ACV E-tech S 160, E-tech S 240, E-tech S 290, E-tech S 380 INSTALLATION OPERATING AND SERVICING INSTRUCTIONS

Page 1

03/02/2005 - 66401700.A

excellence in hot water

Installation, Operating and

Servicing Instructions

E-tech S 160 / 240 / 290 / 380

Page 2

Page 3

1

PEOPLE WHO SHOULD READ

THESE INSTRUCTIONS

These instructions are intended for:

- specifying engineers

- the installing engineers

- end-users

- servicing engineers

SYMBOLS

The following symbols are used in these instructions:

Essential instruction for operating the system

correctly.

Essential instruction for personal safety or

environmental protection

Danger of electrocution.

Risk of scalding.

WARNINGS

These instructions are an integral part of the equipment to which

they refer and must be supplied to the user.

The product must be installed and serviced by qualified engineers,

in compliance with the prevailing standards.

ACV accepts no liability for any damage resulting from incorrect

installation or from the use of components or fittings not specified by

ACV.

Failure to observe instructions regarding tests and

test procedures can result in personal injury or

pollution risks.

Note:

ACV reserves the right to modify the technical specifications and

components of its products without prior notice.

INDEX INTRODUCTION

INTRODUCTION 1

People who should read these instructions 1

Symbols 1

Warnings 1

DESCRIPTION 2

Overview 2

Operating principle 2

Construction features 2

TECHNICAL SPECIFICATIONS 4

Dimensions 4

General features 4

Maximum operating conditions 5

Domestic hot water performances 5

INSTALLATION 6

Boiler room 6

Heating connection 6

Domestic hot water connection 7

Controller kits 7

Electrical connections 8

COMMISSIONING 12

Filling the domestic hot water and heating circuits 12

ENTRETIEN 13

Service intervals 13

Servicing the boiler 13

Servicing the safety devices 13

Boiler draining 13

Spare parts 13

USER GUIDE 14

Using the boiler 14

Boiler shutdown 15

NOTE 16

Page 4

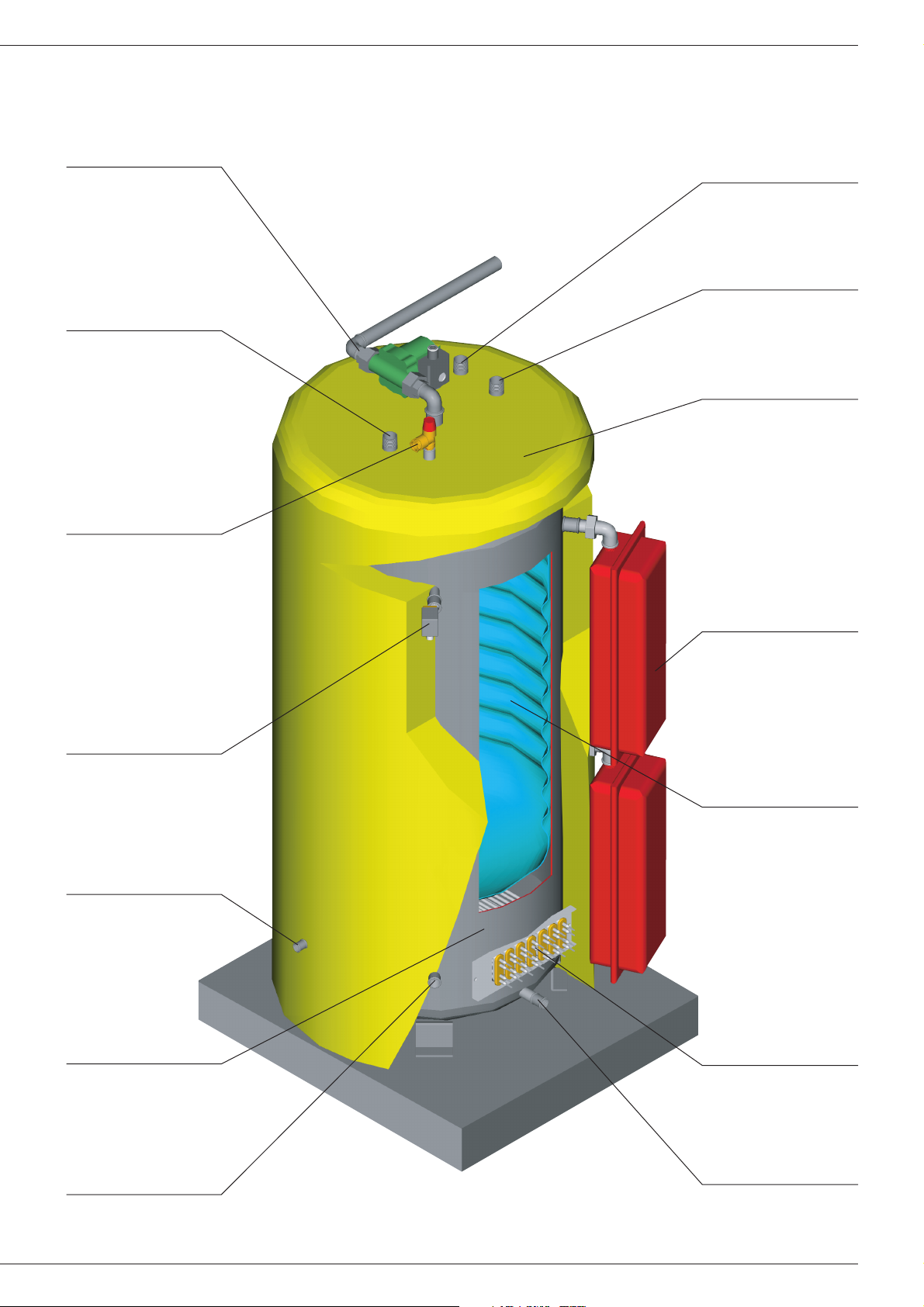

OVERVIEW

• Combination boiler (central heating and domestic hot water).

