Page 1

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

User Manual

PC 6412: 12.1” Fanless Panel PC with Atom N270 1.6GHz processor

PC 6415: 15” Fanless Panel PC with Atom N270 1.6GHz processor

Page 2

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

COPYRIGHT NOTICE

The information in this document is subject to change without prior notice in order to improve reliability, design and function and does not represent a commitment on the part of the manufacturer.

In no event will the manufacturer be liable for direct, indirect, special, incidental, or consequential

damages arising out of the use or inability to use the product or documentation, even if

advised of the possibility of such damages.

This document contains proprietary information protected by copyright. All rights are reserved. No

part of this manual may be reproduced by any mechanical, electronic, or other means in any form

without prior written permission of the manufacturer.

TRADEMARKS

All registered trademarks and product names mentioned herein are used for identification purposes

only and may be trademarks and/or registered trademarks of their respective owners.

Page 3

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

Table of Contents

CHAPTER 1 INTRODUCTION

1.1 GENERAL OVERVIEW .................................................................................................... 2

1.1.1 FEATURES ........................................................................................................ .2

1.1.2 APPLICATIONS ...................................................................................................3

1.2 EXTERNAL OVERVIEW ...................................................................................................4

1.2.1 FRONT PANEL ....................................................................................................5

1.2.2 REAR PANEL ......................................................................................................6

1.2.3 I/O INTERFACE PANEL ......................................................................................6

1.3 INTERNAL OVERVIEW .....................................................................................................9

1.4 SYSTEM SPECIFICATION ...............................................................................................9

CHAPTER 2 SPECIFICATIONS

2.1 DIMENSIONS.................................................................................................................... 25

2.1.1 PC6408 Dimensions ......................................................................................... 25

2.1.2 PC6410 Dimensions ......................................................................................... 26

2.1.3 PC6412 Dimensions ......................................................................................... 27

2.1.4 PC6415 Dimensions ......................................................................................... 28

2.2 INTEL® ATOM™ PROCESSOR ..................................................................................... 28

2.3 MOTHERBOARD COMPONENTS ................................................................................. 29

2.3.1 Memory Support................................................................................................. 29

2.3.1.1 Additional Memory ............................................................................... 29

2.3.2 Storage Capacity .............................................................................................. 29

2.4 AFL-4 SERIES-N270 FRONT SIDE ............................................................................... 30

2.4.1 Monitor ............................................................................................................... 30

2.4.2 Touch-Screen Module........................................................................................ 30

2.4.3 Digital Camera and Digital Microphone........................................................... 30

2.4.4 Stereo Speakers ............................................................................................... 30

2.4.5 USB 2.0 Port ..................................................................................................... 31

Page 4

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

2.5 EXTERNAL PERIPHERAL INTERFACE CONNECTORS ................................................... 31

2.5.1 Serial Port Connectors ............................................................................................. 31

2.5.2 LAN Connectivity ...................................................................................................... 32

2.5.3 External USB Connectors ........................................................................................ 32

2.6 AC'97 AUDIO CODEC CONTROLLER ................................................................................ 32

2.7 SYSTEM POWER .................................................................................................................. 32

2.7.1.1 ATX Power Mode (Default).................................................................................... 33

2.7.1.2 AT Power Mode ..................................................................................................... 33

2.7.2 Power Adapter ......................................................................................................... 33

2.7.3 Power Connector .................................................................................................... 33

2.8 WIRELESS CONNECTIONS ................................................................................................ 34

2.8.1 USB Bluetooth Module ............................................................................................ 34

2.8.2 Wireless Ethernet .................................................................................................... 34

2.9 REMOTE CONTROL ............................................................................................................. 35

CHAPTER 3 UNPACKING

3.1 UNPACKING ......................................................................................................................... 37

CHAPTER 4 INSTALLATION

4.1 ANTI-STATIC PRECAUTIONS ............................................................................................. 43

4.2 INSTALLATION PRECAUTIONS ......................................................................................... 43

4.3 PREINSTALLED COMPONENTS....................................................................................... 44

4.4 INSTALLATION AND CONFIGURATION STEPS ............................................................... 44

4.5 REMOVING THE REAR PANEL .......................................................................................... 45

4.6 CF CARD INSTALLATION ................................................................................................... 45

4.7 HDD INSTALLATION (AFL-412A AND AFL-415A/AE ONLY) ........................................... 47

4.8 AT/ATX MODE SELECTION ............................................................................................... 47

4.8.1 AT Power Mode...................................................................................................... 48

4.8.2 ATX Power Mode ................................................................................................... 48

Page 5

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.9 JUMPER SETTINGS ........................................................................................................ 49

4.9.1 Access the Jumpers ........................................................................................... 50

4.9.2 ATX/AT Power Mode Jumper.............................................................................. 50

4.9.3 Clear CMOS Jumper........................................................................................... 51

4.9.4 COM3 RX Function Select Jumper .................................................................... 52

4.9.5 COM2 RS-232/422/485 Serial Port Select Jumper ......................................... 53

4.9.6 LCD Backlight Select Jumper ........................................................................... 54

4.9.7 LCD Power Select 1 Jumper ............................................................................ 55

4.9.8 LCD Panel Type Jumper .................................................................................... 56

4.9.9 MCU LCD Panel Select Jumper ....................................................................... 57

4.9.10 MCU LCD Type Select Jumper ....................................................................... 58

4.9.11 Touch Screen Select ........................................................................................ 59

4.10 MOUNTING THE SYSTEM ............................................................................................ 60

4.10.1 Wall Surface Mounting...................................................................................... 61

4.10.2 In-wall Mounting ................................................................................................ 63

4.10.3 Arm Mounting .................................................................................................... 67

4.11 BOTTOM PANEL CONNECTORS................................................................................. 68

4.11.1 LAN Connection ............................................................................................... 68

4.11.2 Serial Device Connection................................................................................. 69

4.11.2.1 RJ-45 Serial Port Pinouts .................................................................. 70

4.11.3 USB Device Connection ................................................................................... 71

4.12 FACEPLATE INSTALLATION ......................................................................................... 71

CHAPTER 5 SYSTEM MAINTENANCE

5.1 SYSTEM MAINTENANCE INTRODUCTION ................................................................... 74

5.2 ANTI-STATIC PRECAUTIONS ......................................................................................... 74

5.3 TURN OFF THE POWER ................................................................................................. 75

5.4 OPENING THE SYSTEM.................................................................................................. 75

Page 6

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

5.4.1 Removing the Back Panel .......................................................................................... 75

5.5 REPLACING COMPONENTS........................................................................................ 76

5.5.1 Memory Module Replacement ......................................................................... 76

5.5.2 CF Card Replacement...................................................................................... 78

5.6 REINSTALLING THE COVERS ..................................................................................... 78

CHAPTER 6 BIOS OPTIONS

6.1 INTRODUCTION............................................................................................................. 80

6.1.1 Starting Setup .................................................................................................. 80

6.1.2 Using Setup ......................................................................................................80

6.1.3 Getting Help ..................................................................................................... 81

6.1.4 Unable to Reboot After Configuration Changes............................................. 81

6.1.5 BIOS Menu Bar ................................................................................................ 81

6.2 MAIN................................................................................................................................ 82

6.3 ADVANCED ................................................................................................................... 83

6.3.1 CPU Configuration ........................................................................................... 84

6.3.2 IDE Configuration ............................................................................................. 85

6.3.2.1 IDE Master, IDE Slave .................................................................................. 86

6.3.3 Super I/O Configuration ................................................................................... 90

6.3.4 Hardware Health Configuration ....................................................................... 91

6.3.5 Power Configuration......................................................................................... 93

6.3.5.1 ACPI Configuration ....................................................................................... 93

6.3.5.2 APM Configuration............................................................................. 94

6.3.6 Remote Access Configuration ................................................................................... 97

6.3.7 USB Configuration...................................................................................................... 99

6.4 PCI/PNP......................................................................................................................... 101

6.5 BOOT............................................................................................................................. 103

6.5.1 Boot Settings Configuration...................................................................................... 103

Page 7

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

6.5.2 Boot Device Priority ....................................................................................... 106

6.5.3 Hard Disk Drives ............................................................................................ 107

6.6 SECURITY ..................................................................................................................... 107

6.7 CHIPSET ....................................................................................................................... 108

6.7.1 Northbridge Chipset Configuration ................................................................ 109

6.7.2 Southbridge Configuration ...............................................................................112

6.8 EXIT .................................................................................................................................113

CHAPTER 7 SOFTWARE DRIVERS

7.1 AVAILABLE SOFTWARE DRIVERS .............................................................................116

7.2 STARTING THE DRIVER PROGRAM ...........................................................................116

7.3 CHIPSET DRIVER INSTALLATION ...............................................................................118

7.4 VGA DRIVER INSTALLATION....................................................................................... 122

7.5 REALTEK HD AUDIO DRIVER (ALC883) INSTALLATION ........................................ 126

7.5.1 BIOS Setup ................................................................................................................ 126

7.5.2 Driver Installation ....................................................................................................... 126

7.6 LAN DRIVER INSTALLATION ...................................................................................... 130

7.7 TOUCH SCREEN DRIVER .......................................................................................... 132

7.8 BLUETOOTH DRIVER ................................................................................................. 135

7.9 WIRELESS DRIVER ..................................................................................................... 139

7.10 KEYPADAP DRIVER .................................................................................................. 142

7.11 PC CAMERA ............................................................................................................... 145

A. WATCHDOG TIMER

B. COMPATIBILITY

C. DIGITAL I/O INTERFACE

D. HAZARDOUS MATERIALS DISCLOSURE

D.1 HAZARDOUS MATERIALS DISCLOSURE TABLE FOR IPB PRODUCTS CERTIFIED AS

ROHS COMPLIANT UNDER 2002/95/EC WITHOUT MERCURY ......................................152

Page 8

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

CHAPTER 1 INTRODUCTION

1.1 OVERVIEW

The PC Series-N270 models are Intel® Atom™ powered flat panel PCs with a rich variety of functions

and peripherals. All PC Series-N270 models are designed for easy and simplified integration in conference center, home automation, and building control applications.

An Intel® 945GSE graphics memory controller hub (GMCH) coupled with an Intel® ICH7M input/

output controller hub ensures optimal memory, graphics, and peripheral I/O support. The system

comes with 1.0 GB of preinstalled DDR2 SDRAM and supports a maximum of 2.0 GB of DDR2

SDRAM ensuring smooth data throughputs with reduced bottlenecks and fast system access.

Two serial ports and two external USB 2.0 ports ensure simplified connectivity to a variety of external

peripheral devices. Wi-Fi capabilities and an RJ-45 Ethernet connector ensure smooth connection of

the system to an external LAN.

Page 9

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

1.1.1 FEATURES

There are six models in the PC Series-N270 which feature the following:

" Intel® Atom™ processor

" Intel® 945GSE chipset

" 1GB 533 MHz DDR2 SDRAM preinstalled

" 802.11 b/g/n wireless module

" Five USB 2.0 ports

" Watchdog timer that triggers a system reset if the system hangs for some reason

" IP 64 compliant front panel

" AT or ATX power mode

" Touch screen

" Bluetooth (not available on the PC08B and AFL-W410A)

" RoHS compliance

1.1.2 APPLICATIONS

PC Series-N270 panel PCs are powerful, sophisticated systems that are as easily implemented in

commercial, industrial, and corporate environments as they are suited for home use.

1.2 EXTERNAL OVERVIEW

The stylish PC Series-N270 panel PC comprises of a screen, rear panel, top panel, bottom panel and

two side panels (left and right). An ABS/PC plastic front frame surrounds the front screen. The rear

panel provides screw holes for a wall-mounting bracket compliant with VESA FDMI standard. An I/

O interface panel on the bottom panel of the PC Series-N270 provides access to external interface

connectors that include LAN, USB 2.0, serial port, reset button, power connector and power switch.

