ACV E-tech P 57, E-tech P 115, E-tech P144, E-tech P201, E-tech P 259 INSTALLATION OPERATING AND SERVICING INSTRUCTIONS

Page 1

57 - 115 - 144 - 201 - 259 [Tri phase]

Installation, operating and

servicing instructions

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y3500

EN • 1

Page 2

INDEX

WARNINGS 3

Who should read these instructions 3

Symbols 3

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Recommendations 3

Importants notes 3

INTRODUCTION 4

Description of the specifications 4

Casing 4

Heating body 4

Heating element

Connection 4

Control 4

Electrical protection 4

INSTRUCTIONS 5

User data 5

Setting up 5

Heating system pressure 5

Control panel legend 5

TECHNICAL CHARACTERISTICS 6

Electrical data 7

Power 7

Nominal current per phase 7

s 4

INSTALLATION : GENERAL 8

Dimensions 8

Installation room 8

Boiler room 8

Frost protection 8

Connecting to the system 8

INSTALLATION : HYDRAULIC 9

Heating connection 9

Heating connection + DWL 9

INSTALLATION : ELECTRIC SUPPLY 10

General safety rules 10

Important 10

Electrical connections 10

Sizing of supply wires 11

Power variation (kW) relative to voltage

Wiring diagrams 12

Power limitation 13

Powers wiring / Model : E-Tech P / 57 14

Powers wiring / Model : E-Tech P / 115 15

Powers wiring / Model : E-Tech P / 144 16

Powers wiring / Model : E-Tech P / 201 18

Powers wiring / Model : E-Tech P / 259 20

11

COMMISSIONING 22

Commissioning - Water 22

Commissioning - Electrical 22

Starting the boiler 22

22

MAINTENANCE 23

SPARE PARTS

664Y3500

EN • 2

See at the end of this manual

Page 3

WARNINGS

WHO SHOULD READ THESE INSTRUCTIONS

These instructions should be read by:

- the specifying engineer

- the installer

- the user

- the service engineer

SYMBOLS

Essential instruction for

the correct operation

of the installation.

Essential instruction for

the safety of persons

and the environment.

Danger of electrocution.

IMPORTANTS NOTES

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

The manufacturer reserves the right to change the

technical characteristics and specification of its

products without notice.

The availability of certain versions and their accessories

can vary following the market.

Warning : Do not switch ON if there is a possibility that the

water in heater is frozen.

Danger of burns

RECOMMENDATIONS

• These instructions are an integral part of the equipment to

which they relate and must be handed to the user.

• The product must be installed and serviced by qualified

engineers in accordance with the regulations in force.

• The manufacturer declines all liability for any damage caused

as a result of incorrect installation or in the event of the use

of appliances or accessories that are not specified by the

manufacturer.

• Any failure to follow instructions relating to tests and test

procedures may result in personal injury or risks of pollution.

• It is important to switch the boiler off from the external

switching device before carrying out any work.

• There are no user parts inside the control panel.

• The installation must be in accordance with the current

standards.

664Y3500

EN • 3

Page 4

INTRODUCTION

DESCRIPTION OF THE SPECIFICATIONS:

This floor standing electric boiler is available in 5 models :

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

- Model 57 with a power of 57,6 kW

- Model 115 with a power of 115,2 kW

- Model 144 with a power of 144 kW

- Model 201 with a power of 201,6 kW

- Model 259 with a power of 259,2 kW

The power circuit is supplied with 400 Volt tri phases without

neutral.

The control circuit is supplied with 230 Volt single phase.

CASING

The boiler is protected by a steel casing that has a red stove

enamelled finish.

HEATING BODY

The boiler heating body is constructed from mild steel with

welded joints. It is hydraulic tested at a pressure of 5,2 bar

(maximum working pressure = 4 bar).

HEATING ELEMENTS

Immersion heaters, constructed from stainless steel Incoloy 800

are mounted in the front of the boiler, provide the heating source

to the boiler.

CONNECTION

The boiler is suitable for connection to most heating and water

process systems, with a maximum working pressure of 4 bars and

a maximum temperature of 90°C. It can also be used in multiple

boiler installations allowing greater outputs to be achieved.

The boiler and connection glands are provided for the power

supply, the control supply and optional external controls.

CONTROL

The boiler is equipped with an electronic sequencing control that

constantly adapts the power required thanks to a four stage

modulation.

The boiler is commonly controlled by an external contact

(i.e. room thermostat). The maximum power can be limited to

25%, 50% or 75% by moving electrical bridges.

ELECTRICAL PROTECTION

The control circuit is protected by an internal 3 Amp MCB.

The power circuit is protected at its input by 3 power fuses.

Moreover, each contactor - supplying a pair of electric stars

(28,8kW) - is protected by an automatic thermal and magnetic

safety relay.

