Page 1

INSTALLATION OPERATING AND

SERVICING INSTRUCTIONS

NOTICE D’INSTALLATION,

D’UTILISATION ET D’ENTRETIEN

GEBRUIKSHANDLEIDING EN

INSTALLATIEVOORSCHRIFT

delta

excellence in hot water

EN

NL

FR

delta

performance

performance

ventouse FV

30/09/2004 - 664Y1600

Page 2

INSTALLATION OPERATING AND SERVICING INSTRUCTIONS 1

delta

FV 35

:With ACV BMV1 oil burner

delta

FV 50

:With ACV BMV2 oil burner

NOTICE D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN 13

delta

FV 35

:Avec brûleur fioul ACV BMV1

delta

FV 50

:Avec brûleur fioul ACV BMV2

GEBRUIKSHANDLEIDING EN INSTALATIEVOORSCHRIFT 25

delta

FV 35

: Met fuel brander ACV BMV1

delta

FV 50

: Met fuel brander ACV BMV2

NOTICIAS DE INSTALACIÓN, UTILIZACIÓN Y MANTENIMIENTO 37

delta

FV 35

: Con quemador de gasoil ACV BMV1

delta

FV 50

: Con quemador de gasoil ACV BMV2

INSTRUZIONI DELL’ INSTALLAZIONE, DELL’ USO E DI MANUTENZIONE 49

delta

FV 35

:Con bruciatore a gasolio ACV BMV1

delta

FV 50

:Con bruciatore a gasolio ACV BMV2

ANLEITUNG ZUR INSTALLATION, GEBRAUCH UND WARTUNG 61

delta

FV 35

:Mit Ölbrenner ACV BMV1

delta

FV 50

:Mit Ölbrenner ACV BMV2

EN

DE

IT

ES

NL

FR

Page 3

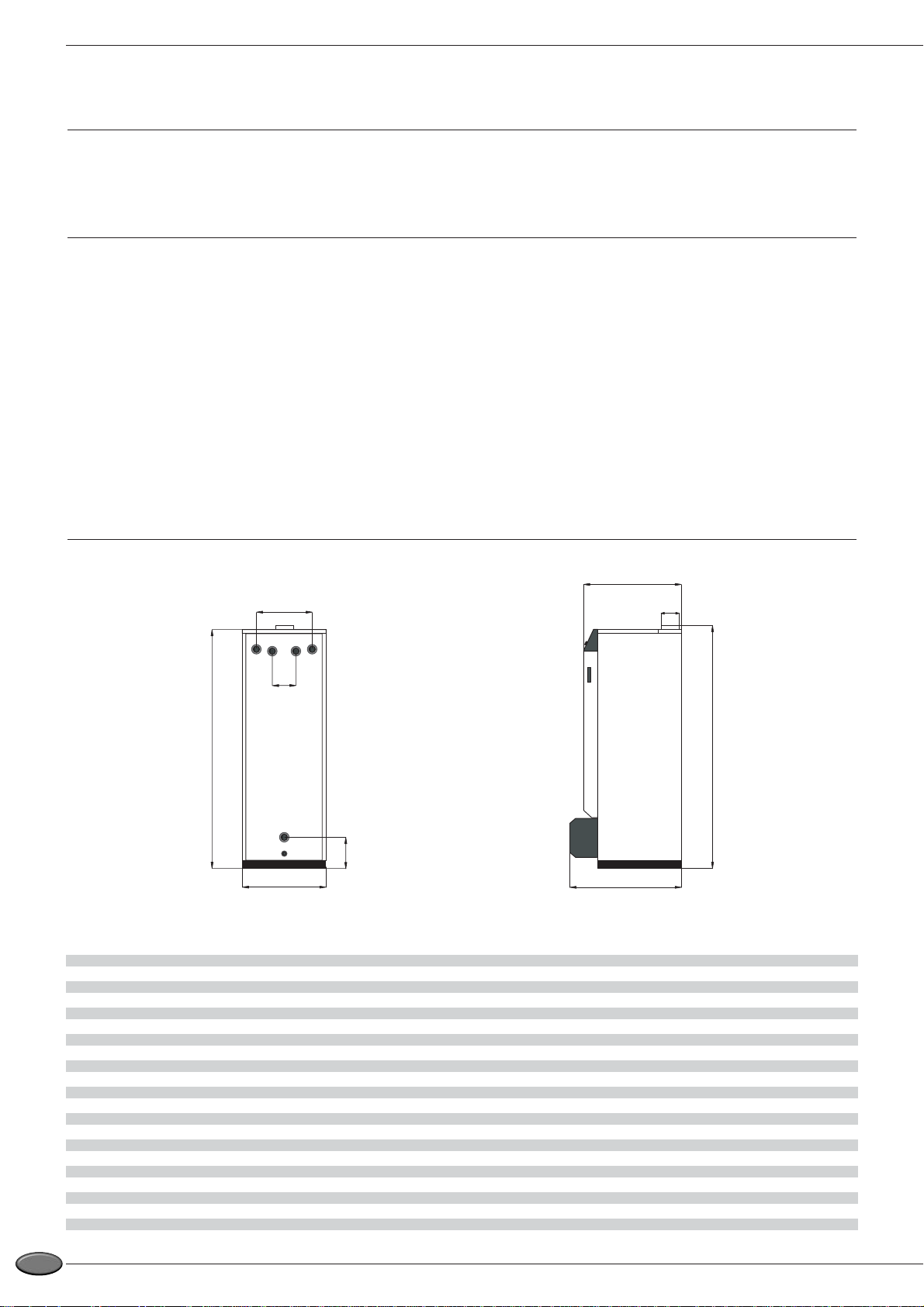

A B

E

D

C

C

z

6A

7

1

9

3

4

2

6

85

1 4 5

2 3

B

Y/Gr

Br

Br

Br

Or

Or

Y/Gr

Or

B

B

Br Br

B

B

B

Br

B

R

B

Y/Gr

Y/Gr

SSY 319 / SQK 349

P1 B5 B9 B3 B2

bk br

bl

QAAD50

(QAAD70)

QAC32 QAD22

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

230V-50 H

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2

P1Y1Y2NB5B9B3B2

1

Page 4

H

F

I

J

G

7

3

10

11

8

4

5

6

9

5

2

1

9

5

6

2

1

3

8 8

4

7

H

H

Page 5

K L

M

N

B 23

C 13 / C 33

5

4

8

7

6

14

13

10

12

11

9

17

21

19

20

26

22

24

23

1 32

25

16

18

15

F

C13

A

B

C33

120

150 min.

E

C

D

C43

C13

2 m min.

Page 6

O

P

Q

R

W

Y/Gr

B

Br

B

Y/Gr

Br

Br

B

Bk

Y/Gr

Y/Gr

Bk

B

Br

B

Y/Gr

Br

B

21 4

6

5

9

8

7

10

16

15

13

3

14

12

11

A1

12 11 4 N 3 N 8 N 3 N 6 4 10 11

M

1~

T2 T1 N L1

B4 S3

T2 T1 N L1

B4 S3

X1

X2

ZMOHBV1QRD

Page 7

1

EN

INSTALLATION, OPERATING

AND SERVICING INSTRUCTIONS

FV 35

with ACV

BMV(K)1

oil burner

FV 50

with ACV

BMV(K)2

oil burner

performance

balanced flue

Page 8

2

EN

INTRODUCTION 2

Intended users of these instructions 2

Symbols 2

Applicable standards 2

Warnings 2

DESCRIPTION 3

Overview 3

Description of operation 3

Construction features 3

Boiler captions 3

TECHNICAL SPECIFICATION 4

General 4

Maximum operating conditions 4

Dimensions 4

Domestic hot water performance 5

General features 5

INSTALLATION 6

Boiler room 6

Chimney connections 6

Heating connections 7

Hot water connections 7

Controller kits 7

Electrical connection 8

Oil supply 8

BURNER FEATURES 9

ACV BMV1 and BMV2 oil burners 9

ACV BMV1 and BMV2 burner factory settings 9

ACV BMV1 and BMV2 burner captions 9

STARTUP 10

Filling the hot water and heating circuits 10

Commissioning ACV BMV1 and BMV2 burners 10

SERVICING 10

Recommendation 10

Servicing the boiler 10

Servicing the safety devices 10

Servicing the burner 10

Emptying the boiler 10

USER GUIDE 11

Using the boiler 11

Resetting ACV BMV1 and BMV2 burners 12

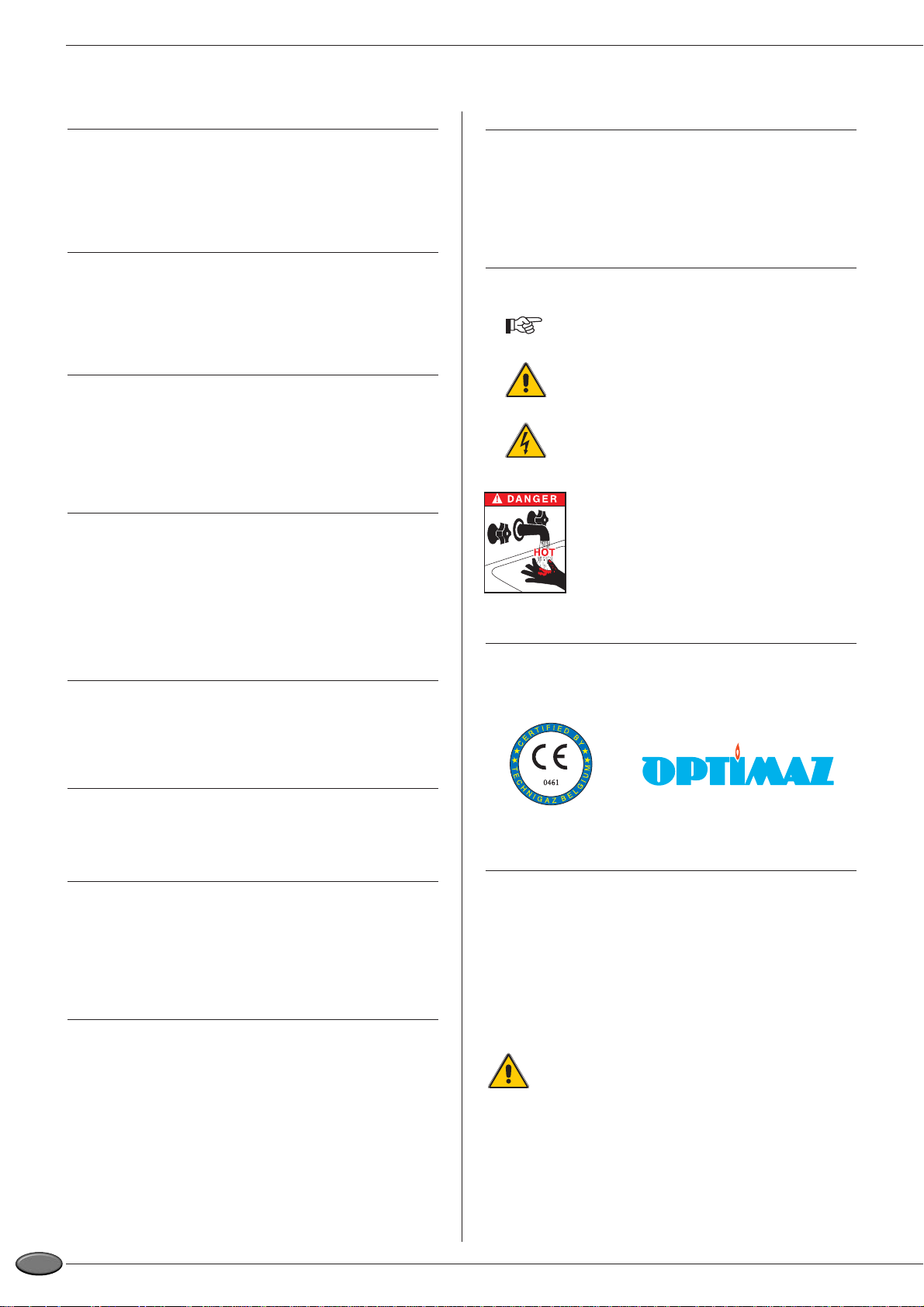

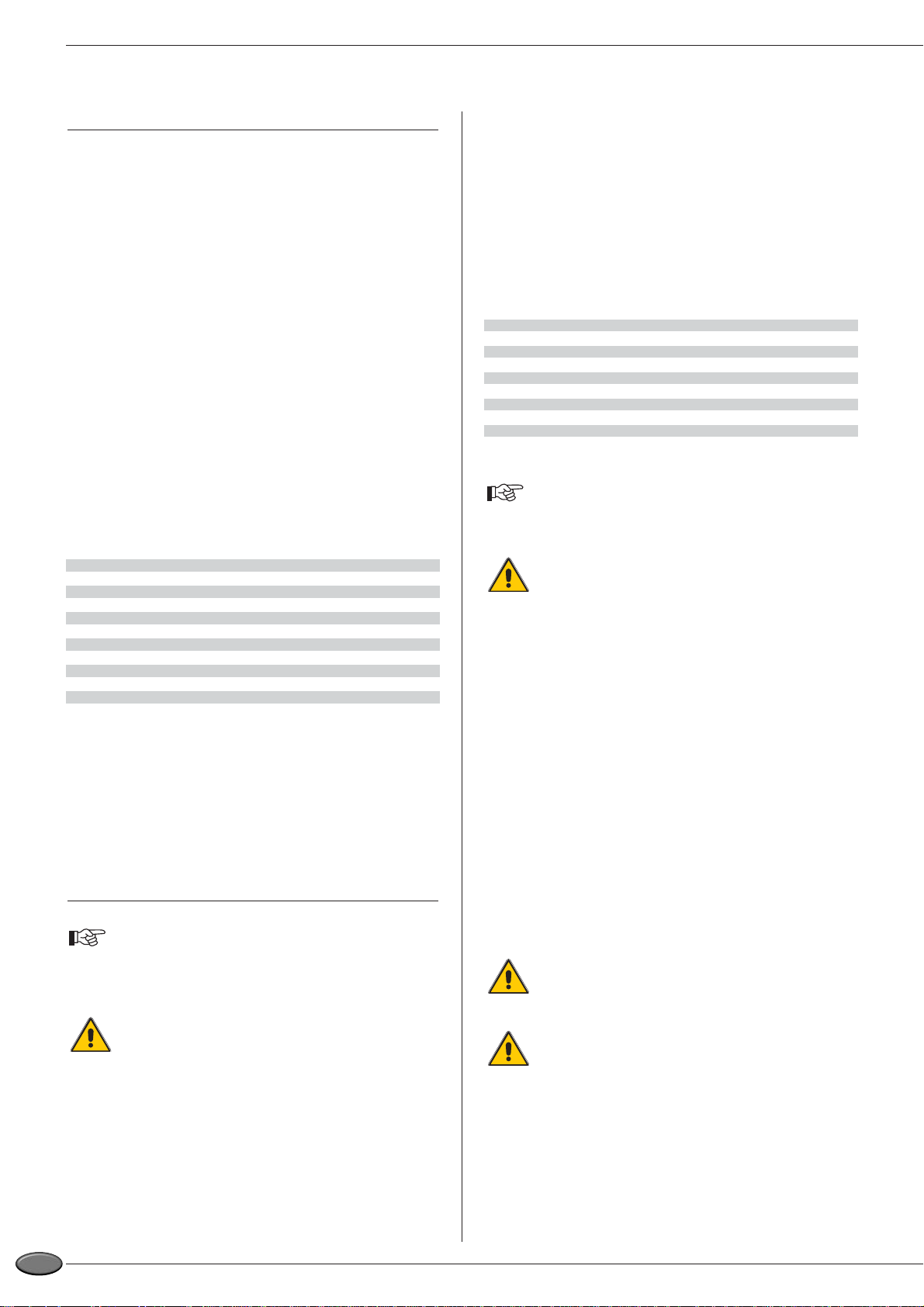

INTENDED USERS OF THESE INSTRUCTIONS

These instructions are intended for:

- specifying engineers

- installing engineers

- users

- servicing technicians

SYMBOLS

The following symbols are used in these instructions:

Essential instruction for operating the system

correctly.