Page 10

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

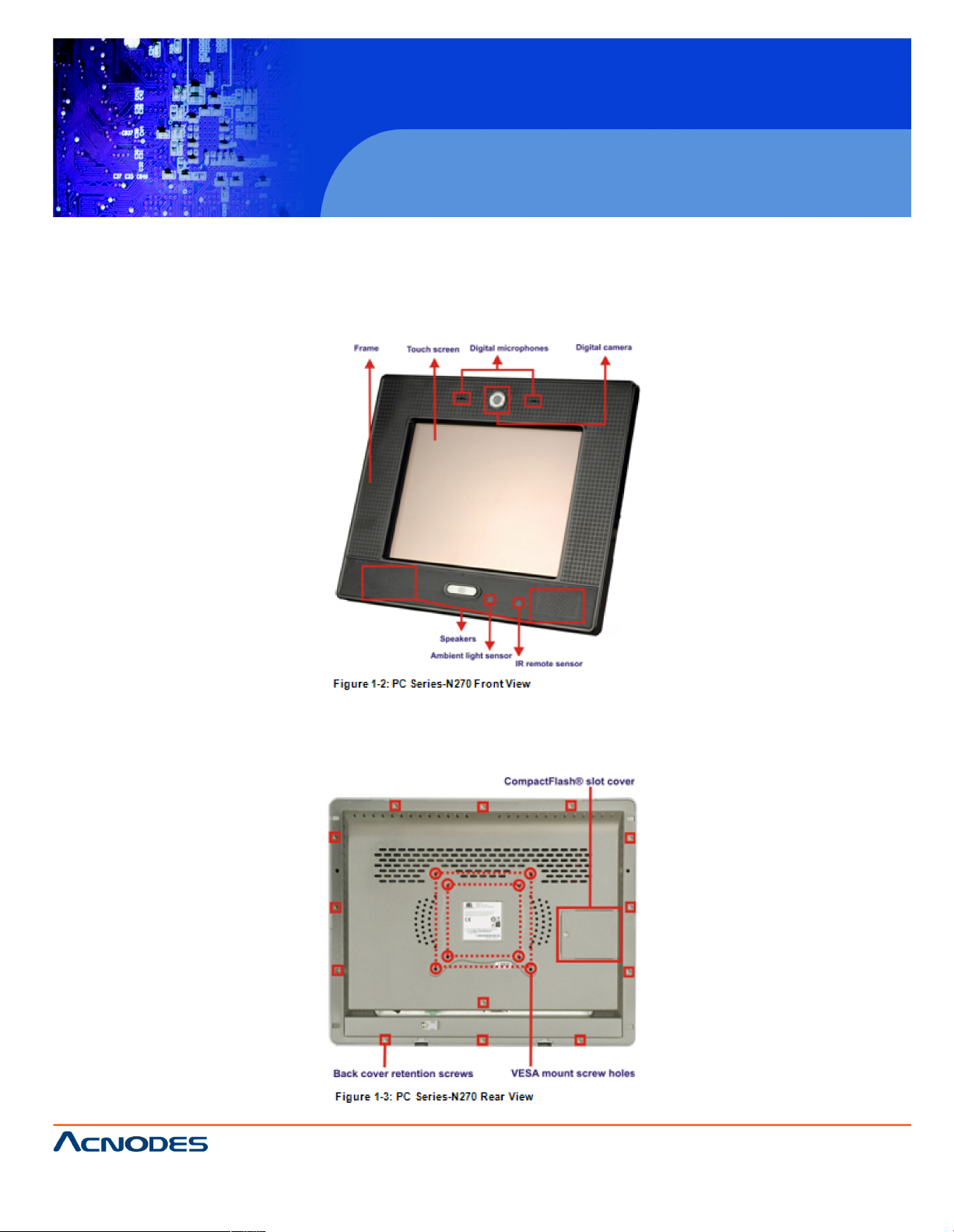

1.2.1 FRONT PANEL

The front side of the PC Series-N270 is a flat panel TFT LCD screen surrounded by an ABS/PC plastic frame. The top of the front panel has a digital camera and microphones. The bottom has stereo

speakers, an ambient light sensor and IR remote sensor. The front panel also includes one USB 2.0

port. Refer to Figure 1-2.

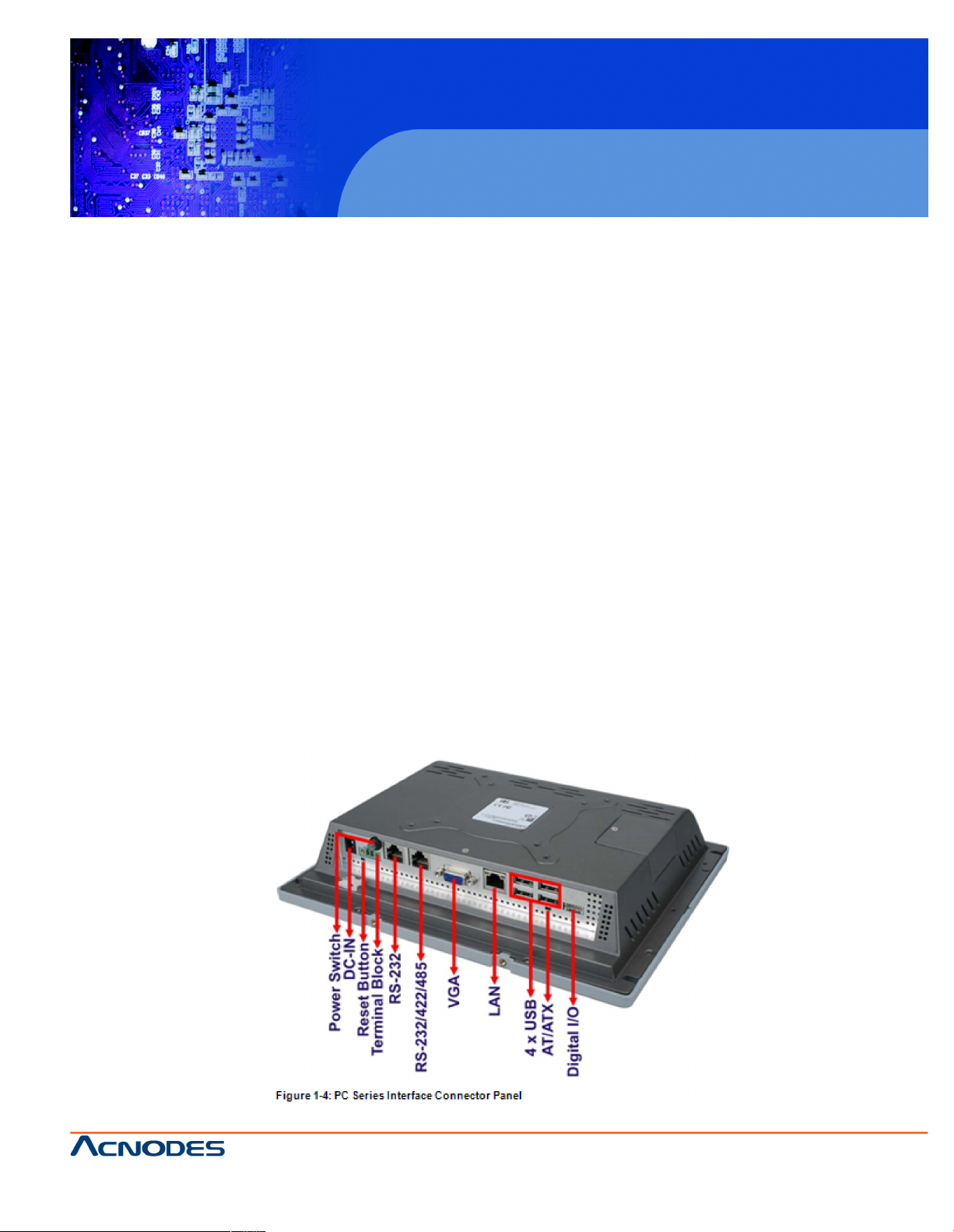

1.2.2 REAR PANEL

The rear panel provides access to the internal components of the PC Series-N270 and CF card slot.

Refer to Figure 1-3 for back cover retention screw, VESA mount screw holes and CompactFlash® slot

locations.

