Page 1

Altos S205F / S200F

User’s Manual

Issue 1.0

1 May, 2004

• Acer and the Acer logo are registered trademarks of Acer Incorporated. Other company's

product names or trademarks are used herein for identification purposes only and belong to

their respective companies.

• All other names, brands, products or services are trademarks or registered trademarks of their

respective companies.

Page 2

Notices

Changes may be made periodically to the information in this publication without obligation to

notify any person of such revision or changes. Such changes will be incorporated in new editions

of this manual or supplementary documents and publications. This company makes no

representations or warranties, either expressed or implied, with respect to the contents hereof

and specifically disclaims the implied warranties of merchantability or fitness for a particular

purpose.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form or by any means, electronic, mechanical, photocopy, recording, or otherwise, without the

prior written permission of Acer Incorporated.

Issue 1.0 1 May, 2004

ii

Page 3

Contents

Preface ................................................................................................................................................... v

International Standards ........................................................................................................................ v

Potential for Radio Frequency Interference ........................................................................................ v

European Regulations .......................................................................................................................... vi

Safety .................................................................................................................................................... vi

Rack System Precautions .................................................................................................................... viii

ESD Precautions .................................................................................................................................... ix

Data Security ......................................................................................................................................... ix

Special Tools and Equipment ................................................................................................................ x

Related Documentation ........................................................................................................................ x

Revision History .................................................................................................................................... xi

1 Introduction .................................................................................................................................... 1

1.1 The Altos S205F / S200F

Storage System ........................................................................................................................... 1

1.2 The Enclosure Core Product ...................................................................................................... 2

1.2.1 Enclosure Chassis ............................................................................................................... 2

1.2.2 Tower Option .................................................................................................................... 4

1.3 The Plug-in Modules .................................................................................................................. 4

1.3.1 Power Supply/Cooling Module ......................................................................................... 4

1.3.2 Operators Panel ................................................................................................................ 6

1.3.3 Controller Input/Output Module ..................................................................................... 8

1.3.4 Supported Configuration Tools ..................................................................................... 11

1.3.5 Drive Carrier Module ...................................................................................................... 11

1.3.6 Dummy Carrier Modules ................................................................................................. 13

1.3.7 Blank Modules ................................................................................................................. 13

1.4 Visible and Audible Alarms ..................................................................................................... 13

1.5 Altos S205F / S200F Storage System Technical Specification ................................................. 14

1.5.1 Dimensions ...................................................................................................................... 14

1.5.2 Weight ............................................................................................................................. 15

1.5.3 AC Power (450W PSU) ..................................................................................................... 15

1.5.4 PSU Safety and EMC Compliance ................................................................................... 15

1.5.5 Power Cord ...................................................................................................................... 15

1.5.6 Environment .................................................................................................................... 16

1.5.7 Altos S205F RAID I/O Module Specification ................................................................... 17

1.5.8 Altos S200F JBOD I/O Module Specification .................................................................. 17

1.5.9 Drive Carrier Module Specification ................................................................................ 18

1.5.10 SCSI Enclosure Services (SES) Support ............................................................................ 18

2 Getting Started ............................................................................................................................. 19

2.1 Introduction ............................................................................................................................. 19

iii

Page 4

2.2 Planning Your Installation ...................................................................................................... 19

2.2.1 Enclosure Bay Numbering Convention .......................................................................... 22

2.3 Enclosure Installation Procedures ........................................................................................... 22

2.3.1 Pre-Requisites .................................................................................................................. 22

2.3.2 Rack Mounting Rail Kit .................................................................................................. 22

2.3.3 Chassis Installation .......................................................................................................... 23

2.4 Power Supply/Cooling Module Installation ............................................................................ 24

2.4.1 Parts Check List ............................................................................................................... 24

2.4.2 AC Power Supply/Cooling Module Procedure .............................................................. 24

2.5 RAID and JBOD I/O Module Configurations ......................................................................... 26

2.5.1 Internal Loop Structures ................................................................................................. 26

2.6 FC-AL Interface ......................................................................................................................... 26

2.6.1 Connecting Multiple Enclosures .................................................................................... 27

2.7 I/O Module Installation ............................................................................................................ 29

2.7.1 Parts Check List ............................................................................................................... 29

2.7.2 Procedure ........................................................................................................................ 30

2.8 Altos S205F Drive Enclosure

Device Addressing .................................................................................................................... 31

2.9 Altos S200F Drive Enclosure

Device Addressing .................................................................................................................... 32

2.10 Drive Carrier Configuration ................................................................................................... 34

2.10.1 Planning and Configuring Your Installation ................................................................. 34

2.11 Drive Carrier Installation ......................................................................................................... 34

2.11.1 Parts Check List ............................................................................................................... 34

2.11.2 Procedure ........................................................................................................................ 35

2.11.3 Dummy Carrier Modules ................................................................................................ 37

2.11.4 Engaging the Anti-tamper Locks ................................................................................... 37

2.12 Power Cord Connection .......................................................................................................... 37

2.12.1 Parts Check List ............................................................................................................... 37

2.12.2 Procedure ........................................................................................................................ 38

2.13 Grounding Checks .................................................................................................................... 38

3 Operation ...................................................................................................................................... 39

3.1 Before You Begin ..................................................................................................................... 39

3.2 Power On .................................................................................................................................. 39

3.2.1 Power Supply/Cooling Module LEDs ............................................................................. 39

3.3 Ops Panel LEDs ......................................................................................................................... 40

3.4 Starting the Drives ................................................................................................................... 41

3.4.1 Disk Drives LEDs .............................................................................................................. 41

3.5 Power Down ............................................................................................................................. 41

Glossary ................................................................................................................................................ 43

Index .................................................................................................................................................... 45

iv

Page 5

Preface

Preface

What is in this manual

This user’s manual gives you step-by-step instructions on how to install, configure and connect a

Altos S205F / S200F storage subsystem to your host computer system, and how to use and maintain

the system.

Who should use this manual

This user’s manual e assumes that you have a working knowledge of the Fibre Channel Arbitrated

Loop (FC-AL) and Advanced Technology Attachment (ATA) environments into which you are

installing the Altos S205F / S200F Storage System system. If you do not have these skills, or are not

confident with the instructions in this manual, do not proceed with the installation.

About this manual

This user’s manual provides the following information:

• Chapter 1, ”Introduction”, on page 1 provides an overview of the Alto S205F / S200F storage

subsystem and describes of the modules which make up the subsystem.

• Chapter 2, ”Getting Started”, on page 19 provides step-by-step instructions for installation

and initial set-up.

• Chapter 3, ”Operation”, on page 39 tells you how to power on/off the Alto S205F / S200F,

monitor the LEDs and start the drives.

International Standards

The Alto S205F / S200F storage system complies with the requirements of the following agencies

and standards:

•CE

• UL 60950

•TUV/GS

•BSMI

Potential for Radio Frequency Interference

USA Federal Communications Commission (FCC)

Note This equipment has been tested and found to comply with the limits for a class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

v

Page 6

Acer S205F / S200F User’s Manual

Properly shielded and grounded cables and connectors must be used in order to meet FCC emission

limits. The supplier is not responsible for any radio or television interference caused by using other

than recommended cables and connectors or by unauthorized changes or modifications to this

equipment. Unauthorized changes or modifications could void the user’s authority to operate the

equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

European Regulations

This equipment complies with European Regulations EN 55022 Class A: Limits and Methods of

Measurement of Radio Disturbance Characteristics of Information Technology Equipments and

EN50082-1: Generic Immunity.