4

5

1. Control panel

2. Heating elements

3. Contactor and safety relays

4. Optional controller

5. Control circuit

6. Main fuses and power connections

7. Removable access panel

1

2

6

3

7

664Y3500

EN • 4

Page 5

INSTRUCTIONS

USER DATA

All user controls are situated on the front panel of the boiler,

there are no user controls inside the boiler casing.

The following instructions assume that the boiler has been

commissioned, and that the system is filled with water and has

been fully vented.

SETTING UP

• Before switching on any electrical supplies to the boiler ensure

that the combined temperature and pressure gauge reads at

least 1 bar and the control thermostat is set to the desired

temperature.

• If any other auxiliary controls are fitted e.g. programmer, room

thermostats, cylinder thermostats etc, consult appropriate

manufacturers’ instructions to switch these on.

• Switch the winter/summer switch to winter position.

• Switch on any local means of isolation to boiler.

Ensure all the jacket panels are secured before

switching on electrical supply from the external

isolator.

• Switch the boiler on using the ON/OFF switch (a test of the

lights is done).

• After a short period of time the boiler temperature should

start to rise, indicated on combined temperature and pressure

gauge. The modulation level is displayed on the front panel

by the stage indicator lights. If the boiler fails to operate, the

overheat safety thermostat should be checked.

Access to the thermostat reset button is obtained by unscrewing

(anti-clockwise) the domed button cover on the front panel

(a screwdriver is not required).The reset button can then

be seen - press the button, a click should be heard and the

button is reset. If no click was heard the device is not at fault

and further investigation is required by a suitably qualified

engineer.

• The external programmer can now be set to allow on/off

periods as desired. The ON/OFF switch should be left in the

ON position during normal use.

• As with most boilers and heating appliances the casing and

pipework can get hot during normal running so the boiler must

not be covered and the surrounding area must be kept clear.

HEATING SYSTEM PRESSURE

The CH pressure must be a minimum of 1 bar and must be

checked by the end user on a regular basis. If the pressure drops

under 0.5 bar, the integrated water pressure switch blocks the

appliance until the pressure in the system returns to a level

above 0.8 bar.

The installer must fit an external filling loop to the system.

For more information, please ask your installer when the system

is delivered.

A pressure safety valve is provided with the appliance. If the

system pressure exceeds 4 bars, this valve opens and drains

the water from the system. In this case, please contact your

installer.