Page 11

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

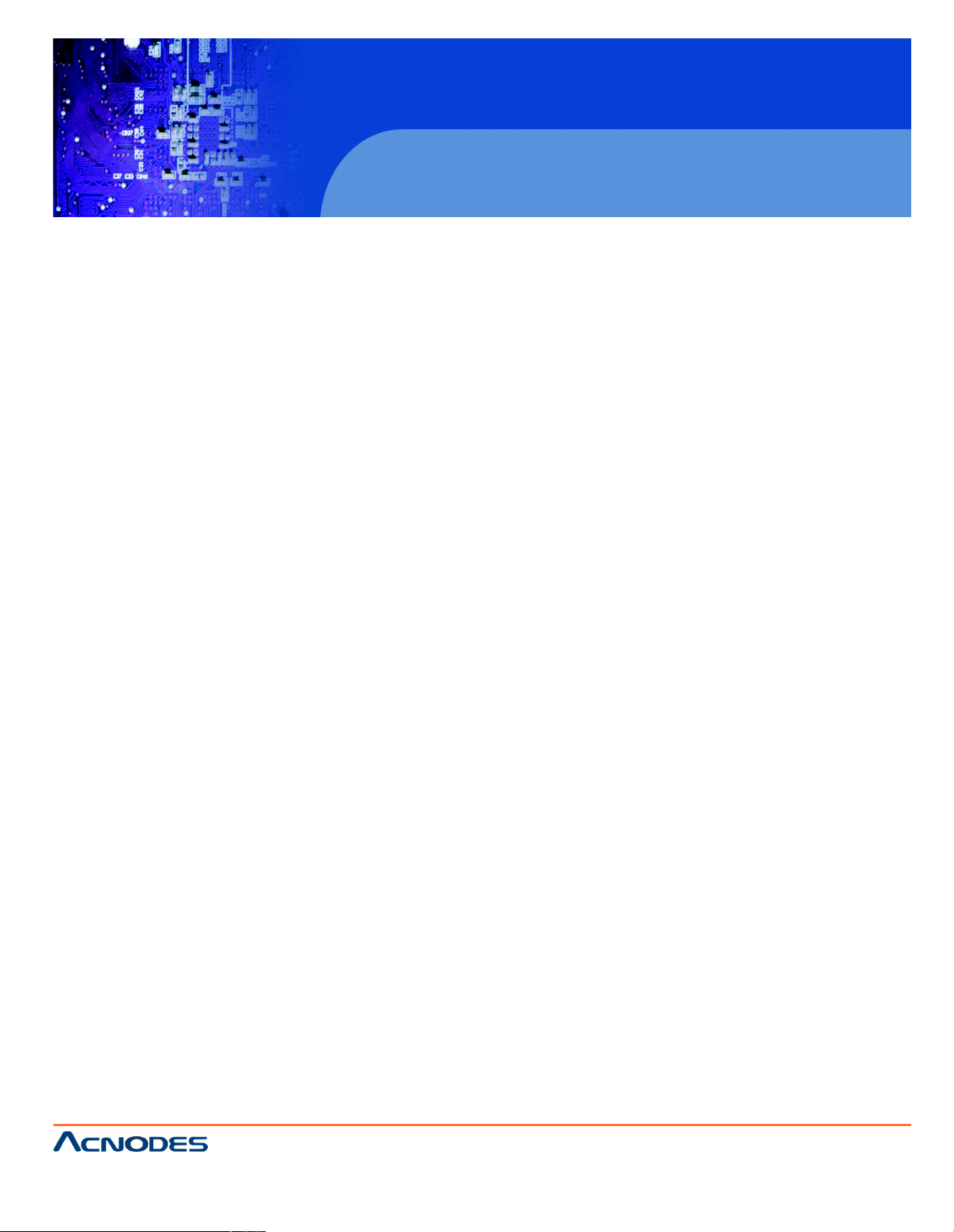

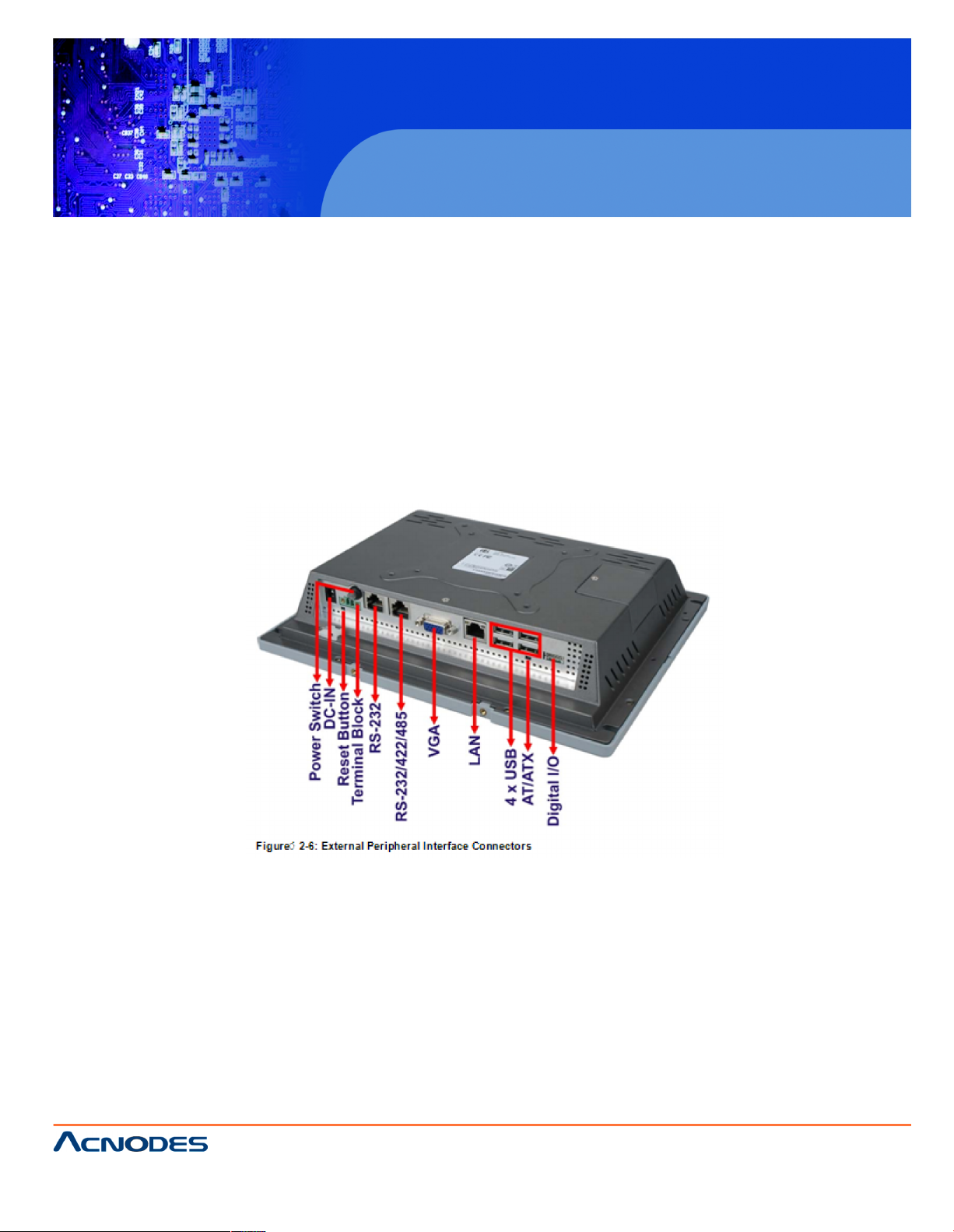

1.2.3 I/O INTERFACE PANEL

The I/O interface panel located on the bottom of the PC Series-N270 has the following I/O

interface connectors:

" 1 x Power switch

" 1 x 12 V DC-IN connector

" 1 x Reset button

" 1 x DC-IN terminal block

" 1 x RS-232 connector by RJ-45

" 1 x RS-232/422/485 connector by RJ-45

" 1 x VGA port

" 1 x LAN connectors

" 4 x USB 2.0 connectors

" 1 x AT/ATX mode select

" 1 x Digital Input/Output

The external I/O interface connector panel is shown in Figure 1-4.

Page 12

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

1.3 INTERNAL OVERVIEW

The PC Series-N270 has the following components installed internally:

" 1 x Motherboard

" 1 x 1.0 GB 533 MHz DDR2 SDRAM SO-DIMM

" 1 x Wireless module

" 1 x Bluetooth module (not available on the PC6408 and PC6410)

1.4 SYSTEM SPECIFICATIONS

Specifications PC6408 PC6410 PC6412 PC6415

LCD Size 8.0” 10.2” 12.1” 15”

Brightness(cd/m2) 250 400 500 250

Contrast Ratio 500:1 400:1 700:1 600:1

LCD color 262K 262K 262K 262K

Pixel Pitch (mm) 0.2025(H) 0.2175(H) 0.3075(H) 0.297 (H)

x 02025(V) x 0.2175(V) x 0.3075(V) x 0.297 (V)

Viewing Angle 140/130 140/110 160/160 160/160

MTBF 30,000 40,000 50,000 40,000

CPU INTEL ATOM N270 1.6GHz CPU

Chipset INTEL 945GSE + ICH7M

RAM Supports one 400MHz or 533MHz DDR2 SO-DIMM (2GB Max.)

I/O Ports and One RJ-45 port for RS-232 One RJ-45 port for RS-232

Switches One DC-IN terminal block One RJ-45 port for RS-232/422/485

One Power jack Four USB 2.0 ports, bottom panel

Two Power switches One USB 2.0 port, front panel

One Reset button One VGA port

One DI/O (4-input / 4-output) One RJ-45 for Giga LAN

Page 13

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

SSD CF Type II

Watchdog Timer Software programmable supports 1~255 sec. System reset

Audio AMP 1.5W + 1.5W internal speakers (PC 6408/6410/6412)

AMP 3W + 3W internal speakers (PC6415)

Digital Camera N/A Yes Yes Yes

Wireless LAN Wireless LAN 802.11 b/g/n (internal Mini PCIe interface)

Bluetooth N/A N/A Yes Yes

HDD Drive Bay N/A N/A 1 x 2.5” SATA HDD bay

HSUPA Mobile N/A 1 x HSUPA Mobile Module

Solution

Contruction Material ABS+PC Plastic front frame

LED Function One Power ON/OFF LED on Front Panel

Mounting Panel, Wall, VESA 75mm x 75mm/ 100mm x 100mm

Color Black (Black U), White (Apple white), Gray (422C)

Operation Temperature -10ºC~50ºC/ 0ºC~40ºC with 2.5" SATA HDD

-10 ºC~50ºC with CF Card or SATA interface 2.5"

SSD HDD

Storage Temperature -20ºC~60ºC

Weight 0.8kg 1.5kg 1.8kg 3.2kg

Power Adapter 36W Power Adapter 90VAC~264VAC, 50/60Hz, 12VDC

50W PowerAdapter 90VAC~264VAC,50/60Hz,12VDC

60W Power Adapter 90VAC~264VAC,50/60Hz, 12VDC

Power Requirement 12VDC or 10~28VDC

Power Consumption 25W 28W 32W 49W

Page 14

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

CHAPTER 2 SPECIFICATIONS

2.1 DIMENSIONS

The following sections provide detailed schematics and information on the dimensions of the

PC Series-N270.

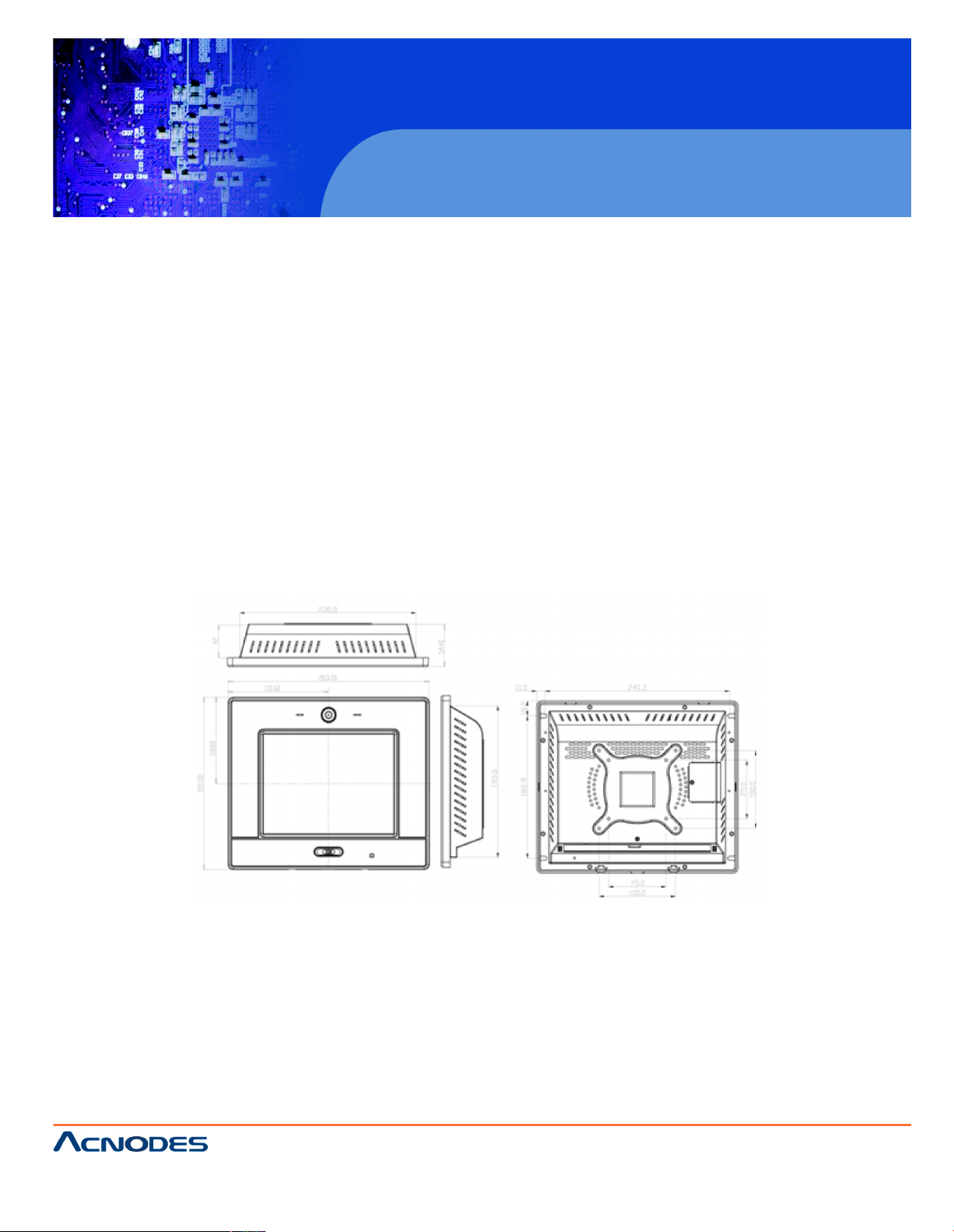

2.1.1 PC6408 DIMENSIONS

The PC6408 dimensions are shown in Figure 2-1 and listed below.

