity

adjustment result, and multiple unit mass (mass per sample in counting mode) (Up to 200 items

are stored for weighing value).

□ The GX-AE/GX-A/GX-AWP series has automatic sensitivity adjustment using the internal mass,

adapting to temperature changes, setting time and interval time.

□ Good Laboratory Practice (GLP) / Good Manufacturing Practice (GMP) data can be output using

the RS-232C serial interface when performing sensitivity adjustment or calibration test. It is

possible to print and record the results using an optional printer.

□ A built-in clock and calendar that can add the time and date to the output data. (Setting and

changing of the time can be limited to only Administrator by using the password lock function.)

□ Comparator Indicators, displaying the comparison results with HI OK LO . (Depending on

the setting, 5-step comparison is also possible.)

□ Capacity Indicator, displaying the weight value in percentage relative to the weighing capacity.

□ Hold Function, provided for weighing a moving object such as an animal.

□ Underhook, for measuring density and weighing magnetic materials.

□ Using the key lock function, key operation of the balance is disabled and operations can be made

by commands from an external device only.

□ Users of the balance can be limited by setting a password. (Password lock function)

□ The balance is equipped with an RS-232C serial interface and a USB interface to communicate

with a computer. Windows computer using the Windows communication tools software (WinCT)

make building a system very easy. The latest WinCT software can be downloaded from the A&D

website.

Windows is a registered trademark or trademark of Microsoft Corporation in the United States and

other countries.

□ A small breeze break is included with the 0.001 g readability model.

□ A glass breeze break is included with the 0.0001 g readability model.

□ Dustproof and waterproof performance (IP65) of the product is that suitable for measuring

powders and liquids. When the optional waterproof RS-232C cable (AX-KO2737-500) is

connected, protection against dust and water can be provided even during communication.

(GX-AWP/GF-AWP only)

*If other than GXA-09 is used, protection against dust and water is not provided.

7

Page 8

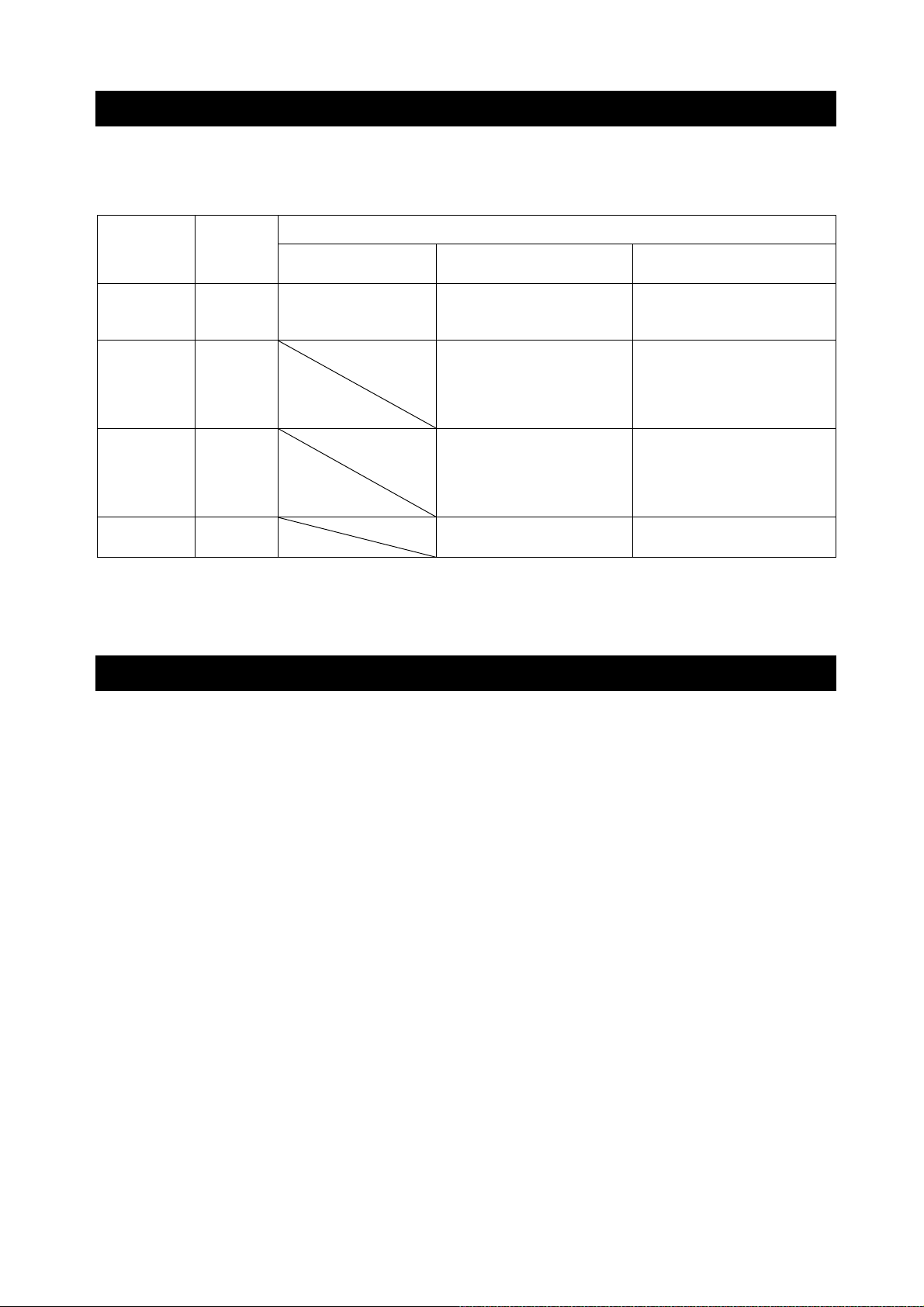

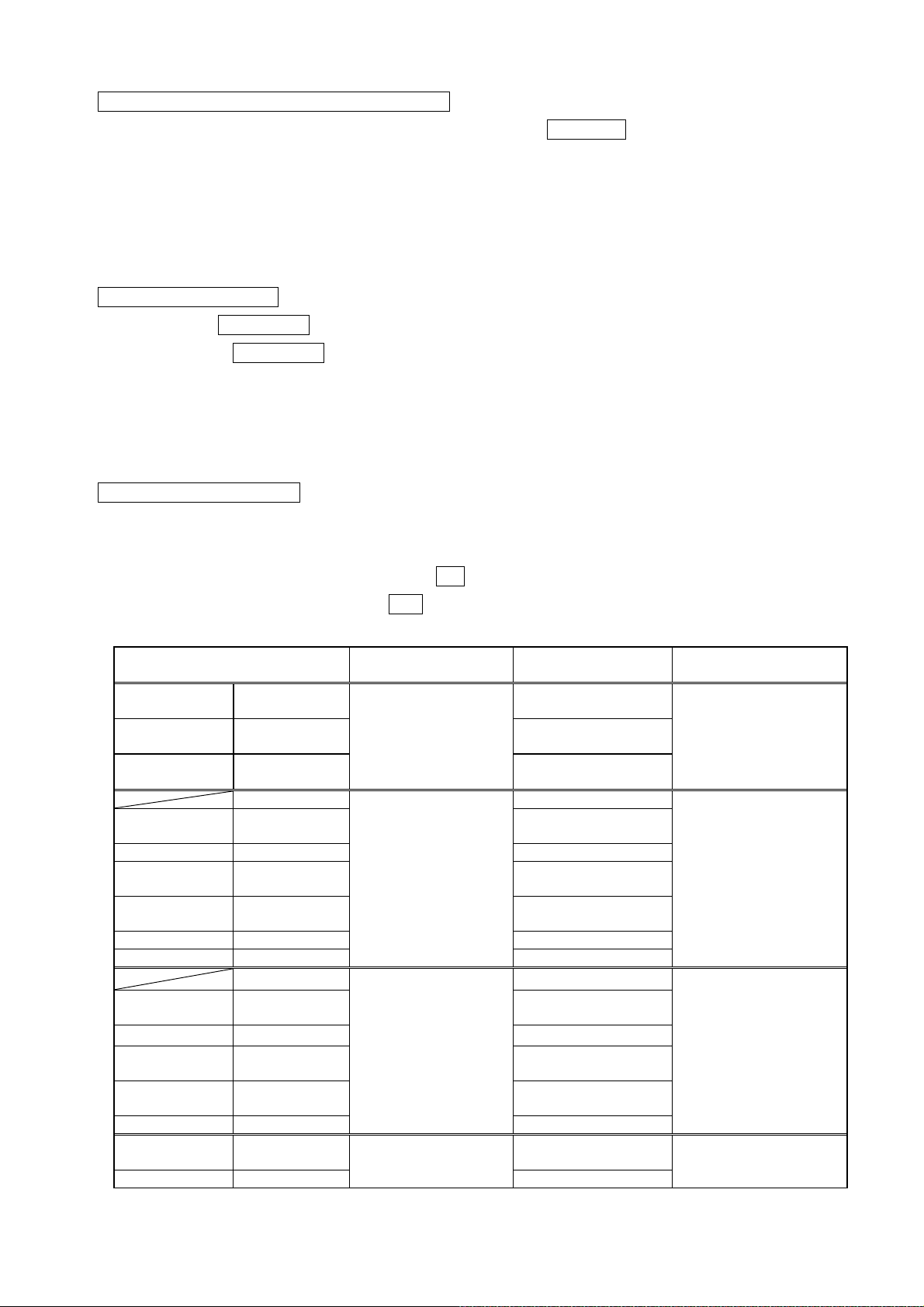

1-2 About The Models

The GX-AE/GX-A/GF-A/GX-AWP/GF-AWP series consists of a variety of models with different

combinations of weighing capacity and readability. In this manual, they are classified by readability as

shown in the table below.

Model

Classification Readability

0.0001 g

model

0.001 g

model

0.01 g

model

0.1 g

model

0.0001 g

0.001 g

0.01 g

0.1 g

□ The GX-AE/GX-A/GX-AWP series has an internal mass for sensitivity adjustment.

□ The GF-A/GF-AWP series does not have an internal mass for sensitivity adjustment, so an

external weight is required separately for sensitivity adjustment.

Internal mass type,

with ionizer

GX-124AE

GX-224AE

GX-324AE

Internal mass type General type

GX-124A

GX-224A

GX-324A

GX-203A / GX-303A

GX-403A / GX-603A

GX-1003A / GX-1603A

GX-203AWP/GX-403AWP

GX-603AWP

GX-2002A / GX-3002A /

GX-4002A / GX-6002A /

GX-10002A

GX-2002AWP/GX-4002AWP

GX-6002AWP

GX-6001A / GX-10001A

GX-6001AWP

GF-123A/ GF-203A /

GF-303A /GF-403A /

GF-603A /GF-1003A /

GF-1603A / GF-203AWP

GF-403AWP / GF-603AWP

GF-1202A/ GF-2002A /

GF-3002A /GF-4002A /

GF-6002A /GF-10002A

GF-2002AWP/GF-4002AWP

GF-6002AWP

GF-6001A / GF-10001A

GF-6001AWP

GF-124A

GF-224A

GF-324A

1-3 About The GX-AE Series

□ An ionizer (static eliminator), which causes no breeze, is built into the breeze break. The ionizer

can eliminate static electricity from the weighing sample before weighing, reducing error due to

static electricity. (Static is eliminated by bipolar ions generated by direct-current corona discharge

being projected onto the sample.)

□ The ionizer electrodes are designed to be removed for cleaning and replacement.

□ An IR (touchless) switch is attached to the ionizer, and static elimination can be started without

touching ionizer.

□ Power is supplied from the balance to allow the ionizer to be operated without using an AC adapter.

□ PRINT or RE-ZERO or the static elimination function of the ionizer can be operated by using the

optional foot switch (AX-SW137-PRINT or AX-SW137-REZERO).

□ A removable glass breeze break is equipped as standard.

□ As an option board is installed, so other options (GXA-03/04/06/09/17/23/24/25/26, FXi-08, etc.)

cannot be used.

□ For instructions on using the ionizer and IR switch, download the instruction manual for "GXA-17

Large Glass Breeze Break with Ionizer" from our website (https://www.aandd.jp) and refer to it.

Static electricity

In general, when the ambient humidity is less than 45%RH, nonconductors such as powders, paper,

and plastics easily become charged with static electricity. The influence of static electricity may

cause a weighing error of several milligrams. The ionizer neutralizes this electrical charge.

8

Page 9

1-4 Compliance

Compliance with FCC Rules

Please note that this equipment generates, uses and can radiate radio frequency energy. This

equipment has been tested and has been found to comply with the limits of a Class A computing

device pursuant to Subpart J of Part 15 of FCC rules. These rules are designed to provide

reasonable protection against interference when equipment is operated in a commercial

environment. If this unit is operated in a residential area, it may cause some interference and under

these circumstances the user would be required to take, at his own expense, whatever measures

are necessary to eliminate the interference.

(FCC = Federal Communications Commission in the U.S.A.)

1-5 About Communication Manual

For details about communication, download "Communication manual" from our website

(https://www.aandd.jp) and refer to it.

9

Page 10

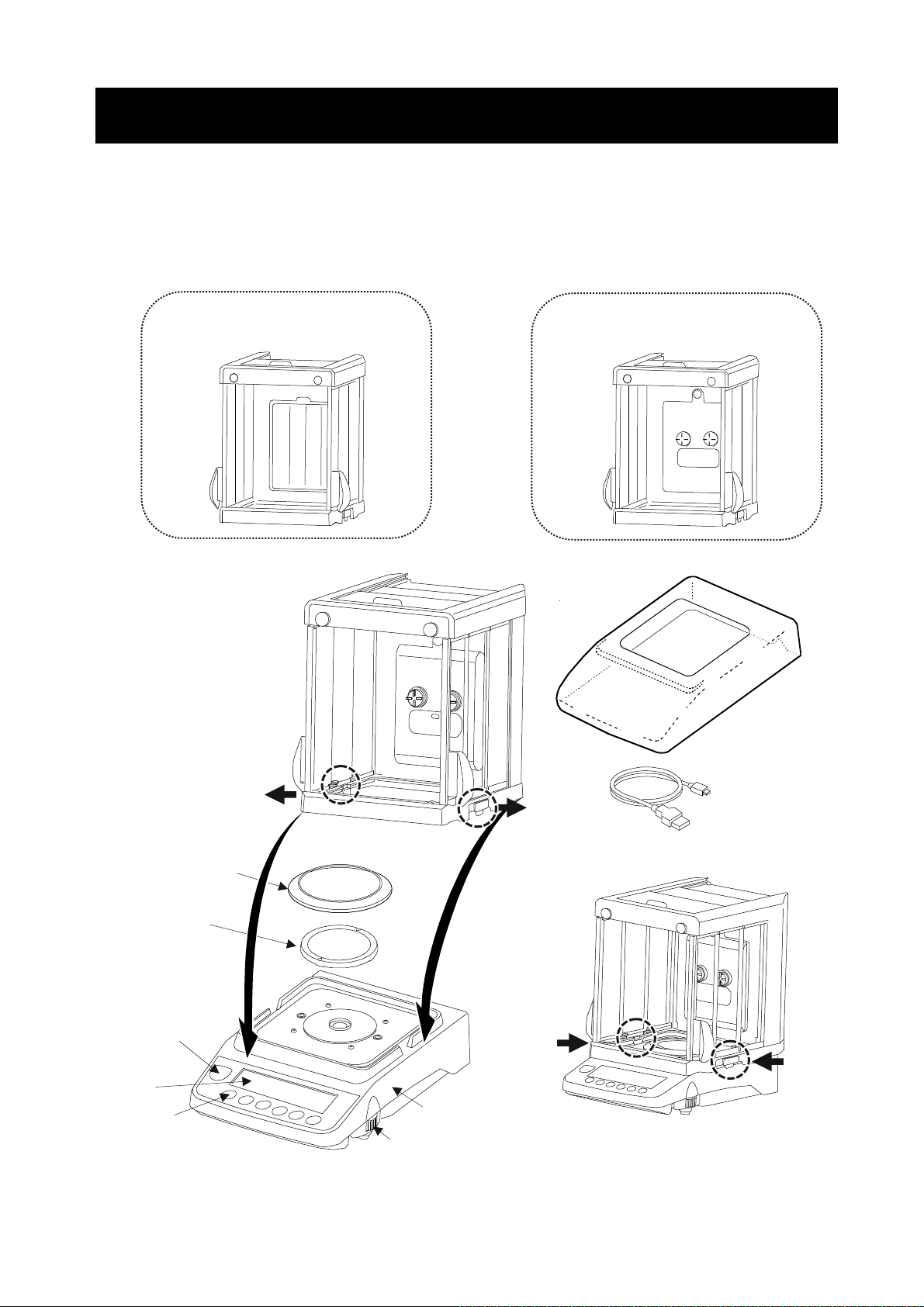

2. Part Names, Installation And Precautions

The balance is a precision instrument. Unpack it carefully. The packing contents depend on the

balance model. See the illustrations to confirm that everything is included. When options are combined

at time of shipping, optional accessories may be included.

