Page 1

Acer Altos R310

User’s Guide

Page 2

Copyright © 2004 Acer Incorporated

All Rights Reserved.

Acer Altos R310

User’s Guide

1st Issue: March 2004

Changes may be made periodically to the information in this publication without obligation

to notify any person of such revision or changes. Such changes will be incorporated in new

editions of this manual or supplementary documents and publications. This company makes

no representations or warranties, either expressed or implied, with respect to the contents

herein and specifically disclaims the implied warranties of merchantability or fitness for a

particular purpose.

Record the model number, serial number, purchase date, and place of purchase information in

the space provided below. The serial number and model number are recorded on the label

affixed to your computer. All correspondence concerning your unit should include the serial

number, model number, and purchase information.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means, electronic, mechanical, photocopy, recording, or otherwise,

without the prior written permission of Acer Incorporated.

Model Number : _________________________________

Serial Number: ___________________________________

Purchase Date: ___________________________________

Place of Purchase: ________________________________

Acer and the Acer logo are registered trademarks of Acer Inc. Other company’s product

names or trademarks are used herein for identification purposes only and belong to their

respective companies.

Page 3

iii

Notices

FCC notice

Class A devices do not have an FCC logo or FCC IDE on the label. Class

B devices have an FCC logo or FCC IDE on the label. Once the class of

the device is determined, refer to the following corresponding

statement.

Class A equipment

This device has been tested and found to comply with the limits for a

Class A digital device pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This device generates, uses, and can radiate radio

frequency energy, and if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

Operation of this device in a residential area is likely to cause harmful

interference in which case the user will be required to correct the

interference at his own expense.

However, there is no guarantee that interference will not occur in a

particular installation. If this device does cause harmful interference to

radio or television reception, which can be determined by turning the

device off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the device and receiver

• Connect the device into an outlet on a circuit different from that

to which the receiver is connected

• Consult the dealer or an experienced radio/television technician

for help

Page 4

iv

Shielded cables

All connections to other computing devices must be made using

shielded cables to maintain compliance with FCC regulations.

Peripheral devices

Only peripherals (input/output devices, terminals, printers, etc.)

certified to comply with the Class A or Class B limits may be attached to

this equipment. Operation with noncertified peripherals is likely to

result in interference to radio and TV reception.

Caution: Changes or modifications not expressly approved by

the manufacturer could void the user’s authority, which is granted

by the Federal Communications Commission, to operate this

server.

Use conditions

This part complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Canadian users

This Class A/Class B digital apparatus meets all requirements of the

Canadian Interference-Causing Equipment Regulations.

Laser compliance statement

The CD-ROM drive in this server is a laser product. The CD-ROM drive’s

classification label (shown below) is located on the drive.

CLASS 1 LASER PRODUCT

CAUTION: INVISIBLE LASER RADIATION WHEN OPEN. AVOID

EXPOSURE TO BEAM.

Page 5

Important safety instructions

Read these instructions carefully. Save these instructions for future

reference.

1 Follow all warnings and instructions marked on the product.

2 Unplug this product from the wall outlet before cleaning. Do not

use liquid cleaners or aerosol cleaners. Use a damp cloth for

cleaning.

3 Do not use this product near water.

4 Do not place this product on an unstable cart, stand, or table. The

product may fall, causing serious damage to the product.

5 Slots and openings on the back or bottom side of the chassis are

provided for ventilation; to ensure reliable operation of the

product and to protect it from overheating, these openings must

not be blocked or covered. The openings should never be blocked

by placing the product on a bed, sofa, rug, or other similar surface.

This product should never be placed near or over a radiator or

heat register, or in a built-in installation unless proper ventilation

is provided.

6 This product should be operated from the type of power indicated

on the marking label. If you are not sure of the type of power

available, consult your dealer or local power company.

7 Do not allow anything to rest on the power cord. Do not locate

this product where persons will walk on the cord.

8 If an extension cord is used with this product, make sure that the

total ampere rating of the equipment plugged into the extension

cord does not exceed the extension cord ampere rating. Also,

make sure that the total rating of all products plugged into the

wall outlet does not exceed the fuse rating.

9 Never push objects of any kind into this product through chassis

slots as they may touch dangerous voltage points or short out

parts that could result in a fire or electric shock. Never spill liquid

of any kind on the product.

10 Do not attempt to service this product yourself, as opening or

removing covers may expose you to dangerous voltage points or

other risks. Refer all servicing to qualified service personnel.

11 Unplug this product from the wall outlet and refer servicing to

qualified service personnel under the following conditions:

v

Page 6

vi

a When the power cord or plug is damaged or frayed

b If liquid has been spilled into the product

c If the product has been exposed to rain or water

d If the product does not operate normally when the operating

instructions are followed. Adjust only those controls that are

covered by the operating instructions since improper

adjustment of other controls may result in damage and will

often require extensive work by a qualified technician to

restore the product to normal condition.

e If the product has been dropped or the cabinet has been

damaged

f If the product exhibits a distinct change in performance,

indicating a need for service.

12 Replace the battery with the same type as the product's battery we

recommend. Use of another battery may present a risk of fire or

explosion. Refer battery replacement to a qualified service

technician.

13 Warning! Batteries may explode if not handled properly. Do not

disassemble or dispose of them in fire. Keep them away from

children and dispose of used batteries promptly.

14 Use only the proper type of power supply cord set (provided in

your accessories box) for this unit. It should be a detachable type:

UL listed/CSA certified, type SPT-2, rated 7A 125V minimum, VDE

approved or its equivalent. Maximum length is 15 feet (4.6

meters).