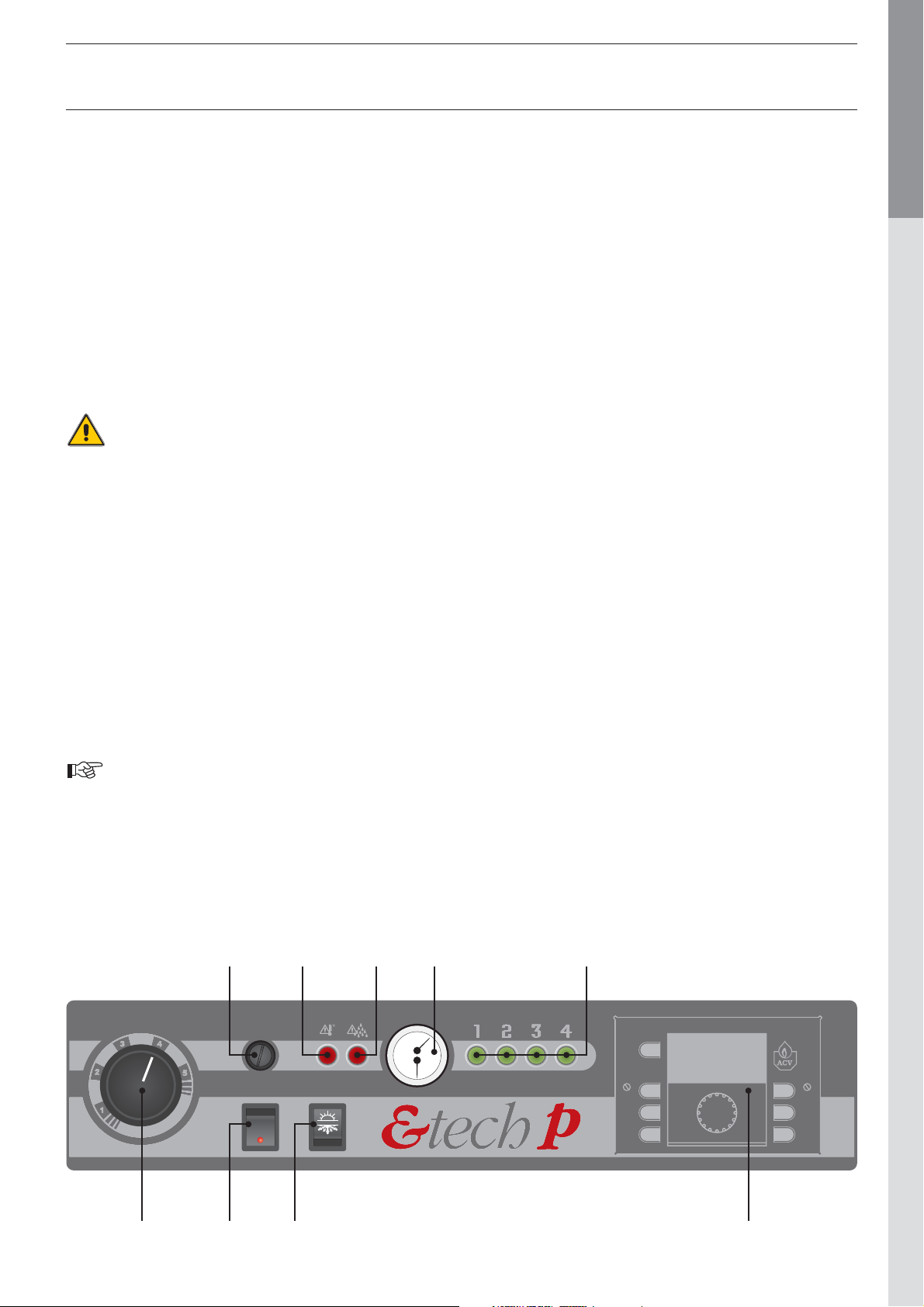

CONTROL PANEL LEGEND

1. Control thermostat :

1 = 25°C

2 = 40°C

3 = 55°C

4 = 70°C

5 = 85°C

2. ON/OFF switch

3. Summer/Winter switch

4. Manual reset high limit thermostat

5. Overheating warning light

6. Minimum water pressure warning light

7. Combined temperature and pressure gauge

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

The power level indicator will automatically light on and

off during normal boiler operation, depending on boiler

temperature.

• If the boiler is not in regular daily use during cold periods, it is

recommended that it is fitted with a frost sensing thermostat

to prevent the system from freezing.

4 5 6 7 8

8. Power level indicators

9. Optional internal controller

664Y3500

1 2 3 9

EN • 5

Page 6

TECHNICAL CHARACTERISTICS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Model 57 115 144 201 259

Power 57,6 kW 115,2 kW 144 kW 201.6 kW 259,2 kW

Nominal supply voltage

Power circuit 3 x 400 V 3 x 400 V 3 x 400 V 3 x 400 V 3 x 400 V

Control circuit

Heating element type 4 x 3 x 2.4 kW 4 x 3 x 2.4 kW 4 x 3 x 2.4 kW 4 x 3 x 2.4 kW 4 x 3 x 2.4 kW

Number of elements 24579

Ohmic value

of single resistance (2,4 kW)

Water capacity

(Litres)

Max. working pressure (bars) 44444

Min. working pressure (bars) 0.8 0.8 0.8 0.8 0.8

Max. working temperature

(°C)

Hydraulic pressure drop

(mbar) [ΔT = 10°C]

1 x 230 V

50/60 Hz

22,0 Ohm 22,0 Ohm 22,0 Ohm 22,0 Ohm 22,0 Ohm

60 60 60 102 102

90 90 90 90 90

20 79 123 20 33

1 x 230 V

50/60 Hz

1 x 230 V

50/60 Hz

1 x 230 V

50/60 Hz

1 x 230 V

50/60 Hz

Heating connection 2” [F] 2” [F] 2” [F] DN 100 (*) DN 100 (*)

Height (mm) 1495 1495 1495 1495 1495

Width (mm) 542 542 542 542 542

Depth (mm) 567 567 567 567 567

Weight empty (kg) 110 123 131 187 200

(*) DN100 fl anges to be welded

664Y3500

EN • 6

Page 7

TECHNICAL CHARACTERISTICS

POWER

Models

E-Tech P / 57 14,4 14,4 14,4 14,4 57,6

E-Tech P / 115 28,8 28,8 28,8 28,8 115,2

E-Tech P / 144 36,0 36,0 36,0 36,0 144,0

E-Tech P / 201 50,4 50,4 50,4 50,4 201,6

E-Tech P / 259 64,8 64,8 64,8 64,8 259,2

Models

Power (kW)

Stage 1

Stage 1

(A)

Power (kW)

Stage 2

NOMINAL CURRENT PER PHASE

Stage 2

(A)

Power (kW)

Stage 3

Stage 3

(A)

Power (kW)

Stage 4

Stage 4

(A)

Total Power

(kW)

Total current

per phase

(A)

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

E-Tech P / 57 20,9 20,9 20,9 20,9 83,6

E-Tech P / 115 41,7 41,7 41,7 41,7 166,8

E-Tech P / 144 62,7 62,7 41,8 41,8 209

E-Tech P / 201 83,5 83,5 62,6 62,6 292,2

E-Tech P / 259 83,5 104,4 83,5 104,4 375,8

664Y3500

EN • 7

Page 8

DIMENSIONS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Models

E-Tech P / 57 1495 567 550 183 542 125 2” [F]