Essential instruction for personal safety and

environmental protection.

Danger of electrocution.

Risk of burns.

APPLICABLE STANDARDS

The products have received the "CE" certificate of compliance with

standards of individual countries (European Directive 92/42/EEC,

"efficiency").These products also have the Belgian OPTIMAZ mark.

WARNINGS

These instructions are an integral part of the equipment to which

they refer and must be supplied to the user.

The product must be installed and serviced by qualified heating

engineers, in compliance with the prevailing standards.

ACV accepts no liability for any damage resulting from incorrect

installation or from the use of components or fittings not specified by

ACV.

Failure to observe instructions regarding tests

and test procedures can result in personal injury or

pollution risks.

Note:

ACV reserves the right to modify the technical specifications and

components of its products without prior notice.

INDEX INTRODUCTION

Page 9

3

EN

OVERVIEW

• Combination boiler (central heating and domestic hot water).

•TANK-IN-TANK indirect storage type domestic hot water production.

• Equipment required: a hydraulic connection kit for the heating

circuit (available as an option).

• The control panel comprises an on/off switch, adjustable

thermostat, thermometer, Summer/Winter selector and knockout

for fitting the ACV integrated control system

(optional).

• The Delta Performance FV can be connected as a balanced flue

system with a type C concentric adapter…, or with a type B23

adapter directly to the chimney.

• The Delta Performance FV 35 with a fixed output of 35 is fitted

with the ACV BMV1 oil burner.

• The Delta Performance FV 50 with a fixed output of 50 is fitted

with the ACV BMV2 oil burner.

DESCRIPTION OF OPERATION

The "Tank-in-Tank" concept

The Delta Performance balanced flue series differs from traditional

hot water generators because of its ring-shaped tank immersed in

the primary fluid contained in the outer body. When there is a

demand for heat from the central heating system or the domestic hot

water system, the potentiometer starts the burner. The combustion

gases quickly heat up the primary fluid, creating a natural circulation

around the tank.

Domestic hot water heated indirectly

This circulation facilitates heat exchange between the primary fluid

and the domestic water, which takes place all over the tank surface.

The corrugations on the inner and outer shells of the ring-shaped

tank further boost the area of heat exchange and speed up the

heating process of the domestic water.

Easy setting with safety assured

With a single command, the water temperature of both the primary

circuit and the hot water circuit is set by the adjustable thermostat

situated under the tank in the primary circuit.

A cut-off thermostat, placed on top of the boiler, automatically cuts

out the burner when the water temperature in the primary circuit

reaches 95 °C. A manually reset safety thermostat shuts off the

burner if the temperature reaches 103 °C.

CONSTRUCTION FEATURES

Corps externe

The outer body containing the primary fluid is made of thick

STW 22 steel.

"Tank-in-Tank" type exchanger accumulator

The ring-shaped inner tank with its large heating surface for

producing domestic hot water is built of Chrome/Nickel 18/10

stainless steel. It is corrugated over its full height by an exclusive

production process and entirely argon arc welded by the TIG

(Tungsten Inert Gas) method.

Combustion gas circuit

The combustion gas circuit is protected by a high temperature

resistant paint. It is composed of:

•Flue pipes. Delta Performance balanced flue models have 8 steel

flue pipes with an internal diameter of 64 mm. Each pipe is fitted

with a special steel baffle designed to improve heat exchange and

reduce flue gas temperature.

• Combustion chamber. The sealed combustion chamber is water

cooled.

Insulation

The boiler body is fully insulated by rigid polyurethane foam with a

high thermal insulation coefficient, sprayed on without the use of

CFCs.

Jacket

The boiler is covered by a steel jacket which has been scoured and

phosphated before being stove enamelled at 220 °C.

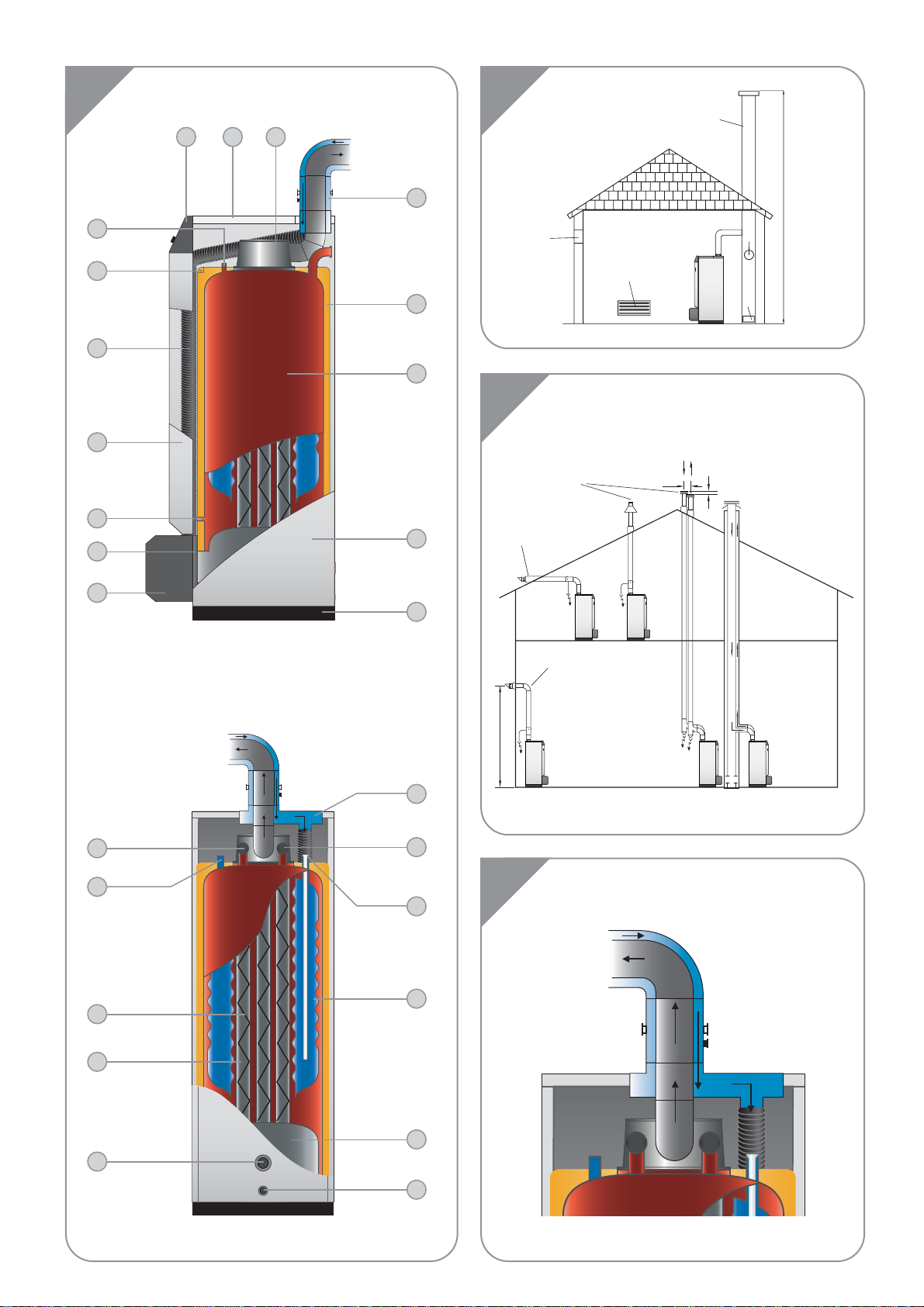

BOILER CAPTIONS (see illustration K)

1. Control panel

2. Removable jacket top

3. Flue reduction collar

4. Measuring unit

5. CFC-free polyurethane foam insulation

6. Inner ring-shaped domestic hot water tank

7. Side panel

8. Base

9. Burner and burner chamber plate cover

10. Burner chamber plate

11. Control thermostat bulb

12. Removable front panel

13. Tube supplying air to venturi

14. Manual reset safety thermostat - 103 °C

15. Cut-off thermostat bulb - 95 °C

16. Balanced flue connection unit

17. Heating return

18. Domestic cold water inlet

19. Inner ring-shaped domestic hot water tank

20. Combustion chamber

21. Boiler drain

22. Lower heating return

23. Flue pipes

24. Turbulators

25. Domestic hot water outlet

26. Central heating flow pipe

DESCRIPTION

Page 10

4

EN

GENERALE

The units are delivered fully assembled, tested and packed on a timber base with shockproof edges and protected by heat-shrunk plastic

film. On reception and after unpacking, check the equipment for damage.

For transport purposes, refer to the weights and dimensions given below.

MAXIMUM OPERATING CONDITIONS

Maximum service pressure (tank full of water)

- Primary circuit: 3 bar

- Secondary circuit: 10 bar

Test pressure

(tank full of water)

- Primary circuit: 4.5 bar

- Secondary circuit: 13 bar

Operating temperature

- Maximum temperature: 90 °C

Water quality

• Chlorides: < 150 mg/l (Stainless steel 304)

< 2000 mg/l (Duplex)

• 6 ≤ ph ≤ 8

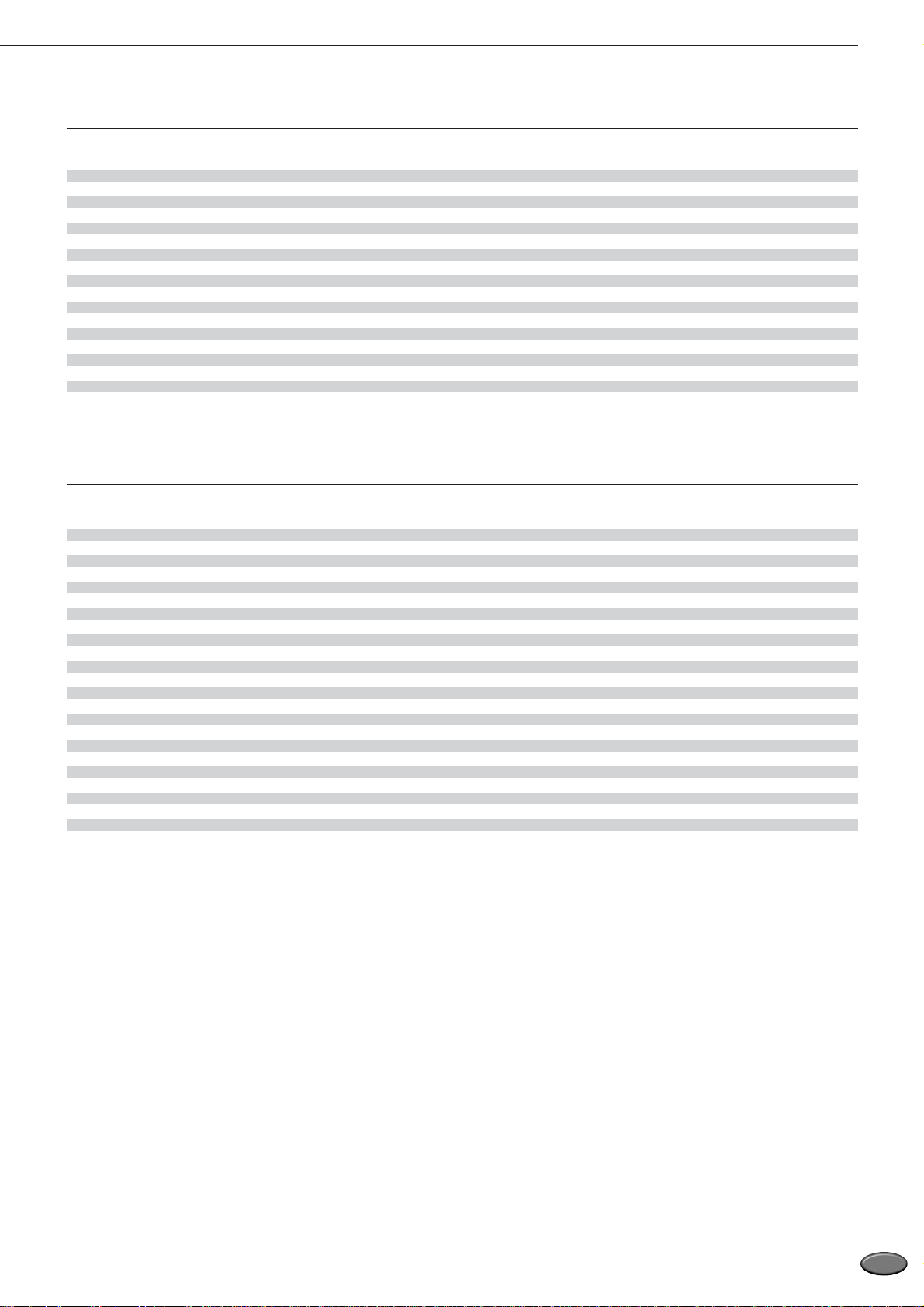

DIMENSIONS

TECHNICAL SPECIFICATION

FV/35 FV/50

A mm 1585 1830

B mm 390 390

C mm 200 200

D mm 542 542

E mm 125 125

F mm 645 645

G mm 80/80/125 100/100/150

H mm 1610 1880

I mm 800 800

Weight empty Kg 182 220

F

G

I

H

B

C

D

A

E

Page 11

5

EN

TECHNICAL SPECIFICATION

GENERAL FEATURES

DOMESTIC HOT WATER PERFORMANCE

FV/35 FV/50

Operating at 80 °C

Peak delivery at 40 °C (≤ T = 30 °C) L/10’ 283 377

Peak delivery at 40 °C (≤ T = 30 °C) L/60’ 1024 1485

Continuous delivery at 40 °C (≤ T = 30 °C) L/h 920 1352

Tank refill time at 60 °C

Initial heating time minutes 20 13

After drawing off 140 L at 45° C minutes 10 8

FV/35 FV/50

Input L/10’ 34.9 50

Output L/60’ 32.62 46.75

Maintenance loss at 60 °C as % of rated value % 0.8/0.7 0.6/0.45

Total capacity L 127 162

Primary capacity L 62 82

Heating connection Ø 1” 1”

Domestic hot water connection Ø 3/4” 3/4”

Hot water tank heat exchange surface m

2

1.99 2.46

Combustion efficiency % 94.7 93.5

Average CO2 % 13 13

Mass rate of combustion products g/sec. 14.8 21.2

Page 12

6

EN

BOILER ROOM

Important

•Keep vents free at all times.

