Page 1

E-Tech W

EN

09 - 15 Mono & Tri

09 - 15 - 22 - 28 - 36 Tri

Installation,

Operation &

Maintenance

Instructions for the User and the Installer

A1007841_664Y7800 • A

Page 2

2

EN

Table of Contents

G I .......................................3

Meaning of Symbols ............................................................ 4

What to Check on a Regular Basis .................................. 4

Boiler Marking ....................................................................... 4

U’ G ........................................................5

Using the Control Panel ..................................................... 5

Product Description .............................................................6

T S ................................ 7

Recommendations for the prevention of corrosion

and scaling in Heating Systems ....................................... 7

Main Characteristics ............................................................ 8

Electrical Characteristics ................................................... 9

Power data - E-Tech W 09 Mono .................................... 9

Power data - E-Tech W 15 Mono ...................................... 9

Power data - E-Tech W 09 Tri ........................................ 10

Power data - E-Tech W 22 Tri .......................................... 10

Power data - E-Tech W 15 Tri .......................................... 10

Power data - E-Tech W 28 Tri ............................................11

Power data - E-Tech W 36 Tri ............................................11

I ...................................................... 12

Tools required for the installation ...................................12

Package Contents ...............................................................13

Handling instructions .........................................................13

Removing the boiler from the packaging .....................13

boiler installation on the wall ...........................................13

Removal and Installation of the Access Panels ..........14

Recommendations for the hydraulic installation ........15

Heating Connection ...........................................................15

Pump Set-up .........................................................................16

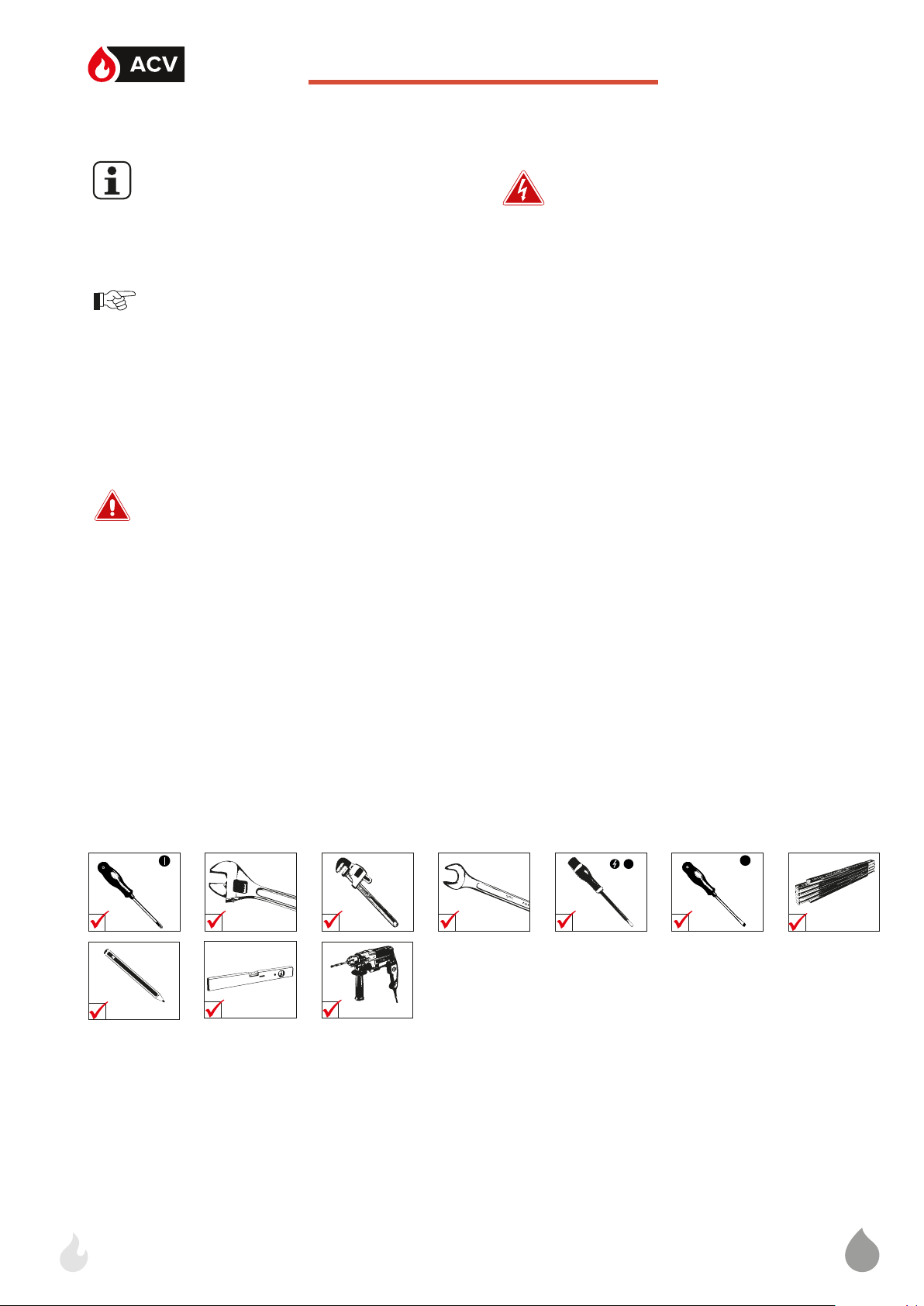

Safety instructions for the electrical installation ........ 17

Sizing the supply wires ......................................................17

Connecting the power supply ......................................... 17

Connecting the electrical Accessories .........................18

Configurations .....................................................................19

Honeywell sundial wiring diagram : Y plan................ 20

Honeywell sundial wiring diagram : S plan ..................21

C ................................................ 22

Checks and setup before start up .................................22

Filling the system ...............................................................22

Starting the boiler ..............................................................23

M .................................................... 24

Recommendations for the boiler maintenance .........24

Boiler Shut-down for Maintenance ...............................24

Draining the Boiler .............................................................24

Boiler maintenance ............................................................25

Checking the Safety Devices .........................................25

Resetting the High Limit Safety Thermostat ..............25

Replacing the Heating Elements ...................................26

T ........................................... 27

Troubleshooting the pump ..............................................27

A1007841-664Y7800 • A

Page 3

3

In order to ensure that the appliance operates

In case of anomaly, please call your service

Faulty parts may only be replaced by genuine

The availability of certain models as well as their

transport, faults may occur. Please immediately

T

,

,

,

C

EN

G I

We accept no liability should any damage result from the failure to comply with theinstructions contained in this technical manual.

This manual contains important information with respect to

the installation, the starting up and the maintenance of the

appliance.

This manual must be provided to the user, who will read it

carefully and keep it in a safe place.

Essential recommendations for safety

• It is prohibited to carry out any modifications to

the appliance without the manufacturer’s prior

and written agreement.

• The product must be installed by a qualified

engineer, in accordance with applicable local

standards and regulations.

• The installation must comply with the instructions

contained in this manual and with the standards

and regulations applicable to heating systems.

• Failure to comply with the instructions in this

manual could result in personal injury or a risk of

environmental pollution.

• The manufacturer declines all liability for any

damage caused as a result of incorrect i nstallation or

in the event of the use of appliances or accessories

that are not specified by the manufacturer.

Essential recommendations for the correct operation

of the appliance

•

correctly, it is essential to have it serviced by a certified

installer or maintenance contractor every year.

•

engineer.

•

factory parts.

General remarks

•

accessories may vary according to markets.

• The manufacturer reserves the right to change the

technical characterist ics and features of its products

without prior notice. Please check for an updated

version of this manual in the documentation page

on the website www.acv.com.

• In spite of the stric t quality standards tha t ACV applies

to its appliances during production, inspection and

notify your approved installer of any faults.

GENERAL SAFETY INSTRUCTIONS FOR ELECTRIC APPLIANCES

B

,

.

M

,

.

D

, , ,

,

.

( )

.

.

A1007841-664Y7800 • A

Page 4

4

EN

General Information

MEANING OF SYMBOLS

Symbols on the packaging

Fragile

Keep dry

Keep standing, up

Danger of tipping over

Hand truck or pallet truck required

for transport

Symbols on the appliance

Domestic Hot Water circuit

WHAT TO CHECK ON A REGULAR BASIS

Essential recommendations for the correct

operation of the appliance

• Check regularly that the system water

pressure is at least 1 bar when cold. If the

pressure drops below 0.5 bar, the built-in

pressure sensor blocks the appliance until

the pressure exceeds 0.8 bar.

• If it is required to top up the system to maintain

the minimum recommended water pressure,

always turn the appliance off and only add

small amounts of water at a time. If a large

amount of cold water is added in a hot boiler,

the appliance can be damaged definitively.

• If the system needs to be refilled repeatedly

with water, or if there is water on the floor

under the boiler, contact your service

engineer.

BOILER MARKING

Location: Bottom panel

Primary circuit

Electricity

Symbols in the manual

Essential recommendation for safety

(of persons and equipment)

Essential recommendation for electrical safety (electrical hazard)

Essential recommendation for the

correct operation of the appliance or

the system

General remark

Safety valve connected to the sewage system

Connection to the sewage system

The part number (Code) and serial number

(S/N) of the appliance are indicated on its

rating plate and must be provided to ACV in

case of warranty claim. Failure to do so will

make the claim void.

A1007841-664Y7800 • A

Page 5

5

USING THE CONTROL PANEL

EN

U’ G

1 - ON/OFF switch - to start and stop the appli-

ance.

2 - Power level switches - The control panel is

comprised of two switches that allow the user

to select the power of the appliance. When

only the first switch is pushed in, the power of

the boiler is limited to the first stage, i.e. about

half the total power. For operation at full power, both switches must be pushed in.

3 - Location for optional internal clock or con-

troller - Refer to the manual provided with the

accessory.

4 - Indicator light - The lamp turns on when the

safety thermostat is activated or when the water pressure in the boiler is too low.

5 - Manual reset high limit thermostat - If the

boiler temperature exceeds 103°C, the safety device is activated and the indicator light

is turned on. Refer to "Resetting the High Limit

Safety Thermostat" on page 25 for the cor-

rect reset procedure.

6 - Combined temperature and pressure gauge

- Allows the direct reading of both temperature and pressure of the boiler primary circuit.

7 Control thermostat Allows to define the tem-

perature setpoint for the primary circuit. Each

number around the dial corresponds to a specific temperature :

1 = 15°C 2 = 30°C 3 = 45°C 4 = 60°C 5 = 80°C

76

43 51 2

A1007841-664Y7800 • A

Page 6

6

PRODUCT DESCRIPTION

EN

User’s Guide

This wall hung electric boiler is available in 7 models,

single or three-phase:

• Models 09 and 15 Mono are supplied with 230 V

(single phase).

• Models 09, 15, 22, 28 and 36 Tri are supplied with

400 V (three phase).

The maximum power can be adjusted by

acting on the terminal bridges.

Adjustable power

MODELS MIN MAX

E-Tech W 09 Mono/Tri 5.6 kW 8.4 kW

E-Tech W 15 Mono/Tri 9.6 kW 14.4 kW

E-Tech W 22 Tr i 14.4 kW 21.6 kW

E-Tech W 28 Tr i 14.4 kW 28.8 kW

E-Tech W 36 Tr i 18 kW 36 kW

Casing

The boiler is protected by a steel casing that first

undergoes a degreasing and phosphation process

before being lacquered and burnt at 220°C.

Heating body

The boiler heat exchanger is constructed from STW

22 steel. It is hydraulically tested under a 4.5 bar

pressure (maximum service pressure = 3 bar).

Heating elements

Removable immersed heating elements, constructed from stainless steel Incoloy 800 and mounted

from the top of the heating body, provide the heating

source for the boiler. Refer to "Replacing the Heating

Elements" on page 26 for more information.

Hydraulic connection

The boiler is suitable for connection to most sealed

heating and hot water systems, with a maximum

working pressure of 3 bar and a maximum temperature of 87°C.

The boiler is equipped with a primary 10 litre expansion vessel, suitable for a system water content of

up to 160 litres. For systems of a larger capacity, it

may be necessary to install an additional expansion

vessel.