E-Tech P / 115 1495 567 550 183 542 125 2” [F]

E-Tech P / 144 1495 567 550 183 542 125 2” [F]

E-Tech P / 201 1495 567 1100 183 542 125 DN 100

E-Tech P / 259 1495 567 1100 183 542 125 DN 100

INSTALLATION : GENERAL

A

mm

B

mm

C

mm

D

mm

B

E

mm

F

mm Heating connection

F

A

INSTALLATION ROOM

The minimum clearance around the appliance must comply

with the figure shown opposite.

BOILER ROOM

• Electric boilers must be installed in boiler rooms complying

with the relevant technical standards and applicable

regulations.

• The appliance should never be installed outdoors, because

it has not been designed for and is not equipped with

automatic defrosting systems.

• If possible, install the boiler above the ground level, to

reduce the risk of flooding the electrical components.

C

E

D

TOP VIEW

500 mm

FROST PROTECTION

The boiler is NOT fitted with frost protection. If the boiler is

being installed in a position where freezing could take place,

then a suitable external frost thermostat should be fitted.

CONNECTING TO THE SYSTEM

The boiler is designed to operate on a sealed system (ie. no

open vent or feed and expansion tank).

An adequate expansion vessel, sized accordingly must be

installed in the system.

664Y3500

500 mm

EN • 8

Page 9

INSTALLATION : HYDRAULIC

HEATING CONNECTION

HEATING CONNECTION + DHW (2 Circulating pumps)

The controller is factory programmed with DHW

priority.

To cancel the DHW priority, remove the black

wire from I7 and connect to I8 in the electronic

controller.

Adjustable temperature

0 - 90°C

1 = 25°C

2 = 40°C

3 = 55°C

4 = 70°C

5 = 85°C

1 = 25°C

2 = 40°C

3 = 55°C

4 = 70°C

5 = 85°C

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

9 10

9 10

11 12

11 12

13 14

13 14

15 16

15 16

17 18

17 18

19 20

19 20

I

max

= 5A

Warning : Size the flow rate in hydraulic circuit to

insure a 10°C maximum ΔT.

BBkPkRWGWBkG

LNI1I2I3I4I5I6I7I8I9

V

Pk

I10

I11

I12

I7 = DHW priority I8 = DHW priority

Q1 Q3 Q5 Q6Q4 Q7 Q8Q2

0 - 90°C

BBkPkRWGWBkG

LNI1I2I3I4I5I6I7I8I9

Q1 Q3 Q5 Q6Q4 Q7 Q8Q2

V

Pk

I10

I11

I12

9 10

9 10

11 12

11 12

13 14

13 14

15 16

15 16

17 18

17 18

19 20

19 20

664Y3500

EN • 9

Page 10

INSTALLATION : ELECTRIC SUPPLY

WARNING !!!

Size the flow rate in the hydraulic circuit to ensure a 10°C

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

maximum ΔT.

GENERAL SAFETY RULES

• The boiler must be installed by a competent person or

registered company.

• After the installation work, the installer must issue a statement

of compliance, declaring that the installation has been carried

out in a workmanlike manner, as defined for by the applicable

regulations.

• Make sure that the wiring system and the power input lines are

designed and installed by skilled engineers in compliance with

the applicable regulations.

IMPORTANT

• As far as the power input to the boiler is concerned, the

installation must comply with IEC 364 standards and other

provisions concerning installation conditions.

• The default electrical safeties integrated in the boiler protect

the internal parts of the boiler. Electrical safeties, including

isolators must be installed in an external box.

• For protection against electrical hazard, it is always

recommended to install a differential cut-out device (Ground

Fault Isolator) on the power supply circuit, upstream of the

boiler.

• For protection against overheating, it is advisable to place an

external positive safety power cut-out, controlled by the boiler

safety thermostat.

8. Remount the bottom protection and close the power

connections box.

1

2

1

ELECTRICAL CONNECTIONS

1. Remove the right panel cover and the top panel

2. Connect the electrical supply to the control circuit and all

accessories (room thermostat, …)

3. Pass the power cabels thought the cable glands located in

the rear panel.

Models

E-Tech P / 57 1 x PG 36 4 x PG 21

E-Tech P / 115 1 x PG 48 4 x PG 21

E-Tech P / 144 1 x PG 48 4 x PG 21

E-Tech P / 201 4 x PG 29 1 x PG 48

E-Tech P / 259 4 x PG 29 1 x PG 48

(*) Optionally, the installer has the possibility to remove the standard cable

glands and install the optional cable glands (not supplied) on site.

