查询EX128-FTQ100供应商

eX Family FPGAs

Leading Edge Performance

•240 MHz System Performance

• 3.9ns Clock-to-Out (Pad-to-Pad)

• 350 MHz Internal Performance

Specifications

• 3,000 to 12,000 Available System Gates

• As Many as 512 Maximum Flip-Flops (Using CC Macros)

µ CMOS Process Technology

•0.22

• Up to 132 User-Programmable I/O Pins

Features

• High-Performance, Low-Power Antifuse FPGA

• LP/Sleep Mode for Additional Power Savings

• Advanced Small-footprint Packages

• Hot-Swap Compliant I/Os

• Single-Chip Solution

• Nonvolatile

•Live on power up

• Power-Up/Down Friendly (No Sequencing Required for

Supply Voltages)

• Configurable Weak-Resistor Pull-Up or Pull-Down for

Tristated Outputs during Power Up

v3.0

• Individual Output Slew Rate Control

• 2.5V, 3.3V, and 5.0V Mixed Voltage Operation with 5.0V

Input Tolerance and 5.0V Drive Strength

• Software Design Support with Actel Designer Series and

Libero Tools

• Up to 100% Resource Utilization with 100% Pin Locking

• Deterministic Timing

• Unique In-System Diagnostic and Verification Capability

with Silicon Explorer II

• Boundary Scan Testing in Compliance with IEEE Standard

1149.1 (JTAG)

• Secure Programming Technology Prevents Reverse

Engineering and Design Theft

General Description

The eX family of FPGAs is a low-cost solution for low-power,

high-performance designs. The inherent low power

attributes of the antifuse technology, coupled with an

additional low static power mode, make these devices ideal

for power-sensitive applications. Fabricated with an

advanced 0.22

achieve high performance with no power penalty

µ CMOS antifuse technology, these devices

.

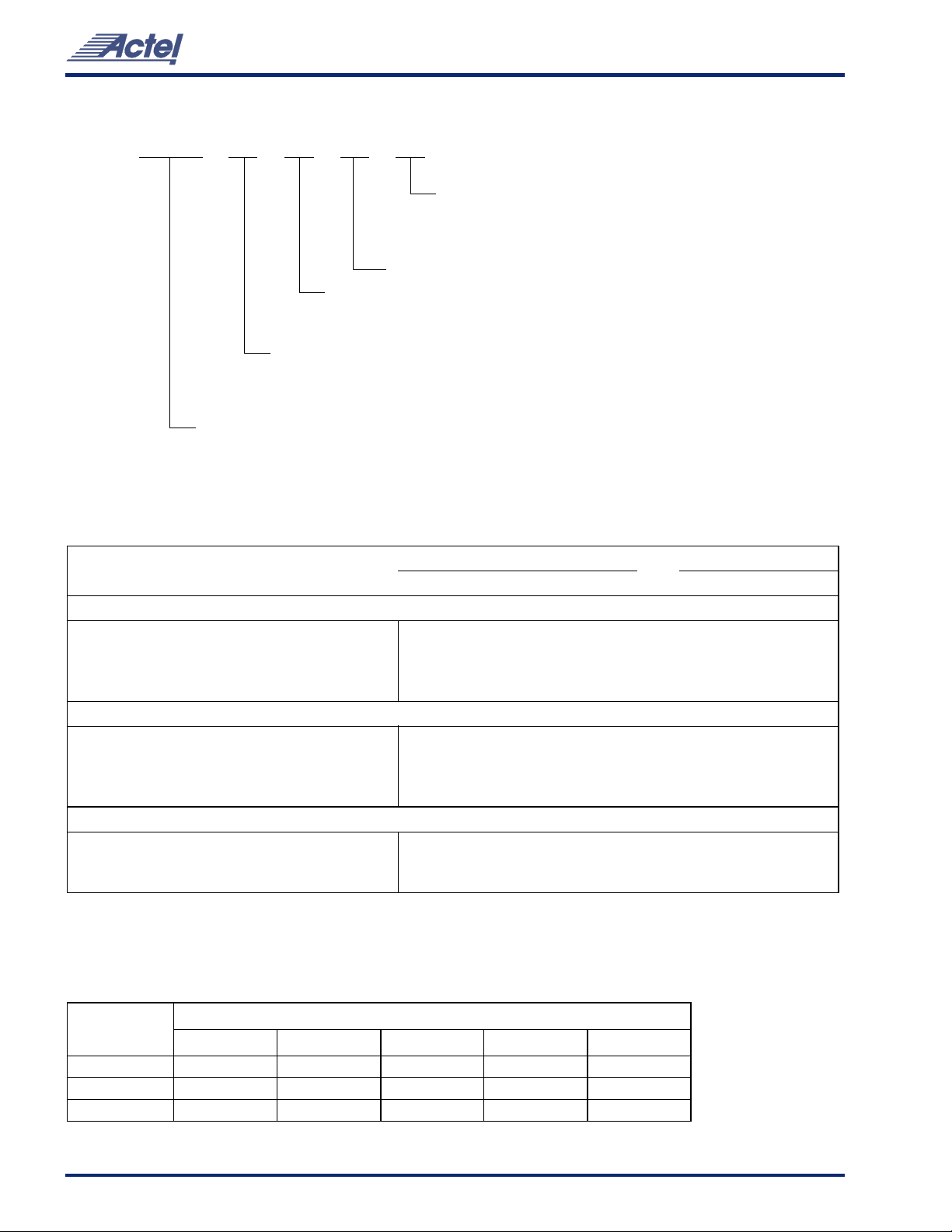

eX Product Profile

Device eX64 eX128 eX256

Capacity

System Gates

Typical Gates

Register Cells (Dedicated Flip-Flops) 64 128 256

Combinatorial Cells 128 256 512

Maximum User I/Os 84 100 132

Speed Grades –F, Std, –P –F, Std, –P –F, Std, –P

Temperature Grades C, I C, I C, I

Package (by pin count)

TQFP

CSP

December 2001 1

© 2001 Actel Corporation

3,000

2,000

64, 100

49, 128

6,000

4,000

64, 100

49, 128

12,000

8,000

100

128, 180

Ordering Information

eX Family FPGAs

eX128 TQ 100

–P

Application (Temperature Range)

Blank = Commercial (0 to +70°C)

I = I ndustrial (–40 to +85°C)

PP = Pre-production

Package Lead Count

Package Type

TQ = Thin (1.4mm) Quad Flat Pack

CS = Chip-Scale Package (0.8mm pitch)

Speed Grade

Blank = Standard Speed

–P = Approximately 30% Faster than Standard

–F = Approximately 40% Slower than Standard

Part Number

eX64 = 64 Dedicated Flip-Flops (3,000 System Gates)

eX128 = 128 Dedicated Flip-Flops (6,000 System Gates)

eX256 = 256 Dedicated Flip-Flops (12,000 System Gates)

