Page 1

User Manual

PCH3591/3791/3991: 15/17/19” Industrial Fanless Panel PC

with P8400 2.26GHz processor

PCH3591/3791/3991

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All righ ts reserved. Product descripti on and product speci ficat ions

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 2

PCH3591/3791/3991

Warning!

This equipment generates, uses and can radiate radio frequency energy and if not installed and

used in accordan ce with th e instructions manual, it may cause interference to radio communications.

It has been tested and found to comply with the li mits for a Class A comp uting devic e pursuant to

FCC Rules, whic h are designed to provid e reasonable protection against such interference when

operated in a com mercial environment. Operation of this equipm ent in a residential area is likely

to cause interference in which case the user at his own expense w ill be required to take whatever

measures ma y be required to co rrect th e interference.

Elect ric Shock Hazard – Do not operate the machi ne with its back cover removed. There are

dangerous high voltages inside.

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All right s reser ved . Produc t descr ipt ion and product speci fi cat io ns

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 3

Packing List

Accessories (as ticked) included in this package are:

AC power cable

Driver & manual CD disc

Other._____________ (please specify)

Safety Precautions

Follow the messages below to p reven t your systems from damage:

Avoid your system from static electricity on all occasions.

Prevent electric shock. Don’ttouch any components of this card when the card

is power-on . Always disconnect power when the system is not in use.

Disconnect power when you change any hardware devices. For instance, when

you connec t a jumper o r install any cards, a surge of power may damage the

elec tronic components or the whole system.

PCH3591/3791/3991

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All righ ts reserved. Product descripti on and product speci ficat ions

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 4

PCH3591/3791/3991

Table of Contents

Warning!………………………………………………………………………… ….……..….2

Packing List…………………………………………………………………………………..3

Safety Precautions……………………………………………………………………… …..3

Chapter 1 Getting Started

1.1 Specifications……………………………………..….……………………..6

1.2 Dimensions………………………………...………………………….......7

1.3 Brief Description…………………………………………………….……10

Chapter 2 Hardware

2.1 Mainboard………………..…….……………………………………..…..11

2.2 Installations…….………………….……………………………………...12

2.2.1 Jumpers Setting and Connectors………………………………….....12

2.3 Jumpers Setting and Connectors........................................................13

Chapter 3 BIOS Setup

3.1 Operations after POST Screen.............................................................24

3.2 BIOS SETUP UTILITY..........................................................................25

3.3 System Overview..................................................................................26

3.4 Advanced Settings............................................................................... 27

3.5 Advanced PCI/PnP Settings................................................................ 36

3.6 Boot Settings....................................................................................... 38

3.7 Security Settings.................................................................................. 40

3.8 Advanced Chipset Settings.................................................................. 41

3.9 Exit Options..........................................................................................48

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All right s reser ved . Produc t descr ipt ion and product speci fi cat io ns

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 5

PCH3591/3791/3991

Chapter 4 Installation of Drivers

4.1 Chipset Driver.…………………………...……...…………………………51

4.2 Graphics Media Accelerator Driver...………………..…………………..54

4.3 Network Adapter……..……………………………………………….…….57

4.4 Realtek ALC662 HD Audio Driver Installation…….………….…………60

Chapter 5 Touch Screen Installation

5.1 Introduction to Controller Board..…………………………..……………62

5.2 Windows 2000/XP USB Driver Installation for 5000 Boards………..….62

Figures

Figure 1.1:Dimensions of PCH3591.…………………………………..…....7

Figure 1.2: Dimensions of PCH3791….………………………………..…....8

Figure 1.3:Dimensions of PCH3991….……………………………………….9

Figure 1.4: Front View of PCH3X91…….…………………………………...10

Figure 1.5: Rear View of PCH3X91…….…………………………………..10

Figure 2.1: Mainboard Dimensions…………………………………..…….....11

Figure 2.2: Jumpers and Connectors Location_ Board Top………………...12

Figure 2.3: Jumpers and Connectors Location_ Board Bottom…………....13

Figure 5.1 Birdeye? s View of Control Board………………………………62

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All righ ts reserved. Product descripti on and product speci ficat ions

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 6

Chapter 1 System

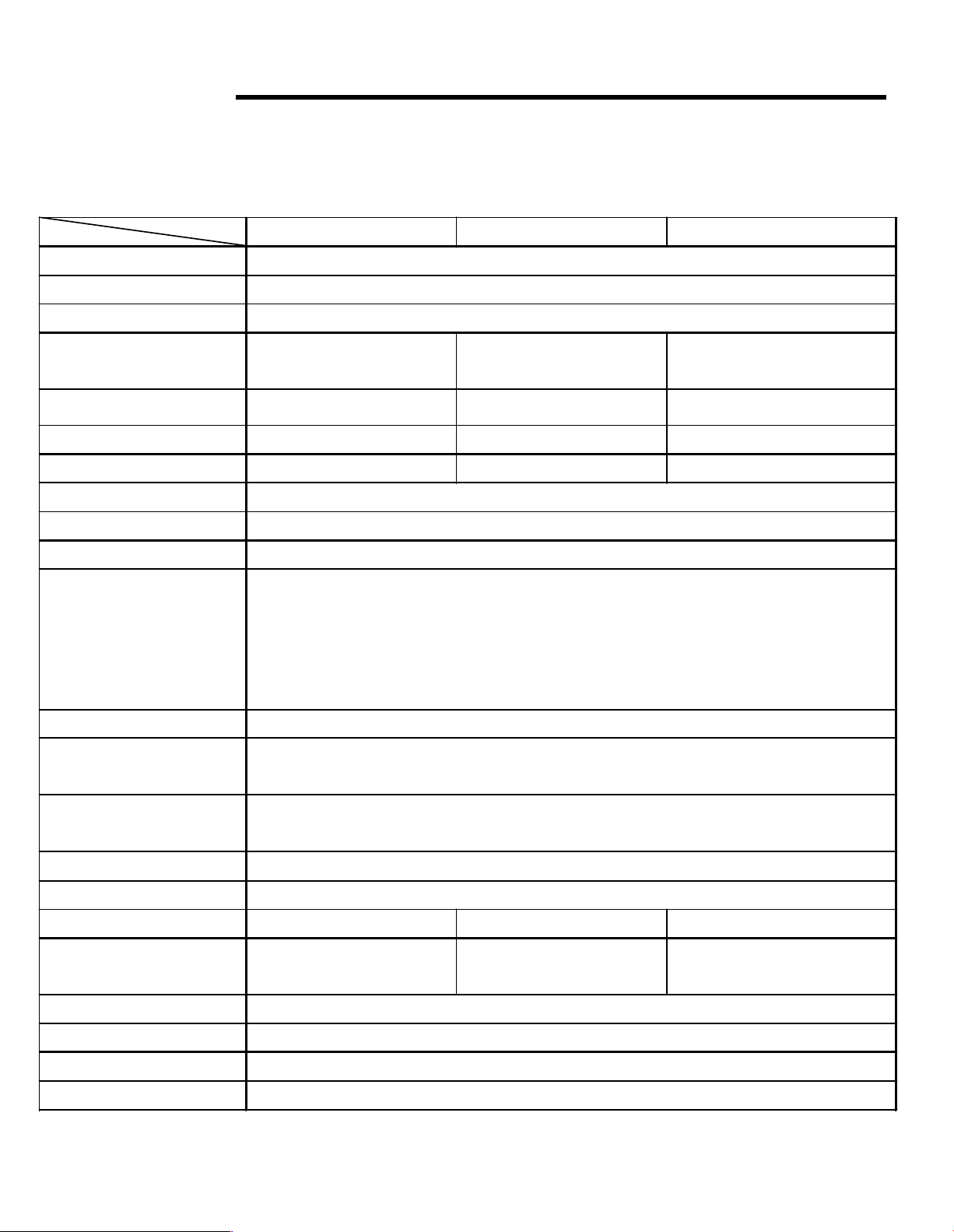

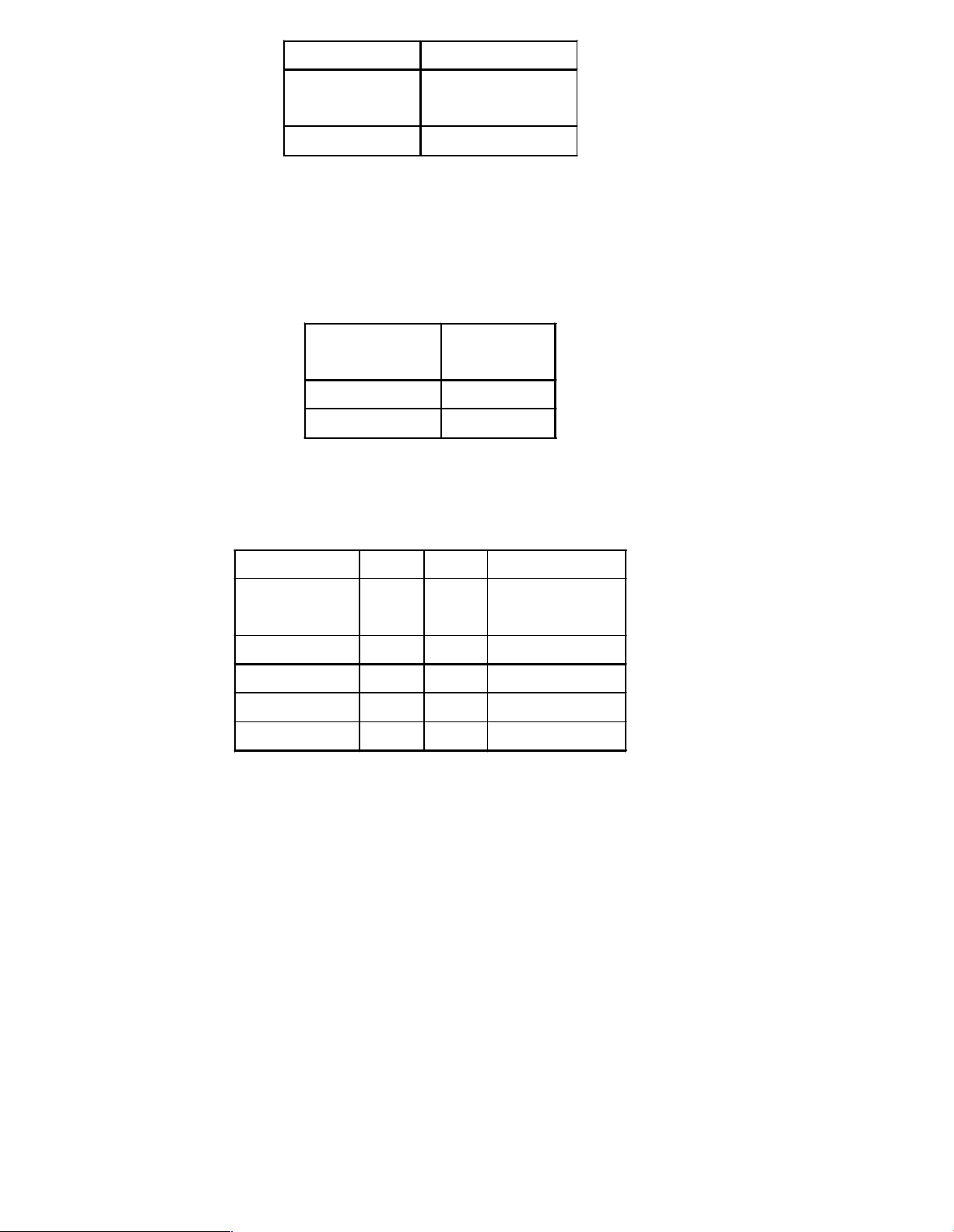

1.1 Specifications

Specs

PCH3591

PCH3791

PCH3991

CPU

Socket P processor support up to P8400 2.26GHz without fan

Chipset

GM45 + ICH9M

System Memory

1 x 204 Pin 800MHz DDR3 SODIMM slot, up to 4GB

Display Size

15”17”19

”

Maximum Colors

262K

16.7M

16.2M

Viewing Angle (Degree)

H:160 / V:145

H:170 / V:160

H:170 / V:160

Luminance (cd/m²)

400

350

350

Backlight Lifetime

50,000 Hours

Rating

IP65

Tou ch Screen Type

Resistive Touch Screen (option)

Outside I/O port

2 x USB2.0 connectors

1 x GbE RJ45 LAN connector

1 x DB-9 RS-232 (COM1)

1 x DB-9 RS-422/485 (COM3), d efault RS-485

1 x DC Power Inp ut

Extension

None

Storage

1 x 2.5" SATA HDD

1 x Internal CF Slot

OS Support

Windows XP Professional, XP Embedded, Windows 7 Pro for Embedded, Windows

Embedded Standard 7

Power Supply

11~32V DC

Construction

Stainless steel

Dimensions (WxHxD)