• Do not store inflammable products in the boiler room.

•Take care not to store corrosive products near the boiler, such as

paints, solvents, chlorine, salt, soap and other cleaning products.

Access

The boiler room must be large enough to allow good access

to the boiler.The following minimum distances (mm) are required

around the boiler:

- front 500

- behind 150

- sides 100

- above 700

Ventilation

The boiler room must be fitted with top and bottom vents as shown

in illustration "L".

The table below is an example compliant with the Belgian

standard.

Note:

(B) and (C) only for B23 type connections

For other countries, refer to their regulations.

Base

The base on which the boiler rests must be made of noncombustible

materials.

CHIMNEY CONNECTIONS

IMPORTANT

Boilers must be installed by a qualified heating

engineer, in accordance with the prevailing local

standards and regulations.

The chimney diameter must not be less than the

diameter of the boiler connection.

Chimney connection type: B23 (See illustration L)

The boiler is connected to the chimney by a metal pipe

rising at an angle from the boiler to the chimney.

A chimney connection is required

A. Top vent

B. Bottom vent

C. Draught regulator

D. Inspection cover

E. Chimney height

F. Chimney diameter

Note:

Since the regulations vary from one country to

another, the table above is given for information only.

Due to the high efficiency of our boilers,the flue gases

are released at high temperature.

Therefore there is a risk of condensation in these flue

gases, which could damage some chimneys.

To avoid this risk, it is strongly recommended to line

the chimney.

Contact your installer for more information.

Chimney connection type: C…

(see illustrations M and N)

• C 13 : concentric horizontal connection

• C 33 : concentric vertical connection

• C 43 : Concentric chimney connection

Maximum length for concentric type : 6 metres

Note:

A pipe bend of 90° = an equivalent length of one metre

There should be a drain outlet close to the boiler to

prevent chimney condensates entering the boiler.

To prevent condensation water running out of the

terminal, all horizontal pipes should slope down to the

boiler.

INSTALLATION

FV/35 FV/50

Ventilation

Min. fresh air requirement m3/h 63 90

Top vent (A) dm

2

1.5 1.5

Bottom vent (B) dm

2

1.5 2

Draught regulator (C) Ø 80 100

FV/35 FV/50

Chimney

E = 5 m Ø min. F mm 213 236

E = 10 m Ø min. F mm 179 199

E = 15 m Ø min. F mm 162 179

Page 13

7

EN

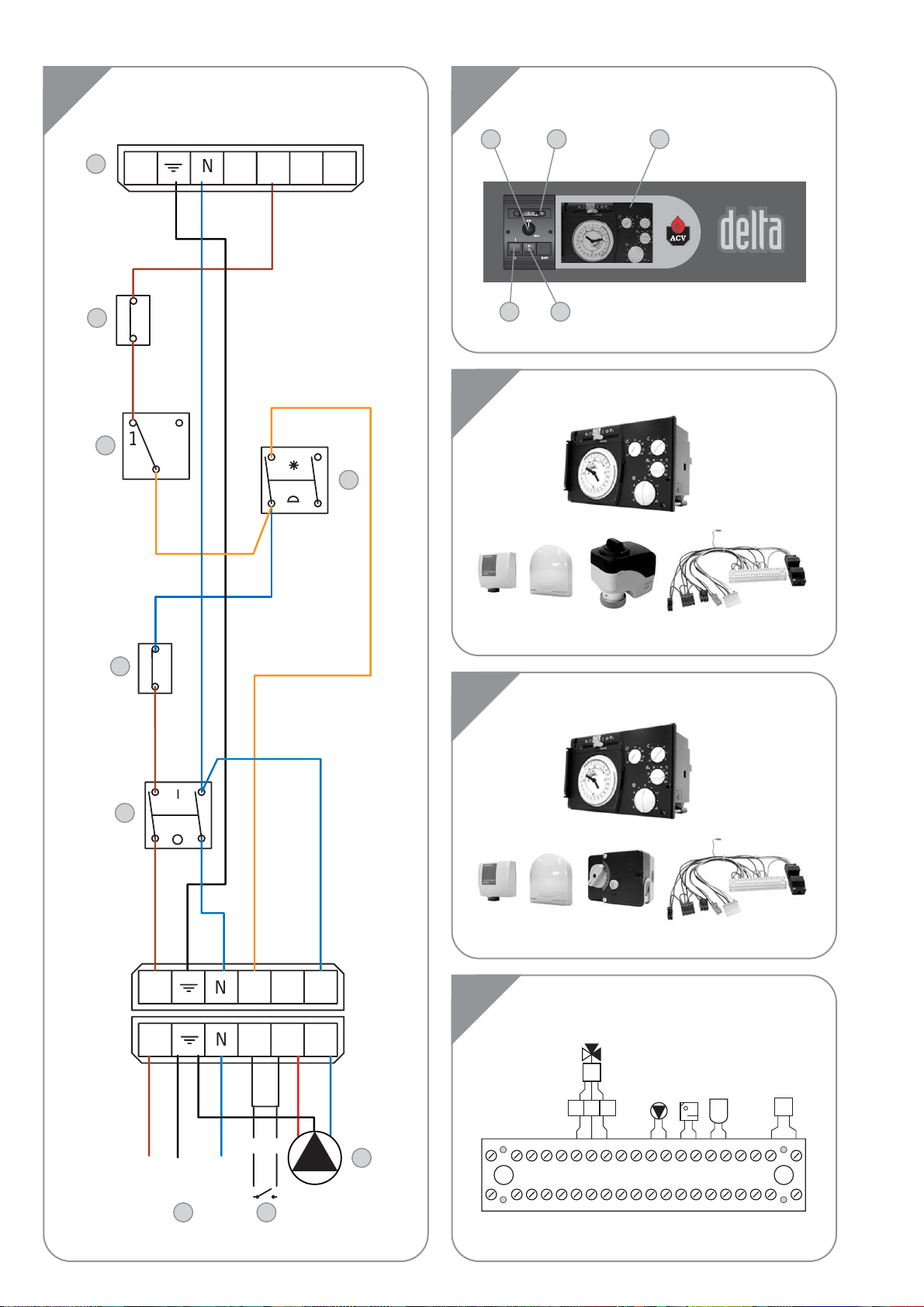

HEATING CONNECTION

Example of a basic circuit configuration

(see illustration G)

1. 3-way motorised mixing valve

2. Safety valve set to 3 bar with pressure gauge

3. Circulator

4. Non-return valve

5. System filling valve

6. Expansion tank

7. ACV 13 controller

(see controller kit page 7)

8. Central heating isolating valve

9. Drain cock

Hydraulic kit + ACV heating kit (see illustration F)

ACV offers an optional pre-assembled circulation kit comprising:

- a circulator.

- a 3-way manual motorisable valve.

- connecting pipes including a second optional circuit.

- two isolating valves.

- adapters for mounting safety valve with pressure gauge and filling

valve to right or left of expansion tank.The expansion tank is not

included.

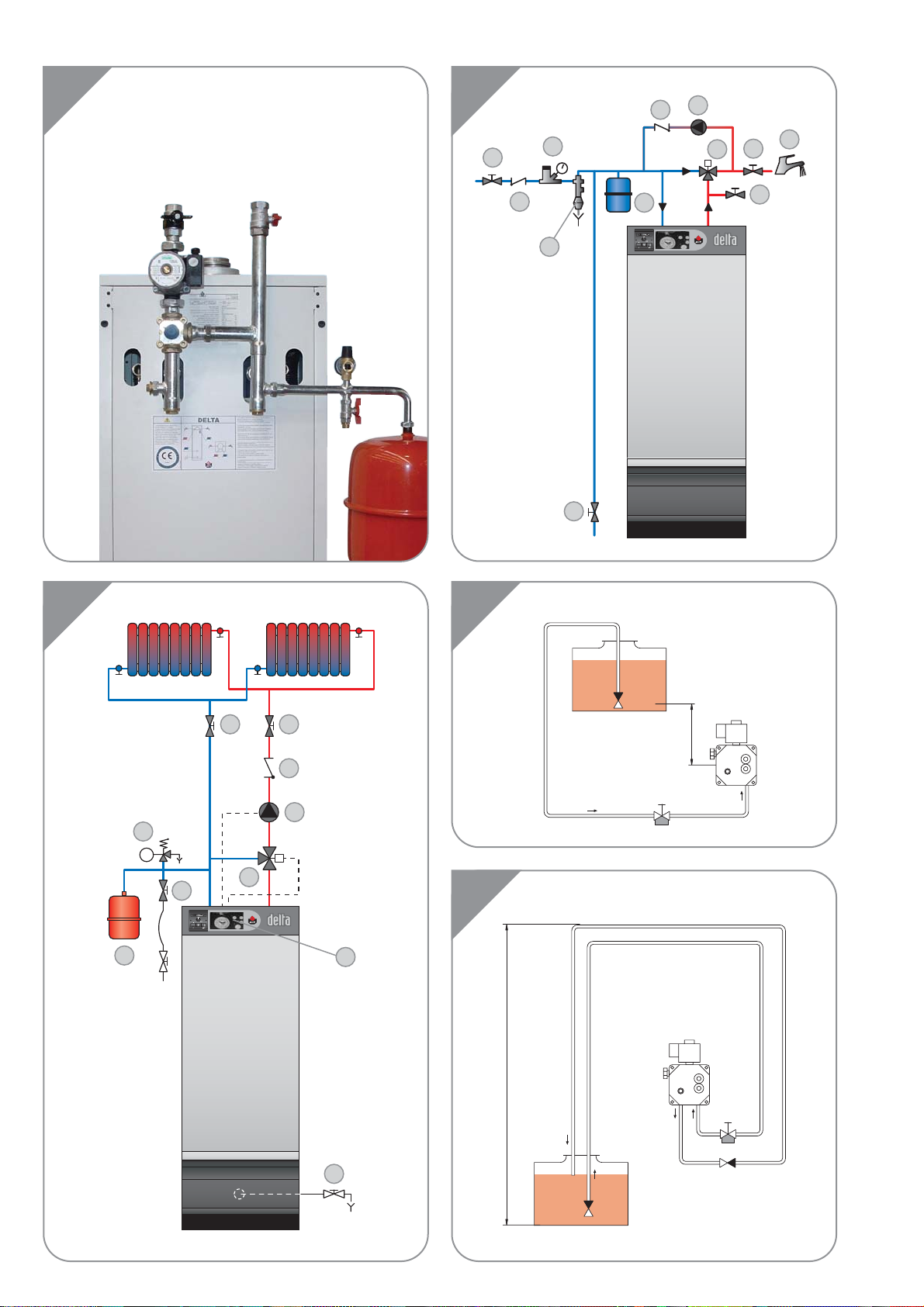

HOT WATER CONNECTION

Pressure reducer

If the water mains pressure is greater than 6 bar, a pressure

reducer calibrated to 4.5 bar must be fitted.

Safety unit

The tank safety unit must be ACV approved and calibrated to 7 bar.

The valve discharge must be connected to the sewer drain.

Hot water expansion tank

Installing a hot water expansion tank avoids any risk of pressure

surges due to water-hammer or pressure variations.

Hot water circulation

If the tank is situated a long way from the point of use, then

installing a closed return circuit can provide a faster supply of hot

water always available.

Example of connection with thermostatic valve

(see illustration H)

1. Safety unit

2. Pressure reducer

3. Thermostatic mixing valve

4. Hot water circulator

5. Non-return valve

6. Hot water type expansion tank

7. Cold water feed valve

8. Drawoff tap

9. Drain cock

10. Bleed valve

11. Isolating valve

IMPORTANT

As a safety measure against burns,we strongly

recommend installing a thermostatic mixer.

