ACT CT1999-FP, CT1999 Datasheet

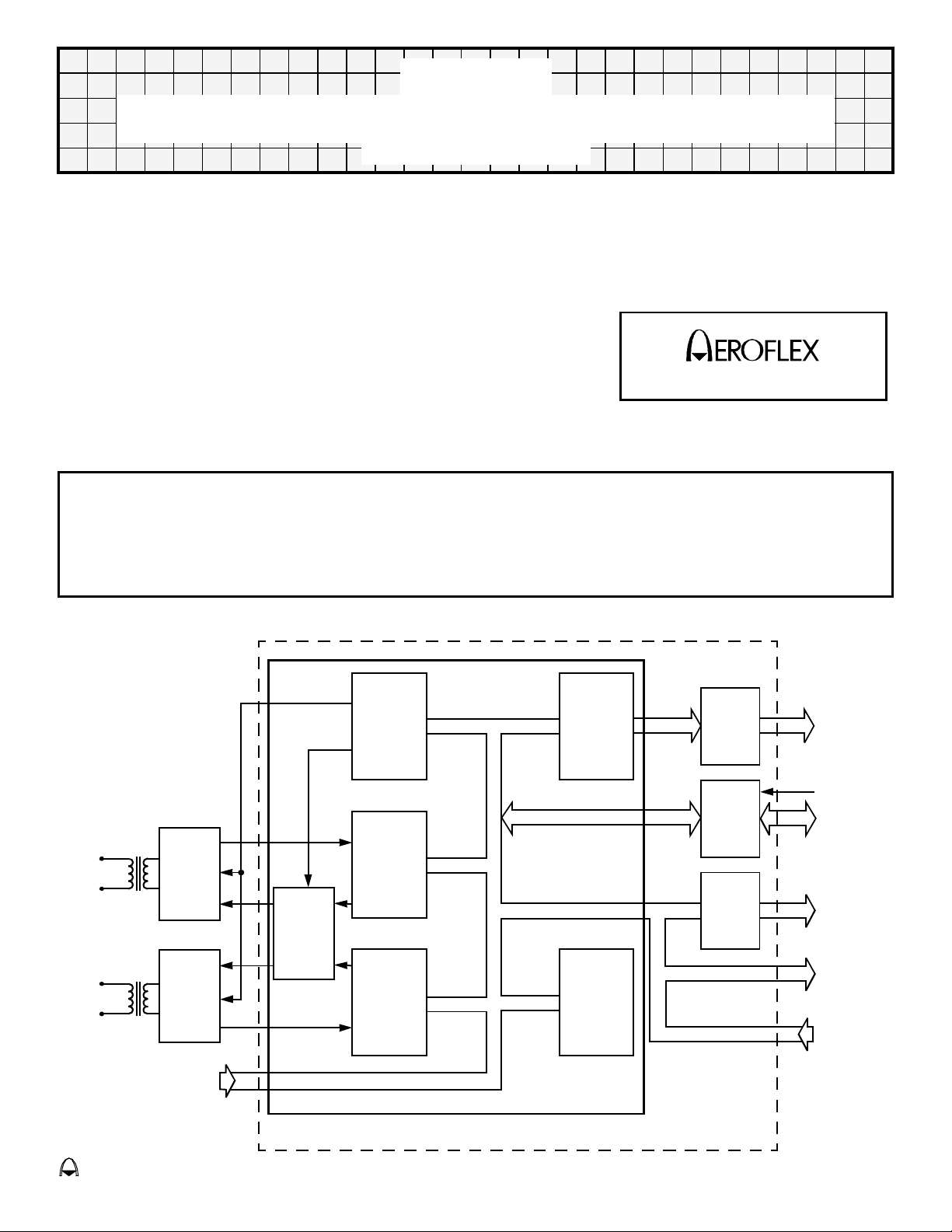

CT1999

Remote Terminal and/or Bus Controller

for MIL-STD-1553B

Features

• Performs the Complete Dual-Redundant Remote Terminal and Bus Controller Protocol

