Page 1

PRODUCT

SUPPORT

MANUAL

Y1-03-0165

Rev. B

SM-2

Product No. 3940.1

Automatic Crew-Overboard Light

ACR Electronics, Inc.

5757 Ravenswood Road

Fort Lauderdale, Fl 33312

+1(954) 981-3333 • Fax +1 (954) 983-5087

www.acrelectronics.com

Email: Info@acrelectronics.com

A Cobham plc Company

Page 2

Forward

Congratulations and thank you for purchasing the ACR SM-2 Automatic Crew-Overboard Light. The

combination of superior design, high quality raw materials and quality controlled manufacturing produces a

product that will perform for years to come. The Test Facility at ACR can reproduce some of the harshest

environmental conditions known to man. This assures that the products we design and manufacture can

stand up to the rigors found in a marine environment. With proper care and maintenance, your SM-2 light

will be in service for years to come.

ACR is proud to be certified to the ISO 9001:2000, the International Standard for Quality.

This manual provides installation, operation and maintenance instructions for the SM-2 light.

* * * Caution * * *

In order for the marker light to float properly, the 6 volt battery MUST not weigh more than 675 grams

(1.49 lbs). Exceeding this weight will cause the light to sink.

Test light buoyancy in shallow water prior to placing in service.

The following battery types are suggested for use in ACR Marker lights:

Suggested Screw Terminal batteries:

ANSI/NEDA: 915, 915C, 915D, 915AC

Duracell: M915, PC915

Rayovac: 942, 945

Eveready: 510S

Suggested spring terminal batteries (for use with optional battery adapter 9434):

ANSI/NEDA: 908, 908C, 908D, 908AC

Duracell: M908, PC908

Eveready: 509, 1209

Energizer: EN529, (not 529)

Rayovac: 941, 944

Panasonic: W-4FD

Note: Check adapter to ensure that screws are tight during regular maintenance.