Optional fittings available

CONTROLLER KITS

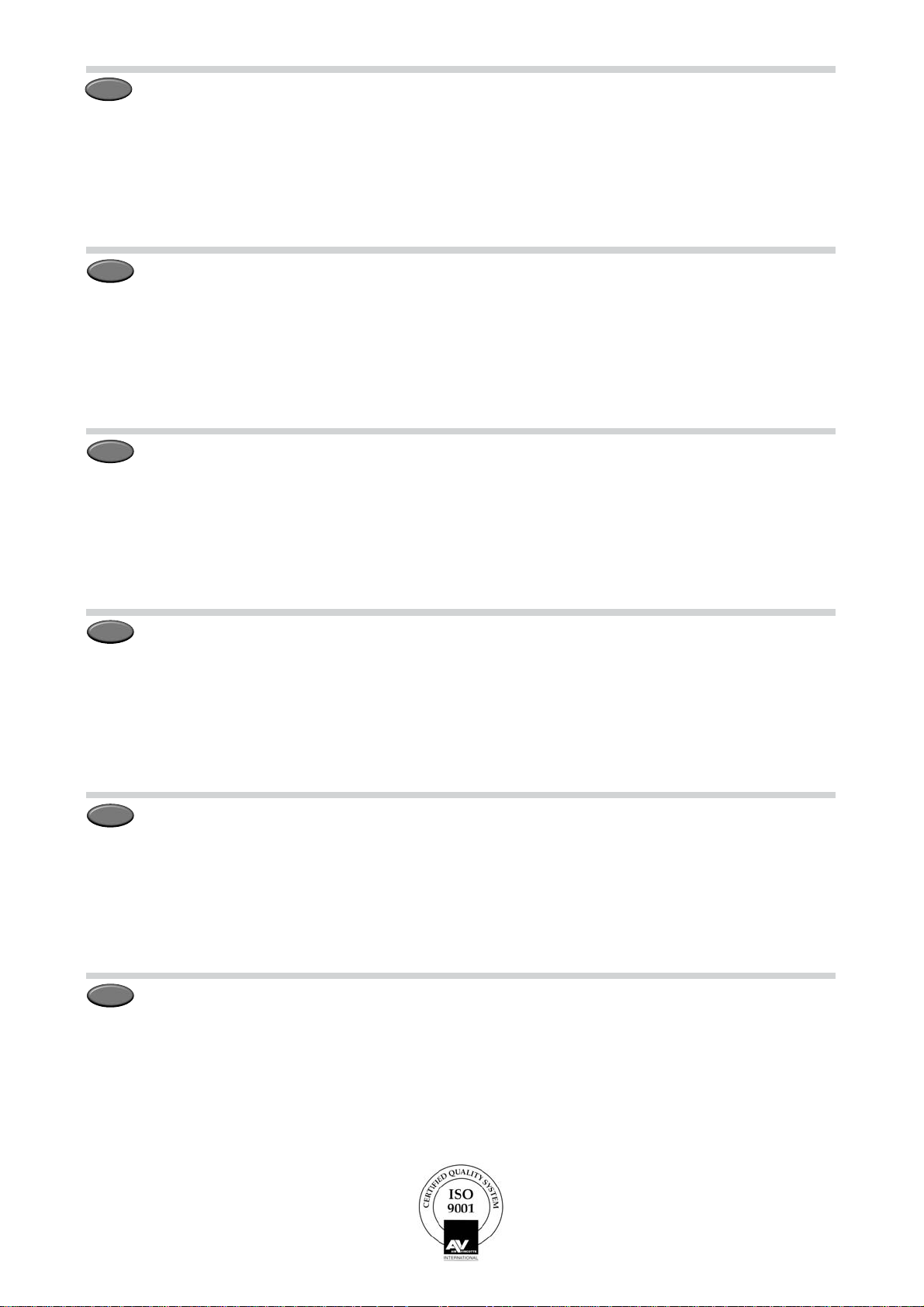

KIT 1: ACV 13.00 / Basic (see illustration C)

Basic kit for regulating flow temperature according to weather

conditions.

It comprises: temperature regulator with analogue timer, water

temperature detector (-30°/130°C), outside temperature detector

(-30°/50°C), 230V - 3 spindle servomotor SSY 319 and intermediate

socket.

KIT 2: ACV 13.00 / Standard (see illustration D)

Standard kit for regulating flow temperature according to weather

conditions.

It comprises: temperature regulator with analogue timer, water

temperature detector (-30°/130°C), outside temperature detector

(-30°/50°C), 230V - 3 spindle servomotor SQK 349 and intermediate

socket.

Wiring diagram of ACV controller kits

(see illustration E)

B2. Temperature probe

B9. Outside temperature probe

B5. Analogue/digital room thermostat

P1. Central heating pump

Y1/Y2/N. Mixer valve (SSY 319 or SQK 349)

bl. Blue N

n/z. Black Y2

br. Bro wn Y1

INSTALLATION

Safety unit Ø 3/4”

Pressure reducer Ø 3/4“

Thermostatic mixing valve Ø 3/4”

Expansion tank 5 litres

Page 14

8

EN

Height H Ø 6 mm Ø 6 mm Ø 8 mm

4.0 m 100 m 100 m 100 m

3.5 m 100 m 100 m 100 m

3.0 m 100 m 197 m 100 m

2.5 m 100 m 181 m 100 m

2.0 m 100 m 165 m 100 m

1.5 m 197 m 149 m 177 m

1.0 m 165 m 132 m 151 m

0.5 m 132 m 116 m 126 m

Nozzle uo to 2.5 Kg uo to 5.0 Kg uo to 10.0 Kg

Height H Ø 6 mm Ø 8 mm Ø 10 mm

0.0 m 17 m 53 m 100 m

0.5 m 15 m 47 m 100 m

1.0 m 13 m 41 m 199 m

1.5 m 11 m 34 m 184 m

2.0 m 19 m 28 m 168 m

2.5 m 17 m 22 m 153 m

3.0 m 15 m 15 m 137 m

3.5 m 13 m 19 m 122 m

ELECTRICAL CONNECTION

Power supply

The boiler operates with a 230 V - 50 Hz single phase supply.

An on-off mains switch box with 6 A fuses must be fitted outside the

boiler to allow power to be shut off during servicing and before any

repairs are carried out on the boiler.

Conformity

Boiler installation must comply with the prevailing local technical

standards and legislation.

Safety

The stainless steel tank must be earthed separately.

The power to the boiler must be switched off before

any work is carried out.

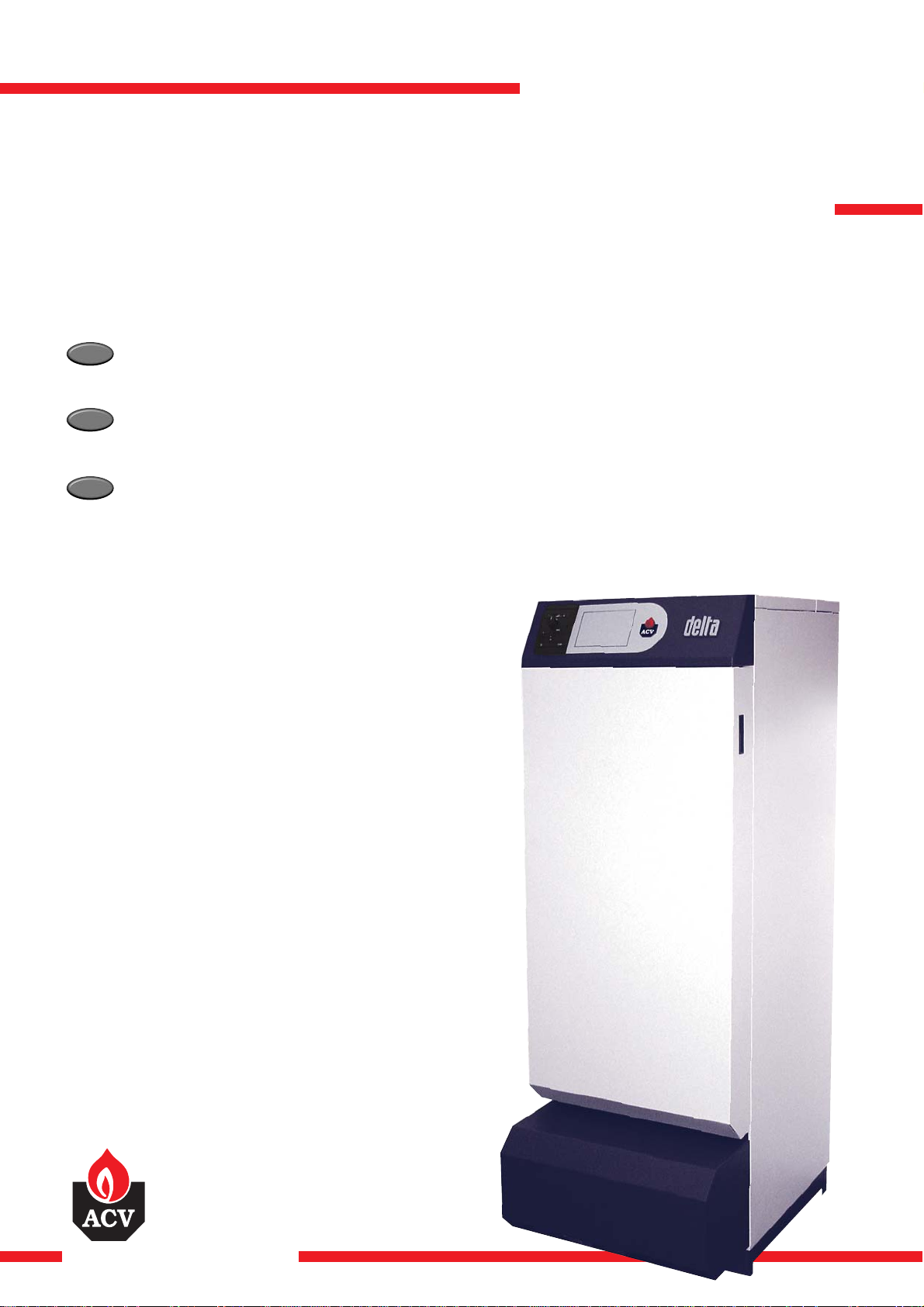

Boiler electrical wiring (see illustration A)

1. Control thermostat (60/90 °C)

2. On/off switch

3. Summer/winter selector

4. Safety thermostat (103 °C max.)

5. Boiler power connection

6. Heating circulator connection

7. Burner connection

8. Room thermostat

9. Cut-off thermostat (95 °C)

10. Boiler power plug

B. Blue

Br. Brown

Gr. Green

Or. Orange

R. Red

Y/Gr. Yellow / Green

BMV1 and BMV2 oil burner electric wiring

(see illustration P)

The burner is supplied with power by a 3-core cable, to be plugged

into the connector situated on the burner.Instructions for connection

are given in the burner technical manual.

A1. Automatic igniting device

M. Burner motor

QRB. Photoelectric resistor

OH. Heater

Z. Transformer

BV1. Magnetic valve

X1. Burner Euro plug connector

X2. Boiler plug connector

B. Blue

Br. Brown

Bk. Black

W. White

Y/Gr. Yellow / Green

OIL SUPPLY

System construction and installation must be in accordance with

DIN 4755. Local regulations must be followed.

Oil pipes must be brought sufficiently close to the burner so that the

tubes can be connected without strain. On the aspiration side of the

line, fit a filter with a quick closing valve. Install a check valve on the

return line.

The Burner can operate with a 1 or 2 line system.

In series, the burner is designed to operate with a two-line system.

The vacuum in the aspiration line should not exceed 0.4 bar.

Refer to the ACV BMV1 and BMV2 burner manual

supplied with them.

Dual-line installation (see illustration J)

INSTALLATION

Single-line installation (see illustration I)

Page 15

9

EN

BURNER FEATURES

ACV BMV1 AND BMV2 OIL BURNERS

Description

For the Delta Performance oil-fuelled balanced flue model, we have

opted for the all-new technology of the ACV BMV1 and BMV2 oil

burner, manufactured from high quality components combining

performance with perfect combustion.

CO2 chart for the ACV BMV1 and BMV2 burner

ACV BMV1 AND BMV2

BURNER FACTORY SETTINGS

FV/35 FV/50

Burner BMV1 BMV2

Input kW 34.9 50

Nozzle gal/h 0,75 1.25

Nozzle angle 60°H 60°H

Oil flow Kg/h 2.95 4.22

Pump pressure bar 11.8 9.5

Flue gas index 0 - 0.5 0 - 0.5

Air reducer % 37 60

Air inlet % 90 90

Nozzle line pressure mbar 3.5 - 4 3.5 - 4

Nozzle line mm 10 10

Weight Kg 14.5 14.5

Outside temperature

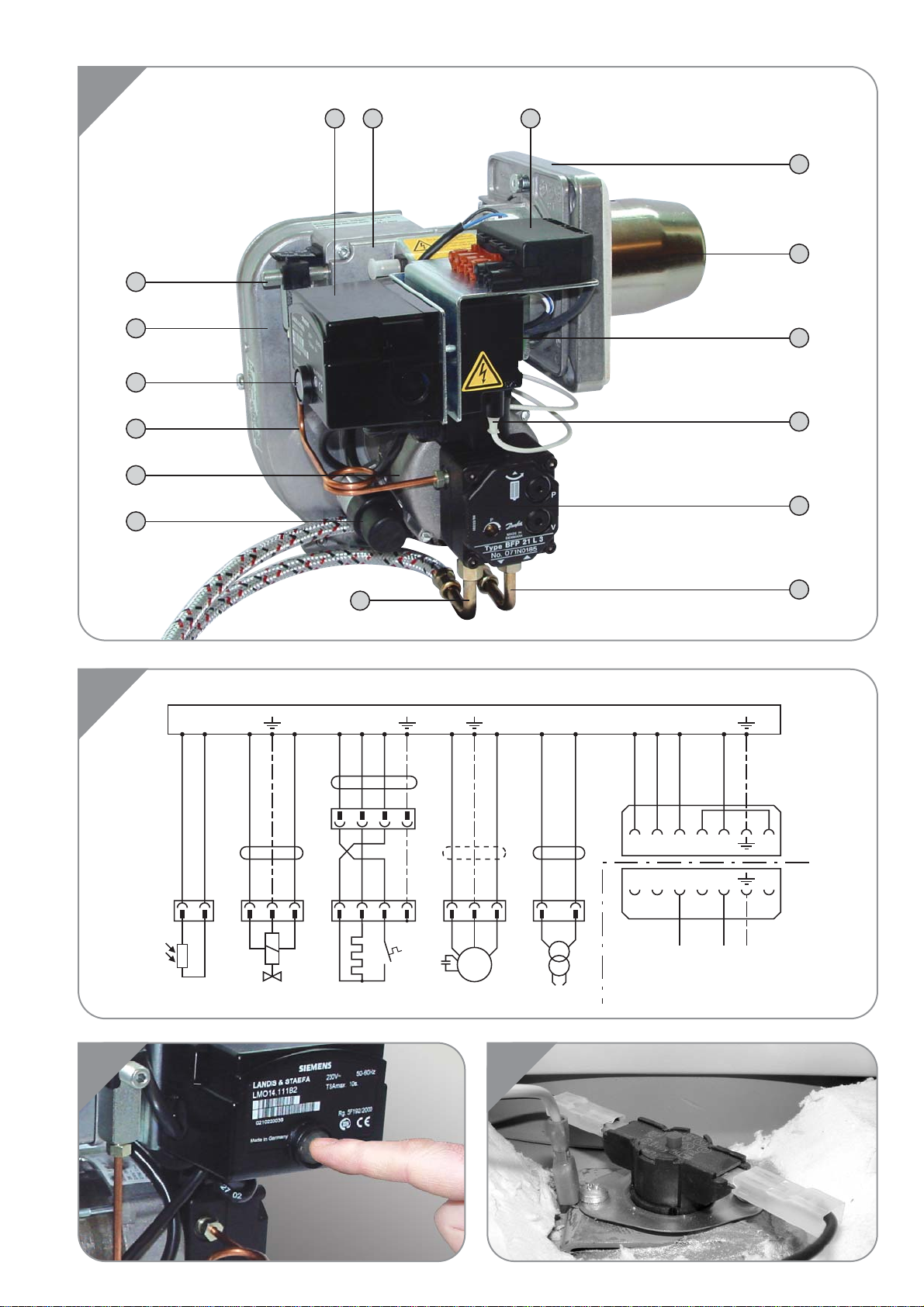

ACV BMV1 AND BMV2 BURNER CAPTIONS

(see illustration O)