It is also comprised of pressure and temperature

sensors, a safety valve, a low water pressure switch,

control and high limit thermostats, on/o and power

level switches.

Circulating Pump

The E-Tech W boiler is equipped with a new-generation high-eciency pump that can be set up to meet

the system requirements. The pump's LED indicators display the operation mode or the status of the

pump, and a pushbutton allows to access the pump

settings.

Indicator lights (LEDs)

Setup pushbutton

Display of the level of

performance (default display)

The first LED is green in normal operation,

red in case of problem. The others are always

yellow when turned on. When the green LED

is flashing, it means that the pump has been

stopped by an external signal.

Electrical connection

The boiler requires two dierent power supply sources,

one for the control circuit, and one for the power circuit.

Connection glands for both the main power supply and

optional external controls are provided, suitable for single or three phase electrical supply depending on the

required boiler output.

An internal 3 amp Magnetic Circuit Breaker is provided

to protect the internal control circuit, from which optional controls can be connected e.g. Internal or external

timeclock that can be installed in the control panel.

Protection against frost

If the boiler is not in regular daily use during

cold periods, it is recommended to fit in

a frost-sensing thermostat to prevent the

system from freezing.

A circulating pump is installed at the bottom of the

boiler, on the supply side.

The boiler can be used in cascaded systems, allowing greater outputs to be achieved.

A1007841-664Y7800 • A

The boiler is NOT fitted with frost protection. If the

boiler is being installed in a position where freezing

could take place, then a suitable external frost-sensing thermostat should be fitted.

Page 7

7

EN

T S

RECOMMENDATIONS FOR THE PREVENTION OF CORROSION AND SCALING IN

HEATING SYSTEMS

How oxygen and carbonates can aect the

heating system

Oxygen and dissolved gasses in the water of the primary circuit contribute to the oxidation and the corrosion of

the system components that are made of ordinary steel

(radiators, ...). The resulting sludge is then deposited in

the appliance exchanger.

The combination of carbonates and carbon dioxide

in the water results in the formation of scale on the

hot surfaces of the installation, including those of the

appliance exchanger.

These deposits in the heat exchanger reduce the water flow rate and thermally insulate the exchange surfaces, which is likely to damage them.

3. Limit the presence of oxygen and sludge in the

water

A deaerator (on the appliance flow line) combined

with a dirt separator (upstream of the appliance) must

be installed according to the manufacturer's instructions.

ACV recommends using additives that keep the oxygen in solution in the water, such as Fernox (www.

fernox.com) and Sentinel (www.sentinel-solutions.

net) products.

The additives must be used in accordance with the

instructions issued by the manufacturer of the water

treatment product.

Sources of oxygen and carbonates in the

heating circuit

The primary circuit is a closed circuit; the water it

contains is therefore isolated from the mains water.

When maintaining the system or filling up the circuit,

water renewal results in the addition of oxygen and

carbonates in the primary circuit. The larger the water

volume in the system, the larger the addition.

Hydraulic components without an oxygen barrier (PE

pipes and connections) admit oxygen into the system.

Prevention Principles

1. Clean the existing system before installing a new

appliance

Before the system is filled, it must be cleaned in accordance with standard EN14336. Chemical cleaning

agents can be used.

If the circuit is in bad condition, or the cleaning operation was not ecient, or the volume of water in the

installation is substantial (e.g. cascade system), it is recommended to separate the appliance from the heating

circuit using a plate-to-plate exchanger or equivalent. In

that case, it is recommended to install a hydrocyclone

or magnetic filter on the installation side.

2. Limit the fill frequency

Limit fill operations. In order to check the quantity of water that has been added into the system, a water meter

can be installed on the filling line of the primary circuit.

Automatic filling systems are not recommended unless

the fill frequency is monitored and the scale and corrosion inhibitor remain at the correct levels.

If your installation requires frequent water refilling,

make sure your system is free of water leaks.

Inhibitors may be used in accordance with standard

EN 14868.

4. Limit the carbonate concentration in the water

The fill water must be softened if its hardness is higher than 20° fH (11,2° dH).

Check regularly the water hardness and enter the

values in the service log.

Water hardness table :

Water hardness °fH °d H mmolCa(HCO3)2 / l

Ver y sof t 0 - 7 0 - 3.9 0 - 0.7

Soft 7 - 15 3.9 - 8.4 0.7 - 1.5

Fairly hard 15 - 25 8.4 - 14 1.5 - 2.5

Hard 25 - 42 14 - 23.5 2.5 - 4.2

Very hard > 42 > 23.5 > 4.2

5. Control the water parameters

In addition to the oxygen and the water hardness,

other parameters of the water must be checked.

Treat the water if the measured values are outside

the range.

Acidity 6,6 < pH < 8,5

Conductivity < 400 S/cm (at 25°C)

Chlorides < 125 mg/l

Iron < 0,5 mg/l

Copper < 0,1 mg/l

A1007841-664Y7800 • A

Page 8

8

EN

Technical Specifications

MAIN CHARACTERISTICS

E-TECH W

Capacity (primary) L 13

Primary circuit expansion vessel volume L 10

Max. service pressure bar 3

Min. service pressure bar 0,8

Max. service temperature °C 87

E-Tech W • 09 Mono / Tri mbar 10

E-Tech W • 15 Mono / Tri mbar 20

Hydraulic pressure drop

Heating connection Ø 3/4” [F]

Empty weight kg 45

E-Tech W • 22 Tri mbar 45

E-Tech W • 28 Tri mbar 85

E-Tech W • 36 Tri mbar 125

A1007841-664Y7800 • A

Page 9

9

12

12

13

13

14

14

15

15

12

12

13

13

14

14

15

15

12

12

13

13

14

14

15

15

12

12

13

13

14

14

15

15

EN

Technical Specifications

ELECTRICAL CHARACTERISTICS

E-Tech W

09 15

Mono Tri Mono Tri

Max Power kW 8.4 8.4 14.4 14.4

Rated voltage of the power supply V 230 3 x 400 230 3 x 400

Rated voltage of the control circuit V 230 230 230 230

Rated frequency Hz 50 50 50 50

Ohmic resistance of element Ohm 37.8 37.8 22 22

Heating element type kW 2 x 1.4 2 x 1.4 2 x 2.4 2 x 2.4

Number of heating elements 3 3 3 3

Electric protection IP 43 43 43 43

P - E-T W 09 M

STAGE

1 2 TOTAL

Single Phase 8.4 kW (*)

Terminal L1 (A) 24 12 36

Terminal N (A) 24 12 36

Power (kW) 5.6 2.8 8.4

Single Phase 5.6 kW (**)

Terminal L1 (A) 12 12 24

Terminal N (A) 12 12 24

Power (kW) 2.8 2.8 5.6

P - E-T W 15 M

STAGE

1 2 TOTAL

Single Phase 14.4 kW (*)

Terminal L1 (A) 41.6 20.8 62.4

Terminal N (A) 41.6 20.8 62.4

Power (kW) 9.6 4.8 14.4

Single Phase 9.6 kW (**)

CONTROL TERMINALS

CONTROL TERMINALS

Refer to ML book for

Control and Power

wiring diagrams

Terminal L1 (A) 20.8 20.8 41.6

Terminal N (A) 20.8 20.8 41.6

Power (kW) 4.8 4.8 9.6

These values are b ased on standard supply voltag e in Europe, that is 1 x 230V for single p hase and 3 x 400 Volt for three phase .

(*) Factor y configuration .

(**) Remove b ridge between termin als 12 a nd 13 o f control wiring to deactivate the re lay.

(***) R emove bridge between te rminals 14 and 15 of control wiring to de activate the relay.

A1007841-664Y7800 • A

Page 10

10

12

12

13

13

14

14

15

15

12

12

13

13

14

14

15

15

EN

Technical Specifications

E-Tech W

22 Tri 28 Tri 36 Tri

Max power kW 21.6 28.8 36

Rated voltage of the power supply V 3 x 400 3 x 400 3 x 400

Rated voltage of the control circuit V 230 230 230

Rated frequency Hz 50 50 50

Ohmic resistance of element Ohm 22 22 17.6

Heating element type kW 2 x 2.4 2 x 2.4 2 x 3.0

Number of heating elements 5 6 6

Electric protection IP 43 43 43

P - E-T W 09 T

STAGE

1 2 TOTAL

Three Phase 8.4 kW

Terminal L1 (A) 6 6 12

Terminal L2 (A) 6 6 12

Terminal L3 (A) 6 6 12

Power (kW) 4.2 4.2 8.4

P - E-T W 22 T

STAGE

1 2 TOTAL

Three phase 21.6 kW (*)

Terminal L1 (A) 20.8 10.4 31.2

Terminal L2 (A) 20.8 10.4 31.2

Terminal L3 (A) 20.8 10.4 31.2

Power (kW) 14.4 7.2 21.6

Three phase 14.4 kW (**)

Terminal L1 (A) 10.4 10.4 20.8

Terminal L2 (A) 10.4 10.4 20.8

Terminal L3 (A) 10.4 10.4 20.8

Power (kW) 7.2 7.2 14.4

P - E-T W 15 T

1 2 TOTAL

Three Phase 14.4 kW

Terminal L1 (A)

Terminal L2 (A)

Terminal L3 (A)

Power (kW)

CONTROL TERMINALS

10.4 10.4 20.8

10.4 10.4 20.8

10.4 10.4 20.8

7.2 7.2 14.4

STAGE

A1007841-664Y7800 • A

Page 11

11

P - E-T W 28 T

12

12

13

13

14

14

15

15

12

12

13

13

14

14

15

15

12

12

13

13

14

14

15

15

12

12

13

13

14

14

15

15

12

12

13

13

14

14

15

15

12

12

13

13

14

14

15

15

EN

Technical Specifications

STAGE

1 2 TOTAL

Three phase 28.8 kW (*)

Terminal L1 (A) 20.8 20.8 41.6

Terminal L2 (A) 20.8 20.8 41.6

Terminal L3 (A) 20.8 20.8 41.6

Power (kW) 14.4 14.4 28.8

Three phase 21.6 kW (***)

Terminal L1 (A) 20.8 10.4 31,2

Terminal L2 (A) 20.8 10.4 31,2

Terminal L3 (A) 20.8 10.4 31,2

Power (kW) 14.4 7.2 21,6

Three phase 14.4 kW (****)

Terminal L1 (A) 10.4 10.4 20.8

Terminal L2 (A) 10.4 10.4 20.8

Terminal L3 (A) 10.4 10.4 20.8

Power (kW) 7.2 7.2 14.4

P - E-T W 36 T

CONTROL TERMINALS

STAGE

1 2 TOTAL

Three phase 36 kW (*)

Terminal L1 (A) 26 26 52

Terminal L2 (A) 26 26 52

Terminal L3 (A) 26 26 52

Power (kW) 18 18 36

Three phase 27 kW (***)

Terminal L1 (A) 26 13 39

Terminal L2 (A) 26 13 39

Terminal L3 (A) 26 13 39

Power (kW) 18 9 27

Three phase 18 kW (****)

Terminal L1 (A) 13 13 26

Terminal L2 (A) 13 13 26

Terminal L3 (A) 13 13 26

Power (kW) 9 9 18

CONTROL TERMINALS

These values are b ased on standard supply voltag e in Europe, that is 1 x 230V for single p hase and 3 x 400 Volt for three phase .

(*) Factor y configuration .

(**) Remove b ridge between termin als 12 a nd 13 o f control wiring to deactivate the re lay.

(***) R emove bridge between te rminals 14 and 15 of control wiring to de activate the relay.

(****) Remove bridge s between terminals 12 and 13, and 14 and 15 of control wiring to deactiva te the relay.

A1007841-664Y7800 • A

Page 12

12

Essential recommendations for the electrical

Only an approved installer is authorized to carry

Install a 2-way switch and a fuse or circuit breaker

so as to be able to shut power down when

Isolate the external electrical supply of the

This appliance is not intended for use by persons

knowledge, unless supervised or unless they

EN

I

SAFETY INSTRUCTIONS FOR THE INSTALLATION

General remarks

• The connections (electrical, hydraulic) must be

carried out in accordance with current applicable

standards and regulations.

