Page 1

INSTALLATION, OPERATING AND

SERVICING INSTRUCTIONS

EN

Comfort

100 - 130 - 160 - 210 - 240

Page 2

Page 3

TABLE OF CONTENTS

GENERAL 4

Notes 4

Packaging 4

SAFETY PRECAUTIONS 5

Symbols used 5

Recommendations 5

APPLIANCE DESCRIPTION 6

Operation in accordance with instructions 6

TECHNICAL CHARACTERI STI CS 7

General characteristics 7

Domestic hot water performance 7

Maximum operating conditions 7

INS TA LLATI ON 8

Position 8

Dimensions 8

Domestic hot water connection (DHW) 9

Connection to the heating circuit 10

Position of DHW sensor 10

BRINGING INTO SERVICE 11

Filling the DHW tank 11

Filling the heating circuit of the tank 11

Checks before bringing into service 12

MAINTENANCE 13

Periodic checks by the user 13

Annual maintenance 13

Drainage 13

EN

661Y1000 • F

en

3

Page 4

EN

GENERAL

NOTES

This manual forms part of the items delivered with the appliance and must be given to the user

to keep in a safe place!

The system must be installed, commissioned, serviced and repaired by an approved installer,

inaccordance with current standards in force.

The manufacturer declines all liability for any damage caused as a result of incorrect installation

or in the event of the use of appliances or accessories that are not specified by the manufacturer.

The manufacturer reserves the right to change the technical characteristics and

features of its products without prior notice.

The availability of certain models as well as their accessories may vary according to

markets.

The installation must comply with the instructions contained in this manual as well as

with the regulations governing installations for hot water production.

PACK AGING

The units are delivered assembled, tested and packaged in a cardboard box.

Package contents

• Hot water production tank.

• Multilingual technical instructions.

en

4

661Y1000 • F

Page 5

SAFETY INSTRUCTIONS

SYMBOLS USED

Description below of the symbols used in this technical manual:

EN

Essential instruction

forthecorrect operation

oftheinstallation.

Danger!

Risk of serious injury.

We accept no responsibility in the event of damage caused by failure to follow

theinstructions appearing in this technical manual.

Essential instruction

forthesafety of persons

andtheenvironment.

RECOMMENDATIONS

Before installing and bringing the appliance into service, first carefully read

thismanual.

It is strictly prohibited to modify the interior of the appliance in any way, without

themanufacturer's prior written agreement.

The appliance must be installed by a qualified engineer, in accordance with current

regulations.

The installation must comply with the instructions contained in this manual as well

as current regulations governing hot water production installations.

Failure to follow the instructions describing test operations and procedures could

result in personal injury or a risk of environmental pollution.

In order to ensure the appliance operates correctly, it is important to have it serviced

by an approved contractor every year.

If there is a problem please contact your contractor for advice.

Faulty parts must only be replaced with original factory parts.

661Y1000 • F

en

5

Page 6

EN

APPLIANCE DESCRIPTION

OPERATION IN ACCORDANCE

WITH INSTRUCTIONS

Our domestic hot water tanks are

designed and manufactured exclusively

for there-heating and storage of domestic

hotwater.

The domestic hot water heaters must only

be heated using heated water in a closed

circuit.

3

1

4

Key

1. Cold water inlet

2. Domestic hot water outlet

3. Manual air vent valve

4. Primary fluid inlet

5. Primary fluid outlet

6. 30 mm of insulation in polyurethane

(without CFCs)

7. Primary carbon steel tank

8. DHW stainless steel tank

9. Rigid polypropylene cover

10. External polypropylene casing

11. Rigid polypropylene base

12. Stainless steel dry-well

2

9

12

8

10

7

5

6

11

en

6

661Y1000 • F

Page 7

TECHNICAL CHARACTERISTICS

General characteristics 100 130 160 210 240

Total capacity L 105 130 161 203 242

Primary capacity L 30 55 62 77 78

Maximum absorbed power kW 23 23 31 39 53

Drained weight kg 37 40 47 58 65

Initial heating time minutes 24 24 22 22 20

Heating surface area m

Operating system: 85°C T° of water supply: 10°C

2

1.03 1.03 1.26 1.54 1.94

MAXIMUM OPER ATING CONDITIONS

Maximum service pressure [tank full of water]