Keep the packing material to be used for transporting the balance in the future.

GX-AE / GX-A / GF-A 0.0001g models

GX-A/GF-A GX-AE

Glass Breeze Break Glass Breeze Break with Ionizer

Main unit cover

(PET resin)

Pull out the left and right

locking handles.

USB cable (approx. 1.8m)

Breeze break ring

Weighing pan

Bubble spirit level

Display

Keys Main unit

Leveling foot Press the left and right locking handles

to secure the breeze break to the balance.

10

Page 11

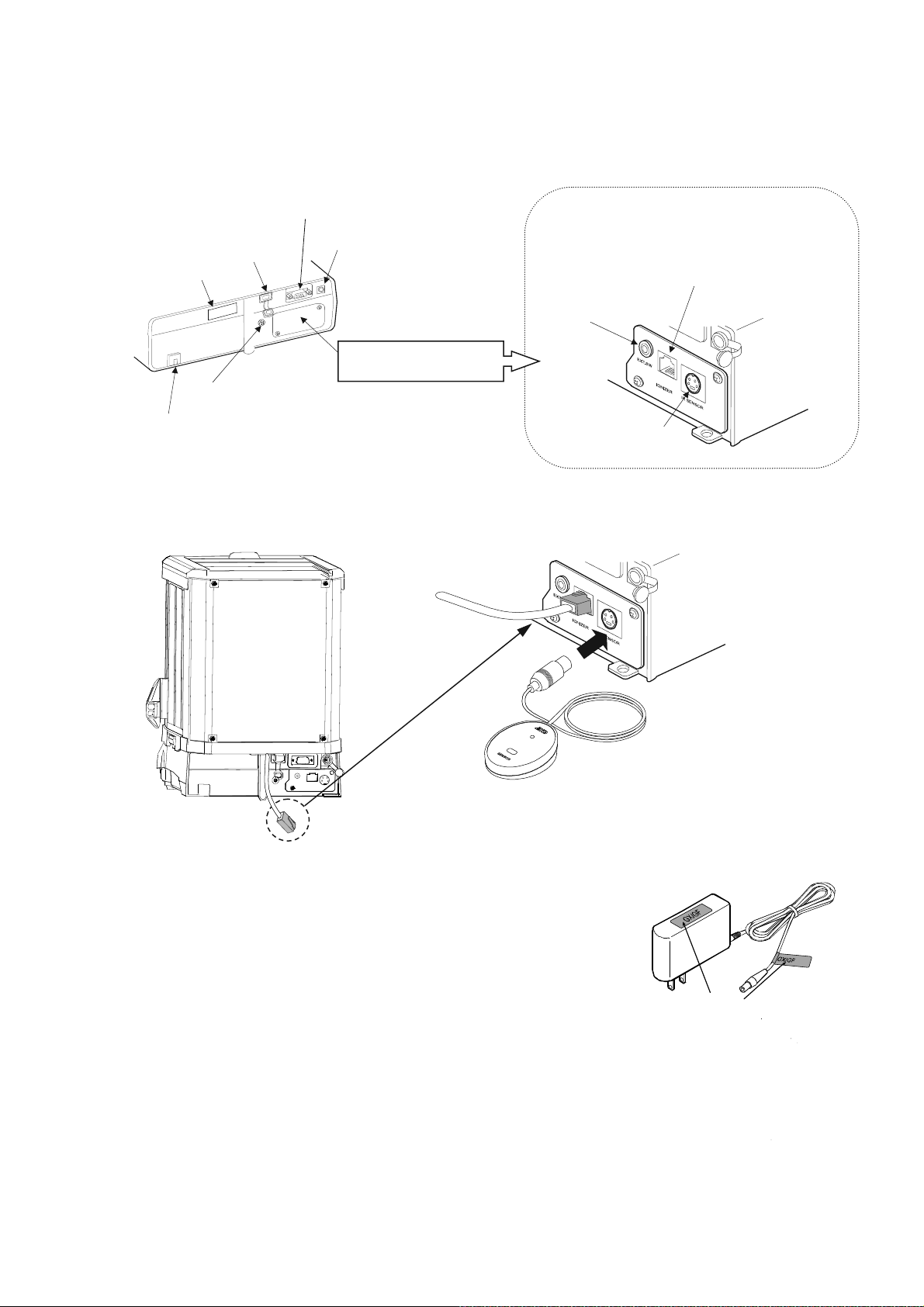

Main unit rear side

A

A

r

A

r

A

The models with an ionizer built in to the glass breeze break (GX-124AE/GX-224AE/GX-324AE) have an

ionizer connector, IR sensor connector and external key jack.

Serial number

USB interface

RS-232C serial interface

C adapter jack

External key jack

Panel of GX-AE series

Ionizer connecto

Panel of GX-AE

series is different

Ground terminal

nti-theft hole

(Please prepare the security cable by yourself)

IR sensor connector

Connecting the glass breeze break with ionizer and the IR sensor

Models: GX-124AE / GX-224AE / GX-324AE

□ Insert the cable extending from the rear of the breeze

break into the ionizer connector at the rear of the

balance.

□ Insert the IR sensor plug into the IR sensor connector

at the rear of the balance.

External IR sensor

ttach the AC adapter label to the

adapter as shown below.

C adapte

AC adapter ID labels

Note

□ Please confirm that the AC adapter type is correct for your local voltage and receptacle type.

□ Please use the dedicated AC adapter specified for the balance.

□ Do not use the AC adapter provided with the balance for other models or equipment with which the

AC adapter may not be compatible.

□ If you use the wrong AC adapter, the balance and other equipment may not operate properly.

11

Page 12

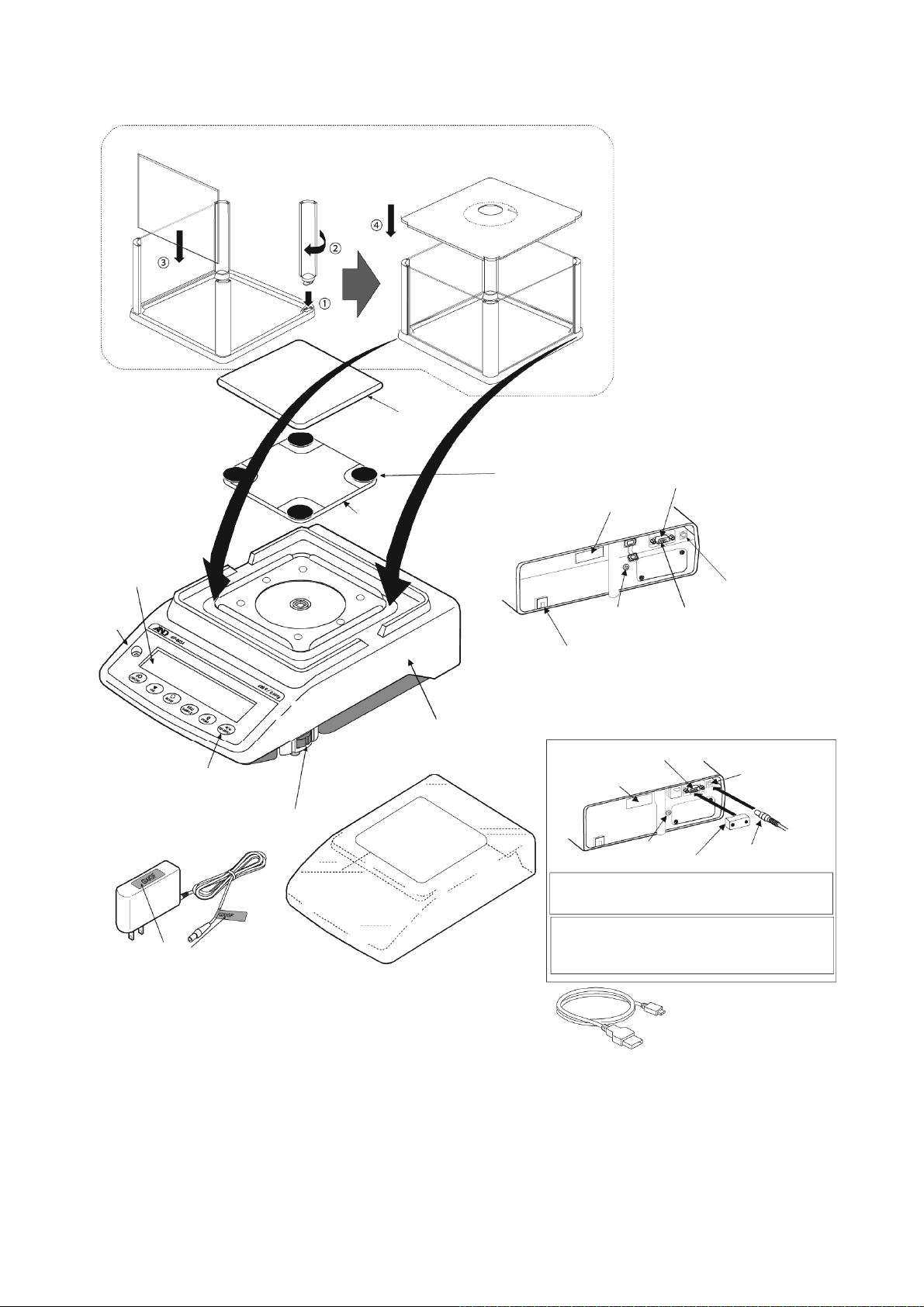

GX-A / GF-A 0.001g models

A

A

r

r

A

k

r

A

r

A

r

A

A

r

f

A

r

j

r

ssemble the small breeze break (0.001g model only)

Follow the sequence as numbered.

Weighing pan

Pan

support

Pan support recepto

Main unit rear side

USB interface

Serial numbe

Display

Bubble

spirit

level

Keys

C adapte

Leveling foot

C adapte

ID label

ttach the AC adapter label to the

C adapter as shown above.

Note

Main unit

Main unit cove

C adapter jac

Ground

terminal

nti-theft hole

(Please prepare the security cable by yourself)

The GX-AWP/GF-AWP series comes with a

terminal cover.

RS-232C interface

Serial numbe

Insert the plug while rotating it. The plug is

designed to fit tight in order to prevent dust

from entering, so it is not easy to insert.

To protect the balance from dust/water,

attach the terminal cover or the waterproo

RS-232C cable (AX-KO2737-500).

RS-232C interface

Ground

terminal

USB cable

(Approx. 1.8 m)

C adapte

ack

AC adapter

Terminal cove

plug

□ Please confirm that the AC adapter type is correct for your local voltage and receptacle type.

□ Please use the dedicated AC adapter specified for the balance.

□ Do not use the AC adapter provided with the balance for other models or equipment with which the

AC adapter may not be compatible.

□ If you use the wrong AC adapter, the balance and other equipment may not operate properly.

12

Page 13

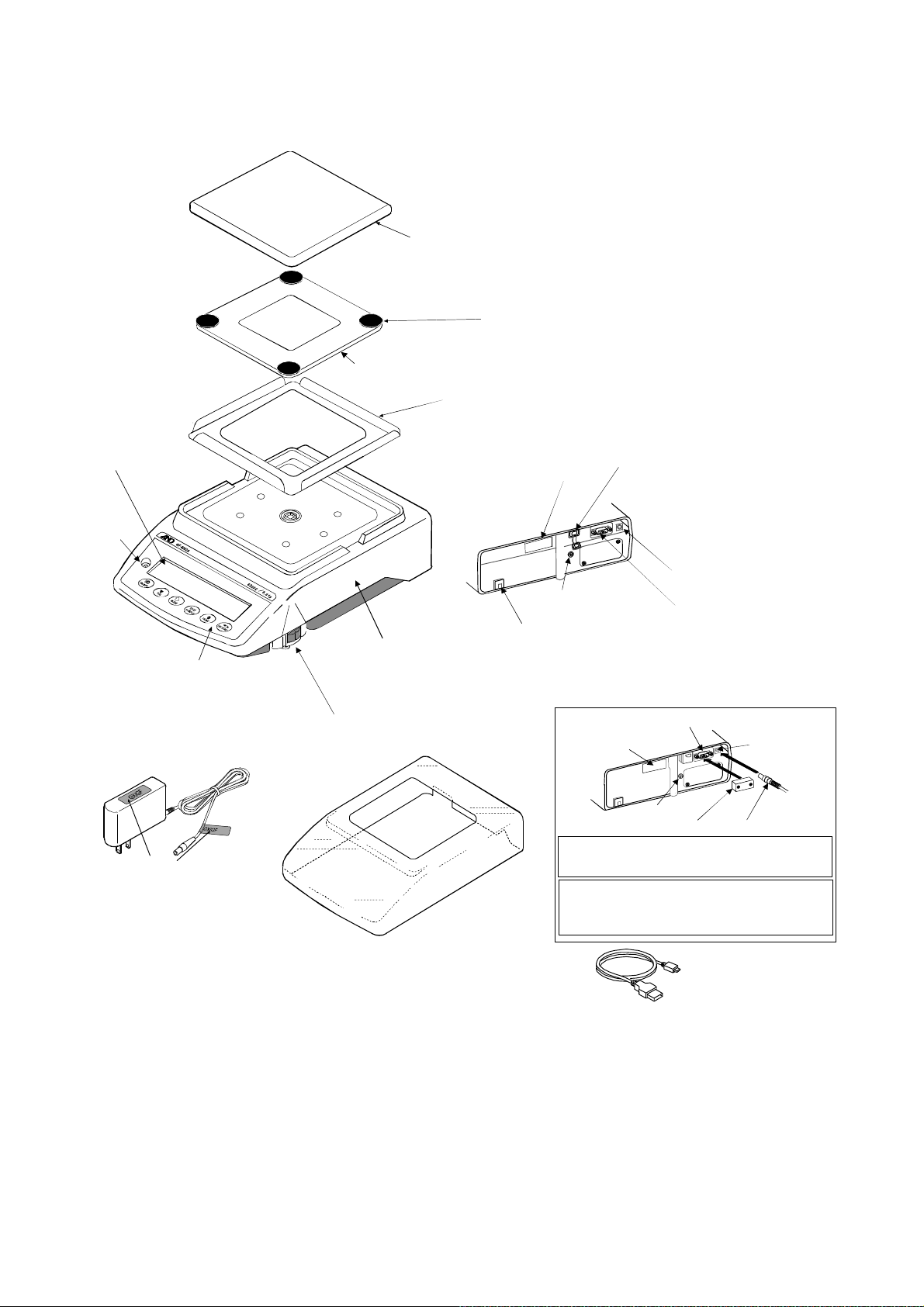

GX-A / GF-A 0.01g/0.1g models

r

r

A

A

r

A

r

j

r

r

I

hil

f

r

A

r

A

A

Weighing pan

Pan support recepto

Pan

support

Dust plate for

0.01g/0.1g

Display

Bubble

spirit

level

Keys

C adapte

C adapter

ID label

ttach the AC adapter label

to the AC adapter as shown

above.

Leveling foot

Main unit

(Please prepare the security cable by yourself)

Main unit cove

USB interface

Serial numbe

Main unit rear side

C adapter jack

Ground

terminal

nti-theft hole

The GX-AWP/GF-AWP series comes with a

terminal cover.

RS-232C interface

Serial numbe

Ground

terminal

nsert the plug w

designed to fit tight in order to prevent dust

from entering, so it is not easy to insert.

To protect the balance from dust/water,

attach the terminal cover or the waterproo

RS-232C cable (AX-KO2737-500).

RS-232C interface

Terminal cove

e rotating it. The plug is

C adapte

ack

AC adapte

plug

USB cable

(Approx. 1.8 m)

Note

□ Please confirm that the AC adapter type is correct for your local voltage and receptacle type.

□ Please use the dedicated AC adapter specified for the balance.

□ Do not use the AC adapter provided with the balance for other models or equipment with which the

AC adapter may not be compatible.

□ If you use the wrong AC adapter, the balance and other equipment may not operate properly.

13

Page 14

2-1 Installing The Balance

Step 1. Decide where to install the balance, taking into consideration the content of “2-2 Precautions”, below.

Step 2. Assemble the balance while referring to the explanations in the previous section.