Essential recommendations for the correct

operation of the appliance

• The boiler must be installed in a dry and protected

area, with an ambient temperature comprised

bewtween 0°C and 45°C.

• Install the appliance to ensure easy access at all

times.

• Make sure to install a pressure reducing valve set

at 4.5 bar if the mains supply pressure is in excess

of 6 bar.

safety

•

out the electrical connections.

• The appliance must be connected to the earth.

•

of the recommended rating outside the appliance,

servicing the appliance or before performing any

operation on it.

•

appliance before performing any operation on the

electrical circuit.

•

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

Essential recommendations for safety

• Install the boiler on a base made of noncombustible materials.

• Do not use or store any flammable, explosive or

corrosive products, such as paint, solvents, salts,

chloride products and other detergent products

near the appliance

• This appliance is not constructed for installation

in zone 3.

TOOLS REQUIRED FOR THE INSTALLATION

have been given instruction concerning the use

of the appliance by a person responsible for their

safety.

A1007841-664Y7800 • A

Page 13

13

EN

Installation

PACKAGE CONTENTS

The E-Tech W boilers are delivered assembled and

packaged.

At product reception and after removal of

packaging, check the package contents and

that the appliance is free of damages.

• One E-Tech W boiler

• Installation, Operation and Maintenance Instructions

• A wall mounting kit

HANDLING INSTRUCTIONS

• The weight of this boiler is 36Kg, which could

present a risk of injury. Ask for help to lift it or

handle it, or use an appropriate lifting means.

• Bring the appliance as close as possible to

the installation location before removing the

packaging.

BOILER INSTALLATION ON THE WALL

• The boiler must be mounted on a non

flammable support.

• Make sure to level the bracket at installation.

1. Observing the distances below, drill 2 holes of

14mm x 100mm.

2. Using the provided hardware, attach the bracket

to the wall, making sure the bracket is level.

3. Hang the boiler on the bracket.

48,4 mm

101,6 mm

101,6 mm

48,4 mm

REMOVING THE BOILER FROM THE

PACKAGING

Before lifting the boiler from the packaging,

ensure that the installation area is clear

and that there are no obstacles making the

installation difficult or unsafe.

1. Open the box and remove the cardboard packaging.

2. Remove the protection pieces and discard in accordance with applicable local regulations.

3. With help from another person, lift the boiler from

the packaging holding the lipped front edges of

the side panels.

Do not lift or carry the boiler using the

automatic air vent installed at the top and

the pump at the bottom.

A1007841-664Y7800 • A

Page 14

14

EN

Installation

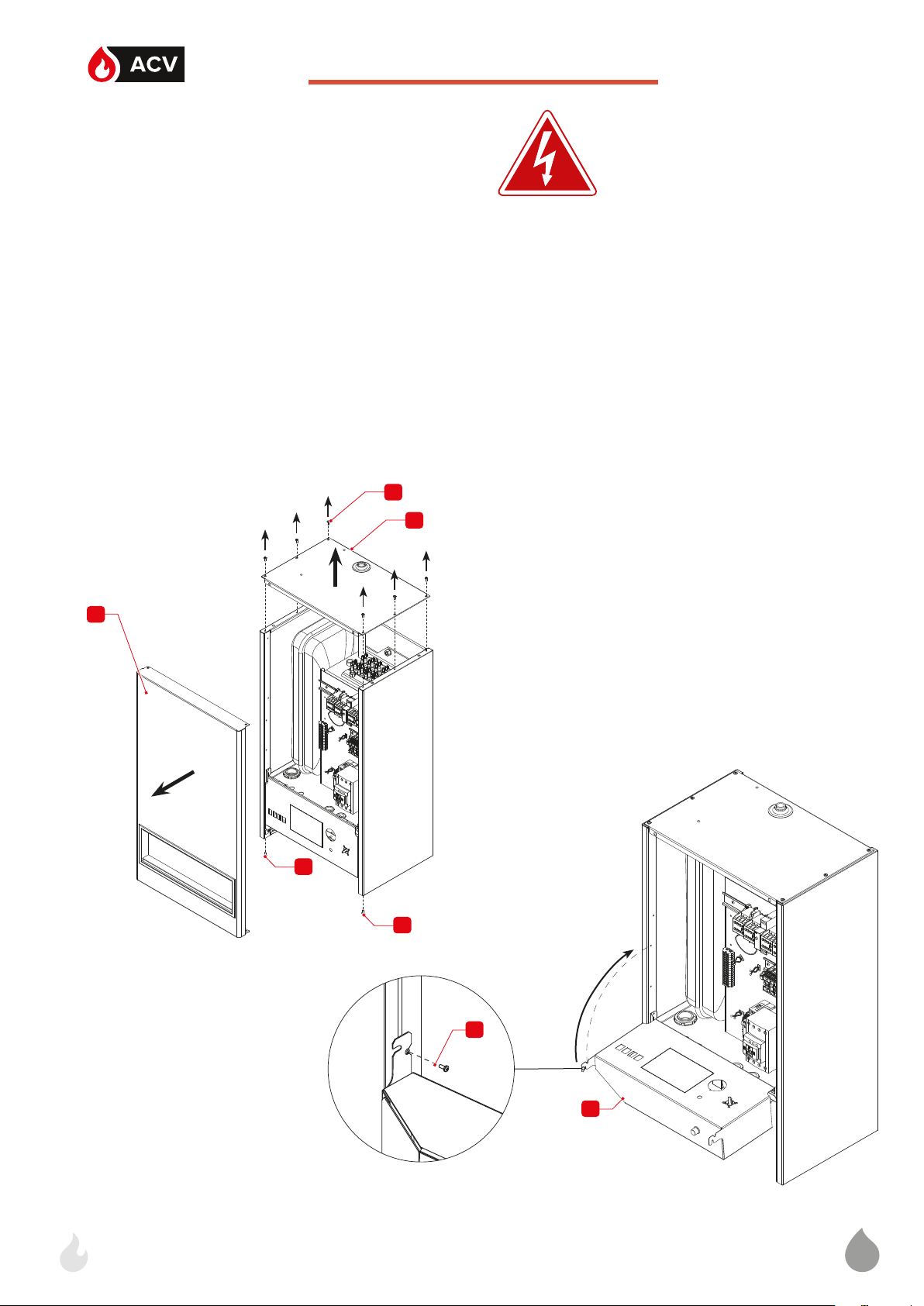

REMOVAL AND INSTALLATION OF THE

ACCESS PANELS

Set-up conditions

• Boiler shut down using the ON/OFF switch

• External power supply isolated (through the external electrical box)

• Boiler cooled down (if it was in operation)

Procedure

1. If the boiler was in operation or filled with water:

• Isolate the heating circuit through the isolating

valve.

• Drain the boiler. See "Draining the Boiler" on

page 24.

1

2

2. Remove the automatic air vent located at the top

of the boiler. Retain for reinstallation.

3. Release six screws (1). Retain for reinstallation.

4. Remove the front panel (3) and top cover (2).

5. To get access to the control panel wiring:

• Release two screws (4) from the bottom of the

control panel (5). Retain for reinstallation.

• Rotate the control panel 180° upwards.

• Block the control panel in position using one of

the two retained screws (4).

6. Perform the procedure in the reverse order for

panel reinstallation.

Follow-on tasks

• Restart the boiler as required, refer to "Starting

the boiler" on page 23.

3

4

4

4

5

A1007841-664Y7800 • A

Page 15

15

EN

Installation

RECOMMENDATIONS FOR THE HYDRAULIC INSTALLATION

• Thoroughly rinse the system before connecting the boiler

• Water treatment is recommended to prevent corrosion and the formation of scale in the boiler and piping.

• If the boiler is to be installed in an existing system, ACV recommends using a cleaning agent in the

systems.

• After connecting the hydraulic circuit, check the absence of leaks.

HEATING CONNECTION

Make sure to install isolating valves on the system heating circuit, so as to be able to drain the boiler,

without draining the whole system.

Typical system - high temperature

KEY

1. Isolation valve

2. Circulating pump (built-in)

3. Filling valve

4. Check valve

5. Expansion vessel (built-in, for a 160L circuit)

6. Safety valve (built-in)

7. Draining valve

8. Automatic air vent (built-in)

8

Typical system - low temperature

KEY

1. Isolation valve

2. 3-way mixing valve

3. Circulating pump (built-in)

4. Filling valve

5. Check valve

6. Expansion vessel (built-in, for a 160L circuit)

7. Safety valve (built-in)

8. Draining valve

9. Automatic air vent (built-in)

Cold water

Hot water

9

6

2

7

11

4

3

5

3

1

2

4

8

1

6

5

7

In the case of a floor heating system, make

sure that the pomp is set to the "Constant

pressure" mode.

A1007841-664Y7800 • A

Page 16

16

EN

Installation

PUMP SET-UP

• Depressing shortly the button allows to display

the current set-up (operation mode)

• Depressing the button for more than 2 sec. gives

access to the setting mode See table below for

the available operation modes.

• After 10 sec. without action, the “Performance”

mode is back.

Available Operation Modes

Constant curve:

The circulation pump works according to a constant

curve, which is the standard operation for a pump.

The pump will then run following the max curve

when demand is high, e.g. in the case of DHW priority, and according to the min curve when demand is

low (night mode).

LED 1 LED 2 LED 3 LED 4 LED 5

Proportional pressure Green

Constant pressure Green

Constant curve Green

Curve 1

Curve 2

Curve 3

Curve 4/Auto

£

¢

¢ ¢

¢

£ £

¢

By default, the pump is set to the

"Porportional Pressure" mode / Curve 3 (See

symbols in bold in the table).

Proportional pressure:

Default mode, applicable to most heating systems.

Pressure increases and decreases according to the

heat demands. Three preset curves are available,

from the lowest to the highest. The AutoAdapt curve

allows the pump to operate with the best eciency

for the type of system. This is the preferred mode for

two-pipe systems, with thermostatic valves and long

piping (high pressure drop).

Once the set-up is completed, the pump can

be locked to prevent any accidental change.

Press the button for more than 10 secondes

and all the LED will light (except the red one)

and blink for 1 second to indicate that the

lock is on. Proceed the same way to unlock.

Constant pressure:

Pressure is kept constant whether there is a heat demand or not. This is the typical mode for floor-heating systems or one-pipe systems with low pressure

drop.

A1007841-664Y7800 • A

Page 17

17

SAFETY INSTRUCTIONS FOR THE

EN

ELECTRICAL INSTALLATION

Installation

SIZING THE SUPPLY WIRES

• Electrical connections must be carried out

by a qualified technician, in accordance with

regulations applicable to electrical systems.

• Make sure that the boiler is connected to the

earth.

• As far as the power input to the boiler is

concerned, the installation must comply

with standard EN 60364-1 that define the

applicable levels of insulation, and with

all provisions applicable to installation

conditions.

• For protection against electrical hazard, it is

always recommended to install a differential

cut-out device (Ground Fault Isolator) on the

power supply circuit, upstream of the boiler.

• The control circuit is protected by a 3A

magnetic circuit breaker.

• The default electrical safeties integrated in

the boiler protect the internal parts of the

boiler.

• Any additional electrical safety device must

be installed outside the boiler.

• For protection against overheating, it is

advisable to place an external positive

safety power cut-out, controlled by the

boiler safety thermostat.

The supply wires are sized depending of the type

and current of the Magnetic Circuit Breaker (MCB),

the latter being sized according to the nominal current of the boiler.

The admissible current of the supply wires depends

on the ambient temperature, the section and length

of the wires, the wires insulation, the wires assembly,

the type of installation and the environment.

The following values are provided for information,

considering an ambient temperature of 30°C and a

maximal length of 5 meters. In all the cases, the installation must be performed in accordance with the

applicable Wiring Regulations.

Nominal section

(mm)

1.5 16

2.5 25

4 32

6 40

10 63

16 80

Nominal current of the

MCB (A)

CONNECTING THE POWER SUPPLY

• This appliance must be permanently connected to fixed wiring and must be earthed.

• The wiring must be carried out by a competent person and in accordance with the current IEE Wiring

Regulations.

