Page 1

General Service Instructions

Acroprint Model 200 Clip-O-Matic Recorder

To Remove Case Cover

1) Turn key one quarter turn clockwise.

2) Lift case cover up then forward.

3) Reverse procedure to replace cover.

To Set Time and/or Date

NOTE: Unless your recorder is equipped with

continental (0-23) hours, all PM hours on the time

card will be printed underscored (Ex.:

change the time and/or date follow these steps:

1) Unplug recorder and remove Case Cover.

2) To Set Time

A) Pull and release Yellow Lever to set the correct

time (see figure 1). If yellow lever does not

work, plug in recorder and wait for minute hand

to advance, then unplug recorder and try lever

again. DO NOT MOVE CLOCK HANDS TO

SET THE TIME.

3) To Set Day/Date

A) Make sure current time setting is between

midnight and noon (see note above).

B) Push and release Blue Lever (see figure 1) to

set correct day/date.

C) Plug in recorder and punch card to verify correct

setting. Repeat steps A-C if reading is incorrect.

1:00). To

4) To Set Month (if so equipped)

A) Turn Month Knob (see figure 1) counter-

clockwise to select correct month.

B) Plug in recorder and punch card to verify correct

setting. Repeat steps A-B if reading is incorrect.

5) To Set Year (if so equipped)

A) Insert point of pen into spoke on side of year

wheel and rotate counter-clockwise.

B) Plug in recorder and punch card to verify correct

setting. Repeat steps A-B if reading is incorrect.

IMPORTANT NOTES

1) The date setting (if so equipped) MUST

be manually reset to the first of the

month each month, following any month

with less than 31 days.

2) The month and year settings (if so

equipped) MUST be manually reset

every month/year.

3) To reset you recorder after a power

failure follow the steps 1-5.

4) HINT: If clock is set slightly ahead of actual

time, you may unplug it until it matches the

correct time.

Figure 1 (front view with cover removed)

Month Knob (turn counter-clockwise)

I2

II

I0

I

2

9

C

I

N

T

O

R

PR

8

7

6

4

5

3

RALEIGH, N.C. USA

Yellow Lever (time)

Blue Lever (day/date)