4. Connect the earth using a ring terminal.

5. Open the power connections box.

6. Remove the bottom protection.

7. Connect the power wires to the main connections using ring

terminals.

(*) a transormation kit is supplied with the boiler in order to

connect the power wires using compression terminals (see

detailled instructions sheet in the kit).

Standard

cable gland

Optional

cable gland (*)

34

5

664Y3500

Optional connection

6

EN • 10

Page 11

INSTALLATION : ELECTRIC SUPPLY

SIZING OF SUPPLY WIRES

The supply wires are sized depending of the type and current of

the MCB. The MCB last is sized depending of the nominal current

of the boiler. The admissible current of the supply wires depends

of the ambient temperature, the section, the length and the

insulation of the wires, the wires ducts, the mounting and the

environment.

The following values are given for information for an ambient

temperature of 25°C and a maximum length of 5 meters. In all

the circumstances, the installation must be in accordance with

the current IEE wiring regulations.

Diameter

2

mm

1,5 16

2,5 25

4,6 36

10 47

16 65

25 87

35 115

50 143

Current

Amp

POWER VARIATION (kW) RELATIVE TO VOLTAGE

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Models 3 x 380 V 3 x 400 V 3 x 415 V 3 x 440 V

E-Tech P / 57 51,4 57,6 62,0 70

E-Tech P / 115 103,8 115,2 124,0 139

E-Tech P / 144 130,0 144,0 155,0 174

E-Tech P / 201 181,4 201,6 217,0 244

E-Tech P / 259 233,7 259,2 279,0 314

70 178

95 220

120 265

150 310

185 355

240 480

For higher temperatures, the supply wire diameter should be

adapter according the derating factor.

T ambient

°C

25 100

30 92

35 85

40 75

45 65

50 53

Current derating

%

664Y3500

55 38

EN • 11

Page 12

WIRING DIAGRAMS

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

INSTALLATION : ELECTRIC SUPPLY

Bk Bk

Br Br Br

1

Y/Gr

2

Y/Gr

Y/Gr

3 Amp

5

15

18

MCB

Bk

A

Bk

B

2

G

C

Or

1

t

Bk

4

BkBk

C

1

Pk

C

RR

2

P

Or

7

Bk W

D

Pk V

E

C

11 12

9 10

1

2

t

2625

B

Bk

L

PkRW

G

N

I1I2I3I4I5I6I7I8I9

Bk

Bk

27 29

WW

V

28 30

W

Bk

G

Pk

I10

I11

I12

F

G

Q1 Q3 Q5 Q6Q4 Q7 Q8Q2

Pk

R R

R

V

R

Bk

R

R

Bk

Bk

BBB

3

B : Blue

Bk : Black

Br : Brown

G : Grey

Or : Orange

Pk : Pink

R : Red

V : Violet

W : White

Y : Yellow

Y/Gr : Yellow/Green

B

8

B

6

B

B

A ON/OFF switch

B Manual reset high limit thermostat

C Water pressure switch

D Summer / Winter switch

E Boiler thermostat 0 - 90°C

F Alarm indicator

G Electronic controller

WW

Pk

Pk

23

24

B

B

K1

B

B

BV

B

BW WK3BBB

K2

Bk

K4

VV

13

16

19

14

18

B

20

B

BR

R

21

22

BOrOr

BOr

I1 High temperature

I2 Water pressure

I3 Common alarm signal

I4 Boiler demand

I5 Central heating demand

I6 DHW demand

I7 DHW priority

I8 Without DHW priority

I9 SW1 (power limitation)

I10 SW2 (power limitation)

Q1 K1

Q2 K2

Q3 K3

Q4 K4

Q5 Heating pump

Q6 DHW pump

Q7 Water pressure warning light

Q8 High temperature warning light

664Y3500

EN • 12

Page 13

INSTALLATION : ELECTRIC SUPPLY

POWER LIMITATION :

The maximum power of the boiler can be limited from 25 to 100%

by acting on the SW1, SW2 electrical bridges as mentioned in

the table below.

Power 25% 50% 75% 100%

SW1 0 1 0 1

SW2 0 0 1 1

25% = Only 1 stage

50% = Only 1 and 2 stages

75% = Only 1 to 3 stages

100% = All stages

Any change to the power limitation will alter the

current once the boiler has switched to stand-by (busy

signal is OFF). The external management system can

then open the ON/OFF link.