•TANK-IN-TANK indirect storage type domestic hot water production.

• The central heating connections are designed so that they can be

connected in all three directions, this means that the boiler can be

installed against a wall or in a corner without having to leave any

free space

(see page 6).

• Internal two-stage temperature control thermostat, which allows

the power to be adapted according to actual heat requirements.

• The boiler is fitted with expansion tanks, a safety valve, a

mano-thermometer, a water low safety device

(pressure switch) and

a circulation pump.

OPERATING PRINCIPLE

The TANK-IN-TANK concept

The Etech’s series differs from traditional hot water producers in that

it has a tank immersed in the primary fluid contained in the outer

body. When there is a temperature drop in the boiler because the

central heating system or the domestic hot water circuit needs hot

water, the internal thermostat starts up the power on the immersed

electrical resistors. The heating elements quickly heat up the primary

fluid, thus creating a natural circulation around the tank.

Indirectly heating domestic hot water

This circulation allows easier heat exchange between the primary

fluid and the domestic water, all over the tank surface.The corrugations

on the outer shell of the tank increase the area of heat exchange still

further and thus speed up the process of heating the domestic

water.

Easy to set

With a single command, the water temperature of both the primary

circuit and the domestic hot water circuit can be set by the adjustable

thermostat situated underneath the tank in the primary circuit.

2

DESCRIPTION

CONSTRUCTION FEAURES

Outer body

The outer body containing the primary fluid is made of thick STW 22

steel.

TANK-IN-TANK type exchanger accumulator

The ring-shaped inner tank with its large heating surface for

producing domestic hot water is built of Chrome/Nickel 18/10

stainless steel. It is corrugated ocer its full height by an exclusive

production process and entirely argon arc welded by the TIG

(Tungsten Inert Gas) method.

Isulation

The boiler body is fully insulated by rigid polyurethane foam, with a

thickness of 70mm, with a high thermal insulation coefficient. This is

sprayed onto the tank without using any CFCs.

Casing

The boiler is covered by a steel jacket which has been scoured and

phosphated before being stove enamelled at 220 °C.

Heating elements

nding on the model, the boiler is fitted with either six or seven

etachable stainless steel AISI 304L immersion heaters.