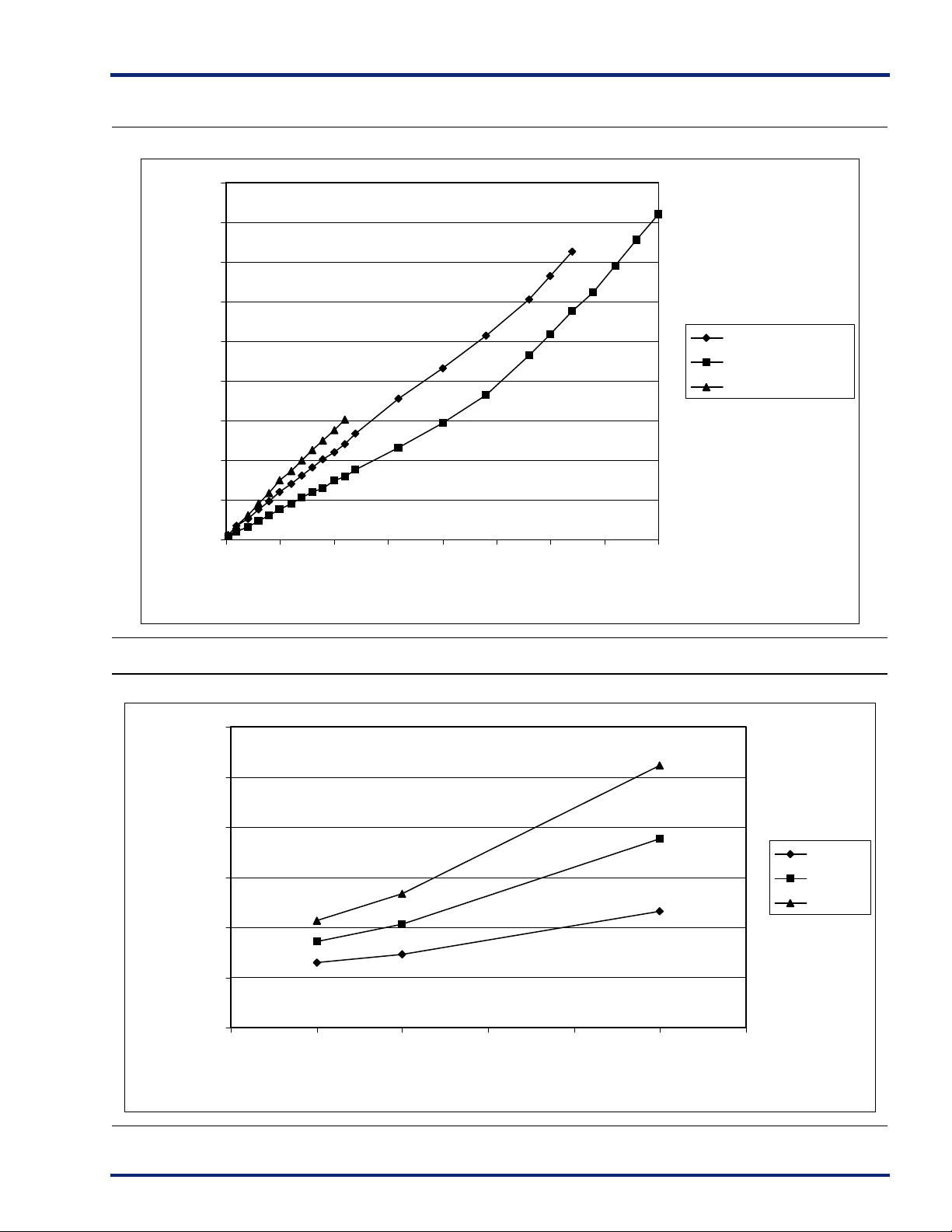

Product Plan

Speed Grade Application

–FStd–PCI

eX64 Device

64-Pin Thin Quad Flat Pack (TQFP) ✔✔✔ ✔✔

100-Pin Thin Quad Flat Pack (TQFP) ✔✔✔ ✔✔

49-Pin Chip Scale Package (CSP) ✔✔✔ ✔✔

128-Pin Chip Scale Package (CSP) ✔✔✔ ✔✔

eX128 Device

64-Pin Thin Quad Flat Pack (TQFP) ✔✔✔ ✔✔

100-Pin Thin Quad Flat Pack (TQFP) ✔✔✔ ✔✔

49-Pin Chip Scale Package (CSP) ✔✔✔ ✔✔

128-Pin Chip Scale Package (CSP) ✔✔✔ ✔✔

eX256 Device

100-Pin Thin Quad Flat Pack (TQFP) ✔✔✔ ✔✔

128-Pin Chip Scale Package (CSP) ✔✔✔ ✔✔

180-Pin Chip Scale Package (CSP) ✔✔✔ ✔✔

Contact your Actel sales representative for product availability.

Speed Grade: –P = Approx. 30% faster than Standard Availability: ✔ = Available Applications: C = Commercial

–F = Approx. 40% slower than Standard I = Industrial

† Only Std Speed Grade

†

Plastic Device Resources

User I/Os (including clock buffers)

Device TQFP 64-Pin TQFP 100-Pin CSP 49-Pin CSP 128-Pin CSP 180-Pin

eX64 41 56 36 84 —

eX128 46 70 36 100 —

eX256 — 81 — 100 132

Package Definitions: TQFP = Thin Quad Flat Pack, CSP = Chip Scale Package

2v3.0

eX Family FPGAs

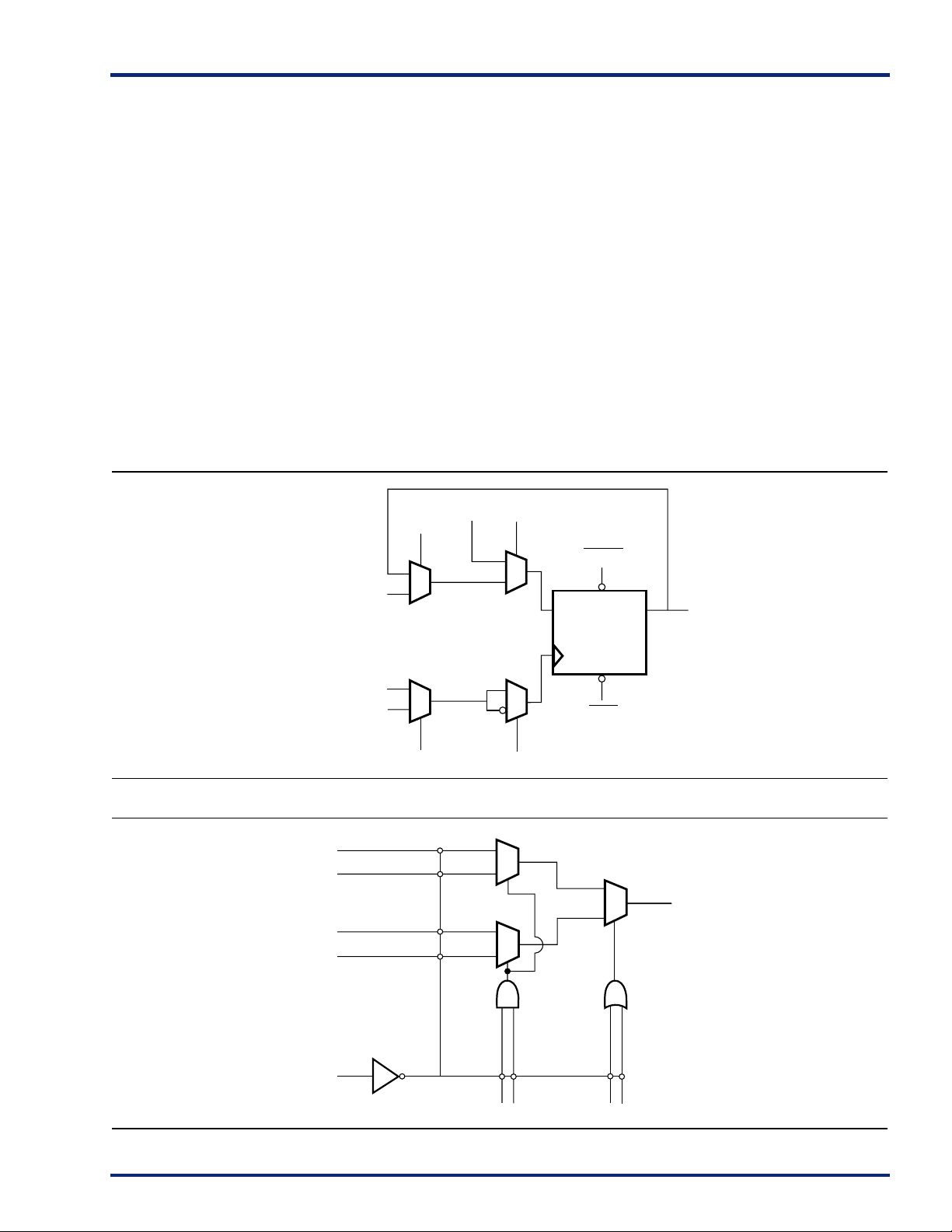

eX Family Architecture

The eX family architecture uses a “sea-of-modules”

structure where the entire floor of the device is covered

with a grid of logic modules with virtually no chip area lost

to interconnect elements or routing. Interconnection

among these logic modules is achieved using Actel’s

patented metal-to-metal programmable antifuse

interconnect elements. Actel’s eX family provides two types

of logic modules, the register cell (R-cell) and the

combinatorial cell (C-cell).