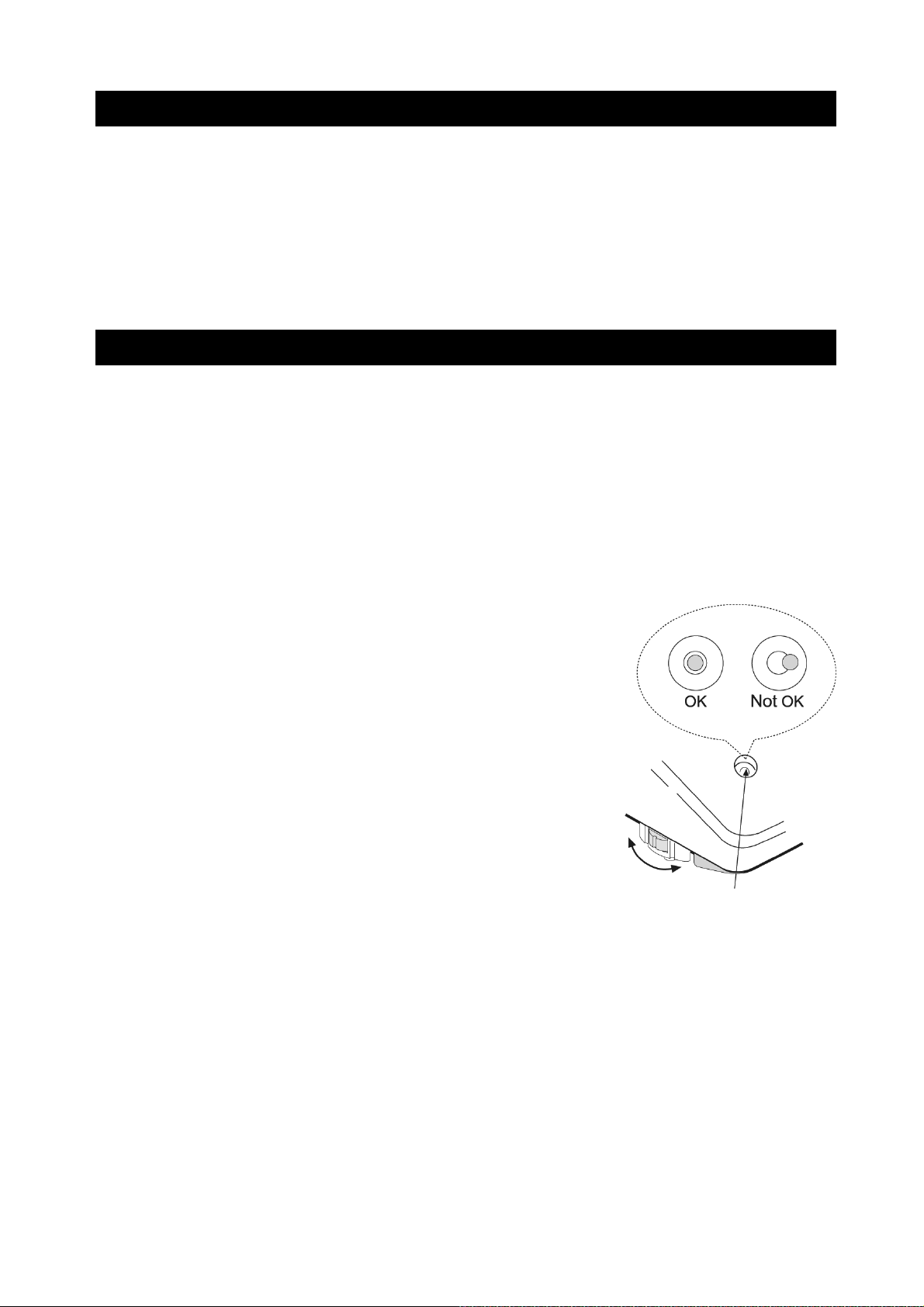

Step 3. To level the balance, adjust the leveling feet so that the air bubble is in the red circle of the

bubble spirit level.

Step 4. Confirm that the adapter type is correct for the local voltage and power receptacle type.

Step 5. Insert the AC adapter into the AC adapter jack on the rear of the balance, and then plug the

AC adapter into an outlet.

2-2 Precautions

To get the optimum performance from the balance and acquire accurate weighing data, note the following:

□ Install the balance in an environment where the temperature and humidity are not excessive.

The best operating temperature is about 20°C ±2°C at about 45~60%RH relative humidity.

□ Install the balance where it is free of dust.

□ The weighing table should be solid, free from vibration and drafts, and as level as possible. (An

anti-vibration table or stone table is ideal)

□ Install the balance in a stable place avoiding vibration and shock. Corners of rooms on the first floor

are best, as they are less prone to vibration.

□ Install the balance where it is not affected by heaters or air conditioners.

□ Install the balance where it is not exposed to direct sunlight.

□ Install the balance away from equipment which produces

magnetic fields.

□ Level the balance by adjusting the leveling feet and confirm

it using the bubble spirit level.

□ Be sure to warm up the balance before use for at least 30

minutes (with the AC adapter connected to the power

supply).

□ Adjust the sensitivity of the balance before use or after

having moved it to another location. Refer to "7. Sensitivity

adjustment".

The GX-AWP/GF-AWP series

□ The dustproof and waterproof level of the balance is equivalent to IP65, and its second digit, “5”,

corresponds to "having no harmful influence by receiving direct jet of water". Washing with strong water

pressure or submersion in water may cause water to enter the balance and cause a malfunction.

□ When installing and using the balance under conditions requiring dustproof and waterproof

performance, make sure that the AC adapter plug is fully inserted into the AC adapter jack and that

the terminal cover is attached to the RS-232C interface or the waterproof RS-232C cable

(AXKO2737-500) is used.

□ If the RS-232C terminal cover is removed or the waterproof RS-232C cable (AX-KO2737-500) is not

used, protection against dust and water is not provided.

Caution

Leveling foot

Bubble spirit level

Do not install the balance where flammable or corrosive gas is present.

14

Page 15

How to adjust the level of the balance

UP DOWN

Red circle

Bubble

OK Not OK

Leveling

foot

Leveling

foot

UPDOWN

When the bubble is off to the left:

Turn the leveling foot on the front right in the clockwise

direction.

When the bubble is off to the backward position:

Turn both leveling feet on the front in the clockwise

direction at the same time.

2-3 During Use

When the bubble is off to the right:

Turn the leveling foot on the front left in the clockwise

direction.

When the bubble is off to the forward position:

Turn both leveling feet on the front in the counter

clockwise direction at the same time.

For precise and accurate weighing, please take notice of the following.

□ Weighing errors may occur due to the influence of static

electricity. Note that if the ambient humidity drops below 45%RH,

insulators such as plastics are liable to have static electricity.

The Charged

sample

Ground the balance and perform the following as needed.

Use the built-in ionizer to remove static electricity (GX-AE

Metal case

series only).

Use the GXA-25 or AD-1683 static eliminator, sold separately,

to directly remove static electricity from the sample.

Increase the relative humidity at the place where the balance

is installed.

Weigh the sample in a conductive metal container or the like.

Ground

Wipe off charged materials such as plastic with a damp cloth

to suppress static electricity.

□ On models that come standard with a small breeze break, the parts of the small breeze break may

be charged for some time after being unpacked or when the humidity is low. If the measured value

is not stable or repeatability is poor, remove the small breeze break and try again. Wipe the

transparent plates with a damp cloth to remove static electricity to solve the problem of them

becoming charged. It is also effective to use the GXA-25 or AD-1683 static eliminator, sold

separately, or a commercially available antistatic agent.

15

Page 16

□ Influence of magnetism may cause weighing errors. When

measuring magnetic materials (iron, etc.), keep the sample away

from the balance main body by means such as underhook

weighing.

□ Weighing errors may occur if there is a difference between the

ambient temperature and temperature of the sample (and the

Magnetic

material

container). For example, when the room temperature is 20 °C,

convection occurs around a flask that is 40 °C and the balance

displays a value lighter than the actual weight. Before weighing

the sample and the container, try to acclimatize them to the

ambient temperature.

□ Perform the weighing operation carefully and quickly. If

Convection

40 C

20 C

measurement takes a long time, error-inducing factors will

increase due to changes in temperature and humidity in the

weighing chamber, air turbulence or reaction/humidity absorption

by the sample.

□ Do not leave the sample on the weighing pan for an extended

period of time. If a sample is left on the weighing pan for a long

time, the measured value will change due to deviation from the

zero point caused by environmental changes or due to creep

phenomenon.

□ When placing a sample on the weighing pan, do not drop it, or do

not place a sample greater than the balance weighing capacity.

Place the sample in the center of the weighing pan.

□ When pressing keys, do not press with a sharp object such as a

pen. Instead, press the center of the key with your finger.

□ Be sure to press the RE-ZERO key before weighing in order

to eliminate measurement errors.

□ Measurement results include error from air buoyancy. The

buoyancy of air varies depending on the sample volume,

atmospheric pressure, temperature and humidity. Correct the

buoyancy for the most precise measurement.

□ It is advisable to use the standard accessory display protection

cover in order to prevent foreign substances such as powder,

liquid and metal pieces from entering the balance.

GX-AWP/GF-AWP series

□ The balance is dustproof and waterproof, and the case is highly airtight. Therefore, for example,

minute pressure fluctuations in the chamber caused by opening and closing the door may cause

instability of the display. Before weighing, allow the pressure fluctuations to settle.

□ If water droplets or powder remains on the waterproof diaphragm and the pan support boss, the

performance of the balance may be impaired. Please clean the balance before using it.

□ If the waterproof diaphragm is deformed due to overload, etc., the weighing value may become

unstable until the deformation subsides.

16

Page 17

2-4 Precautions After Use

□ Avoid mechanical shock to the balance.

□ Do not disassemble the balance. Contact the local A&D dealer if the balance needs service or

repair.

□ Do not use organic solvents to clean the balance. Clean the balance with a lint free cloth that is

moistened with warm water and a mild detergent.

□ Avoid dust and water so that the balance weighs correctly. Protect the internal parts from liquid

spills and excessive dust.

□ The GX-AWP/GF-AWP series is dustproof and waterproof, but it cannot withstand water pressure

due to submersion and the like.

2-5 Power Supply

□ When the AC adapter is connected, the balance is in the standby mode if the standby indicator is

on. This is a normal state and does not harm the balance. For accurate weighing, keep the AC

adapter connected to the balance and AC power unless the balance is not to be used for a long

period of time. Please warm up the balance for at least 30 minutes (one hour for 0.0001g models).

17

Page 18

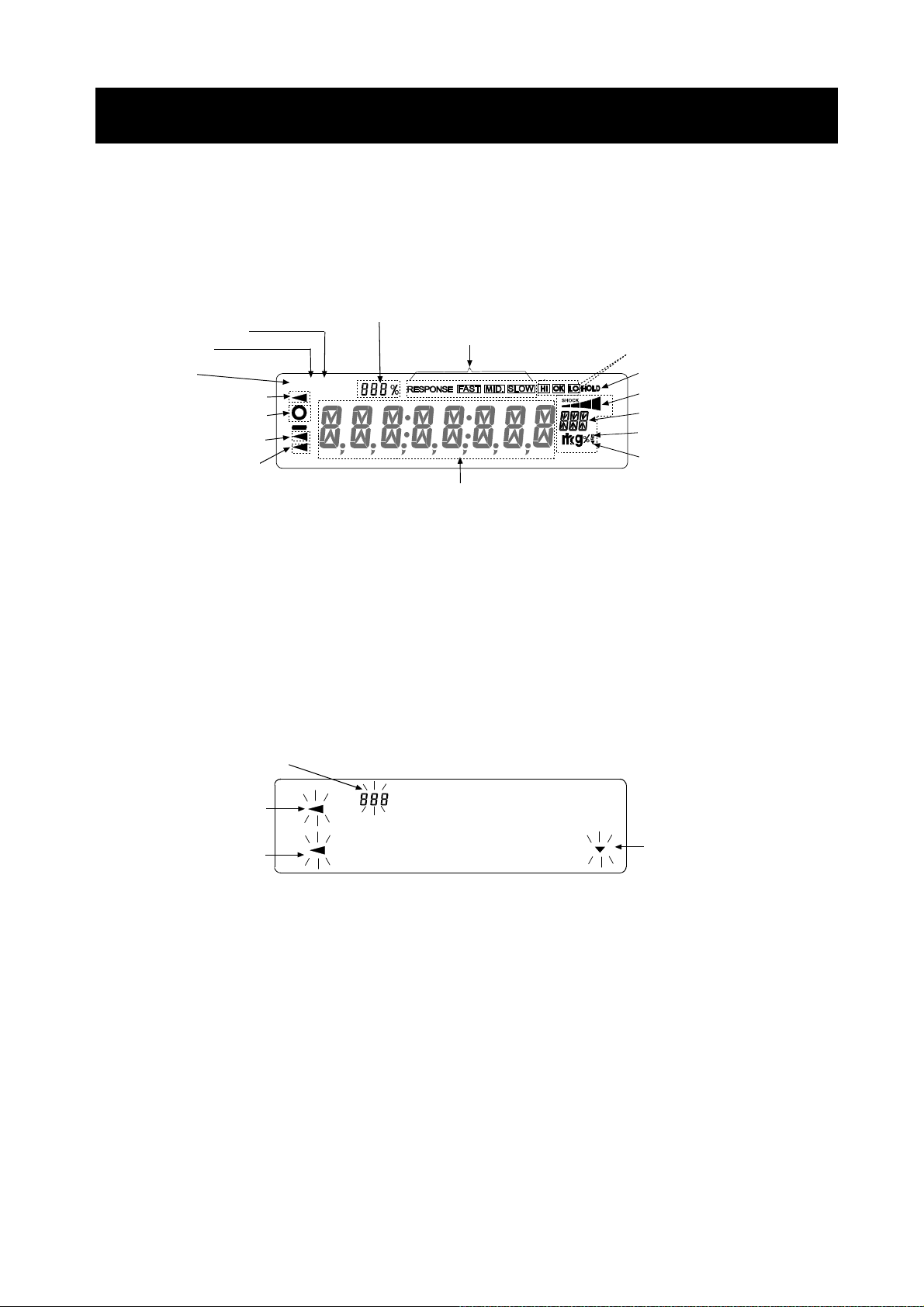

3. Display Symbols And Key Operation

r

A

r

r

Display symbols

Preset tare mark

Gross mark

Net mark

Processing indicato

Stabilization indicato

USB connecting mark

Standby indicator

Number of statistical data

(Statistical calculation mode)

Displays the weight data relative to the weighing

capacity, in percentage, in weighing mode

(Capacity indicator)