Functions of MIL-STD-1553B

• Automatic Switchover to Superseding Input Commands

• MIL-PRF-38534 Compliant Circuits Available

• 750 mw Typical Power Consumption

• Small Size

• Available in Plug-in or Flatpack Configuration

• Compatible with all ACT Driver/Receiver Units

• 5V DC Operation

• Direct replacement for CT1602

• Full Military (-55°C to +125°C) Temperature Range

General Description

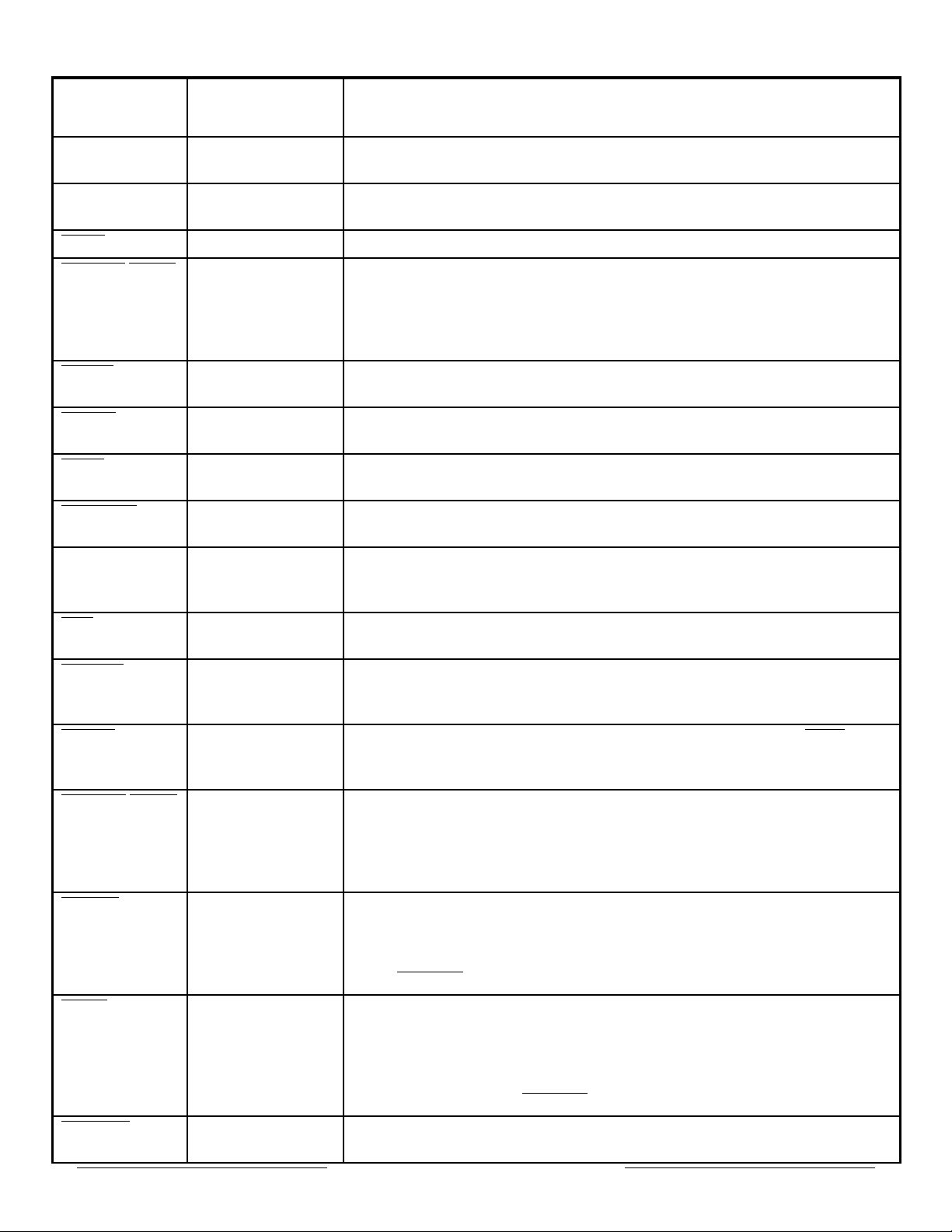

The CT1999 design incorporates ASIC and five Octal Buffers that accomplish the dual redundant

MIL-STD1553B Remote Terminal and/or Bus Controller Protocol Functions. Buffering has been added to the

most commonly used output signals on the CT1999, minimizing external hardware requirements. The CT1999

connects directly to all ACT Driver/Receiver Units.

CIRCUIT TECHNOLOGY

www.aeroflex.com

BUS "0"

BUS "1"

T/R

Hybrid

T/R

Hybrid

Term ina l

Address

Inputs

Block Diagram (With Transformer)

Encoder

Decoder

"O"

Driver

Select

&

Enable

Decoder

"1"