Safety

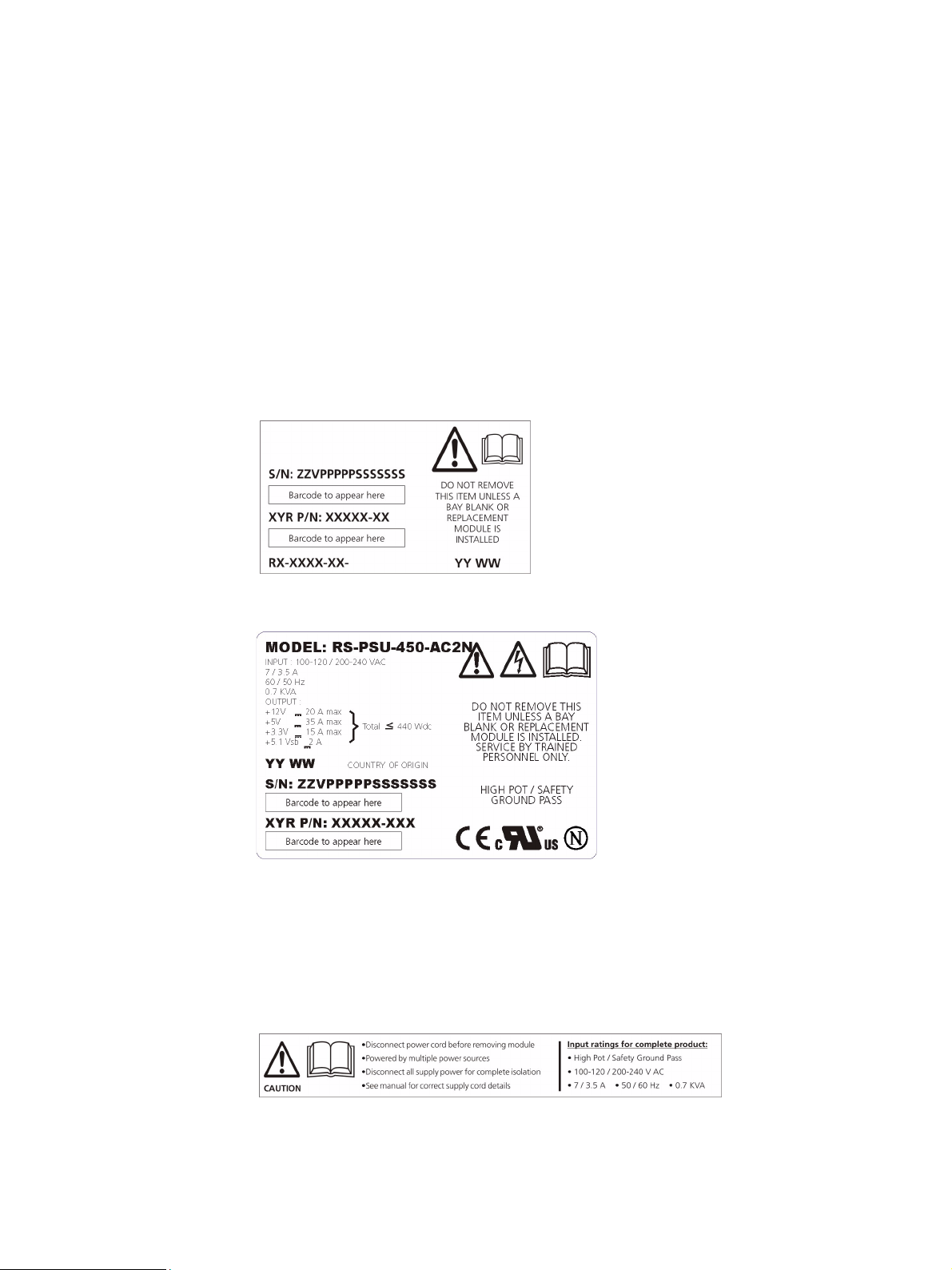

All plug-in modules are part of the fire enclosure and must only be removed when a replacement

can be immediately added. The system must not be run without all units in place.

Permanently unplug the unit if you think that it has become damaged in any way and before you

move it.

Drive Carrier Module Caution Label:

– Do not operate with modules missing

– Spin down time 30 seconds

• An Alto S205F / S200F enclosure can weigh up to 37kg (81lb). Do not try to lift it by yourself.

Chassis Warning Label: Weight Hazard

vi

Page 7

Preface

• Do not lift the Alto S205F / S200F by the handles on the PSU/Cooling module, they are not

designed to support the weight of the populated enclosure.

• In order to comply with applicable safety, emission and thermal requirements no covers should

be removed and all bays must be fitted with plug-in modules.

• The Alto S205F / S200F unit must only be operated from a power supply input voltage range

of 100-120 VAC or 200-240 VAC.

• The plug on the power supply cord is used as the main disconnect device. Ensure that the

socket outlets are located near the equipment and are easily accessible.

• The equipment is intended to operate with two working PSUs.

Controller Module Caution Label: Do not operate with modules missing

PSU/Cooling Module Caution Label: Do not operate with modules missing

• A faulty Power Supply/Cooling module must be replaced with a fully operational module

within 24 hours.

• If powered by multiple AC sources, disconnect all supply power for complete isolation.

PSU Warning Label: Power Hazards

vii

Page 8

Acer S205F / S200F User’s Manual

• The power connection should always be disconnected prior to removal of the Power Supply/

Cooling module from the enclosure.

• A safe electrical earth connection must be provided to the power cord. Check the grounding

of the enclosure before applying power.

• Provide a suitable power source with electrical overload protection to meet the requirements

laid down in the technical specification.

Warning Do not remove covers from the PSU. Danger of electric shock inside. Return the PSU to your supplier

for repair.

PSU Safety Label: Electric Shock Hazard Inside

Caution If this equipment is used in a manner not specified by the manufacturer, the protection provided

by the equipment may be impaired.

Fibre Channel Host & Expansion Connectors

Important If fitted with Optical modules, the modules must be a UL (or other North American NRTL)

RECOGNISED COMPONENT and the laser in the module must comply with Laser Class 1, US 21 CFR

(J) and EN 60825-1.

If passive copper cables are connected, the cable must not have a connection to the supply pins,

pins 15 & 16.

Battery Safety

The battery is user replaceable, please refer to the Battery Replacement Procedure.

Warning There is a danger of explosion if the battery is incorrectly replaced.

• Dispose of used batteries in accordance with the manufacturer’s instructions and National

regulations.

Rack System Precautions

The following safety requirements must be considered when the unit is mounted in a rack.

• The rack design should incorporate stabilizing features suitable to prevent the rack from

tipping or being pushed over during installation or in normal use.

viii

• When loading a rack with the units, fill the rack from the bottom up and empty from the top

down.

• System must be operated with low pressure rear exhaust installation (Back pressure created by

rack doors and obstacles not to exceed 5 pascals [0.5mm Water gauge])

Page 9

Preface

• The rack design should take into consideration the maximum operating ambient temperature

for the unit, which is 35°C with a single Power Supply/Cooling module fitted and 40°C when

dual Power Supply/Cooling modules are fitted.

• The rack should have a safe electrical distribution system. It must provide overcurrent

protection for the unit and must not be overloaded by the total number of units installed in

the rack. Consideration of the units nameplate rating should be used when addressing these

concerns.

• The electrical distribution system must provide a reliable earth for each unit and the rack.

• Each power supply in each unit has an earth leakage current of 1.2mA. The design of the

electrical distribution system must take into consideration the total earth leakage current from

all the power supplies in all the units. The rack will require labelling with "HIGH LEAKAGE

CURRENT. Earth connection essential before connecting supply".

• The rack when configured with the units must meet the safety requirements of UL 60950 and

IEC 60950.

ESD Precautions

Caution It is recommended that you fit and check a suitable anti-static wrist or ankle strap and observe all

conventional ESD precautions when handling Altos S205F / S200F Storage System plug-in modules

and components. Avoid contact with backplane components and module connectors, etc.

Data Security

• Power down your host computer and all attached peripheral devices before beginning

installation.

• Each enclosure contains up to 16 removable disk drive modules. Disk units are fragile. Handle

them with care, and keep them away from strong magnetic fields.

•

All

the supplied plug-in modules and blanking plates must be in place for the air to flow

correctly around the enclosure and also to complete the internal circuitry.

• If the subsystem is used with modules or blanking plates missing for more than a few minutes,

the enclosure can overheat, causing power failure and data loss. Such use may also invalidate

the warranty.

• If you remove any drive module, you may lose data.

– If you remove a drive module, replace it immediately. If it is faulty, replace it with a drive

module of the same type and capacity

• Ensure that all disk drives are removed from the enclosure before attempting to manhandle

or move the rack installation.

ix

Page 10

Acer S205F / S200F User’s Manual

• Do not abandon your backup routines. No system is completely foolproof.