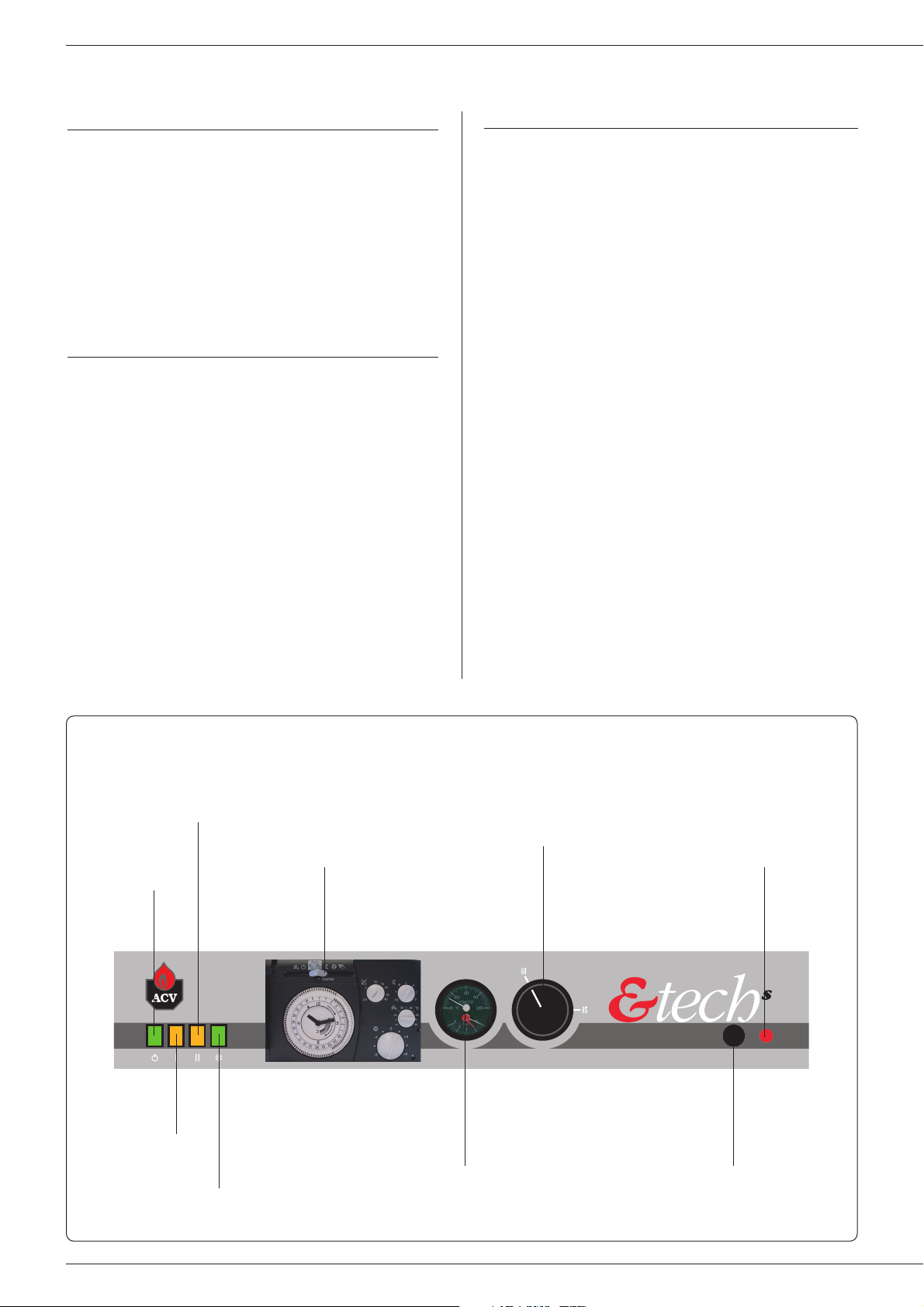

Controller

Control

thermostat

ON/OFF

switch

Power

selection

switch

Summer/Winter

selector switch

Combined temperature

and pressure gauge

Power

selection

switch

Safety

indicator

light

Safety

thermostat

Control panel

Page 5

3

DESCRIPTION

Domestic hot

water return

Domestic hot

water outlet

Insulation

Central heating

flow pipe

Primary

expansion

vessel

Tank-in-Tank

heat exchanger

Drain cock

Control thermostat

Primary circuit

Primary

safety valve

Domestic cold

water inlet

Heating return

Low water

pressure switch

Heating resistors

Page 6

4

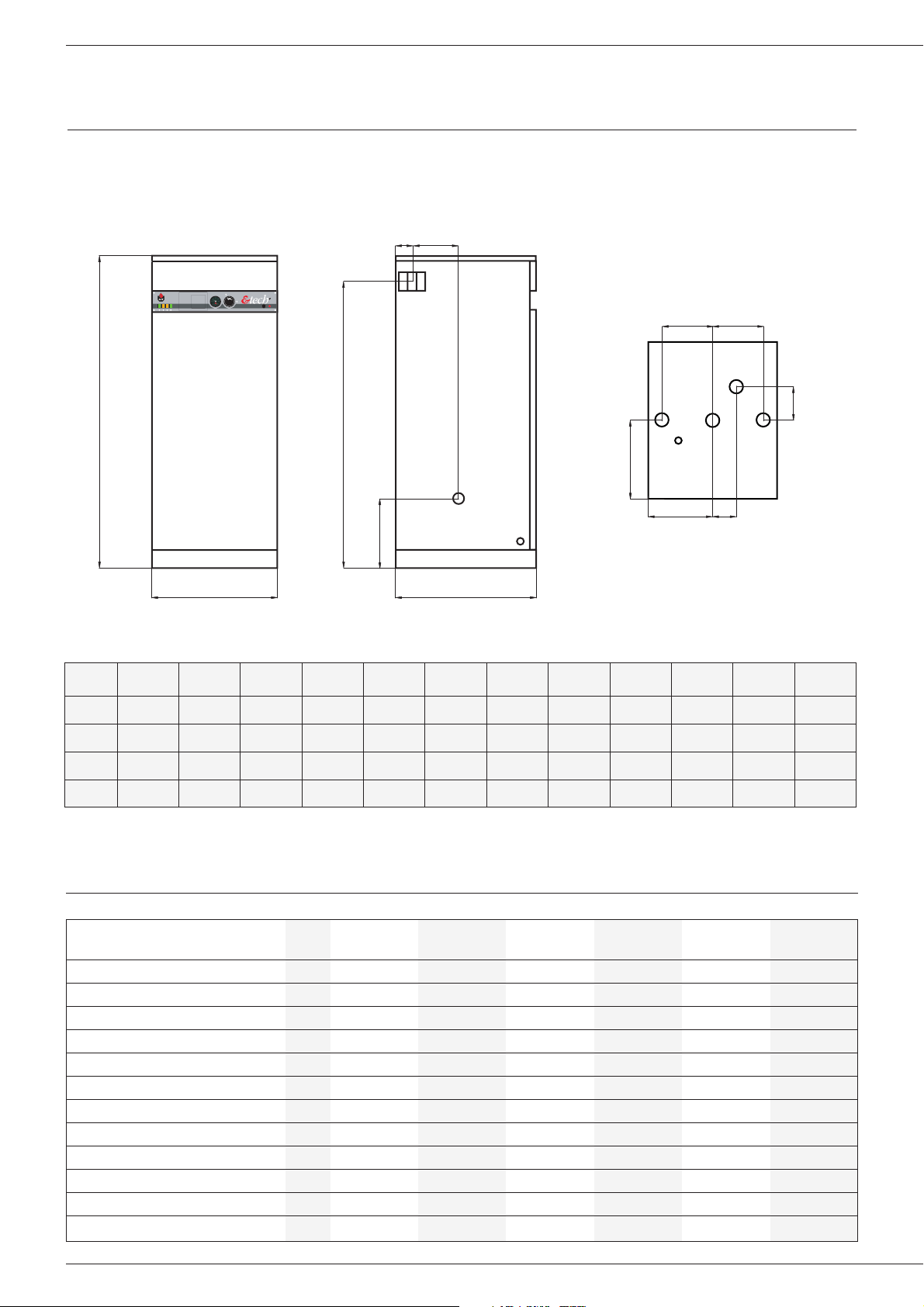

DIMENSIONS

The units are delivered fully assembled, tested and packed on a timber base with shockproof edges and protected by heat-shrunk plastic film.

On reception and after unpacking, check the equipment for domage. For transport purposes, refer to the weight and dimensions give below.