1. Control unit

2. Nozzle line protection

3. Warning lamp

4. Electric plug connector

5. Attachment bracket

6. Burner blast tube

7. Ignition unit

8. High tension ignition cable

9. Oil pump

10. Oil aspiration line connection

(circuit with return only)

11. Oil return connection

12. Motor condenser

13. Motor

14. Pump / nozzle connecting pipe

15. Burner casing

16. Nozzle line adjustment screw

WARNING: Set the % of CO

2 as per the data in the diagram above

14 %

13,5 %

13 %

% CO2

12,5 %

12 %

-10 0 10 203040

Page 16

10

EN

FILLING THE DOMESTIC HOT WATER AND

HEATING CIRCUITS (see illustrations B, G et H)

IMPORTANT

The hot water tank must be pressurised before the

heating circuit is filled.

1. Fill the domestic hot water circuit and bring it up to pressure.

2. Fill the heating circuit taking care not to exceed the 2 bar

pressure limit.

3. Vent the air from the top of the boiler.

4. After venting the air from the system, bring the pressure up to

the static head plus 0.5 bar: 1.5 bar = 10m -2 bar = 15 m.

5. Check the power connection, the boiler room ventilation, and

ensure that there are no leaks in the flue gas discharge pipes.

6. Set the boiler thermostat to between 60 and 90 °C.

7. Set the Summer/Winter selector to the desired position.

8. Switch the on/off switch to the ON position.

9. Check the oil supply

(and return).

10. Carry out the required venting, measurement and setting

procedures.

STARTING ACV BMV1 AND BMV2 BURNERS

Refer to the ACV BMV1 and BMV2 burner manual supplied with them.

RECOMMENDATION

ACV advises that boilers should be serviced at least once a year.

The burner must be serviced and tested by a competent engineer.

SERVICING THE BOILER (see illustration K)

1. Switch off the power at the mains switch outside the boiler and

shut off the oil supply.

2. Set the on/off switch on the control panel to the OFF position.

3. Remove the top cover of the boiler (2) and take off the top of the

chimney reduction (3).

5. Remove the turbulators (23) from the flue pipes (22) for cleaning.

Change them if in poor condition.

6. Unscrew the burner chamber plate (10).

7. Brush the flue pipes (22).

8. Clean the burner chamber (18) and the burner.

9. Check the condition of the burner chamber plate insulation.

SERVICING THE SAFETY DEVICES

- Check that all thermostats and safety devices are working

properly : boiler thermostat, cut-off thermostat and manually reset

safety thermostat.

-Test the safety valv es on the central heating and hot w ater circuits .

SERVICING THE BURNER

Refer to the ACV BMV1 and BMV2 burner manual supplied with them.

EMPTYING THE BOILER

Water flowing out of the drain cock is extremely

hot and can cause severe burns.

Keep people away fr om discharges of hot water.

Emptying the heating circuit (see illustration G)

1. Set the on/off switch on the control panel to the OFF position,

turn off the power at the external mains switch and close the oil

feed valve.

2. Close the isolating valves (8).

3. Connect a hose to the drain cock (9).

4. Open the drain cock to empty the primary circuit.

Emptying the hot water circuit (see illustration H)

1. Set the on/off switch on the control panel to the OFF position,

turn off the power at the external mains switch and close the oil

feed valve.

2. Lower the pressure in the heating circuit until the pressure

gauge indicates zero bar.

3. Close the valves (7 and 11).

4. Open valves (9) and (10) (first 9 then 10).

5. Let the water empty into the drain .

For the tank to be emptied, valve (9) must be situated

at ground level.

SERVICINGSTARTUP

Page 17

11

EN

USING THE BOILER

Have your system serviced every year by a qualified

heating engineer. If the boiler is subject to heavy

usage, it may need more frequent servicing. If this is

the case, ask your installer for advice.

Starting the burner:

In normal operation, the burner starts automatically

whenever the boiler temperature falls below the set

temperature.

Before doing any work on the boiler, switch off the

power at the mains switch installed in the boiler room

by the electrician.

On the control panel, switch off the ON/OFF switch.

Getting to know the control panel (see illustration B)

The user should not access the components inside

the control panel.

1. Control thermostat - 60 to 90 °C

When the boiler is used only to produce domestic hot water, the

temperature can be set between 60 and 90 °C. If the boiler is used

for both hot water and heating, the control thermostat will, as a

general rule, be set to 80 °C to ensure optimum operating conditions.

2. ON/OFF switch

Used to start and stop the boiler.

3. Summer/winter selector

Starts and stops the heating pump

(if fitted).

4. Thermometer

Shows the boiler temperature in the primary circuit.

The temperature should not exceed 90 °C.If it does, switch off the

boiler and check the thermostat settings. If there is a fault, call a

heating engineer.

5. Controller

See the user instructions supplied with the unit if you have chosen

this option.

6. Burner reset

7. Burner indicator lamp

Safety valve (heating)

If water flows from one of the safety valves, shut off the boiler and

call your heating engineer.

A monthly inspection is recommended:

Lift the lever on the emptying de vice for a f e w seconds to ensure that

the safety valve is working properly.

If a fault occurs after this short trial, call the installing

engineer.

Safety unit (domestic hot water)

A monthly inspection is recommended.

Lift the lever on the emptying de vice for a f e w seconds to ensure that

the safety unit is working properly.

If a fault occurs after this short trial, call the installing

engineer.

Water flowing out of the safety valve or safety

unit may be extremely hot and can cause very

serious burns.

USER GUIDE

Page 18

12

EN

RESETTING ACV BMV1 AND BMV2 BURNERS

(see illustration Q)

If the burner is not working:

1. Remove the protective cover of the burner.

2. If the red light is lit, press the button to start the burner.

3. If the burner lights, replace the cover.

If the burner does not operate, switch off the power

before removing the front cover panel.

4. Reset the safety thermostat on top of the boiler. (see illustration R).

Wait until the boiler temperature is below 60 °C then

replace the front cover panel.

5. If the burner lights, replace its cover.

6. If the fault persists, notify the installing engineer.

Starting the burner

In normal operation, the burner starts automatically whenever the

boiler temperature falls below the set temperature.

To ensure your system operates properly, have it

professionally serviced once a year before the central

heating season begins.

USER GUIDE

Page 19

13

FR

NOTICE D’INSTALLATION,

D’UTILISATION ET D’ENTRETIEN

FV 35

avec brûleur

fioul ACV BMV(K)1

FV 50

avec brûleur

fioul ACV BMV(K)2

performance

ventouse

Page 20

14

FR

INTRODUCTION 14

Destinataires de cette notice 14

Symboles 14

Normes en usage 14

Avertissements 14

DESCRIPTION 15

Description générale 15

Principe de fonctionnement 15

Caractéristiques constructives 15

Légende de la chaudière 15

CARACTERISTIQUES TECHNIQUES 15

Généralités 16

Conditions extrêmes d’utilisation 16

Dimensions 16

Performances en eau chaude sanitaire 17

Caractéristiques générales 17

INSTALLATION 18

Chaufferie 18

Raccordements cheminée 18

Raccordements chauffage 19

Raccordements sanitaire 19

Kit de régulation 19

Raccordement électrique 20

Alimentation fioul 20

CARACTERISTIQUES BRULEUR 21

Brûleurs fioul ACV BMV1 et BMV2 21

Réglages usine des brûleurs ACV BMV1 et BMV2 21

Légende des brûleurs ACV BMV1 et BMV2 21

MISE EN SERVICE 22

Remplissage des circuits sanitaire et chauffage 22

Mise en service des brûleurs ACV BMV1 et BMV2 22

ENTRETIEN 22

Recommendation 22

Entretien de la chaudière 22

Entretien des dispositifs de sécurité 22

Entretien du brûleur 22

Vidange de la chaudière 22

GUIDE DE L’UTILISATEUR 23

Utilisation de la chaudière 23

Mise en sécurité des brûleurs ACV BMV1 et BMV2 24

DESTINATAIRES DE CETTE NOTICE

Cette notice s’adresse:

- à l’ingénieur chargé de la prescription

- à l’installateur

- à l’utilisateur

- aux techniciens en charge de l’entretien

SYMBOLES

Les symboles suivants sont utilisés dans cette notice:

Instruction essentielle pour un fonctionnement

correct de l’installation.

Instruction essentielle pour la sécurité des

personnes et de l’environnement.

Danger d’électrocution.

Danger de brûlure.

NORMES EN USAGE

Les produits ont reçu le certificat “CE” selon les normes en vigueur

dans différents pays (Directive Européenne 92/42/CEE “rendement”).

Ces produits ont également reçu le label belge “OPTIMAZ”.

AVERTISSEMENTS

Cette notice fait partie intégrante de l’équipement auquel elle se

rapporte et doit être remise à l’utilisateur.

L’installation et l’entretien du produit seront exécutés par des

techniciens qualifiés, en conformité avec les normes en vigueur.

ACV décline toute responsabilité pour tous dégats consécutifs à une

erreur d’installation et en cas d’utilisation d’appareils ou accessoires

qui ne sont pas spécifiés par ACV.

Le manque d’observation des instructions relatives

aux opérations et procédures de contrôle peut

entraîner des blessures aux personnes ou des risques

de pollution.

Note:

ACV se réserve le droit de modifier les caractéristiques techniques

et les équipements de ses produits sans notification préalable.

INDEX INTRODUCTION

Page 21

15

FR

DESCRIPTION GENERALE

• Chaudière à double service (chauffage et eau chaude sanitaire).

•Production d’eau chaude sanitaire de type accumulation indirecte

TANK-IN-TANK.

• Equipement nécessaire: un kit de raccordement hydraulique pour

l’alimentation du circuit de chauffage (disponible en option).

• Le tableau de commande comporte un interrupteur général, un

thermostat de réglage, un thermomètre, un commutateur

Eté/Hiver et une prédécoupe pour le système de régulation

intégré - ACV

(en option).

• Le modèle Delta Performance FV, peut être raccordé en ventouse

avec une connections cheminée concentrique de type C…, ou

avec une connections cheminée de type B23 directement à la

cheminée.

• Le modèle Delta Performance FV 35 avec une puissance utile fixe

de 35 est équipé du brûleur fioul ACV BMV1.

• Le modèle Delta Performance FV 50 avec une puissance utile fixe

de 50 est équipé du brûleur fioul ACV BMV2.

PRINCIPE DE FONCTIONNEMENT

Le concept “Tank-inTank”

La série Delta Performance ventouse se distingue des producteurs

d’eau chaude traditionnels par son ballon annulaire immergé dans le

fluide primaire contenu dans le corps externe. Lorsqu’il y a une

demande de chaleur du système de chauffage ou du circuit d’eau

chaude sanitaire, le potentiomètre enclenche le brûleur. Les gaz de

combustion réchauffent rapidement le fluide primaire, tout en créant

une circulation naturelle autour du ballon.

Chauffage indirect de l’eau sanitaire

Cette circulation favorise l’échange de chaleur entre le fluide primaire

et l’eau sanitaire, qui s’opère à travers toute la surface du ballon. Les

ondulations sur les viroles intérieure et extérieure du ballon annulaire

augmentent encore la surface d’échange de chaleur et accélèrent le

réchauffement de l’eau sanitaire.

Réglage aisé et sécurité assurée

Une seule commande permet de régler la température de l’eau, tant

du circuit primaire que du circuit sanitaire, grâce au thermostat de

réglage situé sous le ballon dans le circuit primaire.

Un thermostat limite, placé en partie supérieure de la chaudière,

coupe automatiquement le brûleur lorsque la température de l’eau

du circuit primaire atteint 95 °C. Un thermostat de sécurité à

réarmement manuel verrouille le brûleur si la température atteint

103 °C.

CARACTERISTIQUES CONSTRUCTIVES

Corps externe

Le corps externe contenant le fluide primaire est réalisé en acier

STW 22 de forte épaisseur.

Echangeur accumulateur de type “Tank-inTank”

Le ballon interne de type annulaire à grande surface de chauffe pour

la production d’eau chaude sanitaire est construit en acier inoxydable

Chrome/Nickel 18/10.Il est ondulé sur toute sa hauteur par un procédé

de fabrication exclusif et est entièrement soudé à l’argon suivant le

procédé TIG (Tungsten Iner t Gas).