Page 7

Notices iii

FCC notice iii

Class A equipment iii

Shielded cables iv

Peripheral devices iv

Use conditions iv

Canadian users iv

Laser compliance statement iv

Important safety instructions v

1 System information 1

Product briefing 3

Processor 3

Memory subsystem 3

Storage 4

Graphics interface 4

Networking 4

I/O ports 4

Serial ATA ports 4

Caring features 5

Product specification summary 6

2 System tour 7

System board 9

Mainboard layout 9

Jumper settings (JP1) clear CMOS 12

Jumper settings (JP2) Password 12

Jumper settings (JP4) Boot Block 12

External and internal structure 13

Front panel 13

Rear panel 14

Internal components 16

Contents

3 Getting Started 17

Setting up the system 19

Preinstallation requirements 19

Selecting a site 19

Checking the package contents 19

System startup 20

Turning on the system 20

Turning off the system 21

Power-on problems 21

Page 8

BIOS POST Checkpoint Codes 22

4 Configuring the system 37

Upgrading the system 39

Installation precautions 40

ESD precautions 40

Preinstallation instructions 41

Post-installation instructions 41

Opening the server 42

Before opening the server 42

To remove the top panel 43

To replace the top panel 44

Installing expansion cards 45

To install an expansion card 45

Installing and removing a hard disc drive 47

Removing a hard disc 47

Installing a hard disc 48

Upgrading the CPU 50

Removing a CPU 50

Installing a CPU 52

Upgrading the system memory 54

Memory configuration 54

To remove a DIMM 55

To install a DIMM 56

Reconfiguring the system memory 56

5 BIOS setup 57

BIOS setup 59

Entering BIOS setup 60

Main 62

Advanced 64

PCI Configuration 66

Peripheral Configuration 67

Boot Settings Configuration 68

Event Log Configuration 70

Console Redirection 72

System Health Monitoring 74

Alert Standard Format (ASF) configruation 75

Power 76

Boot 77

Security 78

Exit 79

Page 9

Appendix A: Management software installation 81

Installing ASM 83

System requirements 83

ASM Agent 83

ASM Console 83

System setup 83

Installing ASM Agent (Windows version) 84

Installing ASM Console (Windows version) 84

Installing ASM Agent (Linux version) 85

Appendix B: Rack installation 87

System rack installation 89

Equipment rack precautions 89

Vertical mounting hole pattern 91

Screw types for rack installation 92

Installing cage nuts 92

Installing the system into the rack 93

To install the system into the rack: 93

Appendix C: SATA RAID configuration utility 97

Hardware Requirements for R310 SATA RAID 99

SATA RAID POST information 99

Server BIOS settings 100

Using the Adaptec RAID configuration utility 101

Create and Manage RAID 0 104

Disk Utilities 110

Index 111

Page 10

Page 11

1 System

information

Page 12

The Acer Altos R310 is a 1U, high density, rack

optimised single processor system loaded

with features. The system offers a new

standard for flexible productivity ideal for

local or wide area networks and multiuser

server environments.

Page 13

Product briefing

This section provide basic information concerning the configuration of

your Altos R310 system.

Processor

• Single 2.5 GHz Intel Celeron processor with 400 MHz FSB

®

• Single 2.8 GHz Intel

- or -

• Single 3.0 GHz (or faster) Intel

MHz FSB

• CPU Hyper-Threading Technology support

Memory subsystem

• Four (184 - pin) DIMM slots

• DDR 333/400 MHz Unbuffered memory modules supported

• Maximum upgrade - 4 GB

Pentium® 4 processor with 533 MHZ FSB

®

Pentium® 4 processor with 800

3

Warning! Functionality issues may be encountered if mixed

memory types are installed on the same server board. DIMM

modules of identical type, banking and stacking technology, and

vendor should be installed in the Altos R310.

Caution! When using multiple memory modules it is

recommended that you AVOID using modules from different

manufacturers or that run at different speeds from each other.

Note: To run 400 MHz memory at full speed requires a processor

with 800 MHz system bus frequency.

Note: To run 333 MHz memory at full speed requires a processor

with 533 MHz system bus frequency.

Page 14

4

Note: 333 MHz memory will run at 320 MHz when used with a

processor with 800 MHz system bus frequency.

Storage

• Slim-type IDE CD-ROM drive

• Slim-type 3.5 inch Floppy disk drive

• Support for two (max) hard disk drives

Graphics interface

• On-board ATI Rage XL

Networking

• Dual Gigabit Ethernet support

I/O ports

• Front

• One USB 2.0 ports

• Rear

• Two USB 2.0 ports

• Two PS/2 ports (keyboard/mouse)

• Two LAN port (RJ-45)

• One SVGA video port

• One serial port

1 System information

Serial ATA ports

• Two serial ATA ports

• Support RAID 0 or RAID 1

Note: Serial ATA supports drivers for Windows

2003 only.

®

2000/Server

Page 15

Caring features

Part of Acer’s mission, as a company that cares about its end users, is to

provide features that make operation, maintenance, and upgrading

your system simpler and faster. The Altos R310 is no exception to this

rule. The following features and options are provided.

• Cost efficient operation in a value oriented package

• Tool-less design

• Built-in software Serial ATA RAID support for data security and

speed - By default, the Altos R310 supports RAID 0 and 1

• Front accessible USB port

• Acer EasyBUILD

• Acer Server Manager (ASM) suite of comprehensive management

tools

TM

for efficient system setup and installation

5

Page 16

6

1 System information

Product specification summary

Highlighted below are the system’s key features:

• Single Intel

Threading Technology (P4 only)

• 400/533/800 MHz FSB supports processor speeds from 2.8 GHz to

3.2 GHz

•Intel

•Intel

•Intel

•Intel

• Intel 82541GI 10/100/1000Base-T Gigabit LAN controller

• Two 64 bit/ 66 MHz/ 3.3V PCI-X bus slots

• Four DIMM sockets supporting DDR 333/400 MHz ECC modules for

a maximum memory capacity of 4 GB

• Media storage

• One slim-type 3.5 inch 1.44 MB floppy drive

• One slim-type 5.25 inch high speed CD-ROM drive

• Additional media storage capacity

• Support for two 3.5 Inch S-ATA, ATA, or SCSI hard disk drives

• External ports

• PS/2 keyboard and mouse ports • Serial port

• Three USB ports (1 front, 2 rear) • SVGA video port

• Two LAN (RJ-45) ports

®

Celeron or Pentium® 4 processor supporting Hyper-

®

E7210 chipset consisting of:

®

E7210 Memory Controller Hub (MCH)

®

6300ESB I/O Controller

®

82547GI 10/100/1000Base-T Gigabit LAN controller

• Power supply unit (PSU)

• One 300W ATX12, auto-switching power supply

• Operating Systems supported

®

• Microsoft

• Microsoft

• SCO OpenServer

• SCO Unixware

• Novell NetWare

• Red Hat

Windows® Server 2003

®

Windows® 2000

TM

5.0.7

®

7.1.3

®

®

Enterprise Linux 3

6.5

Page 17

2 System tour

Page 18

This chapter provides locations of various

components and ports and instructions on how

to set up the system.