Interface

Unit

Internal

Highway

Control

ASIC

SA & WC

Buffers

Internal

Highway

Buffer

Discrete

Output

Buffers

Sub Address

&

Word Count

Outputs

Control

Data I/O

Buffered

Descrete

Outpu ts

Unbuffered

Outputs

Control

Inputs

eroflex Circuit T

echnology

CT1999

– Data Bus Modules For The Future SCDCT1999 REV B 8/14/01

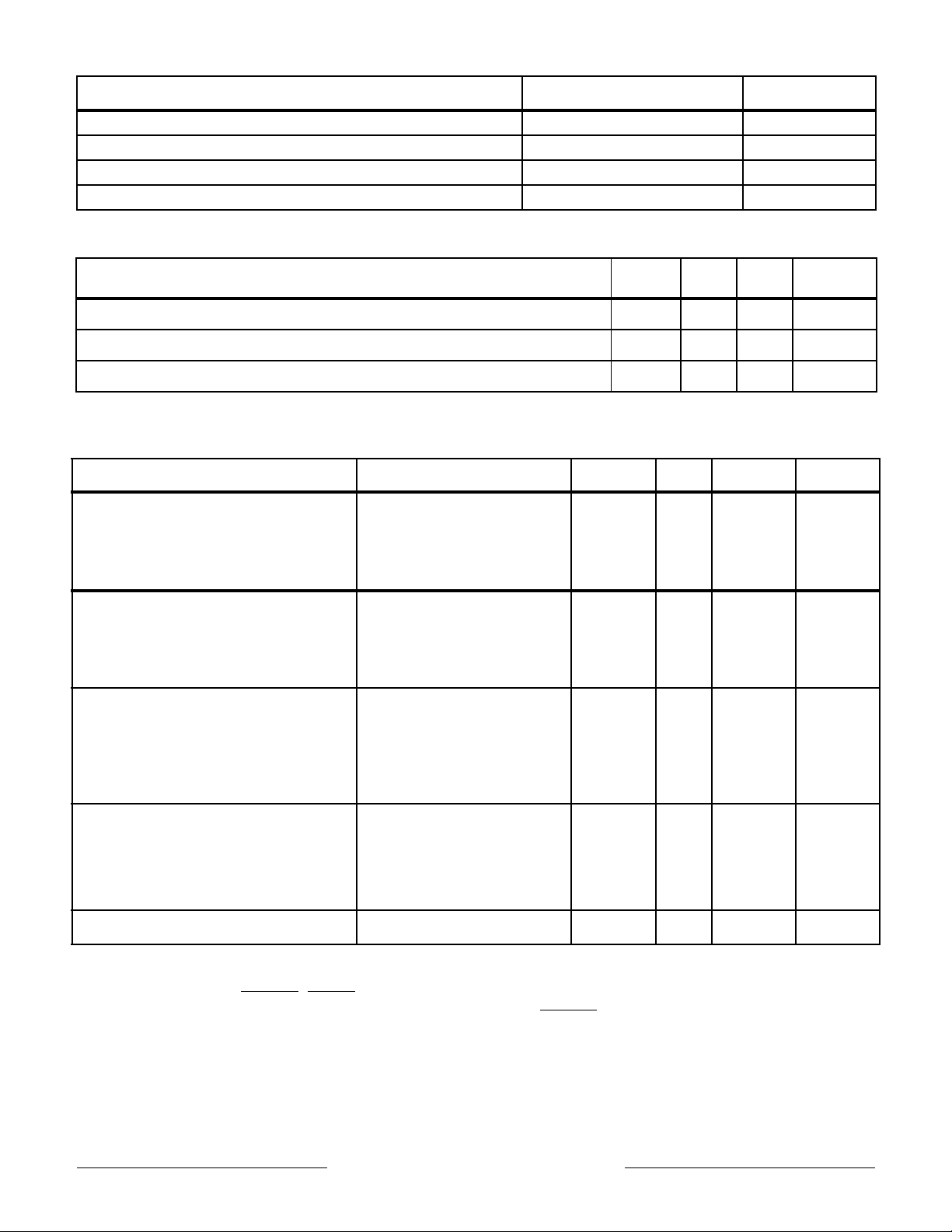

Absolute Maximum Ratings

Parameter Range Units

Operating Free-air Temperature -55°C to +125 °C

Storage Case Temperature -65°C to +150 °C

Power Supply Voltage V

CC

Input Voltage +7 Volts

+7 Volts

Recommended Operating Conditions

Parameter Min Typ Max Unit

VCC Power Supply Voltage V

V

High Level Input Voltage, Vcc = 5V

IH

Low Level Input Voltage, Vcc = 5V

V

IL

CC

4.5

2.2

5.0 5.5

0.7 V

V

V

Electrical Characteristics

(TA = -55°C to +125°C)