TECHNICAL SPECIFICATIONS

I J

KK

H

L

E-tech S 160 E-tech S 240 E-tech S 290 E-tech S 290 E-tech S 380 E-tech S 380

single phase tri phase mono phase tri phase

Output kW 14.4 14.4 14.4 28.8 14.4 28.8

Operating voltage Volt 230 230 230 3 x 400 + N 230 3 x 400 + N

Total capacity L 161 242 295 295 394 394

Primary circuit capacity L 55 68 97 97 127 127

Central heating connections Ø 1” 1” 1” 1” 1” 1”

Domestic hot water connections Ø 3/4” 3/4” 1” 1” 1 1/2” 1 1/2”

Hot water tank exchange surface m

2

1.26 1.87 2.0 2.0 2.6 2.6

Weight when empty kg 115 155 202 202 230 230

Domestic hot water max. pressure bar 10 10 10 10 10 10

Central heating max. pressure bar 333333

Expansion tank 1 x 8 L 1 x 8 L 2 x 8 L 2 x 8 L 2 x 8 L 2 x 8 L

Max. T° setting °C 85 85 85 85 85 85

A mm B mm C mm D mm E mm F mm G mm H mm I mm J mm K mm L mm

160 1432 620 720 1282 290 43 265 405 310 127 180 126

240 1953 620 720 1800 290 43 265 405 310 127 180 126

290 1784 720 800 1627 300 92 265 435 360 94 135 96

380 2134 720 800 1985 300 92 265 435 360 94 135 96

GENERAL FEATURES

GF

A

D

E

B C

Page 7

5

TECHNICAL SPECIFICATIONS

MAXIMUM OPERATING CONDITIONS

Maximum operating pressure (tank full of water)

- Primary circuit: 3 bar

- Secondary circuit: 10 bar

Test pressure (tank full of water)

- Primary circuit: 4.5 bar

- Secondary circuit: 13 bar

Operating temperature

Maximum temperature: 90 °C

Water quality

• Chlorures: < 150 mg/l (304)

< 2000 mg/l (Duplex)

• 8

≥ ph≥ 6

DOMESTIC HOT WATER PERFORMANCES

E-tech S 160 E-tech S 240 E-tech S 290 E-tech S 290 E-tech S 380 E-tech S 380

single phase tri phase mono phase tri phase

Peak delivery at 40 °C L/10’ 310 532 645 660 855 870

Peak delivery at 45 °C L/10’ 250 452 548 561 725 739

Peak delivery at 60 °C L/10’ 168 294 356 365 468 472

Peak delivery at 40 °C L/60’ 690 880 990 1305 1200 1516

Peak delivery at 45 °C L/60’ 570 750 845 1090 1021 1270

Peak delivery at 60 °C L/60’ 375 465 527 625 636 752

Continuous delivery at 40 °C L/h 413 413 413 826 413 826

Continuous delivery at 45 °C L/h 354 354 354 708 354 708

Continuous delivery at 60 °C L/h 248 248 248 415 248 448

Start-up time [10-80°C] min 61 93 113 91 150 120

Start-up time [15-65°C] min 44 66 81 65 107 86

Page 8

6

BOILER ROOM

Important

•Keep vents free at all times.

• Do not store inflammable products in the boiler room.

• Do not store corrosive products near the boiler, such as paints,

solvents, chlorine, salt, soap and other cleaning products.

Accessibility

The boiler room must be large enough to allow proper access to

the boiler. The following minimum distances around the boiler are

required:

- at the front: 500 mm

- above: 300 mm

- on the central heating connection side: 150 mm

This boiler can be connected to the central heating circuit in any one

of three directions.

HEATING CONNECTION

The drain cock (8) and safety valve (2) must be connected to the

waste water disposal system.

The boiler is fitted with an expansion chamber with a

capacity of:

• 8 litres on Etech’s 160 and 240 models.

• 16 litres on Etech’s 290 and 380 models.

If the expansion volume is not sufficient for your

needs then it is possible to install an additional tank.

The boiler is fitted with a safety valve set to 3 bar.

1. 3-way valve

2. Safety valve preset to 3 bar with pressure gauge

3. Heating pump

4. Non-return valve

5. Expansion vessel

6. Controller

7. Isolation valves

8. Drain cock

INSTALLATION

Base

The boiler must be laid on a base made of non-combustible materials.

77

6

4

3

2

1

5

5

8

Y

Y

Page 9

7

INSTALLATION

DOMESTIC HOT WATER CONNECTION

Pressure reducer

If the water mains pressure is greater than 6 bar, a pressure reducer

calibrated to 4.5 bar must be fitted.

Safety unit

The tank safety unit must be ACV approved and calibrated to 7 bar.

The valve discharge must be connected to the waste water disposal

system.

Domestic hot water expassion tank

Installing a domestic hot water expansion tank avoids any risk of

overpressure due to pressure surges and also makes sure that

there is a always water flowing through the safety unit when refilling

the domestic hot water tank.

Hot water circulation

If the tank is located a long way from the point of use, then

installing a closed recirculation circuit ensures that a faster supply

of hot water is always available.

Descriptions

1. Expansion relief valve

2. Pressure reducing valve

3. Thermostatic mixing valve

4. Hot water secondary pump (it fitted)

5. Non-return valve

6. Hot water expansion vessel

7. Stop cock

8. Draw-off valve

9. Drain cock

CONTROLLER KITS

KIT 1: ACV 13.00 / Basic

Basic kit for regulating initial flow temperature according to weather

conditions. It comprises: a temperature regulator with analogue

clock, wall-mounted water temperature sensor (-30/130 °C), external

sensor (-30/50 °C), 3-pin servomotor SQY 31 230 V and an

intermediate base.

KIT 2: ACV 13.00 / Standard

Basic kit for regulating initial flow temperature according to weather

conditions. It comprises: a temperature regulator with analogue

clock, wall-mounted water temperature sensor (-30/130 °C), external

sensor (-30/50 °C), 3-pin servomotor SQY 349,230 V and an

intermediate base.

1

2

4

6

5

7

9

8

3

IMPORTANT

As a safety measure against burns, we strongly advise

installing a thermostatic mixing valve (recommended

temperature: 60° C).