Page 19

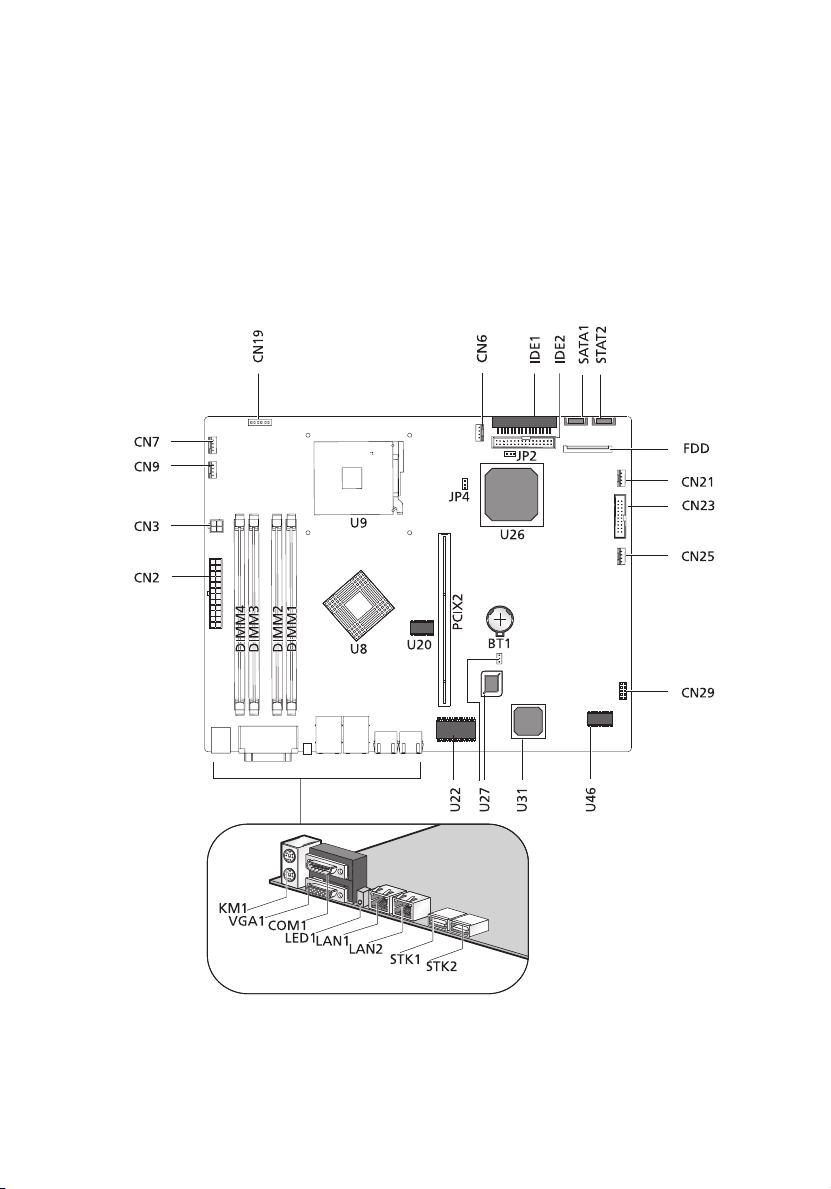

System board

Mainboard layout

The mainboard becomes accessible once you open the system. The

figure below is provided to help you indentify and locate connectors,

slots and ports.

9

Page 20

10

Item Description

BT1 Battery

CN2 ATX power connector (20 pin)

CN3 ATX power connector (4 pin)

2 System tour

CN6

CN7

CN9

CN19 Front Panel connector

CN21 CD-ROM power connector

CN23 ARMC Feature connector

CN25 Add-on card HDD LED connector

CN29 LPC debug card interface connector

COM1 Serial port

DIMM1

DIMM2

DIMM3

DIMM4

FDD Floppy disc drive connector

JP1 Clear CMOS

JP2 Password

JP4 Boot Block

Fan connectors

DIMM slots

KM1 PS/2 Mouse/Keyboard ports

LAN1

LAN2

LED1 Rear panel ID indicator

PCIX2 PCI riser slot

Gigabit Ethernet ports

Page 21

Item Description

11

IDE1

IDE2

STK1

STK2

U8 Canterwood-ES chipset (North bridge)

U9 CPU slot (478 pin)

U20 System clock generator

U22 Super I/O

U26 Hance-Rapids chipset (South bridge)

U27 BIOS

U31 ATI Rage XL

U46 VGA SDRAM

VGA1 VGA monitor port

Primary IDE connector

Secondary IDE connector

USB 2.0 ports

Page 22

12

Jumper settings (JP1) clear CMOS

Pin Number Pin Settings

1-2 Normal (default)

2-3 Clear CMOS

Jumper settings (JP2) Password

Pin Number Pin Settings

1-2 Normal (default)

2-3 Clear password

Jumper settings (JP4) Boot Block

Pin Number Pin Settings

2 System tour

1-2 Disabled (default)