Parameter Test Conditions Min Max Unit Notes

= -400µA

= -800µA

= 4.5V

CC

= +4

= +2

= 4.5V

CC

mA

mA

mA

mA

V

High Level Output Voltage IOH = -3

OH

I

OH

I

OH

V

Low Level Output Voltage IOL = +12

V

OL

I

OL

I

OL

V

High Level Input Current VCC = 5.5V, VIH = 2.4V

I

IH

2.4

2.4

2.4

-700

-20

-700

-400

0.4

0.4

0.4

-200

20

-200

-25

V

V

V

V

V

V

µA

µA

µA

µA

2B,5

6

7

2B,5

6

7

1

2A,2B

3

4

Low Level Input Current

I

IL

Supply Current

I

CC

= 5.5V, VIL = 0.4V

V

CC

V

= 5.5V

CC

-900

-200

-900

-500

-350

0

-350

-25

µA

µA

µA

µA

285 mA

1

2A,2B

3

4

Notes (Pin numbers are for 90 pin Plug in package):

1. Pins 45 through 50 (RTADPAR,RTAD0,1,2,3,4). 2A. Pin 34 (IHDIR). 2B. Pins 37 through 44 (IH08 through

IH715). 3. Pins 24,36 (BUFINH

Buffered Outputs). 6. Pins 68,69,70,71 (TXINH0,TXINH1,TXDATA,TXDATA

, IHENA). 4. ALL remaining inputs ALL versions. 5. Pins 2 through 23 (Remaining

). 7. All remaining outputs.

Clock Requirements

Frequency

Stability (-55°C to +125°C)

Maximum Asymmetry

Rise/Fall Time

Aeroflex Circuit Technology SCDCT1999 REV B 8/14/01 Plainview NY (516) 694-6700

6MHz

±0.01%

48 - 52%

10ns MAX

2

REMOTE TERMINAL OPERATION

Receive Data Operation

All valid data words associated with a valid receive data command word for the RT are passed to the subsystem. The

RT examines all command words from the bus and will respond to valid (i.e. correct Manchester, parity coding etc.)

commands which have the correct RT address (or broadcast address if the RT broadcast option is enabled). When the

data words are received, they are decoded and checked by the RT and, if valid, passed to the subsystem on a word by

word basis at 20 µs intervals. This applies to receive data words in both Bus Controller to RT and RT to RT messages.

When the RT detects that the message has finished, it checks that the correct number of words have been received

and if the message is fully valid, then a Good Block Received signal is sent to the subsystem, which must be used by

the subsystem as permission to use the data just received.

The subsystem must therefore have a temporary buffer store up to 32 words long into which these data words can be

placed. The Good Block Received signal will allow use of the buffer store data once the message has been validated.

If a block of data is not validated, then Good Block Received will not be generated. This may be caused by any sort of

message error or by a new valid command for the RT being received on another bus to which the RT must switch.

Transmit Data Operation

If the RT receives a valid transmit data command addressed to the RT, then the RT will request the data words from the

subsystem for transmission on a word by word basis. To allow maximum time for the subsystem to collect each data

word, the next word is requested by the RT as soon as the transmission of the current word has commenced.

It is essential that the subsystem should provide all the data words requested by the RT once a transmit sequence has

been accepted. Failure to do so will be classed by the RT as a subsystem failure and reported as such to the Bus

Controller.

Control of Data Transfers

This section describes the detailed operation of the data transfer mechanism between RT and subsystems. It covers

the operations of the signals DTRQ

transfers.

Figure 7 shows the operation of the data handshaking signals during a receive command with two data words. When

the RT has fully checked the command word, NBGT

initialization signal. TX/RX

validated, DTRQ

indicates to the RT that the subsystem is ready to accept data The data word is then passed to the subsystem on the

internal highway IH08-IH715 in two bytes using IUSTB as a strobe signal and H/L as the byte indicator (high byte first

followed by low byte). Data is valid about both edges of IUSTB. Signal timing for this handshaking is shown in Figure

12.

If the subsystem does not declare itself busy, then it must respond to DTRQ

approximately 1.5 us. Failure to do so will be classed by the RT as a subsystem failure and reported as such to the Bus

Controller.

It should be noted that IUSTB is also used for internal working in the RT. DTRQ

for clocking data to the subsystem with IUSTB.

Once the receive data block has finished and been checked by the RT, GBR

and valid. This is used by the subsystem as permission to make use of the data block If no GBR signal is generated,

then an error has been detected by the RT and the entire data block is invalid and no data words in it may be used.