410 x 310 x 8 7.8 mm

439 x 348 x 93.3 mm

484 x 400 x 94.3 mm

Mounting

VESA 100x100/200x100

Mount

VESA 75x75 Mount

VESA 100x100 Mount

Operating Temperature

-10~50℃

Storage Temperature

-20~60

Relative Humidity

10%~90%@ 40 , non-condensing

Certificate

CE / FCC Class A

Page 7

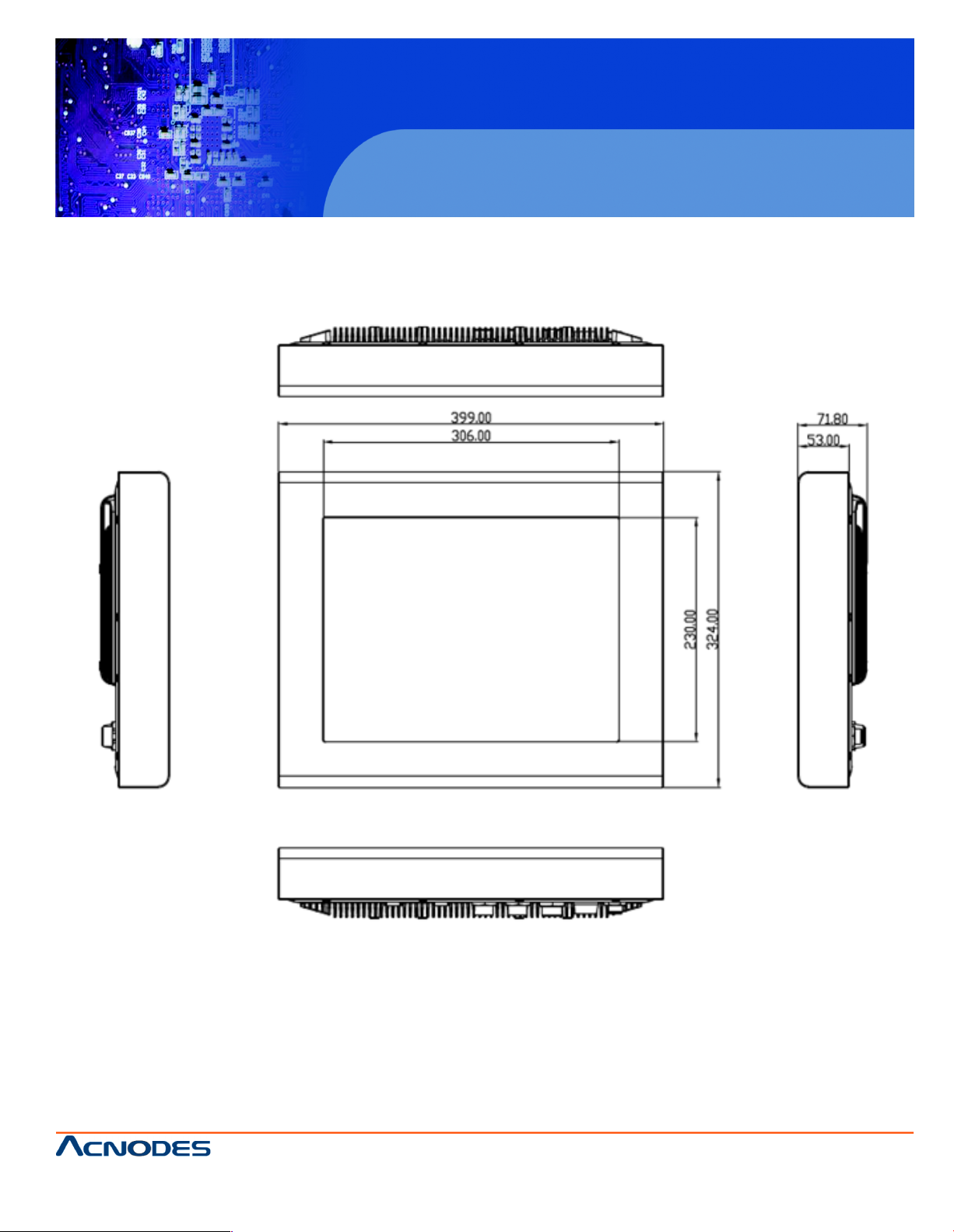

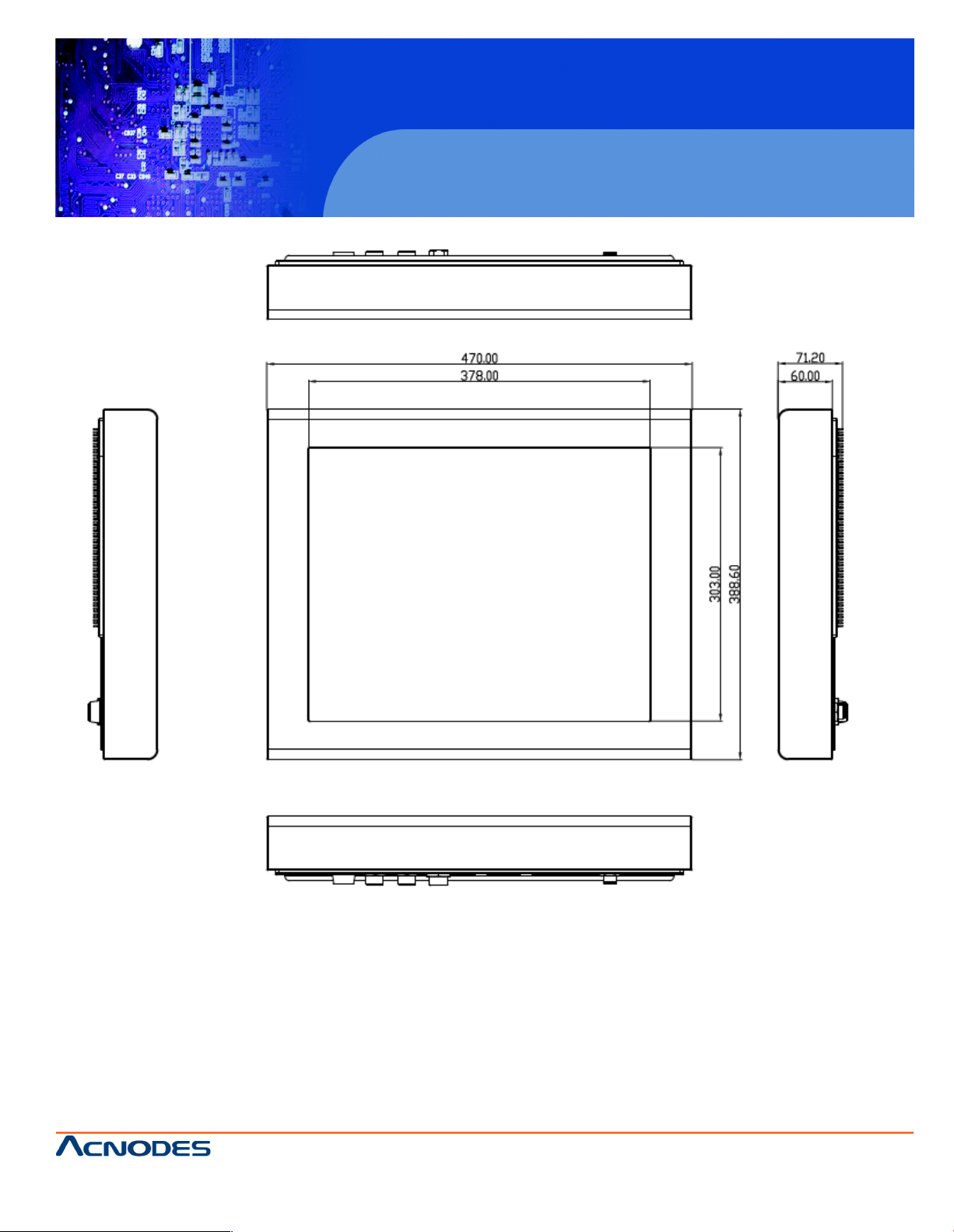

1.2 Dimensions

Figure 1.1: Dimensions of PCH3591

PCH3591/3791/3991

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All righ ts reserved. Product descripti on and product speci ficat ions

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 8

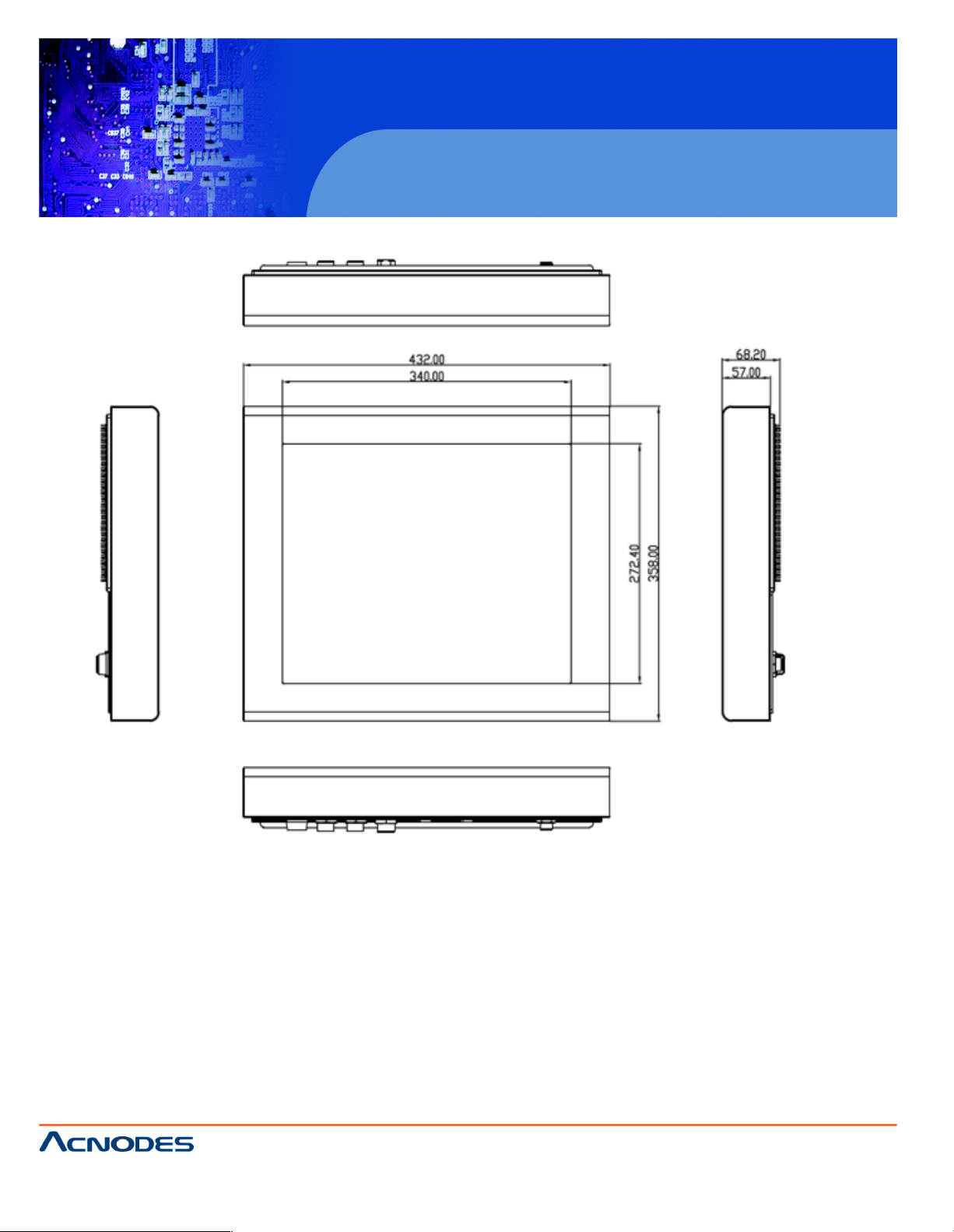

PCH3591/3791/3991

Figure 1.2: Dimensions of PCH3791

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All right s reser ved . Produc t descr ipt ion and product speci fi cat io ns

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 9

PCH3591/3791/3991

Figure 1.3: Dimensions of PCH3991

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All righ ts reserved. Product descripti on and product speci ficat ions

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 10

1.3 Brief Description of the PCH3X91

The PCH3591/3791/3991 is a stainless steel and VESA-mount industrial Panel PC, which comes with

a 15-inch (luminance of 400 cd/m²)/17-inch (luminance of 350 cd/m²)/19-inch (luminance of 350

cd/m²) TFT LCD. It is powered by a Socket P Core 2 Duo Processor, up to Intel P8400 2.26GHz

processor. The industrial panel PC also features two COM ports, two USB 2.0 ports, one 2.5”

HDD,

one internal CF slot, and 11~32V DC, etc. It is ideal for use as a PC-based controller for

Industrial Automation & Factory Automation

Figure 1.4: Front View of PCH3X91

PCH3591 PCH3791/3991

Figure 1.5: Rear View of PCH3X91

Page 11

PCH3591/3791/3991

Chapter 2 Hardware

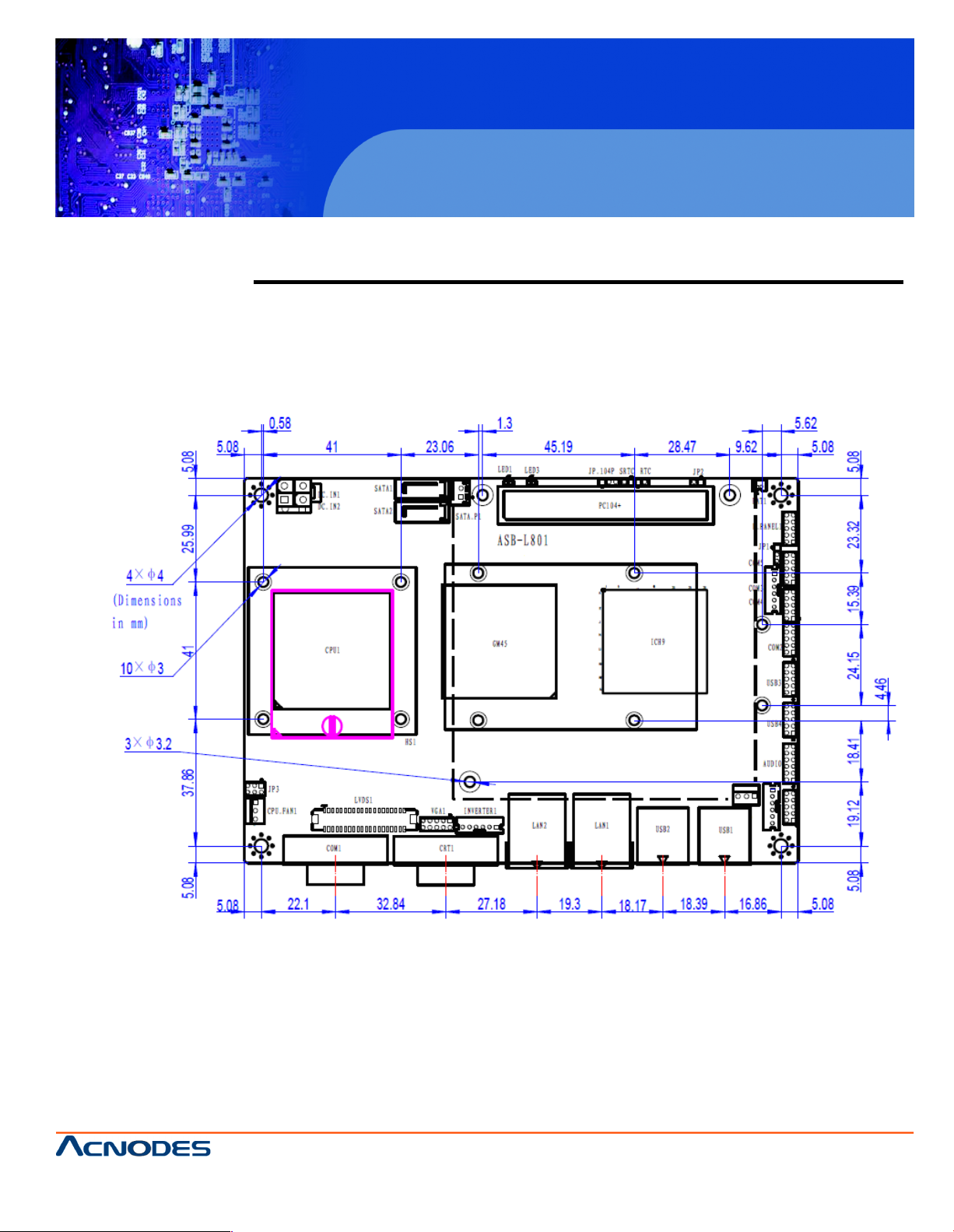

2.1 Mainboard

Figure 2.1: Mainboard Dimensions

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All righ ts reserved. Product descripti on and product speci ficat ions

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 12

PCH3591/3791/3991

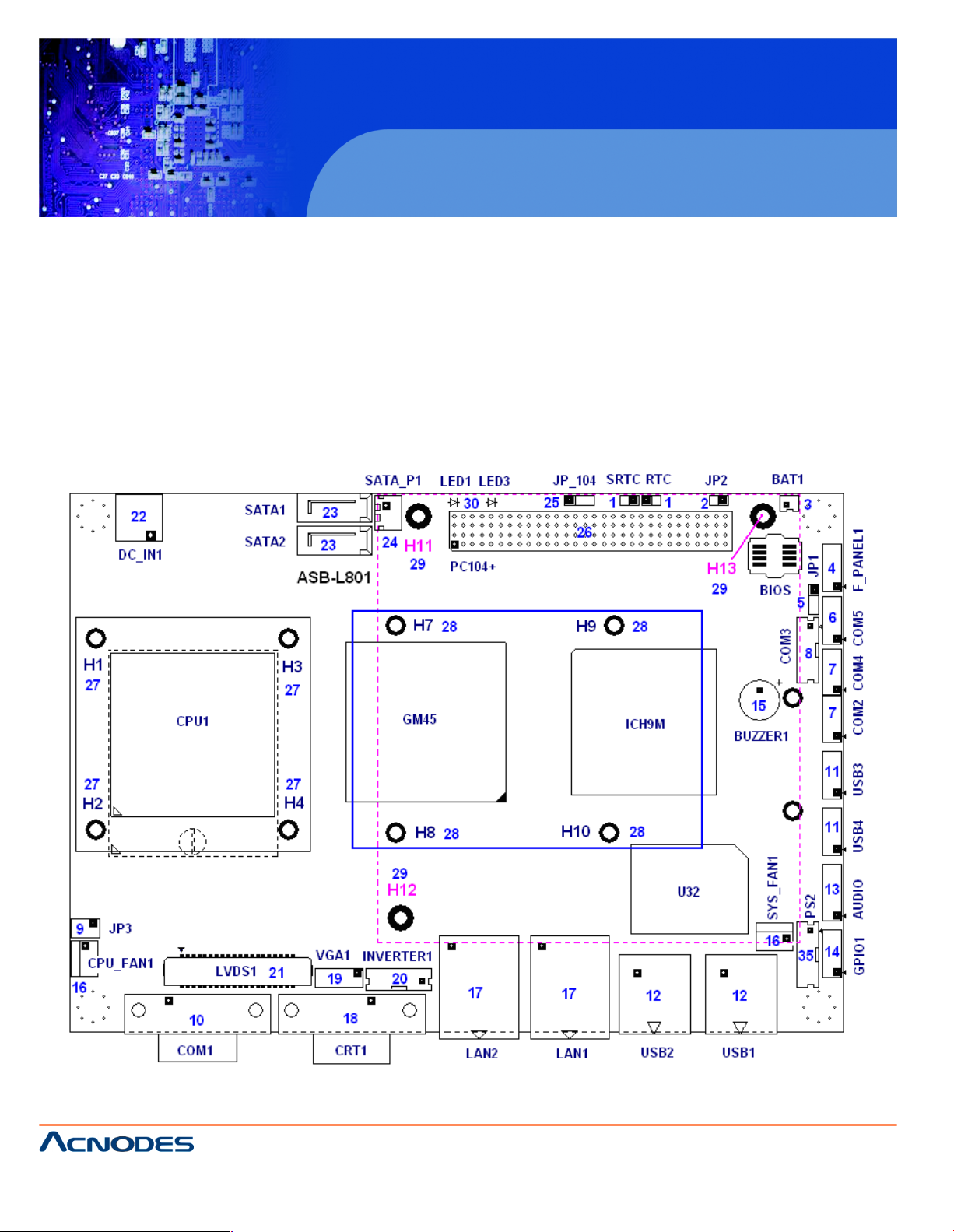

2.2 Installations

ASB-L801 is a 4" industrial Embedded motherboard developed on the basis of Intel G M45+

ICH9M, which provides abundant peripheral interfaces to meet the needs of d ifferent customers. Also,

it features dual 1000M LAN port, 5-COM port and d ual Mini PCIE configuration. To satisfy the special

nee ds of high-end customers, PC104+ port (capable of adjustin g IO voltage) richer extension

functions. Due to its compact size, the product is widely used in various sectors of industrial control..