2-3 Enabled

Page 23

External and internal structure

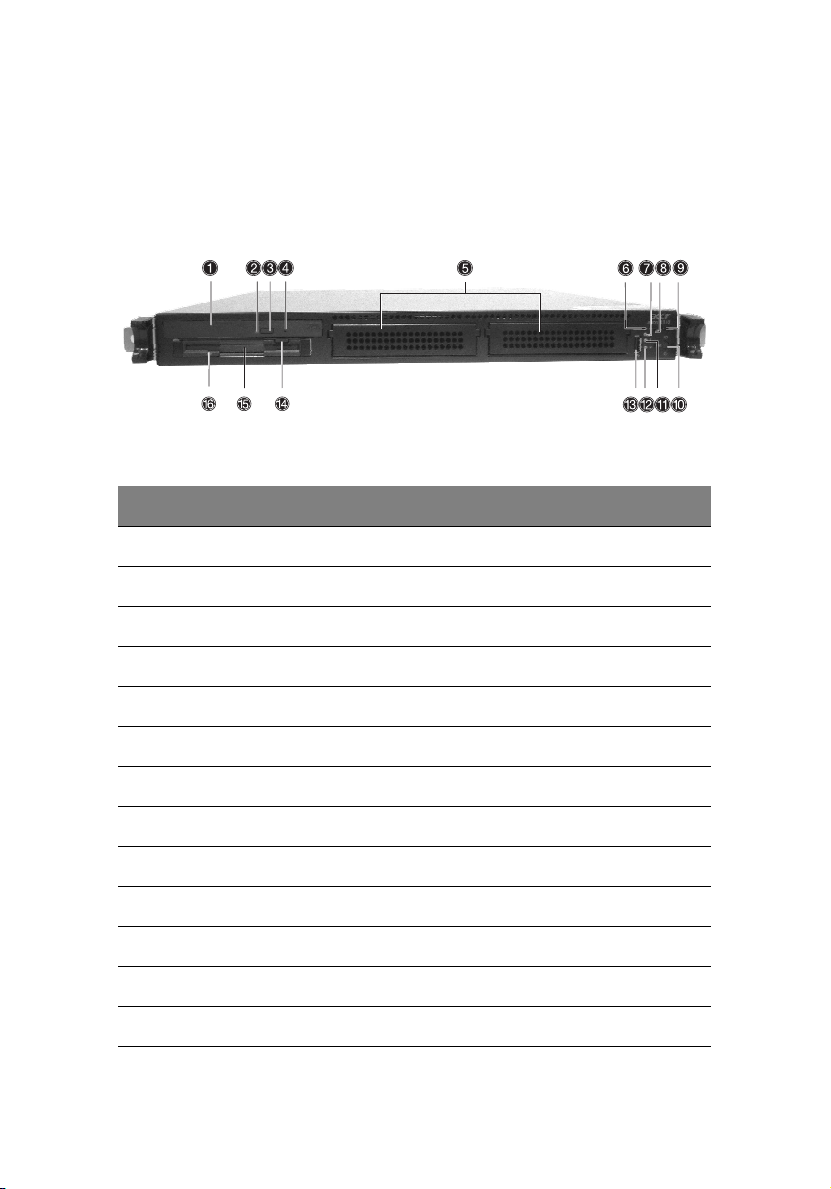

Front panel

No. Description

1 CD-ROM drive

2 CD-ROM activity indicator

3 CD-ROM eject button

13

4 CD-ROM emergency eject hole

5 HDD bays

6ID indicator

7 HDD access indicator

8 System reset button

9 ID button

10 Power button

11 Fault indicator

12 System activity indicator

13 USB 2.0 port

Page 24

14

No. Description

14 FDD eject button

15 Floppy disc drive (FDD)

16 FDD activity indicator

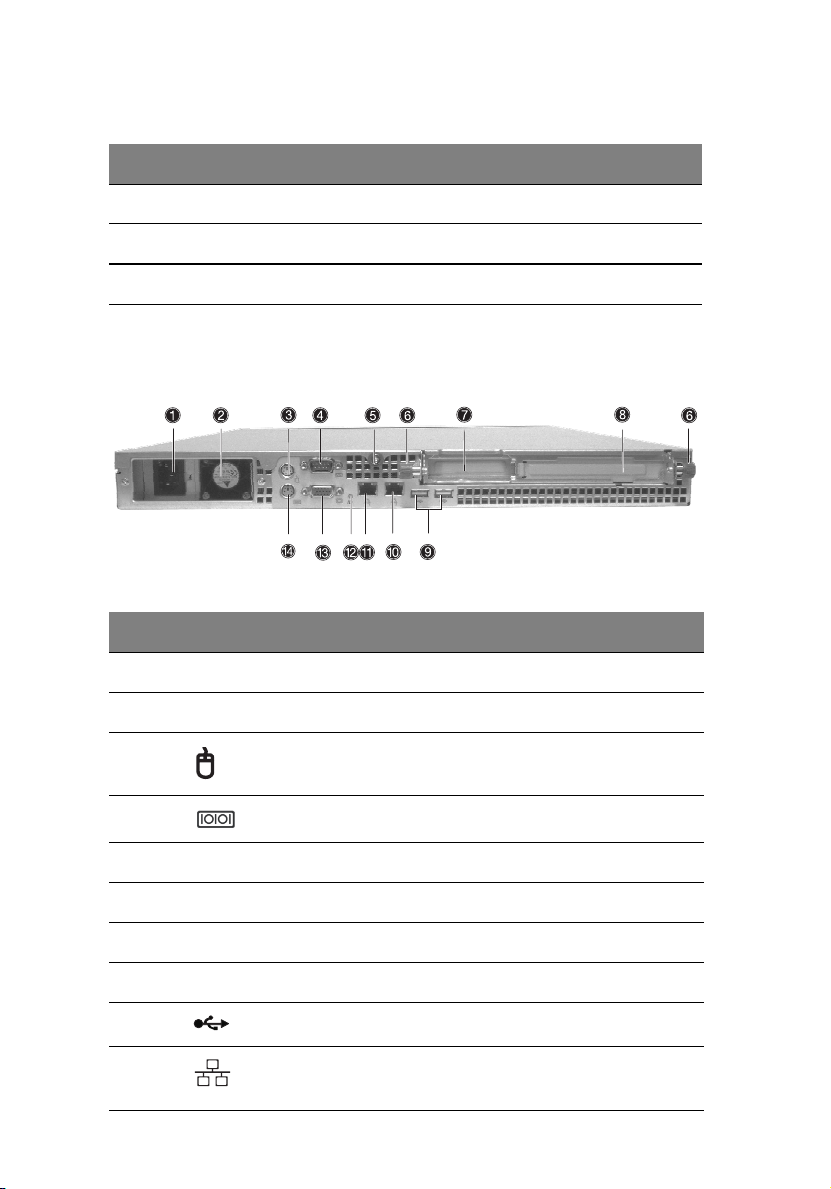

Rear panel

No. Icon Description

2 System tour

1 Main power supply unit

2 Main power supply fan-exhaust

3 PS/2 mouse port

4 Serial port

5 Top panel tool-less screw

6 System expansion card riser tool-less screws

7 Expansion card slot

8 Expansion card slot

9 USB 2.0 ports (two)

10

11

Gigabit LAN ports (10/100/1000 Mbps)