Special Tools and Equipment

There are no special tools required but in order to complete the assembly of some configurations

you may need the following (not supplied):

• Security keys (one of these should be included with your Altos S205F/S200F Storage System

enclosure for use with the drive locks).

Related Documentation

• Altos S200F Storage System Quick Installation Guide

• Altos S205F Storage System Quick Installation Guide

• Altos RAIDWatch User's Guide

• Altos S205F Text-Mode Management Reference Guide

x

Page 11

Revision History

Version Date Description of Change

1.0 1 May, 2004 Initial Release

Preface

xi

Page 12

Acer S205F / S200F User’s Manual

xii

Page 13

Chapter 1

Introduction

1.1 The Altos S205F / S200F

Introduction

Storage System

.

Figure 1–1 Altos S205F / S200F Storage System

1

Page 14

Altos S205F / S200F User’s Manual

1.2 The Enclosure Core Product

The Altos S205F / S200F Storage System design concept is based on a subsystem together with a set

of plug-in modules. The Altos S205F / S200F Storage System subsystem as supplied comprises:

• Chassis and Backplane with integral Operators Panel.(See Figure 1–11)

• Up to 16 Serial ATA (SATA) Drive Carrier modules (See Figure 1–12)

– Serial ATA (SATA) drives with appropriate switching card.

• Dummy drive carrier modules.

• Two plug-in Power Supply/Cooling modules:

– AC, 450W PSU (See Figure 1–7)

• Either one or two I/O Modules:

– For Altos S205F - single or dual RAID I/O Modules(See Figure 1–9)

– For Altos S200F - single or dual JBOD I/O Modules (See Figure 1–10).

• Blank I/O module.

1.2.1 Enclosure Chassis

The chassis consists of a sheet metal enclosure assembly containing a Backplane printed circuit

board (PCB) and module runner system. This chassis assembly also includes an integral Operators

(Ops) Panel, mounted at the rear.

The chassis assembly contains 16 drive bays at the front, each of which accommodates a plug-in

drive carrier module. The 16 drive bays are arranged in 4 rows of 4 drives. At the rear, the chassis

assembly contains the integral ops panel module and four plug-in module bays to house two Power

Supply/Cooling modules and two Controller I/O modules.

The Backplane PCB provides logic level signal and low voltage power distribution paths. Figure 1–

2 and Figure 1–3 show front and rear views of an Altos S205F Storage System chassis. Figure 1–4 and

Figure 1–5 show front and rear views of an Altos S200F Storage System chassis.

The chassis is fitted with 19 inch Rack mounting features which enables it to be fitted to standard

19 inch racks and uses 3EIA units of rack space.

• A Bay is defined as the space required to house a single 1.0" high 3.5 inch disk drive in its carrier

module. e.g. a 1 x 4 bay module would take the space of 1 drive width by 4 drive bays high (in

rack mount configuration).

• A 4 x 4 Chassis fitted with 19 inch Rack mounting features enables it to be fitted to standard

19 inch racks. It uses 3EIA units of rack space

2

Page 15

Introduction

Figure 1–2 Altos S205F Enclosure Chassis (Front) * SES Drives (there must be a drive present in

Bay 1/1 or 4/4 to enable SES communications to operates).

Figure 1–3 Altos S205F Enclosure Chassis (Rear)

Figure 1–4 Altos S200F Enclosure Chassis (Front) * SES Drives (there must be a drive present in

Bay 1/1 or 4/4 to enable SES communications to operates).

Figure 1–5 Altos S200F Enclosure Chassis (Rear)

3

Page 16

Altos S205F / S200F User’s Manual

1.2.2 Tower Option

An optional tower kit is available, which can be fitted to the rack chassis described here.

Figure 1–6 Altos S205F / S200F Storage System Tower Option

1.3 The Plug-in Modules

An Altos S205F / S200F Storage System Enclosure requires the following modules for normal

operation:

• 2 x Power Supply/Cooling modules

• 1 x Operator Panel

• 1 or 2 x I/O modules

– RAID I/O module for Altos S205F

– JBOD I/O module for Altos S200F

• Up to 16 SATA drive carrier modules and/or dummy drive carrier modules, as required.

Note No drive bays should be left completely empty.

1.3.1 Power Supply/Cooling Module

One Power Supply/Cooling module is available for the Altos S205F / S200F Storage System:

• Auto ranging AC 450W Power Supply/Cooling module

4

Page 17

1.3.1.1 AC Power Supply/Cooling Module

Two Power Supply/Cooling modules (Figure 1–7) are supplied mounted in the rear of the enclosure

as part of the subsystem core product.

Introduction

Figure 1–7 AC Power Supply/Cooling Module

PSU voltage operating ranges are nominally 115V or 230V AC, selected automatically.

.

Four LEDs mounted on the front panel of the Power Supply/Cooling module (see Figure 1–7) indicate the status of the PSU and the fans.

1.3.1.2 Multiple Power Supply/Cooling Modules

The Altos S205F / S200F Storage System must always be operated with two Power Supply/Cooling

modules fitted. The two Power Supply/Cooling modules operate together so that if one fails the

other maintains the power supply and cooling while you replace the faulty unit.

Module replacement should only take a few minutes to perform but must be completed within 10

minutes from removal of the failed module.

5

Page 18

Altos S205F / S200F User’s Manual

1.3.2 Operators Panel

Supplied as an integral part of the Enclosure core product, a typical Operators (Ops) Panel is shown

in

Figure 1–8.

Figure 1–8 Ops Panel

The Ops Panel provides the enclosure with a micro controller which is used to monitor and control

all elements of the Enclosure.

1.3.2.1 Ops Panel Indicators and Switches

The Ops Panel includes Light Emitting diodes (LEDs) which show the status for all modules, an

Audible Alarm which indicates when a fault state is present, a push-button Alarm Mute switch and

a thumb wheel SEL_ID Address Range selector switch.

The Ops Panel switch functions are shown in Table 1–1 and Table 1–2.

6

Page 19

Introduction

Table 1–1 Altos S205F Ops Panel Switch Functions (

Switch Number

Function Recommended Setting Definition

*See Sw 11

1 Not Used OFF Not Used

2 Not Used OFF Not Used

3 Hub Mode OFF OFF = Hub Disabled

4 Not Used OFF Not Used

5

RAID host hub

ON

speed

6

ON

7 Not Used OFF Not Used

8 Not Used OFF Not Used

9

Drive Addressing

ON

Mode Selection

10

ON

Default settings at 2Gb/s)

ON = Hub Enabled (Direct Only)

OFF/OFF = 1GB

ON/OFF = 2GB

OFF/ON or ON/ON = Auto Select

ON/ON= Mode 0

11 SOFT SELECT ON ON = Selects functions using the

hardware switches

12 Not Used OFF Not Used

7

Page 20

Altos S205F / S200F User’s Manual

Table 1–2 Altos S200F Ops Panel Switch Functions (

Switch Number

*See Sw 11

1Not Used OFF

2Not Used OFF

3Not Used OFF

4Not Used OFF

5 & 6 Not Used OFF

7 & 8 Drive Loop Speed

9 & 10 Drive Addressing

Function Recommended Setting Definition

Sw 7 Sw 8

Select

ON OFF Force 2Gb/s

OFF OFF Force 1Gb/s

Sw 9 Sw 10

Mode Selection

ON ON Mode 0

OFF ON Mode 1

Default settings at 2Gb/s)

ON OFF Mode 2

OFF OFF Mode 3

11 SOFT SELECT ON Selects functions using the

12 Not Used OFF

Important Switch settings are only read at Power On.

1.3.3 Controller Input/Output Module

The Altos S200F JBOD storage subsystem includes an enclosure with rear facing bays which houses

one or

two SATA control interface adaptor, known as JBOD I/O modules (see Figure 1–10). While

Altos S205F Storage System storage subsystem includes an enclosure with rear facing bays which

houses two Loop Resiliency Circuit (LRC) I/O modules with integrated Infortrend IFT-1728RMN SATA

RAID I/O modules, known as RAID modules (see

1, 0+1, 3, 5, 10, 30 and 50.

The plug-in I/O modules have been designed for integration into a Altos S205F / S200F Storage System storage subsystem, providing external FCAL cable interfacing with up to 16 SATA disk drives.