2.2.1 Jumpers Setting and Connectors

Figure 2.2: Jumpers and Connectors Location_ Board Top

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All right s reser ved . Produc t descr ipt ion and product speci fi cat io ns

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 13

Figure 2.3: Jumpers and Connectors Location_ Board Bottom

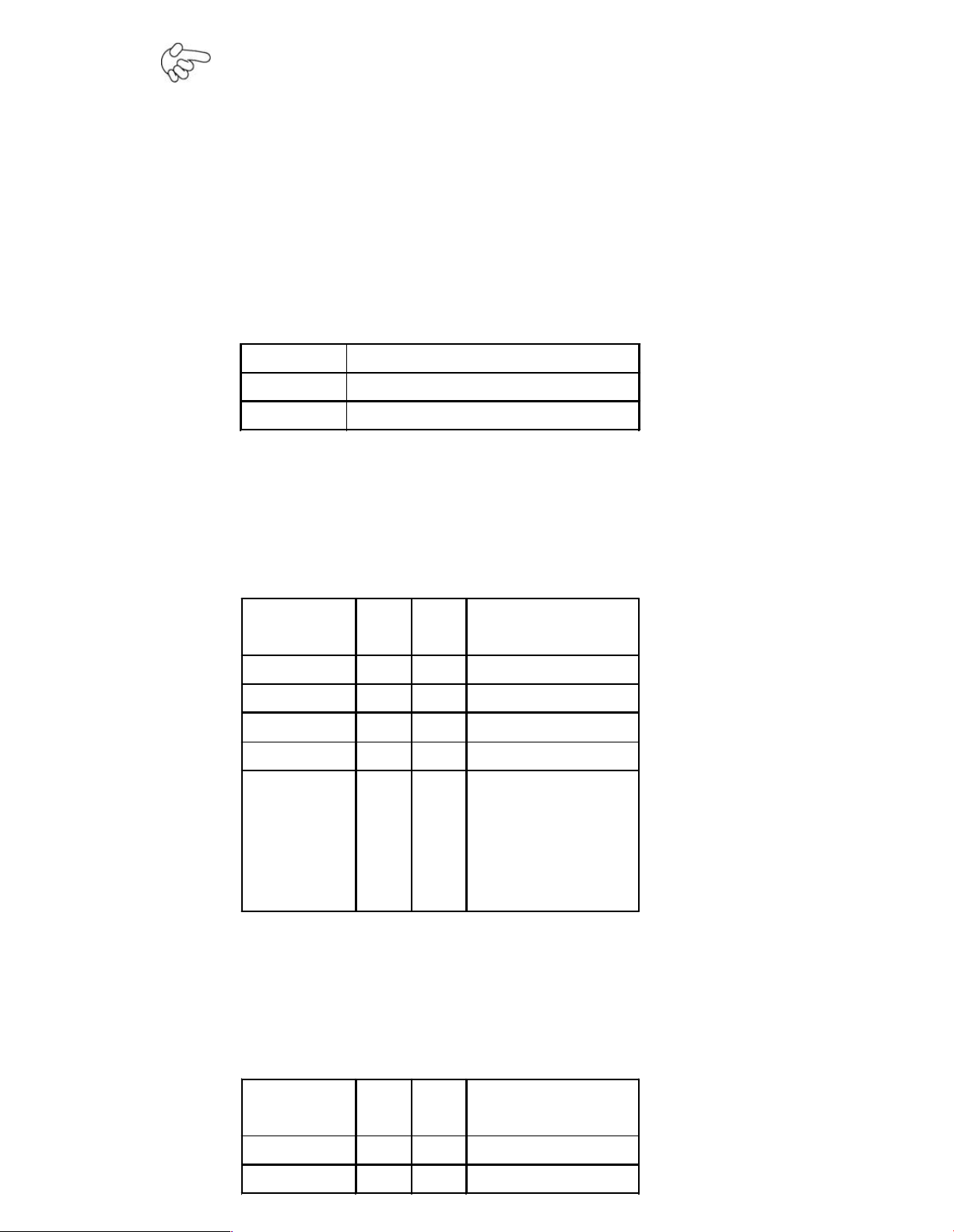

2.3 Jumpers Setting and Connectors

1. RTC/SRTC: (2.0mm Pitch 1X2 Pin Header)CMOS cle ar jumper, CMOS clear

operation will perman ently reset old BIOS settings to fa ctory defaults.

RTC/SRTC

CMOS

OPEN

NORMAL

(default)

CLOSE 1 -2

Clear CMOS

Procedures of CMOS clea r:

5.4.1.1 Turn off the system and unplug the power cord from the power outlet.

5.4.1.2 To cle ar the C MOS s ettings, use the jumper cap to close pins1 and 2 fo r about

3 seconds then reinstall the jumper clip back to pins open.

5.4.1.3 Power on the system again.

5.4.1.4 When entering the POST screen, press the <F1> or <DEL> key to enter CMOS

Setup Utility to load optimal defaults.

5.4.1.5 After the above operations, save changes a nd exit BIOS Setup.

2. JP2: (2.0mm Pitch 1X2 Pin Header), ATX Power and AT Power s etting jumper.

Page 14

JP2

Mode

Open

ATX Power

Mode

Close

Auto Power on

3. BAT1: (1.25mm Pitch 1X2 box Pin Header) 3.0V Li battery is embedded to

provide power for CMOS.

Pin#

Signal

Nam e

Pin1

VBAT

PIN2

Ground

4. F_PANEL: (2.0mm Pitch 2X5 Pin Head er), Front panel connector.

Signal Name

Pin#

Pin#

Signal Name

HD LED+

12POWER

LED+

Ground

34Ground

Ground

56SW +

RESET+

78Ground

SPK+

910SPK-

Pin1-3: HDD LED, They are used to co nnect hard disk a ctivity LED. The LED blinks

when the hard disk is reading or writing data.

Pin2-4: POWER LED, They are used to connect power LED. W hen th e system is

powered on or under S0/S1 state, the LED is normally on; when the

system is under S4/S5 state, the LED is off.

Pin5-6: POWER on/off Button, They are used to connect powe r switch button.

The two pins are disconnected under normal condition. You may short

them temporarily to realize system startup & sh utdown or awaken the

system from sleep state.

Pin7-8: RE SET Button, They are used to connect reset button. The two pins are

dis-

connected under normal condition. You may short them temporarily to

realize

system reset.

Pin9-10: BUZZER , They are used to connect an external buzzer.

Page 15

Note:

W hen connecting LEDs and buzzer, pa y special attention to the si gnal

pola-

rity. Mak e sure that the connector pins have a one-to-one correspondence

with chassis wiring, o r it may cause boot up failure.

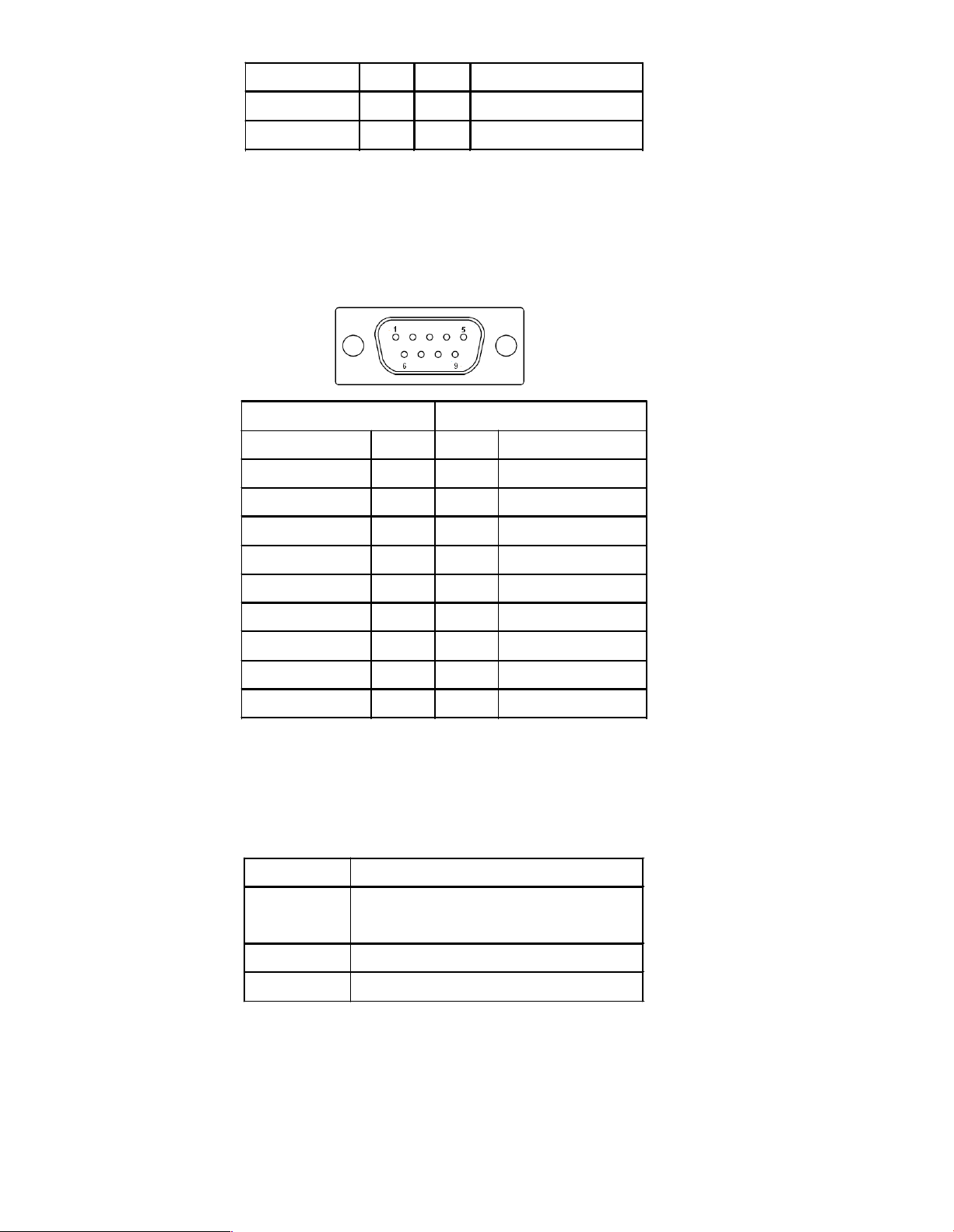

5. JP1: (2.0mm Pitch 1x3 Pin Header) COM5 s etting jumper, pin 1 ~3 are used to

select signal out of pin 10 of COM5 port.

JP1 Pin#

Function

Close 1-2

COM5 Pin10=+5V (default)

Close 2-3

COM5 Pin10=+12V (option)

6. COM5: (2.0mm Pitch 2X5 Pin Header), COM5 Port, standard RS232 ports are

provide d. They can be used directly via COM cable conne ction.

Signal

Nam e

Pin#

Pin#

Signal Name

DCD12

RXD

TXD34

DTR

Ground

56DSR

RTS78

CTS

RI910

Jp1 Setting:

Pin1-2 : 5V

(default)

Pin2-3:12V

(option)

7. COM2/COM4: (2.0mm Pitch 2X5 Pin Header),CO M2 COM4 Port, up to 2

standard RS232 ports are provided. They can be used directly via COM cable

connection.

Signal

Nam e

Pin#

Pin#

Signal Name

DCD12

RXD

TXD34

DTR

Page 16

Ground

56DSR

RTS78

CTS

RI910

NC

8. COM3: (2.0mm Pitch 1x6 box Pin Header),it provides selectable RS422/RS485

serial signal output from BIOS configuration.

RS422 Type (option)

RS485 Type (default)

Signal Name

Pin#

Pin#

Signal Name

422RX-

11NC

422RX+

22NC

422TX-

33485-

422TX+

44485+

Ground

55Ground

+5V66

+5V

NC77

NC

NC88

NC

NC99

NC

9. JP3: (2.0mm Pitch 2x3 Pin Header),COM1 s etting jumper, pin 1~6 are used to

selec t signal out of pin 9 of COM1 port.

JP3 Pin#

Function

Close 1 -2

RI (Ring Indicator)

(default)

Close 3-4

COM1 Pin9=+5V (option)

Close 5-6

COM1 Pin9=+12V (option)

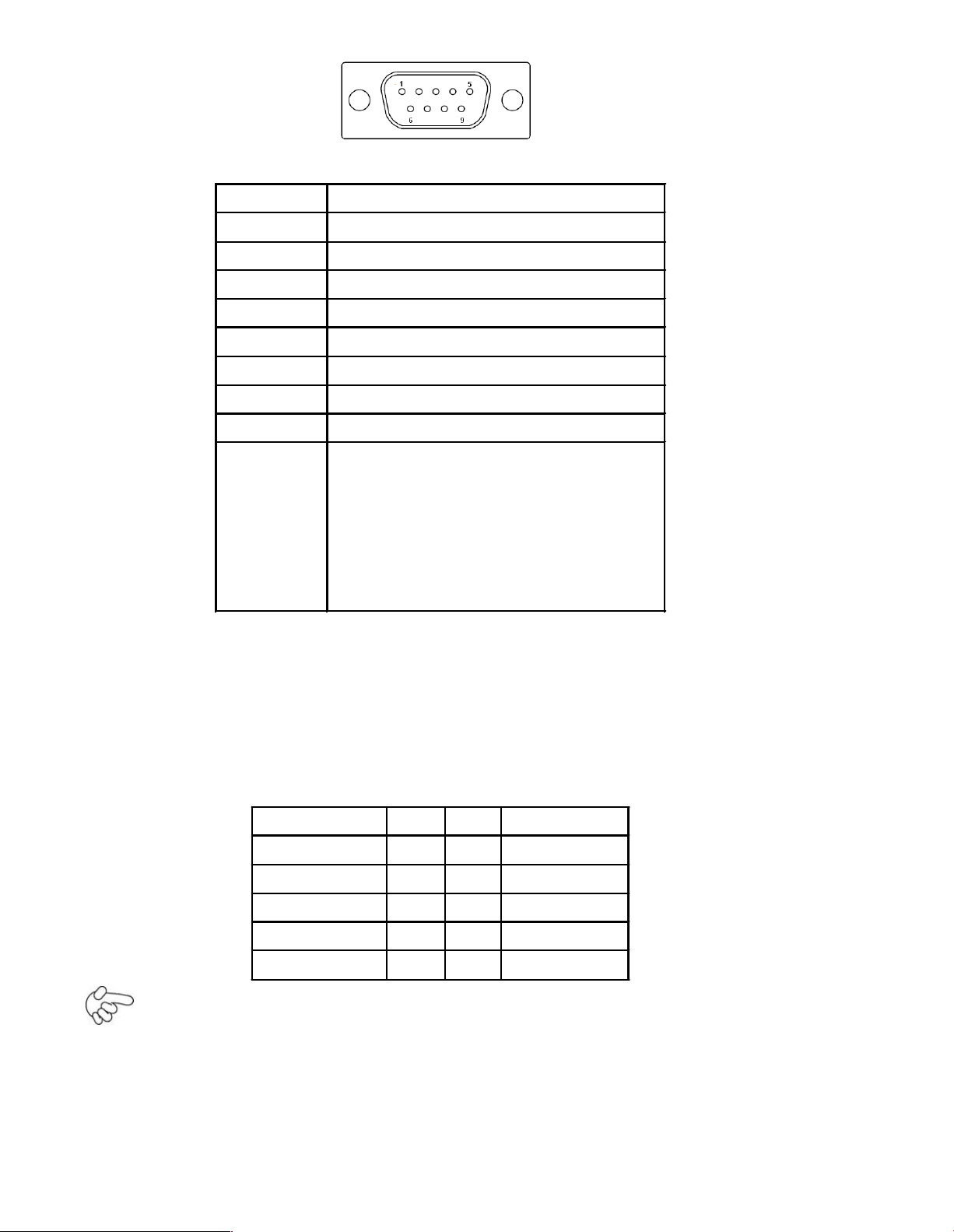

10. COM1: (Type DB9),Rear serial port, standard DB9 serial po rt is

provide d to make a direct con nection to serial devices. COM1 port is controlled by

pins No.1 ~6 of JP3,select output Signal RI or 5V or 12v, For details, please refer to

description of J P3.