" Width: 263.20 mm

" Height: 221.20 mm

" Depth: 54.40 mm

Page 15

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

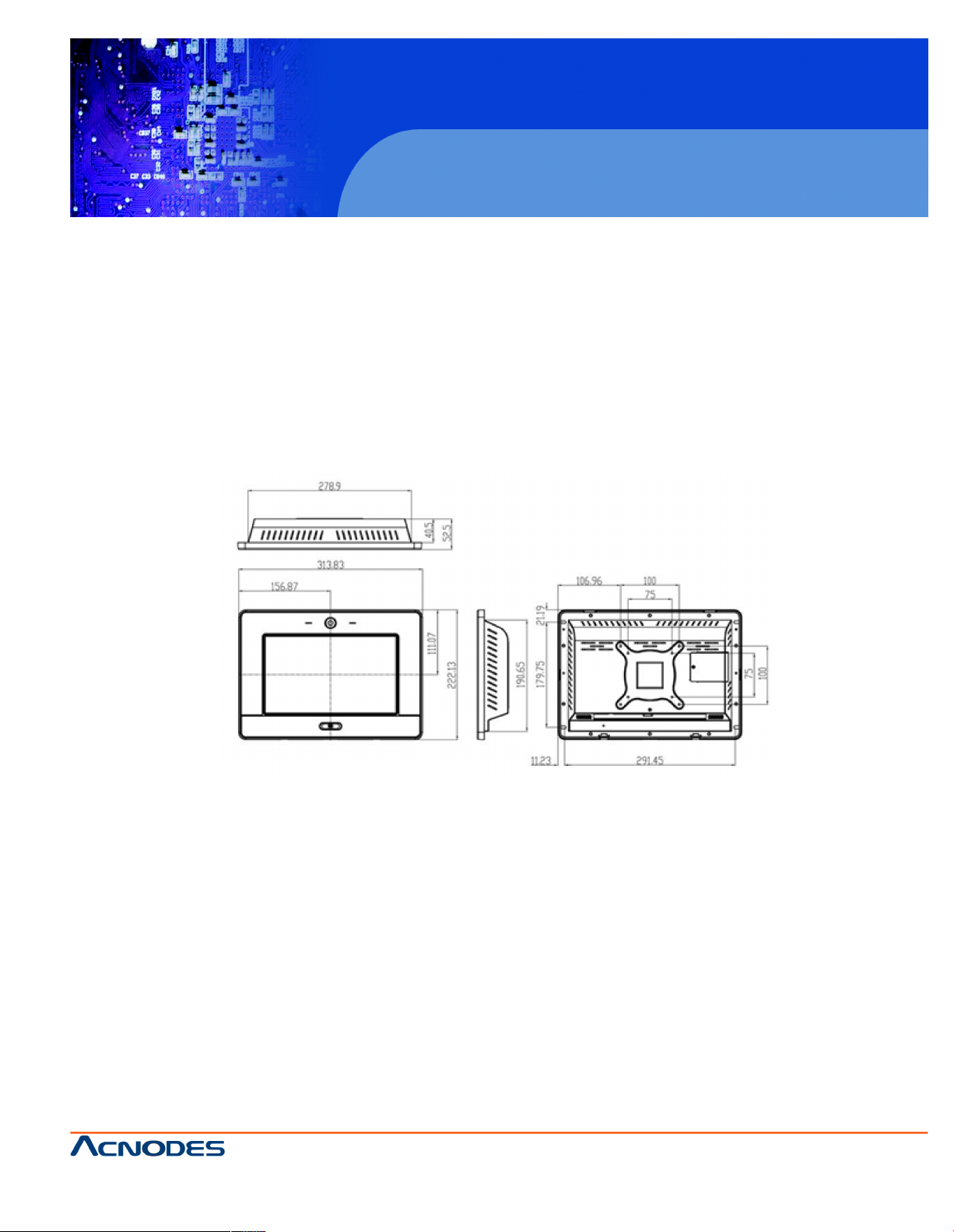

2.1.2 PC6410 DIMENSIONS

The PC6410 dimensions are shown in listed below.

" Width: 313.83 mm

" Height: 222. 13 mm

" Depth: 52.50 mm

Page 16

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

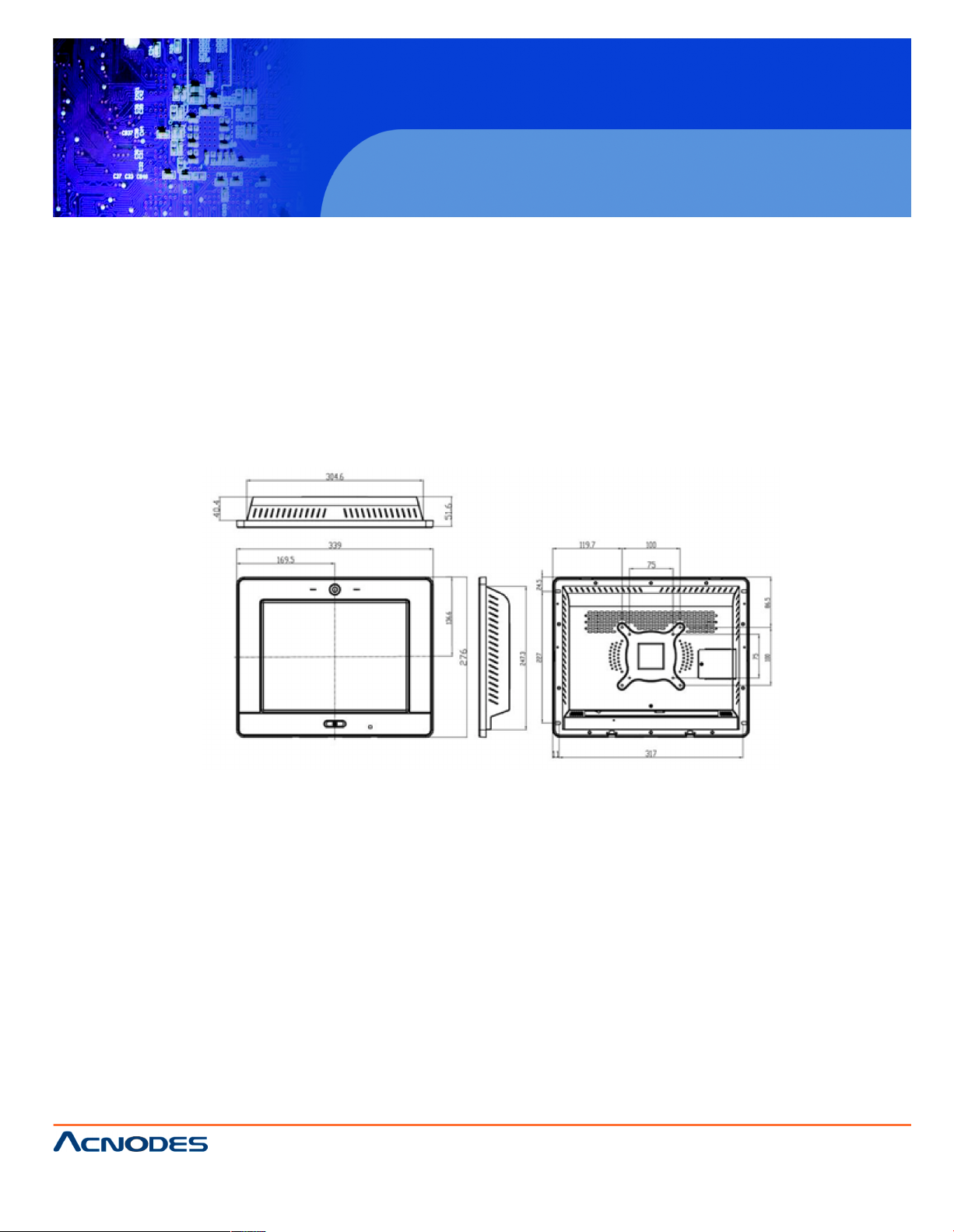

2.1.3 PC6412 DIMENSIONS

The PC6412 dimensions are shown in listed below.

" Width: 339.0 mm

" Height: 276.0 mm

" Depth: 51.6 mm

Page 17

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

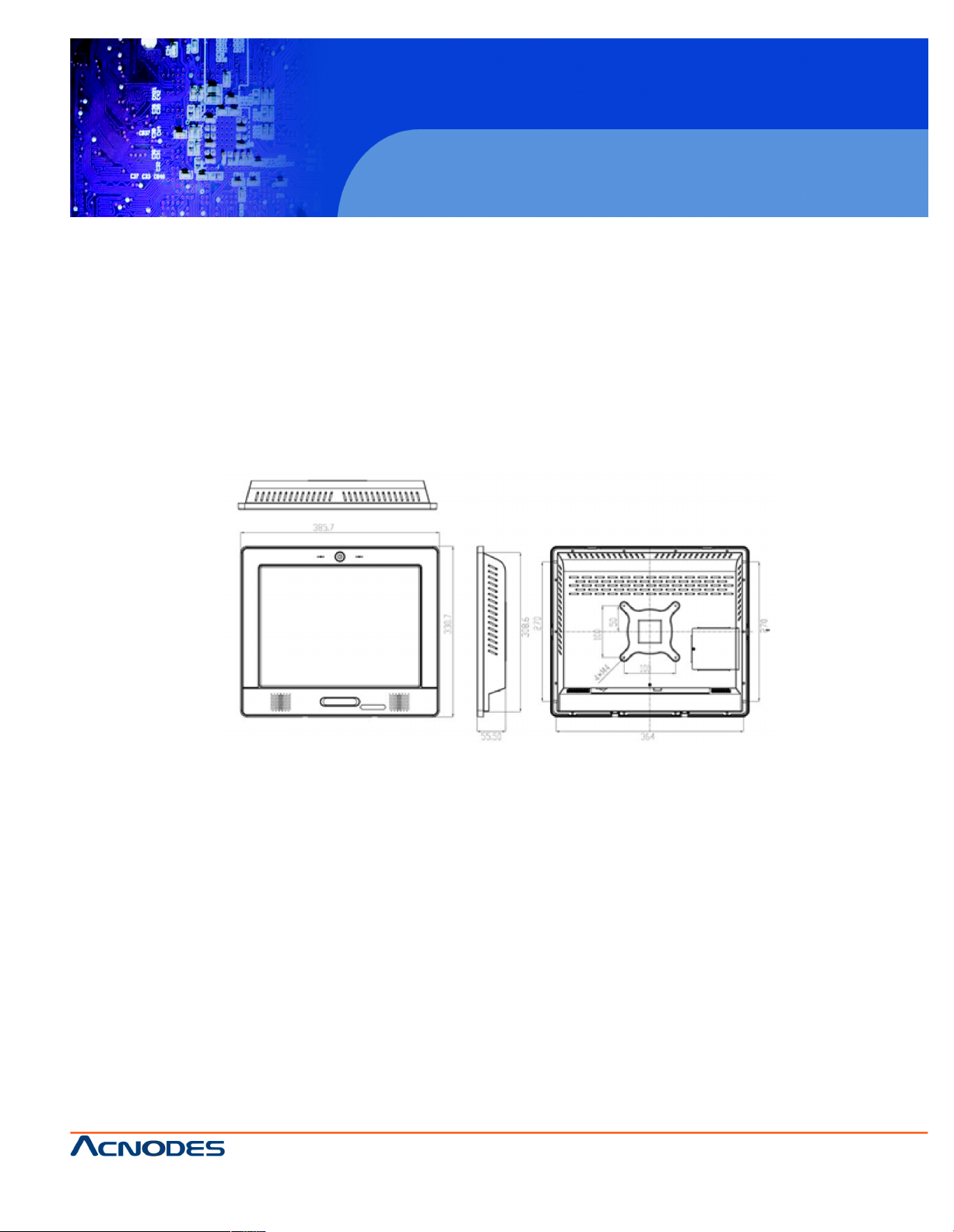

2.1.4 PC6415 DIMENSIONS

The PC6415 dimensions are shown in listed below.