Processors housed on the I/O modules provide enclosure management and interface to devices on

the Backplane, PSU, Controller and Ops Panel, to monitor internal functions.

Figure 1–9). The controller supports RAID levels 0,

(not supported)

(not supported)

hardware switches

The module incorporates the following LED indicators:

8

Page 21

Table 1–3 Altos S205F RAID I/O Module LEDs

LED Functions Color Description

Battery Fail Amber When ON this LED denotes the following status:

• Battery voltage is lower than 2.5V.

• Battery temperature is abnormal (normal 0° - 45°C on charge

state)

• BBU is not present

When FLASHING, the LED denotes BBU is under charging.

When OFF, the LED denotes BBU charge is done.

Introduction

Expansion Port

Green When ON this LED denotes that running FC signal is good.

Signal Good

RJ45 Ethernet Con-

Green

LED1: Static ON while LAN port status is link.

nection

Green

LED2: FLASHING while LAN port status is active.

System Amber When ON this LED denotes that the Controller is failed or SES Ser-

vices card is failed.

Cache Active Amber When ON this LED denotes the following status:

• When system is with power, ON denotes cache memory contains data or ECC errors are detected.

• When system is without power, ON denotes cache memory

contains data and is held up by BBU.

Host Port 1

Green When ON this LED denotes that incoming FC signal is GOOD.

Signal Good

Host port 0

Green When ON this LED denotes that incoming FC signal is GOOD.

Signal Good

Table 1–4 Altos S200F JBOD I/O Module LEDs

LED Definition Color Normal

Status

Fault Status

FC Host Port 0

Signal Good

Incoming FC signal is GOOD.

No connection or incorrect connection

Invalid SFP connection

FC Host Port 1

Not used. Green On

Signal Good

Router Status

Storage Router Device Ready

Storage Router Device not ready or defective

Module Fault Fault present (also

Successful JBOD I/O module initialization

On when booting)

9

Green On

Off

Flashing

Off

Flashing

Green On Off

Amber Off On

Page 22

Altos S205F / S200F User’s Manual

Figure 1–9 Altos S205F RAID I/O Module

The Altos S205F RAID I/O Module operates at 1 or 2 Gb/s.

• One external port for expansion to further enclosures is provided by an SFP connector

• Two external ports to the host controllers are provided from the RAID I/O Module with Form

Factor (SFP) GBIC modules, auto-bypass at the output ports is provided.

• An RJ45 10/100 Base T Ethernet controller management port is provided on the LRC board, interfacing to the controller through 2 RS232 serial and GPIO lines.

Caution The RJ45 Ethernet connector on the LRC module must not be connected to telecommunications

networks.

• The RAID I/O Module also incorporates a standby Li-ion battery pack, 72 hours cache hold up

time (512MB), or 60 hours cache hold up time (1GB). The battery cell has thermal protection

and is connected to the RAID I/O Module by flying lead.

not used

Figure 1–10 Altos S200F JBOD I/O Module

10

Page 23

Introduction

Figure 1–11 Altos S205F / S200F Storage System Enclosure with I/O Modules and AC PSUs

Installed

1.3.4 Supported Configuration Tools

• RAIDWatch

• R232 Management User Interface (MUI)

1.3.5 Drive Carrier Module

The Drive Carrier Module comprises a hard disk mounted in a carrier. Each drive bay will house a

single Low Profile 1.0 inch high, 3.5 inch form factor disk drive in its carrier.The carrier has

mounting locations for SATA drives.

Each disk drive is enclosed in a die-cast aluminum carrier which provides excellent thermal conduction, radio frequency and electro-magnetic induction protection and affords the drive maximum

physical protection.

The front cap also supports an ergonomic handle which provides the following functions:

• Camming of carrier into and out of drive bays.

• Positive 'spring loading' of the drive/backplane connector.

• An anti-tamper lock operated by a torx socket type key.

11

Page 24

Altos S205F / S200F User’s Manual

Figure 1–12 Drive Carrier Module

1.3.5.1 SATA Transition Card

For Serial ATA use a Transition card is attached to the rear of each drive, this provides a SCA-2

interface to the drive carrier using the same pins as Fibre Channel.

There is one Transition card providing 1.5 Gb/s for standard Serial ATA drives.

Transition cards provide two paths to each drive, thus improving system availability.

1.3.5.2 Drive Status Indicators

Each drive carrier incorporates two indicators, an upper (Green) and lower (Amber). In normal

operation the green indicator will be ON and will flicker as the drive operates.

1.3.5.3 Anti-tamper Locks

Anti-tamper locks are fitted in the drive carrier handles (Figure 1–13) and are accessed through the

small cutout in the latch section of the handle.These are provided to disable the normal ‘pinch'

latch action of the carrier handle.

12

Page 25

Figure 1–13 Anti-tamper Lock

1.3.6 Dummy Carrier Modules

Dummy carrier modules are provided for fitting in all unused drive bays. They are designed as

integral drive module front caps with handles and must be fitted to all unused drive bays to

maintain a balanced airflow.

Introduction

1.3.7 Blank Modules

Warning Operation of the Enclosure with

not receive sufficient cooling. It is

Dummy Carriers and/or Blank modules are available for this purpose.

ANY

modules missing will disrupt the airflow and the drives will

ESSENTIAL

that all apertures are filled before operating the unit.

1.4 Visible and Audible Alarms

The functional modules have associated status LEDs. The Ops Panel shows a consolidated status for

all modules.

LEDs show constant green for good or positive indication. Constant Amber LEDs indicate there is a

fault present within that module.

The Ops Panel also incorporates an Audible Alarm to indicate when a fault state is present and also

an Alarm Mute push-button.

Warning The Ops Panel is an integral part of the enclosure chassis assembly and can only be replaced by

trained personnel.

13

Page 26

Altos S205F / S200F User’s Manual

1.5 Altos S205F / S200F Storage System Technical Specification

1.5.1 Dimensions

Rack Enclosure inches millimeters

Height 5.1 130

Width across mounting flange 19 483

Width across body of enclosure 17.6 447

Depth from flange to rear of enclosure body 21 531

Depth from flange to maximum extremity of enclosure (rear hold

down)

Depth from flange to furthest extremity at front of unit 0.5 13

Depth overall 22.2 563

Tower Enclosure inches millimeters

Height 22.27 501

(including mounting feet

Width

Depth 23.24 523

21.7 550

) 10.22 230

Table 1–5 Altos S205F / S200F Storage System Chassis Dimensions

14

Page 27

1.5.2 Weight

Introduction

Maximum Configuration Rack mount:

Tower:

Empty Enclosure (Rack) 9kg (19.8lb)

PSU/Cooling Module 4kg (8.8lb)

Controller I/O Module 0.9kg (1.98lb)

Tower Conversion Kit 3kg (6.6lb)

37kg (81lb)

40kg (88lb)

1.5.3 AC Power (450W PSU)

Voltage Range 100-120 / 200-240 VAC Rated

Voltage Range Selection Automatic

Frequency 50/60 Hz

Inrush Current 50A @ 260VAC

Power Factor >0.98

Harmonics Meets EN61000-3-2

1.5.4 PSU Safety and EMC Compliance

Safety Compliance

UL 60950

IEC 60950

EN 60950

EMC Compliance CFR47 Part 15B Class A

EN55022

EN55024

1.5.5 Power Cord

(minimum requirements)

Cord Type SV 0r SVT, 18 AWG minimum, 3 conductor

Plug 250V, 10A

Socket IEC 320 C-14, 250V, 15A

15

Page 28

Altos S205F / S200F User’s Manual

1.5.6 Environment

Table 1–6 Ambient Temperature and Humidity

Temperature Range Relative Humidity Max. Wet Bulb

Operational 5°C to 40°C 20% to 80%

non-condensing

NonOperational

Storage 1°C to +60°C 8% to 80%

Shipping -40°C to +60°C 5% to 100%

Altitude, Operational 0 to 2000 m (0 to 7,000ft)

Altitude, Non-Operational -305 to 12,192m (-1000 to 40,000ft)

Shock, Operational Vertical axis 5g peak 1/2 sine, 10ms

Shock, Non-Operational 30g 10ms 1/2 sine

0°C to +50°C 8% to 80%

non-condensing

non-condensing

non-precipitating

Airflow System must be operated with low pressure rear exhaust installa-

tion

(Back pressure created by rack doors and obstacles not to exceed

5 pascals [0.5mm Water gauge])

(10,000ft at maximum ambient of 35°C)

23°C

27°C

29°C

29°C

Vibration, Operational 0.21grms 5-500 Hz Random

Vibration, Non-Operational 1.04grms 2-200 Hz Random

Vibration, Relocation 0.3g 2-200 Hz sine

Acoustics Sound Pressure Operating - Less than 58 dB LpA average mea-

sured at the bystander positions.