Page 17

Pin#

Signa l Name

1

DCD# (Data Carrier Dete ct)

2

RXD (Received D ata)

3

TXD (Transmit Data)

4

DTR (Data Terminal Ready )

5

Ground

6

DSR (Data Set Ready)

7

RTS (Request To Send)

8

CTS (Clea r To Send)

9

JP1 Setting:

Pin1-2 : R I (Ring Indica tor)

(default)

Pin3-4 : 5V Standby power (option)

Pin5-6:12V Standby power

(option)

11. USB3/USB4: (2.0mm Pitch 2X5 Pin H eader) ,Front USB connector, it

provides 4 USB ports via a dedicated USB cable, speed up to 480Mb/s.

Signal Nam e

Pin#

Pin#

Signal Name

VCC(+5V)

12VCC(+5V)

USB_DB-

34USB_DA-

USB_DB+

56USB_DA+

Ground

78Ground

NC910

Ground

Note:

Before connection, make sure that pinout of the USB C able is in accordance with th at

of the said tables. Any inconformity may c ause system down and even hardware

damages.

Page 18

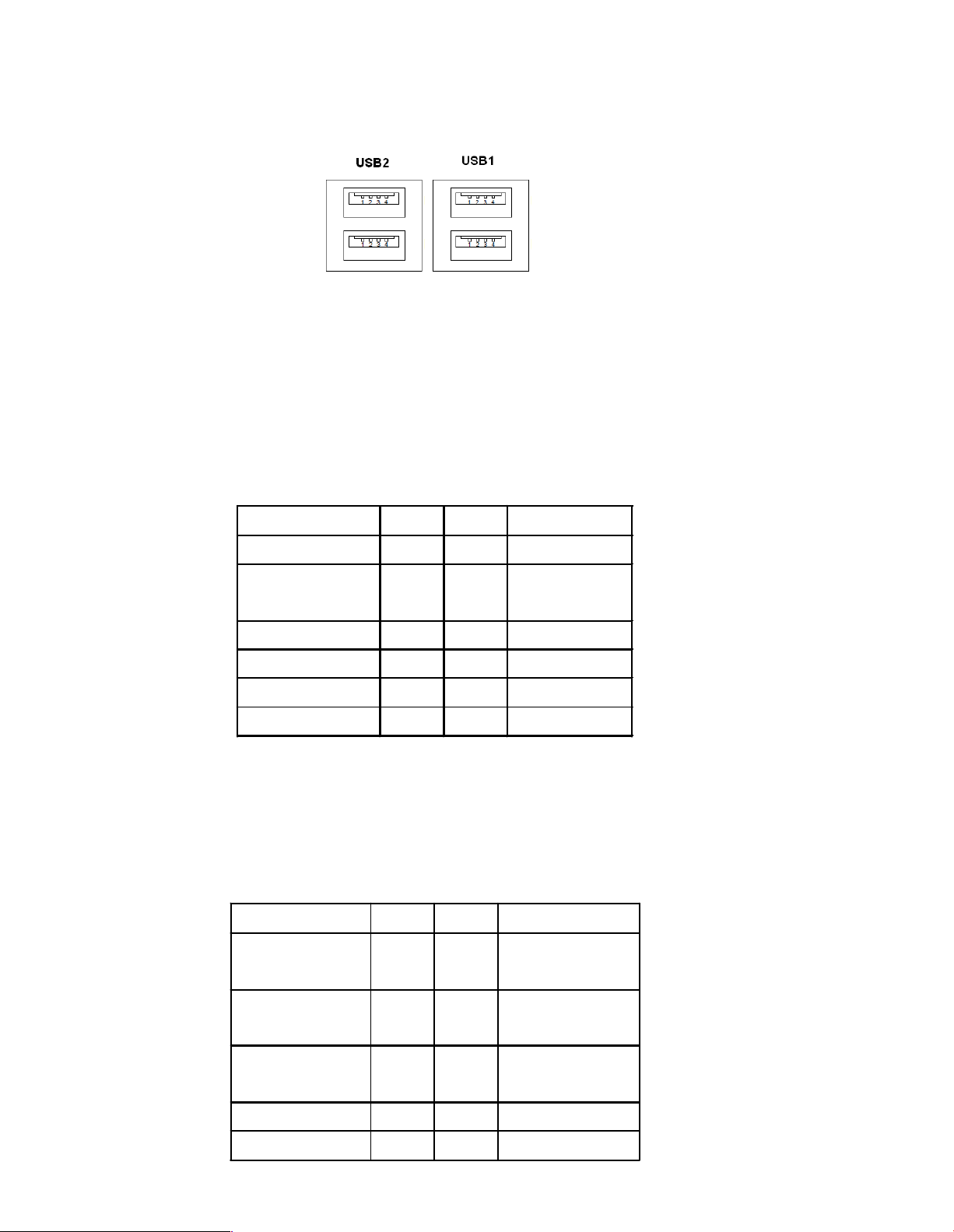

12. USB1/2: (Double stack USB type A), Rear USB connector, it provides up to 4

USB2.0 ports, speed up to 480Mb/s.

13. AUDIO: (2.0mm Pitch 2X6 Pin Header), Front Audio, An onboard Realtek

ALC662 codec is used to provide high-quality audio I/O ports. Line Out can be

connected to a headphone or amplifier. Line In is used for the connection of

external audio source via a Line in cable. MIC is the port for microphone input

audio.

Signal Name

Pin#

Pin#

Signal Name

VCC(+5V)

12Ground

LINE_OUT_L

34LINE_OUT_

R

FRO NT_JD

56LINE1_JD

LINE_IN_L

78LINE_IN_R

MIC _IN_L

910MIC _IN_R

Ground

11

12

MIC 1_JD

14. GPIO1: (2.0mm Pitch 2x5 Pin Header),General-purpose input/ou tput p ort, it

provides a group of self -programming in terfaces to customers for flexible u se.

Signa l Name

Pin#

Pin#

Signal Name

Ground

12GPIO18_OUT

1

GPIO20_OUT

2

34GPIO33_OUT

3

GPIO34_OUT

4

56GPIO18_IN1

GPIO20_IN2

78GPIO33_IN3

GPIO34_IN4

910+5V

Page 19

15. BZ: onboard buzzer.

16. CPU_FAN/SYS_FAN1: (2.54mm Pitch 1x3 Pin He ader),Fan connector,

cooling fans can be connected directly f or use . You may set the rotation condition of

cooling fan in menu of BIOS CMOS Setup.

Pin#

Signal Nam e

1

Ground

2

VCC

3

Rotation

detection

Note:

Output powe r of cooling fan must be limited under 5W.

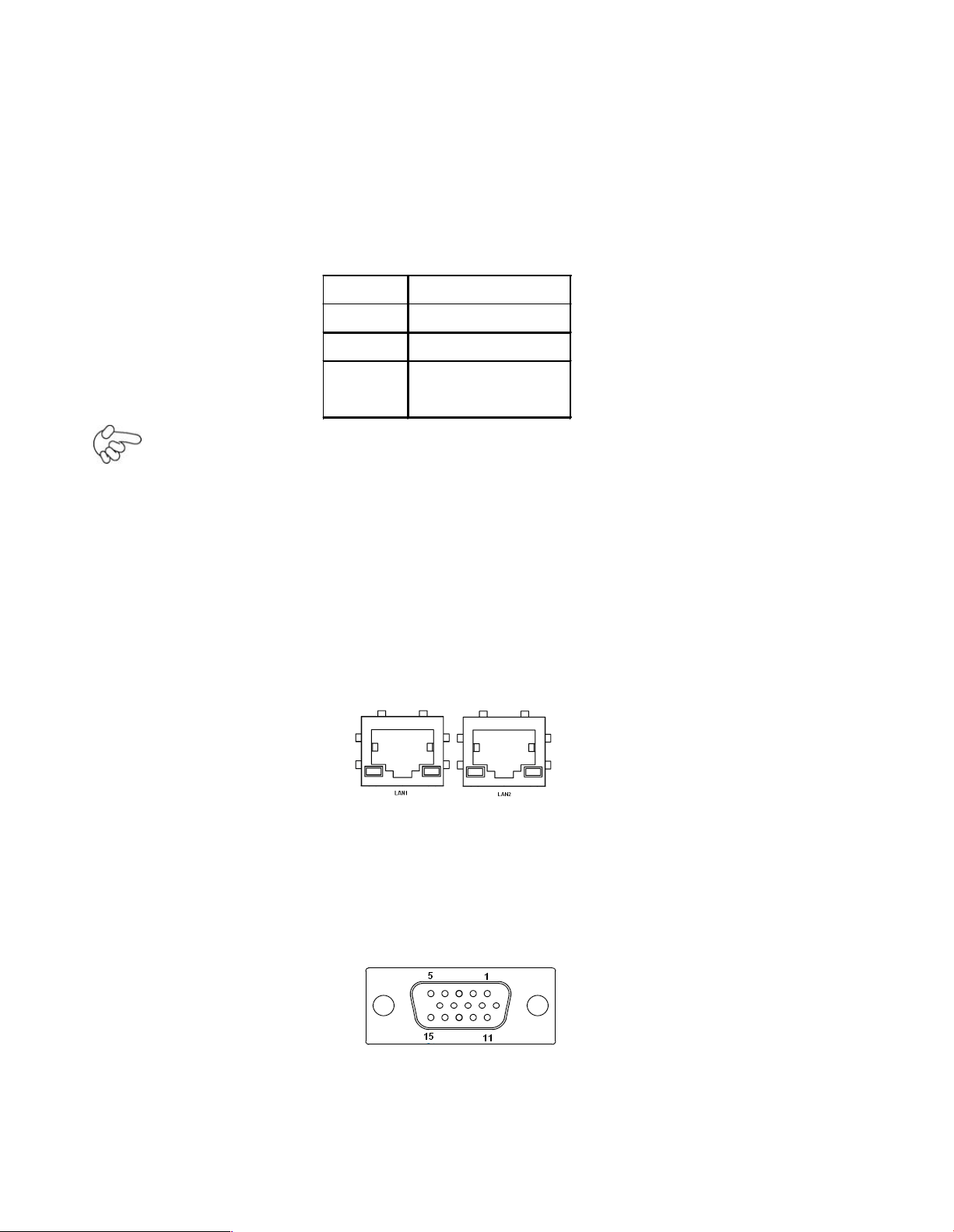

17. LAN1/2: (RJ45 Connector), Rear LAN port,2 standard 10/100/1000M RJ -45

Ethernet ports are provid ed. Used In tel 82574L chipset ,LINK LED (green ) and

ACTIVE LED (yellow) respective ly located a t the l eft-hand and right-hand side of the

Ethernet port indicate the activity and transmission state of LAN.

18. CRT1: (CRT Connector DB15),Video Graphic Array Port, provide high-quality

video output. They cannot w ork at the same time for CRT and VGA1.

19. VGA1: (CRT 2.0mm Pitch 2X5 Pin Head er), Video Graphic Array Port, Provide

2x5Pin cable to VGA Port, the y cannot work at the sa me time for CRT and VGA1.

Page 20

Signal Name

Pin#

Pin#

Signal Nam e

CRT_RED

12Groun d

CRT_GREEN

34Groun d

CRT_BLUE

56VGA_EN

CRT_H_SYN

C

78CRT_DDCDAT

A

CRT_V_SYNC

910CRT_DDCCL

K

20. INVERTER1: (2.0mm Pitch 1x6 box Pin H eader), Bac klight control

connect or for LVDS1.

Pin#

Signa l Name

1

+DC12V

2

+DC12V

3

Ground

4

Ground

5

BKLT_EN

6

BKLT_CTRL

Note:

Pin6 is backlight control signal, support DC or PWM mode, mode select at BIOS CMOS

menu.

21. LVDS1: For 18/24 bit LVDS output connector, Fully supported by Intel GM45

chipset, the interface features dual c hannel 18/24-bit output. Model name of the

interface connector is Hirose DF13-40DP-1.25V.

Signal Name

Pin#

Pin#

Signal Name

VDD521

VDD5

Ground

43Ground

VDD33

65VDD33

LB_D0_N

87LA_D0_N

LB_D0_P

10

9

LA_D0_P

Ground

12

11

Ground

LB_D1_N

14

13

LA_D1_N

LA_D1_P

16

15

LA_D1_P

Ground

18

17

Ground

Page 21

LB_D2_N

20

19

LA_D2_N

LB_D2_P

22

21

LA_D2_P

Ground

24

23

Ground

LB_CLK_N

26

25

LA_CLK_N

LB_CLK_P

28

27

LA_CLK_P

Ground

30

29

Ground

DS_DDC_DATA

32

31

LVDS_DOC_CLK

Ground

34

33

Ground

LB_D3_N

36

35

LA_D3_N

LB_D3_P

38

37

LA_D3_P

NC4039

NC

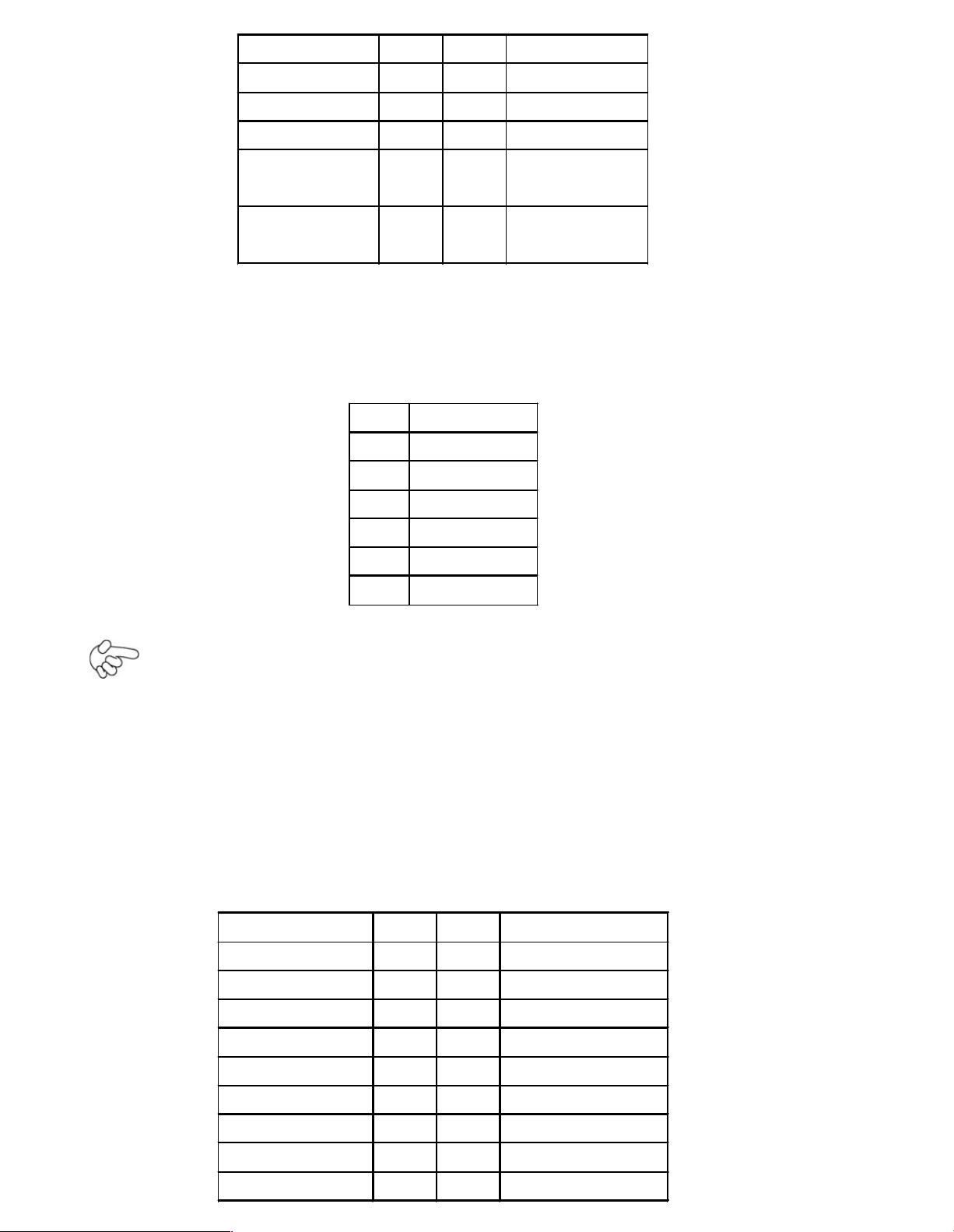

22. DC_IN2: (5.0mm 1x2 Pin Connector),DC 12V System power input connector

Pin#

Signal Name

1

+12V

2

Ground

DC_IN1: (2x2 box Pin Connector),DC12V System power input co nnector

Pin#

Signal Name

1

Ground

2

Ground

3

+12V

4

+12V

Page 22

Note:

Make sure that the voltage of power supply is DC(12± 5%)V before power on, or

it may cause boot up failure and even system damage.