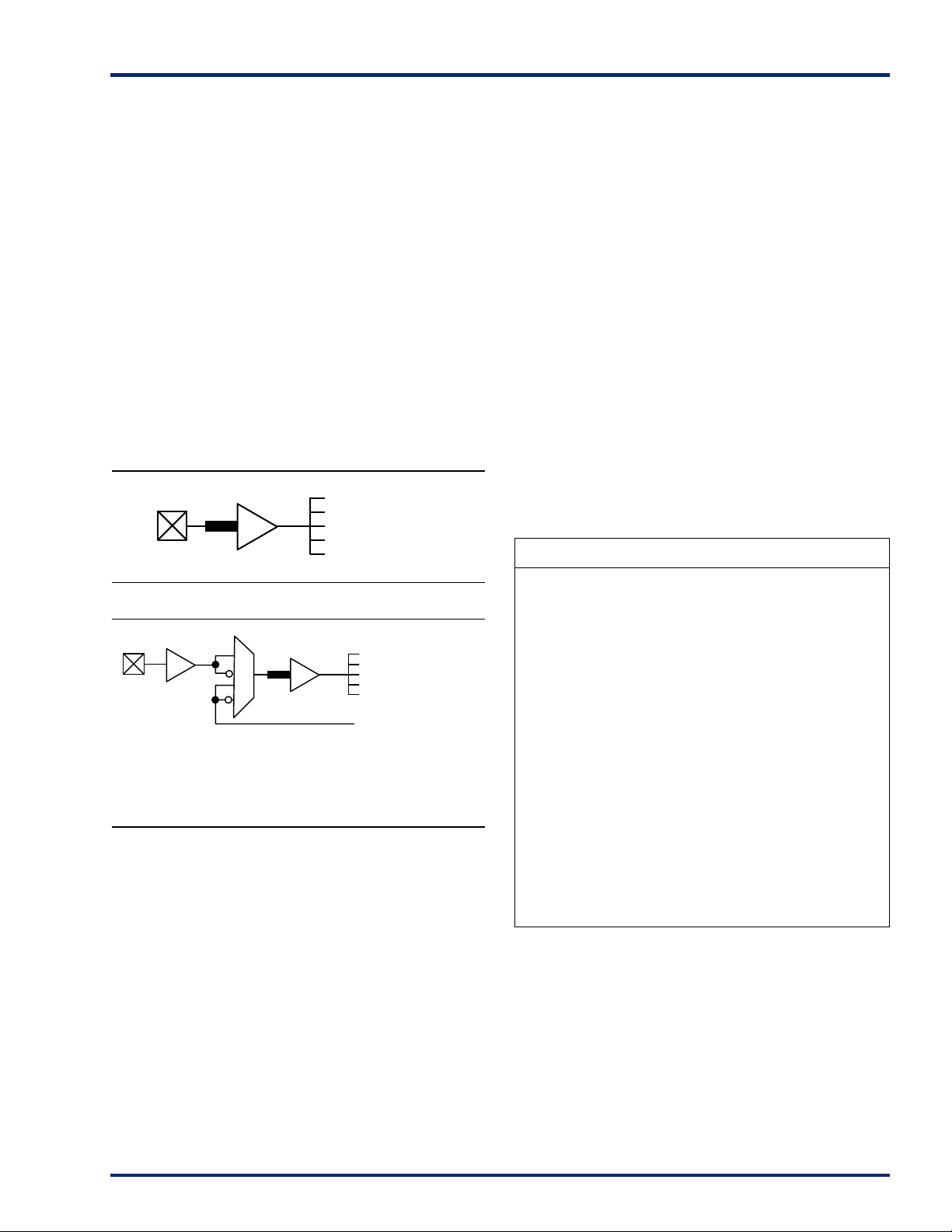

The R-cell contains a flip-flop featuring asynchronous clear,

asynchronous preset, and clock enable (using the S0 and S1

lines) control signals (Figure 1). The R-cell registers

feature programmable clock polarity selectable on a

register-by-register basis. This provides additional flexibility

while allowing mapping of synthesized functions into the eX

FPGA. The clock source for the R-cell can be chosen from

either the hard-wired clock or the routed clock.

Routed

Data Input

S0

The C-cell implements a range of combinatorial functions

up to 5 inputs (Figure 2). Inclusion of the DB input and its

associated inverter function dramatically increases the

number of combinatorial functions that can be

implemented in a single module from 800 options in

previous architectures to more than 4,000 in the eX

architecture.

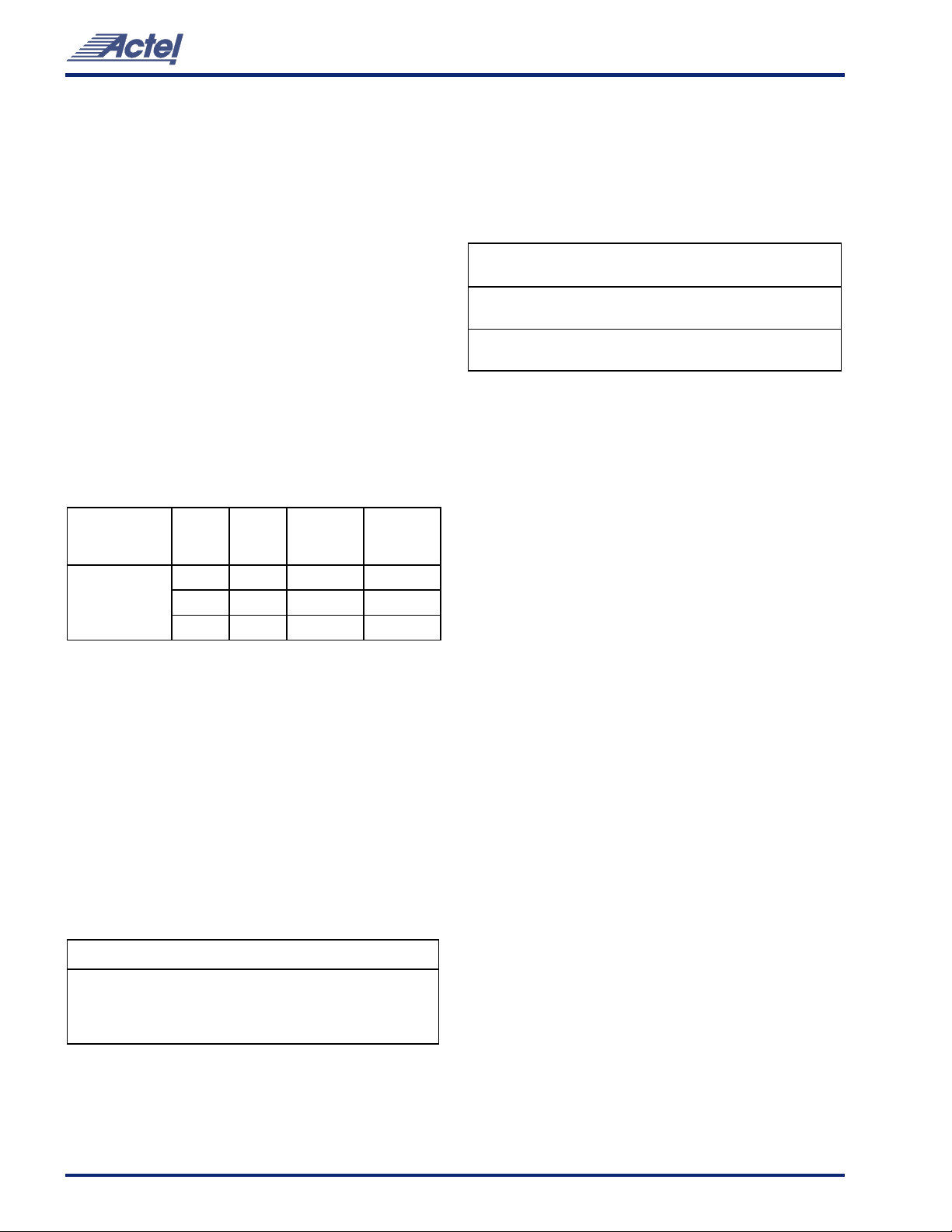

Module Organization

Actel has arranged all C-cell and R-cell logic modules into

horizontal banks called Clusters. The eX devices contain

one type of Cluster, which contains two C-cells and one

R-cell.