Page 25

No. Icon Description

12 ID ID indicator

13 SVGA/monitor port

14 PS/2 keyboard port

15

Page 26

16

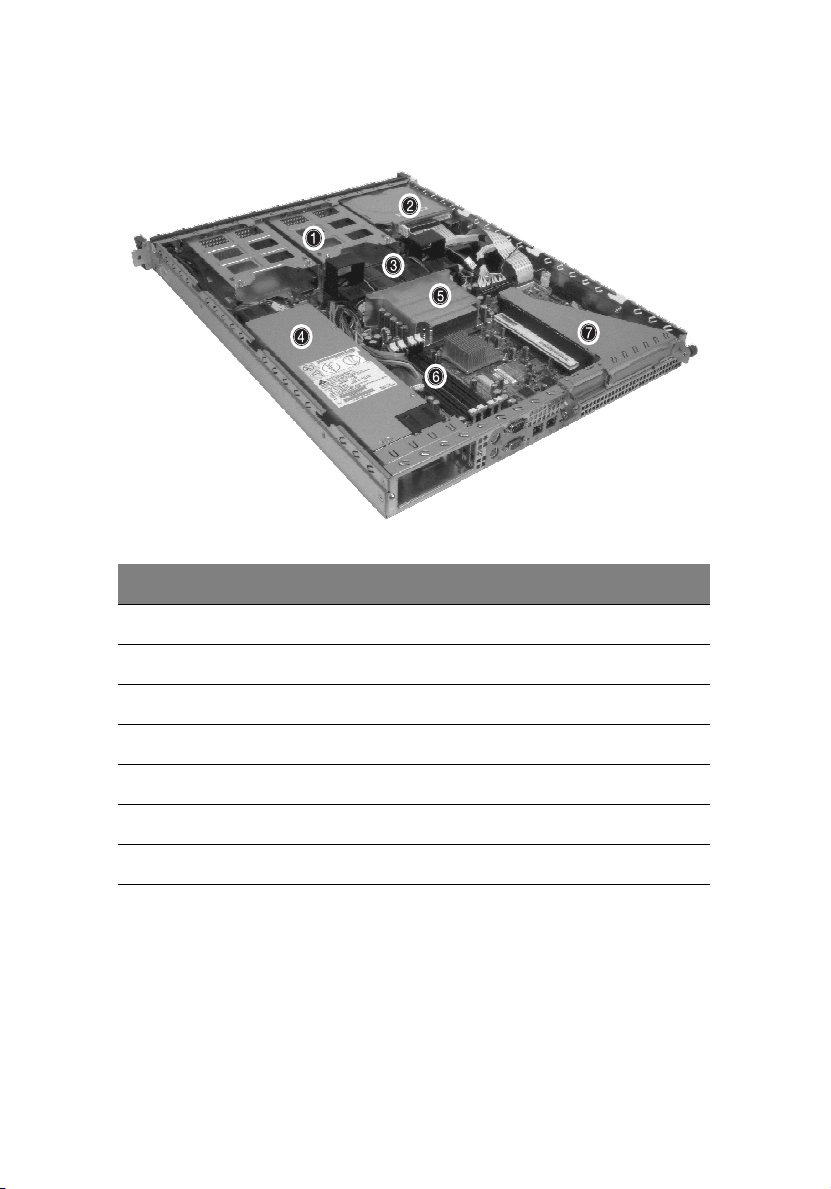

Internal components

No. Description

1 HDD bays

2 System tour

2 CD-ROM/FDD assembly

3 System fans

4 Power supply unit

5 CPU/heatsink/air-baffle assembly

6 DIMM slots

7 Expansion card riser

Page 27

3 Getting Started

Page 28

This chapter gives information on setting up

and starting to use your system

Page 29

Setting up the system

Preinstallation requirements

Selecting a site

Before unpacking and installing the system, select a suitable site for

the system for maximum efficiency. Consider the following factors

when choosing a site for the system:

• Near a grounded power outlet

• Clean and dust-free

• Stable surface free from vibration

• Well-ventilated and away from sources of heat

• Secluded from electromagnetic fields produced by electrical

devices such as air conditioners, radio and TV transmitters, etc.

Checking the package contents

Check the following items from the package:

• Acer Altos R310 system

• Acer Altos R310 User’s guide

• Acer Altos R310 Accessory box

19

If any of the above items are damaged or missing, contact your dealer

immediately.

Save the boxes and packing materials for future use.

Page 30

20

3 Getting Started

System startup

Turning on the system

After making sure that you have properly set up the system and

connected all the required cables, you can now power on the system.

To power on the system, press the power button on the front panel.

Refer to “Front panel” on page 13, for help locating the power button.

The system starts up and displays a welcome message. After that, a

series of power-on self-test (POST) messages appears. The POST

messages indicate if the system is running well or not.

Note: If the system does not turn on or boot after pressing the

power button, go to “Power-on problems” on page 21 for

possible causes of boot failure.

Aside from the POST messages, you can determine if the system is in

good condition by checking if the following occur during startup:

• Power indicator on the front panel lights up (green)

• Num Lock, Caps Lock, and Scroll Lock indicators on the keyboard

light up

Page 31

Turning off the system

To turn off the server, on the Windows task bar click on the Start

button, point to Shut Down..., select Shut down from the dropdown window then click on OK. You can then turn off all peripherals

connected to your server.

If you are unable to shutdown the server within Windows, press and

hold the power button for at least four seconds to force quit all

applications and shut down.

Power-on problems

If the system does not boot after you have applied power, check the

following factors that might have caused the boot failure.

• The external power cable may be loosely connected.

Check the power cable connection from the power source to the

power cable socket on the rear panel. Make sure that the cable is

properly connected to the power source and to the power cable

socket.

• No power comes from the grounded power outlet.

Have an electrician check your power outlet.

• Loose or improperly connected internal power cables.

Check the internal cable connections. If you are not confident to

perform this step, ask a qualified technician to assist you.

21

Warning! Make sure all power cords are disconnected from

the electrical outlet before performing this task.

Note: If you have gone through the preceding actions and the

system still fails to boot, ask your dealer or a qualified technician

for assistance.

Page 32

22

3 Getting Started

BIOS POST Checkpoint Codes

The POST code checkpoints are references and instructions used

during the BIOS pre-boot process. The following table describes

the checkpoints and associated beep codes, if any, that may

occur during the POST portion of the BIOS

.

Checkpoint

Code

01h One short

02h Verify Real Mode. If the CPU is in protected

03h Disabel Non-Maskable Interrupts (NMI).

04h Get CPU type from CPU registers and other

06h Initialize system hardware. Reset the DMA

07h Disable system ROM shadow and start to

Beep Code Description

beep before

boot

mode, turn on A20 and pulse the reset line,

forcing a shutdown 0.