NET G PT

Displays weighing value, stored data, and item name

Blinking display contents

Response indicators

Comparator indicators

nimal weighing mark

Shock indicators

Unit display

Gross zero mark

Interval output mode

standby indicator

Data number being displayed

Processing indicato

Automatic sensitivity

adjustment notice

Interval output mode

active indicator

18

Page 19

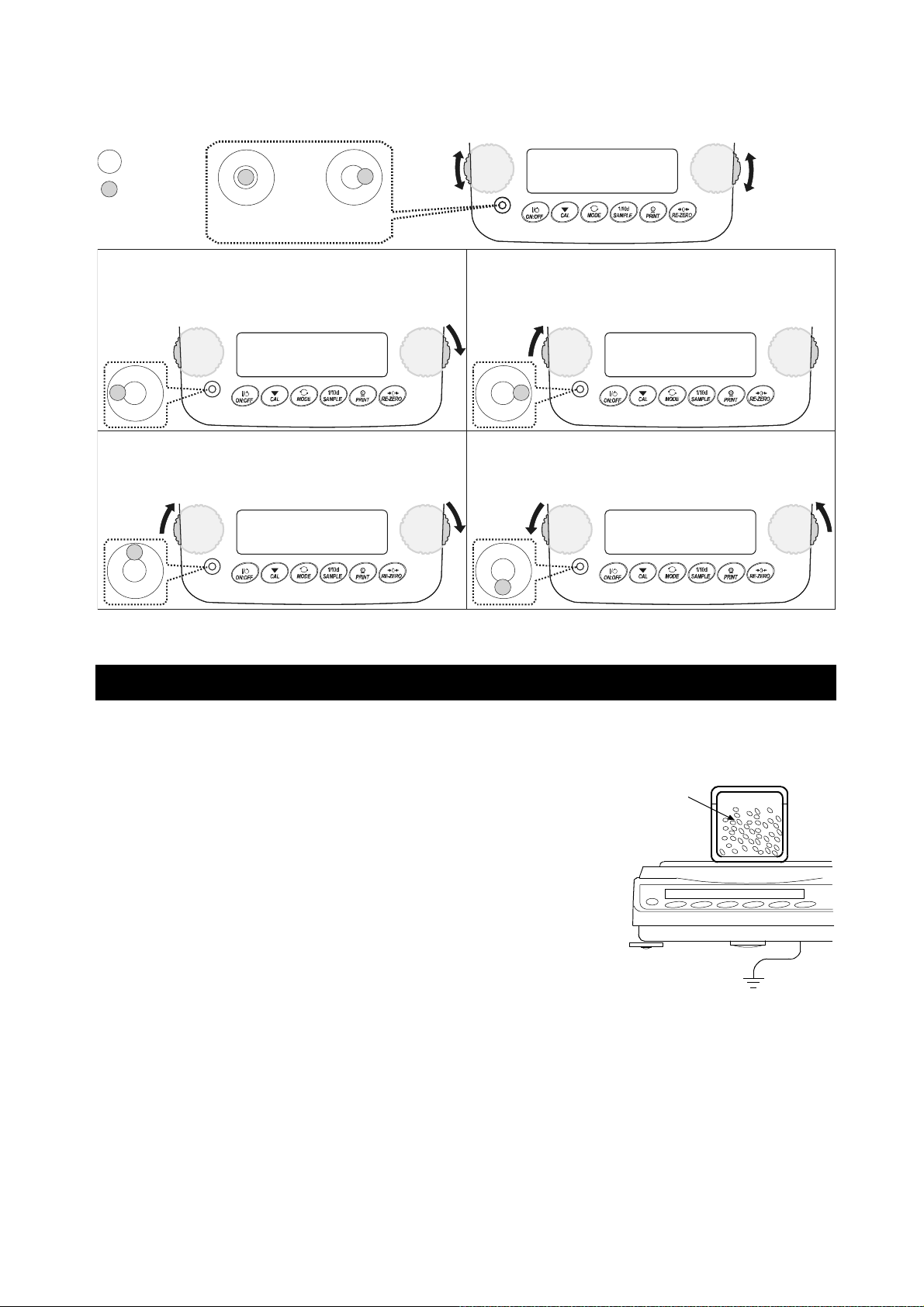

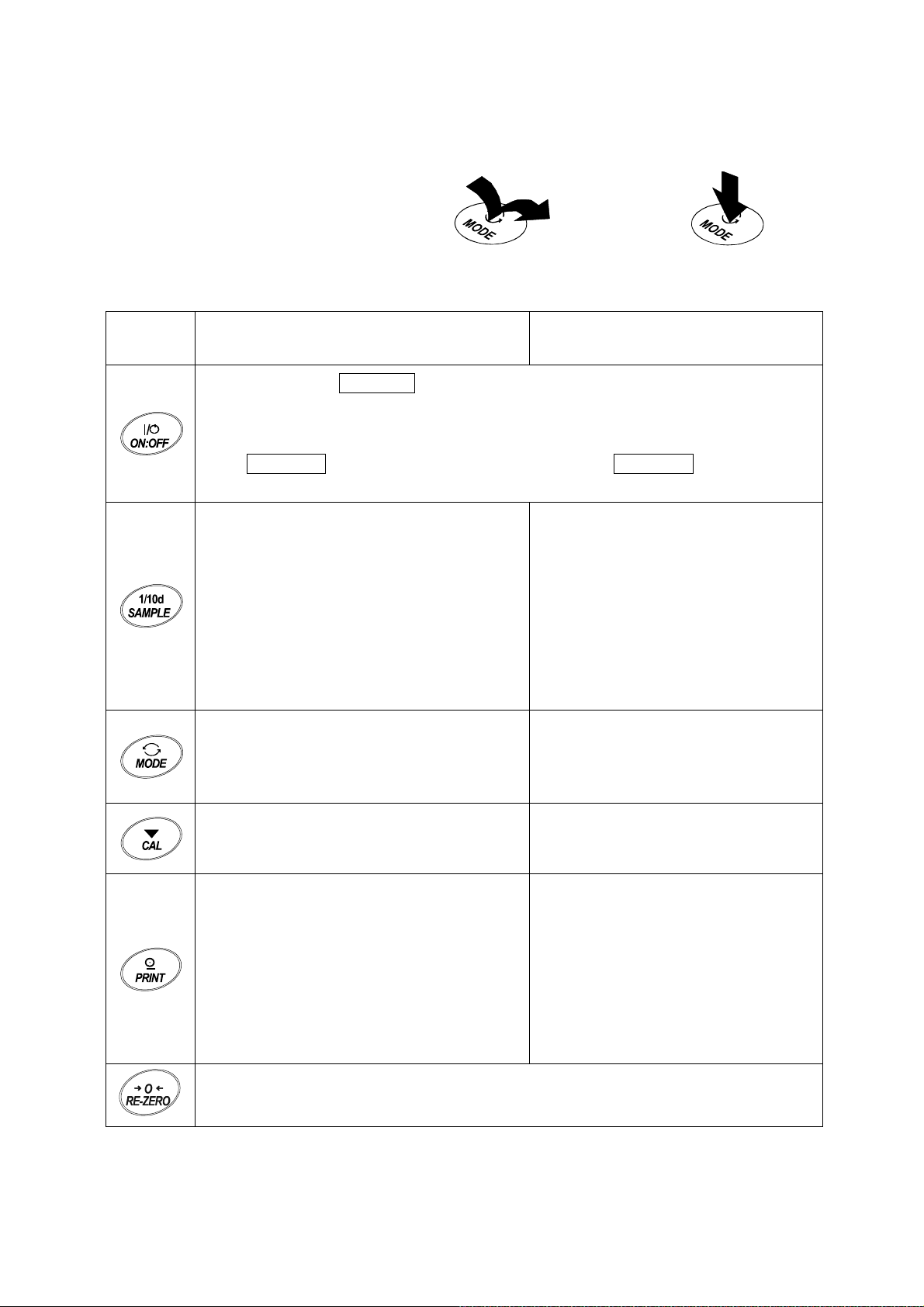

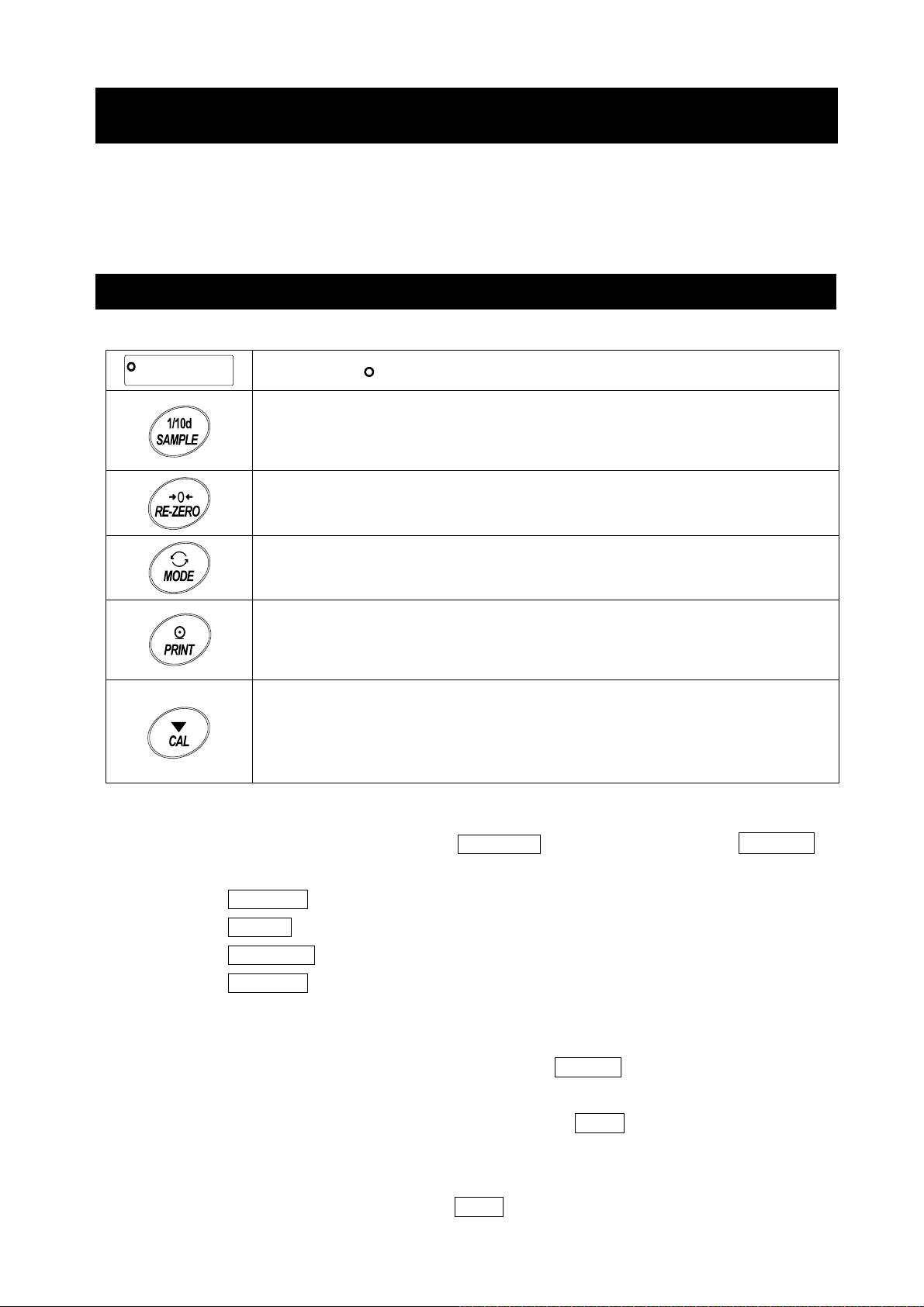

Key operation

Key operations affect how the balance functions. Normal key operation during measurement is “Press

and release the key immediately” or “Press the key”. Please do not “Press and hold the key (for 2

seconds)” unless required.

Press the key Press and hold the key

Key

When pressed and released

Turns the display ON:OFF . The standby indicator is displayed when the display is

turned off. The weighing mode is enabled when the display is turned on.

When the password function is enabled, the password input display will be

displayed. Refer to "19-4 How to Input The Password At The Start Of Weighing"

This ON:OFF key is available anytime. Pressing the ON:OFF key during

operation will interrupt operation and turn the display OFF. *

In the weighing mode, turns the digit for

readability on and off.

In the counting or percent mode, enters the

sample storing mode.

(Press and release the key immediately.) for 2 seconds.

When pressed and held

(for 2 seconds)

Enters the function table mode.

Please refer to "9. Function Table".

Runs the repeatability check

function when pressed and held for

another 2 seconds after the

function table menu is displayed.

(GX-AE/GX-A/GX-AWP series

only)

Please refer to "20. Repeatability

Check Function".

Switches the weighing units stored in the

function table. Refer to “4. Weighing”.

Displaying of the unit mg is available for

0.0001g models only.

Performs sensitivity adjustment of the

balance using the internal mass.

(GX-AE/GX-A/GX-AWP series)

Stores the weighing data in memory or

outputs to a printer or personal computer

depending on the function table settings.

(Factory setting = output)

Sets the display to zero.

* When the "Gross net tare function" is selected, the display is turned off by pressing and holding

(for 2 seconds). Please refer to "14. Gross Net Tare Function".

Please refer to "6-2 Self Check

Function/ Automatic Setting Of

Minimum Weighing Value by ECL".

Displays other items of the sensitivity

adjustment menu.

Enters mode to change the unit mass

registration number in counting

mode.

By changing the function table:

Outputs "Title block" and "End

block" for GLP, GMP report.

Displays the data memory menu.

Enters mode for reading density

number in flow measurement.

19

Page 20

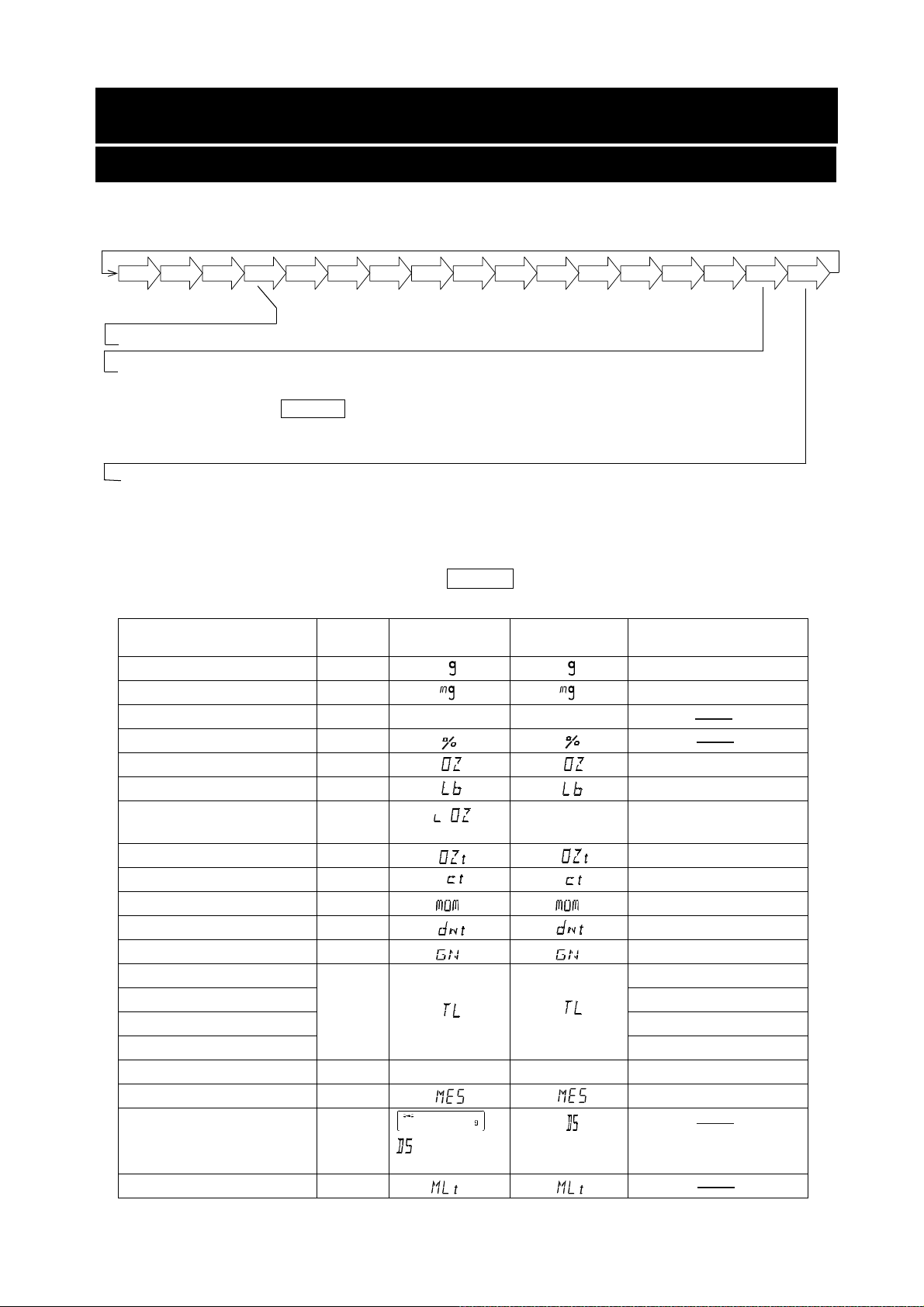

4. Weighing

4-1 Units

With the GX-AE/GX-A/GF-A series balance, the following weighing units and weighing modes are available:

Note: The unit "mg" is available for the 0.0001g models only. "mg" is displayed after "g" on 0.0001g models.

g

mg

PC

Pct OZ

Lb

L

OZ

OZt

Counting mode

Percent mode

Density mode (To use this mode, it must be stored in the function table as described on page

23. For details about this mode, refer to "18. Density (Specific Gravity) Measurement". To select

this mode, press the MODE key until the processing indicator blinks with the unit "g"

displayed. "DS" appears only when the density value is displayed.)

Programmable-unit (No unit displayed. For details, refer to "17. Programmable-Unit".)

A unit or mode can be selected and stored in the function table as described on page 23.

If a weighing mode (or unit of weight) has been turned off, that mode or unit will be missing in the

sequence. Tael has four varieties, one of which can be selected and installed at the factory.

To select a unit or mode for weighing, press the MODE key.

mom

ct

dwt

GN

TL

tol

MES

DS

MLT

For details about the units and modes, see the table below:

Name (unit, mode) Abbrev. Display

Function table

(Storing mode)

Conversion factor

1 g =

Gram g 1 g

Milligram mg 0.001 g

Counting mode PCS

pC5 pC5

Percent mode %

Ounce (Avoir) OZ 28.349523125 g

Pound Lb 453.59237 g

Pound/Ounce L OZ l0

Troy Ounce OZt 31.1034768 g

Metric Carat ct 0.2 g

Momme mom 3.75 g

Pennyweight dwt 1.55517384 g

Grain (UK) GN

Tae l (HK general, Singapore)

Tael (HK jewelry) 37.429 g

TL

37.7994 g

Tael (Taiwan) 37.5 g

Tael (China) 31.25 g

Tola (India) tol

to1

Messghal MES 4.6875 g

Density mode

(See note below)

DS

is used to

show the density.

Programmable-unit (Multi-unit) M LT

Note: The blinking processing indicator with “g” indicates that the density mode is selected.