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

CONTROL CIRCUIT TERMINAL

230 V OUT (PE)

230 V OUT (N)

Safety relay (N)

Central heating demand (OUT)

Central heating demand (IN)

DHW demand (IN)

DHW demand (OUT)

Central heating pump 230 V

Central heating pump (N)

Central heating pump (PE)

DHW pump 230 V

DHW pump (PE)

DHW pump (N)

Water pressure alarm 230 V

Water pressure alarm (N)

Safety thermostat alarm 230 V

Safety thermostat alarm (N)

Heating ON signal (busy) 230 V

Heating ON signal (busy) (N)

ON / OFF switch

ON / OFF switch

Heating power SW1

Heating power SW1

Heating power SW2

Heating power SW2

Power L

Power PE

Power N

230 V OUT (L)

Safety relay (L)

21 3 5 15 174 7 9 10 11 12 13 16 19 21 23 25 26 27 28 29 306 8 14 18 20 22 24

664Y3500

EN • 13

Page 14

INSTALLATION : ELECTRIC SUPPLY

POWER WIRING / MODEL : E-TECH P / 57

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

2

35 mm

F-100A

L1L2L3

20 x 5 mm

Q4 - 1

K4 - 1

K4 - 1

Stage 4

K3 - 1

Stage 3

K2 - 1

Stage 2

K1 - 1

Stage 1

T1

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

K4 - 1

T2

Stage 4

T3

T1

K3 - 1

T2

Stage 3

T3

T1

K2 - 1

T2

Stage 2

T3

T1

K1 - 1

T2

Stage 1

T3

BF09

L1

A1A2 A1A2 A1A2 A1

L2

L3

A2

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

K4 - 1

K3 - 1

K2 - 1

K1 - 1

Q3 - 1

K3 - 1

Q2 - 1

K2 - 1

664Y3500

Q1 - 1

K1 - 1

EN • 14

Page 15

INSTALLATION : ELECTRIC SUPPLY

POWER WIRING / MODEL : E-TECH P / 115

2

95 mm

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

L1L2L3

F-200A

20 x 5 mm

Q4 - 2

K4 - 2

Q3 - 2

K3 - 2

Q4 - 1

K4 - 1

Q3 - 1

K3 - 1

K4 - 2

Stage 4

K4 - 1

Stage 4

K3 - 2

Stage 3

K3 - 1

Stage 3

K2 - 2

Stage 2

K2 - 1

Stage 2

K1 - 2

Stage 1

K1 - 1

Stage 1

T1

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

K4 - 2

T2

Stage 4

T3

T1

K4 - 1

T2

Stage 4

T3

T1

K3 - 2

T2

Stage 3

T3

T1

K3 - 1

T2

Stage 3

T3

T1

K2 - 2

T2

Stage 2

T3

T1

K2 - 1

T2

Stage 2

T3

T1

K1 - 2

T2

Stage 1

T3

T1

K1 - 1

T2

Stage 1

T3

BF09

L1

A1A2 A1A2 A1A2 A1

L2

L3

A2

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

A1A2 A1A2 A1A2 A1

L2

L3

A2

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

K4 - 2

K4 - 1

K3 - 2

K3 - 1

K2 - 2

K2 - 1

K1 - 2

K1 - 1

664Y3500

Q2 - 2

K2 - 2

Q1 - 2

K1 - 2

Q2 - 1

K2 - 1

Q1 - 1

K1 - 1

EN • 15

Page 16

INSTALLATION : ELECTRIC SUPPLY

POWER WIRING / MODEL : E-TECH P / 144

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

2

120 mm

F-250A

L1L2L3

20 x 5 mm

Q4 - 2

K4 - 2

Q3 - 2

K3 - 2

Q4 - 1

K4 - 1

Q3 - 1

K3 - 1

664Y3500

Q2 - 3

K2 - 3

Q1 - 3

K1 - 3

Q2 - 2

K2 - 2

Q1 - 2

K1 - 2

EN • 16

Q2 - 1

K2 - 1

Q1 - 1

K1 - 1

Page 17

INSTALLATION : ELECTRIC SUPPLY

POWER WIRING / MODEL : E-TECH P / 144

T1

T1

K4 - 2

Stage 4

K4 - 1

Stage 4

K3 - 2

Stage 3

K3 - 1

Stage 3

K2 - 3

Stage 2

K2 - 2

Stage 2

K2 - 1

Stage 2

K1 - 3

Stage 1

K1 - 2

Stage 1

K1 - 1

Stage 1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

K4 - 2

T2

Stage 4

T3

T1

K4 - 1

T2

Stage 4

T3

T1

K3 - 2

T2

Stage 3

T3

T1

K3 - 1

T2

Stage 3

T3

T1

K2 - 3

T2

Stage 2

T3

T1

K2 - 2

T2

Stage 2

T3

T1

K2 - 1

T2

Stage 2

T3

T1

K1 - 3

T2

Stage 1

T3

T1

K1 - 2

T2

Stage 1

T3

T1

K1 - 1

T2

Stage 1

T3

BF09

L1

A1A2 A1A2 A1A2 A1

L2

L3

A2

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

A1A2 A1A2 A1A2 A1

L2

L3

A2

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

K4 - 2

K4 - 1

K3 - 2

K3 - 1

K2 - 3

K2 - 2

K2 - 1

K1 - 3

K1 - 2

K1 - 1

664Y3500

EN • 17

Page 18

INSTALLATION : ELECTRIC SUPPLY

POWER WIRING / MODEL : E-TECH P / 201

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

2

185 mm

F-315A

L1L2L3

30 x 5 mm

Q4 - 3

K4 - 3

Q3 - 3

K3 - 3

Q4 - 2

K4 - 2