NOTE: Hook routine should not alter DX,

which holds the powerup CPUID.

methods.

Save CPU type in NVRAM.

NOTE: Hook routine should not alter DX,

which holds the powerup CPUID.

controllers, disable video, clear any pending

interrupts from the real-time clock and

setup port B register.

execute ROMEXEC code from the flash part.

This task is pulled into the build only when

the ROMEXEC relocation is installed.

08h Initialize chipset registers to the Initial POST

Values.

Page 33

23

Checkpoint

Code

09h Set in-POST flag in CMOS that indicates we

0Ah Initialize CPU registers.

0Bh Enable CPU cache. Set bits in CMOS related

0Ch Set the initial POST values of the cache reg-

0Eh Set the initial POST values of registers in the

0Fh Enable the local bus IDE as primary or

Beep Code Description

are in POST. If this bit is not cleared by postClearBootFlagJ (AEh), the BIOS on next boot

determines that the current configuration

caused POST to fail and uses default values

for configuration.

Clear the CMOS diagnostic byte (register E).

Check the real-time clock and verify the battery has not lost power. Checksum the

CMOS and verify it has not been corrupted.

to cache.

isters if not integrated into the chipset.

integrated I/O chip.

secondary depending on other drives

detected.

10h Initialize power management.

11h General dispatcher for alternate register ini-

tialization.

Set initial POST values for other hardware

devices defined in the register tables.

12h Restore the contents of the CPU control

word whenever the CPU is reset.

13h Early reset of PCI devices required to disable

bus master. Assumes the presence of a stack

and running from decompressed shadow

memory.

Page 34

24

3 Getting Started

Checkpoint

Code

14h Verify that the 8742 keyboard controller is

16h 1-2-2-3 Verify that the ROM BIOS checksums to

17h Initialize external cache before autosizing

18h Initialize all three of the 8254 timers. Set the

1Ah Initialize DMA command register with these

Beep Code Description

responding. Send a self-test command to

the 8742 and wait for results. Also read the

switch inputs from the 8742 and write the

keyboard controller command byte.

zero.

memory.

clock timer (0) to binary count, mode 3

(square wave mode), and read/write LSB

then MSB. Initialize the clock timer to zero.

Set the RAM refresh timer (1) to binary

count, mode 2 (Rate Generator), and read/

write LSB only. Set the counter to 12H to

generate the refresh at the proper rate. Set

sound timer (2) to binary count, mode 3,

and read/write LSB, then MSB.

settings:

1. Memory to memory disabled

2. Channel 0 hold address disabled

3. Controller enabled

4. Normal timing

5. Fixed priority

6. Late write selection

7. DREQ sense active

8. DACK sense active low

Initialize all 8 DMA channels with these

settings:

1. Single mode

2. Address increment

3. Auto initialization disabled (channel 4 -

Cascade)

4. Verify transfer

Page 35

25

Checkpoint

Code

1Ch Initialize interrupt controllers for some shut-

20h 1-3-1-1 Verify that DRAM refresh is operating by

22h 1-3-1-3 Reset the keyboard.

24h Set segment-register addressibility to 4 GB.

28h 1-3-3-1 Using the table of configurations supplied

29h 1-3-3-2 Initialize the POST Memory Manager.

2Ah Zero the first 512K of RAM.

2Ch 1-3-4-1 Test 512K base address lines.

2Eh 1-3-4-3 Test first 512K of RAM.

Beep Code Description

downs.

polling the refresh bit in PORTB.

by the specific chipset module, test each

DRAM configuration to see if that particular

configuration is valid. Then program the

chipset to its autosized configuration.

Before autosizing, disable all caches and all

shadow RAM.

2Fh Initialize external cache before shadowing.

32h Compute CPU speed.

33h Initialize the Phoenix Dispatch Manager.

34h 1-4-2-1 CMOS test.

36h Vector to proper shutdown routine.

38h Shadow the system BIOS.

3Ah Autosize external cache and program cache

size for enabling later in POST.

Page 36

26

3 Getting Started

Checkpoint

Code

3Ch If CMOS is valid, load chipset registers with

3Dh Load alternate registers with CMOS values.

41h Initialize extended memory for RomPilot.

42h Initialize interrupt vectors 0 thru 77h to the

45h Initialize all motherboard devices.

46h 2-1-2-3 Verify the ROM copyright notice

47h Initialize support for I2O by initializing glo-

48h Verify that the equipment specified in the

Beep Code Description

values from CMOS, otherwise load defaults

and display Setup prompt. If Auto Configuration is enabled, always load the chipset

registers with the Setup defaults.

Register-table pointers are in the altregtable segment.

BIOS general interrupt handler.

bal variables used by the I2O code. Pause

POST table processing if a CMOS bit is set

(for debugging).

CMOS matches the hardware currently

installed. If the monitor type is set to 00

then a video ROM must exist. If the monitor

type is 1 or 2 set the video switch to CGA. If

monitor type 3, set the video switch to

mono. Also specify in the equipment byte

that disk drives are installed. Set appropriate status bits in CMOS or the BDA if configuration errors are found.

Page 37

27

Checkpoint

Code

49h Perform these tasks:

4Ah Initialize all video adapters in system.

4Bh Initialize QuietBoot if it is installed. Enable

4Ch Shadow video BIOS ROM if specified by

Beep Code Description

1. Size the PCI bus topology and set bridge

bus numbers

2. Set the system max bus number

3. Write a 0 to the command register of

every PCI device

4. Write a 0 to all 6 base registers in every

PCI device

5. Write a -1 to the status register of every

PCI device

6. Find all IOPs and initialize them.

both keyboard and timer interrupts (IRQ0

and IRQ1). If your POST tasks require interrupts off, preserve them with a PUSHF and

CLI at the beginning and a POPF at the end.

If you change the PIC, preserve the existing

bits.

Setup, and CMOS is valid and the previous

boot was OK.

4Eh Display copyright notice.

4Fh Initialize MultiBoot. Allocate memory for

50h Display CPU type and speed.

51h Checksum CMOS and initialize each EISA

52h Verify keyboard reset.

54h Initialize keystroke clicker if not enabled in

55h Enable USB devices.

old and new MultiBoot history tables.

slot with data from the initialization data

block.

Setup.