1

Y1-03-0165 Rev. B

Page 3

TABLE OF CONTENTS

PARA. TITLE PAGE

1.0 SECTION 1 - CHARACTERISTICS 3

1.1 General 3

1.2 Purpose 3

1.3 Component Ratings 3

1.4 Operation 3

1.5 Effect of Testing 3

1.6 Encapsulating Materials 3

1.7 Construction 4

1.8 Lanyard 4

1.9 Case 4

1.10 Lens 4

1.11 Ballast 4

1.12 Mounting Bracket 4

1.13 Dimensional Stability and Vapor proofness 4

1.14 Battery Connection 5

1.15 Buoyancy 5

1.16 Stroboscopic Flashing Light 5

1.17 Technical Data SM-2 6

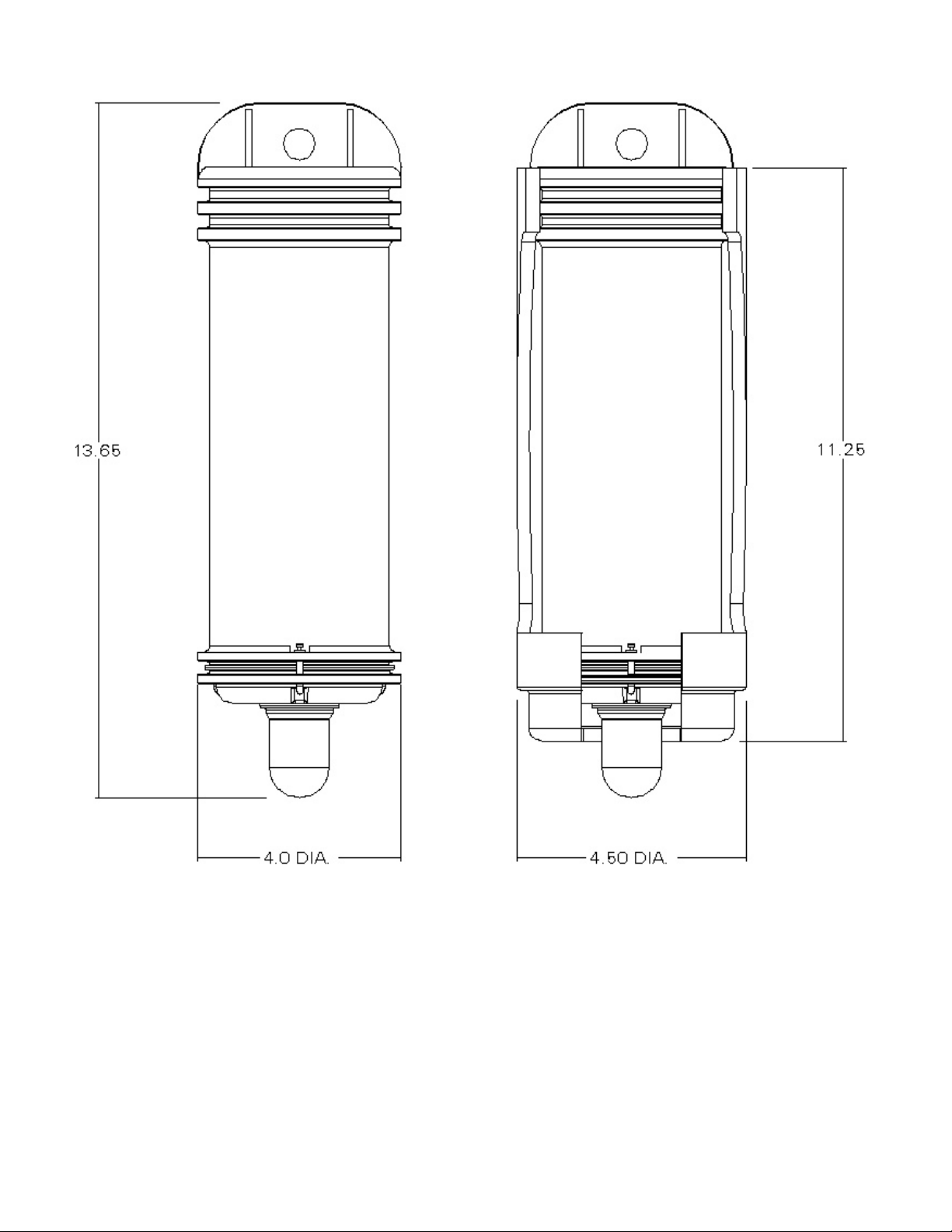

Figure 1 Outline and Dimensional Sketch 7

Figure 2 Instruction Plate Label 8

2.0 SECTION 2 - INSTALLATION 9

2.1 Installation Procedures 9

2.2 Battery Installation 9

3.0 SECTION 3 - TESTING 9 - 10

3.1 Operation 9

3.2 Inspection 9

3.3 Disassembly 9 - 10

3.4 Assembly 10

- - - - SM-2 Parts List 11

Figure 3 SM-2 Exploded View 12

2

Y1-03-0165 Rev. B

Page 4

1.0 SECTION 1 - CHARACTERISTICS

1.1 GENERAL

This section describes operating instructions and operational characteristics of the SM-2 Automatic

Crew-overboard light. The information presented herewith is in conformance with U.S. Coast Guard

Specification 46 CFR 161.010 and 161.110.

The SM-2 is a lightweight, compact, battery operated, portable unit which uses modular

construction for basic circuits to simplify maintenance and replacement procedures.

The SM-2 has been redesigned and strengthened to pass the tough UL 1196 testing and MSC.81(70)

1.2 PURPOSE

This unit, shown in Figure 1, is a portable, electronic, floating strobe light, which automatically

rights itself and begins flashing when dropped into water. The SM-2 Light is designed to be carried

aboard all vessels, as well as artificial islands and fixed structures which are located on the outer

continental shelf. It is to be used as part of the required survival equipment complement. The light is

used to mark a position in the water, particularly in a crew-overboard situation. It must be installed

and used in conjunction with other equipment as required by U.S. Coast Guard Regulations.

1.3 COMPONENT RATINGS

Circuit design and component selection is such that component ratings cannot be exceeded when the

unit is operated throughout the entire range of all environmental tests. The SM-2 uses circuit

components and construction techniques, which have been manufactured to the specifications and

requirements of various civilian and Governmental agencies.

1.4 OPERATION

Instructions for operation and maintenance of the SM-2 Light are given on the instruction plate.

(See Figure 2) This unit does not possess any exterior operating controls. Equipment design is such

that controls for use during normal operation would not be detrimental to the reliability of the Light.

The circuit is electronically activated by a gravity switch when the unit is inverted.

1.5 EFFECT OF TESTING

Equipment design is such that application of specified tests will provide no discernible condition

which would be detrimental to the reliability of equipment manufactured in accordance with such

design.

1.6 ENCAPSULATING MATERIALS

Materials used to encapsulate the Module are of the type that will not have any injurious effect on

the insulating materials to which they are applied and do not cause corrosion or deterioration of any

adjacent part. These compounds do not flow at temperatures below +85° C or crack at temperatures

down to -34° C.