Q3 - 2

K3 - 2

Q4 - 1

K4 - 1

Q3 - 1

K3 - 1

664Y3500

Q2 - 4

K2 - 4

Q1 - 4

K1 - 4

Q2 - 3

K2 - 3

Q1 - 3

K1 - 3

Q2 - 2

K2 - 2

Q1 - 2

K1 - 2

EN • 18

Q2 - 1

K2 - 1

Q1 - 1

K1 - 1

Page 19

INSTALLATION : ELECTRIC SUPPLY

POWER WIRING / MODEL : E-TECH P / 201

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

K4 - 3

Stage 4

K4 - 2

Stage 4

K4 - 1

Stage 4

K3 - 3

Stage 3

K3 - 2

Stage 3

K3 - 1

Stage 3

K2 - 4

Stage 2

K2 - 3

Stage 2

K2 - 2

Stage 2

K2 - 1

Stage 2

K1 - 4

Stage 1

K1 - 3

Stage 1

BF09

T1

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

K4 - 3

T2

Stage 4

T3

T1

K4 - 2

T2

Stage 4

T3

T1

K4 - 1

T2

Stage 4

T3

T1

K3 - 3

T2

Stage 3

T3

T1

K3 - 2

T2

Stage 3

T3

T1

K3 - 1

T2

Stage 3

T3

T1

K2 - 4

T2

Stage 2

T3

T1

K2 - 3

T2

Stage 2

T3

T1

K2 - 2

T2

Stage 2

T3

T1

K2 - 1

T2

Stage 2

T3

T1

K1 - 4

T2

Stage 1

T3

T1

K1 - 3

T2

Stage 1

T3

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1A2 A1A2 A1

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1A2 A1A2 A1

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1A2 A1

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

NO

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

K4 - 3

K4 - 2

K4 - 1

K3 - 3

K3 - 2

K3 - 1

K2 - 4

K2 - 3

K2 - 2

K2 - 1

K1 - 4

K1 - 3

K1 - 2

K1 - 1

K1 - 2

Stage 1

K1 - 1

Stage 1

664Y3500

T1

T1

T2

T3

T1

T2

T3

K1 - 2

T2

Stage 1

T3

T1

K1 - 1

T2

Stage 1

T3

EN • 19

Page 20

INSTALLATION : ELECTRIC SUPPLY

POWER WIRING / MODEL : E-TECH P / 259

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

2

240 mm

F-400A

L1L2L3

30 x 5 mm

Q4 - 5

K4 - 5

Q3 - 4

K3 - 4

Q4 - 4

K4 - 4

Q3 - 3

K3 - 3

Q4 - 3

K4 - 3

Q3 - 2

K3 - 2

Q4 - 2

K4 - 2

Q3 - 1

K3 - 1

Q4 - 1

K4 - 1

664Y3500

Q2 - 5

K2 - 5

Q1 - 4

K1 - 4

Q2 - 4

K2 - 4

Q1 - 3

K1 - 3

Q2 - 3

K2 - 3

Q1 - 2

K1 - 2

EN • 20

Q2 - 2

K2 - 2

Q1 - 1

K1 - 1

Q2 - 1

K2 - 1

Page 21

INSTALLATION : ELECTRIC SUPPLY

POWER WIRING / MODEL : E-TECH P / 259

T1

T1

K4 - 5

Stage 4

K4 - 4

Stage 4

K4 - 3

Stage 4

K4 - 2

Stage 4

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

K4 - 5

T2

Stage 4

T3

T1

K4 - 4

T2

Stage 4

T3

T1

K4 - 3

T2

Stage 4

T3

T1

K4 - 2

T2

Stage 4

T3

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

K4 - 1

Stage 4

K3 - 4

Stage 3

K3 - 3

Stage 3

K3 - 2

Stage 3

K3 - 1

Stage 3

K2 - 5

Stage 2

K2 - 4

Stage 2

K2 - 3

Stage 2

K2 - 2

Stage 2

K2 - 1

Stage 2

K1 - 4

Stage 1

K1 - 3

Stage 1

K1 - 2

Stage 1

K1 - 1

Stage 1

BF09

T1

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

T1

T2

T3

K4 - 1

T2

Stage 4

T3

T1

K3 - 4

T2

Stage 3

T3

T1

K3 - 3

T2

Stage 3

T3

T1

K3 - 2

T2

Stage 3

T3

T1

K3 - 1

T2

Stage 3

T3

T1

K2 - 5

T2

Stage 2

T3

T1

K2 - 4

T2

Stage 2

T3

T1

K2 - 3

T2

Stage 2

T3

T1

K2 - 2

T2

Stage 2

T3

T1

K2 - 1

T2

Stage 2

T3

T1

K1 - 4

T2

Stage 1

T3

T1

K1 - 3

T2

Stage 1

T3

T1

K1 - 2

T2

Stage 1

T3

T1

K1 - 1

T2

Stage 1

T3

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1A2 A1A2 A1

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1A2 A1A2 A1

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1A2 A1A2 A1

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

A2 A1

NO

BF09

L1

L2

L3

A2 A1A2 A1A2 A1

NO

BF09

L1

L2

L3

NO

BF09

L1

L2

L3

NO

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

SMB 52

23

25

20

K4 - 5

K4 - 4

K4 - 3

K4 - 2

K4 - 1

K3 - 4

K3 - 3

K3 - 2

K3 - 1

K2 - 5

K2 - 4

K2 - 3

K2 - 2

K2 - 1

K1 - 4

K1 - 3

K1 - 2

K1 - 1

664Y3500

EN • 21

Page 22

COMMISSIONING

COMMISSIONING - WATER

1. The system must be thoroughly flushed prior to connection

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

of the boiler. The system water should be treated to prevent