Circuit des gaz de combustion

Le circuit des gaz de combustion est protégé par une peinture

résistante à haute température. Celui-ci comprend:

•Tubes de fumée Les différents modèles Delta Performance

ventouse comportent, 8 tubes de fumée en acier d’un diamètre

intérieur de 64 mm. Chacun des tubes est équipé d’un turbulateur

en acier spécial destiné à améliorer l’échange thermique et à

réduire la température des fumées.

• La chambre de combustion étanche est refroidie par eau.

Isolation

Le corps de la chaudière est entièrement isolé par de la mousse de

polyuréthane rigide à haut coefficient d’isolation thermique, projetée

sans CFC.

Jaquette

La chaudière est revêtue d’une jaquette en acier ayant subi un

dégraissage et une phosphatation avant la peinture cuite au four à

220 °C.

LEGENDE DE LA CHAUDIERE (voir illustration K)

1. Tableau de commande

2. Couvercle de la jaquette démontable

(Accès aux turbulateurs)

3. Réduction cheminée

4. Elément de mesure avec récupérateur des condensats

5. Isolation en mousse de polyuréthane sans CFC

6. Ballon interne annulaire contenant l’eau chaude sanitaire

7. Jaquette latéral

8. Socle

9. Coiffe du brûleur

10. Porte foyère

11. Bulbe du thermostat de réglage

12. Face avant démontable

13. Flexible d’amnée d’air au venturi

14. Thermostat de sécurité 103 °C à réarmement manuel

15. Bulbe du thermostat limite 95 °C

16. Adaptateur ventouse

17. Retour chauffage

18. Arrivée eau froide sanitaire

19. Ballon interne annulaire contenant l’eau chaude sanitaire

20. Chambre de combustion

21. Vidange de la chaudière

22. Retour chauffage

23. Tubes de fumée

24. Turbulateurs

25. Sortie eau chaude sanitaire

26. Départ chauffage

DESCRIPTION

Page 22

16

GENERALITES

Les appareils livrés arrivent complètement assemblés, testés et emballés sur un support en bois avec des bords anti-choc et protégés par un film

en plastique thermorétractable.Au moment de la réception et après avoir retiré l’emballage, contrôler que les appareils ne sont pas endommagés.

Pour le transport, vous référer aux dimensions et poids ci-dessous:

CONDITIONS EXTREMES D’UTILISATION

Pression de service maximum (ballon rempli d’eau)

- Circuit primaire: 3 bar

- Circuit secondaire: 10 bar

Pression d’épreuve

(ballon rempli d’eau)

- Circuit primaire: 4.5 bar

- Circuit secondaire: 13 bar

Température d’utilisation

- Température maximum: 90 °C

Qualité de l’eau

• Chlorures: < 150 mg/l (inox 304)

< 2000 mg/l (Duplex)

• 6 ≤ ph ≤ 8

DIMENSIONS

CARACTERISTIQUES TECHNIQUES

FR

FV/35 FV/50

A mm 1585 1830

B mm 390 390

C mm 200 200

D mm 542 542

E mm 125 125

F mm 645 645

G mm 80 / 80 / 125 100 / 100 / 125

H mm 1610 1880

I mm 800 800

Poids à vide Kg 182 220

F

G

I

H

B

C

D

A

E

Page 23

17

CARACTERISTIQUES TECHNIQUES

FR

CARACTERISTIQUES GENERALES

PERFORMANCE EAU CHAUDE SANITAIRE

FV/35 FV/50

Régime de fonctionnement à 80 °C

Débit de pointe à 40 °C (≤ T = 30 °C) L/10’ 291 377

Débit de pointe à 40 °C (≤ T = 30 °C) L/60’ 1044 1485

Débit continu à 40 °C (≤ T = 30 °C) L/h 920 1352

Durée de recharge du ballon à 60 °C

Mise en régime minutes 20 13

Après puisage de 140 L à 45 °C minutes 10 8

FV/35 FV/50

Débit calorifique (input) L/10’ 34.9 50

Puissance nominale utile (output) L/60’ 32.62 46.75

Perte d’entretien à 60 °C de la valeur nominale % 0.8 / 0.7 0.6 / 0.45

Capacité totale L 127 162

Capacité du circuit primaire L 62 82

Raccordement chauffage Ø 1” 1”

Raccordement eau chaude sanitaire Ø 3/4” 3/4”

Surface d’échange du ballon sanitaire m

2

1.99 2.46

Rendement de combustion % 94.7 93.5

CO2 moyenne % 13 13

Débit massique des produits de combustion g/sec. 14.8 21.2

Page 24

18

CHAUFFERIE

Important

• Ne jamais obstruer les ventilations.

• Ne pas entreposer des produits inflammables dans la chaufferie.

•Veiller à ne pas entreposer des produits corrosifs à proximité de la

chaudière, tels que peinture, solvants, chlore , sel, sa von et autres

produits de nettoyage.

Accessibilité

Le local de chauffe sera suffisamment dimensionné pour permettre

une bonne accessibilité à la chaudière. Il convient de respecter les

distances minimales suivantes autour de la chaudière (mm):

- à l’avant 500

- à l’arrière 150

- latéral 100

- au-dessus 700

Ventilation

La chaufferie doit être équipée d’une ventilation basse et d’une

ventilation haute selon l’illustration “L”

Le tableau ci-dessous est un exemple conforme au standard

Belge.

Note:

(B) et (C) uniquement pour les raccordements de type B23

Les autres pays peuvent se référer à leur réglementation.

Socle

Le socle sur lequel sera posée la chaudière doit être construit dans

des matériaux incombustibles.

RACCORDEMENTS CHEMINEE

IMPORTANT

L’installation sera réalisée par un installateur agréé,

en conformité avec les normes et codes locaux en

vigueur.

Le diamètre de la cheminée ne doit pas être inférieur

à celle de la chaudière

Raccordement cheminée de type: B23 (voir illustration L)

Le raccordement à la cheminée se fera au moyen d’un conduit

métallique placé en pente ascendente de la chaudière vers la

cheminée.

Un raccord de cheminée est nécessaire.

A. Ventilation haute

B. Ventilation basse

C. Régulateur de tirage

D. Regard de visite

E. Hauteur de la cheminée tubée

F. Diamètre de la cheminée

Remarque:

Etant donné que les réglementations varient d’un

pays à l’autre, le tableau ci-dessus est donné à titre

indicatif uniquement.

Le rendement élevé de nos chaudières implique que

les fumées sortent à basse température.

Par conséquent, un risque de condensation de ces

fumées existe, qui peut entraîner des dégâts dans

certaines cheminées. Afin d’éviter ce risque, il est

vivement conseillé de faire tuber le conduit de

cheminée.

Veuillez contacter votre installateur pour de plus

amples renseignements à ce sujet.

Raccordement cheminée de type: C…

(voir illustrations M et N)

• C 13 : raccordement horizontal concentrique

• C 33 : raccordement vertical concentrique

• C 43 : raccordement à la cheminée concentrique

Longeur maximal concentrique : 6 metres

Note:

Un coude de 90° = à une longeur équivalent d’un metre

Une sortie à l’égout doit être à proximité de la

chaudière afin d’éviter que les condensats de la

cheminée n’entre dans la chaudière.

Pour éviter que l’eau de condensation ne s’écoule du

terminal, tous les passages de conduits horizontaux

doivents descendre vers la chaudière.

INSTALLATION

FR

FV/35 FV/50

Ventilation

Apport d’air frais min. m3/h 63 90

Ventilation haute (A) dm

2

1.5 1.5

Ventilation basse (B) dm

2

1.5 2

Régulateur de tirage (C) Ø 80 100

FV/35 FV/50

Cheminée

E = 5 m Ø min. F mm 213 236

E = 10 m Ø min. F mm 179 199

E = 15 m Ø min. F mm 162 179

Page 25

19

RACCORDEMENT CHAUFFAGE

Exemple de raccordement simple circuit

(voir illustration G)

1. Vanne mélangeuse à 3 voies motorisée

2. Soupape de sécurité tarée à 3 bar avec manomètre

3. Circulateur

4. Clapet anti-retour

5. Vanne de remplissage de l’installation

6. Vase d’expansion

7. Régulation ACV 13

(voir kit de régulation page 19)

8. Vanne d’isolement chauffage

9. Vidange

Kit hydraulique + Kit chauffage sol ACV (voir illustration F)

ACV offre en option un kit hydraulique pré-assemblé comprenant:

- Un circulateur.

- Une vanne 3 voies manuelle motorisable.

- Les tuyauteries de raccordement incluant un deuxième circuit

possible.

- Deux vannes d’isolement.

- Les raccords pour montage à droite ou à gauche du vase

d’expansion, de la soupape de sécurité avec manomètre et de la

vanne de remplissage.Le vase d’expansion n’est pas inclus.

RACCORDEMENT SANITAIRE

Réducteur de pression

Si la pression de l’eau de distribution est supérieure à 6 bar, il faut

prévoir un réducteur de pression taré à 4,5 bar.

Groupe de sécurité

Le groupe de sécurité du ballon sera agréé par ACV et taré à 7 bar.

Prévoir le raccordement de la décharge de la soupape à l’égoût.

Vase d’expansion sanitaire

L’installation d’un vase d’expansion sanitaire permet d’éviter tout

risque de surpression due aux coups de bélier, ou aux variations de

pression.

Circulation d’eau chaude

En cas de grande distance entre le ballon et le point d’utilisation,

l’installation d’un circuit fermé de recirculation peut assurer en

permanence un puisage d’eau chaude plus rapide.

Exemple de raccordement avec vanne thermostatique

(voir illustration H)

1. Groupe de sécurité

2. Réducteur de pression

3. Mitigeur thermostatique

4. Circulateur sanitaire

5. Clapet anti-retour

6. Vase d’expansion de type sanitaire

7. Robinet d’alimentation d’eau froide

8. Robinet de puisage

9. Robinet de vidange

10. Robinet de purge

11. Vanne d’isolment

IMPORTANT

Par mesure de sécurité pour éviter les brûlures,

l’installation d’un mitigeur thermostatique est

vivement conseillée

Accessoires disponibles en option

KITS DE REGULATION

KIT 1: ACV 13.00 / Basic (voir illustration C)

Kit de base pour la régulation de la température de départ en

fonction des conditions atmosphériques.

Il comprend: régulateur de température avec horloge analogique,

sonde d’applique de température de l’eau (-30/130°C), sonde

extérieure (-30/50°C), servomoteur SSY 319 - 230 V - 3 broches et

un socle intermédiaire.

KIT 2: ACV 13.00 / Standard (voir illustration D)

Kit standard pour la régulation de la température de départ en fonction

des conditions atmosphériques.

Il comprend: régulateur de température avec horloge analogique,

sonde d’applique de température de l’eau (-30/130°C), sonde

extérieure (-30/50°C), servomoteur SQK 349 - 230 V - 3 broches et

un socle intermédiaire.

Schéma électrique des kits de régulation ACV

(voir illustration E)

B2. Sonde de température

B9. Sonde extérieure

B5. Sonde d’ambiance analogique/digital

P1. Pompe chauffage

Y1/Y2/N. Vanne mélangeuse (SSY 319 ou SQK 349)

bl. Bleu N

n/z. Noir Y2

br. Brun Y1

INSTALLATION

FR

Groupe de sécurité Ø 3/4”

Réducteur de pression Ø 3/4“

Mitigeur thermostatique Ø 3/4”

Vase d’expansion 5 litres

Page 26

Hauteur H Ø 6 mm Ø 6 mm Ø 8 mm

4.0 m 100 m 100 m 100 m

3.5 m 100 m 100 m 100 m

3.0 m 100 m 197 m 100 m

2.5 m 100 m 181 m 100 m

2.0 m 100 m 165 m 100 m

1.5 m 197 m 149 m 177 m

1.0 m 165 m 132 m 151 m

0.5 m 132 m 116 m 126 m

Gicleur jusqu’à 2.5 Kg jusqu’à 5.0 Kg jusqu’à 10.0 Kg

Hauteur H Ø 6 mm Ø 8 mm Ø 10 mm

0.0 m 17 m 53 m 100 m

0.5 m 15 m 47 m 100 m

1.0 m 13 m 41 m 199 m

1.5 m 11 m 34 m 184 m

2.0 m 19 m 28 m 168 m

2.5 m 17 m 22 m 153 m

3.0 m 15 m 15 m 137 m

3.5 m 13 m 19 m 122 m

20

RACCORDEMENT ELECTRIQUE

Principe d’alimentation

La chaudière fonctionne en monophasé 230 V - 50 Hz.

A l’extérieur de la chaudière, il faut prévoir un coffret a vec interrupteur

général et fusibles de 6 A pour permettre la coupure de l’alimentation

électrique lors des entretiens et avant toute intervention sur la

chaudière.

Conformité

L’installation sera réalisée en conformité avec les normes

techniques et la législation locale en vigueur.

Sécurité

Le ballon en inox doit être raccordé séparément à la terre.

Il est important de couper l’alimentaion électrique de

la chaudière avant toute intervention.

Cablage électrique de la chaudière (voir illustration A)

1. Thermostat de réglage (60/90 °C)

2. Interrupteur général

3. Interrupteur Eté/Hiver

4. Thermostat de sécurité (103 °C max.)

5. Alimentation chaudière

6. Raccordement du circulateur chauffage

7. Raccordement brûleur

8. Thermostat d’ambiance

(en option)

9. Thermostat de limit (95 °C)

10. Raccordement d’alimentation chaudière (prise 6 broches)

B. Bleu

Br. Marron

Gr. Vert

Or. Orange

R. Rouge

Y/Gr. Jaune / Vert

Cablage électrique des brûleurs fioul BMV1 et BMV2

(voir illustration P)

Le brûleur est alimenté électriquement par un câble à 3 conducteurs,

à raccorder au connecteur situé sur le brûleur. Les indications de

raccordement figurent dans la notice technique du brûleur.

A1. Dispositif d’allumage automatique

M. Moteur du brûleur

QRB. Résistance photo-électrique

OH. Réchauffeur

Z. Transformateur

BV1. Soupape magnétique

X1. Prise Euro du brûleur

X2. Prise chaudière

B. Bleu

Br. Marron

Bk. Noir

W. Blanc

Y/Gr. Jaune / Vert

ALIMENTATION FIOUL

La construction est l’installation du système doivent être réalisées

conformément aux normes DIN 4755. Respecter les prescr iptions

locales.