Optional fittings available

Groupe de sécurité Ø 3/4”

Réducteur de pression Ø 3/4“

Mitigeur thermostatique Ø 3/4”

Vase d’expansion 5 litres

Page 10

8

INSTALLATION

ELECTRICAL CONNECTIONS

Control circuit power supply

The control circuit is automatically powered from the power circuit. It is

also protected by a magneto-thermal circuit breaker.

Control wiring diagram

It is important to switch the boiler off before

carrying out any work.

1

3

4

5

6

7

8

9

C

2

C

2.1. 2.2.

1.1. 1.2.

A1 A2

1

2

1

10 11

12 13

14 15

18

19

br

br

v

r

r

o

o

w

o

w

o

r

w

pgr

w

o

y

w

v

r

y

r

r

r

o

21

bk

b

b

b

b

b

b

b

b

C

1

2

20

o

bk

E-Tech `S` Single Phase Control Circuit - With shunt circuit (factory wired)

CABLE COLOUR CODES

bk- black

br- brown

r-red

w-white

y- yellow

o - orange

b - blue

v - violet

p - pink

gr - grey

All bold numbers indicate a DIN rail terminal connection

Boiler Stat

(78 - 53°C)

PLEASE NOTE: Due to the potential risk of ELECTRIC SHOCK this section of the manual is intended for use

by a service engineer or qualified electrician, not the user

230 - 240 V ac

3 amp

MCB

Panel

On Off

Switch

High Temp

Limit

(manual reset)

Water

Pressure

Switch

Optional

Internal Or

External

Boiler Control

Clock

High Temp

Limit

(Auto Reset)

Boiler Stat

(85 - 60°C)

Panel

Stage 1

Switch

Panel

Stage 2

Switch

Optional Internal -

External Clock Supply

Circulating

Pump

Stage 1

Power

Relay 1

Stage 1

Power

Relay 2

Stage 2

Power

Relay 1

Stage 1

Delay

Timer

Heating Valve

(Not Supplied)

Panel

Heating

Switch

Switch

Indicator

Switch

Indicator

Switch

Indicator

Remove Link If

Option Used

Optional

External Heating

Clock or Stat

M

Switch

Indicator

Lockout

Indicator

Remove Link If

Clock Used

r

Page 11

9

INSTALLATION

E-Tech `S` Tri Phase Control Circuit - With shunt circuit (factory wired)

CABLE COLOUR CODES

bk- black

br- brown

r-red

w-white

y- yellow

o - orange

b - blue

v - violet

p - pink

gr - grey

All bold numbers indicate a DIN rail terminal connection

Boiler Stat

(78 - 53°C)

PLEASE NOTE: Due to the potential risk of ELECTRIC SHOCK this section of the manual is intended for use

by a service engineer or qualified electrician, not the user

230 - 240 V ac

3 amp

MCB

Panel

On Off

Switch

High Temp

Limit

(manual reset)

Water

Pressure

Switch

Optional

Internal Or

External

Boiler Control

Clock

High Temp

Limit

(Auto Reset)

Boiler Stat

(85 - 60°C)

Panel

Stage 1

Switch

Panel

Stage 2

Switch

Optional Internal -

External Clock Supply

Circulating

Pump

Stage 1

Power

Relay 1

Stage 1

Power

Relay 2

Stage 2

Power

Relay 1

Stage 2

Power

Relay 2

Stage 1

Delay

Timer

Heating Valve

(Not Supplied)

Panel

Heating

Switch

Switch

Indicator

Switch

Indicator

Switch

Indicator

Remove Link If

Option Used

Optional

External Heating

Clock or Stat

Switch

Indicator

Lockout

Indicator

Remove Link If

Clock Used

1

3

4

56

7

8

9

C

2

C

2.1. 2.2.

1.1. 1.2.

A1 A2

1

2

1

10 11

12 13

14 15

18

19

r

br

br

v

r

r

o

o

w

o

w

o

r

w

pgr

w

o

y

w

v

r

y

r

r

r

o

21

bk

b

b

b

b

b

b

b

b

M

C

1

2

20

o

16

w

17

r

y

A2A1

r

b

bk

Stage 2

Delay

Timer

Page 12

10

Connecting the accessories

The electrical accessories are connected to the numbered terminals

on the control terminal block as shown on the control wiring diagram.

Power wiring diagram

•For the mono phase model (In top of the page 11)

•For the tri phase model (In bottom of the page 11)

Electrical safety devices

• The boiler must be effectively earthed.

•A box fitted with a magneto-thermal circuit breaker must be fitted on

the outside of the boiler. This is to protect the boiler and allow the

power supply to be switched off during servicing or other work on

the boiler.

First make sure that the system complies with all

current standards.

•To avoid any risk of electrocution, the electrical circuit must be

fitted with a differential circuit breaker.

• The control circuit is protected by a magneto-thermal circuit breaker.

Compliance

The installation must be carried out in accordance with the current

local technical standards and legislation.

Electrical terminal block

INSTALLATION

Power

terminal

block

Calibrator

relay

Control

terminal

block

Magneto-therminal

circuit breaker

Power

Switches

Page 13

L

N

3 x Red

3 x Red

3 x Blue

3 x Blue

To Boiler Body

Green / Yellow

Stage 1 Power Relay 1

Stage 1 Power Relay 2

Stage 2 Power Relay 1

To Control

Circuit MCB

E-Tech Single Phase

Power Wiring

L1

L2

L3

N

To C ontrol

Circuit MCB

4 x Orange

4 x Black

4 x Red

4 x Blue

To Boiler Body

Green / Yellow

Stage 1

Power Relay 1

Stage 1

Power Relay 2

Blue

Red

Black

Orange

Blue

Red

Black

Orange

Orange

Black

Red

Blue

Orange

Black

Red

Blue

Stage 2

Power Relay 2

Stage 2

Power Relay 1

E-Tech S Tri Phase

Power Wiring

11

INSTALLATION

Page 14

12

COMMISSIONING

FILLING THE DOMESTIC HOT WATER AND

HEATING CIRCUITS

1. Fill the domestic hot water circuit and bring it up to pressure

IMPORTANT

The hot water tank must be pressurised before the

heating circuit is filled.