1Lb=16 oz,

1 oz=28.349523125 g

0.06479891 g

11.6638038 g

to1

20

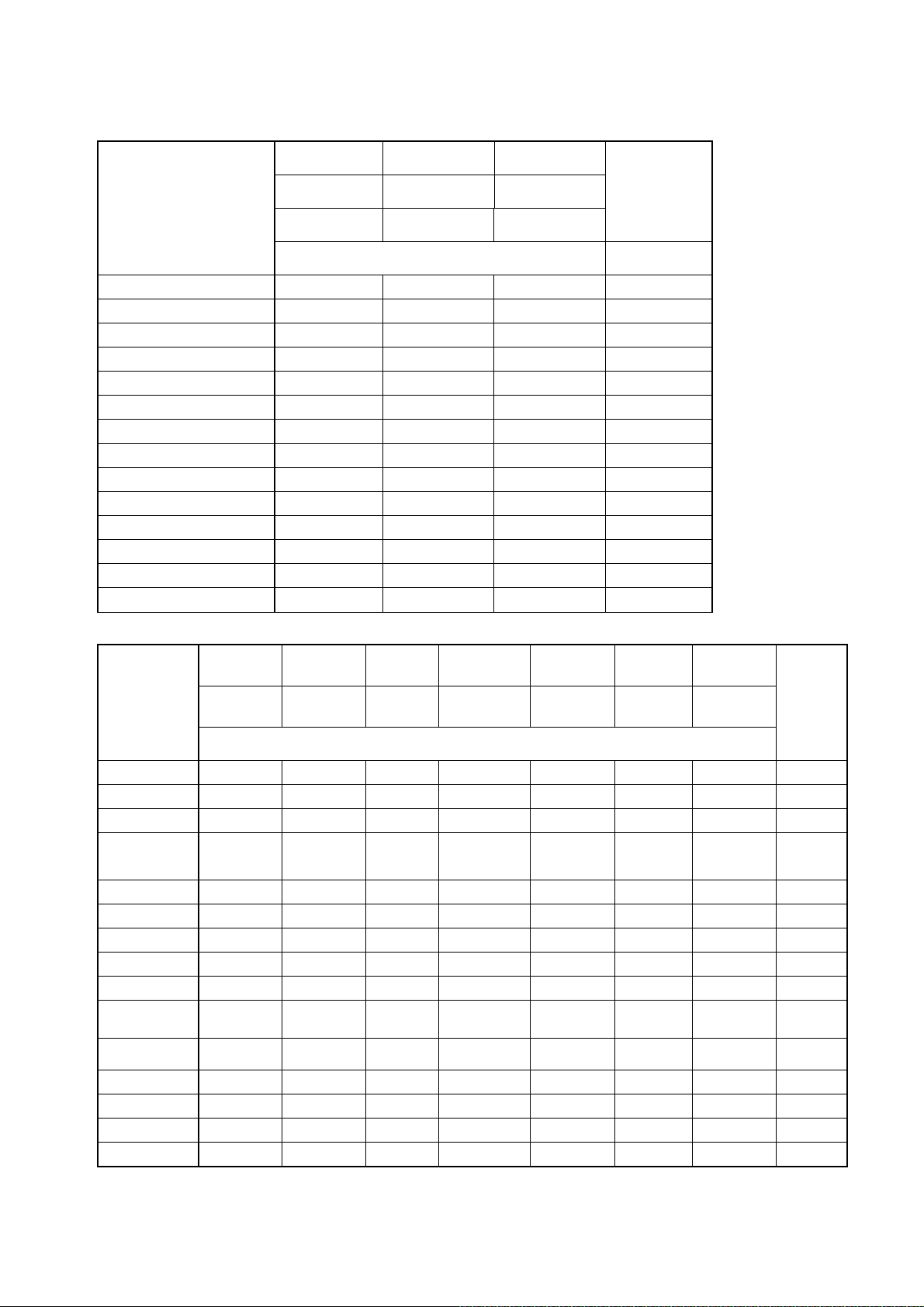

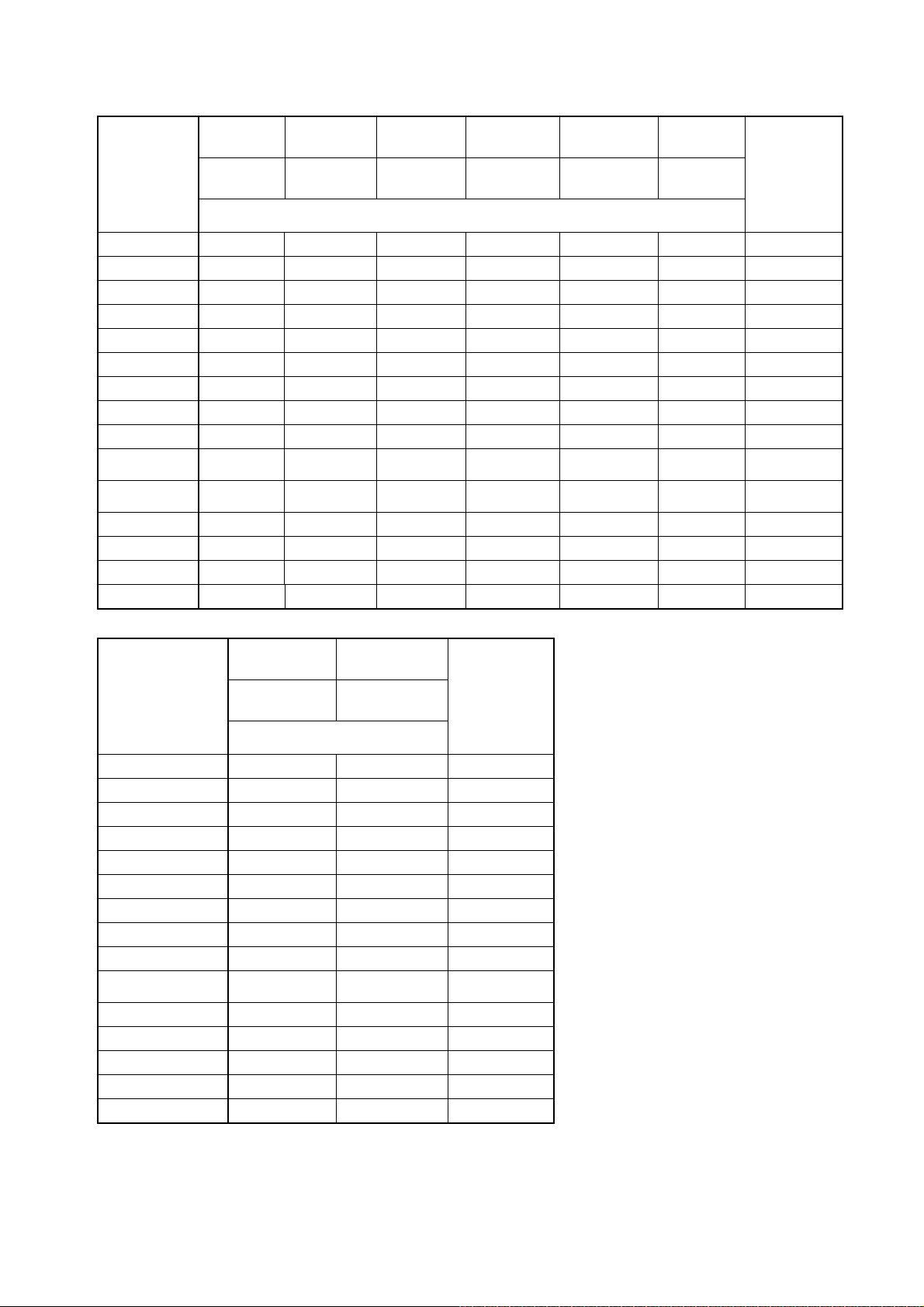

Page 21

The tables below indicate the weighing capacity and the readability for each unit, depending on the

(

)

balance model.

GX-124AE GX-224AE GX-324AE

Readability GX-124A GX-224A GX-324A

Unit

GF-124A GF-224A GF-324A

Gram

Milligram

Ounce (

Avoir

Troy Ounce

Metric Carat

Momme

Pennyweight

Grain (UK)

Tael (

HK general, Singapore

Tael (

HK jewelry

Tael (

Taiwan

Tael (

China

Tola (

India

Messghal

Unit

Capacity

122 220 320 0.0001

122000 220000 320000 0.1

)

)

)

)

)

)

GF-123A

GX-203A

GX-203AWP

GF-203A

GF-203AWP

4.30 7.05 10.50 0.00001

3.92 6.43 9.64 0.00001

610 1000 1500 0.001

32.5 53.3 80.0 0.0001

78.4 128 192 0.0001

1882 3086 4629 0.002

3.22 5.29 7.93 0.00001

3.25 5.34 8.01 0.00001

3.25 5.33 8.00 0.00001

3.90 6.40 9.60 0.00001

10.4 17.1 25.7 0.00001

26.0 42.6 64.0 0.0001

GX-303A

GF-303A

GX-403A

GX-403AWP

GF-403A

GF-403AWP

GX-603A

GX-603AWP

GF-603A

GF-603AWP

GX-1003A GX-1603A

GF-1003A GF-1603A

Readability

Gram

Ounce (

Avoir

Pound

Pound/Ounce

Troy Ounce

Metric Carat

Momme

Pennyweight

Grain (UK)

Tael (

HK general,

Singapore

)

Tael

HK jewelry

Tael (

Taiwan

Tael (

China

Tola (

India

Messghal

Capacity

122 220 320 420 620 1100 1620

)

)

)

)

4.30 7.76 11.28 14.81 21.86 38.80 57.14

0.268 0.485 0.705 0.925 1.366 2.425 3.571

0Lb 4.30oz 0Lb 7.76oz

3.92 7.07 10.28 13.50 19.93 35.36 52.08

610 1100 1600 2100 3100 5500 8100

32.5 58.6 85.3 112.0 165.3 293.3 432.0

78.4 141 205 270 398 707 1041

1882 3395 4938 6481 9568 16975 25000

3.22 5.82 8.46 11.11 16.40 29.10 42.85

3.25 5.87 8.54 11.22 16.56 29.38 43.28

3.25 5.86 8.53 11.20 16.53 29.33 43.20

3.90 7.04 10.24 13.44 19.84 35.20 51.84

10.4 18.8 27.4 36.0 53.1 94.3 138.8

26.0 46.9 68.2 89.6 132.2 234.6 345.6

0Lb

11.28oz

0Lb 14.81oz 1Lb 5.86oz 2Lb 6.80oz 3Lb 9.14oz

0.001

0.00005

0.000005

0.01oz

0.00005

0.005

0.0005

0.001

0.02

0.00005

0.00005

0.00005

0.00005

0.0001

0.0005

21

Page 22

(

)

)

)

Unit

GF-1202A

GX-2002A

GX-2002AWP

GF-2002A

GF-2002AWP

GX-3002A

GF-3002A

GX-4002A

GX-4002AWP

GF-4002A

GF-4002AWP

GX-6002A

GX-6002AWP

GF-6002A

GF-6002AWP

GX-10002A

GF-10002A

Capacity

Gram

1220 2200 3200 4200 6200 10200 0.01

Ounce (

Avoir

)

43.0 77.6 112.8 148.1 218.6 359.7 0.0005

Pound

2.68 4.85 7.05 9.25 13.66 22.48 0.00005

Pound/Ounce

Troy Ounce

Metric Carat

Momme

Pennyweight

Grain (

Tael

HK general,

Singapore

Tael (

HK

jewelry

Tael (

Taiwan

Tael (

China

Tola (

India

Messghal

2Lb 11.03oz 4Lb 13.60oz 7Lb 0.87oz 9Lb 4.15oz 13Lb 10.69oz 22Lb 7.79oz 0.01oz

39.2 70.7 102.8 135.0 199.3 327.9 0.0005

6100 11000 16000 21000 31000 51000 0.05

325 586 853 1120 1653 2720 0.005

784 1414 2057 2700 3986 6558 0.01

UK)

18827 33951 49383 64815 95680 157410 0.2

)

32.5 58.6 85.3 112.0 165.3 272.0 0.0005

)

39.0 70.4 102.4 134.4 198.4 326.4 0.0005

)

104 188 274 360 531 874 0.001

32.2 58.2 84.6 111.1 164.0 269.8 0.0005

32.5 58.7 85.4 112.2 165.6 272.5 0.0005

260 469 682 896 1322 2176 0.005

Unit

GX-6001A

GX-6001AWP

GF-6001A

GF-6001AWP

GX-10001A

GF-10001A

Readability

Readability

Gram

Ounce (

Avoir

Pound

Pound/Ounce

Troy Ounce

Metric Carat

Momme

Pennyweight

Grain (UK)

Tael (

HK general,

Singapore

Tael (

HK jewelry

Tael (

Taiwan

Tael (

China

Tola (

India

Messghal

Capacity

6200 10200 0.1

)

13Lb 10.69oz 22Lb 7.79oz 0.01oz

)

)

)

)