Page 38

28

3 Getting Started

Checkpoint

Code

58h 2-2-3-1 Test for unexpected interrupts. First do an

59h Register POST Display Services, fonts, and

5Ah Display prompt “Press F2 to enter SETUP.”

5Bh Disable CPU cache.

5Ch Test RAM between 512K and 640K.

60h Determine and test the amount of extended

62h Perform an address line test on A0 to the

Beep Code Description

STI for hot interrupts. Secondly, test the NMI

for an unexpected interrupt. Thirdly, enable

the parity checkers and read from memory,

checking for an unexpected interrupt.

languages with the POST Dispatch Manager.

memory available. Determine if memory

exists by writing to a few strategic locations

and see if the data can be read back. If so,

perform an address-line test and a RAM test

on the memory. Save the total extended

memory size in the CMOS at cmosExtended.

amount of memory available. This test is

dependent on the processor, since the test

will vary depending on the width of memory (16 or 32 bits). This test will also use A20

as the skew address to prevent corruption

of the system memory.

64h Jump to UserPatch1. See "The POST Compo-

66h Set cache registers to their CMOS values if

67h Quick initialization of all Application Proces-

nent."

CMOS is valid, unless auto configuration is

enabled, in which case load cache registers

from the Setup default table.

sors in a multi-processor system.

Page 39

29

Checkpoint

Code

68h Enable external cache and CPU cache if

69h Initialize the handler for SMM.

6Ah Display external cache size on the screen if it

6Bh If CMOS is bad, load Custom Defaults from

6Ch Display shadow message.

6Eh Display the starting offset of the non-dis-

70h Check flags in CMOS and in the BIOS data

Beep Code Description

present.

Configure non-cacheable regions if neces-

sary.

NOTE: Hook routine must preserve DX,

which carries the cache size to the DisplayCacheSizeJ routine.

is non-zero.

NOTE: Hook routine must preserve DX,

which carries the cache size from the cacheConfigureJ routine.

flash into CMOS. If successful, reboot.

posable segment of the BIOS.

area for errors detected during POST. Display error messages on the screen.

72h Check status bits to see if configuration

76h Check status bits for keyboard-related fail-

7Ch Initialize the hardware interrupt vectors

7Dh Initialize Intelligent System Monitoring.

problems were detected. If so, display error

messages on the screen.

ures. Display error messages on the screen.

from 08 to 0F and from 70h to 77h. Also set

the interrupt vectors from 60h to 66h to

zero.

Page 40

30

3 Getting Started

Checkpoint

Code

7Eh The Coprocessor initialization test. Use the

80h Disable onboard COM and LPT ports before

81h Run late device initialization routines.

82h Test and identify RS232 ports.

83h Configure Fisk Disk Controller.

84h Test and identify parallel ports.

85h Display any ESCD read errors and configure

86h Initialize onboard I/O and BDA according to

87h Initialize motherboard configurable devices.

88h Initialize interrupt controller.

Beep Code Description

floating point instructions to determine if a

coprocessor exists instead of the ET bit in

CR0.

testing for presence of external I/O devices.

all PnP ISA devices.

CMOS and presence of external devices.

89h Enable NMI.

8Ah Initialize Extended BIOS Data Area and ini-

8Bh Setup interrupt vector and present bit in

8Ch Initialize both of the floppy disks and dis-

8Fh Count the number of ATA drives in the sys-

tialize the mouse.

Equipment byte.

play an error message if failure was

detected. Check both drives to establish the

appropriate diskette types in the BIOS data

area.

tem and update the number in bdaFdiskcount.

Page 41

31

Checkpoint

Code

90h Initialize hard-disk controller. If the CMOS

91h Configure the local bus IDE timing register

92h Jump to UserPatch2.

93h Build MPTABLE for multi-processor boards.

95h 1. Check CMOS for CD-ROM drive present

96h Reset segment-register addressibility from

Beep Code Description

RAM is valid and intact, and fixed disks are

defined, call the fixed disk init routine to

intialize the fixed disk system and take over

the appropriate interrupt vectors.

based on the drives attached to it.

2. Activate the drive by checking for media

present

3. Check sector 11h (17) for Boot Record Volume Descriptor

4. Check the boot catalog for validity

5. Pick a boot entry

6. Create a Specification Packet

4GB to normal 64K by generating a Shutdown 8.

97h Create pointer to MP table in Extended

BDA.

98h 1-2 Search for option ROMs. ROM scan the area

99h Check support status for Self-Monitoring

9Ah Shadow miscellaneous ROMs if specified by

from C800h for a length of

BCP_ROM_Scan_Size (or to E000h by

default) on every 2K boundry, looking for

add on cards that need initialization.

Analysis Reporting Technology (disk-failure

warning).

Setup and CMOS is valid and the previous

boot was OK.

Page 42

32

3 Getting Started

Checkpoint

Code

9Ch Set up Power Management. Initiate power -

9Dh Initialize Security Engine.

9Eh Enable hardware interrupts.

9Fh Check the total number of Fast Disks (ATA

A0h Verify that the system clock is interrupting.

A2h Setup Numlock indicator. Display a message

A4h Initialize the typematic rate.

A8h Overwrite the "Press F2 for Setup" prompt

AAh Scan the key buffer to see if the F2 key was

ACh Enter SETUP

Beep Code Description

management state machine.

and SCSI) and update the bdaFdiskCount.

if key switch is locked.

with spaces, erasing it from the screen.

struck after keyboard interrupts were

enabled. If an F2 keystroke is found, set a

flag.

If (F2 was pressed)

go to SETUP

Else if (errors were found)

display "Press F1 or F2" prompt

if (F2 is pressed)

go to setup

else if (F1 is pressed)

boot

Else boot

AEh Clear ConfigFailedBit and InPostBit in

CMOS.

Page 43

33

Checkpoint

Code

B0h Check for errors

B1h Inform RomPilot about the end of POST.

B2h Change status bits in CMOS and/or the BIOS

B4h One quick beep.

B5h Turn off <Esc> and <F2> key checking.

Beep Code Description

If (errors were found)

beep twice

display "F1 or F2" message

if (F2 keystroke) go to SETUP

if (F1 keystroke) go to BOOT

data area to reflect the fact that POST is

complete.

IF (VGA adapter is present)

IF (OEM screen is still up)

Note OEM screen is gone.

Fade out OEM screen.

Reset video: clear screen, reset cursor, reload

DAC.