3

Y1-03-0165 Rev. B

Page 5

1.7 CONSTRUCTION

The SM-2 Light essentially consists of a case with a battery, switch, electric circuit, flashlamp,

globe, lanyard attachment flange, a mounting bracket, and a buoyant, non-absorbent unicellular

polyfoam, used as filler material.

1.8 LANYARD

The size, weight, and shape of the light are suitable for conveniently throwing overboard, while

attached to a life ring buoy by means of a lanyard. A hole is provided in the bottom flange of the

case for lanyard attachment.

1.9 CASE

The case is made of a high-impact plastic; International Orange in color, which is constructed to

receive all components necessary to produce the required light output. No additional signaling

devices are incorporated in the unit. An attachment point for lanyards is provided on the side of the

case opposite the globe. It can be used to attach a life buoy ring.

1.10 LENS

The lens is made of a colorless, polycarbonate plastic (lexan) which is free mechanical defects

which would impede its primary function of radiating light. The Lens is of such design as to

withstand all impact tests that are required in this application.

1.11 BALLAST

Ballast consists of a metallic weight permanently secured in the bottom of the case.

1.12 MOUNTING BRACKET

The mounting bracket is designed to hold the light in the inverted position and prevent free

movement of the light when properly secured within the bracket. The bracket is made of a

corrosion-resistant plastic and is arranged for mounting on a vertical surface.

1.13 DIMENSIONAL STABILITY AND VAPOR PROOFNESS

The SM-2 Light is capable of undergoing specified temperature humidity cycles with no signs of

shrinkage or distortion which might impair its serviceability, watertightness or vapor proofness.

The watertight integrity of the equipment is assured by O-Ring seals between surfaces. The unit's

ability to withstand any anticipated external forces is assured by the combination of material

strength and assembly methods.

4

Y1-03-0165 Rev. B

Page 6

1.14 STROBOSCOPIC FLASHING LIGHT

The SM-2 Flashing Light uses a capacitor discharge xenon flashtube and meets the following

requirements.

A. A completely sealed solid state circuit converts power from the battery and supplies it to the

flashtube.

B. A suitable capacitor discharge, xenon flashtube is provided which is compatible with the

electronic flashing circuit and lens which will provide the required light output. The service life of

this flashtube is rated for 5,000,000 flashes.

C. The light will flash at a rate of 60 ± 1 flashes per minute with a minimum intensity of 2 CD for a

minimum of 15 hours. Light from each flash is radiated in all directions of upper hemisphere.

1.15 BATTERY CONNECTION

All operating voltages are furnished by an integral battery pack. Operating voltage is 6.0 VDC.

(Shipped without battery from factory)

Electrical connections between the main circuit board and the associated battery are accomplished

by the use of clearly marked terminals and color-coded lead wires.

1.16 BUOYANCY

The SM-2 is independently buoyant and will float for an indefinite time interval with the center of

the flashtube at least 2 inches above the water surface.

A matter of balance

Marker lights, by design need not only to float upright for maximum visibility. The 6 volt lantern

batteries provide the ballast for these lights. Although these batteries are the same size, their

different chemistries cause them to have varying weights. It is imperative that only the 6 volt

battery models suggested are used. Too little ballast and the light will lie over on its side and be

ineffective; too much weight and the light could sink. If you have any doubts that you are using a

battery of appropriate weight, test the light by placing it into shallow water. The results will be

obvious; if the light floats upright, it's good. If the light sinks, the battery is too heavy.

Maximum battery weight: 675 grams (1.49 lbs)

(See list of suggested batteries on Page 1)

5

Y1-03-0165 Rev. B

Page 7

1.17 TECHNICAL DATA - SM-2

Pertinent Technical Data is listed below:

ITEM CHARACTERISTICS

Dimensions 13.65" (34.67 cm) length

4" (10.16 cm) diameter

Weight 3 lbs, 4 oz. (1.474 Kg), including battery

1 lb, 13 oz. (.822 Kg), excluding battery

Modules (1) completely sealed electronics

Flashing Rate 60 times per minute ± 1

Flashing Light Intensity Minimum of 2 candelas per flash in all directions of upper

hemisphere

Power Requirement Standard 6.0 Volt lantern battery with screw terminals

Material Plastic Blend Case, Lexan Lens

Activation Automatic Gravity Switch

Bracket Plastic Blend Mounting Bracket

Recommended Battery

Replacement Interval 1 Year

Accessory (Optional) 4D6V SP Battery Adapter

Max Battery Weight 675 grams or 1.49 lbs or unit will sink

6

Y1-03-0165 Rev. B

Page 8

FIGURE 1

OUTLINE AND DIMENSIONAL SKETCH

7

Y1-03-0165 Rev. B

Page 9

FIGURE 2

INSTRUCTION PLATE LABEL

8

Y1-03-0165 Rev. B

Page 10

2. SECTION 2 - INSTALLATION

2.1 INSTALLATION PROCEDURES

The installation procedure requires that the mounting bracket be securely fastened in any convenient

location which would provide immediate access in the event of emergency situations.