(The 4 bystander positions are 1m horizontal and 1.5m off the

floor positioned front, back, left and right. The unit under test

will be measured on the floor)

Measured at 20°C

Orientation & Mounting 19" Rack mount (3EIA Units)

• Rack Rails To fit 800mm depth Racks compliant with IEC 297

• Rack Characteristics

Safety & Approvals CE, UL, cUL

• EMC EN55022 (CISPR - A), FCC A

Back pressure not exceeding 5 pascals (0.5mm water gauge)

16

Page 29

1.5.7 Altos S205F RAID I/O Module Specification

Speed 1.5Gb/s internal to each drive, 1Gb/s or 2Gb/s external host ports

• Creates connections to a single loop of 16 drives

Mounting Rear, single bays 3 and/or 4

Connectors • Expansion Port: 1 x SFP connector

• Host Port:

– 2 x SFP connector, optical LC to LC cable

Power Dissipation 5A @ 3.3V, 1A @ 5V

RAID Levels supported 0, 1, 0+1, 3, 5, 10, 30, and 50

(see Figure 1–3)

1.5.8 Altos S200F JBOD I/O Module Specification

Speed 1.5Gb/s internal to each drive, 1Gb/s or 2Gb/s external

• Creates connections to a dual loop of 16 drives

Introduction

• 1 External FC loop with two SFP connections

Mounting Rear, single bays 3 and/or 4

Connectors • 1 or 2 x Expansion Ports: SFP connector

• Host Port 1 In/Out: Not used.

Power Dissipation 20W max.

(see Figure 1–5)

17

Page 30

Altos S205F / S200F User’s Manual

1.5.9 Drive Carrier Module Specification

Please contact your supplier for details of approved drives.

Important Operating the Altos S205F / S200F Storage System subsystem with non-approved drives may

invalidate the warranty.

Module Dimensions

Weight 0.98kg (1.0” 36Gb drive)

Transition card Provides dual path emulation to Serial ATA drives.

Operating Temperature 5° C to 40° C (with dual Power Supply/Cooling Modules)

Power Dissipation 17 Watts maximum

Height 29.1mm Width 106.55mm Depth 251 mm

1.5.10 SCSI Enclosure Services (SES) Support

The enclosure has a sophisticated self-monitoring and reporting function which conforms to ANSI

SES specifications.This reports on such topics as:

– Enclosure temperature

– Fan speed

– Drive condition

– Operator panel status

18

Page 31

Chapter 2

Getting Started

2.1 Introduction

In this chapter, you are shown how to install your Altos S205F / S200F Storage System enclosure and

plug-in modules into an industry standard 19 inch rack cabinet.

Getting Started

Caution When connecting up the Altos S205F / S200F Storage System , use only the power cords supplied or

cords which match the specification quoted in section

1.5.5.

2.2 Planning Your Installation

Before you begin installation you should become familiar with the configuration requirements of

your Altos S205F / S200F Storage System. The correct positions of each of the optional plug-in

modules are shown in

I/O module configurations and installation.

Table 2–1 Altos S205F Storage System Configuration

Module Location

Drive Bays

Power Supply/Cooling

Modules

Figure 2–1 and Figure 2–2 . Please refer to sections 2.5 - 2.7 for details of

ALL

drive bays must be fitted with either a drive carrier module or a

dummy carrier, no bays should be left completely empty. All drive

carrier modules provide SES Management Services.

Two Power Supply/Cooling modules must be fitted. Full power and

cooling redundancy is provided while a faulty module is replaced. Install

the Power Supply/Cooling modules in rear Bays 1 & 5.

Note: Rear bays are numbered from 1 to 5 commencing from the right

hand side)

RAID I/O Module Install in rear Bays 3 and 4.

(If only 1 controller is fitted it must be installed in bay 4).

19

Page 32

Acer S205F / S200F User’s Manual

Table 2–1 Altos S205F Storage System Configuration

Module Location

Blank I/O Module If only one RAID I/O moudle is installed a blank module must be fitted

Ops Panel (integral part of chassis assembly) Installed in rear Bay 2

Table 2–2 Altos S200F Storage System Configuration

Module Location

in the unused bay. No bays should be left completely empty.

Drive Bays

ALL

drive bays must be fitted with either a drive carrier module or a

dummy carrier, no bays should be left completely empty.

All drive

carrier modules provide SES Management Services.

Power Supply/Cooling

Modules

Two Power Supply/Cooling modules must be fitted. Full power and

cooling redundancy is provided while a faulty module is replaced. Install

the Power Supply/Cooling modules in rear Bays 1 & 5.

Note: Rear bays are numbered from 1 to 5 commencing from the right

hand side)

JBOD I/O Module Two JBOD I/O modules should be Installed in rear bays 3 and 4. If only

one module is fitted. Install in rear Bay 4

Blank I/O Module If only one JBOD I/O moudle is installed a blank module must be fitted

in the unused bay. No bays should be left completely empty.

Ops Panel (integral part of chassis assembly) Installed in rear Bay 2

Caution Dummy Carriers and Blank Modules MUST be fitted to ALL unused bays, there will be inadequate

drive cooling if any are left open.

20

Page 33

Getting Started

Figure 2–1 Altos S205F Module locations * SES Drives (there must be a drive present in Bay 1/

1 or 4/4 to enable SES communications to operates).

Figure 2–2 Altos S200F Module locations * SES Drives (there must be a drive present in Bay 1/

1 or 4/4 to enable SES communications to operates).

21

Page 34

Acer S205F / S200F User’s Manual

2.2.1 Enclosure Bay Numbering Convention

The enclosure bay numbering convention is shown in Figure 2–1. A Bay is defined as the space

required to house a single 1.0" high 3.5 inch disk drive in its carrier module. e.g. a 1 x 4 bay module

would take the space of 1 drive width by 4 drive bays high (in the rack mount configuration).

The Altos S205F / S200F subsystem is housed in a 4 x 4 enclosure, i.e. 4 bays wide by 4 bays high. The

front bays are numbered 1 to 4 from left to right, viewed from the front. Bays are numbered from

1 (top row) to 4 (bottom row). Drive Carrier Module locations are identified from a matrix of the

top and side numbers. The rear bays are numbered 1 to 5 from right to left, viewed from the rear.

Important Drive carrier module must always be fitted in locations 1/1 (Top Left) and 4/4 (Bottom Right). This

is the minimum configuration required for the system to operate and provide SES Management

Services.

2.3 Enclosure Installation Procedures

Caution The Altos S205F / S200F Storage System enclosure with all its component parts installed is too heavy

for easy installation into a Rack cabinet. The following procedures describe the installation of the

Altos S205F / S200F Storage System enclosure and highlights any critical co-requisite requirements

and good handling practices which we encourage you to follow so as to ensure that a successful

installation is achieved in the easiest manner.

Warning Ensure that you have fitted and checked a suitable anti-static wrist or ankle strap and observe all

conventional ESD precautions when handling Altos S205F / S200F Storage System modules and

components. Avoid contact with Backplane components and module connectors, etc.

2.3.1 Pre-Requisites

The Altos S205F / S200F Storage System enclosure is designed for installation into an industry

standard 19 inch cabinet capable of holding the unit.

• Minimum depth 531 mm from front flange to rear metalwork (excludes rear cabling).

• Weight: up to 37kg dependent upon configuration per enclosure.

• A minimum gap of 25mm (1inch) clearance between the rack cover and front of drawer; and

50mm (2 inches) rear clearance between rear of drawer and rear of rack is recommended in

order to maintain the correct air flow around the enclosure.