La conduites de fioul doit être amenée suffisamment près du brûleur

pour que les flexibles puissent être raccordés sans contraintes.

Dans la conduite, côté aspiration, monter un filtre à fioul muni d’un

robinet à fermeture rapide.Installer une soupape de retenue dans la

canalisation de retour.

Le Brûleur peut fonctionner avec le système à 1 ou à 2 conduites.

En série, le brûleur est prévu pour fonctionner avec un système à

deux conduites.Le vide dans la conduite d’aspiration ne doit dépasser 0,4 bar.

Pour de plus amples informations spécifiques aux

brûleurs, vous référer à la notice des brûleurs ACV

BMV1 et BMV2 jointe à ceux-ci.

Installation à deux conduites (voir illustration J)

INSTALLATION

FR

Installation à une conduite (voir illustration I)

Page 27

21

CARACTERISTIQUES BRULEUR

FR

BRULEURS FIOUL ACV BMV1 ET BMV2

Description

Pour équiper le modèle Delta Performance fioul ventouse, nous

avons opté pour la toute nouvelle technologie du brûleur fioul ACV

BMV1 et BMV2, fabriqué à partir de composnants de première

qualité, combinant performance et parfaite combustion.

Diagramme de CO2 du brûleur ACV BMV1 et BMV2

REGLAGES USINE DES BRULEURS

ACV BMV1 ET BMV2

FV/35 FV/50

Brûleur BMV1 BMV2

Puissance kW 34.9 50

Gicleur gal/h 0,75 1,25

Angle du gicleur 60°H 60°H

Débit fioul Kg/h 2.95 4.22

Pression pompe bar 11.8 9.5

Indice de fumées 0 - 0.5 0 - 0.5

Réducteur d’air % 37 60

Entrée d’air % 90 90

Pression ligne gicleur mbar 3.5 - 4 3.5 - 4

Ligne gicleur mm 10 10

Poids Kg 14.5 14.5

Température extérieure

LEGENDE DES BRULEURS ACV BMV1 ET BMV2

(voir illustration O)

1. Boîtier de contrôle

(relais)

2. Protection ligne gicleur

3. Lampe témoin

4. Fiche de raccordement électrique 7 broches

5. Bride de fixation sur la porte

6. Tube de flamme

7. Unit d’allumage

8. Cable d’allumage haute tension

9. Pompe fioul

10. Raccordement d’aspiration fioul

11. Raccordement de retour fioul

(uniquement circuit avec retour)

12. Condensateur du moteur

13. Moteur

14. Tube de liaison pompe/gicleur

15. Carter du brûleur

16. Vis de réglage de la ligne gicleur

ATTENTION : Régler le % de CO

2 suivant les données reprisent dans le diagramme ci-dessus.

14 %

13,5 %

13 %

% CO2

12,5 %

12 %

-10 0 10 203040

Page 28

REMPLISSAGE DES CIRCUITS SANITAIRE

ET CHAUFFAGE (voir illustrations B, G et H)

IMPORTANT

Il est essentiel que le ballon sanitaire soit sous

pression avant de remplir le circuit de chauffage.

1. Remplir le circuit sanitaire et le mettre sous pression.

2. Remplir le circuit chauffage en veillant à ne pas dépasser la

pression de 2 bar.

3. Purger l’air contenu en partie supér ieure de la chaudière.

4. Après purge d’air de l’installation, ramener la pression à la

pression statique

(hauteur) augmentée de 0,5 bar: 1,5 bar = 10

- 2 bar = 15 m.

5. Vérifier le raccordement électrique, la ventilation du local de

chauffe et l’étanchéité des conduits d’évacuation des gaz de

combustion.

6. Régler le thermostat chaudière entre 60 et 90 °C.

7. Positionner l’interrupteur Eté/Hiver sur la sélection désirée.

8. Mettre l’interrupteur général sur position ON.

9. Vérifier l’alimentation

(et le retour) fioul.

10. Effectuer les purges, mesures et réglages nécessaires.

MISE EN SERVICE DES BRULEURS

ACV BMV1 ET BMV2

Référez-vous à la notice des brûleurs ACV BMV1 et BMV 2 jointe à

ceux-ci.

RECOMMANDATION

ACV conseille d’assurer l’entretien des chaudières au minimum une

fois l’an. Cet entretien ainsi que le contrôle du brûleur seront effectués

par un technicien compétent.

ENTRETIEN DE LA CHAUDIERE (voir illustration K)

1. Couper le courant d’alimentation avec l’interrupteur du coffret à

l’extérieur de la chaudière et fermer l’alimentation fioul.

2. Mettre l’interrupteur général sur le tableau de commande en

position OFF.

3. Déboîter la jaquette supérieur de la chaudière (2) et démonter

la partie supérieur de la réduction cheminée (3).

5. Extraire les turbulateurs (24) des tubes de fumées (23) pour

nettoyage.Les remplacer en cas d’usure.

6. Démonter la por te foyère (10).

7. Brosser les tubes de fumées (23).

8. Nettoyer le foyer (18) et le brûleur.

9. Vérifier l’état de l’isolation de la por te foyère.

ENTRETIEN DES DISPOSITIFS DE SECURITE

- Vérifier le bon fonctionnement de tous les thermostats et dispositifs

de sécurité: thermostat chaudière, thermostat limite et thermostat

de sécurité à réarmement manuel.

- Contrôler les soupapes de sécurité du circuit chauffage et du

circuit sanitaire.

ENTRETIEN DU BRULEUR

Référez-vous à la notice des brûleurs ACV BMV1 et BMV 2 jointe à

ceux-ci.

VIDANGE DE LA CHAUDIERE

L’eau s’écoulant du robinet de vidange est très

chaude et peut causer de très graves brûlures.

Eviter la présence de toute personne à

proximité des écoulements d’eau chaude.

Vidange du circuit chauffage (voir illustration G)

1. Mettre l’interrupteur général sur le tableau de commande en

position OFF, couper l’alimentation électrique extérieure et

fermer la vanne d’alimentation du fioul.

2. Fermer les robinets d’isolement (8).

3. Connecter un tuyau souple au robinet de vidange (9).

4. Ouvrir le robinet de vidange pour vider le circuit primaire.

Vidange du circuit sanitaire (voir illustration H)

1. Mettre l’interrupeur général sur le tableau de commande en

position OFF, couper l’alimentation électrique extérieure et

fermer la vanne d’alimentation du fioul.

2. Diminuer la pression du circuit chauffage jusqu’à ce que le

manomètre indique zéro bar.

3. Fermer les robinets (7 et 11).

4. ouvrir les robinets (9 et 10) (d’abord 9 puis 10).

5. Laisser la vidange s’écouler vers l’égout.

Pour que la vidange puisse s’effectuer, le robinet (9)

doit être situé au niveau du sol.

ENTRETIEN

22

MISE EN SERVICE

FR

Page 29

UTILISATION DE LA CHAUDIERE

Veuillez faire entretenir votre système chaque année

par un technicien professionnel. Si la chaudière est

confrontée à une forte utilisation, celle-ci peut

nécessiter de plusieurs entretiens par an. Dans ce

cas, demandez conseil à votre installateur.

Démarrage du brûleur:

En fonctionnement normal, le démarrage du brûleur

est automatique dans la mesure où la tempèrature de

la chaudière est inférieur à la consigne.

Avant toute intervention sur la chaudière couper son

alimentation électrique au tableau général installé

dans la chaufferie par l’électricien.

Sur le tableau de commande, couper l’interrupteur

général.

Se familliariser avec le tableau de commande

(voir illustration B)

L’utilisateur n’a pas à accéder aux composants interne

du tableau de commande.

1. Thermostat de réglage - 60 à 90 °C

Lorsque le chaudière est utilisé uniquement comme producteur

d’eau chaude, la température peut être réglée entre 60 et 90 °C.

Si la chaudière est utilisé pour une production d’eau chaude et de

chauffage, le thermostat de réglage sera généralement réglé sur

80 °C afin de garantir des conditions optimales de fonctionnement.

2. Interrupteur général

Cet interrupteur permet de démarrer et d’arrêter la chaudière

3. Interrupteur Eté/Hiver

Il permet d’actionner et d’arrêter la pompe de circulation chauffage

(si celle-ci est installée).

4. Thermomètre

Cette jauge affiche la tempèrature de la chaudière au sein du circuit

primaire. La temperature ne devrait pas dépasser 90 °C.Si elle est

supérieur, il convient d’arrêter la chaudière et de faire contrôler les

réglages du thermostat. Si la panne persiste, appeler un technicien.

5. Régulation

Se référer à la notice d’utilisation jointe à l’appareil, si vous avez

choisi cette option.

6. Réarmement du brûleur

7. Lampe témoin du brûleur

Soupapes de sécurité (chauffage)

Si l’eau s’écoule de l’une des vannes de sécurité, arrêter la

chaudière et appeler votre technicien.

Un contrôle mensuel est recommandé: Lever pendant quelques

secondes le levier du dispositif de vidange pour s’assurer du bon

fonctionnement de la soupape de sécurité.

En cas d’anomalie après ce court essai, prévenir

l’installateur.

Groupe de sécurité (sanitaire)

Un contrôle mensuel est recommandé: Lever pendant quelques

secondes le levier du dispositif de vidange pour s’assurer du bon

fonctionnement du groupe de sécurité.

En cas d’anomalie après ce court essai, prévenir

l’installateur.

L’eau pouvant s’écouler de la soupape de

sécurité ou du groupe de sécurité peut être

extrêmement chaude et causer de très graves

brûlures.

23

GUIDE DE L’UTILISATEUR

FR

Page 30

24

MISE EN SECURITE DES BRULEURS

ACV BMV1 ET BMV2

(voir illustration Q)

Si le brûleur est inopérant:

1. Retirer la coiffe de protection du brûleur.

2. Si le voyant rouge est allumé, appuyer sur le bouton pour faire

démarrer le brûleur.

3. Si le brûleur fonctionne, remettre la coiffe.

Si le brûleur ne fonctionne pas, couper l’alimentation

électrique avant de retirer la face avant de la jaquette.

4. Réarmer le thermostat de sécurité sur le dessus de la chaudière.

(voir illustration R).

Attendre que la température de la chaudière soit

inférieure à 60 °C. Puis remettre la face avant de la

jaquette.

5. Si le brûleur fonctionne remonter sa coiffe.

6. En cas d’anomalie persistante, prévenir l’installateur.

Démarrage du brûleur.

En fonctionnement normal, le démarrage du brûleur est automatique

dans la mesure où la température de la chaudière est inférieure à la

température de consigne.

Pour assurer un bon fonctionnement de votre

système, veuillez le faire entretenir annuellement par

un professionnel, avant la saison de chauffe.

GUIDE DE L’UTILISATEUR

FR

Page 31

25

NL

HANDLEIDING VOOR DE INSTALLATIE,

HET GEBRUIK EN HET ONDERHOUD

FV 35

met stookoliebrander

ACV BMV(K)1

FV 50

met stookoliebrander

ACV BMV(K)2

performance

met muur- of

dakdoorvoer

Page 32

26

NL

INLEIDING 26

Geaddresseerden 26

Symbolen 26

Toepasselijke normen 26

Waarschuwingen 14

BESCHRIJVING 27

Algemene beschrijiving 27

Werkingsprincipe 27

Constructiekenmerken 27

Legende van de ketel 27

TECHNISCHE KENMERKEN 28

Algemeenheden 28

Extreme gebruiksvoorwaarden 28

Afmetingen 28

Sanitair warm waterprestaties 29

Algemen kenmerken 29

INSTALLATIE 30

Stookruimt 30

Schouwaannsluitingen 30

CV-aansluiting 31

Sanitair aansluiting 31

Regulatiekits 31

elektrische aansluiting 32

Toevoer stookolie 32

BRANDERKENMERKEN 33

ACV-stookoliebranders BMV1 en BMV2 33

Fabrieksinstelling van de ACV-branders BMV1 en BMV2 33

Legende van de ACV-branders BMV1 en BMV2 33

INDIENSTSTEILING 34

Vulling van de sanitair kring en de CV kring 34

Indieststelling van de ACV-branders BMV1 en BMV2 34

ONDERHOUD 34

Aanbeveling 34

Onderhoud van de ketel 34

Onderhoud van de veiligheidselementen 34

Onderhoud van de brander 34

Leegloop van de ketel 34

GEBUIKERSGIDS 35

Gebruik van de ketel 35

Beveiling van de ACV-branders BMV1 en BMV2 36

GEADRESSEERDEN

Deze brochure richt zich tot:

- de zaakgelastigde van het lastenboek

- de installateur

- de gebruiker

- de techniekers belast met het onderhoud

SYMBOLEN

In deze brochure vindt u de volgende symbolen terug:

Essentiële instructie voor een correcte werking

van de installatie.

Essentiële instructie voor de veiligheid van de

personen en het leefmilieu.

Gevaar van elektrocutie.

Verbrandingsgevaar

TOEPASSELIJKE NORMEN

De toestellen werden “CE” gekeurd overeenkomstig de geldende

normen in de verschillende landen (Europese Richtlijnen

92/42/EEG “rendement”). Deze toestellen hebben eveneens het

Belgisch labels “Optimaz” ontvangen.

WAARSCHUWINGEN

Deze brochure maakt integraal deel uit van het toestel en moet aan

de gebruiker overhandigd worden.

De installatie en het onderhoud van het toestel dienen uitgevoerd te

worden door bevoegde techniekers, overeenkomstig de geldende

normen.

ACV wijst elke ver antwoordelijkheid af voor schade veroorzaakt door

een foutieve installatie en bij gebruik van niet door ACV gekeurde

toestellen of accessoires.

Het veronachtzamen van de instructies betreffende

de werking en de controleprocedures kan aanleiding

geven tot verwondingen van personen of tot

milieuverontreiniging.

Nota:

ACV behoudt zich het recht voor de technische kenmerken en

de uitrusting van haar toestellen zonder voorafgaand bericht te

wijzigen.

INDEX INLEIDING

Page 33

27

NL

ALGEMENE BESCHRIJVING

• Combi-ketel (centrale verwarming en sanitair warm waterproductie).

•Indirect gestookte “TANK-IN-TANK”sanitaire warm water productie

van het accumulatietype.