To increase design efficiency and device performance, Actel

has further organized these modules into SuperClusters

(Figure 3 on page 4). The eX devices contain one type of

SuperClusters, which are two-wide groupings of one type of

clusters.

S1

Figure 1 • R-Cell

DirectConnect

Input

HCLK

CLKA,

CLKB,

Internal Logic

D0

D1

D2

D3

CKS

CKP

PSET

DQ

CLR

Sa

Y

Y

Sb

Figure 2 • C-Cell

DB

B1

A0 B0

v3.0 3

A1

eX Family FPGAs

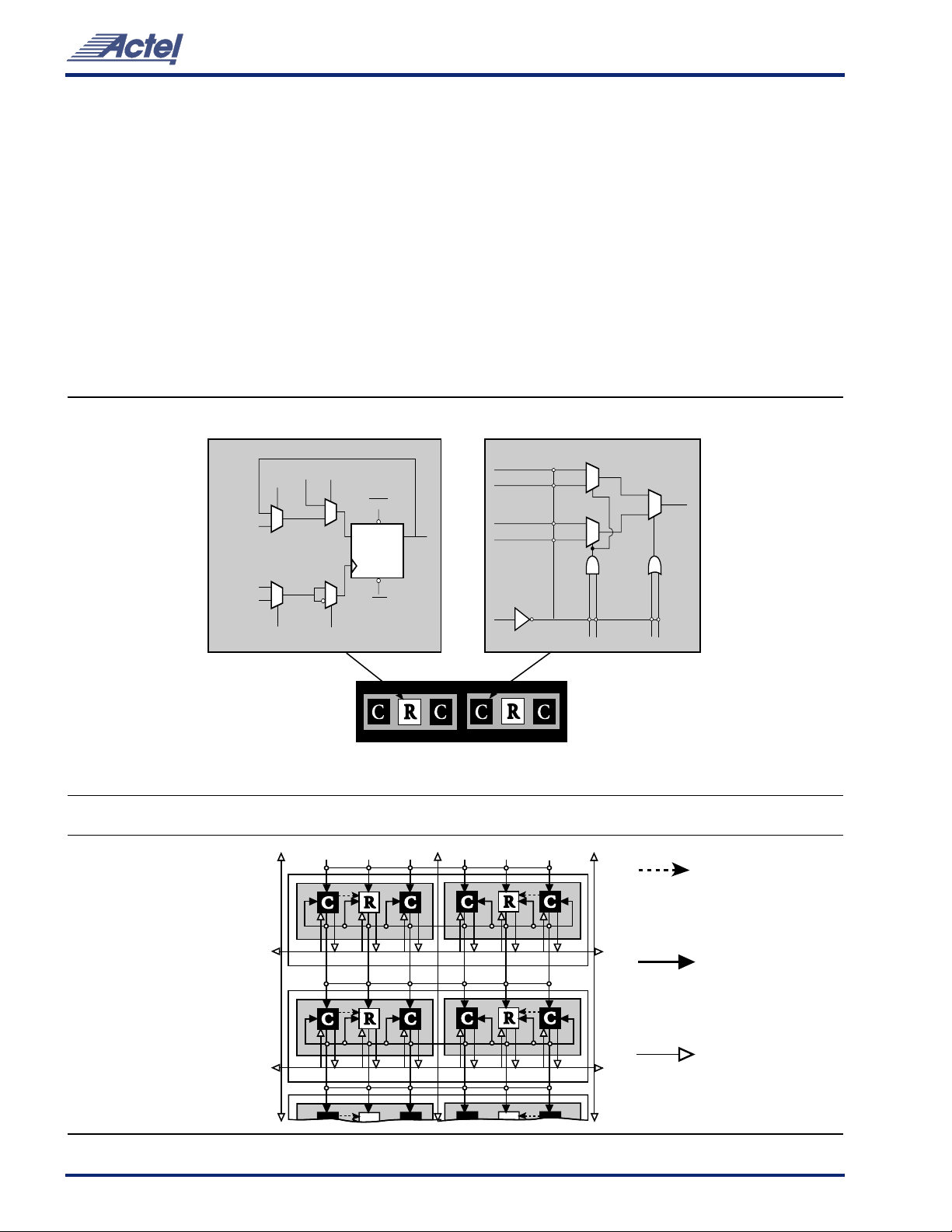

Routing Resources

Clusters and SuperClusters can be connected through the

use of two innovative local routing resources called

FastConnect and DirectConnect, which enable extremely

fast and predictable interconnection of modules within

Clusters and SuperClusters (Figure 4). This routing

architecture also dramatically reduces the number of

antifuses required to complete a circuit, ensuring the

highest possible performance.

DirectConnect is a horizontal routing resource that provides

connections from a C-cell to its neighboring R-cell in a given

SuperCluster. DirectConnect uses a hard-wired signal path

requiring no programmable interconnection to achieve its

fast signal propagation time of less than 0.1 ns (–P speed

grade).

R-Cell C-Cell

Routed

S1

Data Input

S0

PSET

DirectConnect

Input

FastConnect enables horizontal routing between any two

logic modules within a given SuperCluster and vertical

routing with the SuperCluster immediately below it. Only

one programmable connection is used in a FastConnect

path, delivering maximum pin-to-pin propagation of 0.3 ns

(–P speed grade).

In addition to DirectConnect and FastConnect, the

architecture makes use of two globally oriented routing

resources known as segmented routing and high-drive

routing. Actel’s segmented routing structure provides a

variety of track lengths for extremely fast routing between

SuperClusters. The exact combination of track lengths and

antifuses within each path is chosen by the 100 percent

automatic place-and-route software to minimize signal

propagation delays.