general corrosion and deposition of scale or sludge in the

boiler. If installing the boiler onto an existing system, ACV

recommend that an approved system cleaner is used.

2. Fill and pressurise the boiler and system to 1.5 bar, making

sure to vent the boiler via the automatic air vent on top of the

boiler. Note that the black dust cap on the air vent should be

left loose to allow the auto vent to function.

3. Check for leaks.

COMMISSIONING - ELECTRICAL

The Electrical installation supplying this boiler must conform to

the current IEE Regulations.

1. Remove the front and the right-handside. Check all electrical

connections for tightness.

2. Ensure all internal relays, contactors etc are secure on the

DIN rails.

3. Set panel control main switches to off.

4. Set internal MCB to off position.

5. Set the control thermostat to desired temperature.

STARTING THE BOILER

1. Switch on internal MCB

2. Fit and secure all panels

3. Switch on local isolator to boiler

4. Turn the boiler on using the ON/OFF switch

5. The first stage energises as indicated by the panel light.

The temperature will now rise as indicated by the combined

temperature and pressure gauge. As long as the control

thermostat set-point is not reached, the next stage is

energised every 2 minutes until all the stages are energised.

When the control thermostat set-point is reached, the last

stage is de-ernergized every 30 seconds until all the stages

are de-energized.

Once these procedures have been followed the system can be

left to operate normally.

After one week of operation all electrical connections

should be re-checked. The fixing nuts must of the

heating elements must be re-tightened at the nominal

torque of 10 Nm following the tightening sequence

mentioned in maintenance section.

664Y3500

EN • 22

Page 23

MAINTENANCE

MAINTENANCE

For safety reasons it is recommended that the boiler is serviced

annually and that servicing is carried out by a qualified service

engineer.

Before carrying out any work on the system

ensure that the boiler is cool and all

electrical supplies are isolated.

1. After removing the front and the right panels, Undertake

a visual inspection of the boiler checking for signs of water

leakage from gaskets, and the components on top of the

boiler.

2. Undertake a visual inspection of all wiring in the boiler casing

checking for signs of overheating or burning.

3. Check all push-on electrical connectors for tightness and

good connection to the relative components.

4. Using a correct fitting screwdriver check all electrical

terminals on DIN rails and on all components for tightness.

5. Re-tight the fixing nuts of the heating element at nominal

torque of 10 Nm following the tightening sequence.

6. Check all individual circuit breakers are in the normal

position. If some fuses have tripped, check the wiring and the

resistance before reactivating them.

7. Replacement of the heating element (if required).

7. Replacement of the main fuses (if required)

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

Models Fuses ACV code

E-Tech P / 57 100 A 5476C006

E-Tech P / 115 200 A 5476C007

E-Tech P / 144 250 A 5476C008

E-Tech P / 201 315 A 5476C009

E-Tech P / 259 400 A 5476C010

1

2

5476D003

557A0088

Ohmic value : 22 Ω

1

5 7

3 4

8 6

2

torque = 10 Nm

8. Fit the right-hand panel and the boiler front cover and refit

screws.

9. Switch ON the electrical supply and following the procedures

described in the commissioning section.

Before opening any cover and/or caring

and any work on the system, ensure that

the system is electrically disconnected

from the power supply.

664Y3500

Please follow the tightening sequence

EN • 23

Page 24

ENGLISHFRANCAISNEDERLANDSESPAÑOLITALIANODEUTSCH

664Y3500

EN • 24

Loading...

Loading...