E-Tech W 09 - 15 Mono E-Tech W 09 - 15 - 22 - 28 Tri E-Tech W 36 Tri

T1 T2 T3 T4

T1 T2 T3 T4

L1PE L1

400 V ~ 50 Hz

N L2 L3 PE

230 V ~ 50 Hz

(3A)

PE L1

230 V ~ 50 Hz

(3A)

T1 T2 T3 T4

T1 T2 T3 T4

N NL1 PE

230 V ~ 50 Hz

N L2 L3 PE

230 V ~ 50 Hz

(3A)

T1 T2 T3

T1 T2 T3

L1PE L1

400 V ~ 50 Hz

A1007841-664Y7800 • A

Page 18

18

EN

Installation

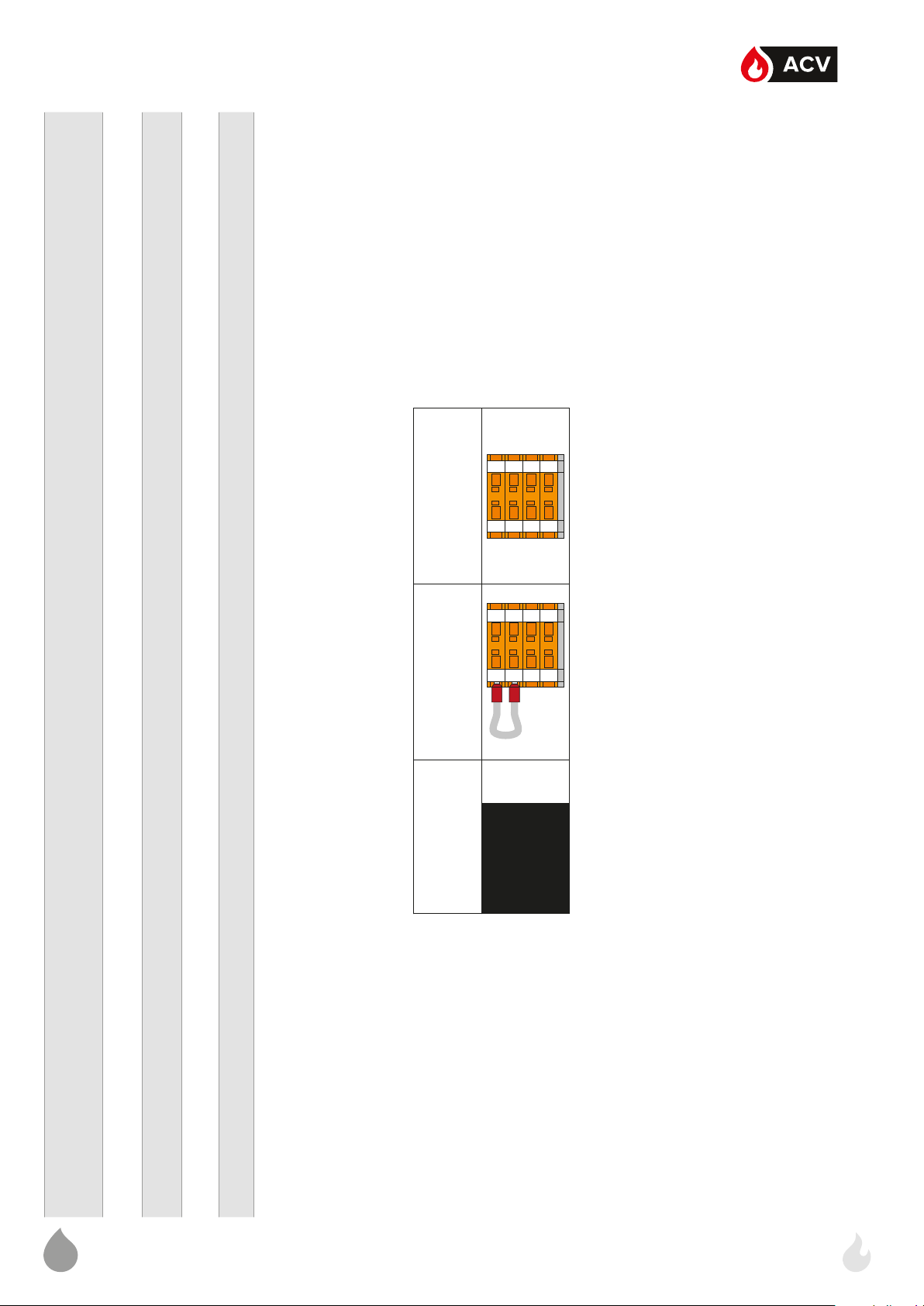

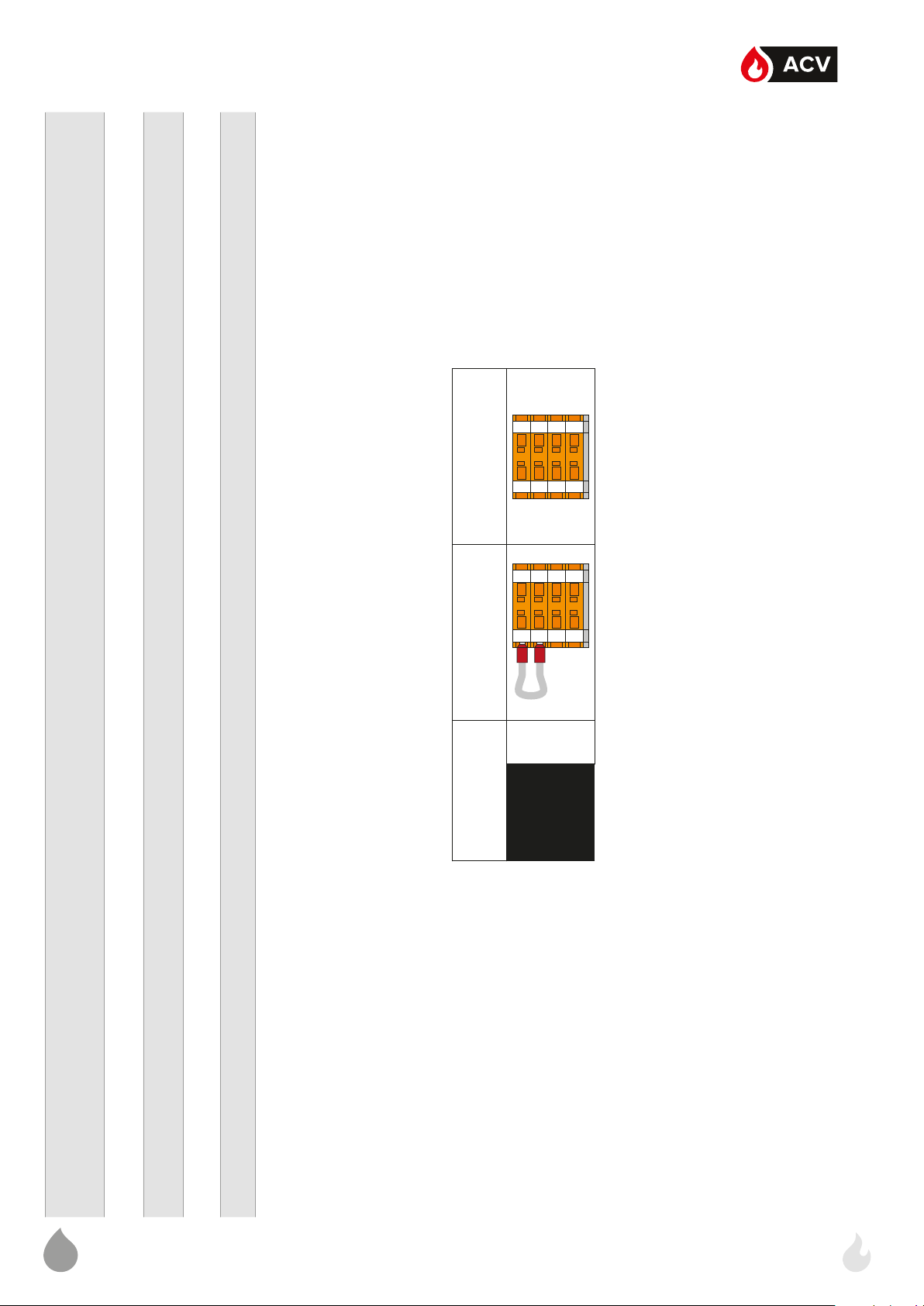

CONNECTING THE ELECTRICAL ACCESSORIES

Models : • E-Tech W 09 - 15 Mono

• E-Tech W 22 Tri

1-2 : Time clock or controller supply (optional)

3-4 : DHW kit (optional)

5-6 : Stop Bridge or time clock switch control (optional)

7-8 : Room thermostat (optional)

9-10-11 : Heating pump

12-13 : Relay K3 deactivated

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

TB1

Models : E-Tech W 09 - 15 Tri

1-2 : Time clock or controller supply (optional)

3-4 : DHW kit (optional)

5-6 : Stop Bridge or time clock switch control (optional)

7-8 : Room thermostat (optional)

9-10-11 : Heating pump

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Models : E-Tech W 28 - 36 kW Tri

1-2 : Time clock or controller supply (optional)

3-4 : DHW kit (optional)

5-6 : Stop Bridge or time clock switch control (optional)

7-8 : Room thermostat (optional)