D0

D1

D2

YDQ

D3

Y

Sa Sb

HCLK

CLKA,

CLKB,

Internal Logic

CKS CKP

Figure 3 • Cluster Organization

Type 1 SuperClusters

CLR

DB

Cluster 1 Cluster 1

Type 1 SuperCluster

A0 B0 A1 B1

DirectConnect

• No antifuses

• 0.1 ns routing delay

FastConnect

• One antifuse

• 0.3 ns routing delay

Routing Segments

• Typically 2 antifuses

• Max. 5 antifuses

Figure 4 • DirectConnect and FastConnect for Type 1 SuperClusters

4v3.0

eX Family FPGAs

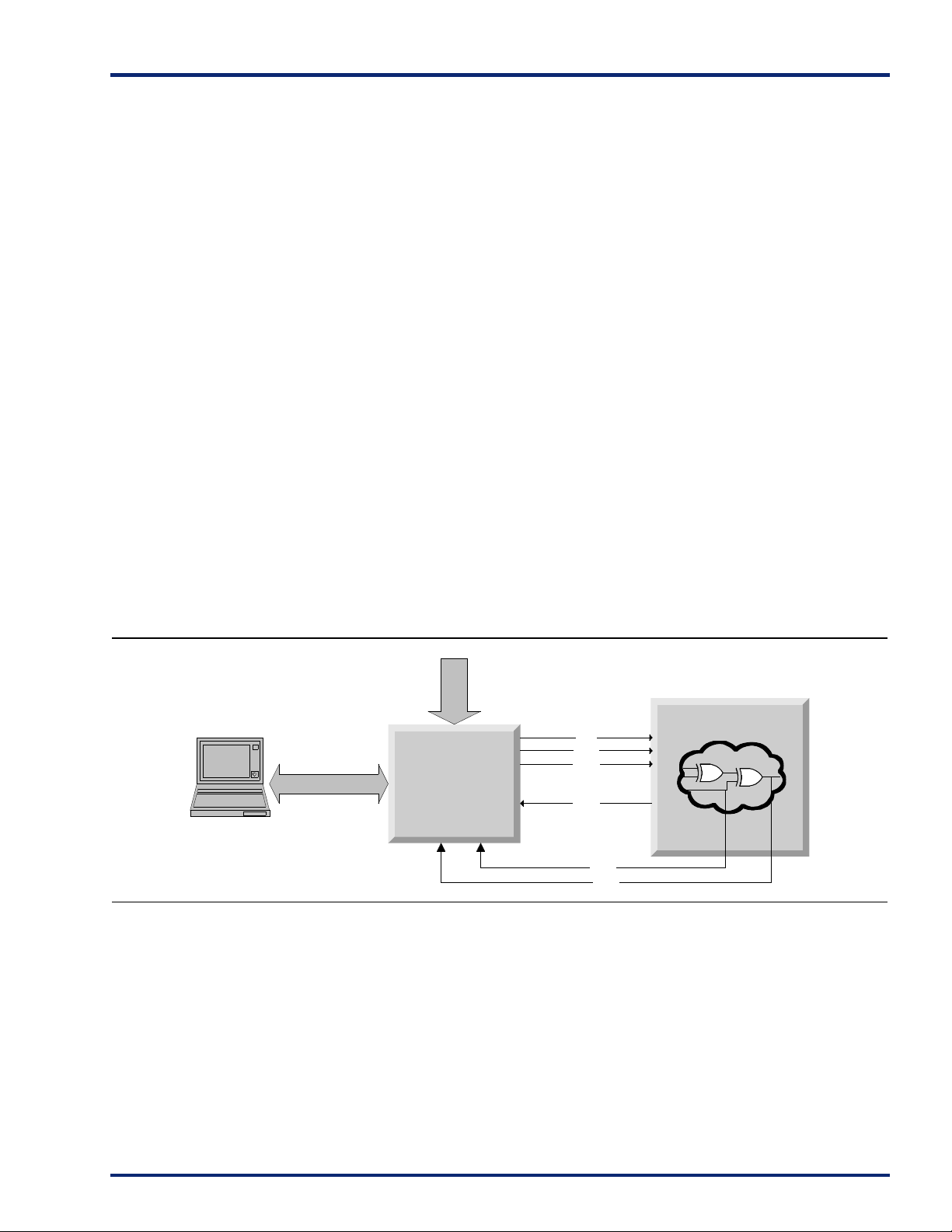

Clock Resources

Actel’s high-drive routing structure provides three clock

networks. The first clock, called HCLK, is hardwired from

the HCLK buffer to the clock select MUX in each R-Cell.

HCLK cannot be connected to combinational logic. This

provides a fast propagation path for the clock signal,

enabling the 3.9ns clock-to-out (pad-to-pad) performance of

the eX devices. The hard-wired clock is tuned to provide a

clock skew of less than 0.1ns worst case.

The remaining two clocks (CLKA, CLKB) are global clocks

that can be sourced from external pins or from internal

logic signals within the eX device. CLKA and CLKB may be

connected to sequential cells or to combinational logic. If

CLKA or CLKB is sourced from internal logic signals then

the external clock pin cannot be used for any other input

and must be tied low or high. Figure 5 describes the clock

circuit used for the constant load HCLK. Figure 6 describes

the CLKA and CLKB circuit used in eX devices.

Constant Load

Clock Network

HCLKBUF

Figure 5 • eX HCLK Clock Pad

Clock Network

From Internal Logic

CLKBUF

CLKBUFI

CLKINT

CLKINTI

Figure 6 • eX Routed Clock Buffer

Other Architectural Features

Technology

Actel’s eX family is implemented on a high-voltage twin-well

CMOS process using 0.22

µ design rules. The metal-to-metal

antifuse is made up of a combination of amorphous silicon

and dielectric material with barrier metals and has an “on”

state resistance of 25

Ω with a capacitance of 1.0 fF for low

signal impedance.

Performance

The combination of architectural features described above

enables eX devices to operate with internal clock

frequencies exceeding 350 MHz for very fast execution of

complex logic functions. Thus, the eX family is an optimal

platform upon which to integrate the functionality

previously contained in CPLDs. In addition, designs that

previously would have required a gate array to meet

performance goals can now be integrated into an eX device

with dramatic improvements in cost and time to market.

Using timing-driven place-and-route tools, designers can

achieve highly deterministic device performance.

I/O Modules

Each I/O on an eX device can be configured as an input, an

output, a tristate output, or a bidirectional pin. Even without

the inclusion of dedicated I/O registers, these I/Os, in

combination with array registers, can achieve clock-to-out

(pad-to-pad) timing as fast as 3.9ns. I/O cells that have

embedded latches and flip-flops require instantiation in HDL

code; this is a design complication not encountered in eX

FPGAs. Fast pin-to-pin timing ensures that the device will

have little trouble interfacing with any other device in the

system, which in turn enables parallel design of system

components and reduces overall design time. See Table 1 for

more information.

Table 1 • I/O Features

Function Description

Input Buffer

Threshold

Selection

Flexible

Output

Driver

Output

Buffer

Power Up Individually selectable pull ups and pull

Hot Swapping

• TTL/3.3V LVTTL

• 2.5V LVCMOS 2

• 3.3V LVTTL

• 5.0V TTL/CMOS

“Hot-Swap” Capability

• I/O on an unpowered device does not

sink current

• Can be used for “cold sparing”

Selectable on an individual I/O basis

Individually selectable low-slew option

downs during power up (default is to power

up in tristate)

Enables deterministic power up of device

V

CCA

and V

can be powered in any order

CCI

eX I/Os are configured to be hot swappable. During power

up/down (or partial up/down), all I/Os are tristated. V

and V

do not have to be stable during power up/down,

CCI

CCA

and they do not require a specific power-up or power-down

sequence in order to avoid damage to the eX devices. After

the eX device is plugged into an electrically active system,

the device will not degrade the reliability of or cause

damage to the host system. The device’s output pins are

driven to a high impedance state until normal chip

v3.0 5

eX Family FPGAs

operating conditions are reached. Please see the Actel SX-A

and RT54SX-S Devices in Hot-Swap and Cold-Sparing

Applications application note for more information on hot

swapping.

Power Requirements

The eX family supports mixed voltage operation and is

designed to tolerate 5.0V inputs in each case (Table 2).

Power consumption is extremely low due to the very short

distances signals, which are required to travel to complete a

circuit. Power requirements are further reduced because of

the small number of low-resistance antifuses in the path.

The antifuse architecture does not require active circuitry

to hold a charge (as do SRAM or EPROM), making it the

lowest-power architecture FPGA available today. Also, when

the device is in low power mode, the clock pins must not

float. They must be driven either HIGH or LOW. We

recommend that signals driving the clock pins be fixed at

HIGH or LOW rather than toggle to achieve maximum power

efficiency.

Table 2 • Supply Voltages

V

CCA

eX64

eX128

eX256

Low Power Mode

2.5V 2.5V 5.0V 2.5V

2.5V 3.3V 5.0V 3.3V

2.5V 5.0V 5.0V 5.0V

Maximum

V

CCI

Input

Tolerance

Maximum

Output

Drive

The new Actel eX family has been designed with a Low

Power Mode. This feature, activated with a special LP pin, is

particularly useful for battery-operated systems where

battery life is a primary concern. In this mode, the core of

the device is turned off and the device consumes minimal

power with low standby current. In addition, all input

buffers are turned off, and all outputs and bidirectional

buffers are tristated when the device enters this mode.

Since the core of the device is turned off, the states of the

registers are lost. The device must be re-initialized when

normal operating mode is achieved.

2.5V LP/Sleep Mode Specifications

Typical Conditions, V

Product Low Power Standby Current Units

eX64 100 µA

eX128 111 µA

eX256 134 µA

Boundary Scan Testing (BST)

CCA

, V

= 2.5V, TJ = 25° C

CCI

All eX devices are IEEE 1149.1 compliant. eX devices offer

superior diagnostic and testing capabilities by providing

Boundary Scan Testing (BST) and probing capabilities.

These functions are controlled through the special test pins

in conjunction with the program fuse. The functionality of

each pin is described in Table 3. In the dedicated test mode,

TCK, TDI, and TDO are dedicated pins and cannot be used

as regular I/Os. In flexible mode, TMS should be set HIGH

through a pull-up resistor of 10k

Ω. TMS can be pulled LOW

to initiate the test sequence.

Table 3 • Boundary Scan Pin Functionality

Program Fuse Blown

(Dedicated Test Mode)

TCK, TDI, TDO are

dedicated BST pins

No need for pull-up resistor

for TMS

Configuring Diagnostic Pins

Program Fuse Not Blown

(Flexible Mode)

TCK, TDI, TDO are flexible

and may be used as I/Os

Use a pull-up resistor of

10k

Ω on TMS

The JTAG and Probe pins (TDI, TCK, TMS, TDO, PRA, and

PRB) are placed in the desired mode by selecting the

appropriate check boxes in the “Variation” dialog window.