• The rack should present a maximum back pressure of 5 pascals (0.5mm water gauge).

2.3.2 Rack Mounting Rail Kit

A set of mounting rails is available for use in 19 inch rack cabinets. These rails have been designed

and tested to handle the maximum enclosure weight and to ensure that multiple Altos S205F /

S200F enclosures may be installed without loss of space within the rack. Use of other mounting

hardware may cause some loss of rack space.

22

The rack mounting rail kit also incorporates a rear hold down mechanism to ensure shock and

vibration immunity.

Page 35

2.3.2.1 Parts Check List

• Rack Mounting Rail Kit.

2.3.2.2 Installation Procedure

Please see detail drawings supplied with the rack mounting rail kit for assembly details.

Getting Started

Figure 2–3 Rack Mounting Rail Kit

2.3.3 Chassis Installation

2.3.3.1 Parts Check List

• Chassis (complete with Backplane and Ops Panel installed but excluding all plug-in modules).

• Rack mount front flange mounting screws (4 off).

2.3.3.2 Procedure

1 Check for damage.

2 Slide the chassis assembly onto the rack rails until the front flanges engage on the rack. Ensure the

chassis is centrally located.

3 If in doubt about correct orientation, the drive bays (at front) should have their black drive

connectors toward the bottom of each bay.

4 Screw the 4 front rack mount screws through the flanges and tighten.

5 Fit and tighten the rear hold down screws ensuring the enclosure is in tight contact to both the side

and top of the chassis to avoid any movement of the chassis in the rack.

23

Page 36

Acer S205F / S200F User’s Manual

2.4 Power Supply/Cooling Module Installation

Install in the rear of the enclosure in positions 1 and 5.

Warning Do not remove covers from the Power Supply/Cooling (PSU) module. Danger of electric shock

inside. Return the PSU to your supplier for repair.

2.4.1 Parts Check List

Power Supply/Cooling Modules of the following type:

• AC’ 450W PSU

2.4.2 AC Power Supply/Cooling Module Procedure

Important If the cable strain relief wire tab is upside down it must be inverted by squeezing together the two

sides of the tab removing them from their mountings, inverting and then replacing them, as shown

in Figure 2–4.

Figure 2–4 Inverting the Cable Strain Relief

1 Check for damage, especially to the rear connector on the supply.

Caution Handle the module carefully and avoid damaging the connector pins. Do not install the module if

any pins appear to be bent.

2 With the PSU handle in the open position (Figure 2–5), slide the module into the enclosure (Figure

2–6).

Important install the Power Supply/Cooling module in the right hand bay (Rear Bay 1) of the enclosure in an

“upside down* orientation.

3 Cam the module home by manually closing the PSU handle (Figure 2–7). A click should be heard as

the handle latches engage.

4 Connect the power supply cord to the power source and switch the power supply ON.

24

Page 37

Getting Started

Figure 2–5 AC Power Supply/Cooling Module - Handle in Open Position

Figure 2–6 Installing an AC Power Supply Cooling Module (1)

25

Page 38

Acer S205F / S200F User’s Manual

Figure 2–7 Installing an AC Power Supply Cooling Module (2)

2.5 RAID and JBOD I/O Module Configurations

Important Please refer to section 2.10 for information on SATA drive configurations.

2.5.1 Internal Loop Structures

The Altos S205F / S200F Storage System enclosure is configured with two internal loop of 16 drives

per enclosure.

2.6 FC-AL Interface

The I/O module provides dual FC-AL SFP interface connections.

The I/O module provides bi-directional conversion between the Fibre Channel host side interface

and the SATA drives.The drives will not be presented to the Host until they are configured and

mapped by the controller.

When Logical Arrays are configured and mapped, each drive array appears as a single Fibre Channel

drive in a single loop.

Note There are no external terminators required with Fibre Channel architecture and any drive may be

hot plugged during operation.

26

Page 39

Getting Started

2.6.1 Connecting Multiple Enclosures

Altos S205F Storage System enclosure expansion is achieved by connecting additional Altos S200F

JBOD enclosures to the expansion port of the Altos S205F Storage System RAID controllers.

Important Optical modules must be UL (or other North American NRTL) RECOGNISED COMPONENT and the

laser in the module must comply with Laser Class 1, US 21 CFR (J) and EN 60825-1.

If passive copper cables are connected, the cable must not have a connection to the 3.3V supply

(pins 15 and 16).

Expansion enclosures are Altos S200F Storage System.

Note A maximum of 6 Altos S200Fs can be attached to an Altos S205F Storage System enclosure and a

typical expansion configuration is shown in

Figure 2–8,Figure 2–9 .

Figure 2–8 Single loop conection

Each connection can see all the drives in the enclosure. J7 jumper of Altos S200F is open.

27

Page 40

Acer S205F / S200F User’s Manual

28

Figure 2–9 Dual loops connection

Each connection can see all the drives in the enclosure. J7 jumper of Altos S200F is

open.

Page 41

Getting Started

J7

Figure 2–10 Jumper setting for JBOD I/O module: set jumper J7 open. Each connection can see all

drives in the enclosure.

2.7 I/O Module Installation

Warning Operation of the Enclosure with

not receive sufficient cooling. It is

Dummy Carriers and/or Blank modules are available for this purpose.

2.7.1 Parts Check List

Important The enclosure may be configured with either one or two I/O modules. If only one I/O module is

fitted it must be installed in rear bay 4 and a Blank I/O module fitted in the unused bay.

• Two RAID I/O Modules ,or one RAID I/O Module with one Blank I/O module for Altos S205F

• Two JBOD I/O Modules ,or one JBOD I/O Module with one Blank I/O module for Altos S200F

ANY

modules missing will disrupt the airflow and the drives will

ESSENTIAL

that all apertures are filled before operating the unit.

29

Page 42

Acer S205F / S200F User’s Manual

2.7.2 Procedure

Check for damage especially to the interface connector, do not install if any pins are bent.

Figure 2–11 Controller Module Latch Operation

1 The modules should be installed in rear bays 3 and 4 of the Enclosure (Figure 2–1, Figure 2–2).

2 With the latch in the open position (see Figure 2–11), slide the Controller module into the enclosure

until the latch engages automatically.

3 Cam the module home by manually closing the latches (see Figure 2–12).

4 A click should be heard as the latch engages.

30

Figure 2–12 Installing an I/O Module

Page 43

2.8 Altos S205F Drive Enclosure Device Addressing

Each enclosure has 16 drives. The SEL_ID of each drive is determined by the device slot (0-15) in

which it is installed and the address range setting, which is set by means of the Enclosure ID switch.

The Mode selection is also set on the Ops Panel (shown in Figure 1–8 on page 6) at the rear of the

enclosure. The switch settings are as follows:

Mode Switch 9 Switch 10

0 ON ON

Getting Started

Notes 1 ON = switch to the

2 Switch 3 for hub.

3 Switch 5 and 6 for host port speed.

4 Modes 1, 2 and 3 are

Warning Switches 9 and 10 should not be turned Off together, damage may occur as a result.

Table 2–3 Mode 0 Drive Enclosure Device Settings

Mode 0

0 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

1 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

2 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35

3 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

4 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67

5 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83

6 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

7 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

8 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

Left

, OFF = switch to the

Not Used.

Right

.

9 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

10 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

11 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

12 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

13 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

14 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

15 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

Device Slot SEL_ID

31

Page 44

Acer S205F / S200F User’s Manual

Notes 1 Drives are numbered row/column.

2 With only one active PSU the enclosure will take approximately 96 seconds to start

)

Table 2–4 Drive Slot Arrangement: Enclosure Front View

Column / row 1/# 2/# 3/# 4/#

#/1 Drive 0* Drive 1 Drive 2 Drive 3

#/2 Drive 4 Drive 5 Drive 6 Drive 7

#/3 Drive 8 Drive 9 Drive 10 Drive 11

#/4 Drive 12 Drive 13 Drive 14 Drive 15*

Important SES drives: Drive bay set for immediate start, all other bays are delayed spin start (12 seconds x

Module 8 of the SEL_ID) unless there are two active PSUs when they all start immediately.

all drives from Power On.