9-10-11 : Heating pump

12-13 : Relay K3 deactivated

14-15 : Relay K4 deactivated

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

TB1

TB1

A1007841-664Y7800 • A

Page 19

19

CONFIGURATIONS

39

38

37

36

35

34

33

32

31

29

28

27

26

25

24

23

22

21

19

40

20

18

17

16

15

14

13

12

11

9

30

10

8

7

6

5

4

3

2

1

39

38

37

36

35

34

33

32

31

29

28

27

26

25

24

23

22

21

19

40

20

18

17

16

15

14

13

12

11

9

30

10

8

7

6

5

4

3

2

1

39

38

37

36

35

34

33

32

31

29

28

27

26

25

24

23

22

21

19

40

20

18

17

16

15

14

13

12

11

9

30

10

8

7

6

5

4

3

2

1

39

38

37

36

35

34

33

32

31

29

28

27

26

25

24

23

22

21

19

40

20

18

17

16

15

14

13

12

11

9

30

10

8

7

6

5

4

3

2

1

EN

CH Connection

Installation

CH + DHW Connection: “Y” PLAN - See

page 20

Limiting the maximum temperature setpoint

Factory setting

0 - 87°C

Floor heating

0 - 50°C

Limiting the maximum temperature setpoint

60 - 87°C

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

CH + DHW Connection: “S” PLAN - See page 21

Limiting the maximum adjustable temperature

60 - 87°C

A1007841-664Y7800 • A

M M

Page 20

20

EN

Installation

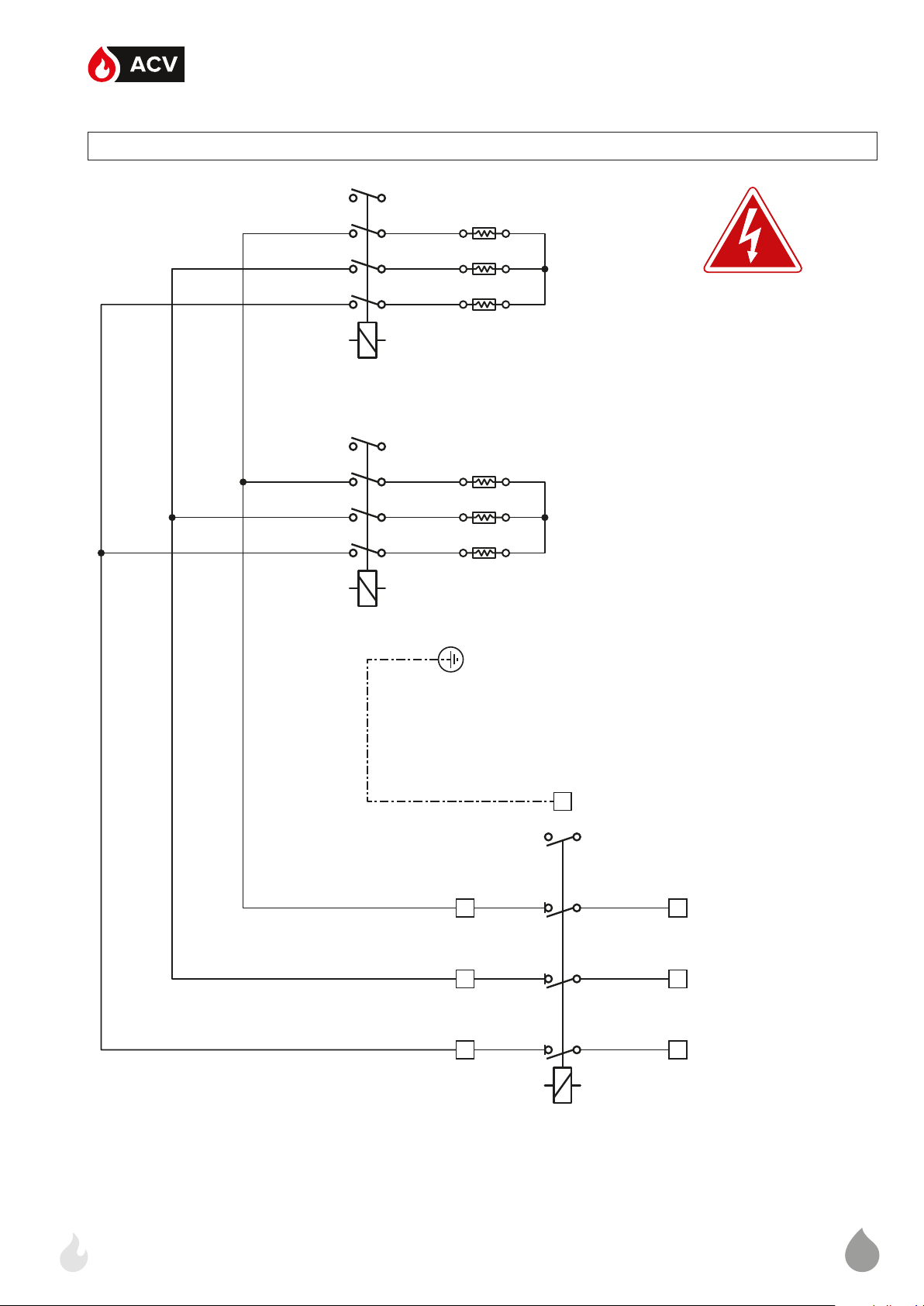

HONEYWELL SUNDIAL WIRING DIAGRAM : Y PLAN

15

1133224455667788991010111112121313141415

Note: All bold numbers indicate a DIN rail terminal connection

V4073A

b

MID POSITION

w

bk- black

br- brown

r-red

w-white

y- yellow

o - orange

b - blue

v - violet

p - pink

CABLE COLOUR CODES

ZONE VALVE

o

gr - grey

Note: Illustrated model: 22 kW Tri

gr

CYLINDER

T6306B

ROOM STAT

b

STAT

2C

1

w

3

1

2

b

7 8 9 10

E

1 432 5 6

N L

HTG

HW ON

HW OFF

Honeywell

Sundial Wiring Centre

`Y ` Plan

Note: Earth wires not shown for clarity

During installation the earth wires from each

component connect to terminal 3 in the wiring centre

A1007841-664Y7800 • A

Page 21

21

EN

Installation

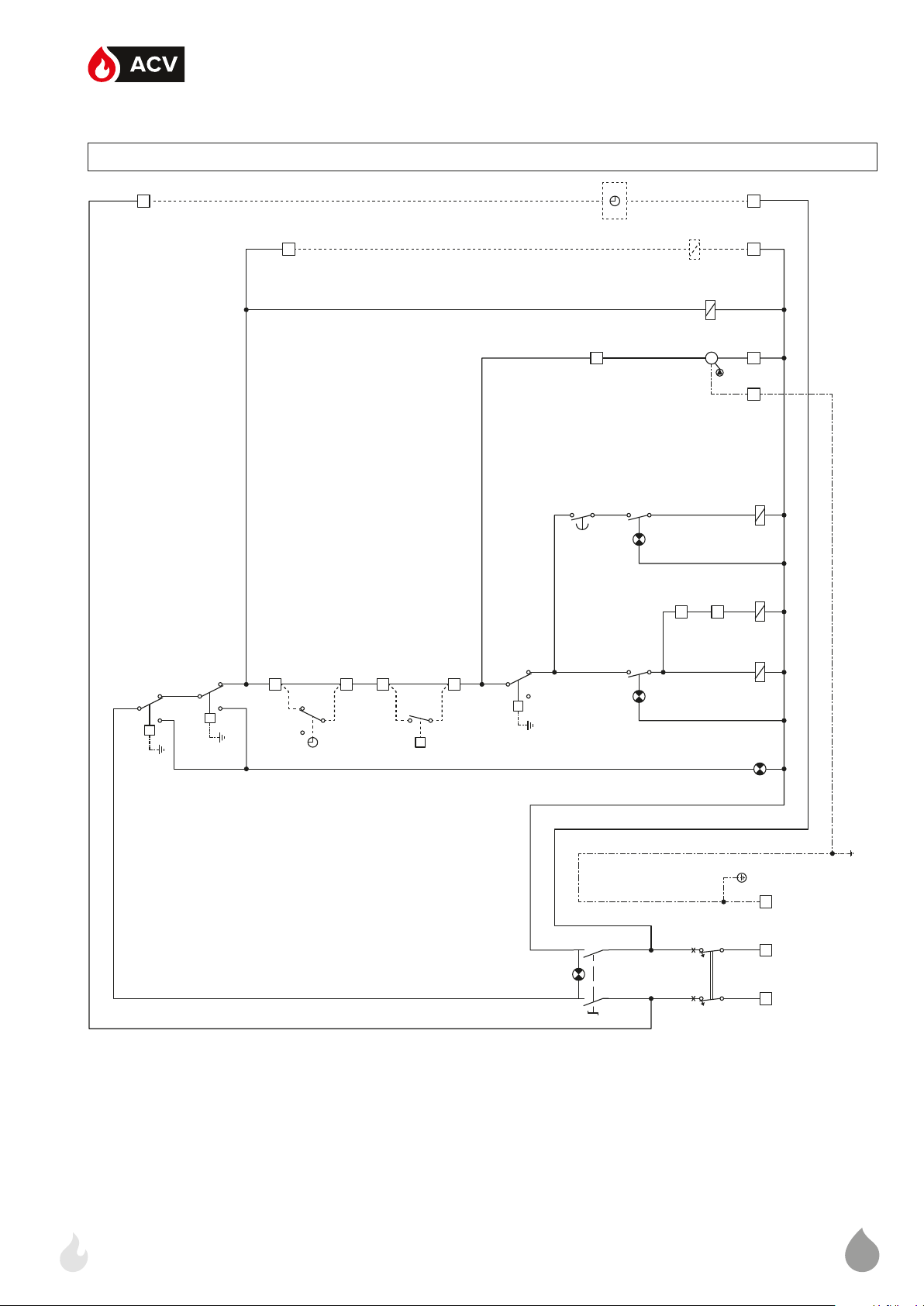

HONEYWELL SUNDIAL WIRING DIAGRAM : S PLAN

15

1133224455667788991010111112121313141415

Note: All bold numbers indicate a DIN rail terminal connection

o

gr

MOTOR

b

brbr

gr

MOTOR

b

V4043H

DHW ZONE VALVE

o

CYLINDER

STAT

3

1

2

T6306B

V4043H

HTG ZONE VALVE

ROOM STAT

b

o

o

br

C

b

gr

gr

7 8 9 10

br

b

1 432 5 6

bk- black

CABLE COLOUR CODES

E

HTGHW

br- brown

r-red

w-white

y- yellow

o - orange

b - blue

v - violet

p - pink

gr - grey

Note: Illustrated model: 22 kW Tri

N L

Honeywell

Sundial Wiring Centre

`S ` Plan

Note: Earth wires not shown for clarity

During installation the earth wires from each

component connect to terminal 3 in the wiring centre

A1007841-664Y7800 • A

Page 22

22

EN

C

CHECKS AND SETUP BEFORE START UP

Set-up conditions

• External power supply isolated

Procedure

1. Remove the boiler front panel, refer to "Removal and In-

stallation of the Access Panels" on page 14.

2. Set the internal MCB to OFF (See ML book).

3. Check all electrical connections for tightness.

4. Ensure all internal relays, contactors, etc. are secure on the

DIN rails.

5. Set all the control panel control switches to OFF.

6. Check the power stage delay timer settings:

• Adjustment screw (A) is factory set to the “1 to 10 min.”

position which is the optimum setting for the boiler. The

timer can be adjusted from 0.1 sec. to 10 hours.

• Adjustment screw (B) is used to set the DELAY ON time

of the following stage contactors, the available settings

are in 1 minute increments if A is set to 1 to 10 minutes.

• This function is particularly useful in areas where gradu-

al switching of electrical load is required and the resulting maximum demand kept to a minimum. The timers

add to the flexibility of the installation but must be optimised by a qualified engineer. The nominal setting is “1”.

7. Set the control thermostat to the desired temperature.

FILLING THE SYSTEM

If the system is fitted with an external

hot water tank, first put the DHW circuit

under pressure before pressurizing the

heating (primary) circuit. Refer to the hot

water preparation tank manual for more

information.

Set-up conditions

• External power supply isolated

• DHW circuit (if any) under pressure

Filling procedure

1. Open the isolating valves (1).

2. Make sure that the drain valve (2) is tightly closed.

3. Open the filling valve (3).

4. Make sure the air vent is open, as required.

5. Once the system is bled from air, bring the pressure to the

static pressure between 1.5 bar and 2 bar.

6. Close the filling valve (3)

Follow-on tasks

• Check there is no leak.

A

2

1

B

1

3

Cold water

Hot water

A1007841-664Y7800 • A

Page 23

23

STARTING THE BOILER

EN

Set-up conditions

• Hydraulic and electric connections made

• External power supply isolated

• Boiler filled and pressurised

Procedure

Before starting the boiler, make sure that the

air is bled from the heating circuit using the

automatic air vent located at the top of the

boiler. Note that the black dust cap on the

air vent should be left loose to allow the auto

vent to function.

Commissioning

11. The boiler temperature will now rise as indicated by the

combined temperature and pressure gauge (3).

12. The temperature will continue to rise until the control thermostat temperature setting is reached then the boiler will switch

o.

13. Set timeclock (if fitted) and/or external controls to desired

boiler operating on/o times.

Follow-on Task(s)

1. Remove the red sticker from the front face of the boiler.

After several days of operation, re-check all

electrical and hydraulic connections for tightness,

as well as the system operating pressure. Correct

and adjust as necessary.

3

4

1 2

1. Place all the switches (1 & 2) of the control panel to OFF.

2. Set the internal MCB to ON (See ML book).

3. Install the boiler front panel, refer to "Removal and In-

stallation of the Access Panels" on page 14.

4. Provide power supply to boiler through the external electrical box.

5. Turn the boiler on using the ON/OFF switch (1).

6. After a few minutes of operation of the circulating pump,

check the circuit pressure on the boiler manometer (3).

7. If necessary, place the ON/OFF switch (1) to OFF, bleed

the air from the circuit and top-up the circuit with water to

reach the minimum pressure of 1 bar, then turn the boiler

ON again.

8. If necessary, perform any additional set-up of the pump, according to the type of system. Refer to "Pump Set-up" on

page 16.

9. Switch on the power levels switch stage 1, the first stage

contactors will energise.

10. Switch on the power levels switch stage 2, after a short

delay the second stage contactors will energise.

A1007841-664Y7800 • A

Page 24

24

EN

M

RECOMMENDATIONS FOR THE BOILER

MAINTENANCE

Essential recommendations for the electrical

safety

• Before opening the boiler for maintenance,

turn off the boiler by pushing on the ON/OFF

master switch.

• Isolate the external power supply of the

appliance before performing any operation,

unless it is required to take measurements or

perform system setup.

Essential recommendations for safety

• Water flowing out of the drain valve may be

extremely hot and could cause severe scalding.