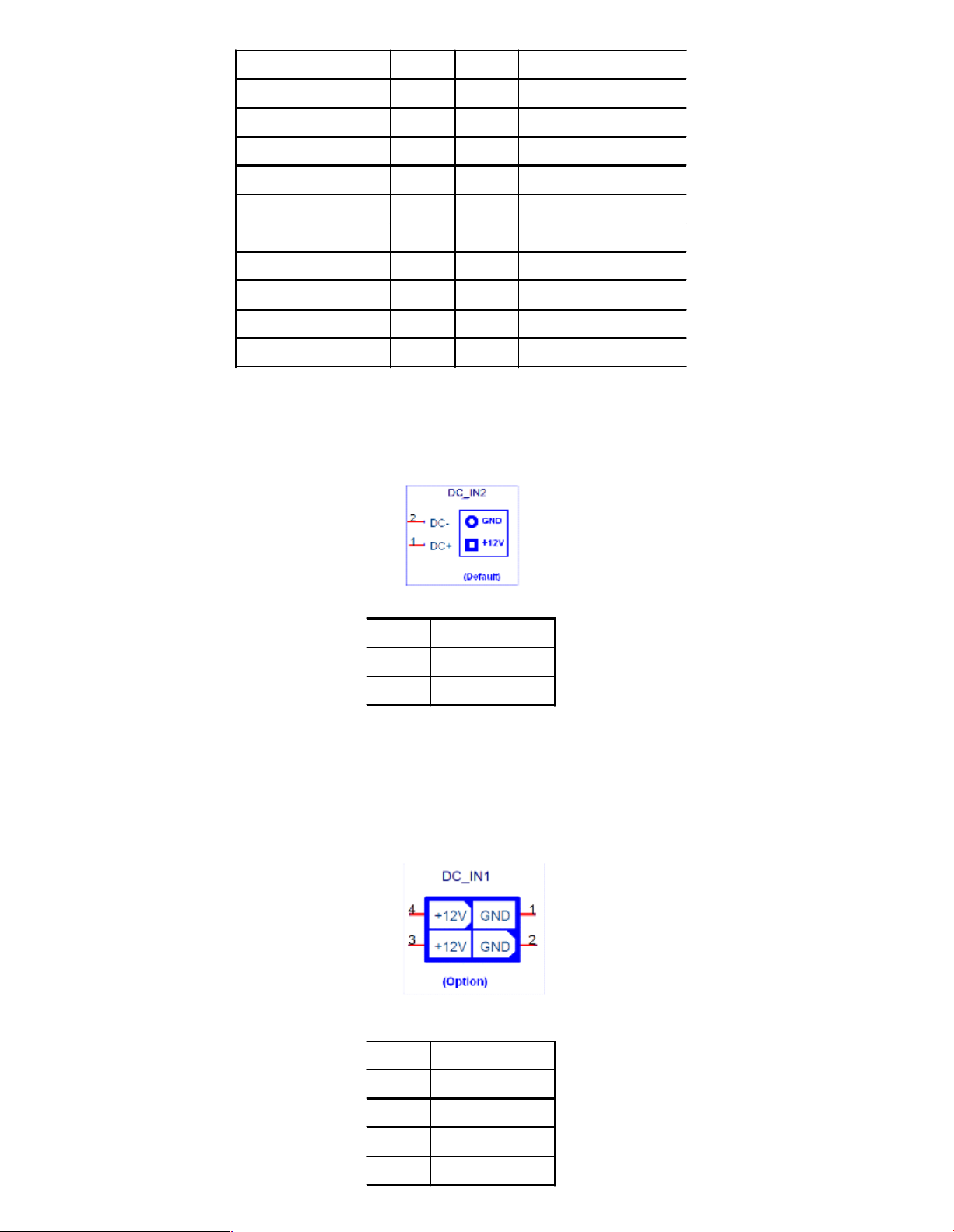

23. SATA1/2: (SATA 7P),SATA1,SATA2 SATA Connectors, Two SATA conne ctors are

provided, with transfer speed up to 3.0Gb/s.

24. SATA_P1: (2.5mm Pitch 1x2 box Pin Header),an onboard 5V output

connector is reserved to provide power for IDE/SATA devices.

Pin#

Signal

Name

1

+DC5V

2

Ground

Note:

Output current of the conne ctor must not be above 1A.

25. JP_104P: (2.0mm Pitch 1X3 Pin Head er) PC104+ port voltage selection jumper,

select voltage for PCI-104 Plus device. The default for this jumper is

“

all open

”

, meaning the user must select the voltage to be used.

JVCCIO

PC104+ VCCIO

Voltage

all O pen

Default

CLOSE 1-2

+3.3V PCI C ard

CLOSE 2-3

+5V PCI Card

26. PC104+: (4x30 Pin), PC104 plus connector, it conforms to standard PC104+

specification. Can expand support fou r PCI devices.

27. H1/H2/H3/H4: CPU FAN SCREW HOLES, Four screw holes for fixed CPU Cooler

assemble.

Page 23

28. H7/H8/H9/H10: GM45+ICH9M Heat Sink SCREW HOLES, Four screw holes for

intel GM45 and ICH9M Heat Sink assemble.

29. H11/H12/H13: PC104+ CARD SCREW HOLES, Three screw holes f or PC104+

card assemble.

30. LED1/LED3: LED STATUS. LED1:Motherboard Standby Power Good

status LED3: Mot herboard CPU Power Go od status.

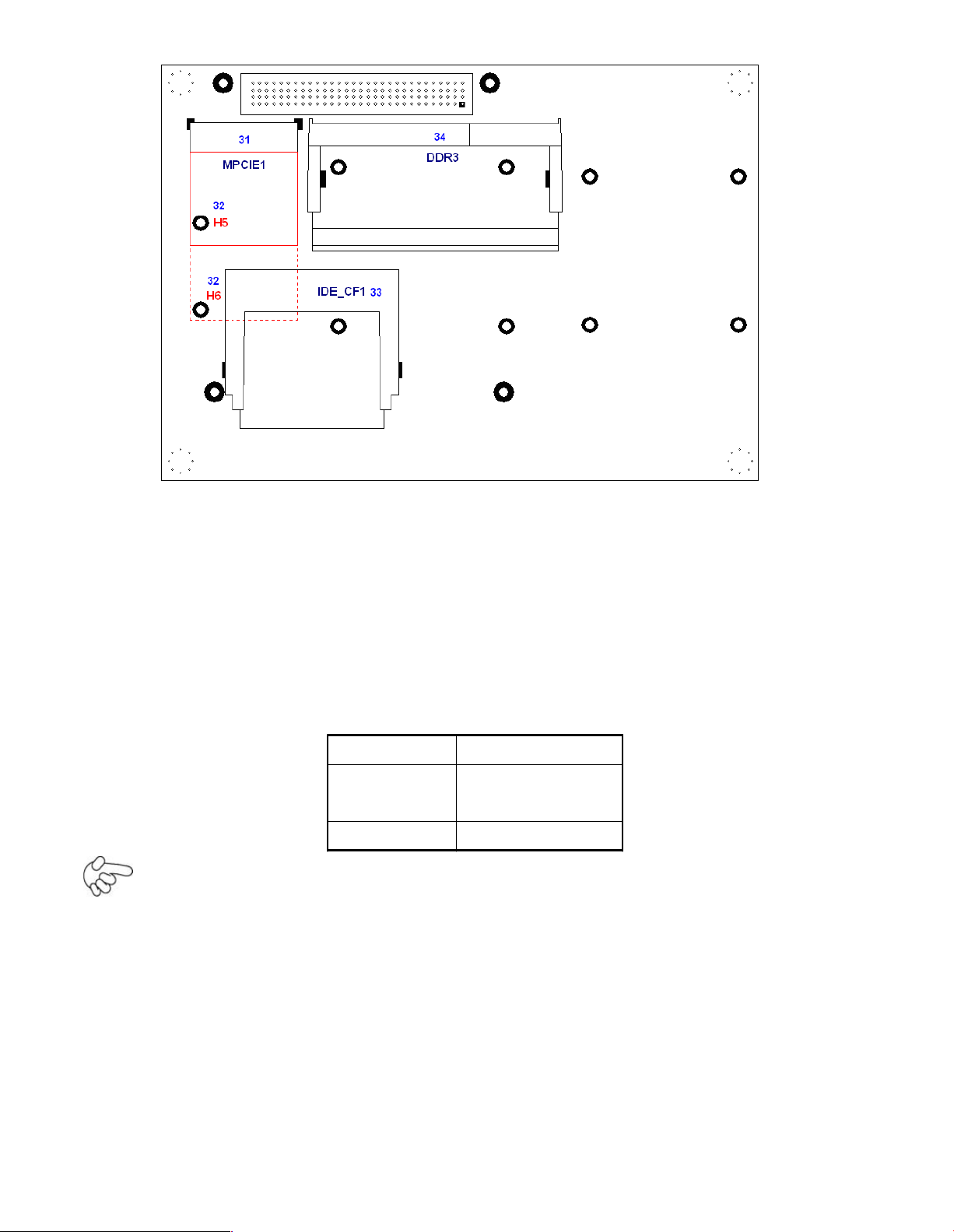

31. MPCIE1: (30mmx30mm Socket 52Pin),mini PCIE socket, it is located at the

bottom, it supp orts mini PCI-E devices with USB2.0, SMBUS and PCI-E signal.

32. H5/H6: MPCIE1 SCREW HOLES, H5 for mini PCIE c ard (30mmx30mm Socket 52

Pin)

assemble. H6 Reserve.

33. IDE_CF1: (CF Card socket), it is located at the bo ttom of the board an d

serves as an insert interface for Type I and Type II Compact Flash card. The

operating voltage of CF card can be set as 3.3V or 5 V. The default setting of the

product is 3.3V.

34. DDR3: (SO-DIMM 204Pin socket), DDRIII memory socket, the so cket is located at

the bottom of the board and supports 204Pin 1.5V DDR III 800/1066MHz FSB

SO-DIMM memory module up to 4GB.

35. PS2: (2.0mm Pitch 1X6 box Pin He ader), PS/2 keyboard and mouse port, the

port can be connected to PS/2 keyboard or m ouse via a dedicated cable for direct

used.

Pin#

Signal

Name

1

KBDATA

Page 24

2

MSDATA

3

Ground

4

+5V

5

KBCL K

6

MSCLK

3 BIOS Setup Description

3.1 Operations after POST Screen

After CMOS discharge or BIOS flashing operation, the system will display the

following s creen for your further operation. Press F2 key to continue or F1 key to

enter CMOS Setup.

AMIBIOS©2006 American Mega trends , Inc.

BIOS Date: 03/08/11 2 3:27:33 Ver: 08.00.15

CPU : GenuineIntel(R) CPU 575 @ 2.00GHz

Speed : 2.00 GHz

Press F11 for BBS POPUP

Initializing US B Controllers. . Done.

2013M B OK

Auto-Detecting Pri Master.. IDE Hard Disk

Pri Master : Hitachi HTS545016B9A300 PB0C64G

Ultra DMA – 5, S.M.A.R.T. Capable and Status

OK Auto – detecting USB Mass Storage Devices ..

00 USB Mass storage devices found and configured

CMOS Settings Wrong

CMOS Data / Time Not Set

Press F1 to Run SETUP

Press F2 to load default values and continue

0085

After optimizing a nd exiting CMOS Setup, the POST screen displayed for the first time is

as follows and includes basic information on BIOS, CPU, memory, and storage devices.

AMIBIOS©2009 American Mega trends , Inc.

BIOS Date: 03/08/11 23:27:3 3 Ver: 08.00.15

CPU : GenuineIntel(R) CPU

575

@ 2.00GHz

Speed : 2.00 GHz

Press DEL to Run Setup

Press F11 for BBS POPUP

Page 25

Initializing USB Controllers. . Done.

2013MB OK

Auto-Detecting Pri Master.. IDE Hard Disk

Pri Master : Hitachi HTS545016B9A300 PB0C64G

Ultra DMA – 5, S.M.A.R.T. Capable and Status OK

Auto – detecting USB Mass Storage Devices ..

00 USB Mass storage devices found and configured.

Checking NVRAM..

0085

Press F11 key to enter Boot Menu during POST, as shown by th e following figure.

Please selec t boot device

Hitachi HTS545016B9A300

USB: USB Hotplug FDD

SATA:4M-C SS H AK40 -004G

?

and to move selection

ENTER to select Boot device

ESC to boot using defaults

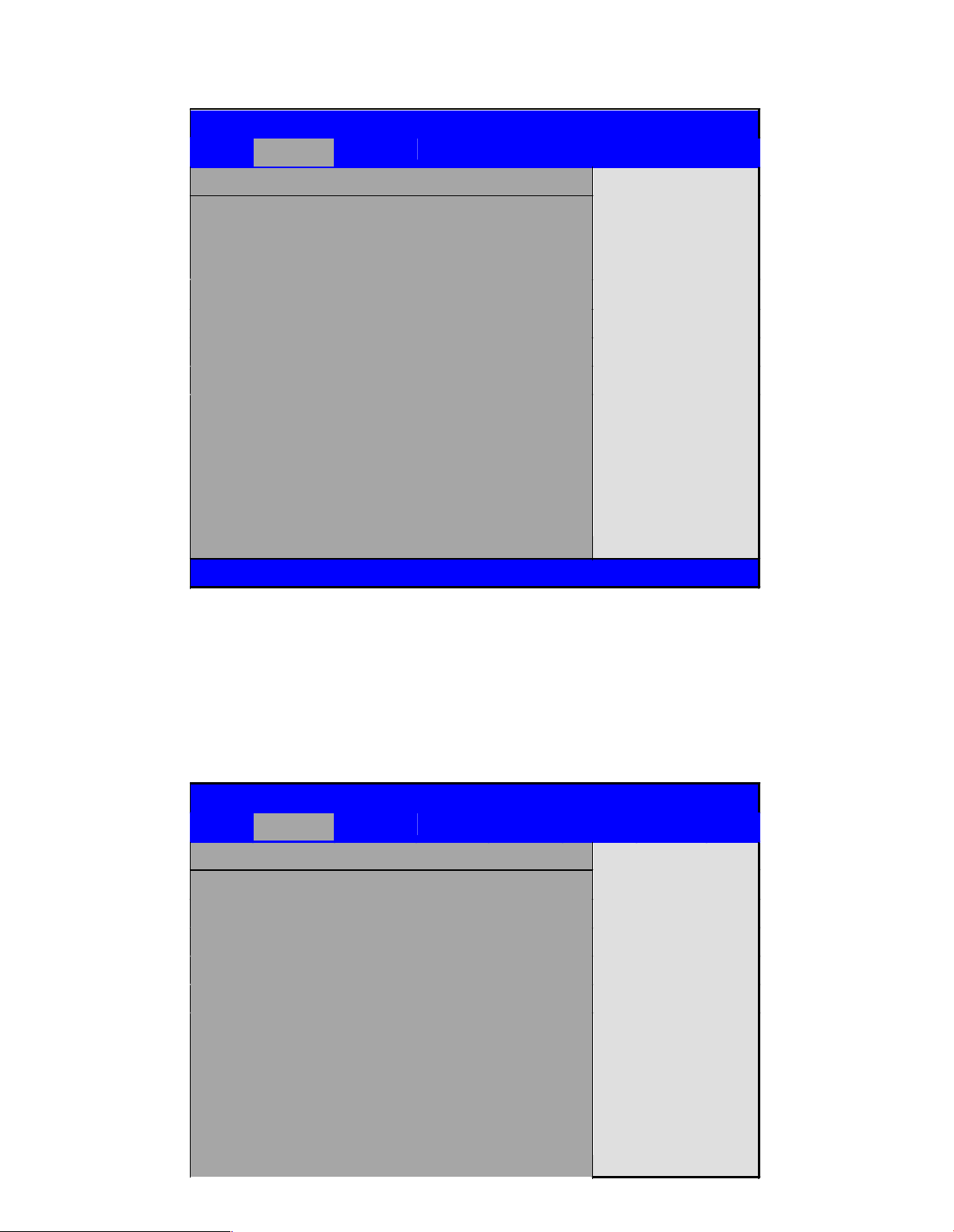

3.2 BIOS SETUP UTILITY

Press [Del] ke y to enter BIOS Setup utility during POST, and then a main menu

containing system summary information will app ear.