" Width: 385.70 mm

" Height: 330.70 mm

" Depth: 55.50 mm

Page 18

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

2.2 INTEL ATOM PROCESSOR

A 45nm N270 Intel® Atom™ processor is installed in the system. The processor has

a CPU speed of 1.6 GHz and a 533 MHz front side bus (FSB). The processor also

comes with a 512 KB L2 cache and a 1.6 GHz L2 cache speed. Some of the features of the Intel® Atom™ processor N270 are listed below:

" On-die, primary 32-KB instructions cache and 24-KB write-back data cache

" 533-MHz source-synchronous front side bus (FSB)

" 2-Threads support

" On-die 512-KB, 8-way L2 cache

" Support for IA 32-bit architecture

" Intel® Streaming SIMD Extensions-2 and -3 (Intel® SSE2 and Intel® SSE3)

support and Supplemental Streaming SIMD Extension 3 (SSSE3) support

" Micro-FCBGA8 packaging technologies

" Thermal management support via Intel® Thermal Monitor 1 and Intel Thermal

Monitor 2

" FSB Lane Reversal for flexible routing

" Supports C0/C1(e)/C2(e)/C4(e)

" L2 Dynamic Cache Sizing

" Advanced power management features including Enhanced Intel SpeedStep®

Technology

" Execute Disable Bit support for enhanced security

Page 19

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

2.3 MOTHERBOARD COMPONENTS

The following sections describe features on the motherboard.

2.3.1 MEMORY SUPPORT

One 200-pin 1.0 GB 533 MHz DDR2 SDRAM SO-DIMM is installed in the PC

Series-N270 and controlled by the Intel® 945GSE GMCH installed on the internal

motherboard.

2.3.1.1 Additional Memory

The Intel® 945GSE is capable of supporting one 200-pin 2.0 GB (max.) 533 MHz or

400 MHz DDR2 SDRAM SO-DIMM. If additional memory is required, please contact an

Acnodes sales representative and discuss the necessary system requirement.

2.3.2 Storage Capacity

The PC Series-N270 supports an easily installed CompactFlash® Type II (CF Type II)

memory disk. The PC6408, PC6410, PC6412, and PC6415 models can also support

either an internal 2.5" SATA hard disk drive or a HSDPA module.

2.4 PC SERIES N270 FRONT SIDE

LCD specifications PC6408 PC6410 PC6412 PC6415

LCD size 8.0” 10.2” 12.1” 15”

Max. Resolution 800x600 1024x600 1024x768 1024x768

Brightness 250 400 500 250

2.4.2 TOUCH SCREEN MODULE

A controller for the 4-wire/5-wire resistive touch screen is installed on the motherboard.

The sensitive touch screen is accurate, reliable and durable.

2.4.3 Digital Camera and Digital Microphone

The PC Series-N270 has a built in 300K pixel digital camera and a digital microphone

(not available on the PC08B) on the front panel. The user can use the camera and microphone for facial and voice recognition for access control applications.

Page 20

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

2.4.4 STEREO SPEAKERS

Two 1.5 W stereo speakers on the front side of the PC Series-N270 are interfaced to

the system through a class-B dual output amplifier.

2.4.5 USB 2.0 Port

One USB 2.0 port is located on the front side of the PC Series-N270.

2.5 External Peripheral Interface Connectors

The following section describes the external peripheral interface connectors on the

bottom panel of the subsystem.

2.5.1 Serial Port Connectors

The PC Series-N270 has two COM ports by RJ-45. One of these ports (COM1) is RS232 only port. The other COM port (COM3) can be configured as a RS-232, RS-422 or

an RS-485 serial port. See figure Figure? 2-6.

Page 21

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

2.5.2 LAN Connectivity

The PC Series-N270 has two RJ-45 LAN connectors on the bottom panel. See figure

Figure? 2-6.

The PCIe lane from the Intel® ICH7 chipset of the PC Series-N270 is interfaced to the

Realtek RTL8111CP PCIe gigabit Ethernet (GbE) controllers. The RTL8111CP controllers are connected directly to the RJ-45 connectors on the bottom panel and provide

external GbE connectivity. Some of the RTL8111CP controller features are listed below:

" Integrated 10/100/1000 transceiver

" Supports PCI Express™ 1.1

" Fully compliant with IEEE 802.3, IEEE 802.3u, IEEE 802.3ab

" Supports IEEE 802.1P Layer 2 Priority Encoding

" Supports IEEE 802.1Q VLAN tagging

" Serial EEPROM

" Transmit/Receive on-chip buffer support

" 64-pin QFN package (Green package)

2.5.3 External USB Connectors

There are two USB 2.0 connectors on the bottom panel of the PC Series-N270. Both

USB 2.0 connectors are interfaced directly to the USB controllers on the ICH7M

Southbridge. These USB connectors are fully compliant with USB specification Revision 2.0 and USB specification Revision 1.1 and can be interfaced to both USB 1.1 and

USB 2.0 compliant devices. See figure Figure? 2-6.

2.6 AC'97 Audio Codec Controller

The integrated AC'97 Audio compliant audio controller on the Intel® ICH7M

Southbridge is integrated to a Realtek ALC888 audio codec. The Realtek ALC888 is

connected to an amplifier which powers the two 1.5 Watt speakers.

2.7 System Power

The system can be run in the AT power mode or the ATX power mode. Both these

power modes are described below.

Page 22

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

2.7.1.1 ATX Power Mode (Default)

With the ATX mode selected, the PC Series-N270 panel PC goes in a standby mode

when it is turned off. The panel PC can be easily turned on via network or a power

switch in standby mode. Remote power control is perfect for advertising applications

since the broadcasting time for each panel PC can be set individually and controlled

remotely. Other possible application includes

" Security surveillance

" Point-of-Sale (POS)

" Advertising terminal

2.7.1.2 AT Power Mode

With the AT mode selected, the power is controlled by a central power unit rather than a

power switch. The PC Series-N270 panel PC turns on automatically when the power is

connected. The AT mode benefits a production line to control multiple panel PCs from

a central management center and other applications including:

" ATM

" Self-service kiosk

" Plant environment monitoring system

" Factory automation platform

" Manufacturing shop flow

2.7.2 Power Adapter

The PC Series-N270 is shipped with a 90 V to 264 V AC power adapter. The adapter

shipped with the PC08A/B or AFL-W410 have a maximum power output of 36 W. The

PC12A power adapter has a maximum output of 50 W. The PC15A/AE power adapters

have a maximum of 60 W. The power adapter has a 12 V DC output connector.

2.7.3 Power Connector

There is one 12 V DC-IN center-pin power input connector and one DC-IN terminal

block power input connector on the bottom panel. The power connector is shown in

figure Figure? 2-6.

Page 23

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

2.8 Wireless Connections

The following section describes the wireless modules on the circuit.

2.8.1 USB Bluetooth Module

An integrated Bluetooth module (not available on the PC08B and AFL-W410A) is connected to ICH7 chipset through the USB bus. The PC Series-N270 Bluetooth module

enables wireless communications between the PC Series-N270 and various peripheral

devices through a Bluetooth network. The peripheral devices may include:

" Headsets

" Barcode readers

" PDA

" Printers

" Cell phones

" Keyboard and mouse

The technical specifications of the Bluetooth module are listed in the Appendix.

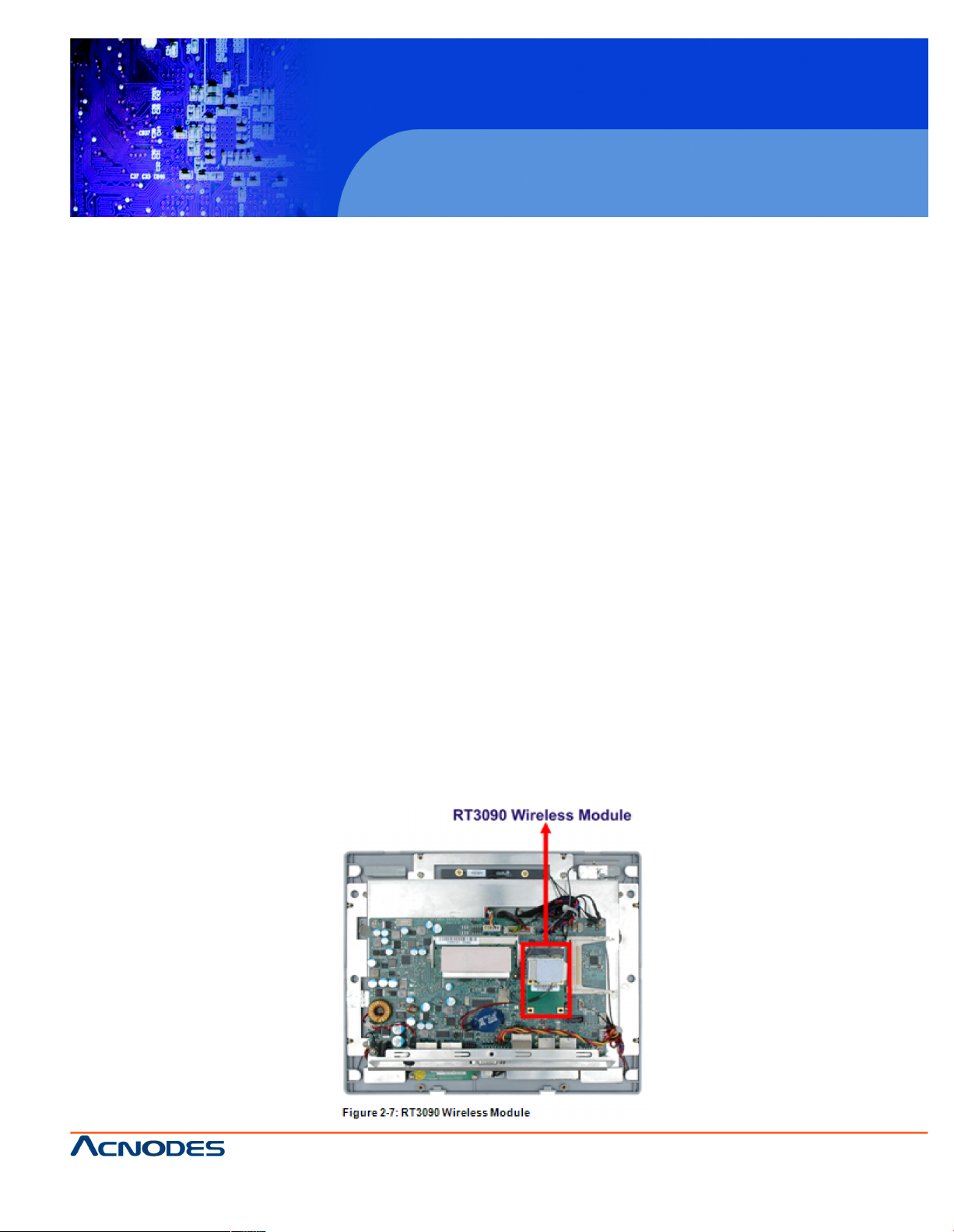

2.8.2 Wireless Ethernet

An integrated 802.11 b/g/n wireless LAN module and PIFA antenna on the PC

Series-N270 ensure an uninterrupted wireless connection. The wireless LAN module is

preinstalled in the Mini-PCIe slot. PIFA antennas can receive high quality, uniform signals in any location from all directions without any degradation of signal or impedance

and are the most efficient antennas on the market.