• Do not use solvents to clean any of the

components. The components could be

damaged, resulting in unreliable or unsafe

operation.

Essential recommendations for the correct

operation of the appliance

• It is recommended to have the boiler serviced

at least once a year or every 1,500 hours by a

qualified technician, preferably at the start of

the heating season. More frequent servicing

may be required depending on boiler use.

Please consult your installer for advice.

• The boiler maintenance will be carried out by

a qualified engineer, and the defective parts

may only be replaced by genuine factory

parts.

• Make sure to replace any gaskets or seals on

the removed components before reinstalling

them.

• To ensure maximum efficiency and reliability

of the unit, it is recommended that the enduser perform the periodic checks mentioned

in the Safety section of this manual.

• Control the tightness of the hydraulic circuit

connections.

BOILER SHUT-DOWN FOR

MAINTENANCE

1. Switch the boiler o using the ON/OFF master switch

2. Isolate the external power supply.

DRAINING THE BOILER

Set-up conditions

• Boiler shut down through the ON/OFF switch

• External power supply isolated (through the external elec-

trical box)

• Boiler cooled down (if it was in operation)

Procedure

1. Close the heating circuit isolating valves (1)

2. Open the draining valve (2) and allow the water to flow to

the drain

3. Actuate the automatic air vent (3).

Follow-on Task(s)

None

3

2

1

1

Cold water

Hot water

A1007841-664Y7800 • A

Page 25

25

EN

Maintenance

Before carrying out any work on the system ensure that the boiler is cool and all electrical supplies

are isolated.

BOILER MAINTENANCE

Set-up conditions

• Boiler shut down through the ON/OFF switch

• External power supply isolated (through the external elec-

trical box)

• Boiler cooled down (if it was in operation)

Procedure

1. Remove the top panel and front face of the boiler. Refer to

"Removal and Installation of the Access Panels" on

page 14.

2. Perform a visual inspection of the boiler looking out for

signs of water leakage from joints, expansion vessel, and

the area around the elements on top of the boiler.

3. Perform a visual inspection of all wiring and cables in the

boiler casing, checking for signs of overheating or burning.

4. Check all push-on electrical connectors for tightness and

good connection to the relative components.

5. Using an appropriate screwdriver, check all electrical terminals on DIN rails and on all components for tightness.

6. Check the settings on the internal timers in accordance with

"Checks and setup before start up" on page 22.

Follow-on task(s)

7. Replace the heating elements if necessary. See "Replac-

ing the Heating Elements" on page 26.

8. Restart the boiler, refer to "Starting the boiler" on page

23.

RESETTING THE HIGH LIMIT SAFETY

THE RMOSTAT

Set-up conditions

• Boiler shut down through the ON/OFF switch

• External power supply isolated (through the external electri-

cal box)

• Boiler cooled down (if it was in operation)

Procedure

1. Unscrew and remove the safety thermostat (1) cover, at the

bottom of the boiler.

2. Push on the safety thermostat (1) to reset it. A “click” sound

should be heard.

In case no “click” sound is heard, the safety

device is not the cause of the shut-off.

Troubleshooting should be performed by a

qualified service engineer.

3. Reinstall the safety thermostat cover.

Follow-on task(s)

1. Activate electrical power through the external electrical box

2. Turn the boiler on using the ON/OFF switch.

3. Make sure that the indicator light (2) is o.

CHECKING THE SAFETY DEVICES

9. Check the correct operation of:

• the thermostats.

• the safety valve(s).

• the automatic air vent.

2 1

A1007841-664Y7800 • A

Page 26

26

EN

Maintenance

REPLACING THE HEATING ELEMENTS

Set-up conditions

• Boiler shut down through the ON/OFF switch

• External power supply isolated (through the external elec-

trical box)

• Boiler cooled down (if it was in operation)

• Top cover removed (see "Removal and Installation of

the Access Panels" on page 14).

Removal Procedure

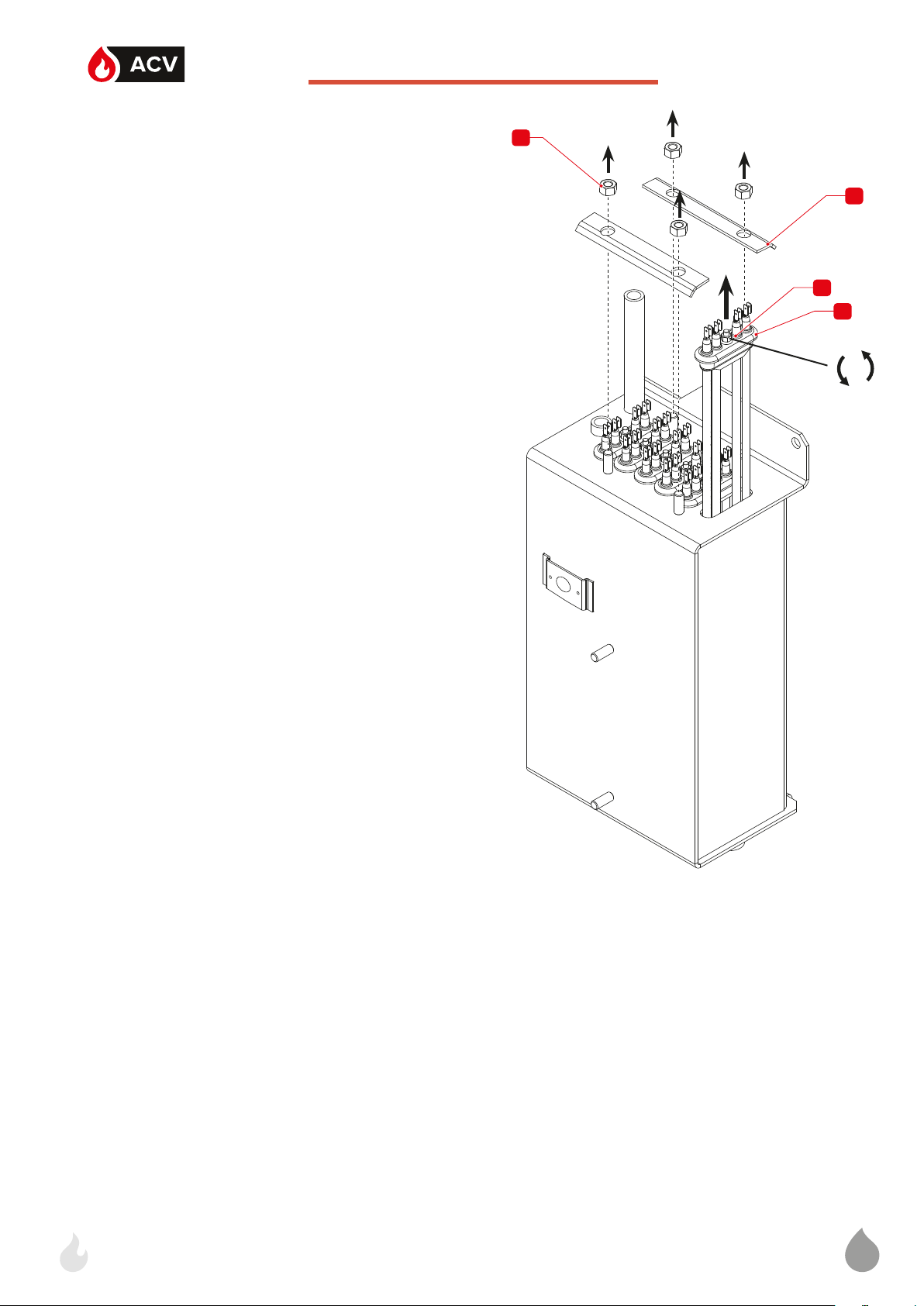

1. Release four nuts (1). Retain for reinstallation.

2. Remove two holders (2). Retain for reinstallation.

3. Release the center nut (3) of the heating element (4) to be

removed.

4. Remove heating element (4). Clean or discard it as required.

Installation Procedure

1. Install the clean/new heating element (4) in position. Do not

tighten the center nut (3) at this stage.

2. Install two holders (2) and tighten with two retained nuts (1).

3. Tighten the center nut (3) of the heating element (4).

1

2

3

3

4

Follow-on Task(s)

1. Check that all nuts are tight.

2. Reinstall the top cover. Refer to "Removal and Installa-

tion of the Access Panels" on page 14.

3. Restart the boiler as required, refer to "Starting the boil-

er" on page 23.

A1007841-664Y7800 • A

Page 27

27

TROUBLESHOOTING THE PUMP

EN

ALARM STATUS

T

Blocking

Voltage too low

Electrical failure

Pump rotor blocked; wait for the pump to restart or mechanically unblock the shaft with a screwdriver.

Supply voltage too low; check the supply voltage.

The pump has stopped because of a lack of voltage supply

or a serious failure; check the supply voltage or replace the

pump, as required.

A1007841-664Y7800 • A

Page 28

ACV International

Oude Vijverweg, 6

B-1653 Dworp

Belgium

belgium.service@acv.com

www.acv.com

Page 29

E-Tech W

ML

09 - 15 Mono

09 - 15 - 22 - 28 - 36 Tri

A1007841_664Y7800 • A

Page 30

2

...................................................................3

ML

..................................................................4

E-Tech W 09 Mono .................................................................. 4

E-Tech W 15 Mono ................................................................... 8

E-Tech W 09 - 15 Tri ...............................................................12

E-Tech W 22 Tri .......................................................................16

E-Tech W 28 Tri ..................................................................... 20

E-Tech W 36 Tri ......................................................................24

.................................................................. 28

MONO

TRI

Dimensions - Afstanden - Dimensiones - Dimensioni - Abmessungen - Wymiary Габаритные размеры

Wiring diagrams - Schémas électriques - Elektrische schema's - Diagramas de cableado

- schema elettrico - schematy połączeń - схемы подключения

Information - Informatie - Informaciones - Informazioni - Informationen - Informacje Информация

Single phase - monophasé - Eenfasig - Monofasico - Monofase - Wechselstrom - Jednofazowe - однофазный ток

Three phase - Triphasé - Driefasig - Trifasico - Trifase - Drehstrom - Trójfazowy трехфазный ток

Page 31

3

763 mm

442 mm

332 mm

185 mm

370 mm

105 mm

ML

Min.

25 mm

Min.

400 mm

Min.

200 mm

Page 32

4

E-TECH W 09 MONO

ML

Control - Commande - Besturing - Mando - Comando - Kontrol - regulacja - регулирование

1

Br

3

OrOrR

1

B

B

K4

Or Or

9

S5

W

A1

A2

1.1

1.2

T1

2.2

B

Or

R

M

Pk

12

13

B

B

B Br G

11 10 4 2

B

B

B

B

W W

5

P

Br

P

Bk

2 1

t

S2

PS

P

OrYOr Y

2 1

6

7

7

P

8

Y

1

t

C

GG Or

S3

2 1

t

B

Or Or

B

B

S4

1.1

1.2

2.2

B

B

S1

1.2 2.2

1.1 2.1

Bk Bk

Br

Br

R

R RR

4

B

CB

Br

2

K1 K3 K2

B

B

DS1

B

B

PE

3

B

1 2

Br

1

- Blu - Blau -Niebieski -

Голубой

Negro - Nero - Schwarz

- Czarny - Черный

Marrón - Marrone - Braun

- Brązowy - Коричневый

- Grigio - Grau - Siwy -

Серый

Naranja - Arancione

- Pomarańczowy -

B : Blue - Bleu - Blauw - Azul

Bk : Black - Noir - Zwart -

Br : Brown - Brun - Bruin -

G : Grey - Gris - Grijs - Gris

Or : Orange - Oranje -

- Różowy - Розовый

- Rojo - Rosso - Rot -

Czerwony - Красный

Blanco - Bianco - Weiß -

Biały - Белый

Amarillo - Gallo - Gelb -

Оранжевый

Pk : Pink - Rose - Roze - Rosa

R : Red - Rouge - Rood

W : White - Blanc - Wit -

Żółty - Желтый

Y : Yellow - Jaune - Geel -

Page 33

5

étage + lampe - Vermogenschakelaar 2 + lampje - Interruptor del segundo nivel + luz - Interruttore luminoso