This dialog window is accessible through the Design Setup

Wizard under the Tools menu in Actel's Designer software.

TRST Pin

When the “Reserve JTAG Reset” box is checked, the TRST

pin will become a Boundary Scan Reset pin. In this mode,

the TRST pin will function as an asynchronous, active-low

input to initialize or reset the BST circuit. An internal

pull-up resistor will be automatically enabled on the TRST

pin.

The TRST pin will function as a user I/O when the “Reserve

JTAG Reset” box is not checked. The internal pull-up

resistor will be disabled in this mode.

Dedicated Test Mode

When the “Reserve JTAG” box is checked, the eX device is

placed in Dedicated Test mode, which configures the TDI,

TCK, and TDO pins for BST or in-circuit verification with

Silicon Explorer II. An internal pull-up resistor is

automatically enabled on both the TMS and TDI pins. In

Dedicated Test Mode, TCK, TDI, and TDO are dedicated test

pins and become unavailable for pin assignment in the Pin

Editor. The TMS pin will function as specified in the IEEE

1149.1 (JTAG) Specification.

Flexible Mode

When the “Reserve JTAG” box is not selected (default

setting in Designer software), eX is placed in Flexible mode,

which allows the TDI, TCK, and TDO pins to function as user

I/Os or BST pins. In this mode the internal pull-up resistors

on the TMS and TDI pins are disabled. An external 10k

pull-up resistor to V

is required on the TMS pin.

CCI

Ω

The TDI, TCK, and TDO pins are transformed from user I/Os

into BST pins when a rising edge on TCK is detected while

TMS is at logical low. Once the BST pins are in test mode

they will remain in BST mode until the internal BST state

6v3.0

eX Family FPGAs

machine reaches the “logic reset” state. At this point the

BST pins will be released and will function as regular I/O

pins. The “logic reset” state is reached five TCK cycles after

the TMS pin is set to logical HIGH.

The Program fuse determines whether the device is in

Dedicated Test or Flexible mode. The default (fuse not

programmed) is Flexible mode.

Development Tool Support

The eX devices are fully supported by Actel’s line of FPGA

development tools, including the Actel Designer Series suite

and Libero, the FPGA design tool suite. Designer Series,

Actel’s suite of FPGA development tools for PCs and

Workstations, includes the ACTgen Macro Builder, timing

driven place-and-route, timing analysis tools, and fuse file

generation. Libero is a design management environment

that integrates the needed design tools, streamlines the

design flow, manages all design and log files, and passes

necessary design data between tools. Libero includes

Synplify, ViewDraw, Actel’s Designer Series, ModelSim HDL

Simulator, WaveFormer Lite, and Actel Silicon Explorer.

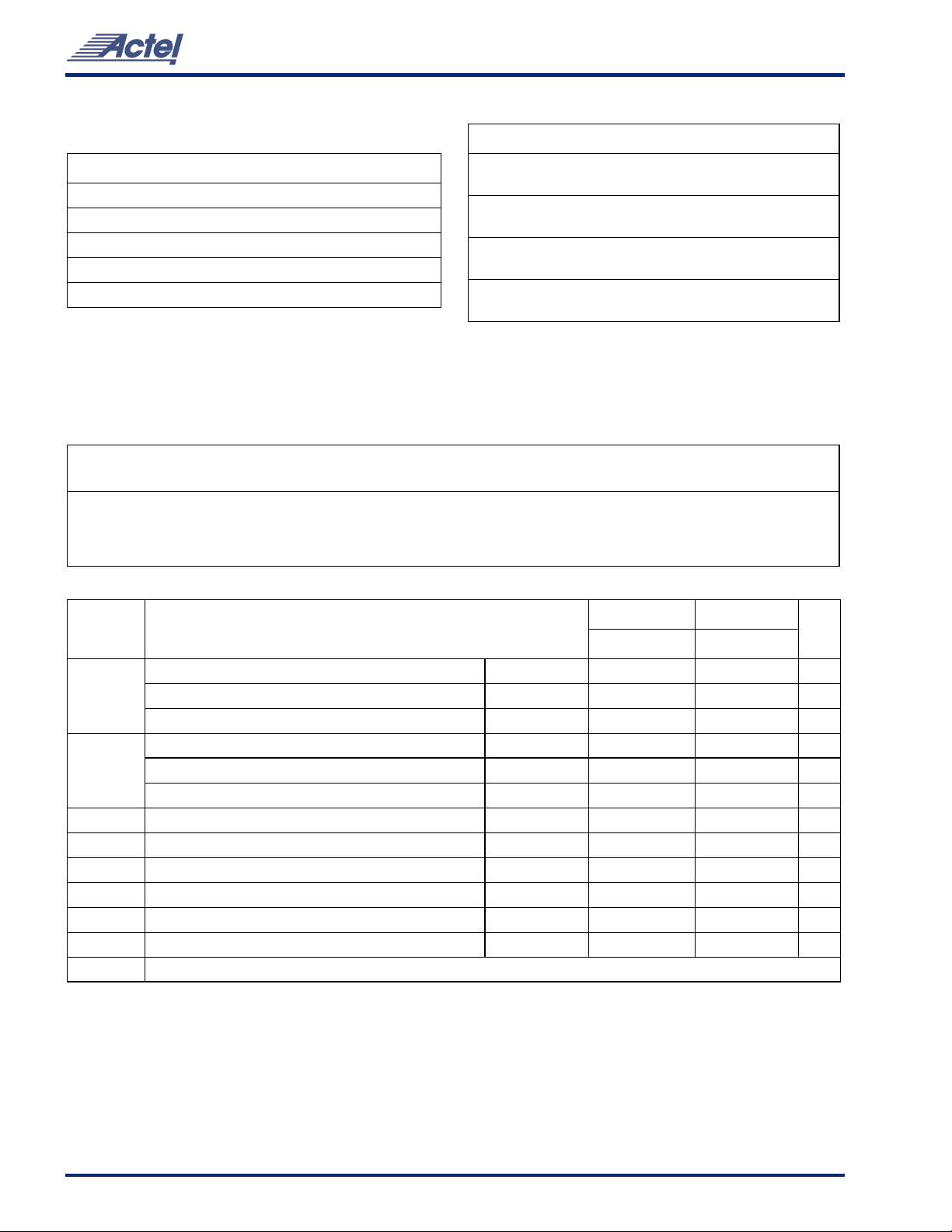

In addition, the eX devices contain internal probe circuitry

that provides built-in access to the output of every C-cell,

R-cell, and routed clock in the design, enabling 100-percent

real-time observation and analysis of a device's internal

logic nodes without design iteration. The probe circuitry is

accessed by Silicon Explorer II, an easy-to-use integrated

verification and logic analysis tool that can sample data at

100 MHz (asynchronous) or 66 MHz (synchronous). Silicon

Explorer II attaches to a PC’s standard COM port, turning

the PC into a fully functional 18-channel logic analyzer.

Silicon Explorer II allows designers to complete the design

verification process at their desks and reduces verification

time from several hours per cycle to only a few seconds.

eX Probe Circuit Control Pins

The Silicon Explorer II tool uses the boundary scan ports

(TDI, TCK, TMS and TDO) to select the desired nets for

verification. The selected internal nets are assigned to the

PRA/PRB pins for observation. Figure 7 illustrates the

interconnection between Silicon Explorer II and the FPGA

to perform in-circuit verification. The TRST pin is equipped

with an internal pull-up resistor. To remove the boundary

scan state machine from the reset state during probing, it is

recommended that the TRST pin be left floating.

Design Considerations

For prototyping, the TDI, TCK, TDO, PRA, and PRB pins

should not be used as input or bidirectional ports. Because

these pins are active during probing, critical signals input

through these pins are not available while probing. In

addition, the Security Fuse should not be programmed

because doing so disables the probe circuitry.