BIOS SETUP UTILITY

Main

Advanced

PCIPnP

Boot

Security

Chipset

Exit

System Ove rview

User [ENTER] [TAB]

or [SHIFT-TAB] to

Select a field

Use[+] or [-] to

configure system Time.

AMIBIOS

Build Date : 03/08/11

ID : L801V 010

Processor

Genuine Intel(R) CPU 575 @ 2.00GHz

Speed :2000MHz

Page 26

Select Screen

Select Item

+- Charge Field

Tab Select Field

F1 General Help

F10 Save and Exit

ESC Exit

System Memory

Size :1981MB

System Time [00:0 1:09]

System Date [Tue

v02.61©Copyright 1985-2006 American Megatrends , Inc.

3.3 System Overview

BIOS SETUP UTILITY

Main

Advanced

PCIPnP

Boot

Security

Chipset

Exit

System Overview

User [ENTER] [TAB]

or [SHIFT-TAB] to

Select a field

Use[+] or [-] to

configure system Time.

Select Screen

Select Item

+- Charge Field

Tab Select Field

F1 General Help

F10 Save and Exit

ESC Exit

AMIBIOS

Version : 08.00.15

Build Date : 03/0 8/11

ID : L801V010

Processor

Genuine Intel(R) CPU 575 @ 2.00G Hz

Speed :2000MHz

System M emory

Size :1981MB

System Time [00:02:26]

System Date [Tue 03/08 /2011]

V02.61©Copyright 1985-2006 American Mega trends , Inc.

System Time:

Set the system time, the time format is:

Hour : 0 to 23

Minute : 0 to 59

Second : 0 to 59

System Date:

Set the system date, the date format is:

Day: Note that th e „ Day?automatically changes when y ou set the

Page 27

Month: 01 to 12

Date: 01 to 31

Year: 2009 to 2099

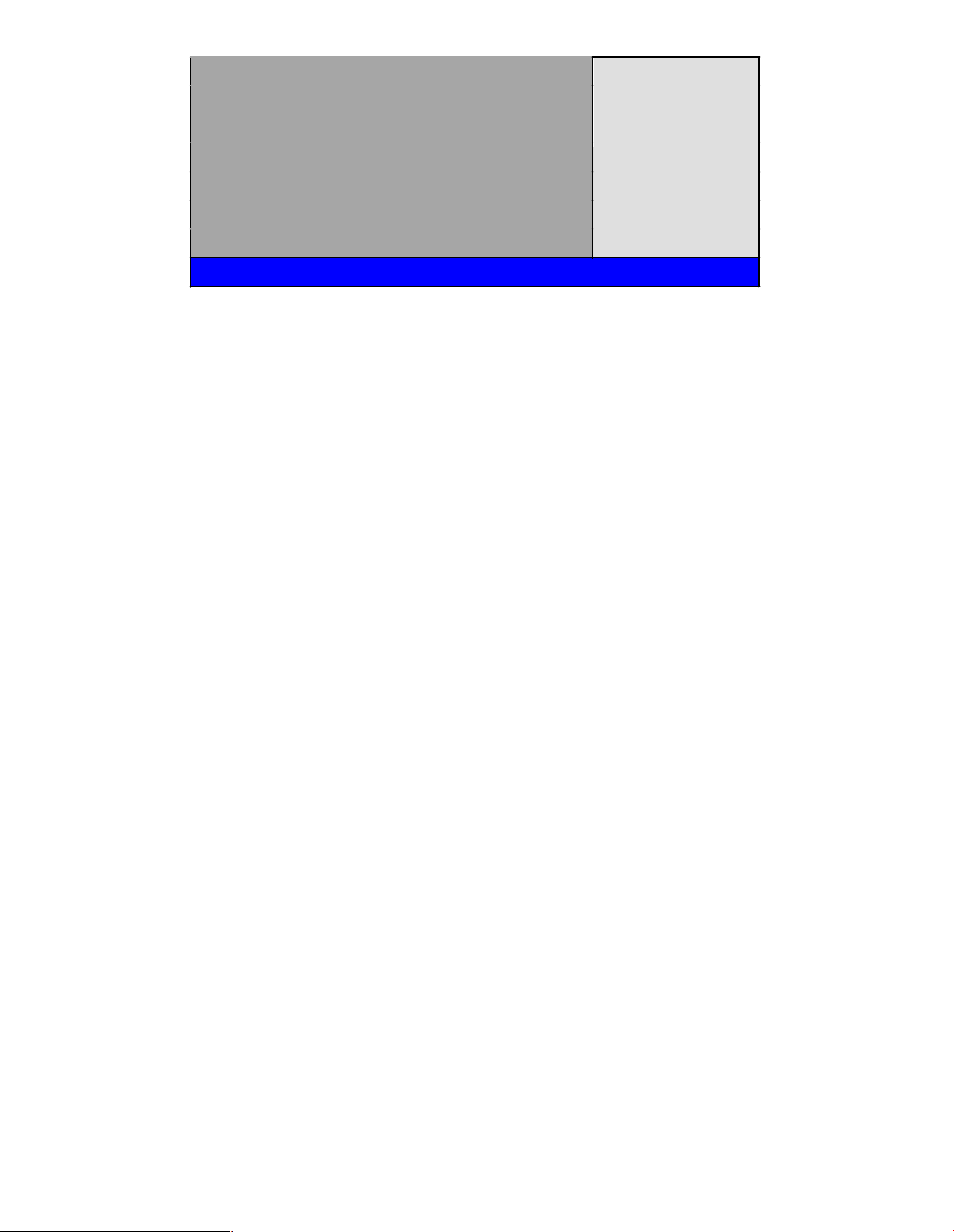

3.4 Advanced Settings

BIOS SETUP UTILITY

Main

Advanced

PCIPnP

Boot

Security

Chipset

Exit

Advanced Settin gs

Configure CPU

Select Screen

Select Item

Enter Charge Field

F1 General Help

F10 Save and Exit

ESC Exit

WARNING: Setting wrong values In below

sections

may cause system to malfunction.

? CPU Configuration

? IDE Configuration

? Super IO Configurati on

? Hardware Health Con figuration

? ACP I Configuration

? AHCI Configuration

? MPS Configuration

? PCI Express Configuration

? Smbios Configuratio n

? USB Configuration

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

3.4.1 CPU Configuration

BIOS SETUP UTILITY

Advanced

Configure adv anced CPU settings

Module Version: 3F.10

For UP platforms,

Leave it enabled.

For DP/MP serves,

Manufacturer : Intel

Page 28

Genuine Intel (R) CPU 575 @ 2.00 GHz

It may use to tune

Performance to the

Specific application.

Select Screen

Select Item

+- Charge Field F1

General Help F10

Save and Exit ES C

Exit

Frequency :2.00GHz

FSB Speed : 668MHz

Cache L1 :32 KB

Cache L2 :1024 KB

Ratio Actual Value :L2

Hardw are Prefetch er [Enabled]

Adjacent Cache Line Pre fetch [Enable d]

Max CPU ID Value Limit [Disabled]

Ex ecu te-Disable Bit Cap ability [Enabled]

Inte l(R) C-STATE tech [Disabled]

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

Hardware Prefetcher:

[Enabled]

[Disabled]

Adjacent Cache Line Prefetch:

[Enabled]

[Disabled]

Max CPUID Value Limit:

[Enabled]

[Disabled]

Execute-D isable Bit Capability:

[Disabled]

[Enabled]

Intel(R) C-STATE tech:

[Disabled]

[Enabled]

3.4.2 IDE Configuration

BIOS SETUP UTILITY

Advanced

Page 29

IDE Configur ation

Disabled

Compa tible

Enhanced

Select Screen

Select Item

+- Charge Field F1

General Help F10

Save and Exit ESC

Exit

SATA#1 Configuration [Compatible]

Configure SATA as [IDE]

SATA#1 Configuration [Enhanced]

? Primary IDE Master : [No t

Detected]

? Primary IDE Slaver : [Not

Detected]

? Secondar y IDE Master : [N ot

Detected]

? Secondar y IDE Slaver : [N ot

Detected]

? Third IDE Master : [Not

Detected]

? Fo urth IDE Master : [H ard

Disk]

Hard Disk Write Protect [Disabled]

IDE De tect Time Out (Se c) [35]

ATA(PI) 80Pin Cable Detection [Host &

Device]

V02.61©Copyright 1985-2006 American Mega trends , Inc.

SATA# 1 Configuration:

[Compatible]

[Disabled]

[Enhanced]

Configure SATA as:

[IDE]

[AHCI]

SATA# 2 Configuration:

[Enhanced]

[Disabled]

Hard Disk Write Protect:

[Disabled]

Page 30

[Enabled]

IDE Detect Time O ut :

[35]

[0]

[5,10,15,20,25,30]

ATA(PI) 80Pin Cable Detection:

[Host & Device]

[Host]

[Device]

3.4.3 Super IO Configuration

BIOS SETUP UTILITY

Advanced

Configure Win627UHG Super IO Chipset

Allow BIOS to Select

Serial Port Base

Address.

Select Screen

Select Item

+- Charge Field F1

General Help F10

Save and Exit ESC

Exit

Serial Port1 Address [3F8]

Serial Port2 Address [2F8]

Serial Port3 Address [3E8]

Serial Port3 IRQ [IRQ 4]

Serial Port3 Mode [RS-485]

Serial Port4 Address [2E8]

Serial Port4 IRQ [IRQ 3]

Serial Port5 Address [238]

Serial Port5 IRQ [IRQ 5]

V02.61©Copyright 1985-2006 American Mega trends , Inc.

Serial Port3 Mode:

COM3 Opti ons: [RS485 ]

[RS42 2]

[RS422] for RS422 Mode

[RS48 5] for RS485 Mod e

Page 31

3.4.4 Hardware Health Configuration

BIOS SETUP UTILITY

Advanced

Hardw are Hea lth Configuration

55 /131

?

60 /140

?

65 /149

?

70 /158

?

Select Screen

Select Item

+- Charge Field F1

General Help F10

Save and Exit ESC

Exit

System Temperature :36? /96

?

CPU Temperature :45? /113

?

CPUFAN Spee d :5018 RPM

Vcore :1.064V

AVC C :5.091 V

5VCC :5.100 V

3.3V :3.328 V

5.0V :5.01 V

12V :12.01 V

VSB :5.10 V

VBAT :3.400 V

Smart Fan Configuration

Maximum CPU Temperature [60? /140?]

Maximum PWM Duty for CPU Fan [60 %]

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

System Temperature:

Show you the current system temperature.

CPU Temperature:

Show you the current CPU temperature.

CPUFAN Speed:

Show you the current CPU Fan operating speed.

Maximum CPU Temperature:

[60 /140?]

[55 /131?]

[65 /149?]

[70 /158?]

Page 32

Minimum PWM Duty for CPU Fan:

[60% ]

[50%]

[70%]

[80%]

3.4.5 ACPI Configuration

ACPI Se tting:

[Advanced ACPI Configuration]

ACPI Version Features:

[ACPI V1.0]

[ACPI V2.0]

[ACPI V3.0]

ACPI APIC support:

[Enabled]

[Disabled]

AMI OEMB table:

Headless mode:

[Enabled]

[Disabled]

[Disabled]

[Enabled]

[Chipset ACPI Configuration]:

APIC ACPI SCI IRQ:

[Disabled]

[Enabled]

High Performance Event Timer:

[Disabled]

[Enabled]

3.4.6 AHCI Configuration

BIOS SETUP UTILITY

Advanced

AHCI Setting

Enables For supporting

AHCI BIOS Support [Enable d]

Page 33

AHCI CD/DVD Boot Time out [35]

Select Screen

Select Item

Enter Go to sub screen

F1 General Help

F10 Save and Exit

ESC Exit

? AHCI Port0 : [Not Detected]

? AHCI Port1 : [Not Detected]

? AHCI Port2 : [Not Detected]

? AHCI Port3 : [Not Detected]

? AHCI Port4 : [Not Detected]

? AHCI Port5 : [Not Detected]

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

While entering setup, BIOS auto detects the presence of IDE devices. This displays the

status of auto detecting of IDE devices

3.4.7 MPS Configuration

BIOS SETUP UTILITY

Advanced

MPS Co nfiguration

Select MP S

Revision

Select Screen

Select Item

+- Charge Field F1

General Help F10

Save and Exit ECS

Exit

MPS Revision [1.1]

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

MPS Revis ion:

[1.1]

[1.4]

Page 34

3.4.8 PCI Express Configuration

BIOS SETUP UTILITY

Advanced

PCI Express Configuration

Enables/Disables

PCI Express L0s and

L1 Link Power

States.

Select Screen

Select Item

+- Charge Field

F1 General Help

F10 Save and Exit

ESC Exit

Active State Power -Management

[Disab led]

V02.61©Copyright 1985-2006 American Mega trends , Inc.

Active State Pow er Management :

[Disabled]

[Enabled]

3.4.9 Smbios Configuration

BIOS SETUP UTILITY

Advanced

Smbios Configuration

SMBIOS SMI Wrapper

Support for PnP Func

50h-54h

Select Screen

Select Item

+- Charge Field

F1 General Help

F10 Save and Exit

ESC Exit

Smbios Sm i Support [Enabled]

Page 35

V02.61©Copyright 1985-2006 American Mega trends , Inc.

Smbios Smi Support:

[Enabled]

[Disabled]

3.4.10 USB Configuration

BIOS SETUP UTILITY

Advanced

USB Configuration

Enables support for

legacy USB.ATUO

option disables legacy

support if no USB

devices are connected

Select Screen

Select Item

+- Charge Field

F1 General Help

F10 Save and Exit

ESC Exit

Mo dule Ve rsion – 2.24.3-13.4

USB Devices Enabled :

1Keyboard

Leg acy USB Support [Enabled]

USB2.0 Controller Mode [Fullspeed ]

BIOS EHCI Hand-Off [Enabled]

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

Legacy USB Support:

[Enabled]

[Disabled ]

USB2.0 C ontroller Mode:

[FullSpeed]

[HiSpeed]

BIOS EHCI Hand-Off:

[Enabled]

[Disabled]

Page 36

3.5 Advanced PCI/PnP Settings

This part describes conf igurations to be made on PCI bus s ystem. PCI, namely

Personal Computer Interconnect, is a computer bus that allows I/O device to operate

nearly as fast as CPU in its own way. Some technical terms will be mentioned here. We

recommend that non-professional users not make changes from factory default

settings.

BIOS SETUP UTILITY

Main

Advanced

PCIPNP

Boot

Security

Chipset

Exit

Advanced PCI/PnP Settings

Clear NURAM during

System Boot.

Select Screen

Select Item

+- Charge Field F1

General Help F10

Save and Exit ESC

Exit

WARNING: Setting wrong values In below

sections

may cause system to malfunction.

Clear NVRAM [No]

Plug & Play O/S [No]

PCI Latency Timer [64]

Allocate IRQ to PCI VGA [Yes]

Palette Snooping [Disabled]

PCI IDE BusMaster [Disabled]

OffBoard PCI/ISA IDE Card [Auto]

IRQ3

[Available]

IRQ4

[Available]

IRQ5

[Available]

IRQ7

[Available]

IRQ9

[Available]

IRQ10

[Available]

IRQ11

[Available]

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

Clear NVRAM:

[No]

Page 37

[Yes]

Plug & Play OS:

[ No]

[Yes]

PCI Latency Timer:

[32]

[96]

[64]

[128]

[160]

[192]

[224]

[248]

Allocate IRQ to PCI VG A:

[Yes]

[

No]

Palette Snooping:

[Disabled]

[Enabled]

PCI IDE BusMaster:

[Disabled]

[Enabled]

OffBoard PCI/ISA IDE Card:

Some PCI IDE cards m ay require this to be set to the PCI slot number that is

hold ing the card. Auto:Works for most PCI IDE Cards.