2. Fill the central heating circuit making sure that any air in the upper

part of the boiler and any air in the system is bled.

3. Remove the front of the boiler.

4. Check the electrical connections paying particular attention to the

quality of the connections on the power circuit terminals.

5. Set all the switches on the control panel to the OFF position and

set the internal magneto-thermal circuit breaker to ON. Replace

the front of the boiler.

6. Switch the boiler on from the external box.

7. Set the on/off switch to the ON position and the summer/winter

selector switch to the winter position.

8. After allowing the circulator to work for a few minutes, set the

on/off switch to the OFF position, bleed the circulation pump and

make sure that both the boiler and the system are properly bled.

Adjust the pressure to the static pressure (1 bar = 10 m – 1.5 bar

= 15 m) + 0.5 bar.

9. The boiler is now ready to operate. Set the on/off switch to the ON

position, the summer/winter selector, the half and full power

switches and the control thermostat all to the desired positions

After a few days in operation check for any leaks the

quality of the electrical connections and also make sure

there is no air in either the boiler or the system.

Switch the power supply off from the outside box

before carrying out any work.

Page 15

13

MAINTENANCE

SERVICE INTERVALS

ACV recommend that boilers should be serviced at least once a year.

This servicing work should be carried out by a competent technician.

SERVICING THE BOILER

1. Set the on/off switch on the control panel to the OFF pos tion and

switch the power off from the external box.

2. Remove the top panel and the front and carry out a visual

inspection of the boiler looking out for any leaking water.

3. Inspect the wiring looking for any sign of overheating.

4. Check that the screws on the connection terminal block are

properly tightened.

5. Replace the front and the top panel.

6. Switch the boiler back on again.

SERVICING THE SAFETY DEVICES

- Check that the thermostats and safety devices are working

properly.

- Check the safety valves on both the central heating and the hot

water circuits.

DRAINING THE BOILER

Water flowing out of the drain cock may be

extremely hot and could cause severe scalding.

Keep people away from discharges of hot water.

Draining the heating circuit

1. Switch the power to the boiler “OFF” at the mains switch installed

by the electrician.

2. Close the boiler system’s isolating valves (1).

3. Connect a hose to the drain cock (2) and make sure that it is

properly connected.

4. Open the drain cock and allow hot water to flow out into the waste

water disposal system, check that air is being taken into the

system, by opening the air vent, for instance.

5. Once you have finished, put the drain cocks back into their

original positions and adjust the pressure to the static pressure

+ 0.5 bar.

Draining the domestic hot water circuit

1. Switch the mains power to the boiler off at the external switch

installed by the electrician.

2. Close valves (A) and (B).

3. Open valves (C) and (D) (first C then D).

4. Let the water drain away.

5. When you have finished, return the valves to their initial positions.

To allow the tank to be emptied, valve (C) must be

situated at ground level.

SPARE PARTS

Please refer to the specific document available from ACV or your

distributor.

A

C

B

D

60

85

1

1

2

Y

Y

Page 16

14

7 - Safety thermostat

When the temperature in the boiler exceeds 103 °C, the manually

reset safety thermostat is started up.

8 - Boiler shutdown indicator light

This light is lit when the safety thermostat starts up or when the

water pressure in the boiler is too low.

Central heating system gauge pressure

Your boiler is fitted with a central heating safety valve, set to 3 bar,

and with a pressure gauge.

First make sure that the water in the system is still pressurised.

When cold and after the air in the system has been bled, the

pressure gauge should show a pressure of between 1 and 2,

depending on the height of the building: (1 bar = 5m / 1.5 bar = 10

m and 2 bar = 15 m). To add water, open the filling valve (Fig. 2a and

2b on page 3). Make sure that the drain cock is properly closed after

filling and isolate the filling circuit from the central heating circuits.

Bleed the air in the system to get an accurate water pressure

reading.

Safety valve (central heating)

A monthly inspection is recommended:

Lift the lever on the emptying device for a few seconds to ensure that

the safety valve is working properly

The water which may flow out of the safety

valve is very hot and may cause serious burns.

The pipe discharging into the waste water

disposal system should be open to the

atmosphere.

Make sure there is nobody near the flow of hot

water.

If you notice anything unusual after this short trial,

please inform the installing engineer.

Safety unit (domestic hot water)

A monthly inspection is recommended:

Lift the lever on the emptying device for a few seconds to ensure that

the safety valve is working properly.

The water flowing out of the safety unit may be

extremely hot.

The pipe discharging into the waste water

disposal system should be open to the

atmosphere.

Make sure there is nobody near the flow of hot

water.

If you notice anything unusual after this short trial,

please inform the installing engineer.

USER GUIDE

USING THE BOILER

Your system should be serviced at least once year by

a qualified engineer.

If the boiler is subject to heavy use, it may require

servicing more than once a year - consult your service

engineer for advice.

Before carrying out any work on the boiler, switch the

power off at the mains switch fitted in the boiler room

by the electrician.

Understanding the control panel

There are no user parts inside

the control panel.

1 - ON/OFF switch

This must be used to switch the boiler off before carrying out any

work on it.

2 - Power selection switches

The control panel is fitted with two switches allowing the user to

select the boiler power according to his needs.

When only the first switch is pressed down, the boiler power is

limited to the first stage using +/- half of the power (ideal in summer).