If the RT is receiving data in an RT to RT transfer, the data handshaking signals will operate in an identical fashion but

there will be a delay of approx 70 µs between NBGT

Figure 6 shows the operation of the data handshaking signals during transmit command with three, data words. As with

the receive command discussed previously, NBGT

set high indicating a transmit data command. While the RT is transmitting its status word, it requests the first data word

from the subsystem by setting DTRQ

DTAK

low. By setting DTAK low, the subsystem is indicating that it has the data word ready to pass to the RT. Once

DTAK

is set low by the subsystem, DTRQ should be used together with H/L and TX/RX to enable first the high byte and

then the low byte of the data word onto the internal highway IH08-IH715. The RT will latch the data bytes during IUSTB,

and will then return DTRQ

this handshaking is shown in Figure 11.

is set low. The subsystem must then reply within approximately 1.5 µs by setting DTAK low. This

will be set low indicating a receive command. When the first data word has been fully

high. Data for each byte must remain stable until IUSTB has returned low. Signal timing for

, DTAK, IUSTB, H/L, GBR, NBGT, TX/RX during receive data and transmit data

is pulsed low, which can be used by the subsystem as an

going low by setting DTAK low within

being low should be used as an enable

is pulsed low if the block is entirely correct

going low and DTRQ first going low. See Figure 10.

is pulsed low if the command is valid and for the RT. TX/RX will be

low. The subsystem must then reply within approximately 13.5 µs by setting

Aeroflex Circuit Technology SCDCT1999 REV B 8/14/01 Plainview NY (516) 694-6700

3

Additional Data Information Signals

At the same time as data transfers take place, a number of information signals are made available to the subsystem.

These are INCMD

Use of these signals is optional.

INCMD

and word count from the command word are all ma a vailable to the subsystem as SA0-4, TX/RX and WC0-4

respectively. They may be sampled when INCMD

The subaddress is intended to be used by the subsystem as an address pointer for the data block Subaddress 0 and

31 are mode commands, and there can be no receive or transmit data blocks associated with these. (Any data word

associated with a mode command uses different handshaking operations. If the subsystem does not use all the

subaddresses available, then some of the subaddress lines may be ignored.

The TX/RX

the previous section.

The word count tells the subsystem the number of words to expect to receive or transmit in a message, up to 32 words.

A word count of all 0s indicates a count of 32 words.

The current word count is set to 0 at the beginning of a new message and is incremented following each data word

transfer across the RT - subsystem interface. (It is clocked on the falling edge of the second IUSTB pulse in each word

transfer). It should be noted that there is no need for the subsystem to compare the word count and current word count

to validate the number of words in a message. This is done by the RT.

will go active low while the RT is servicing a valid command for the RT. The subaddress, transmit/receive bit.

signal indicates the direction of data transfer across the RT - subsystem interface. Its use is described in

, the subaddress lines SA0-4, the word count lines WC0-4 and current word count lines CWC0-4.

goes low and will remain valid while INCMD is low.

Subsystem Use of Status Bits and Mode Commands

General Description

Use of the status bits and the mode commands is one of the most confusing aspects of MIL-STD-1553B. This is

because much of their use is optional, and also because some involve only the RT while others involve both the RT and

the subsystem.

The CT1999 allows full use to be made of all the status bits, and also implements all the mode commands. The

subsystem is given the opportunity to make use of status bits, and is only involved in mode commands which have a

direct impact on the subsystem.

The mode commands in which the subsystem may be involved are Synchronize, Sychronize with data word, Transmit

Vector Word, Reset and Dynamic Bus Control Allocation. The status bits to which the subsystem has access are

Service Request, Busy, Subsystem Flag and Dynamic Bus Control Acceptance. Operation of each of these mode

commands and of the status bits is described in the following sections.

The subsystem designer should note that all other mode commands and status bits are serviced internally by the RT,

and the subsystem has no access to them. In particular, the terminal flag and message error status bits and BIT word

contents are all controlled internally by the RT.

Synchronize Mode Commands

Once the RT has validated the command word and checked for the correct address, the SYNC line is set low. The

signal WC4 will be set low for a Synchronize mode command Figure 16, and high for a Synchronize with data word

mode command Figure 15. In a Synchronize with data word mode command, SYNC

the data word is received. Once the data word has been validated, it is passed to the subsystem on the internal

highway IH08-IH715 in two bytes using IUSTB as a strobe signal and H/L as the byte indicator (high byte first followed

by low byte). SYNC

subsystem.

If the subsystem does not need to implement either of these mode commands, the SYNC

the RT requires no response from the subsystem.

being low should be used on the enable to allow IUSTB to clock synchronize mode data to the

remains low during the time that

signal can be ignored, since

Transmit Vector Word Mode Command

Figure 14 illustrates the relevant signal timings for an RT receiving a valid Transmit Vector Word mode command. The

RT requests data by setting VECTEN

byte of the Vector word onto the internal highway IH08-IH715.