Suitable length ¼ - 20 stainless screws should be used for mounting the bracket. Screw heads

should not protrude inside the bracket surface.

2.2 BATTERY INSTALLATION

The SM-2 is normally shipped from the factory without a battery. Follow disassembly instructions

in Section 3 of this Manual for battery installation. The SM-2 uses a standard 6 Volt lantern type

battery with screw terminals. A list of recommended batteries can be found on Page 1. Note

maximum allowable battery weight.

3.0 SECTION 3 - TESTING

3.1 OPERATION

The unit should be tested monthly. Remove the SM-2 from its bracket and invert it. The unit should

begin flashing immediately, at a rate of about one flash per second. Re-invert the unit after

ascertaining correct operation.

3.2 INSPECTION

Check the exterior of the unit for damage which might affect proper operation (damage to globe,

cracks in case, etc.) Check bracket security.

3.3 DISASSEMBLY

This will ordinarily be required only if testing shows that the light is malfunctioning, or if battery

replacement is required. Recommended interval for battery replacement is one year.

A. Hold the unit on a flat, firm surface, lens side up. Depress the top cap of the unit, by pushing

straight down on the top cap assembly, until the swivel locks may be turned outward, clear of the

cap.

B. Grip the light lens (using a clean cloth or gloves for a better grip on the smooth surface and to

avoid marring the lens surface) and pull upwards until the top cap is clear of the case.

C. Turn the unit on its side, open end slightly downwards, to allow the foam filler and battery to

slide out.

D. Disconnect the battery by unscrewing the terminals from the battery posts.

E. Replace the strobe module, if required, as follows:

1. Remove foam filler from strobe module, by sliding it off.

2. Slip foam spacer over new strobe module to seat in cap recess.

9

Y1-03-0165 Rev. B

Page 11

3. Inspect O-Ring seal for proper fit. Lubricate with silicone grease.

F. Replace the battery by securing the two terminals to the battery posts. Assure tightness.

NOTE: Connect black lead to center (-) post of battery. Connect red lead to outer (+) post of battery.

G. Check for proper operation by holding the top cap assembly vertical (light lens up). The unit

should flash about once each second. If the unit does not operate, check for proper battery

connection.

3.4 ASSEMBLY

Hold the case horizontally and slide the battery in, terminal end up (towards the open end of the

case).

Lubricate the top cap O-ring with silicone grease and insert the cap and foam spacer into the case.

Place the unit upright on a firm surface, and press the top cap assembly until the cap slips into the

case. Depress the cap until the locking swivels can seat into the provided recesses. Turn the locking

swivels, seat them into the cap recesses and remove pressure from the top to allow it to move

upwards and lock. Check unit operation.

CAUTION: Assure that the locking swivels are properly seated in the cap grooves. Rotate the

cap, if necessary, to assure proper seating of the swivels.

10

Y1-03-0165 Rev. B

Page 12

SM-2

PARTS LIST

ITEM DESCRIPTION PART NUMBER

1 Case Assembly A3-06-2295

*2 Case A1-18-1878

*3 Washer, 3 each A1-05-0659-3

*4 Locking Swivel, 3 each A1-17-1283

5 Battery Pad, Foam A1-18-0773

6 Battery Not Included

6 Volt Lantern Type

(See Tech. Data 2.17 for recommended battery)

7 Foam Filler A1-18-1877

8 O-Ring (Top Cap) A1-05-0001-64

9 Top Cap and Lens Tube Assembly 9021.1

10 Mounting Bracket 9438.1

11 Stainless Steel Bracket (Sold separately) 9566

12 6VST Battery Adapter (Sold separately) 9434

* Included with Item 1

REPAIR KIT DESCRIPTION PART NUMBER

SM-2 Retaining rings and locking swivels, 3 ea. 9286

O-ring and manual, 1 ea.

11

Y1-03-0165 Rev. B

Page 13

FIGURE 3

EXPLODED VIEW SM-2

12

Y1-03-0165 Rev. B

Loading...

Loading...