2.9 Altos S200F Drive Enclosure Device Addressing

Each enclosure has 16 drive bays. The SEL_ID of each drive is determined by the device slot (0-15) in

which it is installed and the address range setting, which is set by means of the Enclosure ID switch

on the Ops Panel (shown in

are shown in Table 2–5

Table 2–5 Ops Panel Switch Functions

Switch Number Function Recommended Setting Definition

1 Not Used Off

2 Not Used Off

3 Not Used Off

4 Not Used Off

5 & 6 Not Used Off

7 & 8 Drive Loop Speed

Select

Figure 1–8 on page 6) at the rear of the enclosure. The switch settings

Sw 7 Sw 8

On Off Force 2Gb/s

Off Off Force 1Gb/s

32

9 & 10 Drive Addressing

Mode Selection

Sw 9 Sw 10

On On Mode 0 (recommended)

Off On Mode 1 (not recommended)

Page 45

Table 2–5 Ops Panel Switch Functions

Switch Number Function Recommended Setting Definition

Getting Started

On Off

Off Off

*

Mode 2

*

Mode 3

(not supported

(not supported)

11 SOFT SELECT On Selects functions using the

hardware switches

12 Not Used Off

Notes 1 ON = switch to the Right, OFF = switch to the Left.

Table 2–6 Mode 0 Drive Addressing

Thumb

Wheel

Device Slot SEL_ID

Mode 0

Switch

1 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

2 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35

3 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

4 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67

5 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83

6 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

7 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

8 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

9 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

10 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

11 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

12 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

13 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

14 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

15 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115

)

Table 2–7 Drive Slot Arrangement: Enclosure Front View

Row/Column 1/# 2/# 3/# 4/#

#/1 Drive 0* Drive 1 Drive 2 Drive 3

#/2 Drive 4 Drive 5 Drive 6 Drive 7

33

Page 46

Acer S205F / S200F User’s Manual

Table 2–7 Drive Slot Arrangement: Enclosure Front View

Row/Column 1/# 2/# 3/# 4/#

#/3 Drive 8 Drive 9 Drive 10 Drive 11

#/4 Drive 12 Drive 13 Drive 14 Drive 15*

Notes 1 Drives are numbered row/column.

With only one active PSU the enclosure will take approximately 96 seconds to start all drives from

Power On.

2.10 Drive Carrier Configuration

2.10.1 Planning and Configuring Your Installation

2.10.1.1 System Configuration

Important Before you begin installation you should become familiar with the configuration requirements of

your Altos S205F / S200F Storage System system. Please refer to Section

overall system configurations.

There must be a drive present in Bay 1/1 or 4/4 to enable SES Communications to operate. Installing

drives in both of these bays will provide redundant SES communication paths.

When planning your system configuration, please remember that:

• All Altos S205F / S200F Storage System enclosure drive bays must be filled with either a drive

carrier or front dummy carrier module, no bays should be left completely empty.

Warning Operation of the Enclosure with

not receive sufficient cooling. It is

Dummy Carriers and/or Blank modules are available for this purpose.

ANY

modules missing will disrupt the airflow and the drives will

ESSENTIAL

that all apertures are filled before operating the unit.

2.2 for information on your

2.10.1.2 Drive Configuration

Important After you have installed the drive carrier modules in your Altos S205F / S200F Storage System

enclosure, please refer to Section

are installing.

2.5 for configuration information relevant to the I/O module you

2.11 Drive Carrier Installation

2.11.1 Parts Check List

• Drive Carrier module, or

• Dummy Carrier module

34

Page 47

Getting Started

2.11.2 Procedure

1 Release the carrier handle, by pressing the latch in the handle towards the right and insert the

carrier into the enclosure (

Important For a Rack Mounted System: Ensure that the carrier is orientated so that the drive is uppermost and

the handle opens from the left.

For a Tower System: Ensure that the carrier is orientated so that the carrier lock position is

uppermost and the handle opens from the top

2 Slide the carrier, gently, all the way into the enclosure until it is stopped by the camming lever on

the right of the carrier (

3 Cam the carrier home - the camming foot on the base of the carrier will engage into a slot in the

enclosure. Continue to push firmly until the handle fully engages. A click should be heard as the

latch engages and holds the handle closed (

Note Ensure that the Handle always opens from the left.

Figure 2–13).

Figure 2–14)

Figure 2–15).

Figure 2–13 Installing a SATA Drive Carrier Module (1)

Note Removal is the reverse of this procedure (press on the latch to release the handle).

35

Page 48

Acer S205F / S200F User’s Manual

Figure 2–14 Installing a SATA Drive Carrier Module (2)

36

Figure 2–15 Installing an SATA Drive Carrier Module (3)

Page 49

2.11.3 Dummy Carrier Modules

Any unused drive bays must be fitted with a dummy carrier module.

2.11.4 Engaging the Anti-tamper Locks

The anti-tamper locks are fitted in the drive carrier handles and are accessed through the small

cutout in the latch section of the handle.

Drives are supplied with the locks set in the locked position.

2.11.4.1 Activating the Locks

1 Carefully insert the lock key provided into the cutout in the handle.

2 Locate the key into its socket.

3 Rotate the key in a clockwise direction until the indicator is visible in the aperture beside the key.

).

Getting Started

Figure 2–16 Activating the Anti-tamper Lock

4 Remove the key.

De-activation is the reverse of this procedure, that is:

• Rotate the key in a anti-clockwise direction until the indicator is no longer visible in the

aperture beside the key.

Note A drive carrier cannot be installed if its anti-tamper lock is activated outside the Enclosure.

2.12 Power Cord Connection

2.12.1 Parts Check List

• Power cord to requisite local standards

37

Page 50

Acer S205F / S200F User’s Manual

2.12.2 Procedure

1 Attach the power cord to the Power Supply/Cooling Modules,

2 Attach the power cord to the in-line IEC connector in this cord.

Caution These power splitting cables are provided so that the system is operated from a SINGLE power

source thus providing a single point of disconnect.

3 Switch on each Power Supply/Cooling Module.

4 A POWER LED on the Ops Panel indicates whether AC power is present.

Caution The power connections must always be disconnected prior to removal of the Power Supply/Cooling

module from the enclosure.

2.13 Grounding Checks

Perform these checks to ensure that a safe grounding system is provided.

• If a rack distribution system is being used.

– Ensure power is removed from the rack.

– Connect the Altos S205F / S200F Storage System power cord to the rack distribution and the

enclosure.

• If a direct connection is made with the Altos S205F / S200F Storage System power cord, ensure

that it is connected to the enclosure.

Warning Some electrical circuits could be damaged if external signal cables or power control cables are

present during the grounding checks.

• Check for continuity between the earth pin of the IEC 320 connector on one of the Power

Supply/Cooling modules and any exposed metal surface of the Altos S205F / S200F Storage

System enclosure.

38

Page 51

Chapter 3

Operation

3.1 Before You Begin

Before powering up the enclosure please ensure that all the modules are firmly seated in their

correct bays.

Operation

3.2 Power On

Caution Do not operate the subsystem until the ambient temperature is within the specified operating

range. If the drives have been recently installed ensure they have had time to acclimatize before

operating them.

Note Please refer to Section 3.3 for details of the Ops Panel LEDs and related fault conditions.

Follow the procedure below to Power On the enclosure.

1 Apply AC power to the enclosure. Turn the Power Supply modules to ON.

2 On the Ops Panel, the Audible Alarm beeps once, all LEDs flash for 7 seconds then the Alarm double

beeps.

3 All LEDs on the Ops Panel should be lit (Green) when the enclosure power is activated (and the disk

drive motors should start).

Note All LEDs on the Ops Panel should be lit Green at power up to indicate that the system is functioning

correctly. If any show Amber then a problem exists and please contact certificated supplier.

Important If AC power is lost for any reason, on restoration of power the enclosure will re-start automatically.

3.2.1 Power Supply/Cooling Module LEDs

The Power Supply/Cooling module incorporates 4 LEDs, located below the On/Off switch and shown

Table 3–1.

in

• Under Normal conditions the LEDs should all be illuminated constant GREEN

• If a problem is detected the color of the relevant LED will change to AMBER.