In order for the boiler to run at full power, both of the switches must

be pressed down.

3 - Summer/Winter selector switch

“Winter” position: provides both domestic hot water and central

heating functions. “Summer” position: The central heating circulator

is switched off. Only the domestic hot water function is provided. If

there is not enough hot water available, we recommend setting the

thermostat (9) to a higher value.

When the weather turns cold again, simply select “Winter” to

reactivate the heating system.

4 - Controller

Please see the enclosed instructions if you have chosen this option.

5 - Mano-thermometer

Reads the boiler primary circuit (central heating) temperature and

pressure directly.

6 - Thermostat adjustable between 60 and 85° C

Central heating systems are generally designed to operate at a

maximum of 80° C.When used at lower temperatures, a 3-way mixer

valve installed on the heating flow pipe (see Fig. 2b on page 3)

allows the temperature to be set manually or, if you decide to install

a regulator (§ 2.2.4), automatically.

We recommend that you set the thermostat to the maximum values

to get the best out of the domestic hot water system.

There is a risk of burns from hot water!

The water stored in the domestic hot water tank in the boiler can be

at a very high temperature.

In all cases, install the thermostatic mixer (Fig. 3b on page 4) on the

domestic hot water flow pipe which must not exceed 60° C.

A mixer or mixing valve at each point of use is recommended.

Page 17

15

BOILER SHUTDOWN

If the red light on the control panel lights up, this indicates an

operating fault.

1. Check the boiler pressure, it should be between 1 and 2 bar

depending on the height of the building.

2. Once you have checked the pressure, wait until the boiler has

cooled down before resetting the safety thermostat.

3. Unscrew the safety thermostat’s protective cap.

4. Restart the thermostat using a blade end.

5. If the system shuts down again, please inform the installing

engineer.

To ensure your system operates properly, have it

professionally serviced once a year before the cold

weather starts.

USER GUIDE

Controller

Control

thermostat

ON/OFF

switch

Power

selection

switch

Summer/Winter

selector switch

Combined temperature

and pressure gauge

Power

selection

switch

Safety

indicator

light

Safety

thermostat

Control panel

Page 18

16

NOTE

Page 19

Page 20

INTERNATIONAL

ACV international n.v

KERKPLEIN, 39

B-1601 RUISBROEK - BELGIUM

TEL.: +32 2 334 82 20

FAX: +32 2 378 16 49

E-MAIL: international.info@acv-world.com

BELGIUM

ACV BELGIUM nv/sa

KERKPLEIN, 39

B-1601 RUISBROEK-BELGIUM

TEL.: +32 2 334 82 40

FAX: +32 2 334 82 59

E-MAIL: belgium.info@acv-world.com

CHILE

ALBIN TROTTER Y ACV LTDA

SAN PABLO 3800

QUINTA NORMAL - SANTIAGO - CHILE

TEL.:+56 2 772 01 69

FAX:+56 2 772 92 62/63

E-MAIL: chile.info@acv-world.com

CZECH REPUBLIC

ACV CR SPOL. s.r.o

NA KRECKU 365

CR-109 04 PRAHA 10 - CZECH REPUBLIC

TEL.:+420 2 720 83 341

FAX:+420 2 720 83 343

E-MAIL: ceskarepublika.info@acv-world.com

DEUTSCHLAND

ACV WÄRMETECHNIK GMBH & CO KG

GEWERBEGEBIET GARTENSTRASSE

D-08132 MÜLSEN OT ST. JACOB - DEUTSCHLAND

TEL.:+49 37601 311 30

FAX:+49 37601 311 31

E-MAIL: deutschland.info@acv-world.com

ESPAÑA

ACV ESPAÑA

C/DE LA TEIXIDORA, 76

POL. IND. LES HORTES

E-08302 MATARÓ - ESPANA

TEL.:+34 93 759 54 51

FAX:+34 93 759 34 98

E-MAIL: spain.info@acv-world.com

FRANCE

ACV FRANCE sa

31, RUE AMPERE - Z.I MI - PLAINE

F-69680 CHASSIEU - FRANCE

TEL.:+33 4 72 47 07 76

FAX:+33 4 72 47 08 72

E-MAIL: france.info@acv-world.com

ITALIA

ACV ITALIA

VIA PANA 92

I-48018 FAENZA (RA) - ITALIA

TEL.:+39 0546 64 61 44

FAX:+39 0546 64 61 50

E-MAIL: italia.info@acv-world.com

NEDERLAND

ACV NEDERLAND bv

POSTBUS 350

NL-2980 AJ RIDDERKERK - NEDERLAND

TEL.:+31 180 42 10 55

FAX:+31 180 41 58 02

E-MAIL: nederland.info@acv-world.com

POLAND

ACV POLSKA sp. z.o.o.

UL.WITOSA 3

87 - 800 WLOCLAWEK - POLAND

TEL.:+48 54 412 56 00

FAX:+48 54 412 56 01

E-MAIL: polska.info@acv-world.com

PORTUGAL

BOILERNOX LDA

RUA OUTEIRO DO POMAR

CASAL DO CEGO, FRACÇÃO C,

PAVILHÃO 3 - MARRAZES

2400-402 LEIRIA - PORTUGAL

TEL.:+351 244 837 239/40

FAX:+351 244 823 758

E-MAIL: boilernox@mail.telepac.pt

RUSSIA

ACV RUSSIA

1/9, MALYI KISELNYI

103031 MOSCOW - RUSSIA

TEL.:+7 095 928 48 02 / +7 095 921 89 79

FAX:+7 095 928 08 77

E-MAIL: russia.info@acv-world.com

SLOVAK REPUBLIC

ACV SLOVAKIA s.r.o.