It should be noted that the RT expects the Vector word contents to be already prepared in a latch ready for enabling

onto the internal highway when VECTEN

Aeroflex Circuit Technology SCDCT1999 REV B 8/14/01 Plainview NY (516) 694-6700

low. The subsystem should use H/L to enable first the high byte and then the low

goes low. If the subsystem has not been designed to handle the Vector word

4

mode command, it will be the fault of the Bus Controller if the RT receives such a command. Since the subsystem is

not required to acknowledge the mode command, the RT will not be affected in any way by Vector word circuitry not

being implemented in the subsystem. It will however transmit a data word as the Vector word, but this word will have

no meaning.

Reset Mode Command

Figure 8 shows the relevant signal timings for an RT receiving a valid reset mode command. Once the command

word has been fully validated and serviced, the RESET

function for subsystem interface circuitry.

signal is pulsed low. This signal may be used as a reset

Dynamic Bus Allocation

This mode command is intended for use with a terminal which has the capability of configuring itself into a bus

controller on command from the bus. The line DBCREQ

of the valid command, i.e. tied low. For terminals acting only as RTs, the signal DBCACC

(inactive), and the signal DBCREQ

should be ignored and left unconnected.

cannot go true unless the DBCACC line was true at the time

should be tied high

Use of the Busy Status Bit

The Busy Bit is used by the subsystem to indicate that it is not ready to handle data transfers either to or from the RT.

The RT sets the bit to logic one if the BUSY

edge of INCLK after INCMD

and transmit data word transfers to and from the subsystem. The data transfers in the Synchronize with data word

and Transmit Vector word mode commands are not affected by the Busy bit and will take place even if it has been set.

It should be noted that a minimum of 0.5 µs subaddress decoding time is given to the subsystem before sending of

status bits. This allows the subsystem to selectively set the Busy bit if for instance one subaddress is busy but others

are ready. This option will prove useful when an RT is interfacing with multiple subsystems.

goes low. This is shown in Figure 13. Once the Busy bit is set, the RT will stop all receive

line from the subsystem is active low at the time of the second falling

Use of the Service Request Status Bit

The Service Request bit is used by the subsystem to indicate to the Bus Controller that an asynchronous service is

requested.

The timing of the setting of this bit is the same as the Busy bit and is shown in Figure 13. Use of SERVREQ

effect on the RT apart from sening the Service Request bit.

It should be noted that certain mode commands require that the last status word be transmitted by the RT instead of

the current one, and therefore a currently set status bit will not be seen by the Bus Controller. Therefore the user is

advised to hold SERVREQ

low until the requested service takes place.

has no

Use of the Subsystem Status Bit

This status bit is used by the RT to indicate a subsystem fault condition. If the subsystem sets SSERR low at any

time, the subsystem fault condition in the RT will be set, and the Subsystem Flag status bit will subsequently be set

The fault condition will also be set if a handshaking failure takes place during a data transfer to or from the

subsystem. The fault condition is cleared on power-up or by a Reset mode command.

Dynamic Bus Control Acceptance Status Bit

DBCACC, when set true, enables an RT to configure itself into a Bus Controller, if the subsystem has the capability,

by allowing DBCREQ

required then DBCACC

response.

to pulse true and BIT TIME 18 to be set in the status response. If Dynamic Bus Control is not

must be tied high. DBCACC tied high inhibits DBCREQ and clears BIT TIME 18 in the status

Bus Driver/Receiver Interface

Receive Data

The decoder chip requires two TTL signals (PDIN & NDIN) to represent the data coming in from the bus. PDIN should

be driven to a logic level ‘1’ when the bus waveform exceeds a specified positive threshold and NDIN should be

driven to a logic level ‘1’ when a specified negative threshold is exceeded. During the quiet period on the bus both

signals should be at the same logic level. All the bus receivers must be permanently enabled, the selection if the bus

in use is done within the ASIC.

Aeroflex Circuit Technology SCDCT1999 REV B 8/14/01 Plainview NY (516) 694-6700

5

Transmit Data

The signals generated by the encoder chip (PDOUT & NDOUT) are of the same format as the receive data The only

difference is that the TTL signals are negative logic, e.g. the signal is active when on logic level "0". This means that

when the encoder is quiet both PDOUT

with TXEN

should be transmitting, and the driver enable routes the data on to the bus in use.

Figure 5 shows an example of a typical interface circuit between the CT1999 and a driver/receiver unit.

and the appropriate driver enable, e.g. (CS0 - enable for bus 0). TXEN only enables the driver when it

& NDOUT are at logic level ‘1’. Both the signals should be used in conjunction

BUS CONTROL OPERATION

To enable its use in a bus controller each chip in the chipset has additional logic within it. This logic can be enabled by

pulling the pin labelled RT/BC

bus control processor correctly commanding the chipset via the subsystem interface. In bus control mode six inputs are

activated which in RT mode are inoperative and four signals with dual functions exercise the second function (the first

being for the RT operation).