ML

étage + lampe - Vermogenschakelaar 1 + lampje - Interruptor del primer nivel + luz - Interruttore luminoso del

er

obwodu regulacji - Цепь управления

Leuchte - ON/OFF zał/wyłącznik + lampa - Переключатель ВКЛ/ВЫКЛ + лампы

mostato de seguridad de rearme manual [103°C] - Termostato di sicurezza a riarmo manuale [103°C] - Manuell entriegelbares Sicherheitsthermostat [103°C] - Termostat

CB Circuit breaker - Disjoncteur - Magnetothermische Schakelaar - Disyuntor magnetotérmico - Interruttore magnetotermico generale ON/OFF - Sicherung - Bezpiecznik

S2 Manual reset safety thermostat [103°C] - Thermostat de sécurité à réarmement manuel [103°C] - Veiligheidsthermostaat met handmatige herinschakeling [103°C] - Ter-

S1 ON/OFF switch + lamp - Interrupteur ON/OFF + lampe - ON/OFF- schakelaar + lampje - Interruptor ON/OFF + luz - Interruttore luminoso ON/OFF - ON/OFF-Schalter +

stato di sicurezza mancanza acqua - Wassermangelsicherung - Czujnik ciśnienia wody - Реле минимального давления

bezpieczeństwa z ręcznym odblokowaniem [103°C] - Защитный термостат с ручным перезапуском [103°C]

PS Low-water pressure switch - Pressostat de sécurité manque d’eau - Veiligheidsdrukschakelaar watergebrek - Presostato de seguridad en caso de falta de agua - Presso-

вочный термостат

primo livello di potenza - Stufenschalter 1 + Leuchte - Przełącznik poziomu mocy 1 + lampa - Переключатель уровня мощности - ступень1 + лампы

kaźnik mocy 1 - poziom 1 - Силовое реле 1 - ступень 1

Przekaźnik mocy 2 - poziom 1 - Силовое реле 2 - ступень 1

DS1 Alarm - Signal de mise en sécurité - Alarm - Alarma - Allarme - Alarm - Alarm - Сигнализация

S3 Control thermostat - Thermostat de commande - Regelthermostaat - Termostato de mando - Termostato di comando - Einstellthermostat - Termostat kotłowy - Регулиро-

S4 Power switch level 1 + lamp - Commutateur de puissance 1

K1 Power relay 1 - level 1 - Relais de puissance 1 - étage 1 - Vermogensrelais 1 - trap 1 - Relé de potencia 1 - nivel 1 - Relè di potenza 1 - livello 1 - Leistung Relais 1 - Stufe 1 - Prze-

K3 Power relay 2 - level 1 - Relais de puissance 2 - étage 1 - Vermogensrelais 2 - trap 1 - Relé de potencia 2 - nivel 1 - Relè di potenza 2 - livello 1 - Leistung Relais 2 - Stufe 1 -

éme

электромагнитное реле

externeregeling (optioneel) - Alimentación eléctrica para optimizador o regulador (opcional) - Alimentazione elettrica per un regolatore o per un orologio per programmazione

giornaliera (in opzione) - Strom Versorgung für Schaltuhr oder Regler (Optional) - Zasilanie z zegara czasowego (opcja) - Перемычка или таймер часов работы (опция)

ГВС комплект (опция)

neel) - Puente de parada general o interruptor del optimizador (opcional) - Ponte di arresto generale o comando di un orologio per programmazione giornaliera

del secondo livello di potenza - Stufenschalter 2 + Leuchte - Przełącznik poziomu mocy 2 + lampa - Переключатель уровня мощности - ступень2 + лампы

Przekaźnik mocy 1 - poziom 2 - Силовое реле 1 - ступень 2

T1 Timer - Temporisateur - Timer - Temporizador - Temporizzatore - Zeitschalter - Przekaźnik czasowy - Реле времени включения второй ступени

S5 Power switch level 2 + lamp - Commutateur de puissance 2

K2 Power relay 1 - level 2 - Relais de puissance 1 - étage 2 - Vermogensrelais 1 - trap 2 - Relé de potencia 1 - nivel 2 - Relè di potenza 1 - livello 2 - Leistung Relais 1 - Stufe 2 -

K4 Safety switch - Contacteur de sécurité - Veiligheidscontact - Contactor de seguridad - Contattore di sicurezza - Sicherheitsrelais - Przekaźnik główny - Отключающее

1-2 Time clock or controller supply (optional) - Alimentation électrique pour un régulateur ou un programmateur journalier optionnel - Voedingsspanning voor Schakelklok of

3-4 DHW kit (optional) - Kit sanitaire (en option) - Sanitaire kit (optioneel) - Kit sanitario (opcional) - Kit sanitario (opzionale) - Sanitärer Satz (Optional) - Zestaw CWU (opcja) -

(in opzione) - Schaltuhr oder Regler Eingang (Optional) - Mostek wyłączający lub wyłącznik czasowy (opcja) - Перемычка или таймер часов работы (опция)

le) - Raumthermostat (Optional) - Termostat pokojowy (opcja) - Комнатный термостат (опция)

5-6 Stop Bridge or time clock switch control (optional) - Pont d’arrêt général ou commande du programmateur journalier optionnel - Aansluiting Schakelklok of regeling (optio-

7-8 Room thermostat (optional) - Thermostat d’ambiance (en option) - Omgevingsthermostaat (optioneel) - Termostato de ambiente (opcional) - Termostato ambiente (opziona-

9-10-11 Heating pump - Pompe chauffage - Warmtepomp - Circulador de calefacción - Circolatore di riscaldamento - Heizpumpe - Pompa kotła - Насос котла

Перемычка ограничения мощности

12-13 Relay K3 deactivated - Relais K3 désactivé - Desactivering van relais K3 - Descarga del relé K3 - Esclusione del relè K3 - Abschaltung Relais K3 - Mostek przekaźnika K3 -

Page 34

6

E-TECH W 09 MONO

ML

Power - Puissance - Vermogen - Potencia - Potenza - Leistung - Zasilania - Силовая часть

BB

R

B

Br

BB

Br

B

Bk

BB

Bk

R

B

Br

Br

B

Bk

Bk

B

B

R

R

K1 K2 K3

B : Blue - Bleu - Blauw - Azul - Blu - Blau -Niebieski - Голубой

Bk : Black - Noir - Zwart - Negro - Nero - Schwarz - Czarny - Черный

Br : Brown - Brun - Bruin - Marrón - Marrone - Braun - Brązowy - Коричневый

G : Grey - Gris - Grijs - Gris - Grigio - Grau - Siwy - Серый

Or : Orange - Oranje - Naranja - Arancione - Pomarańczowy - Оранжевый

Pk : Pink - Rose - Roze - Rosa - Różowy - Розовый

R : Red - Rouge - Rood - Rojo - Rosso - Rot - Czerwony - Красный

W : White - Blanc - Wit - Blanco - Bianco - Weiß - Biał y - Белый

Y : Yellow - Jaune - Geel - Amarillo - Gallo - Gelb - Żółty - Желтый

PE

B

B

B

R

Bk

Br

B

B

B

R

Bk

Br

L N

K4

Page 35

7

12121313141415

15

12121313141415

15

ML

Силовое реле 1 - ступень 1

K1 Power relay 1 - level 1 - Relais de puissance 1 - étage 1 - Vermogensrelais 1 - trap 1 - Relé de potencia 1 - nivel 1 - Relè di potenza 1 - livello 1 - Leistung Relais 1 - Stufe 1 - Przekaźnik mocy 1 - poziom 1 -

K2 Power relay 1 - level 2 - Relais de puissance 1 - étage 2 - Vermogensrelais 1 - trap 2 - Relé de potencia 1 - nivel 2 - Relè di potenza 1 - livello 2 - Leistung Relais 1 - Stufe 2 - Przekaźnik mocy 1 - poziom

2 - Силовое реле 1 - ступень 2

K3 Power relay 2 - level 1 - Relais de puissance 2 - étage 1 - Vermogensrelais 2 - trap 1 - Relé de potencia 2 - nivel 1 - Relè di potenza 2 - livello 1 - Leistung Relais 2 - Stufe 1 - Przekaźnik mocy 2 - poziom

1 - Силовое реле 2 - ступень 1

K4 Safety switch - Contacteur de sécurité - Veiligheidscontact - Contactor de seguridad - Contattore di sicurezza - Sicherheitsrelais - Przekaźnik główny - Отключающее электромагнитное реле

E-Tech W 09 8.4 kW 5.6 kW

Mono TB1

Page 36

8

E-TECH W 15 MONO

ML

Control - Commande - Besturing - Mando - Comando - Kontrol - regulacja - регулирование

1

Br

3

OrOrR

1

B

B

K4

Or Or

9

S5

W

A1

A2

1.1

1.2

T1

2.2

B

Or

R

M

Pk

12

13

B

B

B Br G

11 10 4 2

B

B

B

B

W W

5

P

Br

P

Bk

2 1

t

S2

PS

P

OrYOr Y

2 1

6

7

7

P

8

Y

1

t

C

GG Or

S3

2 1

t

B

Or Or

B

B

S4

1.1

1.2

2.2

B

B

S1

1.2 2.2

1.1 2.1

Bk Bk

Br

Br

R

R RR

4

B

CB

Br

2

K1 K3 K2

B

B

DS1

B

B

PE

3

B

1 2

Br

1

- Blu - Blau -Niebieski -

Голубой

Negro - Nero - Schwarz

- Czarny - Черный

Marrón - Marrone - Braun

- Brązowy - Коричневый

- Grigio - Grau - Siwy -

Серый

Naranja - Arancione

- Pomarańczowy -

B : Blue - Bleu - Blauw - Azul

Bk : Black - Noir - Zwart -

Br : Brown - Brun - Bruin -

G : Grey - Gris - Grijs - Gris

Or : Orange - Oranje -

- Różowy - Розовый

- Rojo - Rosso - Rot -

Czerwony - Красный

Blanco - Bianco - Weiß -

Biały - Белый

Amarillo - Gallo - Gelb -

Оранжевый

Pk : Pink - Rose - Roze - Rosa

R : Red - Rouge - Rood

W : White - Blanc - Wit -

Żółty - Желтый

Y : Yellow - Jaune - Geel -

Page 37

9

étage + lampe - Vermogenschakelaar 2 + lampje - Interruptor del segundo nivel + luz - Interruttore luminoso

ML

étage + lampe - Vermogenschakelaar 1 + lampje - Interruptor del primer nivel + luz - Interruttore luminoso del

er

obwodu regulacji - Цепь управления

Leuchte - ON/OFF zał/wyłącznik + lampa - Переключатель ВКЛ/ВЫКЛ + лампы

mostato de seguridad de rearme manual [103°C] - Termostato di sicurezza a riarmo manuale [103°C] - Manuell entriegelbares Sicherheitsthermostat [103°C] - Termostat

CB Circuit breaker - Disjoncteur - Magnetothermische Schakelaar - Disyuntor magnetotérmico - Interruttore magnetotermico generale ON/OFF - Sicherung - Bezpiecznik

S2 Manual reset safety thermostat [103°C] - Thermostat de sécurité à réarmement manuel [103°C] - Veiligheidsthermostaat met handmatige herinschakeling [103°C] - Ter-

S1 ON/OFF switch + lamp - Interrupteur ON/OFF + lampe - ON/OFF- schakelaar + lampje - Interruptor ON/OFF + luz - Interruttore luminoso ON/OFF - ON/OFF-Schalter +

stato di sicurezza mancanza acqua - Wassermangelsicherung - Czujnik ciśnienia wody - Реле минимального давления

bezpieczeństwa z ręcznym odblokowaniem [103°C] - Защитный термостат с ручным перезапуском [103°C]

PS Low-water pressure switch - Pressostat de sécurité manque d’eau - Veiligheidsdrukschakelaar watergebrek - Presostato de seguridad en caso de falta de agua - Presso-