218 359 0.005

13.6 22.4 0.0005

199 327 0.005

31000 51000 0.5

1653 2720 0.05

3986 6558 0.1

95680 157410 2

164.0 269.0 0.005

165.0 272.0 0.005

165.0 272.0 0.005

198.0 326.0 0.005

531.0 874.0 0.01

1322 2176 0.05

22

Page 23

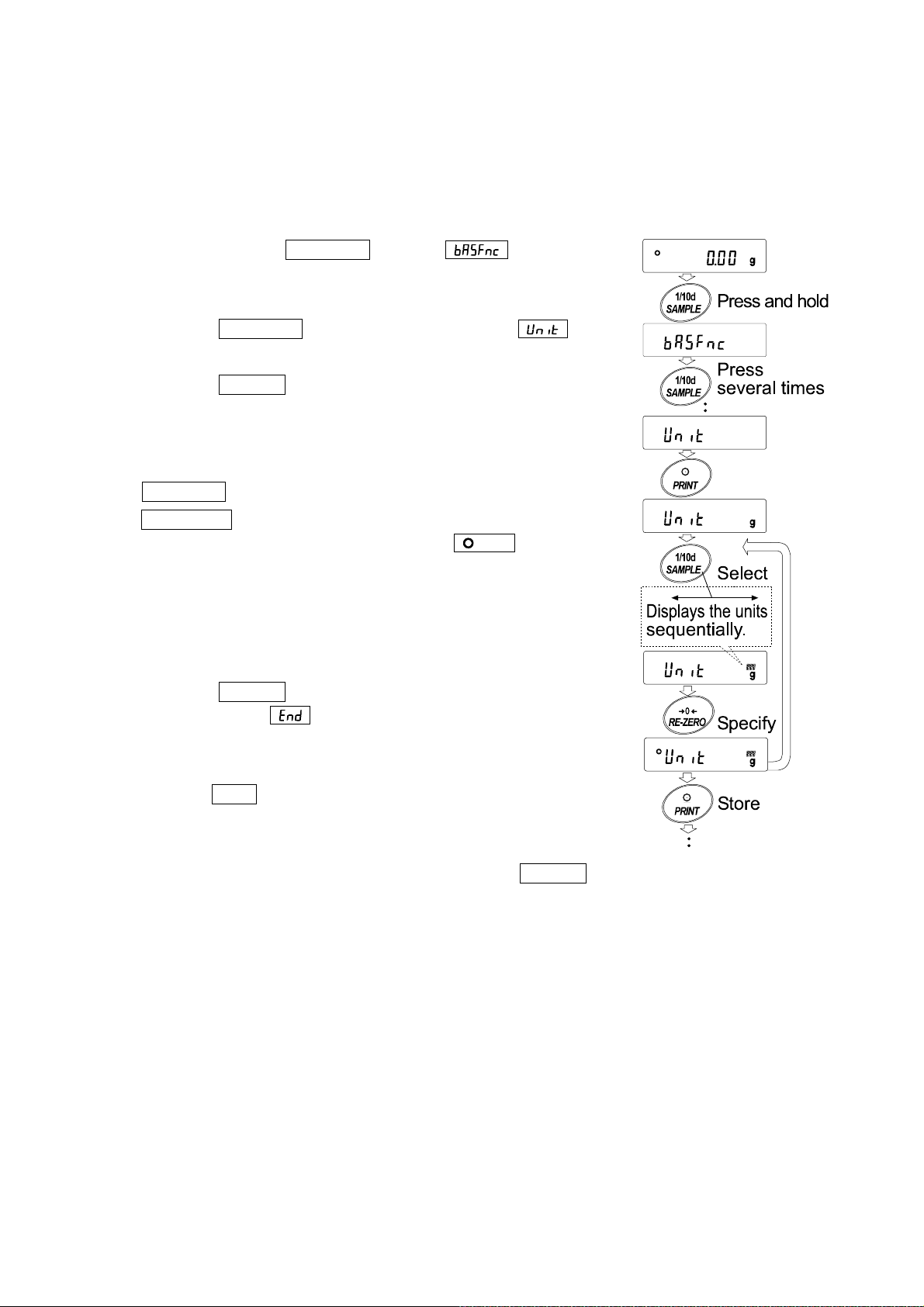

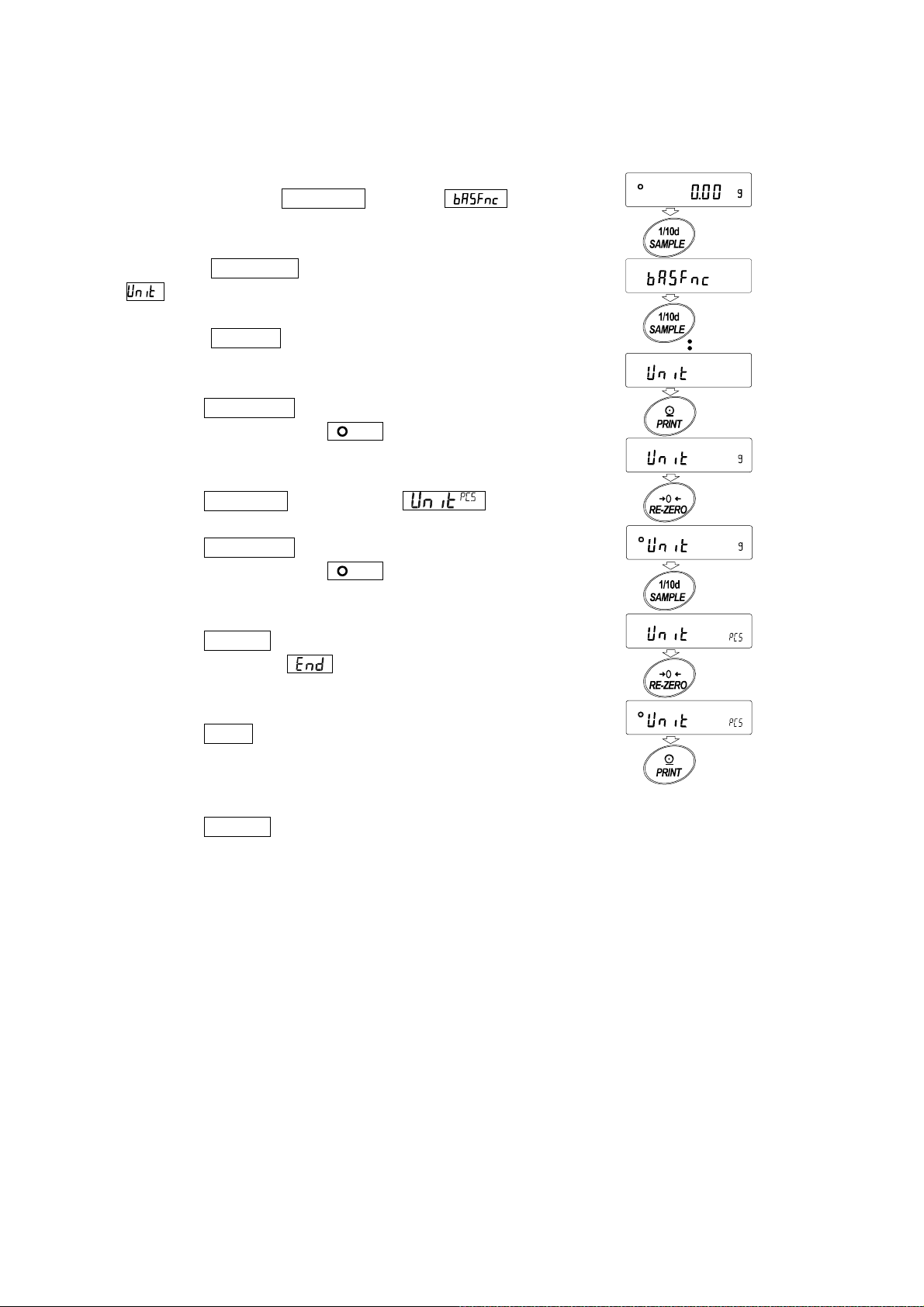

Storing Units

The units or modes can be selected and stored in the function table. The sequence of displaying the

units or modes can be arranged to fit the frequency of use.

The units are stored in non-volatile memory, even if the AC adapter is removed.

Select a unit or mode and arrange the sequence of display as follows:

1. Press and hold the SAMPLE key until of the

function table is displayed, then release the key.

2. Press the SAMPLE key several times to display

3. Press the PRINT key to enter the unit selection mode.

4. Specify a unit or mode in the order to be displayed using

the following keys.

SAMPLE key ꞏꞏꞏꞏꞏꞏ Displays the units sequentially.

RE-ZERO key ꞏꞏꞏꞏ Specifies a unit or mode. The

stabilization indicator

appears when the displayed unit or

mode is specified.

If the key is pressed in units already

selected, the stability mark disappears.

5. Press the PRINT key to store the units or modes. The

balance displays and then displays the next menu

of the function table.

.

6. Press the CAL key to exit the function table. Then the

balance returns to the weighing mode with the selected unit.

7. To select other unit or mode for weighing, press the MODE key.

23

Page 24

Unit setting example

The example below sets the units in the order with "g" (gram) as the first unit followed by pcs

(counting mode).

1. Press and hold the SAMPLE key until of

the function table is displayed, then release the key.

2. Press the SAMPLE key several times to display

.

3. Press the PRINT key to enter the unit selection

mode.

4. Press the RE-ZERO key to specify the unit of "g"

The stabilization indicator appears when the

unit is specified.

5. Press the SAMPLE key to display

6. Press the RE-ZERO key to specify the unit of pcs.

The stabilization indicator appears when the

unit is specified.

7. Press the PRINT key to store the units.

The balance displays and then displays the next

menu item of the function table.

8. Press the CAL key to exit the function table. Then

the balance returns to the weighing mode with g, the

unit selected first.

9. Press the MODE key to switch between g and pcs

(gpcs).

.

Press and hold

Press

several times

Specify

Select

Specify

Store

24

Page 25

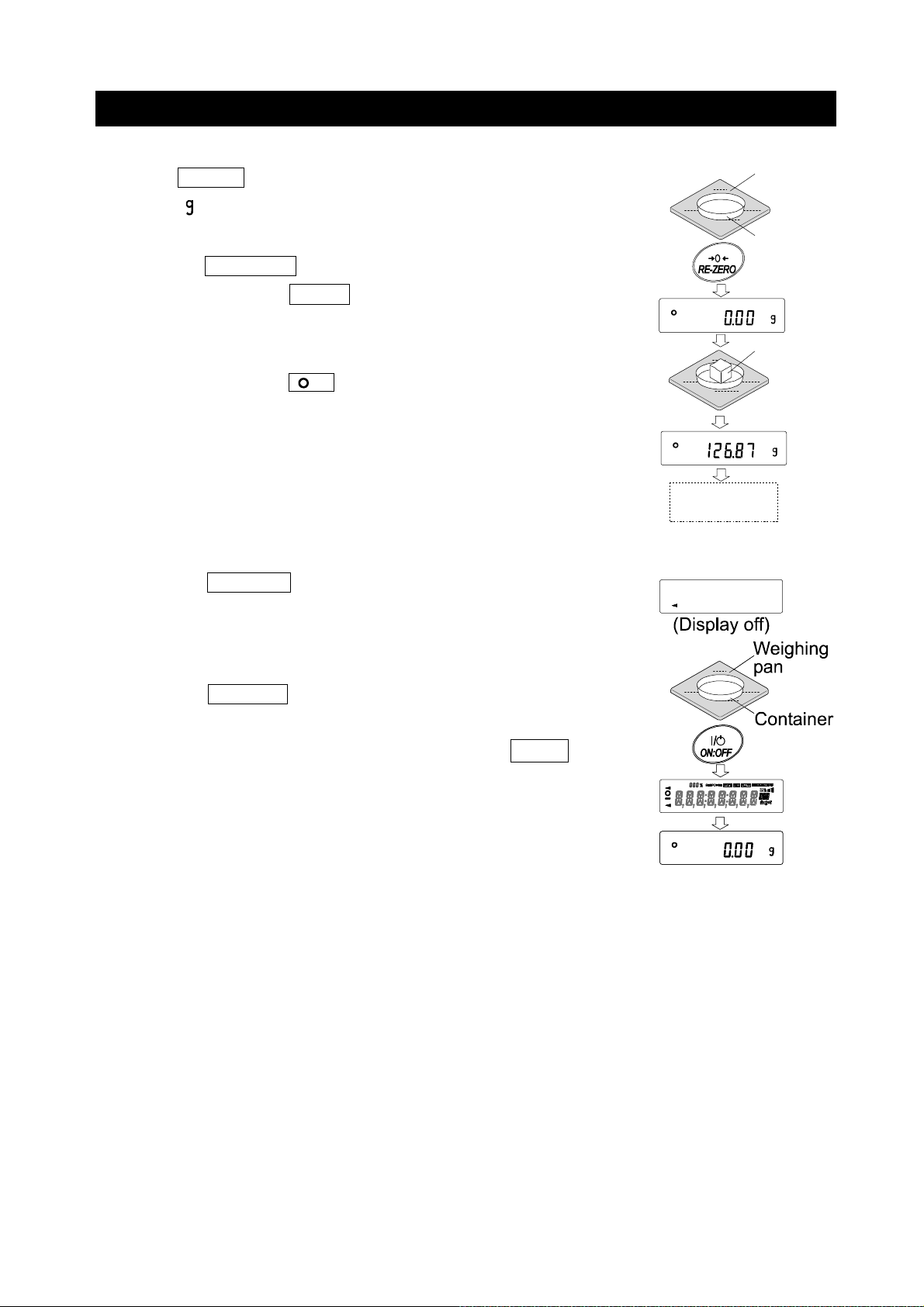

4-2 Basic Operation

1. Press MODE key to select a unit.

Here, “ ” is selected as an example.

2. Place a container on the weighing pan if necessary.

Press the RE-ZERO key to cancel the weight (tare).

The balance displays 0.00

g

. (The decimal point position

depends on the balance model.)

3. Place a sample on the pan or in the container. Wait for the

stabilization indicator

to be displayed. Read the

value.

4. Remove the sample and container from the pan.

Note

□ Press the SAMPLE key to turn on or off the digit for the

Weighing

pan

Container

Sample

Remove the

sample

readability.

□ The weighing data can be stored in memory. For details, refer

to “11. Data Memory”.

□

When the ON:OFF key is pressed with a container placed

on the weighing pan and weighing is started, the balance

automatically cancels the weight (tare) and displays

0.00 g

.

25

Page 26

About the operation at when power is turned on

g

P

P

P

P

P

The balance will determine the reference zero point when the ON:OFF key is pressed to enter the

weighing mode.

Depending on the load condition at that time, it will automatically judge whether to perform zero or tare

operation. The condition for determining which is used is "power on zero range", and when power on

zero range is exceeded, the tare subtraction operation is performed.

About re-zero operation

By pressing the RE-ZERO key, the display can be changed to zero.

Re-zero with the RE-ZERO key will automatically determine whether zero or tare operation is

performed.

The condition for determining which is used is "zero range", and when zero range is exceeded, the tare

subtraction operation is performed.

About measurement range

For the balance, the range that can be weighed is determined by model.

The total amount (net amount + tare quantity) up to the maximum display of each model is displayed,

and when the maximum display is exceeded, E is displayed to indicate that the weighing range is

exceeded. When in excess in negative, -E is displayed.

Model

GX-124AE,

GX-124A,

GX-224AE,

GX-224A,

GX-324AE,

GX-324A,

GF-123A

GX-203A

GX-203AW

GX-303A GF-303A Approx.±6g

GX-403A

GX-403AW

GX-603A

GX-603AW

GX-1003A GF-1003A Approx.±20g

GX-1603A GF-1603A Approx.±32g

GF-1202A

GX-2002A

GX-2002AW

GX-3002A GF-3002A Approx.±60g

GX-4002A

GX-4002AWP,

GX-6002A

GX-6002AWP,

GX-10002A GF-10002A Approx.±200g

GX-6001A

GX-6001AW

GX-10001A GF-10001A Approx.±200g

GF-124A

GF-224A

GF-324A

GF-203A

,

GF-203AWP

GF-403A

,

GF-403AWP

GF-603A

,

GF-603AWP

GF-2002A

,

GF-2002AWP

GF-4002A

GF-4002AWP

GF-6002A

GF-6002AWP

GF-6001A

,

GF-6001AWP

Power on zero

ran

e

Approx.±50g

Approx.±100g

Approx.±1kg

Approx.±1kg

Zero range -E display range

Approx.±2g

Approx.±4g

Approx.±6g

Approx.±2g

Approx.±4g

Approx.±8g

Approx.±12g

Approx.±20g

Approx.±40g

Approx.±80g

Approx.±120g

Approx.±120g

Approx.-50g or less

Approx.-100g or less

Approx.-1kg or less

Approx.-1kg or less

26

Page 27

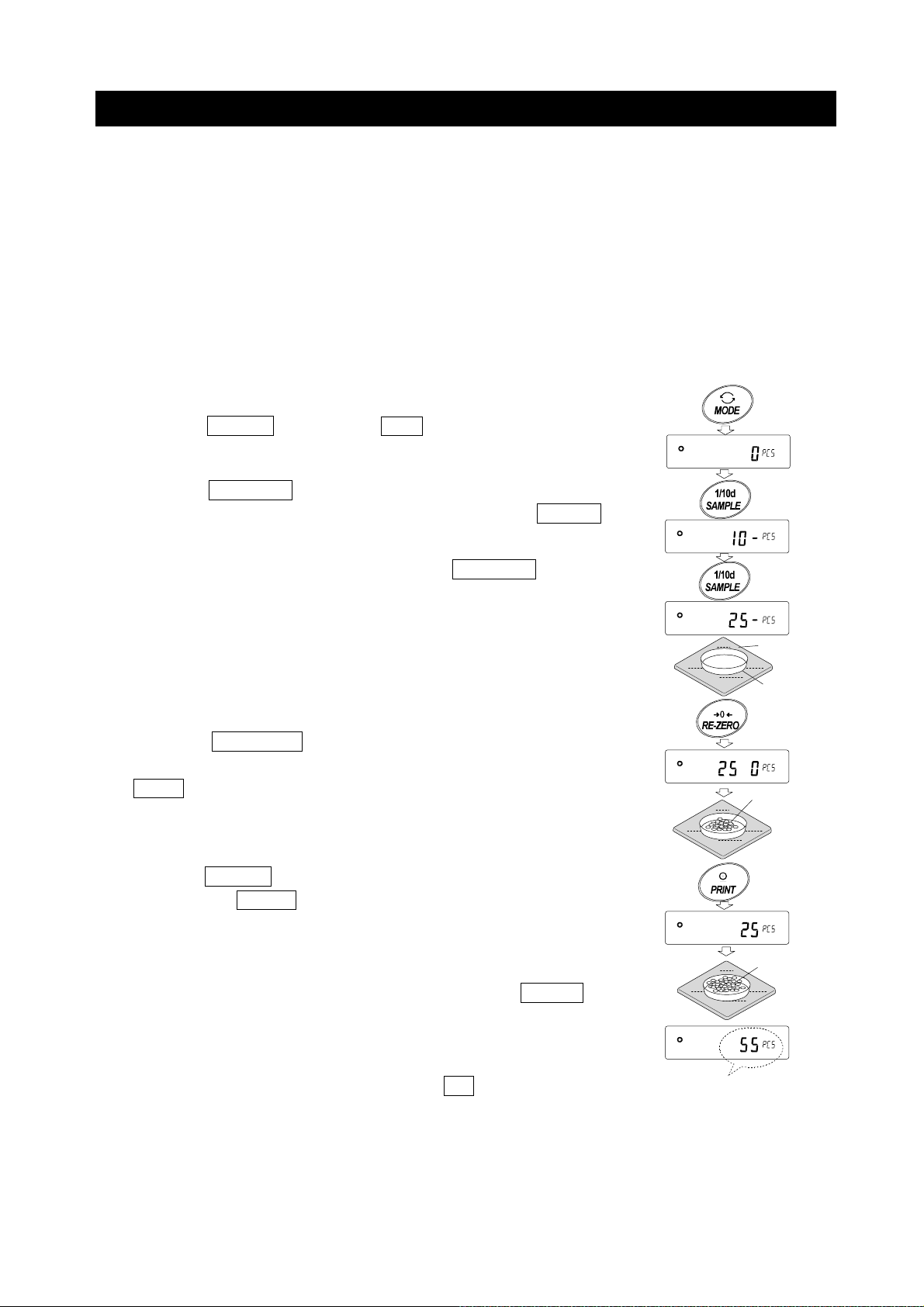

4-3 Counting Mode (PCS)

This is the mode to check the number of pieces. Based on the unit mass of the reference sample

(weight of one piece), the balance calculates and displays how many pieces are weighed. The smaller

the variation in the unit mass, the more accurate the count (the number of pieces). In addition, the ACAI

function described later can be used to further improve the counting accuracy while weighing.

Note

* It is recommended that the unit mass (weight of one piece) of the sample to be weighed should

be at least 10 times the readability (g) of the balance.

* If there is a large variation in the sample unit mass values, it may not be possible to count

accurately.

* If counting error is large, frequent use of the ACAI function is advisable. As one of the other

methods, try dividing the measurement into multiple times.

Selecting the counting mode

1. Press the MODE key to select PC5 ( PC5 = unit)

Storing a sample unit mass

2. Press the SAMPLE key to enter the sample unit mass storing

mode. Note that even in the storing mode, pressing the MODE.

key switches to the next mode.

3. To select the number of samples, press the SAMPLE key

several times. (1025501005 pieces)

Note

Since the sample unit mass is usually considered to have some

variation, the larger the number of samples for registration, the

more accurate the count can be.

4. Place a container on the weighing pan, if necessary.

Press the RE-ZERO key to cancel the weight (tare). The

number specified in step 3 appears.

25.0 is displayed if 25 is selected in step 3.

5. Place the specified number of samples on the pan. In this

example, 25 pieces.