To use the CT1999 as a 1553B bus control interface, the bus control processor must be able to carry out four basic

bus-related functions. Two inputs, BCOPA and BCOPB allow these four options to be selected. The option is then

initiated by sending a negative-going strobe on the BCOPSTB input. BCOPSTB

is high. This is particularly important when two options are required during a single transfer.

With these options all message types and lengths can be handled. Normal BC/RT exchanges are carried out in the

chipset option zero. This is selected by setting BCOPA and BCOPB to a zero and strobing BCOPSTB

strobe, the CT1999 loads the command word from an external latch using CWEN and H/L The command word is

transmitted down the bus. The TX/RX

command is sent to a RT, Figure 17, the chipset in BC mode believes it has been given a receive command. As the RT

returns the requested number of data words plus its status, the BC chipset carries out a full validation check and

passes the data into the subsystem using DTRQ

GBR

at the end of a valid transmission. Conversely, a receive command sent down the bus is interpreted by the BC

chipset as a transmit command, and so the requisite data words are added to the command word, see Figure 18.

For mode commands, where a single command word is required, option one is selected by strobing BCOPSTB

BCOPA is high and BCOPB is low. On receiving the strobe, the command word is loaded from the external latch using

CWEN

followed by a data word requires option two. Option two, selected by strobing BCOPSTB

BCOPB is high, loads a data word via DWEN

21. If the mode code transmitted required the RT to return a data word, then selecting option three by strobing

BCOPSTB

subsystem interface using RMDSTB and H/L

differently from ordinary data words and routed accordingly, see Figure 22. All received status words are output to the

subsystem interface using STATSTB and H/L

In BC option three, if the signal PASMON

subsystem using STATSTB for command and status words or RMDSTB for data words.

RT to RT transfers require the transmission of two command words. A receive command to one RT is contiguously

followed by a transmit command to the the other RT. This can be achieved by selecting option one followed by option

zero for the second command. The strobe (BCOPSTB

returned high following the strobe for option one. The RT transmissions are checked and transferred in the subsystem

interface to the bus control processor, see Figure 19.

Note: For all BC operations, BCOPA and BCOPB must remain valid and stable for a minimum of 1 µs following the

leading (negative going) edge of BCOPSTB

and H/L, the correct sync and parity bits are added and the word transmitted, see Figure 20. Mode commands

when BCOPA and BCOPB are both high will identify that data word and if validated, output it to the

low. Once the chipset is in bus control mode, all data transfers must be initiated by the

must only be strobed low when NDRQ

. On receipt of the

bit is, however, considered by the chipset as being its inverse and so if a transmit

, DTAK, H/L, IUSTB and CWC as in RT operation. It also supplies

when

while BCOPA is low and

and H/L, adds sync and parity and transmits them to the bus, see Figure

This allows data words resulting from mode codes to be identified

.

is active, then all data appearing on the selected bus is output to the

) for option zero must be delayed until NDRQ has gone low and

.

Aeroflex Circuit Technology SCDCT1999 REV B 8/14/01 Plainview NY (516) 694-6700

6

Pin Description

Signal

RX DATA 0/1 SINK Positive Date In. This should be a TTL description of the positive, half of the

RX DATA

TX INHIBIT 0/1 SOURCE Transmitter Enable. Goes low when the transmitter is transmitting. Should be

TX DATA SOURCE Positive Data Out - When this signal goes high the bus should be driven

TX DATA

RTAD 0-4 SINK RT address lines - These should be hardwired by the user. RTAD4 is the most

RTADPAR SINK RT address parity line - This must be hardwired by the user to give odd parity.

BCSTEN 0/1 SINK Recognition of Broadcast command enable - When low the recognition of

6MCK SINK 6 Megahertz master clock.

0/1 SINK Negative Data In. This should be a TTL description of the negative half of the

Hybrid

Sink or Source

Manchester code data on the bus. It should be driven to a logic level “1” when

a predetermined positive threshold is exceeded on the bus.

Manchester code data on the bus. It should be driven to a logic level “1” when

a predetermined negative threshold is exceeded on the bus.

used to enable the bus drivers.

positive.

SOURCE Negative Data Out - When this signal goes high the bus should be driven

negative.

significant bit.

broadcast command is prevented on the specified bus.