Page 24

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

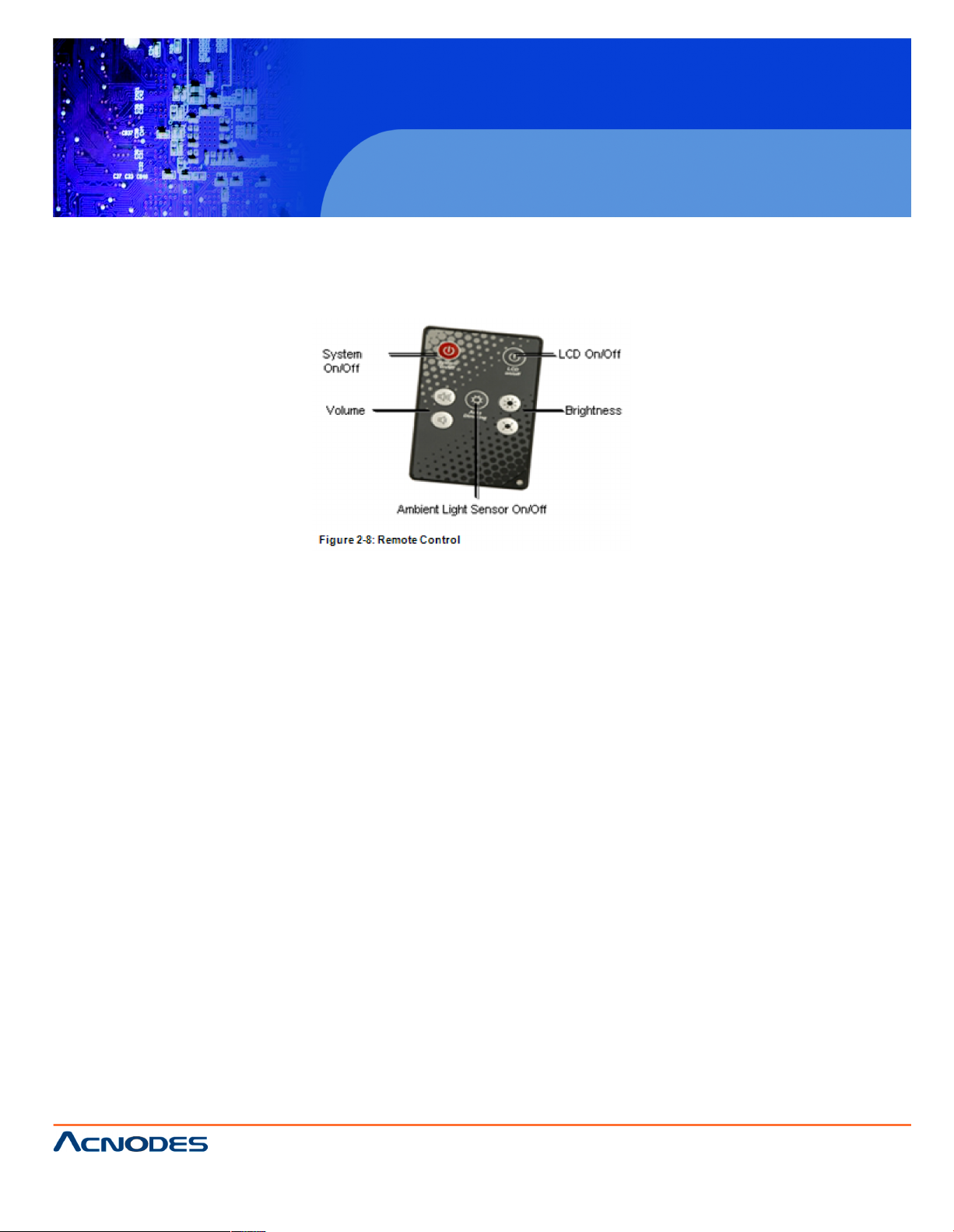

2.9 Remote Control

The PC Series-N270 is shipped with a remote control which controls system on/off,

LCD on/off, Ambient Light Sensor on/off, speaker volume, and LCD brightness.

Page 25

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

CHAPTER 3 UNPACKING

3.1 UNPACKING

To unpack the flat panel PC, follow the steps below:

WARNING!

The front side LCD screen has a protective plastic cover stuck to the screen. Only remove the plastic cover after the flat panel PC has been properly installed. This ensures the screen is protected during the installation process.

Step 1: Use box cutters, a knife or a sharp pair of scissors that seals the top side of

the external (second) box.

Step 2: Open the external (second) box.

Step 3: Use box cutters, a knife or a sharp pair of scissors that seals the top side of

the internal (first) box.

Step 4: Lift the monitor out of the boxes.

Step 5: Remove both polystyrene ends, one from each side.

Step 6: Pull the plastic cover off the flat panel PC.

Page 26

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

CHAPTER 4 INSTALLATION

4.1 ANTI-STATIC PRECAUTIONS

WARNING:

Failure to take ESD precautions during the maintenance of the PC Series-N270 may

result in permanent damage to the PC Series-N270 and severe injury to the

user.

Electrostatic discharge (ESD) can cause serious damage to electronic components, including the PC Series-N270. Dry climates are especially susceptible to ESD. It

is therefore critical that whenever the PC Series-N270 is accessed internally, or any

other electrical component is handled, the following anti-static precautions are strictly

adhered to.

" Wear an anti-static wristband: - Wearing a simple anti-static wristband can help to

prevent ESD from damaging the board.

" Self-grounding: - Before handling the board touch any grounded conducting mate

rial. During the time the board is handled, frequently touch any conducting materi

als that are connected to the ground.

" Use an anti-static pad: - When configuring the PC Series-N270, place it on an

antic-static pad. This reduces the possibility of ESD damaging the PC SeriesN270.

" Only handle the edges of the PCB: - When handling the PCB, hold the PCB

by the edges.

4.2 INSTALLATION PRECAUTIONS

When installing the flat panel PC, please follow the precautions listed below:

" Power turned off: When installing the flat panel PC, make sure the power is off.

Failing to turn off the power may cause severe injury to the body and/or damage

to the system.

" Certified Engineers: Only certified engineers should install and modify onboard

functionalities.

" Anti-static Discharge: If a user open the rear panel of the flat panel PC, to config

ure the jumpers or plug in added peripheral devices, ground themselves first and

wear and anti-static wristband.

Page 27

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.3 PREINSTALLED COMPONENTS

The following components are all preinstalled.

" Motherboard

" TFT LCD screen

" 1.0 GB DDR2 memory module

" Resistive type touch screen

" Wireless LAN module

" Bluetooth module

" AT/ATX power switch

Preinstalled customizations may include the following.

" Different DDR2 memory module

" Hard disk drive (PC12A/PC15A/AE only) Component installation is described in

the following sections.

4.4 INSTALLATION AND CONFIGURATION STEPS

The following installation steps must be followed.

Step 1: Unpack the flat panel PC.

Step 2: Install a CF card

Step 3: Install an HDD (PC6412 and PC6415 only)

Step 4: Configure the system

Step 5: Connect peripheral devices to the bottom panel of the flat panel PC

Step 6: Mount the flat panel PC

Step 7: Install faceplate onto the flat panel PC

Page 28

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

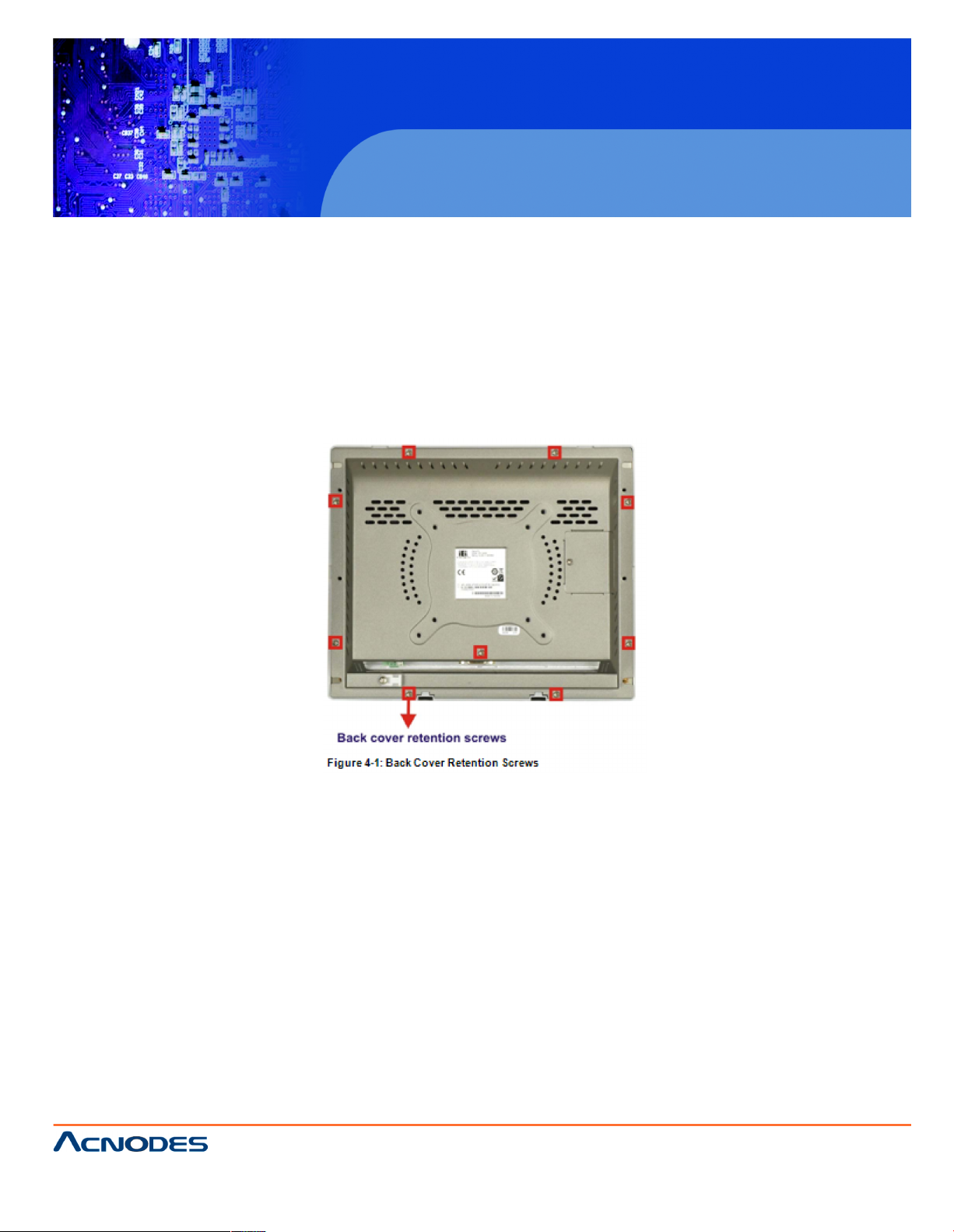

4.5 REMOVING THE REAR PANEL

To access the PC Series-N270 internally the rear panel must be removed. To remove

the rear panel, please follow the steps below.

Step 1: Place the PC Series-N270 face down on a flat surface.