- Primary circuit: 3 bar

- Hot water circuit: 10 bar

Test pressure [tank full of water]

- Primary circuit: 3.9 bar

- Hot water circuit: 13 bar

EN

Operating temperature

- Maximum temperature: 90°C

Water quality

• Chlorides < 150 mg/L

• 6 ≤ pH ≤ 8

• If the water hardness is > 20°fH, it is advisable to install a water softener.

661Y1000 • F

en

7

Page 8

EN

Ø 3/4" Ø 3/4"

INSTALLATION

POSITION

The hot water cylinder must be installed in an area that is dry and protected from the elements.

Choose the most suitable location according to the position of the boiler and distance

tothedomestic hot water supply, in order to reduce temperature and pressure drops within the

pipe work.

The unit should be positioned to allow the replacement, if required, of the sparge

tube and dry well during servicing.

The unit can be floor standing or wall mounted (using correct mounting available as an option).

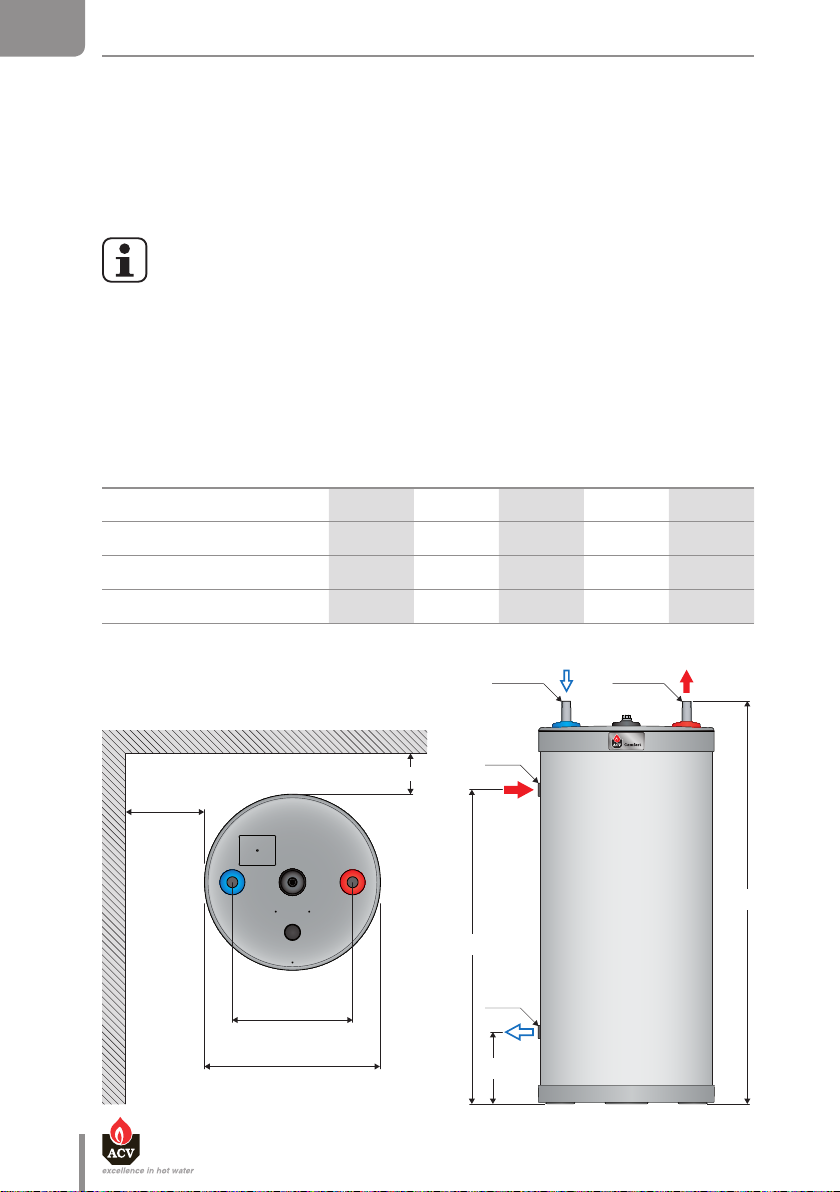

DIMENSIONS

A mm 845 1005 1205 1475 1720

B mm 580 740 940 1210 1455

C mm 215 215 215 215 210

D Ø 1" 1" 1" 1"1/4 1"1/4

100 130 160 210 240

50 mm

D

500 mm

B

360 mm

D

A

Ø 525 mm

en

8

661Y1000 • F

C

Page 9

INSTALLATION

1

1

5

9

6

3

1

2

4

7

8

10

EN

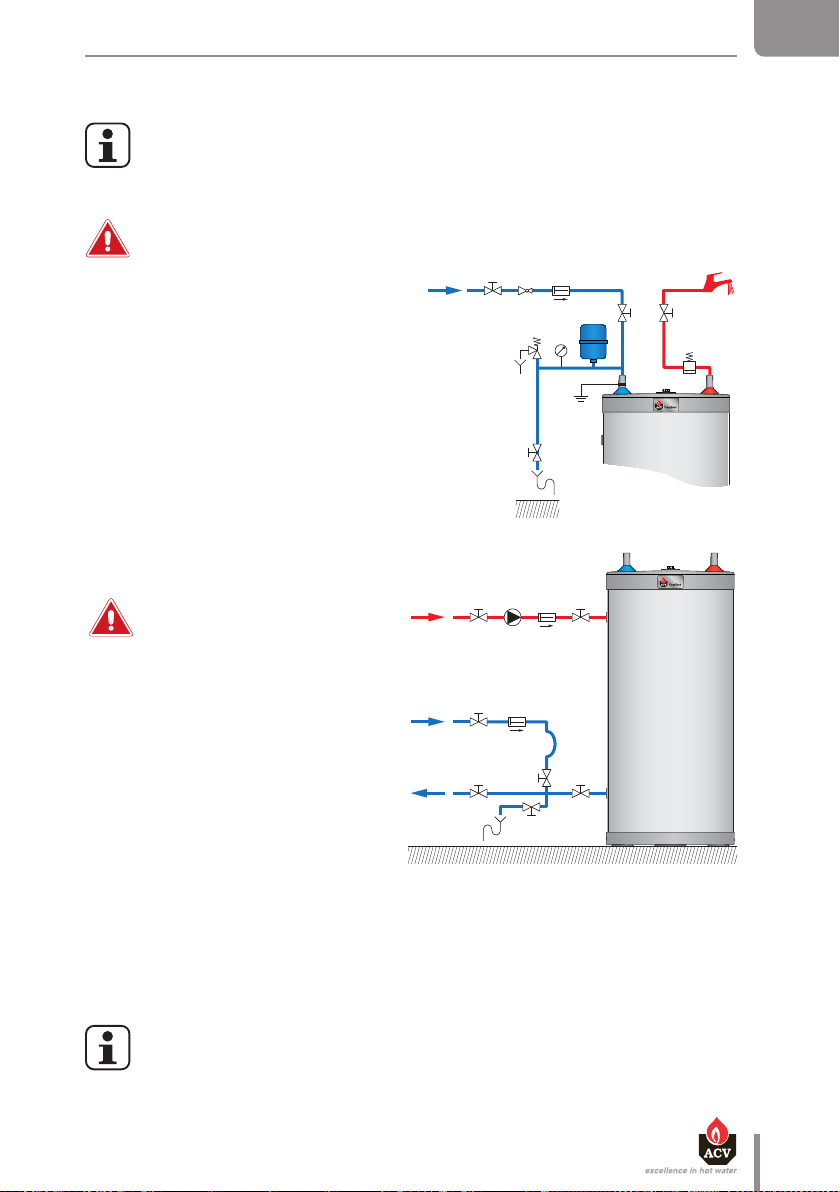

DOMESTIC HOT WATER

CONNECTION

The installation of a safety unit

iscompulsory.