39

Page 52

Acer S205F / S200F User’s Manual

Table 3–1 PSU LEDs

PSU Good Green

AC input Fail Amber

Fan Fault Amber

DC Output Fail Amber

AC PSU

3.3 Ops Panel LEDs

The Ops Panel LEDs fault and status conditions are defined in Table 3–2 and shown in Figure 3–1.

Hub Mode

LED (for Altos

S205F only)

Figure 3–1 Ops Panel LEDs and Switches

40

Table 3–2 Ops Panel LED States

LED Definition Color Normal Status Fault Status

Power On Enclosure Powered On Green On Off

System Fault System/ESI Fault Amber Off On

Page 53

Table 3–2 Ops Panel LED States

LED Definition Color Normal Status Fault Status

PSU Fault PSU Fault/ Cooling Temperature Fault Amber Off On

2Gb Link Speed Indicates link speed Green On = 2Gb -

Hub Mode for Altos S205F only - -

Invalid Address Not Used - -

3.4 Starting the Drives

Unless otherwise selected during installation, all drives in the enclosure should automatically start

their motors. If this has not occurred one of the following conditions may exist:

• There may be a power problem (an alarm and power fault indication would normally be

active).

Operation

Off = 1Gb -

• if there is only one Power Supply/Cooling Module present, the drive motors will spin up in a

delayed sequence.

3.4.1 Disk Drives LEDs

Each drive carrier incorporates two indicators, an upper (GREEN) and lower (AMBER).

• In normal operation the Green LED will be ON and will flicker as the drive operates.

• The Amber LED will be OFF In normal operation. It will only be ON if there is a drive fault

3.5 Power Down

To power the Enclosure down,

either

• Switch off the Power Supply/Cooling modules installed in the Enclosure.

or

• Remove AC at the power source

41

Page 54

Acer S205F / S200F User’s Manual

42

Page 55

Glossary

Glossary

In glossary definitions

for the items shown in brackets after the main heading of the entry.

ASCII American Standard Code for Information Interchange. A 7-bit binary code (0's, 1's) used to

represent letters, numbers, and special characters such as $,!, and /. Supported by almost every

computer and terminal manufacturer.

ATA (Advance Technology Attachment) A disk drive interface standard based on a 16-bit bus

and dealing with the power and data signal interfaces between the motherboard and the

integrated disk controller and drive. The ATA "bus" only supports two devices - master and slave.

Attribute Setting that controls access to a specific file. Often used to protect important files (such

as the Registry files) from accidental change or deletion. Set using the ATTRIB command in MS-DOS.

Backplane A printed circuit board incorporated in the chassis assembly to provide logic level

signal, and low voltage power distribution paths.

Bay The slot that a unit or media device fits into.

Byte A group of binary digits stored and operated upon as a unit. A byte may have a coded value

equal to a character in the ASCII code (letters, numbers), or have some other value meaningful to

the computer. In user documentation, the term usually refers to 8-bit units or characters.

1 kilobyte (K) is equal to 1,024 bytes or characters; 64K indicates 65,536 bytes or characters.

, italics

are used for items defined elsewhere in the glossary and bold is used

Cable Throughout this Altos S205F / S200F User’s Manual this term is used in accordance with the

preferred US context of: “an insulated flexible electric wire used for the transmission of data signals

between computer equipment.”

Note: Cable is UK preferred terminology for either a power cord or a data cable:

Character A representation, coded in binary digits, of a letter, number, or other symbol.

Characters Per Second A data transfer rate generally estimated from the bit rate and the character

length. For example, at 2400 bps, 8-bit characters with Start and Stop bits (for a total of ten bits per

character) will be transmitted at a rate of approximately 240 characters per second (cps).

Chassis A sheet metal enclosure incorporating a Backplane PCB and module runner system. The

chassis contains a number of 'Bays', each of which can accommodate a plug in module. There are

drive

sixteen

cooling modules,

Configure To set up a hardware device and its accompanying software.

I/O module (Serial ATA RAID or JBOD I/O module) A plug-in module providing FC-AL channel

external cable interface with 16

Data Communications A type of communications in which computers and terminals are able to

exchange data over an electronic medium.

carrier bays at the front and five bays at the rear which house two

two

I/O modules

and also the

SATA drives

Ops Panel.

.

power supply/

43

Page 56

Altos S205F / S200F User’s Manual

Disk (drive, carrier, module) A SATA disk drive mounted in a carrier. You can have up to sixteen

disk drive carrier modules in each Altos S205F / S200F Storage System enclosure.

Enclosure The chassis assembly which houses the plug-in modules that make up the Altos S205F /

S200F Storage System.

ESI/Ops module A unit used to monitor and control all elements of the Enclosure. The ESI/

Operators (Ops) panel is supplied as an integral part of the Altos S205F / S200F Storage System

Enclosure core product.

Hot plugging A device with the capability of being connected to a subsystem without interrupting

the power supplies to that subsystem.

Hot swap Hot swapping is the term used for manually swapping a failed disk unit with a

replacement while the Altos S205F / S200F Storage System is in normal use.

Hz (Hertz) A frequency measurement unit used internationally to indicate cycles per second.

Initialize To prepare a hardware device for use.

LED Light Emitting Diode. A small light displayed on the cabinet, disk units and power supply

units.

Module (power supply, drive, I/O) A module is a power supply, disk drive or electronics unit held

in a carrier that plugs into a bay inside the enclosure. An Altos S205F / S200F Storage System

enclosure can contain sixteen drive modules, two power supply/cooling modules and two I/O

modules.

Operating system The software running the host computer. For example, on PCs it is often

Windows® 2000 or Windows® NT.

Power Cord Throughout this Altos S205F / S200F Storage System user’s manual this term is used in

accordance with the preferred US context of: “an insulated flexible electric wire fitted with

connectors at each end and used for the transmission of electrical power to computer equipment.

Protocol A system of rules and procedures governing communications between two or more

devices. Protocols vary, but communicating devices must follow the same protocol in order to

exchange data. The format of the data, readiness to receive or send, error detection and error

correction are some of the operations that may be defined in protocols.

Redundant Not essential.

ATA

SATA Serial

drive interface standard based on serial signaling technology, faster and using

much smaller connectors and cables, improving performance and air circulation efficiency.

Serial Transmission The transfer of data characters one bit at a time, sequentially, using a single

electrical path.

44

Page 57

Index

Index

a

AC PSU 2, 4, 24

Alarm Mute push-button 13

anti-static wrist or ankle strap 22

anti-tamper lock 12, 37

Audible Alarm 6, 13

b

Backplane 2, 22, 23

bay 2, 19, 20, 22

c

chassis 2, 23

d

Disk 41

disk drive 2, 22

Disk Drives LEDs 41

drive array 26

drive carrier 35

drive carrier handles 12

Drive Carrier Module 2, 11, 22, 34, 41

drive status indicators 12

dummy carrier module 2, 13, 37

l

LED 5, 6, 13

LED indicators 8

Li-ion battery pack 10

Logical Arrays 26

o

Operators Panel 2, 6

Ops Panel 6, 13, 20, 23, 38, 39

Ops Panel LEDs 40

Ops Panel Switch Functions 7, 32

p

plug-in module 2, 19

Power Down 41

Power On 39

power supply cord 24, 38

Power Supply/Cooling 2, 4, 5, 19, 20, 24, 38, 39

PSU LEDs 39

PSU voltage operating ranges 5

r

Rack mounting 2

rack mounting rail kit 22, 23

RJ45 Ethernet connector 10

e

Enclosure 2, 4, 13, 19, 22, 29, 34

enclosure bay numbering convention 22

enclosure expansion 27

Enclosure System Interface/Operators Panel 6

ESD 22

expansion configuration 27

g

grounding system checks 38

i

IEC 320 connector 38

s

SATA - PATA Transition card 12

SATA Control Interface Adaptor (JBOD I/O) module 8

SATA disk drive 8

SEL_ID Address Range selector switch 6

SEL_ID base address 31, 32

Serial ATA (SATA) Drive Carrier module 2

Serial ATA Control (JBOD) Input/Output module 2

SES 34

SES drives 32

SFP connector 10

starting drives 41

t

tower kit 4

45

Page 58

Acer S205F / S200F User’s Manual

v

Visible and Audible Alarms 13

46

Loading...

Loading...