PLUHOVÁ 49

831 04 BRATISLAVA - SLOVAK REPUBLIC

TEL.:+421 2 444 62 276

FAX:+421 2 444 62 275

E-MAIL: slovakia.info@acv-world.com

SLOVENIA

ACV D.O.O. SLOVENIA

OPEKARNA 22b

1420 TRBOVLJE - SLOVENIA

TEL.:+386 356 32 830

FAX:+ 386 356 32 831

E-MAIL: slovenia.info@acv-world.com

UK

ACV UK Ltd

ST. DAVID’S BUSINESS PARK

DALGETY BAY - FIFE - KY11 9PF

TEL.:+44 1383 82 01 00

FAX:+44 1383 82 01 80

E-MAIL: uk.info@acv-world.com

USA

TRIANGLE TUBE PHASE III

FREEWAY CENTER - 1 TRIANGLE LANE

BLACKWOOD NJ 08012 - USA

TEL.:+1 856 228 8881

FAX:+1 856 228 3584

E-MAIL: sales@triangletube.com

excellence in hot water

www.acv-world.com

ARGENTINA

TECNOPRACTICA

ALFEREZ BOUCHARD 4857

1605 CARAPACHAY - BUENOS AIRES

TEL.: +54 11 47 65 33 35

FAX: +54 11 47 65 43 07

E-MAIL: jchas@tecnopractica.com

AUSTRALIA

HUNT HEATING PTY LTD

10 GARDEN BOULEVARD

3172 VICTORIA - AUSTRALIA

TEL.: +61 3 9558 7077

FAX: +61 3 9558 7027

E-MAIL: enquiries@huntheat.com.au

BRAZIL

SIMETAL INDUSTRIA E COMERCIO

DE FERRAMENTAS LTDA

RUA GERSON ANDREIS 535

95112 - 130 CAXIAS DO SUL - BRAZIL

TEL.: +55 54 227 12 44

FAX: +55 54 227 12 26

E-MAIL: export@simetall.com.br

BULGARIA

PROXIMUS ENGINEERING LTD

7 BIAL KREM STR.

9010 VARNA - BULGARIA

TEL.:+359 52 500 070

FAX:+359 52 301 131

E-MAIL: info@proximus-bg.com

CHINA

BEIJING HUADIAN HT POWER TECHNOLOGY

DEVELOPMENT CO. LTD

ROOM B-912, TOWER B, COFCO PLAZA

N°. 8, JIANGUOMENNEI AVENUE

BEIJING 100005 - PEOPLE’S REPUBLIC OF CHINA

TEL.:+86 10 652 30 363/393 EXT 101

FAX:+86 10 652 27 071

E-MAIL: li.zheng@acv-world.com

SHANGHAI COOLTECH LTD

14/F E. CHINA MERCHANTS PLAZA

N°. 333 CHENGDU ROAD (N)

200041 SHANGHAI - CHINA

TEL.:+86 21 52 98 11 22 - 820

FAX:+86 21 52 98 13 58

E-MAIL: cooltech@cooltech.sh.cn

DENMARK

VARMEHUSET

FRICHSVEJ 40 A

8600 SILKEBORG - DENMARK

TEL.:+45 86 82 63 55

FAX:+45 86 82 65 03

E-MAIL: vh@varmehuset.dk

ESTONIA

TERMOX AS

TAHE 112A

51013 TARTU - ESTONIA

TEL.:+372 736 73 39

FAX:+372 736 73 44

E-MAIL: termox@termox.ee

GREECE

ESTIAS

MARASLI STREET 7

54248 THESSALONIKI - GREECE

TEL.:+30 23 10 31 98 77 / +30 23 10 32 03 58

FAX:+30 23 10 31 97 22

E-MAIL: info@genikithermanseon.gr

ÎLE MAURICE

SOTRATECH

29, RUE MELDRUM

BEAU BASSIN - ÎLE MAURICE

TEL.:+230 46 76 970

FAX:+230 46 76 971

E-MAIL: stech@intnet.mu

LITHUANIA

UAB “GILIUS IR KO”

SAVARNORIU PR. 192

3000 KAUNAS - LITHUANIA

TEL.:+370 37 308 930

FAX:+370 37 308 932

MAROC

CASATHERM

PLACE EL YASSIR

20300 CASABLANCA - MAROC

TEL.:+212 22 40 15 23

FAX:+212 22 24 04 86

NEW ZEALAND

ENERGY PRODUCTS INTERNATIONAL

8/10 BELFAST PLACE

PO BOX 15058 HAMILTON - NEW ZEALAND

TEL.:+64 7 847 27 05

FAX:+64 7 847 42 22

E-MAIL: pmckenzie@tycoint.com

ÖSTERREICH

PROTHERM HEIZUNGSTECHNIK Gmbh

TRAUNUFERSTRASSE 113

4052 ANSFELDEN - ÖSTERREICH

TEL.:+43 7229 804 82

FAX:+43 7229 804 92

E-MAIL: protherm@nextra.at

ROMANIA

SC TRUST EURO THERM SA

D.N PIATRA NEAMT - ROMAN

km 2 C.P 5 O.P 3 jud. Neamt

5600 PIATRA NEAMT - ROMANIA

TEL.:+40 233 20 62 06

FAX:+40 233 20 62 00

E-MAIL: office@eurotherm.ro

TUNISIE

SO.CO.ME CHAUMAX

BOÎTE POSTALE N°44

1002 TUNIS - TUNISIE

TEL.:+216 71 78 15 91

FAX:+216 71 78 87 31

UKRAINE

UKRTEPLOSERVICE LTD

PR. LAGUTENKO 14

83086 DONETSK - UKRAINE

TEL.:+38 062 382 60 47/48

FAX:+38 062 335 16 89

Loading...

Loading...