6. Press the PRINT key to store the unit mass. The count display

appears. (e.g. 25 PC5 is displayed with 25 pieces.)

Note

* The balance prompts to add more samples if it judges that the

loaded sample is too light (resulting in large counting error).

Add the displayed number of samples and press the PRINT

key again. When the unit mass is stored correctly, the counting

display appears.

* If the balance judges that the mass of the sample is too light to

be registered as the unit mass, it displays Lo .

* Registered unit mass is stored even when the power is turned off.

Weighing pan

Container

Sample

(25 pieces)

place

(The counting result)

Counting mode

7. Counting operation is now possible.

27

Page 28

Automatic Counting Accuracy Improvement (ACAI)

This function automatically improves the counting accuracy as the

number of samples increases. (Errors will be reduced as sample

weight variations are averaged.)

After registering the unit mass in step 6, proceed to step 8 below.

8. Add a few samples. Then the processing indicator turns on. (Three or more samples are required

in order to prevent errors. The processing indicator does not turn on if overloaded. Add as many

samples as the displayed number.)

9. Do not touch or move the samples on the pan while the processing indicator is blinking. (The

accuracy is being updated.)

10. The accuracy is updated after the processing indicator turns out. Each time this process is

repeated, the counting accuracy will improve further. The range of ACAI after exceeding 100 is not

predetermined. Add as many samples as the displayed number.

11. Remove all the samples used with ACAI from the pan and start counting work.

Note

□ Do not change units during ACAI processing.

Processing mark

Storing the unit mass

With the data memory function, up to 50 unit masses can be stored.

1. Set the function setting item "Data memory (

unit mass in counting mode (

Refer to "9. Function Table".

2. The selected unit mass registration number is displayed in

)".

)" to "Stores

Press and

hold

" ** ".

3. Press and hold the PRINT key for 2 seconds to go to the

mode for changing the unit mass registration number.

RE-ZERO key (+) Changes the registration number.

MODE key (-) ꞏꞏꞏꞏꞏꞏ Changes the registration number.

PRINT key ꞏꞏꞏꞏꞏꞏꞏꞏꞏ Confirms the displayed registration number.

CAL key ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ Cancels the displayed registration number.

4. Register the unit mass, if necessary. Multiple unit masses can be stored by registering them with

different unit mass registration numbers.

**: The unit weight registration number is displayed.

□

Note

□ Unit weight can be read by ″ UN:mm ″ command.

(mm corresponds to P01 to P50 with 01 to 50.)

For details about the communication, download "Communication manual" from our website

(https://www.aandd.jp) and refer to it.

□ The read unit mass can output by ″ ?UW″ command and can be changed by ″UW: ″

command.

Caution

□ ACAI is not applicable to the read unit mass.

28

Page 29

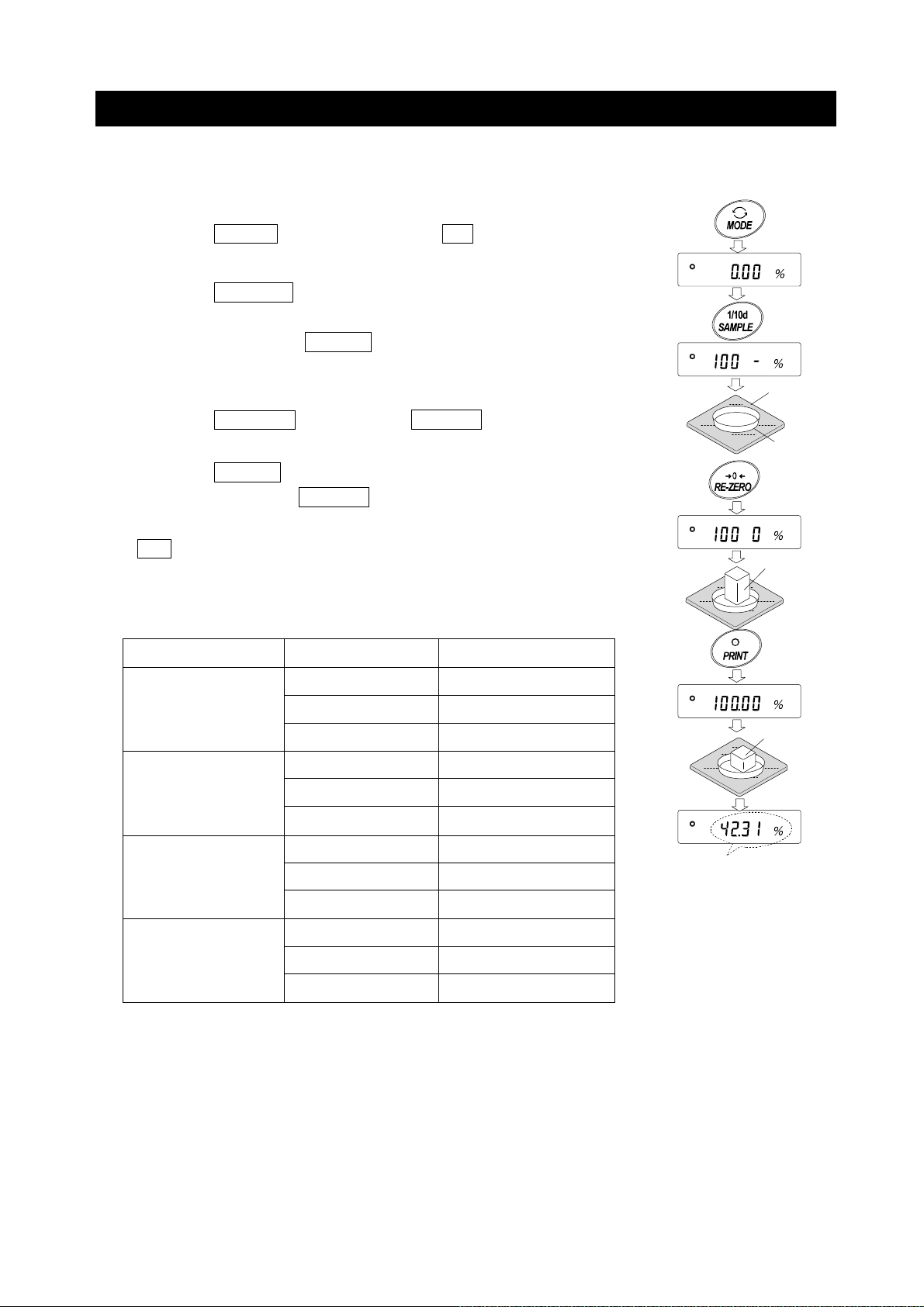

4-4 Percent Mode (%)

The percent mode displays the weighting value in percentage compared with a reference mass as

100%. This is useful for target weighing or sample variance check.

Selecting Percent Mode

1. Press the MODE key to select the unit % (percent mode).

Storing a Reference Mass as 100%

2. Press the SAMPLE key to enter the mode for storing a 100%

reference mass.

Note that pressing the MODE key switches from this mode to

the next mode.

3. Place a container on the weighing pan, if necessary.

Weighing pan

Press the

RE-ZERO key to display 100.00 % .

4. Place a sample of 100% reference mass on the pan/container.

5. Press the PRINT key to store the 100% reference mass.

The balance displays 100.00

%

.

Note

□ Lo appears if the balance judges that the sample is too light to

be registered as a 100% reference mass.

□ The decimal point position varies according to the 100% reference

mass.

Model 100% mass Decimal point position

0.0001g readability

0.001g readability

0.01g readability

0.0100g to 0.0999g

0.1000g to 0.9999g

1.0000g or more

0.100g to 0.999g

1.000g to 9.999g

10.000g or more

1.00g to 9.99g

10.00g to 99.99g

100.00g or more

1%

0.1%

0.01%

1%

0.1%

0.01%

1%

0.1%

0.01%

Container

Sample

(100%)

place

Display % of weighing object

0.1g readability

1.0g to 9.9g

10.0g to 99.9g

100.0g or more

1%

0.1%

0.01%

□ The stored reference mass is stored in non-volatile memory even if the AC adapter is removed.

Percentage weighing

6. Percentage weighing is now possible.

29

Page 30

4-5 Animal Weighing Mode (Hold Function)

This is the mode to weigh a moving object such as an animal, even when the display of the weighing

data fluctuates. The hold function allows the average weight of the animal to be displayed. To use

the hold function, set the function in the function table. Refer to "9. Function Table" and "9-3

Description Of The Class Environment Display" for details.

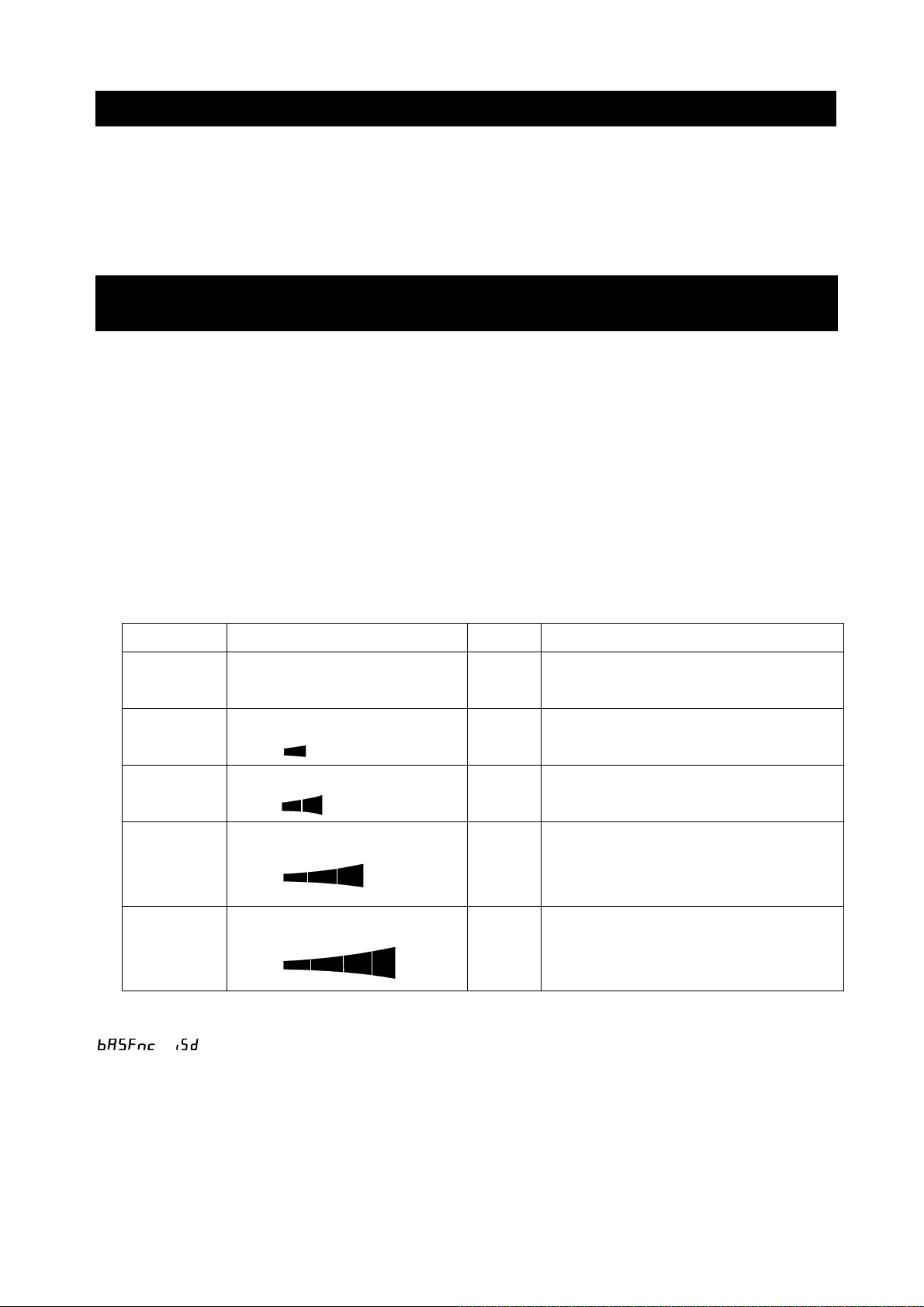

5. Impact Shock Detection Function

The GX-AE/GX-A/GF-A series has a function to detect impact shocks to the mass sensor section

and to display the impact level.

By lowering the impact level at the time of loading, it is possible not only to alleviate variation in the

weighing value but also to reduce the risk of failure of the mass sensor section.

Especially when incorporating the balance in a production line, etc. and weighing by means such as

an automated system, impact to the sensor may be applied greater than expected. When designing

automatic systems and the like, it is recommended that you minimize the impact level as much as

possible while checking the shock indicator.

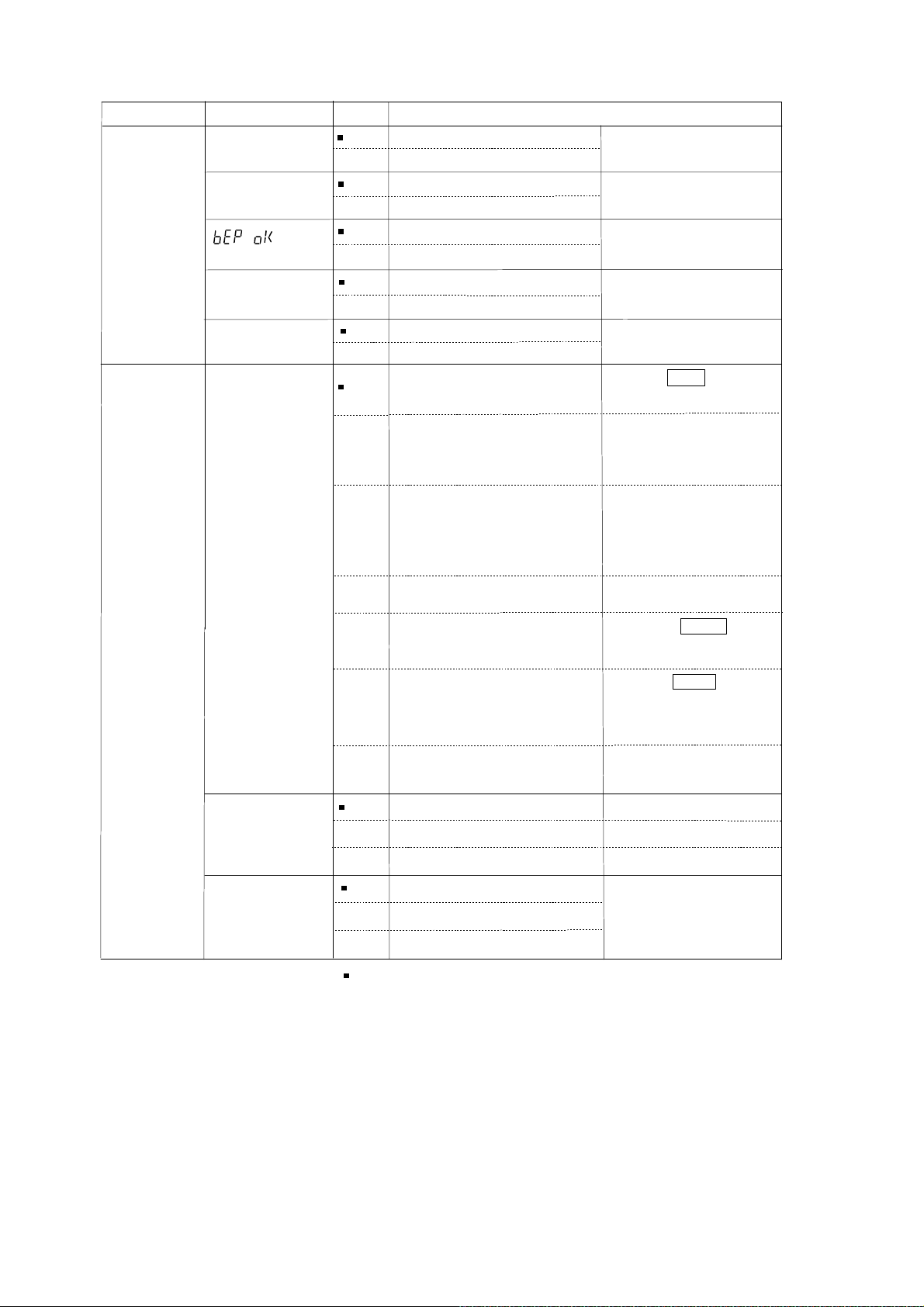

The shock indicator has 5 levels from level 0 to level 4.

Impact level Shock indicator Buzzer Contents

0 No indicator

SHOCK

1

SHOCK

2

SHOCK

3

SHOCK

4

With balance software version 1.300 or later, you can turn off the impact shock detection by setting

No

beeps

No

beeps

No

beeps

One

beep

Two

beeps

Safe

Caution

Caution:

Alleviate impact shocks

Warning:

Do not apply any more impact shocks

Danger:

Sensor may be damaged

/ to 0 in the function table. Even if the impact shock detection function is turned off, a

record is kept in the balance when there is a shock impact.