[Auto]

[PCI Slot1]

[PCI Slot2]

[PCI Slot3]

[PCI Slot4]

[PCI Slot5]

[PCI Slot6]

IRQ3/4/5/7/9/10/11/14/15:

[Available]

Page 38

[

Reserved]

Ava ilable: Specified IRQ is available to be used by PCI/PnP dev ices.

Reserved: Spe cified IRQ is reserved f or use by legacy ISA devices.

DM A Channel 0/1/3/5/6/7:

[Available]

[

Reserved]

Available: Specified DMA is available to be used by PCI/PnP devices.

Reserved: Spe cified DMA is reserved for use by legacy ISA devices.

Reserved Memory Size:

Size of m emory block to reserve for legacy ISA devices.

[Disabled]

[16k]

[32k]

[64k]

3.6 Boot Settings

BIOS SETUP UTILITY

Main

Advanced

PCIPnP

Boot

Security

Chipset

Exit

Boot Settings

Configure Settings

During System Boot

Select Screen

Select Item

Enter Go to sub screen

F1 General Help

F10 Save and Exit

ESC Exit

? Boot Setting Configuration

? Boot Device Priority

? H ard Disk Drives

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

Page 39

Boot Setting Configuration

Conf igure Settings during System Boot.

Quick Boot:

[Enabled]

[Disabled]

Allows BIOS to skip certain tests while b ooting .This will decrease the time

needed to boot the system.

Quiet Boo t:

[Disabled]

[Enabled]

Disabled: Displays normal PO ST messages.

Enabled: Displays O EM lo go instead of POST messages.

AddOn ROM Dis play Mode:

Set display mode for Option ROM.

[Force BIOS]

[Keep Current]

Bootup N um Lock:

Select Power-on state for Numlock.

[On]

[Off]

PS/2 Mouse Support:

Select support for PS/2 Mou se.

[Auto]

[Enabled]

[Disabled]

Wait For „ F1? If Error:

W ait for F1 key to be press ed if error occurs.

[Enabled]

[Disabled]

Hit „ DEL? MessgaeDisplay :

Displays “ press” DEL to run Setup in

POST.

[Enabled]

[Disabled]

Interrupt 1 9 Capture:

Page 40

Enabled: Allows option ROMs to trap interrupt 19.

[Disabled]

[Enabled]

Boot Device Priority:

Specifies the Boot Device Priority s equence.

Hard Disk De vices :

Specifies the Boot Device Priority s equence from available Hard Drives.

3.7 Security Settings

BIOS SETUP UTILITY

Main

Advanced

PCI PnP

Boot

Security

Chipset

Exit

Security Settings

Install or Change the

password.

Select Screen

Select Item

Enter Charge

F1 General Help

F10 Save and Exit

ESC Exit

Supervisor Password :Not Installed

User Password :Not Installed

Change Supervisor Password

Change User Password

Boot Sector Virus Protect ion [D isabled]

V02.61©Copyright 1985-2006 Amer ican Mega trends , Inc.

Change Supervisor Pass word:

Install or Change the password.

Change U ser Password:

Install or Change the password.

Password Check:

[Setup]

Page 41

[Always]

Setup: Check password while invoking s etup.

Always: Check password while invoking setup a well as on each boot.

Boot Sector Virus Protection:

[Disabled]

[Enabled]

Enabled / Disabled Boot Sector Virus Protection.

Type the password with u p to 6 characters and then press Enter key. This will

clear all previously typed CMOS passwords. You will be requested to co nfirm the

pas sword. Type the password again a nd press Enter key. You may press Esc

key to abandon password entry operation.

To clear the password, just press Enter key w hen password input window

pops u p. A confirmation mes sage will be shown on the scree n as to whether the

pas sword will be disabled. You will ha ve direct access to BIOS setup without typing

any password after system reboot once the password is disabled.

Once the password feature is us ed, you will be requested to type the password

eac h time you enter BIOS setup. This will prevent u nauthorized persons from

changing your system configurations.

Also, the feature is capable of requesting users to enter the passwo rd prior to

system boot to control unauthorized access to your computer. Users may enable the

feature in Security Option of Advanced BIOS Fea tures. If Security Option is set to

System, you will be requested to enter the password befo re system boot and when

ent ering BIOS setup; if Security Option is set to Setup, you wi ll be requested for

pas sword for entering BIO S setup.

3.8 Advanced Chipset Settings

BIOS SETUP UTILITY

Main

Advanced

PCIPnP

Boot

Security

Chipset

Exit

Advanced Ch ipset Settings

Configure North Bridge

feature

WARNING: Setting wrong values in below

sections

may cause system to malfunction

? No rth Bridge Configuration

? South Bridge Configuration

Page 42

Select Screen

Select Item

Enter Go to sub screen

F1 General Help

F10 Save and Exit

ESC Exit

V02.61©Copyright 1985-2006 American Mega trends , Inc.

Note: Due to limited add ress length of BIOS, only a portion of panel parame ters are listed in

BIOS Setup. If the connecte d panel is not included in the parameter list, d isplay

problem will occur. In this case, Please do not change BIOS setup.

3.8.1 North Bridge Configuration

BIOS SETUP UTILITY

Chipset

North Bridge Chipset Con figuration

ENABLE: Allow

Remapping of

Over lapped PCI Memory

Above the total

Physical memory

DISABLE: Do not allow

remapping of memory

Select Screen

Select Item

+- Charge Field

F1 General Help

F10 Save and Exit

ESC Exit

Memor y Remap Feature

[Enabled]

PCI MMIO Allocation: 4Gb To 307 2MB

Memory Hole

[Disabled]

Initate Graphic Adapter [PCI/IGD]

IGD Graphics Mod e Select

[Enabled ,64M B]

IGD GTI Graphic smem ory size [No VT

mode,2MB]

PEG Port Configuration

? Video Function Configuration

V02.61©Copyright 1985-2006 American Mega trends , Inc.

Page 43

Memory Remap Feature:

[Enabled]

[Disabled]

Memory Hole:

[Disabled]

[15MB-16MB]

Initate Graphic Adapter:

Select w hich graphics controller to use as th e primary boot device.

[IGD ]

[PCI/IG D]

IGD G raphics Mode Select:

[Enabled, 64MB]

[Disabled]

[Enabled, 32MB]

[Enabled, 128MB]

Video Function Configuration:

BIOS SETUP UTILITY

Chipset

Video Function Con figuration

Options

Fixed Mode

DVMT Mode

Select Screen

Select Item

+- Charge option

DVMT Mode Select [DVM

Mo de]

DVMT/FIXED Memory

[256M B]

Boot Display Device

[VBIOS-D efault]

Flat Panel Type [1024x768

18bit 1c]

Backlight Control Su pport

[VBIOS-D efault]

Backlight Control Level [Level 5]

Page 44

Backlight Control Mode [DC]

F1 General Help

F10 Save and Exit

ESC Exit

Backlight Image Adaptation

[VBIOS-D efault]

V02.61©Copyright 1985-2006 American Mega trends , Inc.

DVMT Mode Select:

[DVMT Mode]

[FIXED Mode]

DVMT/FIXED Memory Size:

[256MB ]

[128MB]

[Maximum DVMT]

Boot Display Device:

[BIOS-Default]

[CRT]

[LVDS]

[CRT + LVDS]

Flat Panel Type:

[1024x 768 18bit 1ch]

[640x480 1 8bit 1ch]

[800x600 18bit 1ch]

[1280x800 18bit 1c h]

[1366x768 18bit 1c h]

[1024x 768 2 4bit 2ch]

[1440x900 24bit 2ch]

[1600x900 24bit 2c h]

[1680x1050 24bit 2ch]

[1920x1080 24bit 2ch ]

Backlight Control Support

[VBIOS-Default]

[Both BLC & BIA Disabled]

[BLC Enabled]

Page 45

Backligh t Control Control:

[Level5]

[Level0]

[Level1]

[Level2]

[Level3]

[Level4]

[Level6]

[Level7]

Note: Panel support PWM Function.

Backligh t Control Mode:

[DC]

[PW M]

Backligh t Imag e Ada ptation:

[VBIOS-Defau lt]

[BIA Disa bled]

[BIA Enabled at Level1]

[BIA Enabled at Level2]

[BIA Enabled at Level3]

[BIA Enabled at Level4]

[BIA Enabled at Level5]

3.8.2 South Bridge Configuration:

BIOS SETUP UTILITY

Chipset

South Bridg e Chipset Configuration

Options

Disabled

2 USB Ports

4 USB Ports

6 USB Ports

8 USB Ports

USB Functions [8 USB

Ports]

USB2.0 Controller [Enabled]

Keep USB Power at S5 [Enab led]

Wireless Controller [Enabled]

HAD Cont roller [Enabled]

SMBUS Controller [Enabled]

Page 46

SLP_S4 # Min. Assertion Width [4 to 5

Seconds]

Select Screen

Select Item

+- Charge Field F1

General Help F10

Save and Exit ESC

Exit

Restore on AC Power loss [Power off]

PCIE Ports Configurat ion

PCIE Port 0 [Auto]

PCIE Port 1 [Auto]

PCIE Port 2 [Auto]

PCIE Port 3 [Auto]

PCIE Port 4 [Auto]

PCIE H igh Priority Port [Disabled]

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

USB Functions:

[8 USB Ports]

[Disabled ]

[2 USB Ports]

[4 USB Ports]

[6 USB Ports]

USB 2.0 C ontroller:

[Enabled]

Keep USB Power at S5:

[Enabled]

[Disabled ]

Wireless Controller

[Enabled]

[Disabled ]

HDA Controller:

[Enabled]

[Disabled]

SMBUS Controller:

[Enabled]

[Disabled]

SLP_S4# Min. Assertion Width:

[1 to 2 Seconds]

Page 47

[4 to 5 Seconds]

[3 to 4 Seconds]

[2 to 3 Seconds]

Restore on AC Power Loss:

[Power Off]

[Powe r On]

[La st Status]

PCIE Ports Configuration:

PCIE Port 0:

PCIE Port 1:

[Auto]

[Enabled]

[Disabled]

[Auto]

[Enabled]

[Disabled]

PCIE Port 2:

[Auto]

[Enabled]

[Disabled]

PCIE Port 3:

[Auto]

[Enabled]

[Disabled]

PCIE Port 4:

[Auto]

[Enabled]

[Disabled]

PCIE High priority Po rt:

[Disabled]

[Port 0~Port5]

PCIE Port 0 IOxAPIC Enabled:

[Disabled]

[Enabled]

Page 48

PCIE Port 1 IOxAPIC Enabled:

[Disabled]

[Enabled]

PCIE Port 2 IOxAPIC Enabled:

[Disabled]

[Enabled]

PCIE Port3 IOxAPIC Enabled:

[Disabled]

[Enabled]

PCIE Port4 IOxAPIC Enabled:

[Disabled]

[Enabled]

PCIE Port5 IOxAPIC Enabled:

3.9 Exit Options

[Disabled]

[Enabled]

BIOS SETUP UTILITY

Main

Advanced

PCIPnP

Boot

Security

Chipset

Exit

Exit Options

Exit system setup

after saving the

changes

F10 key can be used

For this operation

Select Screen

Save Chan ges and Exit

Discard Chan ges and Exit

Discard Ch an ges

Load Optimal Defaults

Load Failsafe Defaults

Page 49

Select Item

Enter Go to sub screen

F1 General Help

F10 Save and Exit

ESC Exit

V02.61©Copyr ight 1985-2006 American Mega trends , Inc.

Save Changes and Exit:

Save confi guration changes and exit setup?

(F10 key can be used for this operation)

[OK]

[Cancel]

Discard Changes and Exit:

Discard Changes and Exit setup?

(ESC key can be used for this operation)

[OK]

[Cancel]

Discard Changes:

Discard changes?

(F7 key can be used for thi s operation)

[OK]

[Cancel]

Load Optimized Defaults:

Load Optimized D efaults?

(F9 key can be used for this operation)

[OK]

[Cancel]

Load Fail-Safe Defaults:

Load Fail-Safe Defaults?

(F9 key can be used for this operation)

[OK]

[Cancel]

Page 50

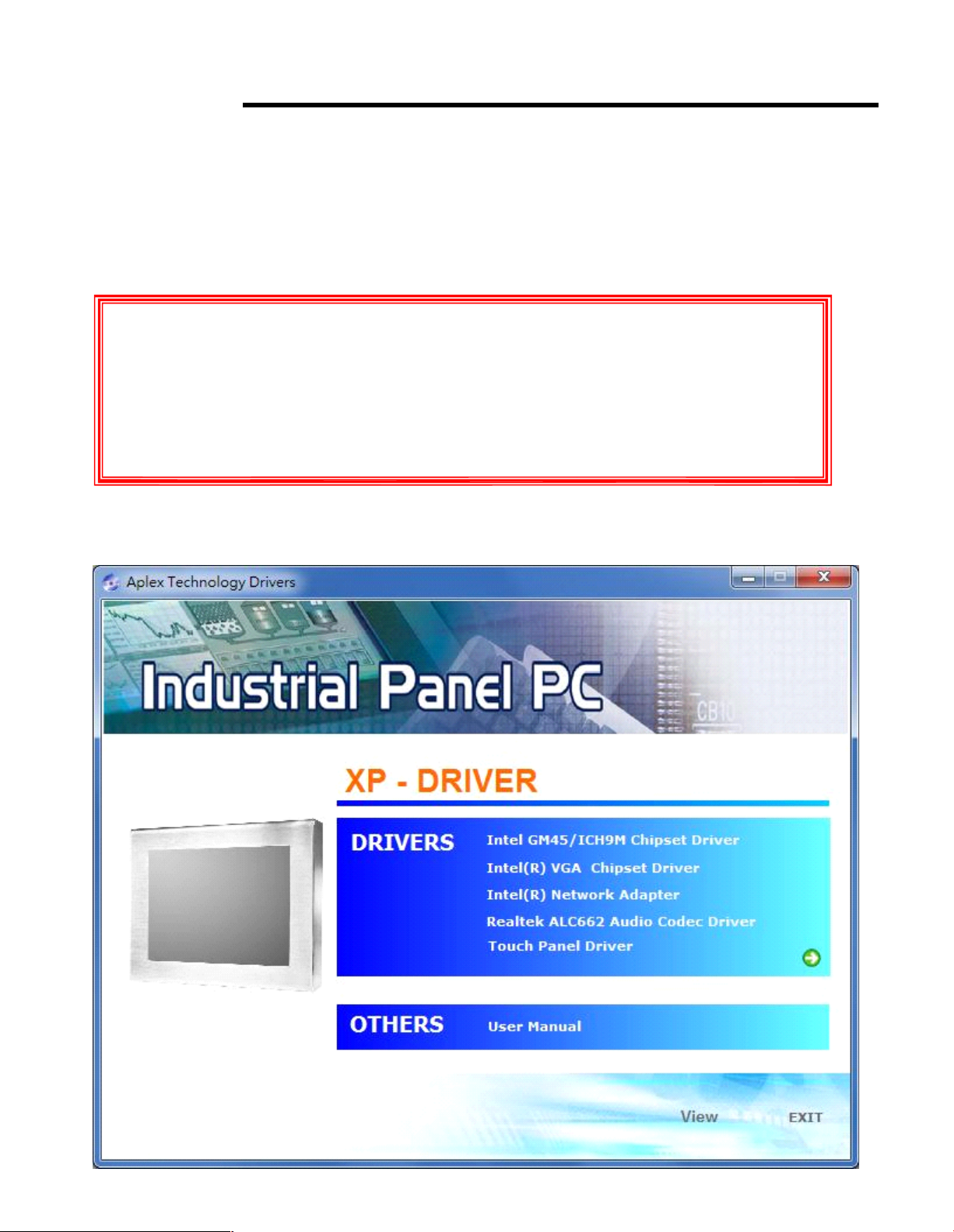

Chapter 4 Installation of Drivers

This chapter describes the installation procedures for software and drivers under the windows XP. The

software and drivers are include d with the motherboard. The contents include Intel chipset driver

VGA driver LAN drivers Audio driver Installation instructions are given below.

Important Note:

After installing your Windows o perating system (Windows XP), you must install

first the Chipset Software Installation Utility befo re proceeding with the

installation of drivers.

I

Page 51

4.1 Chipset Driver

To install the chipset driver, please follow the steps be low.

Step 1. Access Industrial Pa nel PC. Select GM45/ICH9M Chipset Driver from the list

Step 2. Click Next to setup p rogram.

Page 52

Step 3. Read the license agreement. Clic k Yes to accept all of the terms of the license agreement.

Step 4. Click Next to continue.

Page 53

Step 5. Click Next.

Step 6 . Select Yes, I want to restart this computer now. Click Finish, then remove any installation

med ia from the drives.