Signal Description

IH 08

IH 19

IH 210

IH 311

IH 412

IH 513

IH614

IH715

DTRQ

DTAK

IUSTB SOURCE Interface Unit Strobe - This is a double pulse strobe used to transfer the two

H/L

GBR

NBGT

TX/RX

SINK/SOURCE Internal Highway - Bi-directional 8 bit highway on which 16 bit words are

passed in two bytes. IH 715 is the most significant bit of each byte, the most

significant byte being transferred first. The highway should only be driven by

the subsystem when data is to be transferred to the RT.

SOURCE Data Transfer Request - Goes low to request a data transfer between the

ASIC and subsystem. Goes high at the end of the transfer.

SINK Data Transfer Acknowledge - Goes low to indicate that the subsystem is

ready for the data transfer.

bytes of data

SOURCE High/Low - Indicates which byte of data is on the internal highway. Logic level

"0" for least significant byte.

SOURCE Good Block Received - Pulses low for 500ns when a block of data has been

received by the ASIC and has passed all the validity and error checks.

SOURCE New Bus Grant - Pulses low whenever a new command is accepted by the

ASIC.

SOURCE Transmit/Receive - The state of this line informs the subsystem whether it is

to transmit or receive data The signal is valid while INCMD

is low.

INCMD

WC 0-4 SOURCE Word Count - These five lines specify the requested number of data words to

Aeroflex Circuit Technology SCDCT1999 REV B 8/14/01 Plainview NY (516) 694-6700

SOURCE In Command - Goes low when the RT is servicing a valid command. The

subaddress and word count lines are valid while the signal is low.

be received or transmitted. Valid when INCMD

7

is low.

Pin Description (Cont.)

Signal

SA 0-4 SOURCE Sub Address - These five lines are a label for the data being transferred. Valid

CWC 0-4 SOURCE Current Word Count - These five lines define which data word in the message

SYNC

VECTEN

RESET

SSERR

BUSY

SERVREQ

/DWEN SOURCE Vector Word Enable/DataWord Enable - In the RT mode, this signal is

Hybrid

Sink or Source

when INCMD is low.

is currently being transferred.

SOURCE Synchronize - Goes low when a synchronize mode code is being serviced.

provided to enable the contents of the vector word latch (which is situated in

the subsystem) onto the ASIC’s internal highway. This signal, when in the Bus

Controller mode, is used to enable mode code data from the subsystem onto

the internal highway.

SOURCE Reset - This line pulses low for 500ns on completion of the servicing of a valid

and legal mode command to reset remote terminal.

SINK Subsystem Error - By taking this line low, the subsystem can set the

Subsystem Flag in the Status Word.

SINK Busy - This signal should be driven low if the subsystem is not ready to

perform a data transfer to or from the ASIC.

SINK Service Request - This signal should be driven low to request an

asynchronous transfer and left low until the transfer has taken place.

Signal Description

INCLK SOURCE Internal Clock (2 MHz) - This is made available for synchronization use by the

subsystem if required. However, many of the outputs to the subsystem are

asynchronous.

EOT

RTADER

HSFAIL

LSTCMD

STATEN

STATSTB

/

BITEN

RMDSTB

/CWEN SOURCE Last Command/Command Word Enable - This line pulses low when

/

SOURCE End of Transmission - Goes low if a valid sync plus two data bits do not

appear in time to be contiguous with preceding word.

SOURCE Remote Terminal Address Error - This line goes low if an error is detected in

the RT address parity of the selected receiver. Any receiver detecting an error

in the RT address will turn itself off.

SOURCE Handshake Failure - This line pulses low if the allowable time for DTAK

response has been exceeded during the ASIC/subsystem data transfer

handshaking.

servicing a valid and legal mode command to transmit last command. When in

RT mode this line must not be used to enable data from the subsystem. This

line also pulses low, when in the Bus Control mode, when a command word is

required for transmission.

SOURCE Status Enable/Status Strobe - This line pulses low to enable the status word

onto the internal highway for transmission. When in RT mode this line must not

be used to enable data from the subsystem. This line also pulses high, when in

the Bus Control mode, to strobe received status words into the subsystem.

When PASMON

SOURCE Built In Test Enable/Receive Mode Data Strobe - This line pulses low when

servicing a valid and legal mode command to transmit the internal BIT word.

This signal is for information only and must not be used to enable data from the

subsystem. This line also pulses high when in the Bus Control mode when

mode data is received to be passed to the subsystem and when data is passed

to the subsystem during PASMON

is true this line pulses high for Command and Status words.

.

DWSYNC

Aeroflex Circuit Technology SCDCT1999 REV B 8/14/01 Plainview NY (516) 694-6700

SOURCE Data Word Sync - This line goes low if a data word sync and two Manchester

biphase bits are valid.

8

Loading...

Loading...