Page 2

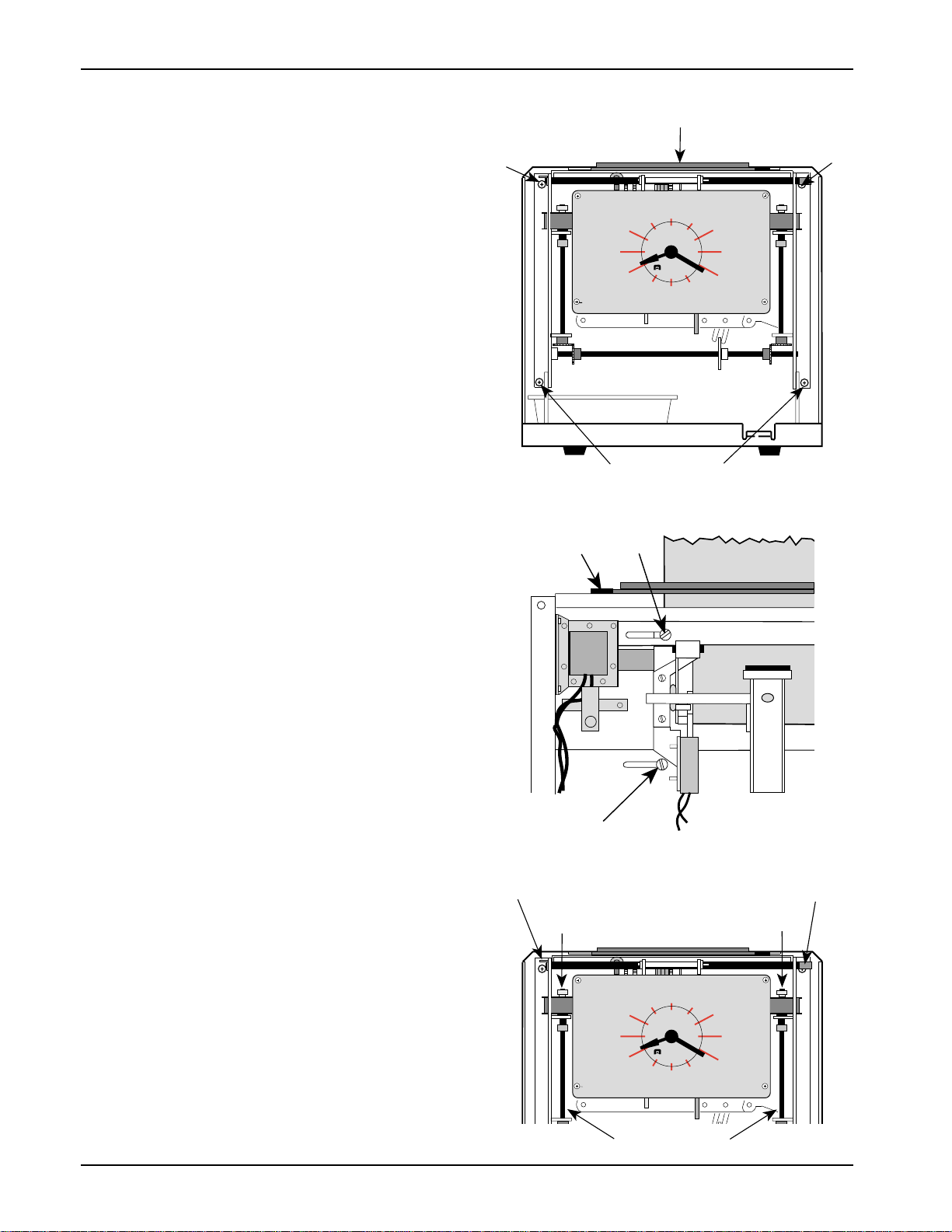

To Adjust Card Receiver Width

Your Model 200 recorder is set to accept a

standard 3 3/8" wide time card. If you wish to use

a card with a different width you must adjust the

Card Receiver. It can accommodate any card

width from 3 3/8" to 4 1/4". To adjust the Card

Receiver width, perform the following steps.

1) Unplug recorder and remove Case Cover.

2) Remove both Top Screws and loosen both

Bottom Screws (see figure 2). Swing the

recorder out from the backplate to access the

adjustment screws.

3) Loosen screws A, B, and C to slide top and

bottom of card receiver to accommodate the

time card (see figure 3). To function properly,

the card receiver should not be set to more

than 1/32" wider than the card you are using.

4) Plug in recorder and punch time card several

times to assure proper print alignment. Readjust

Card Receiver if needed.

5) Swing recorder into back plate. Tighten Bottom

Screws and replace and tighten Top Screws.

Replace Case Cover.

To Change Ribbon

Figure 2

Top Screw

Figure 3

Screw A

(front view with cover removed)

Card Receiver

Top Screw

I2

II

I0

9

8

7

I

2

C

I

R

PR

O

3

N

T

4

5

6

RALEIGH, N.C. USA

Bottom Screws

(rear view of recorder when pivoted out)

Screw B

Time Card

1) Unplug recorder and remove Case Cover.

2) Unclip Left Bar Clip and pull Front Support Rod

out through the right side (see figure 4). Let

clock face tilt down. Note how ribbon is threaded

though ribbon guides.

3) Unscrew left and right Thumb Nuts on Ribbon

Spool Shafts and remove left and right ribbon

spools. Remove ribbon from ribbon guides, and

keep right spool for use with replacement ribbon.

4) Place new ribbon spool on left Ribbon Spool

Shaft with hex hole down, and make sure ribbon

unwinds from rear of spool. Replace Thumb

Nut and tighten.

5) Pull out 18" of ribbon and attach to right spool.

Wind ribbon on right spool counter clockwise

until rivet in ribbon is wound on the spool. Place

right spool on right Ribbon Spool Shaft with

hex hole down, and make sure ribbon unwinds

from rear of spool. Replace Thumb Nut and

tighten.

6) Slide ribbon into ribbon guides, as noted in

step 2. Make sure ribbon threads through shaft

arm guides and between center ribbon guide

and tension spring.

7) Tilt clock face up. Replace Front Support Rod,

and lock with Left Bar Clip. Retension ribbon by

turning right ribbon spool clockwise. Replace

Case Cover.