Page 54

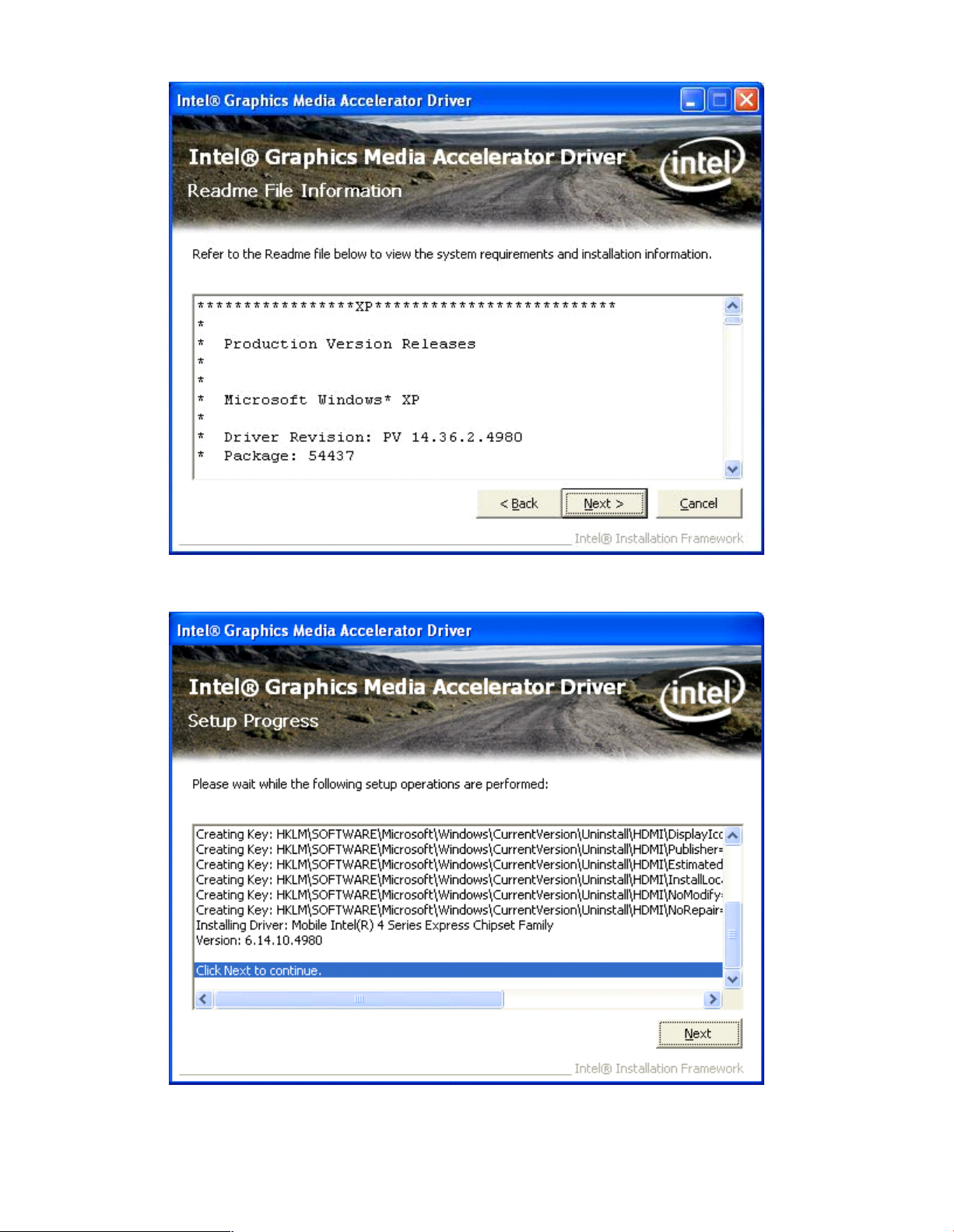

4.2 Graphics Media Accelerator driver

To install the VGA drivers, follow th e steps below to proceed with the installation.

Step 1.Select VGA Chipset Driver.

Step 2. Click Next to continue.

Page 55

Step 3. Click Next to continue s etup program.

Step 4. Read the lic ense agreement. Clic k Yes to accept all of the terms of the license agreement.

Page 56

Step 5. Clic k Next.

Step 6. Clic k Next to continue.

Page 57

Step 7 . Selec t Yes, I w ant to restart this computer now . Click Finish to complete installation.

4.3 Network Adapter

To install the N etwork Adapter device driver, please follow the steps below.

Step 1. Select Network Adapter.

Page 58

Step 2. Click Next to continue.

Step 3. Read the license agreement. Select I accept the terms in the license agreement then click

Next to continue.

Page 59

Step 4. Select Drivers, PROSet for Windows* Device Manager, Advanced Network

Services. Click Next to continue.

Step 5. Click Install to begin the insta llation.

Page 60

Step 6. Click Finish to complete the installation.

4.4 Realtek ALC662 HD Audio Codec Driver Installation

To install the Realtek ALC662 HD Audio Codec Driver, please f ollow the steps below.

Step 1. Select Realtek AL662 Audio Codec Driver from the list

Page 61

Step 2. Click Next to continue.

Step 3. Click Yes , I want to res tart my computer now. Click Finish to complete the in stallation.

Page 62

Chapter 5 Touch Screen Installation

This chapter describes how to install drivers a nd other software that will al low your PenMount 6000

Controller Board to w ork with different operating system s.

NOTE: PenMou nt USB drivers support up to 15 USB controllers.

5.1 Introduction to Touch Screen Controller Board

PenMount 6300 USB control board is a touch screen control board designed for USB interface an d

specific for 4, 5, 8-wire touch screens. It is designed with USB interface features with multiple devices

supporting function. PenMount 6300 control board using PenMount 6000 controller that has been

designed for those who may like and all-in-one solution with 10-bit A/D converter built-in to make the

tota l printed circuit b oard dense r, circuit diagram also designed for 12-bit ADC f or optional. There are

two connectors on this board, one connector is for 4, 5, 8-wire touch screen cable (optional), and

ano ther is for 4-pin USB A type cable (optional).

Figure 5.1: Bird?s Eye View of Control Board

5.2 Windows 2000/XP/2003/Vista Universal Driver Installation

for PenMount 6000 Series

Before installing the Windows 2000/XP driver software, you must have the Windows 2000/XP system

installed and running on your computer. You must also have one of the following PenMount 6000

series controller or control boards installed: PM6500, PM6300.

Page 63

PCH3591/3791/3991

5.2.1 Installing Software

If you have an older version of the PenMount Windows 2000/XP driver installed in your system, please

remove it first. Follow the steps below to install th e PenMount D MC6000 W indows 2000/XP driver.

Step 1. Insert the product CD, the screen below would appear. Click touch panel driver.

15/17/19 inch Fanless Panel PC

14628 Ce ntral Ave,

Chino , CA 91710

tel:909.597.7 588, fax:909.597.1939

© Copyright 2013 Acnodes, Inc.

All righ ts reserved. Product descripti on and product speci ficat ions

are subj ect to change w ith out n oti ce. F or lates t product inform ati on,

ple ase vis it Acnod es’ we b site at www.ac nodes.c om.

Page 64

Step 2. Click Next to continue.

Step 3. Read the license agreement. Click I Agree to agree the license agreemen t.

Page 65

Step 4. Choose the folder in which to install PenMount Windows U niversal D river. Click Install to

start the installatio n.

Step 5. Wait for installation. Then click Next to contin ue.

Page 66

Step 6. Clic k OK.

Step 7. Clic k Finish to comp lete installation.

Page 67

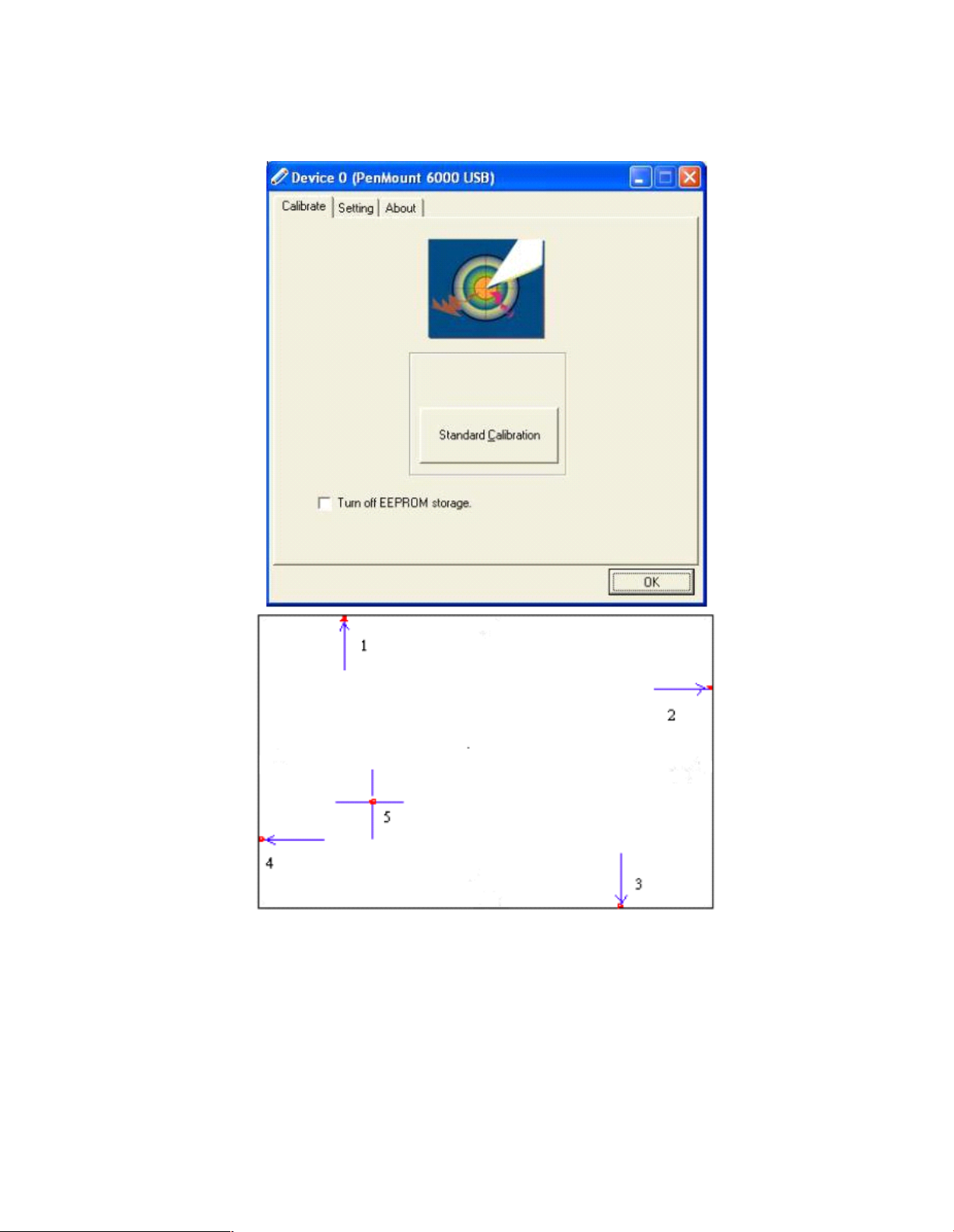

5.2.2 Software Functions

Upon rebooting, the computer automatically finds th e new 6000 controller board. The touch screen is

con nected but not calibrated. Follow the procedures below to carry out calibratio n.

1. After installation, click the Pe nMou nt Monitor icon “ PM” in the menu bar.

2. W hen the PenMount Control Panel appears, select a device to “ Calibrate.”

PenMount Control Panel

The functions of the PenMount Control Panel are D evice, Multiple Monitors ,Tools and About,

which are explained in the following sections.

Device

In this window, you can find out that how many devices be detected on your sys tem.

Calibrate

This fu nction offers two wa ys to calibrate your touch screen. „ Standard Calibration?adjusts mos t

touch screens. „ Advanced Calibratio n?adjusts aging touch screens.

Standard Calibration Click this button and arrows appea r

pointing to red squares. Use your finger or

stylus to touch the red squares in

sequence. After the fifth red point

calibration is complete. To skip, press

ESC

Page 68

Advance d Calibratio n

Advanced Calibration uses 4, 9, 16 or 25

points to effectively calibrate touch panel

linearity of aged touch scree ns. C lick this

button and touch the red squares in

sequence with a stylus. To skip, press

ESC ? .

Command C alibration

Command call calibration function. U se

comm and mode call calibration function,

this can uses Standard, 4, 9, 16 or 25

points to calibrate E.g. Please run ms-dos

prompt or command prompt c:\Program

Files\PenMount Universa Drive r\Dmcctrl.e xe

-calibration 0 ( Standard Ca libration)

Dmcctrl.exe - calibration ($) 0= Stan dard

Calibration 4=Advanced Calibration 4

9=Advanced Calibration 9 16=Advanced

Calibration 16 25=Advanc ed Calibration 25

Step 1. Please select a devic e then click “ Configure” . You can also doub le click the device

too.

Page 69

Step 2.Click “ Standard Calibration” to start calibration procedure

NOTE: The older the touch screen, the more Advance d Mode calibration p oints you need for an

accurate calibration. Use a stylus during Advanced Ca libration for greater accuracy. Please follow the

step as below:

Page 70

Step 3 .Come back to “ Pen Mount Control Panel” and select Tools then click

Advanced

Calibration.

Step 4. Select Device to calibrate, then you can start to do Advanced Calibration.

NOTE: Recommend to use a stylus during Ad vanced Calibration f or greater accuracy.

Page 71

Setting

Page 72

About

This panel disp lays information about the PenMount controller and driver version.

Page 73

Multiple Monitors

Multiple Monitors supports from two to six touch screen displays for one system. The PenMou nt

drivers f or W in dows 2000/XP su pport Multiple Monitors. This function supports from two to six touch

screen displays f or one system. Each monitor requires its own PenMou nt touch screen control board,

either installed inside the display or in a central unit. The PenMoun t control boards must be conne cted

to th e computer COM ports via the RS-232 interface. Driver installation proce dures are the same as

for a single monitor. Multiple Monitors supports the following modes:

Windows Extend Monitor Function

Matrox DualHead Multi-Screen Function

nVidia nView Function

NOTE: The Multiple Monitors function is for use with multiple displays only. D o not use this function if

you ha ve only one touch screen display. Please note once you turn on this function the Rotating

function is disabled.

Enable the multiple display function a s follows:

Step 1. Check the Multiple Monitor Support box; then click Map Touch Screens to assign touch

controllers to displays.

Page 74

Step 2. When the mapping screen message appears, click OK.

Step 3. Touch each screen as it displays Please touch this monitor. Press

„ S ?

to skip. Following

this sequence and touching each screen is called mapping the touch screens.

Step 4. After the setting procedure is finished, m ayb e you need to calibrate for each p anel and

controller

NOTES:

1. If you used a single VGA output for multiple m onitors, please do not use th e Multiple Monitors

function. Just follow the regular procedure for calibration on each of you r desktop monitors.

2. The R otating function is disabled if you use the Multiple Monitors function.

3. If you change the resolution of display or screen address, you have to redo Map Touch Screens so

Page 75

the system understands where the displays are.

4. If you more monitor mapping one touch screen, Please press

„ S ?

to skip mapping

step.

Tools

Draw

Tests or demonstrates the PenMount touch

screen operation.

Advanced Calibration

Enable Advanced Calibration function

Right Button Icon

Enable right button function. The icon can

show on D esktop or System Tray (menu bar).

Page 76

About

You can see how many devices of PenMount controller that are plugged to your syste m

PenMount Monitor Menu Ic on

The PenMount monitor icon (PM) appears in the menu bar of Windows 2000/XP system when you

turn on PenMount Monitor in PenMount Uti lities.

PenMount Monitor has the fo llowing function

Page 77

PenMount Rotating Functions

The PenMount driver for W indows 2000/XP supports several display rotating softw are pa ckages.

W indows Me/2000/XP support display rotating software packa ges such as:

• Portrait? s Pivot Screen Rotation Software

• ATI Display Driver Rotate Function

• nVidia Dis play Driver Rotate Function

• SMI Display Driver Rotate Function

• 845G/GE Display Driver Rotate Fun ction

Configuring the Rotate Function

1. Install the rotation software package.

2. C hoose the rotate function (0°, 90°, 180°, 270°) in the 3rd party software. The calibration screen

appears automatically. Touch this point and rotation is mapped.

NOTE: The R otate function is d isabled if you us e Monitor Mapping

Loading...

Loading...