To avoid water discharge on to the

tank, the safety unit must never

be installed above the tank.

In certain countries the domestic

kits must be approved and

included a temperature and

pressure relief valve fitted in the

hot outlet.

The circuit illustrations are basic

principle diagrams only.

To avoid any risk of corrosion,

connect the stainless steel tank

directly to the earth.

ACV recommends using

Hot water can burn!

apre-set thermostatic mixer

valve in order to provide hot

water at a maximum of 60°C.

• The installation of a domestic expansion

vessel avoids discharge from the safety

valve (loss of water).

• Capacity of domestic water vessels:

5 Litres: for models: 100 / 130

8 Litres: for models: 160 / 210

12 Litres: for model: 240

Refer to the manufacturer’s

technical instructions on the

expansion vessel for more details.

Connection to the DHW circuit

1. Isolating valve

2. Pressure reducer

3. Non-return valve

4. DHW expansion vessel

5. Safety valve

6. Drain down valve

7. Air vent valve

8. Hot water outlet

9. Pressure gauge

10. Earth connection

Recommendations

• The tank’s cold water supply pipe must

be fitted with a safety unit that includes

at least: an isolating valve (1), anon-re-

turn valve (3), a domestic safety valve

calibrated to 10 bar (5) and an expansion

vessel (4) of suitable size.

• When the operating pressure exceeds

6 bar, a pressure reducer (2) must be

installed before the safety unit.

• Union fittings are recommended for the

easy dismantling of the DHW connections. Ideally, the “dielectric” version is favourable to protect theconnections from

corrosion with the presence of different

metals such ascopper and galvanised

steel.

661Y1000 • F

en

9

Page 10

EN

INSTALLATION

DHW connection kit available

(code:1080 0102)

S

A. DHW temperature control valve

B. Mixed domestic hot water outlet

C. Cold water supply

D. Drainage connection

E. DHW expansion vessel connection

D

S. Safety valve (10 bar)

TH. Tank hot water outlet

TC. Tank cold water inlet

CONNECTION TO THE HEATING CIRCUIT

1. Heating isolating valve

2. Charging pump

3. Non-return valve

4. Preheater isolating valve

5. Primary circuit filling valve

6. Drain down valve

B

E

A

C

5

1

TC TH

21

3

4

3

4

5

6

POSITION OF DHW SENSOR

1

en

10

3

4

2

661Y1000 • F

Page 11

BRINGING INTO SERVICE

1

1

5

9

3

1

2

4

7

8

10

11

5

9

3

2

4

7

8

10

FILLING THE DHW TANK

Before bringing the hot water tank into service, check the connections to avoid any

any risk ofleaks during filling.

The sealing of the DHW tank must only be checked with the feed water.

Thetestpressure on the site must not exceed a pressure surge of 10 bar.

The DHW tank must always be filled and pressurised before filling and pressurising

the heating circuit.

• To vent the DHW installation, simply open

the highest hot water valve (8).

• Fill the domestic hot water tank, by opening

the stop valves (1).

• Close the hot water valve (8), after the water

flow has stabilised and the air has been

completely evacuated.

• Check all connections of the installation for leaks.

6

FILLING THE HEATING CIRCUIT

OF THE TANK

EN

Do not use vehicle or

21

4

3

non-dilutedantifreeze.

This can causeserious injury, lead

toloss of life or damage rooms.

• Check that the drainage valve (6) for your

5

3

primary installation is fully closed.

• Open the isolation valves (1) and (4) of the

• Open the air vent valve located in the

upper part of the hot water tank.

• In addition, follow the instructions

provided with the boiler for filling.

• Open the valves (5) to start filling.

heating circuit connected to the boiler.

1

4

5

6

• When the air is eliminated, first close the

airvent valve, then the filling valves (5).

• If antifreeze is needed in the primary circuit, it must comply with Public Hygiene Regulations

and must not be toxic. A food grade of Propylene Glycol is recommended. Consult the

manufacturer to determine the compatibility of the antifreeze with the tank ’s construction

materials.