Figure 7 • Probe Setup

Serial Connection

16

Channels

eX FPGA

TDI

TCK

TMS

Silicon Explorer II

TDO

PRA

PRB

v3.0 7

eX Family FPGAs

2.5V/3.3V/5.0V Operating Conditions

Absolute Maximum Ratings

Symbol Parameter Limits Units

V

V

V

V

T

CCI

CCA

I

O

STG

DC Supply Voltage –0.3 to +6.0 V

DC Supply Voltage –0.3 to +3.0 V

Input Voltage –0.5 to +5.5 V

Output Voltage –0.5 to +V

Storage Temperature –65 to +150 °C

Note:

1. Stresses beyond those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device. Exposure

1

+ 0.5 V

CCI

Recommended Operating Conditions

Parameter Commercial Industrial Units

Temperature

1

Range

2.5V Power Supply

Range (V

CCA, VCCI

3.3V Power Supply

Range (V

CCI

)

5.0V Power Supply

Range (V

CCI

)

0 to +70 –40 to +85 °C

2.3-2.7 2.3-2.7 V

)

3.0-3.6 3.0-3.6 V

4.75-5.25 4.5-5.5 V

Note:

1. Ambient temperature (TA).

to absolute maximum rated conditions for extended periods

may affect device reliability. Devices should not be operated

outside the Recommended Operating Conditions.

Typical eX Standby Current at 25°C

V

Product

V

CCA

CCI

= 2.5V

= 2.5V

V

CCA =

V

CCI

= 3.3V

eX64 397µA 497µA

eX128 696µA 795µA

eX256 698µA 796µA

2.5V

2.5V Electrical Specifications

Commercial Industrial

Symbol

V

OH

V

OL

V

IL

V

IH

I

OZ

1,2

tR, t

F

C

IO

3,4

I

CC

Parameter Min. Max. Min. Max. Units

V

= MIN, VI = V

DD

V

= MIN, VI = V

DD

V

= MIN, VI = V

DD

V

= MIN, VI = V

DD

V

= MIN, VI = V

DD

V

= MIN,VI = V

DD

Input Low Voltage, V

Input High Voltage, V

3-St ate Ou tput Le akage C ur rent, V

Input Transition Time tR, t

IH

IH

IH

IH

IH

IH

or V

or V

or V

or V

or V

or V

OUT

OUT

IL

IL

IL

IL

IL

IL

≤ V

VOL(max)

≥ V

F

VOH(min)

OUT

(I

= -100 µA) 2.1 2.1 V

OH

(I

= -1 mA) 2.0 2.0 V

OH

(I

= -2 mA) 1.7 1.7 V

OH

(IOL= 100µA) 0.2 0.2 V

(IOL= 1mA) 0.4 0.4 V

(IOL= 2 mA) 0.7 0.7 V

-0.3 0.7 -0.3 0.7 V

1.7 V

= V

or GND –10 10 –10 10 µA

CCI

I/O Capacitance 10 10 pF

Standby Current 1.0 3.0 mA

IV Curve5Can be derived from the IBIS model at www.actel.com/custsup/models/ibis.html.

Notes:

1. tR is the transition time from 0.7 V to 1.7V.

2. tF is the transition time from 1.7V to 0.7V.

3. ICC max Commercial –F = 5.0mA

4. ICC=I

CCI

+ I

CCA

+ 0.3 1.7 V

DD

+ 0.3 V

DD

10 10 ns

8v3.0

eX Family FPGAs

3.3V Electrical Specifications

Commercial Industrial

Symbol Parameter

V

= MIN, VI = V

V

OH

V

OL

V

IL

V

IH

IIL/ I

I

OZ

tR, t

C

IO

I

CC

IH

F

3,4

DD

V

= MIN, VI = V

DD

V

= MIN, VI = V

DD

V

= MIN, VI = V

DD

Input Low Voltage 0.8 0.8 V

Input High Voltage 2.0 2.0 V

Input Leakage Current, VIN = V

3-State Output Leakage Current, V

1,2

Input Transition Time tR, t

I/O Capacitance 10 10 pF

Standby Current 1.5 10 mA

IH

IH

IH

IH

or V

or V

or V

or V

(I

IL

IL

IL

IL

or GND –10 10 –10 10 µA

CCI

= V

OUT

F

or GND –10 10 –10 10 µA

CCI

= -1mA) 0. 9 V

OH

(I

= -8mA) 2.4 2.4 V

OH

(IOL= 1mA) 0.1 V

(IOL= 12mA) 0.4 0.4 V

Min. Max. Min. Max. Units

CCI

IV Curve5Can be derived from the IBIS model at www.actel.com/custsup/models/ibis.html.

Notes:

1. tR is the transition time from 0.8 V to 2.0V.

2. tF is the transition time from 2.0V to 0.8V.

3. ICC max Commercial –F=5.0mA

4. ICC=I

CCI

+ I

CCA

5.0V Electrical Specifications

Commercial Industrial

0.9 V

CCI

CCI

0.1 V

CCI

10 10 ns

V

V

Symbol Parameter

V

= MIN, VI = V

V

OH

V

OL

V

IL

V

IH

IIL/ I

I

OZ

tR, t

C

IO

I

CC

IH

F

3,4

DD

V

= MIN, VI = V

DD

V

= MIN, VI = V

DD

V

= MIN, VI = V

DD

Input Low Voltage 0.8 0.8 V

Input High Voltage 2.0 2.0 V

Input Leakage Current, VIN = V

3-State Output Leakage Current, V

1,2

Input Transition Time tR, t

I/O Capacitance 10 10 pF

Standby Current 15 20 mA

IH

IH

IH

IH

or V

or V

or V

or V

(I

IL

IL

IL

IL

or GND –10 10 –10 10 µA

CCI

= V

OUT

F

or GND –10 10 –10 10 µA

CCI

= -1mA) 0. 9 V

OH

(I

= -8mA) 2.4 2.4 V

OH

(IOL= 1mA) 0.1 V

(IOL= 12mA) 0.4 0.4 V

Min. Max. Min. Max. Units

CCI

IV Curve5Can be derived from the IBIS model at www.actel.com/custsup/models/ibis.html

Notes:

1. tR is the transition time from 0.8 V to 2.0V.

2. tF is the transition time from 2.0V to 0.8V.