Note

□ Impact on the weighing sensor is not only that applied to the weighing pan when loaded, but also

may be impact applied from the table on which the balance is installed. The impact detection

function also works for impact coming from the table.

30

Page 31

5-1 Recording Impact History

Impacts of impact level 3 or higher are stored on the balance with data and time (up to 50 instances).

When the password lock function is ON (

when outputting the impact history. (Balance software version 1.211 or later.)

Note

□ If data instances exceeds 50, the stored data with the lowest impact level will be overwritten.

□ The stored impact history cannot be deleted.

□ Impact data where the balance is not energized (during transport, etc.) is not stored.

or

2

), the login user information is added

5-2 Output Impact History

The stored impact history can be output by sending a specified command to the balance or performing

key operation.

Note

□ The impact history format differs depending on the software version of the balance.

Output by command

The stored impact data will be output all at once by sending a “ ?SA” command to the balance.

Output by key operation (Balance software version 1.200 or later.)

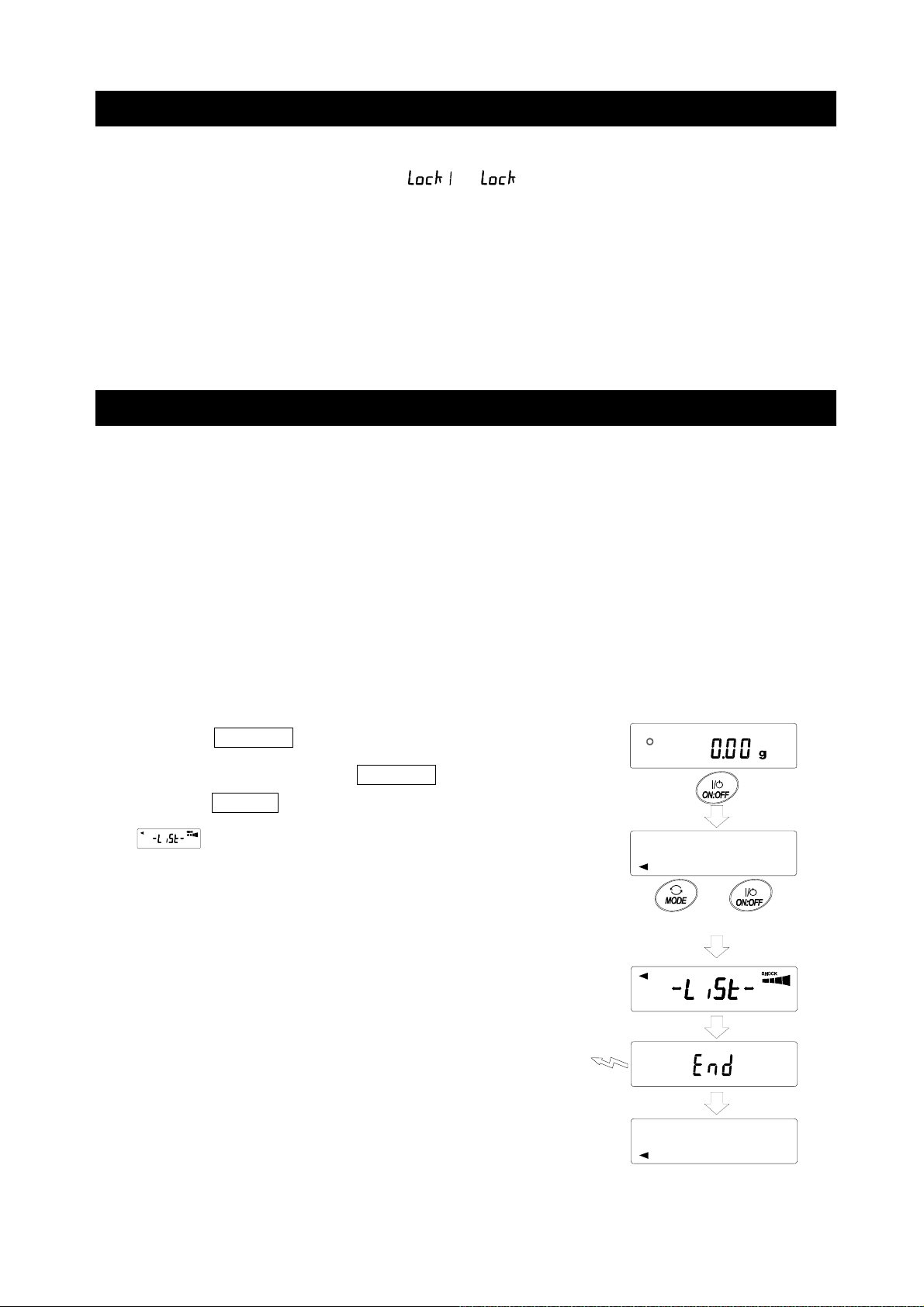

1. Press the ON:OFF key to turn off the display.

2. With the display off, press the ON:OFF key while holding

down the MODE key.

3. is displayed, and the stored impact data is output

all at once.

Press and Hold

Output

Press

31

Page 32

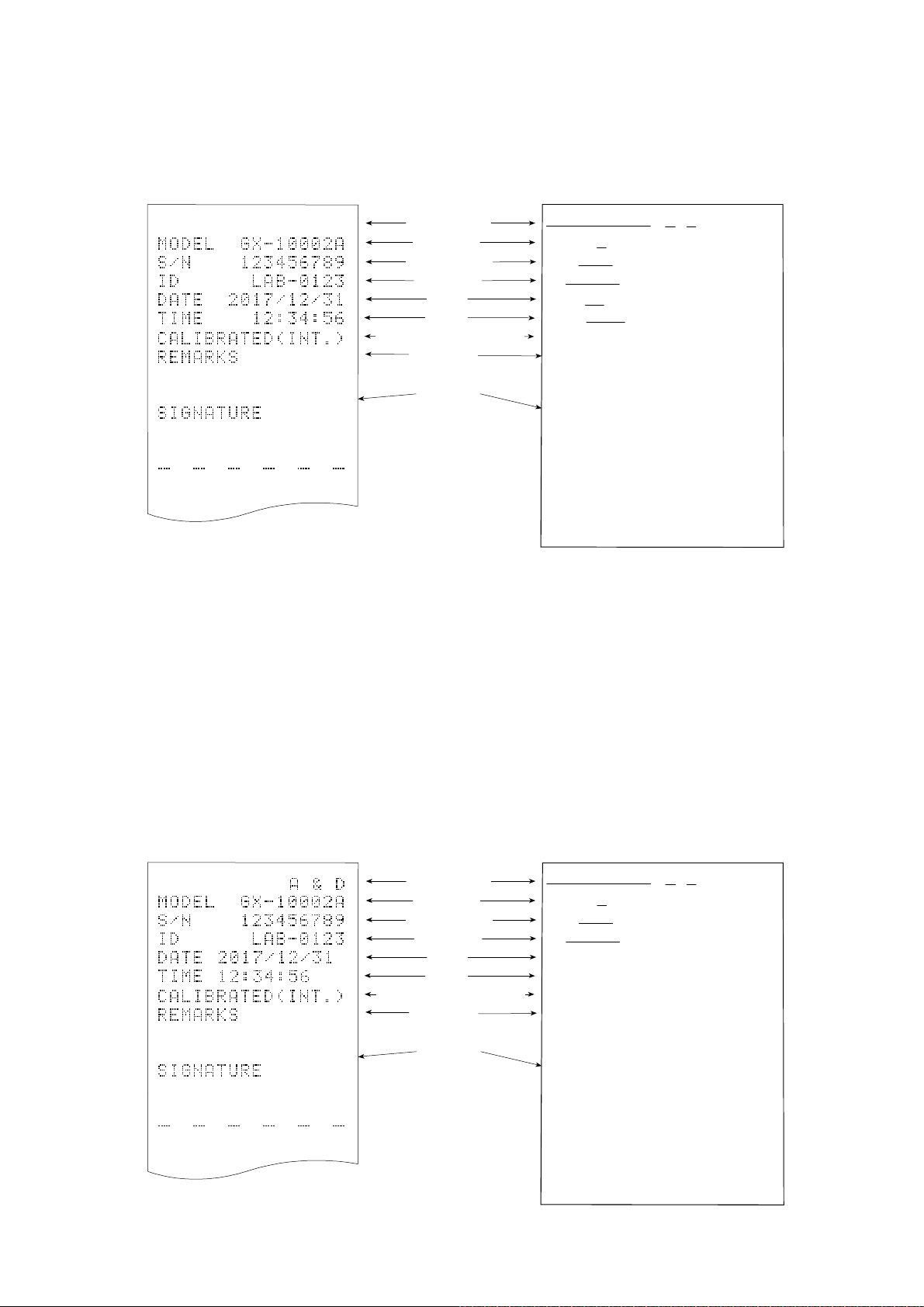

Impact history output example

The impact history format differs depending on the balance software version.

□ With balance software version 1.200

Date, time, and impact level are each output on a separate line.

Output example,

2018/05/29

11:08:18

SHOCK LV4

□ With balance software version 1.211 or later

Date, time, impact level, login and login user information are output together on one line.

The login user information varies depending on the setting of the login user and the setting of

Lock

in the function table when receiving impact.

Output Login user

, --,

,00, ADMIN Administrator

,01~10,USER User

, --,GUEST

Output example

2018/05/29,11:08:18,SHOCK LV,3, --,

2018/05/29,11:12:27,SHOCK LV,4,00,ADMIN

2018/05/29,11:13:38,SHOCK LV,3,01,USER

2018/05/29,11:17:04,SHOCK LV,4, -- ,GUEST

No login user

Guest

Function table

, ,

Lock

6. Response Adjustment / Self Check Function

Disturbances such as drafts and vibration at the place where the balance is installed affect weighing. In

the response adjustment settings, the response characteristics of the balance can be set in three

stages according to the disturbance. With the self check function, the balance itself inspects balance

operation and checks balance performance.

Indicator

FAST

MID.

SLOW

Function

setting

Faster response, Lower display stability

Slower response, Higher display stability

Response characteristic

32

Response indicator

Page 33

6-1 Response Adjustment

Response adjustment can be changed by the following method.

1. Press and hold the

RESPONSE is displayed, and then press the MODE

key again.

2. Press the

FAST , MID or SLOW can be selected.

3. After a few seconds of inactivity the balance displays

End .

Then, the balance returns to the weighing mode and

displays the updated response indicator.

The response indicator remains displayed for a while

(for 30 seconds).

Note

When setting the Response adjustment, "Condition (Cond)"

and "Display refresh rate (

"Environment display (

MODE key to select a weighing speed.

MODE key for 2 seconds until

)" in the Function Table

)" are changed as below.

Press and Hold

Release and

press again

Each pressing switches

the indicators

After a while

Display (Condition) (Display refresh rate)

FAST

MID.

SLOW

When using a combination other than the above, set individually as shown in "9. Function Table".

Note

If RESPONSE is displayed and you leave it without pressing the MODE key, the "Self-check

function" is activated. Refer to "6-2 Self Check Function". For the setting method, refer to "9.

Function Table".

(Stability band width)

6-2 Self Check Function / Automatic Setting Of Minimum

Weighing Value By ECL

With the self check function, repeatability can be confirmed and displayed in addition to performing

failure diagnosis, and whether or not the balance's performance is being exhibited can be easily

checked. It is also possible to display and register the minimum weighing value (reference value)

using repeatability data. For details of the minimum weighing value, refer to the technical information

on our website. (https://www.aandd.jp)

33

Page 34

6-2-1 With Balance Software Version 1.200 To Version 1.220

1. Press and hold the MODE key for 2 seconds in weighing mode.

2. Release the key when the RESPONSE display blinks.

3.

be displayed in a few seconds. If the MODE key is pressed with

displayed, changes in weighing values in the

repeatability measurement with the electronically controlled load

(ECL) can be seen.

(Available with balance software

version 1.100 or later)

4. When the diagnosis is completed, the

diagnosis result is displayed.

If there are no problems inside the

balance,

blinking.

If

a possibility that a fatal fault has

occurred inside the balance. Please

contact your local A&D dealer for repair.

SAMPLE

key…Switches the display between

diagnostic result, repeatability, and minimum

appears, and the self check function starts. "ECL" will

displays

displays blinking, there is

weighing value (reference value).

PRINT key…Outputs the displayed content.

When repeatability is displayed,

specifications are met. If catalog specifications are

exceeded,

review of the installation environment is issued.

(Available with balance software version 1.100 or later)

5. Press the CAL key to display End and return to

weighing mode.

6. To register as minimum weighing value of the minimum

weight value display warning function, press the RE-ZERO

key, which toggles between “No” and “Go”. When is

displayed, press the PRINT key.

If you do not want to register, press the PRINT key with

displayed or press the CAL key to return to weighing

mode.

* For minimum weighing warning function, refer to "15. Minimum Weighing Warning Function".

displays blinking and a request for

lights if catalog

Note

With the balance software version 1.200, the self check function can only be executed when the

login is made by Administrator (AdMin) if the password lock function is ON.

34

Page 35

6-2-2 With Balance Software Version 1.300 or Later

Setting procedure (See also the setting procedure flowchart on the next page)

1. Press and hold the MODE key for 2 seconds in weighing mode.

2. Release the key when the RESPONSE display blinks.

3.

If the MODE key is pressed with

repeatability measurement with the electronically controlled load (ECL) can be seen.

4. When the diagnosis is completed, the diagnosis result is displayed.

If there are no problems inside the balance, the

displays blinking, there is a possibility that a fatal fault has occurred inside the balance. Please

contact your local A&D dealer for repair.

When repeatability is displayed,

specifications are exceeded,

environment is issued.

SAMPLE key ꞏꞏ Switches the display between diagnostic result, repeatability, and minimum

PRINT key ꞏꞏꞏꞏꞏ Outputs the displayed content.

MODE key ꞏꞏꞏꞏꞏ Switches the measurement tolerance of the minimum weighing value

appears, and the self check function starts. "ECL" will be displayed in a few seconds.

lights if catalog specifications are met. If catalog

displays blinking and a request for review of the installation

weighing value (reference value).

(reference value).

displayed, changes in weighing values in the

displays blinking. If

With the minimum weighing value (reference value) displayed, the following operations can be

performed with the keys.

5. Batch output of the minimum weighing value data

Press and hold the PRINT key for 2 seconds to display out . When batch output is

completed, End will be displayed.

6. Registration of the minimum weighing value (reference value) described in "15. Minimum

Weighing Warning Function"

Press and hold the SAMPLE key for 2 seconds to display MW 5Et

minimum weighing value (reference value). When registration is completed,

displayed, and then the balance returns to weighing mode.

7. No registration

Press the CAL key to display End . The balance returns to weighing mode.

8. Diagnostic result display

Press the SAMPLE key to return to the diagnostic result display (step 4).

* For minimum weighing warning function, refer to " 15. Minimum Weighting Warning Function".

and to register the

End

will be

35

Page 36

Setting procedure flowchart

Step 1

Press and hold

for 2 seconds

Change in weighing value of repeatability

4.82

[ Diagnosis result ]

Request for repair

Output

Output

0 . 1

Output

fail

No problem in

performance

%

ref

Step 2

Release

Step 3

A few seconds later

1

[ Diagnosis result ]

No problem Step 4

12.3

Improvement of

installation environment

is required

0 . 1

1

%

0.96

0.96

ref

%

54.60

ref

1

%

ref

5.46

Example of

batch output

Batch

output

Step 5

Press and hold

for 2 seconds

out

Step 6

Press and hold for

2 seconds

go

Resister the minimum weighing value

When MW-CP is set to 0,

automatically set to 1 and

comparator function is available.

5et

Step 7

Step 8

36

Page 37

7. Sensitivity Adjustment

Since the balance's resolution is high, weighing values may change due to gravity and daily

environmental changes. It is necessary to perform sensitivity adjustment with the weight in order to

keep the weighing values from changing even if gravity or the environment changes.

It is recommended that you perform sensitivity adjustment if the balance is installed for the first time or

relocated, or when the weighing values change significantly in daily inspection, etc.

Sensitivity adjustment means to adjust the weighing value of the balance using the reference weight or

internal mass. Calibration test is to weigh with the reference weight and compare how much the result

deviates from the reference value. (Sensitivity adjustment is not performed in calibration test.)

Sensitivity adjustment

Automatic sensitivity adjustment ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ Automatically adjust the balance using the internal

mass according to ambient temperature change, set

time or interval time. (GX-AE/GX-A/GX-AWP series)

Sensitivity adjustment using the internal mass ꞏꞏꞏ Using the internal mass, adjust the balance with a

single touch. (GX-AE/GX-A/GX-AWP series)

Sensitivity adjustment using an external weight ꞏꞏ Using an external mass, adjust the balance with an

external mass.

Calibration test

Calibration test with an external weight ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ Output the result of checking the accuracy of

weighing using your own weight.

* No adjustment is made.

Calibration test with an internal mass ꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏꞏ Output the result of checking the accuracy of

weighing using the internal mass.

* No adjustment is made.