Fill the system with the fresh tap water. Contact your ACV representative or installer

about the use of inhibitors.

en

661Y1000 • F

11

Page 12

EN

BRINGING INTO SERVICE

CHECKS BEFORE BRINGING INTO SERVICE

• Check that the safety valves (DHW) and (heating) are correctly installed and that the outlets

are connected to the drain.

• Check that the DHW tank and the primary circuit are filled with water.

• Check that the air has been correctly vented on both circuits.

• Check that the heater’s upper air vent valve is water tight.

• Check that the DHW and heating pipes are correctly connected and not leaking.

Recommendations

The risk of developing bacteria exists, including “Legionella pneumophila”,

ifaminimum temperature of 60°C is not maintained in both the storage tank

andinthe hot water distribution network.

In the event of small amounts of hot water repeatedly being drawn, a stratification

effect can develop in the tank. The upper hot water layer may then reach very high

temperatures.

A thermostatic mixer valve will ensure that extremely hot water does not run

fromthe taps.

Water heated for washing clothes, dishes and other uses can cause serious burns.

In order to avoid exposure to extremely hot water that can cause serious burns,

never leave children, old people, disabled or handicapped people in the bath

orshower alone.

12

Never allow young children to turn on the hot water or fill their own bath.

Adjust the water temperature in accordance with usage and plumbing regulations.

en

661Y1000 • F

Page 13

MAINTENANCE

PERIODIC CHECKS BY THE USER

• Check the pressure on the boiler pressure gauge: this should be between 0.5 and 1.5 bar.

• Each month visually inspect the valves, connections and accessories in order to detect any

leaks or malfunction.

• Periodically check the air vent valve located in the upper part of the tank to ensure that

itisnot leaking.

• Check the DHW safety valves are in good working order.

• In the event of a problem, please contact an engineer or your installer.

ANNUAL MAINTENANCE

The annual maintenance service, performed by an engineer, must include:

• A check of the air vent valve:

The venting of air can lead to the need for adding water to the system.

Check the pressure on the boiler’s pressure gauge.

• The manual activation of the DHW safety valve once a year.

This operation will lead to a discharge of hot water.

Before draining hot water through the safety valve, ensure that the outlet goes

directly to the drain to avoid any risk of burning and potential damage as a result.

• The discharge pipe must be open to the outside.

• If the safety unit drips periodically, this may be due to an expansion problem or clogging

ofthe valve.

• Follow the circulator’s maintenance instructions.

• Check that the valves are in good working order.

EN

Drain valve

Recommendations

Drain the tank if it is not used in winter and is at risk from exposure to ice.

If the primary circuit water contains antifreeze, only the DHW tank must be drained.

Before draining the DHW, isolate the tank and lower the pressure of the primary

circuit to 1 bar, in order to protect the DHW tank from crushing.

If the heating circuit does not contain antifreeze, the heating circuit and domestic

water must be drained. Always drain the heating circuit before draining the DHW.

661Y1000 • F

en

13

Page 14

EN

MAINTENANCE

DRAINAGE O F THE HEATING TANK

To drain the primary circuit of the hot water heater:

• Isolate the hot water primary circuit

byclosing valves (A) and (B).

• Connect the drain valve (C) to the drain

using a flexible hose.

• Open the drain valve (C) and drain

thewater from the primary circuit

tothedrain.

• Open the tank’s air vent valve (D)

toaccelerate drainage.

• Close the drain valve (C) and air vent (D)

after draining the tank.

DRAINAGE O F THE DHW TANK

To drain the hot water heater’s DHW tank:

• Close the isolation valves (1).

• Connect the drain valve (2) to the drain using

a flexible hose.

D

A

B

C

1

1

3

• Open the drain valve (2) and drain the water

from the DHW tank to the drain.

• Open the circuit’s air vent valve (3)

toaccelerate the tank’s drainage.

• Close the drain valve (2) and the air vent

valve(3) after draining the cylinder’s

DHWtank.

en

14

2

661Y1000 • F

Loading...

Loading...