• Noodzakelijke uitrusting: een hydraulische aansluitkit voor de

voeding van de cv-kring

(in optie beschikbaar).

• Het bedieningspaneel bevat een hoofdschakelaar, een

regelthermostaat, een thermometer, een zomer/winter schakelaar

en een geponste ruimte voor het aanbrengen van een ingebouwd

regulatiesysteem ACV

(in optie).

•Het model DEL TA Performance FV kan op de schouw aangesloten

worden met concentrische schouwaansluitingen van het type C...

of met een schouwaansluiting van het type B23 rechtstreeks op

de schoorsteen.

• Het model DEL TA Performance FB 35 met een nuttig vast v ermogen

van 35 kW is uitgerust met een stookoliebrander ACV BMV1.

• Het model DELT A FV 50 met een n uttig v ast vermogen van 50 kW

is uitgerust met een stookoliebrander ACV BMV2.

WERKINGSPRINCIPE

Het "Tank-in-Tank" concept

De serie DELTA Performance met muur- of dakdoorvoer

onderscheidt zich van de traditionele warm waterbereiders door zijn

ringvormige boiler die ondergedompeld is in de primaire vloeistof

van het buitenlichaam.Als er vraag is naar sanitair warm water door

de cv- of sanitaire kring, wordt de brander door de potentiometer

gestuurd. De verbrandingsgassen warmen de primaire vloeistof

zeer snel op, terwijl rond de boiler een natuurlijke circulatie

gecreëerd wordt .

Indirect gestookt sanitair water

Deze circulatie begunstigt de warmtewisseling tussen de primaire

vloeistof en het sanitair water over het totale boileroppervlak.

De inkepingen van de binnen- en buitenwanden van de ringvormige

boiler bevorderen deze warmtewisseling en versnellen de

opwarming van het sanitair water.

Eenvoudige afstelling en verzekerde veiligheid

De watertemperatuur van de primaire en sanitaire kring kan door

middel van één enkele sturing geregeld worden dankzij de regelbare

ketelthermostaat die zich onderaan de boiler in de primaire kring

bevindt.

Een limietthermostaat bovenaan de ketel doet de brander

automatisch stoppen wanneer de watertemperatuur van de primaire

vloeistof 95° C bereikt. Een handbediende herinschakelbare

veiligheidsthermostaat vergrendelt de brander wanneer de

temperatuur 103° C bereikt.

CONSTRUCTIEKENMERKEN

Buitenlichaam

Het buitenlichaam met de primaire vloeistof is vervaardigd uit dik

staal STW 22.

Accumulator warmtewisselaar type "Tank-in-Tank"

De ringvormige binnenboiler met groot warmteoppervlak voor de

productie van sanitair warm water is vervaardigd uit roestvrij

chroom-nikkelstaal 18/10. Hij is voorzien van inkepingen over zijn

totale hoogte - een exclusief fabricatieprocédé - en is integraal

gelast met argon volgens het TIGprocédé (Tungsten Inert Gas).

Omloop van de verbrandingsgassen

De omloop van de verbrandingsgassen is beschermd door een

vuurvaste verflaag en is samengesteld uit:

• De verschillende modellen DELTA Performance met muur- of

dakdoorvoer hebben elk 8 stalen rookgaskanalen, met een

binnendiameter van 64 mm. Elk kanaal is uitgerust met een

retarder uit speciaal staal om de thermische uitwisseling te

verbeteren en de rookgastemperatuur te reduceren.

•De luchtdichte verbrandingskamer wordt met water gekoeld.

Isolatie

Het ketellichaam is volledig geïsoleerd met een dikke laag

CFK-vrij gespoten pur-schuim, met een hoogwaardige thermisch

isolatiecoëfficiënt.

Ommanteling

De ketel wordt bekleed met een stalen ommanteling die vooraleer

in de oven op 220° gelakt te worden, een ontvettings- en

fosfatatiebehandeling onderging.

LEGENDE VAN DE KETEL (zie afbeelding K)

1. Bedieningspaneel

2. Deksel van de ketel mantel demonteerbaar.

(Toegang tot de retarders)

3. Schouwreductiestuk

4. Meetelement met condensopvang

5. Isolatie in CFK-vrij PUR-schuim

6. Interne ringvormige boiler met sanitair warm water

7. Zijmantel

8. Sokkel

9. Branderkap

10. Vuurhaarddeur

11. Regelthermostaat voeler

12. Demonteerbare voorzijde

13. Luchttoevoer soepele leiding naar venturi

14. Veiligheidsthermostaat 103 °C met manuele herinschakeling

15. Limietthermostaat 95 °C voeler

16. Concentrisch adapter

17. Ter ugloop centrale verwarnming (cv)

18. Toevoer van sanitair koud water

19. Interne ringvormige boiler met sanitair warm water

20. Verbrandingskamer

21. Leegloop van de ketel

23. Vertrek centrale verwarnming (cv)

23. Rookgaskanalen

24. Retarders

25. Vertrek van sanitair warm water

26. Vertrek centrale verwarnming (cv)

BESCHRIJVING

Page 34

28

NL

ALGEMEENHEDEN

De geleverde toestellen zijn volledig geassembleerd, getest en verpakt op een houten console met schokwerende boorden en beschermd met

krimpfolie. Nadat u het toestel in ontvangst genomen en uitgepakt heeft, moet u controleren of het toestel geen schade geleden heeft.Voor het

transport, verwijzen wij naar de hieronder vermelde afmetingen en gewichten.

EXTREME GEBRUIKSVOORWAARDEN

Maximale werkingsdruk (boiler gevuld met water)

• Primaire kring : 3 bar

• Secundaire kring : 10 bar

Proefdruk

(boiler gevuld met water)

• Primaire kring : 4,5 bar

• Secundaire kring : 13 bar

Gebruikstemperatuur

• Maximale temperatuur: 90°C

Kwaliteit van het water

• Chloride: < 150 mg/l (inox 304)

< 2000 mg/l (Duplex)

• 6 ≤ ph ≤ 8

AFMETINGEN

TECHNISCHE KENMERKEN

FV/35 FV/50

A mm 1585 1830

B mm 390 390

C mm 200 200

D mm 542 542

E mm 125 125

F mm 645 645

G mm 80 / 80 / 125 100 / 100 / 150

H mm 1610 1880

I mm 800 800

Leeg gewicht Kg 182 220

F

G

I

H

B

C

D

A

E

Page 35

29

NL

TECHNISCHE KENMERKEN

ALGEMENE KENMERKEN

SANITAIR WARM WATERPRESTATIES

FV/35 FV/50

Werkingsregime op 80 °C

Piekdebiet op 40 °C (≤ T = 30 °C) L/10’ 283 377

Piekdebiet op 40 °C (≤ T = 30 °C) L/60’ 1024 1485

Continu debiet op 40 °C (≤ T = 30 °C) L/uur 920 1352

Oplaadtijd van de boiler op 60°C

Oplaadtijd minuten 20 13

Na aftapping van 140 L. op 45 °C minuten 10 8

FV/35 FV/50

Belasting (input) kW 34.9 50

Nominaal nuttig vermogen (output) kW 32.62 46.75

Stilstandverlies op 60° C van de nominale waarde% 0.8 / 0.7 0.6 / 0.45

Totale capaciteit L 127 162

Capaciteit primaire kring L 62 82

CV-aansluiting Ø 1” 1”

Sanitaire aansluiting Ø 3/4” 3/4”

Warmteoppervlak van de boiler m

2

1.99 2.46

Verbrandingsrendement % 93.5 93.5

Gemiddelde CO2 % 13 13

Massadebiet van de verbrandingsproducten g/sec. 14.8 21.2

Page 36

30

NL

STOOKRUIMTE

Belangrijk

• De verluchtingsgaten nooit afstoppen.

•Geen brandbare stoffen in de stookruimte opbergen.

•Erover waken dat er zich geen corrosieve producten in de buurt

van de ketel bevinden zoals verf, solventen, chloor, zout, zeep en

andere onderhoudsproducten.

Bereikbaarheid

De stookruimte dient ruim genoeg te zijn voor een probleemloze

toegang tot de ketel. Het volstaat rond de ketel de volgende

minimumafstanden te respecteren (mm) :

- vooraan 500

- achteraan 150

- zijwaarts 100

- bovenaan 700

Verluchting

De stookruimte moet voorzien zijn van een boven- en

benedenverluchting overeenkomstig afbeelding "L".

De onderstaande tabel is een voorbeeld conform de Belgische

norm.

Nota:

(B) en (C ) enkel voor de aansluitingen van het type B23.

De andere landen kunnen zich naar hun eigen reglementeringen

verwijzen.

Sokkel

De ketel zal op een sokkel van onbrandbare materie gemonteerd

worden.

SCHOUWAANSLUITINGEN

BELANGRIJK

De installatie moet gebeuren door een erkend

installateur, overeenkomstig de plaatselijk geldende

normen.

De diameter van de schouw mag niet kleiner zijn dan

deze van de ketel.

Schouwaansluiting van het type: B23 (zie afbeelding L)

De aansluiting op de schouw gebeurt door middel van een metalen

aansluitstuk in stijgende lijn naar de schouw toe.

Een muur- of dakdoorvoer is noodzakelijk..

A. Bovenverluchting

B. Benedenverluchting

C. Trekregelaar

D. Kijkgat

E. Schouwhoogte

F. Diameter van de schouw

Opmerking:

Aangezien de reglementeringen van land tot land

verschillen, wordt de bovenstaande tabel enkel ter

indicatie gegeven.

Het hoge rendement van onze ketels zorgt ervoor dat

de rookgassen op lage temperatuur afgevoerd w or den.

Dit kan condens veroorzaken, wat schadelijk kan zijn

voor de schouw. Om dit risico te vermijden, is het sterk

aangeraden om de schouw te tuberen.

Neem voor meer informatie hierover contact op met

uw installateur.

Schoorsteenaansluiting van het type: C...

(zie afbeeldingen M en N)

• C 13 : concentrische horizontale aansluiting

• C 33 : concentrische verticale aansluiting

• C 43 : concentrische schouwaansluiting

Maximum concentrische lengte : 6 meter

Nota:

Een bocht van 90° = een lengte evenwaardig met één meter

Er moet een afvoerleiding in de buurt van de ketel

zijn om te vermijden dat de condensaten van de

schoorsteen terug in de ketel komen.

Om te vermijden dat het condensatiewater uit de

terminal loopt, moeten alle passages van horizontale

leidingen naar de ketel lopen.

INSTALLATIE

FV/35 FV/50

Verluchting

Min. frisse luchtaanvoer m3/uur 63 90

Bovenverluchting (A) dm

2

1.5 1.5

Benedenverluchting (B) dm

2

1.5 2

Trekregelaar (C) Ø 80 100

FV/35 FV/50

Schoorsteen

E = 5 m Ø min. F mm 213 236

E = 10 m Ø min. F mm 179 199

E = 15 m Ø min. F mm 162 179

Page 37

31

NL

CV-AANSLUITING

Voorbeeld van aansluiting met één kring

(zie afbeelding G)

1. Motoriseerbare 3-wegmengkraan

2. Veiligheidsklep afgesteld op 3 bar met manometer

3. Circulator

4. Terugslagklep

5. Vulset van de installatie

6. Expansievat

7. ACV 13 regulatie

(zie regulatiekit pagina 30)

8. CV- afsluitkraan

9. Leegloop

Hydraulische kit + Cv-kit ACV (zie afbeelding F)

ACV biedt een voorafgemonteerde hydraulische kit in optie,

samegesteld uit:

- Een circulator

-Een motoriseerbare 3-wegmengkraan

- De aansluitingen van de leidingen met een mogelijke tweede kring

-Twee afsluitkranen

- De aansluitingen voor het monteren aan de rechter- of linkerkant

van het expansievat, de veiligheidsklep met manometer en de

vulklep.Het expansievat is niet inbegrepen.

SANITAIRE AANSLUTING

Drukregelaar

Indien de druk van het leidingwater meer dan 6 bar is, dient een

drukregelaar afgesteld op 4,5 bar voorzien te worden.

Veiligheidsgroep

De veiligheidsgroep van de boiler zal een ACV type zijn, afgesteld

op 7 bar.De leegloop dient aangesloten te worden op een sterfput.

Sanitair expansievat

Met het sanitair expansievat wordt elk risico tot overdruk door

waterslag of drukschommelingen vermeden.

Warm watercirculatie

Wanneer de afstand tussen de ketel en het aftappunt groot is, kan

de plaatsing van een gesloten omloop doorlopend zorgen voor een

snellere warm wateraftapping.

Voorbeeld van een aansluiting met thermostatische

mengkraan (zie afbeelding H)

1. Veiligheidsgroep

2. Drukregelaar

3. Thermostatische mengkraan

4. Sanitaire circulator

5. Terugslagklep

6. Sanitair expansievat

7. Kraan voor aanvoer koud water

8. Aftapkraan

9. Leegloopkraan

10. Leegloopkraan voor de aftapping

11. Afsluitkraan

BELANGRIJK

Om brandwonden te voorkomen wordt uit

veiligheidsoverweging aanbevolen een

thermostatische mengkraan te installeren.

In optie verkrijgbaar toebehoren

REGULATIEKITS

KIT 1: ACV 13.00 / Basis (zie afbeelding C)

Basiskit voor de regeling van de vertrektemperatuur op basis van de

weersomstandigheden.Deze kit omvat: de temperatuurregelaar met

analoge klok, een klemtemperatuurvoeler voor het water

(-30°/130°C), een buitentemperatuurvoeler (-30/50°C), een

servomotor SSY 319 - 230 V - 3 puntsturing en een tussensokkel.

KIT 2: ACV 13.00 / Standaard (zie afbeelding D)

Standaardkit voor de regulatie van de vertrektemperatuur op basis

van de weersomstandigheden.Deze kit omvat: de temperatuurregelaar met analoge klok, een klemtemperatuurvoeler voor het water

(-30°/130°C), een buitentemperatuurvoeler (-30/50°C), een

servomotor SQK 349 - 230 V - 3 puntsturing en een tussensokkel.

Elektrisch schema van de regulatiekits ACV

(zie afbeelding E)

B2. Klemtemperatuurvoeler

B9. Buitenvoeler

B5. Analoge/digitale ruimtevoeler

P1. CV-pomp.