вочный термостат

primo livello di potenza - Stufenschalter 1 + Leuchte - Przełącznik poziomu mocy 1 + lampa - Переключатель уровня мощности - ступень1 + лампы

kaźnik mocy 1 - poziom 1 - Силовое реле 1 - ступень 1

Przekaźnik mocy 2 - poziom 1 - Силовое реле 2 - ступень 1

DS1 Alarm - Signal de mise en sécurité - Alarm - Alarma - Allarme - Alarm - Alarm - Сигнализация

S3 Control thermostat - Thermostat de commande - Regelthermostaat - Termostato de mando - Termostato di comando - Einstellthermostat - Termostat kotłowy - Регулиро-

S4 Power switch level 1 + lamp - Commutateur de puissance 1

K1 Power relay 1 - level 1 - Relais de puissance 1 - étage 1 - Vermogensrelais 1 - trap 1 - Relé de potencia 1 - nivel 1 - Relè di potenza 1 - livello 1 - Leistung Relais 1 - Stufe 1 - Prze-

K3 Power relay 2 - level 1 - Relais de puissance 2 - étage 1 - Vermogensrelais 2 - trap 1 - Relé de potencia 2 - nivel 1 - Relè di potenza 2 - livello 1 - Leistung Relais 2 - Stufe 1 -

éme

электромагнитное реле

externeregeling (optioneel) - Alimentación eléctrica para optimizador o regulador (opcional) - Alimentazione elettrica per un regolatore o per un orologio per programmazione

giornaliera (in opzione) - Strom Versorgung für Schaltuhr oder Regler (Optional) - Zasilanie z zegara czasowego (opcja) - Перемычка или таймер часов работы (опция)

ГВС комплект (опция)

neel) - Puente de parada general o interruptor del optimizador (opcional) - Ponte di arresto generale o comando di un orologio per programmazione giornaliera

del secondo livello di potenza - Stufenschalter 2 + Leuchte - Przełącznik poziomu mocy 2 + lampa - Переключатель уровня мощности - ступень2 + лампы

Przekaźnik mocy 1 - poziom 2 - Силовое реле 1 - ступень 2

T1 Timer - Temporisateur - Timer - Temporizador - Temporizzatore - Zeitschalter - Przekaźnik czasowy - Реле времени включения второй ступени

S5 Power switch level 2 + lamp - Commutateur de puissance 2

K2 Power relay 1 - level 2 - Relais de puissance 1 - étage 2 - Vermogensrelais 1 - trap 2 - Relé de potencia 1 - nivel 2 - Relè di potenza 1 - livello 2 - Leistung Relais 1 - Stufe 2 -

K4 Safety switch - Contacteur de sécurité - Veiligheidscontact - Contactor de seguridad - Contattore di sicurezza - Sicherheitsrelais - Przekaźnik główny - Отключающее

1-2 Time clock or controller supply (optional) - Alimentation électrique pour un régulateur ou un programmateur journalier optionnel - Voedingsspanning voor Schakelklok of

3-4 DHW kit (optional) - Kit sanitaire (en option) - Sanitaire kit (optioneel) - Kit sanitario (opcional) - Kit sanitario (opzionale) - Sanitärer Satz (Optional) - Zestaw CWU (opcja) -

(in opzione) - Schaltuhr oder Regler Eingang (Optional) - Mostek wyłączający lub wyłącznik czasowy (opcja) - Перемычка или таймер часов работы (опция)

le) - Raumthermostat (Optional) - Termostat pokojowy (opcja) - Комнатный термостат (опция)

5-6 Stop Bridge or time clock switch control (optional) - Pont d’arrêt général ou commande du programmateur journalier optionnel - Aansluiting Schakelklok of regeling (optio-

7-8 Room thermostat (optional) - Thermostat d’ambiance (en option) - Omgevingsthermostaat (optioneel) - Termostato de ambiente (opcional) - Termostato ambiente (opziona-

9-10-11 Heating pump - Pompe chauffage - Warmtepomp - Circulador de calefacción - Circolatore di riscaldamento - Heizpumpe - Pompa kotła - Насос котла

Перемычка ограничения мощности

12-13 Relay K3 deactivated - Relais K3 désactivé - Desactivering van relais K3 - Descarga del relé K3 - Esclusione del relè K3 - Abschaltung Relais K3 - Mostek przekaźnika K3 -

Page 38

10

E-TECH W 15 MONO

ML

Power - Puissance - Vermogen - Potencia - Potenza - Leistung - Zasilania - Силовая часть

BB

R

B

Or

BB

Or

B

Bk

BB

Bk

R

B

Or

Or

B

Bk

Bk

B

R

B

R

B : Blue - Bleu - Blauw - Azul - Blu - Blau -Niebieski - Голубой

Bk : Black - Noir - Zwart - Negro - Nero - Schwarz - Czarny - Черный

Br : Brown - Brun - Bruin - Marrón - Marrone - Braun - Brązowy - Коричневый

G : Grey - Gris - Grijs - Gris - Grigio - Grau - Siwy - Серый

Or : Orange - Oranje - Naranja - Arancione - Pomarańczowy - Оранжевый

Pk : Pink - Rose - Roze - Rosa - Różowy - Розовый

R : Red - Rouge - Rood - Rojo - Rosso - Rot - Czerwony - Красный

W : White - Blanc - Wit - Blanco - Bianco - Weiß - Biał y - Белый

Y : Yellow - Jaune - Geel - Amarillo - Gallo - Gelb - Żółty - Желтый

K1 K2 K3

PE

B

B

B

B

B

B

R

R

Bk

Bk

Or

Or

2

2

2

2

2

2

1

B

1

B

1

B

1

R

1

Bk

1

Or

L N

S6

(F25A)

K4

Page 39

11

E-Tech W 15 14.4 kW 9.6 kW

12121313141415

15

12121313141415

15

ML

Mono TB1

di 25A - Leistungsklemmen mit Sicherung 25A - Zaciski zasilania z zabezpieczeniem 25A - Клеммная колодка силовой цепи с предохранителями 25A

Power relay 1 - level 1 - Relais de puissance 1 - étage 1 - Vermogensrelais 1 - trap 1 - Relé de potencia 1 - nivel 1 - Relè di potenza 1 - livello 1 - Leistung Relais 1 - Stufe 1 - Przekaźnik mocy 1 - poziom 1 -

Силовое реле 1 - ступень 1

Power relay 1 - level 2 - Relais de puissance 1 - étage 2 - Vermogensrelais 1 - trap 2 - Relé de potencia 1 - nivel 2 - Relè di potenza 1 - livello 2 - Leistung Relais 1 - Stufe 2 - Przekaźnik mocy 1 - poziom

2 - Силовое реле 1 - ступень 2

Power relay 2 - level 1 - Relais de puissance 2 - étage 1 - Vermogensrelais 2 - trap 1 - Relé de potencia 2 - nivel 1 - Relè di potenza 2 - livello 1 - Leistung Relais 2 - Stufe 1 - Przekaźnik mocy 2 - poziom

1 - Силовое реле 2 - ступень 1

Power terminals with 25A fuse - Bornier de puissance avec fusible 25A - Vermogensklemmen met zekering van 25A - Bornes de potencia con fusible 25A - Morsettiera di potenza con fusibili

Safety switch - Contacteur de sécurité - Veiligheidscontact - Contactor de seguridad - Contattore di sicurezza - Sicherheitsrelais - Przekaźnik główny - Отключающее электромагнитное реле

S6

K1

K2

K3

K4

Page 40

12

E-TECH W 09 - 15 TRI

ML

Control - Commande - Besturing - Mando - Comando - Kontrol - regulacja - регулирование

1

Br

3

OrOrR

1

B

B

K3

Or Or

9

S5

W

A1

A2

1.1

1.2

T1

2.2

B

Or

M

Pk

B

B

B Br G

11 10 4 2

B

B

B

5

P

Br

P

Bk

2 1

t

S2

PS

P

OrYOr Y

2 1

6

7

7

P

8

Y

1

t

C

GG Or

S3

2 1

t

B

Or Or

B

B

S4

1.1

1.2

2.2

B

B

S1

1.2 2.2

1.1 2.1

Bk Bk

Br

Br

R

R RR

4

B

CB

Br

2

K1 K2

B

B

DS1

B

B

PE

3

B

1 2

Br

1

- Blu - Blau -Niebieski -

Голубой

Negro - Nero - Schwarz

- Czarny - Черный

Marrón - Marrone - Braun

- Brązowy - Коричневый

- Grigio - Grau - Siwy -

Серый

Naranja - Arancione

- Pomarańczowy -

Оранжевый

- Różowy - Розовый

- Rojo - Rosso - Rot -

Czerwony - Красный

Blanco - Bianco - Weiß -

Biały - Белый

Amarillo - Gallo - Gelb -

Żółty - Желтый

B : Blue - Bleu - Blauw - Azul

Bk : Black - Noir - Zwart -

Br : Brown - Brun - Bruin -

G : Grey - Gris - Grijs - Gris

Or : Orange - Oranje -

Pk : Pink - Rose - Roze - Rosa

R : Red - Rouge - Rood

W : White - Blanc - Wit -

Y : Yellow - Jaune - Geel -

Page 41

13

étage + lampe - Vermogenschakelaar 2 + lampje - Interruptor del segundo nivel + luz - Interruttore luminoso

ML

étage + lampe - Vermogenschakelaar 1 + lampje - Interruptor del primer nivel + luz - Interruttore luminoso del

er

obwodu regulacji - Цепь управления

Leuchte - ON/OFF zał/wyłącznik + lampa - Переключатель ВКЛ/ВЫКЛ + лампы

mostato de seguridad de rearme manual [103°C] - Termostato di sicurezza a riarmo manuale [103°C] - Manuell entriegelbares Sicherheitsthermostat [103°C] - Termostat

CB Circuit breaker - Disjoncteur - Magnetothermische Schakelaar - Disyuntor magnetotérmico - Interruttore magnetotermico generale ON/OFF - Sicherung - Bezpiecznik

S2 Manual reset safety thermostat [103°C] - Thermostat de sécurité à réarmement manuel [103°C] - Veiligheidsthermostaat met handmatige herinschakeling [103°C] - Ter-

S1 ON/OFF switch + lamp - Interrupteur ON/OFF + lampe - ON/OFF- schakelaar + lampje - Interruptor ON/OFF + luz - Interruttore luminoso ON/OFF - ON/OFF-Schalter +

stato di sicurezza mancanza acqua - Wassermangelsicherung - Czujnik ciśnienia wody - Реле минимального давления

bezpieczeństwa z ręcznym odblokowaniem [103°C] - Защитный термостат с ручным перезапуском [103°C]

PS Low-water pressure switch - Pressostat de sécurité manque d’eau - Veiligheidsdrukschakelaar watergebrek - Presostato de seguridad en caso de falta de agua - Presso-

вочный термостат

primo livello di potenza - Stufenschalter 1 + Leuchte - Przełącznik poziomu mocy 1 + lampa - Переключатель уровня мощности - ступень1 + лампы

kaźnik mocy 1 - poziom 1 - Силовое реле 1 - ступень 1

DS1 Alarm - Signal de mise en sécurité - Alarm - Alarma - Allarme - Alarm - Alarm - Сигнализация

S3 Control thermostat - Thermostat de commande - Regelthermostaat - Termostato de mando - Termostato di comando - Einstellthermostat - Termostat kotłowy - Регулиро-

S4 Power switch level 1 + lamp - Commutateur de puissance 1

K1 Power relay 1 - level 1 - Relais de puissance 1 - étage 1 - Vermogensrelais 1 - trap 1 - Relé de potencia 1 - nivel 1 - Relè di potenza 1 - livello 1 - Leistung Relais 1 - Stufe 1 - Prze-

éme

электромагнитное реле

externeregeling (optioneel) - Alimentación eléctrica para optimizador o regulador (opcional) - Alimentazione elettrica per un regolatore o per un orologio per program-

mazione giornaliera (in opzione) - Strom Versorgung für Schaltuhr oder Regler (Optional) - Zasilanie z zegara czasowego (opcja) - Перемычка или таймер часов работы

(опция)

ГВС комплект (опция)

neel) - Puente de parada general o interruptor del optimizador (opcional) - Ponte di arresto generale o comando di un orologio per programmazione giornaliera