Step 2: Remove the retention screws (Figure 4-1).

Step 3: Lift the cover off and pull down the cover a bit to make it possible to lift the

cover further more after removing the retention screws. More strength is required to

separate the cover from the chassis.

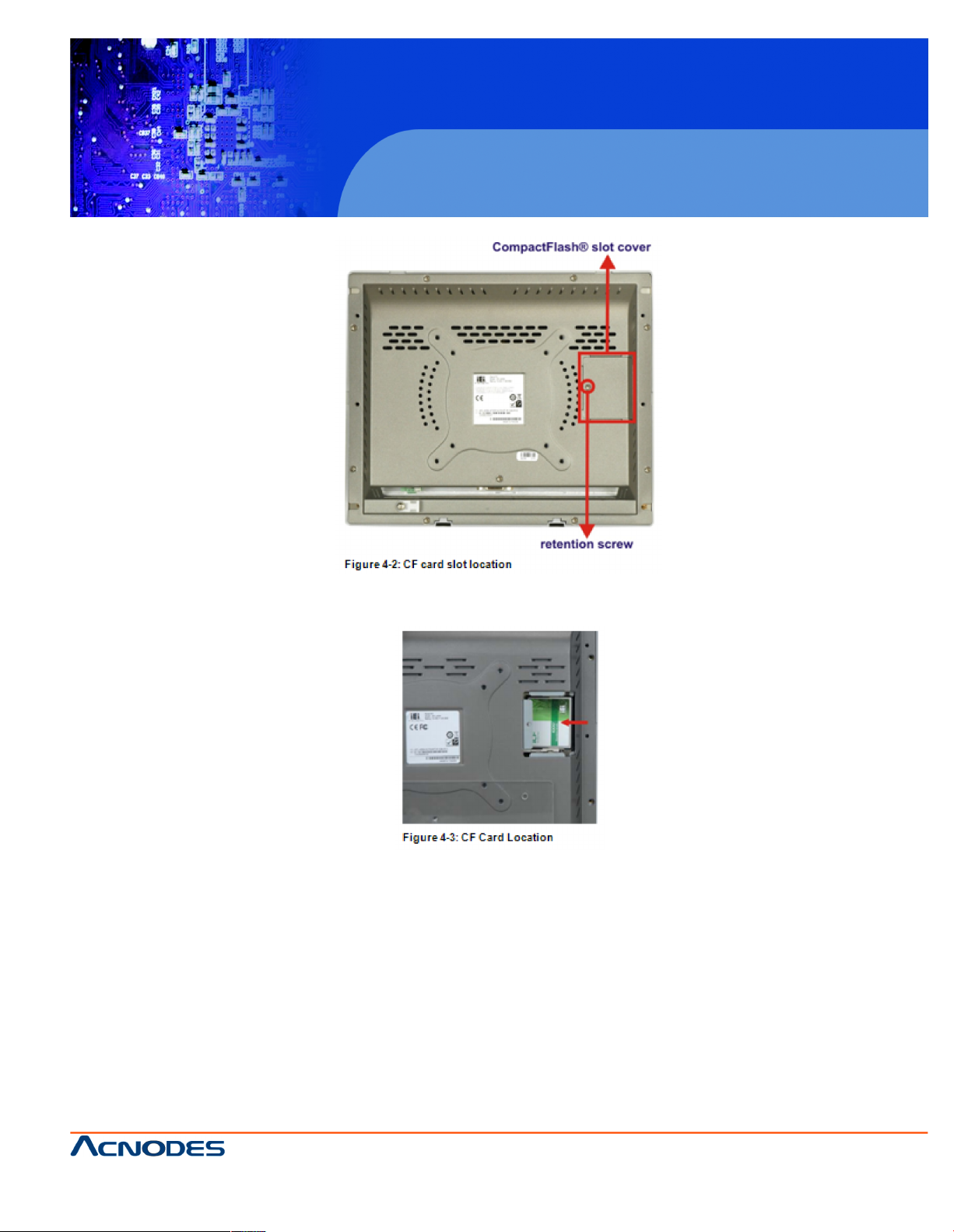

4.6 CF CARD INSTALLATION

The PC Series-N270 has one CF Type II slot inside the rear panel. The slot can be

accessed without removing the back cover. To install the CF card, follow the instructions below.

Step 1: Locate the CF slot cover. Remove the retention screw and cover (Figure 4-2).

Page 29

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

Step 2: Insert a CF card into the slot (Figure 4-3).

Step 3: Replace the CF card slot cover.

Step 4: Reinsert the retention screw.

Page 30

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.7 HDD INSTALLATION (PC6412 AND PC6415 ONLY)

To install the HDD into the PC6412/ PC6415, please follow the steps below:

Step 1: Remove the aluminum cover.

Step 2: Remove the four HDD bracket retention screws and lift the HDD bracket off

the panel PC.

Step 3: Attach the HDD brackets to the HDD. To do this, align the four retention screw

holes in the both sides of the HDD bracket with the retention screw holes on the sides

of the HDD. Insert four retention screws into the HDD bracket (Figure 4-4).

Step 4: Connect the SATA cable to the rear of the HDD and the SATA connector on

the motherboard.

Step 5: Install the HDD into the PC6412/ PC6415 by aligning the retention screw holes

in the HDD brackets with the retention screw holes on the chassis. Insert the four retention screws.

Step 6: Replace the aluminum back cover to the chassis.

Step 7: Replace the plastic back cover.

4.8 AT/ATX MODE SELECTION

AT and ATX power modes can both be used on the PC Series-N270. The selection is

made through an AT/ATX switch on the bottom panel. To select AT mode or ATX mode,

follow the steps below.

Step 1: Locate the AT/ATX switch on the bottom panel (Figure? 2-6).

Step 2: Adjust the AT/ATX switch.

Page 31

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.8.1 AT POWER MODE

When AT mode is selected, power is controlled by a central power unit rather than a

power switch. The PC Series-N270 panel PC turns on automatically when the power is

connected. The AT mode benefits a production line to control multiple panel PCs from

a central management center and other applications including:

" ATM

" Self-service kiosk

" Plant environment monitoring system

" Factory automation platform

" Manufacturing shop flow

4.8.2 ATX POWER MODE

When ATX mode is selected, the PC Series-N270 panel PC goes into a standby mode

when turned off. The panel PC can be easily turned on via network or a power switch in

standby mode. Remote power control is perfect for advertising applications since the

broadcasting time for each panel PC can be set individually and controlled remotely.

Other possible applications include:

" Security surveillance

" Point-of-Sale (POS)

" Advertising terminal

4.9 Jumper Settings

NOTE:

A jumper is a metal bridge used to close an electrical circuit. It consists of two or

three metal pins and a small metal clip (often protected by a plastic cover) that slides

over the pins to connect them. To CLOSE/SHORT a jumper means connecting

the pins of the jumper with the plastic clip and to OPEN a jumper means removing the

plastic clip from a jumper.

The following jumpers can be found on the motherboard installed in the PC Series-N270. Before the PC Series-N270 is installed, the jumpers must be set in accordance with the desired configuration. The jumpers on the PC Series-N270

motherboard are listed in Table 4-1.

Page 32

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.9.1 ACCESS THE JUMPER

To access the jumpers, remove the back panel. To remove the back panel, please refer

to Section 4.5.

4.9.2 ATX/AT Power Mode Jumper

Jumper Label: JP4

Jumper Type: 2-pin header

Jumper Settings:See Table 4-3

Jumper Location: See Figure 4-5

The ATX/AT Power Select jumper specifies the systems power mode as AT or ATX.

Page 33

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.9.3 Clear CMOS Jumper

Jumper Label: J_CMOS1

Jumper Type: 3-pin header

Jumper Settings:See Table 4-3

Jumper Location: See Figure 4-6

If the PC Series-N270 fails to boot due to improper BIOS settings, the clear CMOS

jumper clears the CMOS data and resets the system BIOS information. To do this, use

the jumper cap to close the pins for a few seconds then remove the jumper clip.

If the "CMOS Settings Wrong" message is displayed during the boot up process, the

fault may be corrected by pressing the F1 to enter the CMOS Setup menu. Do one of

the following:

" Enter the correct CMOS setting

" Load Optimal Defaults

" Load Failsafe Defaults.

After having done one of the above, save the changes and exit the CMOS Setup menu.

The clear CMOS jumper settings are shown in Table 4-3.

Page 34

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

The location of the clear CMOS jumper is shown in Figure 4-6 below.

4.9.4 COM3 RX Function Select Jumper

Jumper Label: JP6

Jumper Type: 12-pin header

Jumper Settings:See Table 4-4

Jumper Location: See Figure 4-7

The COM3 RX Function Select jumper sets the communication protocol used by the

COM3 port as RS-232, RS-422 or RS-485. The COM3 RX Function Select jumper

settings are shown in the table below.

Page 35

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

The COM3 RX Function Select jumper location is shown in Figure 4-7.

4.9.5 COM2 RS-232/422/485 Serial Port Select Jumper

Jumper Label: JP9

Jumper Type: 8-pin header

Jumper Settings:See Table 4-5

Jumper Location: See Figure 4-8

The COM2 RS-232/422/485 Serial Port Select jumper sets the communication protocol

used by the second serial communications port (COM2) as RS-232, RS-422 or RS-

485. The COM2 RS-232/422/485 Serial Port Select settings are shown in Table 4-5.

Page 36

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

The COM2 RS-232/422/485 Serial Port Select jumper location is shown in Figure 4-8.

4.9.6 LCD BACKLIGHT SELECT Jumper

Jumper Label: J_BL1

Jumper Type: 3-pin header

Jumper Settings:See Table 4-5

Jumper Location: See Figure 4-8

The backlight inverter connector provides power to an LCD panel.

The LCD Backlight Select jumper location is shown in Figure 4-8.

Page 37

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.9.7 LCD POWER SELECT JUMPER

Jumper Label: J_VLVDS1

Jumper Type: 3-pin header

Jumper Settings:See Table 4-5

Jumper Location: See Figure 4-8

The LCD Power Select jumper sets the power setting of the LCD panel.

Setting Description

Short 1-2 +3.3V

Short 2-3 +5V

The LCD Power Select jumper location is shown in Figure 4-8.

Page 38

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.9.8 LCD PANEL TYPE JUMPER

Jumper Label: JP14

Jumper Type: 2-pin header

Jumper Settings:See Table 4-5

Jumper Location: See Figure 4-8

The LCD Panel Type jumper sets the panel type.

Setting Description

OpenLED Panel

Closed LCD Panel

4.9.9 MCU LCD PANEL SELECT JUMPER

Jumper Label: JP13

Jumper Type: 3-pin header

Jumper Settings:See Table 4-5

Jumper Location: See Figure 4-8

The MCU LCD Panel Type jumper sets

the MCU LCD panel power setting.

Setting Description

Short 1-2 +5V

Short 2-3 +3.3V

Page 39

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.9.10 MCU LCD Type Select Jumper

Jumper Label: JP17

Jumper Type: 2-pin header

Jumper Settings:See Table 4-5

Jumper Location: See Figure 4-8

The MCU LCD Type Select jumper sets

the MCU LCD type setting.

Setting Description

OpenLCD Panel

Closed LED Panel

4.9.11 Touch Screen Select

Jumper Label: J1

Jumper Type: 4-pin header

Jumper Settings:See Table 4-5

Jumper Location: See Figure 4-8

The Touch Screen Select jumper sets the

touch screen as resistive 4 or 5 wire.

Setting Description

Short 1-2 5W

Short 3-4 4W

Page 40

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.10 Mounting the System

WARNING!

When mounting the flat panel PC onto an arm, onto the wall or into a wall, it is better to

have more than one person to help with the installation to make sure the panel PC does

not fall down and get damaged.