Screw C

Figure 4

Left Bar Clip

Thumb Nut

(front view, cover removed)

Front Support Rod

Thumb Nut

I2

II

I0

9

8

7

I

2

C

I

R

PR

O

3

N

T

4

5

6

RALEIGH, N.C. USA

Ribbon Spool Shafts

Page 3

Installing the Time Recorder

Unpacking and Inspection

Carefully unpack your recorder and inspect it for

any damage. Verify that the following accessories

are included: three mounting screws, a case lock

key, and the General Service Instructions. Report

damage or shortages to the company from which

the unit was purchased.

Site Requirements

The recorder should be mounted on a sturdy wall,

shelf, or other support area. Do not use the recorder

under the following conditions:

extremely high or low temperature

[operating range: 0° to 50° C (32° to 122° F)]

extremely high or low humidity

[operating range: 0 to 90% RH non-condensing]

areas of high dust concentration

areas with extreme vibration or when placed on

an unstable or unlevel surface

Mounting the Recorder and Card Racks

The recorder requires an uninterrupted AC power

supply, and should be mounted within 6 feet of a

power receptacle to accommodate the unit's power

cord. The suggested wall mounting layout for the

recorder and optional card racks is shown in figure

5. Suggestions for mounting on specific wall and

shelf surfaces follow.

Figure 5

(suggested mounting layout)

Wooden/Plywood Walls

You may use the three screws included with the

recorder to mount the recorder. Mark a location on

the wall 53" above the floor. Tighten a screw at this

location, leaving about 1/8" protruding, and hang

the recorder through its "keyhole" on the screw.

Level the recorder, fully tighten the screw, and

insert and tighten screws through the lower left

and right mounting holes. Use the same type of

fasteners to attach card racks.

Masonry Walls

You may use plastic masonry anchors and screws

available at your local hardware store to mount the

recorder. Mark a location on the wall 53" above

the floor. Drill a hole with a 1/4" masonry bit and

insert a plastic anchor. Tighten a screw at this

location, leaving about 1/8" protruding, and hang

the recorder through its "keyhole" on the screw.

Level the recorder, and mark the location or the

lower left and right mounting holes. Remove the

recorder, drill holes, and insert anchors. Replace

the recorder, insert and tighten screws through the

lower left and right mounting holes, and fully tighten

the "keyhole" screw. You may wish to attach

plywood to masonry walls to ease installation of

multiple card racks.

Sheetrock/Hollow Core Walls

You may use "molly" fasteners available at your

local hardware store to mount the recorder. Follow

the procedure for masonry walls, using the "molly"

fasteners instead. Alternatively, you may use longer

wood screws to attach the recorder to a stud behind

the sheetrock, using the "keyhole" and the lower

center mounting hole on the recorder. You may

wish to attach plywood to sheetrock walls to ease

installation of multiple card racks.

32"

45"

RECEPTACLE

40"

Table Tops, Benches, and Shelves

You may use the two mounting holes in the bottom

of the recorder and the provided screws to secure

it to table tops, benches, or shelves.

NOTE: Always consult with a professional

contractor/carpenter and obey all local

building and fire codes when installing your

recorder and card racks.

Page 4

Maintenance

IMPORTANT: Empty the recorder's Chip Box at least once every month. When replacing the Chip Box

in the recorder, be sure that it is positioned far enough to the left to prevent a long time card from

hitting the side of the box (see figure 6).

Figure 6

(front view with Case Cover removed)

I2

II

I0

9

8

7

I

2

3

C

I

N

R

PR

T

O

4

5

6

RALEIGH, N.C. USA

Chip Box

To obtain the best results from your recorder, we recommend periodic inspection, cleaning, and oiling

throughout each year by an authorized dealer. For further information, contact your dealer or Acroprint

Time Recorder Co., 5640 Departure Dr., Raleigh, NC 27616, U.S.A. IN USA 800.334.7190

Declaration Of Conformity According To EMC Directive 73/23/EEC

We declare under our sole responsibility that the magnetic stripe and/or bar code reading and/or data

recording equipment Model 200 Clip-O-Matic Recorder to which this declaration relates are in conformity

with the following standards: EN 60950-1:1992. I, the undersigned, hereby declare that the equipment

specified above conforms to the above directive and standards.

Raleigh, North Carolina USA

March 15, 1996 Michael W. Bolch

All Rights Reserved. © COPYRIGHT 1996

Acroprint Time Recorder Company

PART NO: 06-0105-000 REV: D

Loading...

Loading...