3. ICC max Commercial –F=20mA

4. ICC=I

CCI

+ I

CCA

0.9 V

CCI

CCI

0.1 V

CCI

10 10 ns

V

V

v3.0 9

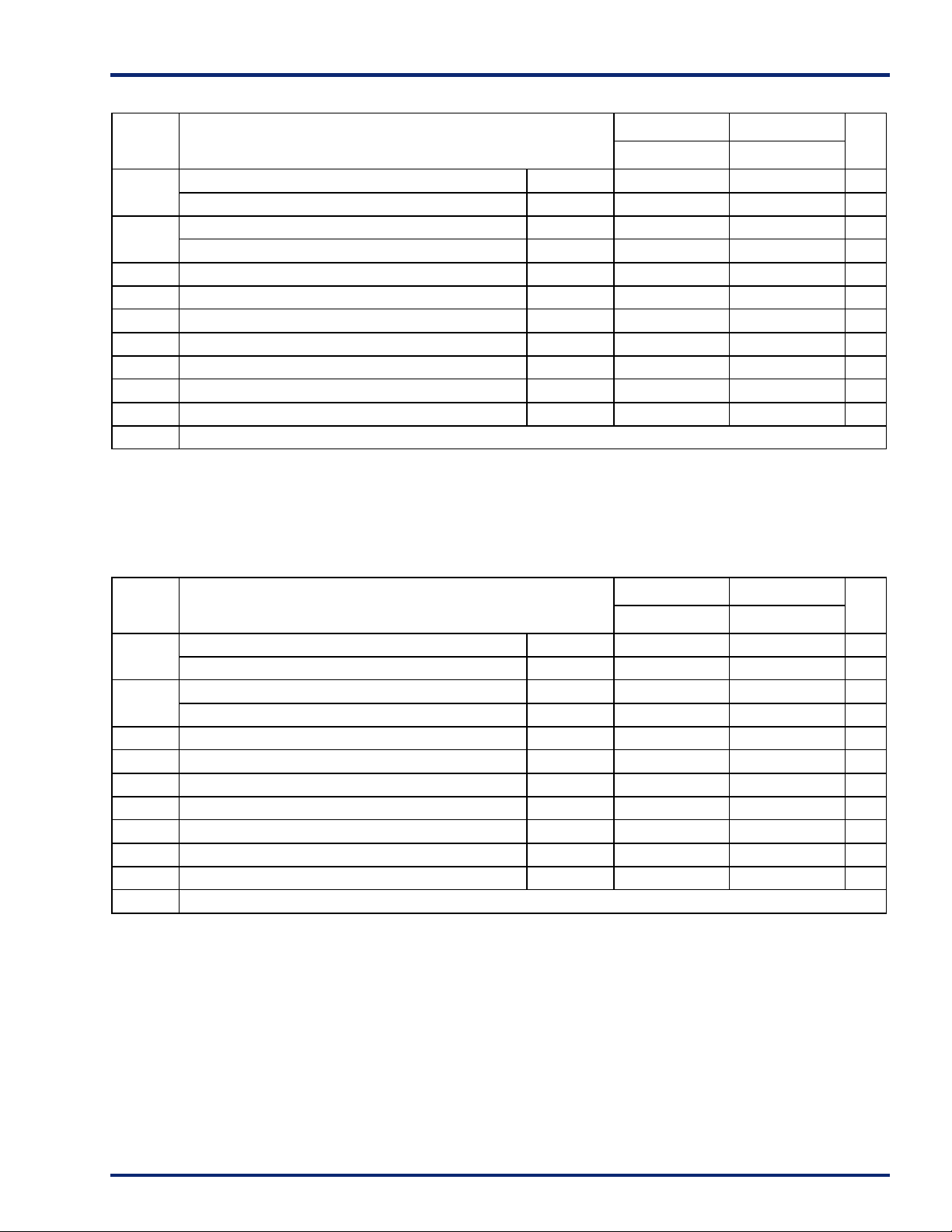

eX Dynamic Power Consumption – High Frequency

300

250

200

150

100

Power (mW)

50

0

50 100 150 200

Frequency (MHz)

Notes:

1. Device filled with 16-bit counters.

2. V

CCA

, V

= 2.7V, device tested at room temperature.

CCI

eX Dynamic Power Consumption – Low Frequency

eX Family FPGAs

eX 64

eX 128

eX 256

Notes:

1. Device filled with 16-bit counters.

2. V

CCA

, V

= 2.7V, device tested at room temperature.

CCI

80

70

60

50

40

30

Power (mW)

20

10

0

0 1020304050

Frequency (MH z)

eX64

eX128

eX256

10 v3.0

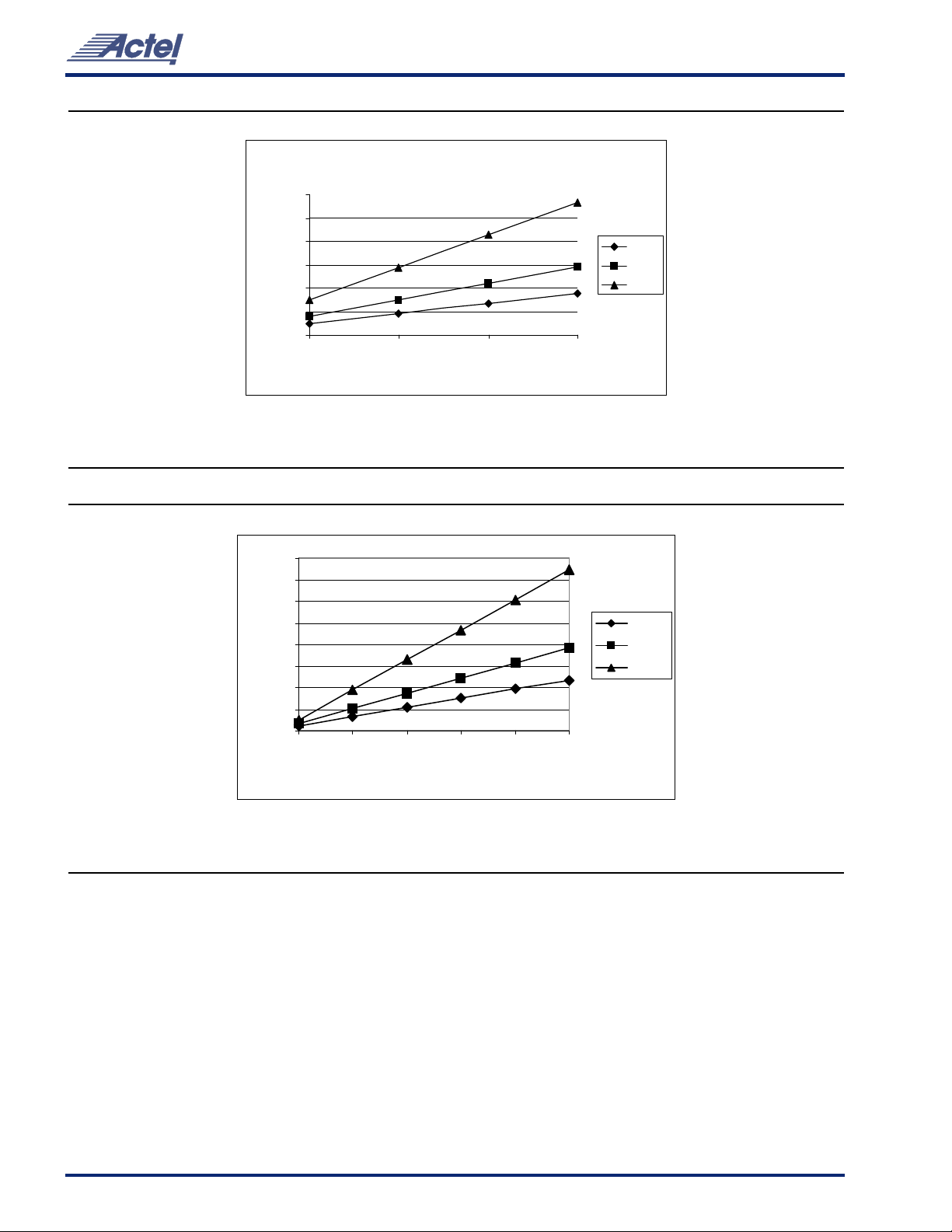

eX Family FPGAs

Total Dynamic Power (mW)

180

160

140

120

100

80

60

40

Total Dynamic Power (mW)

20

0

0 25 50 75 100 125 150 175 200

Freque nc y (MHz)

System Power at 5%, 10%, and 15% Duty Cycle

12,000

10,000

32-bit Dec ode r

8 x 8-bi t Count e rs

SDRAM Controller

8,000

6,000

4,000

System Power (uW)

2,000

0

5% DC

10% DC

15% DC

0 102030405060

Freque ncy ( M Hz)

v3.0 11

Junction Temperature (TJ)

The temperature variable in the Designer Series software

refers to the junction temperature, not the ambient

temperature. This is an important distinction because the

heat generated from dynamic power consumption is usually

hotter than the ambient temperature. Equation 1, shown

below, can be used to calculate junction temperature.

Junction Temperature =

∆T + T

a

(1)

Where:

= Ambient Temperature

T

a

∆T = Temperature gradient between junction (silicon) and

ambient

∆T = θ

ja

* P

P = Power

eX Family FPGAs

θ

= Junction to ambient of package. θja numbers are

ja

located in the Package Thermal Characteristics section

below.

Package Thermal Characteristics

The device junction to case thermal characteristic is θjc,

θ

and the junction to ambient air characteristic is

thermal characteristics for

θ

are shown with two different

ja

. The

ja

air flow rates.

The maximum junction temperature is 150

°C.

A sample calculation of the absolute maximum power

dissipation allowed for a TQFP 100-pin package at

commercial temperature and still air is as follows:

Max. junction temp. (°C) Max. ambient temp. (°C)–

Maximum Power Allowed

Package Type Pin Count θ

Thin Quad Flat Pack (TQFP) 64 14 51.2 35 °C/W

Thin Quad Flat Pack (TQFP) 100 12 37.5 30 °C/W

Chip Scale Package (CSP) 49 3 71.3 56.0 °C/W

Chip Scale Package (CSP) 128 3 54.1 47.8 °C/W

Chip Scale Package (CSP) 180 3 57.8 51 °C/W

---------------------------------------------------------------------------------------------------------------------------------

θ

ja

(° C/W)

jc

150° C70°C–

-----------------------------------

37.5°C/W

θ

ja

Still Air

2.1W===

θ

ja

300 ft/min Units

12 v3.0

Loading...

Loading...