The methods of mounting the PC Series-N270 are listed below.

" Wall mounting

" Arm mounting

" Rack mounting

The mounting methods are described in the following sections.

4.10.1 WALL SURFACE MOUNTING

To mount the panel PC onto a wall, please follow the steps below.

Step 1: Select the location on the wall for the wall-mounting bracket.

Step 2: Carefully mark the locations of the four bracket screw holes on the wall.

Step 3: Drill four pilot holes at the marked locations on the wall for the bracket retention

screws.

Step 4: Align the wall-mounting bracket screw holes with the pilot holes.

Step 5: Secure the mounting-bracket to the wall by inserting the retention screws into

the four pilot holes and tightening them.

Step 6: Insert the four monitor mounting screws provided in the wall mounting kit into

the four screw holes on the real panel of the flat panel PC and tighten until the screw

shank is secured against the rear panel (Figure 4-16).

Step 7: Align the mounting screws on the monitor rear panel with the mounting holes

on the bracket.

Step 8: Carefully insert the screws through the holes and gently pull the monitor downwards until the monitor rests securely in the slotted holes (Figure 4-16).

Ensure that all four of the mounting screws fit snuggly into their respective slotted holes.

Page 41

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

Step 9: Secure the panel PC by fastening the retention screw of the wall-mounting

bracket. (Figure 4-17).

4.10.2 In-wall Mounting

Before installing into a wall mounting, attach the foam adhesive strips to the sides as

shown below:

Step 1: Place the PC Series-N270 face down on a flat surface.

Step 2: Cut the adhesive foam tape as shown above.

Step 3: Attach the adhesive foam tape to the edge of rear panel of the PC SeriesN270 (see Figure 4-19). Make sure the adhesive tape does not cover the screw holes

as shown below.

Page 42

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

To mount the PC Series-N270 panel PC into a wall, please follow the steps below.

Step 1: Select the position on the wall to mount the flat panel PC.

Step 2: Cut out a section from the wall that corresponds to the dimensions in Figure 421 for the PC6408 or Figure 4-214 for the PC6410 or Figure 4-23 for the PC6412 or

Figure 4-216 for the PC6415. Take care that the wall section that is cut out is no larger

than the suggested cut out size for the corresponding panel PC.

Page 43

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

Step 3: Slide the flat panel PC through the hole until the frame is flush against the wall.

Step 4: Tighten the screws that pass through the wall mounting screw holes in the PC

Series-N270 until the screws are firmly secured to the wall (Figure 4-25).

Page 44

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.10.3 Arm Mounting

The PC Series-N270 is VESA (Video Electronics Standards Association) compliant and

can be mounted on an arm with a 75mm or 100mm interface pad. To mount the PC

Series-N270 on an arm, please follow the steps below.

Step 1: The arm is a separately purchased item. Please correctly mount the arm onto

the surface it uses as a base. To do this, refer to the installation documentation that

came with the mounting arm.

NOTE:

When purchasing the arm please ensure that it is VESA compliant and that the arm has

a 75 mm interface pad. If the mounting arm is not VESA compliant it cannot be used to

support the PC Series-N270 flat panel PC. The PC Series-N270 also support VESA

MIS-D 100.

Step 2: Once the mounting arm has been firmly attached to the surface, lift the flat

panel PC onto the interface pad of the mounting arm.

Step 3: Align the retention screw holes on the mounting arm interface with those in the

flat panel PC. The arm mount retention screw holes are shown in Figure 4-26.

Page 45

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

Step 4: Secure the flat panel PC to the interface pad by inserting four retention screws

through the bottom of the mounting arm interface pad and into the flat panel PC.

4.11 Bottom Panel Connectors

4.11.1 LAN Connection

There is one external RJ-45 LAN connector. The RJ-45 connector enables connection

to an external network. To connect a LAN cable with an RJ-45 connector, please follow

the instructions below.

Step 1: Locate the RJ-45 connector on the bottom panel of the PC Series-N270 Series.

Step 2: Align the connector. Align the RJ-45 connector on the LAN cable with one of

the RJ-45 connectors on the bottom panel of the PC Series-N270.

Step 3: Insert the LAN cable RJ-45 connector. Once aligned, gently insert the LAN

cable RJ-45 connector into the onboard RJ-45 connector.

Page 46

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

4.11.2.1 RJ-45 Serial Port Pinouts

The pinouts for RS-232, RS-422 and RS-485 communication are shown below. The

COM1 serial port is RS-232 only.

4.11.3 USB Device Connection

There are four external USB 2.0 connectors. All connectors are perpendicular to the PC

Series-N270. To connect a USB 2.0 or USB 1.1 device, please follow the instructions below.

Step 1: Locate the USB connectors. The locations of the USB connectors are shown

in Chapter 2.

Step 2: Align the connectors. Align the USB device connector with one of the connectors on the bottom panel. See Figure 4-29.

Step 3: Insert the device connector. Once aligned, gently insert the USB device connector into the onboard connector.

4.12 Faceplate Installation

An optional faceplate in a variety of colors is available for mounting onto the PC SeriesN270 frame.

Step 1: Install the faceplate by snapping the faceplate onto the PC Series-N270

frame. See Figure 4-30.

Page 47

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

Page 48

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

CHAPTER 5 SYSTEM MAINTENANCE

5.1 SYSTEM MAINTENANCE INTRODUCTION

If the components of the PC Series-N270 fail they must be replaced. Components that

can be replaced include:

" CF Module

" Bluetooth module

" Wireless LAN module

" SO-DIMM module

Please contact the system reseller or vendor to purchase the replacement parts. Back

cover removal instructions for the PC Series-N270 are described below.

5.2 Anti-static Precautions

WARNING:

Failure to take ESD precautions during the maintenance of the PC Series-N270 may

result in permanent damage to the PC Series-N270 and severe injury to the

user.

Electrostatic discharge (ESD) can cause serious damage to electronic components, including the PC Series-N270. Dry climates are especially susceptible to ESD. It

is therefore critical that whenever the PC Series-N270 is accessed internally, or any

other electrical component is handled, the following anti-static precautions are strictly

adhered to.

" Wear an anti-static wristband: - Wearing a simple anti-static wristband can help to

prevent ESD from damaging the board.

" Self-grounding: - Before handling the board touch any grounded conducting mate

rial. During the time the board is handled, frequently touch any conducting materi

als that are connected to the ground.

" Use an anti-static pad: - When configuring the PC Series-N270, place it on an

antic-static pad. This reduces the possibility of ESD damaging the PC SeriesN270.

Page 49

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

" Only handle the edges of the PCB: - When handling the PCB, hold the PCB

by the edges.

5.3 Turn off the Power

WARNING:

Failing to turn off the system before opening it can cause permanent damage to the

system and serious or fatal injury to the user.

Before any maintenance procedures are carried out on the system, make sure the system is turned off.

5.4 Opening the System

5.4.1 Removing the Back Panel

To access the PC Series-N270 internally the back panel must be removed. To remove

the back panel, please follow the steps below.

Step 2: Follow all anti-static procedures. See Section 5.2.

Step 3: Turn off the power. See Section 5.3.

Step 4: Remove the retention screws on the back. Remove the retention screws (Figure5-1) from the rear panel.

Page 50

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

Step 5: Lift the cover off and pull down the cover a bit to make it possible to lift the

cover further more after removing the retention screws. More strength is required to

separate the cover from the chassis.

5.5 Replacing Components

5.5.1 Memory Module Replacement

The flat panel PC is preinstalled with a 1 GB DDR2 memory module. If the memory

module fails, follow the instructions below to replace it.

Step 1: Remove the aluminum back cover. See Section 5.4.1 above.

Step 2: Locate the DDR2 SO-DIMM on the motherboard (Figure 5-2).

Step 3: Remove the DDR memory module by pulling both the spring retainer clips

outward from the socket.

Step 4: Grasp the DDR memory module by the edges and carefully pull it out of the

socket.

Step 5: Install the new DDR memory module by pushing it into the socket at an angle.

Step 6: Gently pull the spring retainer clips of the SO-DIMM socket out and push the

rear of the DDR memory module down (Figure 5-3).

Step 7: Release the spring retainer clips on the SO-DIMM socket. They clip into place

and secure the DDR memory module in the socket.

Page 51

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

5.5.2 CF Card Replacement

The PC Series-N270 has one CF Type II slot. Follow the instructions below to replace

the CF card.

Step 1: Follow all anti-static procedures. See Section 5.2.

Step 2: Turn off the power. See Section 5.3.

Step 3: Follow the instruction listed in Section 4.6 to replace the CF card.

5.6 Reinstalling the Covers

WARNING:

Failing to reinstall the covers may result in permanent damage to the system. Please

make sure all coverings are properly installed.

When maintenance procedures are complete, please make sure all the covers

are replaced, including the following:

" Aluminum cover

" CF card slot cover

Page 52

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

CHAPTER 6 BIOS OPTIONS

6.1 Introduction

The BIOS is programmed onto the BIOS chip. The BIOS setup program allows

changes to certain system settings. This chapter outlines the options that can be

changed.

6.1.1 Starting Setup

The AMI BIOS is activated when the computer is turned on. The setup program can be

activated in one of two ways.

1. Press the DELETE key as soon as the system is turned on or

2. Press the DELETE key when the "Press Del to enter SETUP" message appears on

the screen. 0.

If the message disappears before the DELETE key is pressed, restart the computer

and try again.

6.1.2 Using Setup

Use the arrow keys to highlight items, press ENTER to select, use the PAGEUP and

PAGEDOWN keys to change entries, press F1 for help and press ESC to quit. Navigation keys are shown below.

Page 53

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

6.1.3 Getting Help

When F1 is pressed a small help window describing the appropriate keys to use and

the possible selections for the highlighted item appears. To exit the Help Window press

ESC or the F1 key again.

6.1.4 Unable to Reboot After Configuration Changes

If the computer cannot boot after changes to the system configuration is made, CMOS

defaults. Use the jumper described in Chapter 5.

6.1.5 Main BIOS Menu

The menu bar on top of the BIOS screen has the following main items:

Main Changes the basic system configuration.

Advanced Changes the advanced system settings.

PCIPnP Changes the advanced PCI/PnP Settings

Boot Changes the system boot configuration.

Security Sets User and Supervisor Passwords.

Chipset Changes the chipset settings.

Power Changes power management settings.

Exit Selects exit options and loads default settings

The following sections completely describe the configuration options found in the menu

items at the top of the BIOS screen and listed above.

Page 54

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All rights reserve d. Produ ct des cri pti on and produc t speci fi catio ns

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

6.2 Main

The Main BIOS menu (BIOS Menu 1) appears when the BIOS Setup program is entered. The Main menu gives an overview of the basic system information.

System Overview

The System Overview lists a brief summary of different system components. The fields in System Overview

cannot be changed. The items shown in the system overview include:

-AMI BIOS: Displays auto-detected BIOS information

o Version: Current BIOS version

o Build Date: Date the current BIOS version was made

o ID: Installed BIOS ID

-Processor: Displays auto-detected CPU specifications

o Type: Names the currently installed processor

o Speed: Lists the processor speed

o Count: The number of CPUs on the motherboard

Page 55

14628 Central Blvd ,

Chino , CA917 10

tel:909.597.7588, fax:909.59 7.1939

© Copyright 2011 Acnodes, Inc .

All righ ts reserved. Product description and product specifications

are subj ect t o change without notic e. F or late st produc t infor mat ion ,

ple ase vis it Acno des’ web s it e at w ww.acnodes.com .

PC 6412

12.1” Fanless Panel PC

-System Memory: Displays the auto-detected system memory.