ENDIF

ENDIF

B6h If password on boot is enabled, a call is

made to Setup to check password. If the

user does not enter a valid password, Setup

does not return.

B7h Initialize ACPI BIOS.

B9h Clear all screen graphics before booting.

BAh Initialize the SMBios header and sub-struc-

BCh Clear parity-error latch.

BDh Display Boot First menu if MultiBoot is

tures.

intstalled.

Page 44

34

3 Getting Started

Checkpoint

Code

BEh If BCP option is enabled, clear the screen

BFh Check virus and backup reminders. Display

C0h Try to boot with INT 19.

C1h Initialize the Post Error Manager.

C2h Write PEM errors.

C3h Display PEM errors.

C4h Initialize system error handler.

C5h PnPnd dual CMOS (optional).

C6h Initialize note dock.

C7h Initialize note dock late.

C8h Force check (optional).

C9h Extended checksum (optional).

Beep Code Description

before booting.

System Summary.

CAh Redirect Int 15h to enable target board to

CBh Redirect Int 13h to Memory Technologies

CDh Redirect Int 10h to enable target board to

CEh Initialize digitizer device and display

D2h Unknown interrupt.

Dfh 4-2-4-4 A20 test error.

E0h Initialize the chipset.

use remote keyboard (PICO BIOS).

Devices such as ROM, RAM, PCMCIA, and

serial disk (PICO BIOS).

use a remote serial video (PICO BIOS).

installed message if successful.

Page 45

35

Checkpoint

Code

E1h Initialize the bridge.

E2h Initialize the CPU.

E3h Initialize system timer.

E4h Initialize system I/O.

E5h Check force recovery boot.

E6h Checksum BIOS ROM.

E7h Go to BIOS.

E8h Initialize Multi-Processor

E9h Set huge segment.

EAh Initialize OEM special code.

EBh Initialize PIC and DMA.

ECh Initialize Memory type.

EDh Initialize Memory size.

Beep Code Description

EEh Shadow Boot Block.

EFh System memory test.

F0h Initialize interrupt vectors.

F1h Initialize Run Time Clock.

F2h Initialize video.

F3h Initialilze System Management Mode.

F4h Output one beep.

F5h Boot to Mini DOS.

F6h Clear Huge Segment.

F7h Boot to Full DOS.

Page 46

36

3 Getting Started

Page 47

4 Configuring

the system

Page 48

This chapter discusses the precautionary

measures and installation procedures you

need to know when upgrading the system.

Page 49

Upgrading the system

Certain components of the server are upgradeable such as the drives,

the CPU, the memory, and the expansion cards. However, for safety

purposes, we do not recommend that you perform these upgrades

yourself. If you want to replace or upgrade any of these components,

contact your dealer or a qualified service technician for assistance.

Important: Observe the installation precautions described in the

subsequent section when installing or removing a server

component.

39

Page 50

40

4 Configuring the system

Installation precautions

Before you install any server component, we recommend that you read

the following sections. These sections contain important ESD

precautions along with preinstallation and post-installation

instructions.

ESD precautions

Electrostatic discharge (ESD) can damage the processor(s),

motherboard, disk drive(s), expansion board(s), or other components.

Always observe the following precautions before you install server

components:

1 Do not remove a component from its protective packaging until

you are ready to install it.

2 Wear a wrist grounding strap and attach it to a metal part of the

server before handling components. If a wrist strap is not

available, maintain contact with the server throughout any

procedure requiring ESD protection.

Page 51

Preinstallation instructions

Always observe the following before you install any component:

1 Turn off the system and all the peripherals connected to it.

2 Unplug all cables from the power outlets.

3 Open the system according to the instructions on page 42.

4 Follow the ESD precautions described in this section when

handling a server component.

5 Remove any expansion board(s) or peripheral(s) that block access

to the DIMM socket or other component connector.

See the following sections for specific installation instructions on the

component you want to install.

Warning! Failure to properly turn off the server before you

start installing components may cause serious damage. Do

not attempt the procedures described in the following

sections unless you are a qualified service technician.

Post-installation instructions

Observe the following after installing a server component:

1 See to it that all components are installed according to the

described step-by-step instructions.

2 Reinstall any expansion board(s) or peripheral(s) that you have

previously removed.

3 Reinstall the chassis panels.

4 Connect the necessary cables.

5 Turn on the system.

41

Page 52

42

4 Configuring the system

Opening the server

Caution! Before you proceed, make sure that you have turned off

your system and all peripherals connected to it. Read the

“Preinstallation instructions” on page 41.

You need to open the server before you can install additional

components. The top panel is removable to allow access to the system’s

internal components. Refer to the following sections for instructions.

Before opening the server

Before opening the server, observe the following precautions:

1 Turn off the system and all the peripherals connected to it.

2 Unplug all cables from the power outlets.

3 Place the system unit on a flat, stable surface.

Note: Because of the R310 design specification, the top panel

needs to be removed to access the system board.

Page 53

To remove the top panel

The top panel is attached to the server by one (non-removable)

thumbscrew. See “Rear panel” on page 14 for help locating the

screw.

To remove the top panel:

1 Loosen the thumbscrew located at the top-middle of the rear

panel (1).

2 Slide the panel rearward (2) and lift to detach it from the

chassis.

43

Page 54

44

4 Configuring the system

To replace the top panel

Align the cover over the chassis, with the tool-less screw oriented

toward the back panel of the server. Slide the cover toward the front

(1) and secure the cover by tightening the thumbscrew (2).

Observe the post-installation instructions described on page 41.

Page 55

Installing expansion cards

This section explains how to install an expansion card. The onboard

expansion slots support PCI (Peripheral Component Interconnect)

cards. Before installing expansion cards, observe ESD precautions and

Pre-installation precautions as noted on page 40.

Note: The BIOS setup automatically detects and assigns resources

to the new device (applicable only to Plug-and-Play expansion

cards).

To install an expansion card

1 Remove the system cover. See “To remove the top panel” on page

43 for more information.

2 Loosen the thumbscrews on the expansion card riser bracket (1),

then gently lift the riser from the chassis (2).

45

3 Remove the expansion slot cover from the rear of the metal

bracket.

Page 56

46

4 Configuring the system

4 Align and insert the PCI card onto the slot bracket (1), then

reinstall the PCI riser into the housing (2). Turn the thumbscrews

clockwise to secure the bracket (3).

5 Observe the post-installation instructions described on page 41.

Page 57

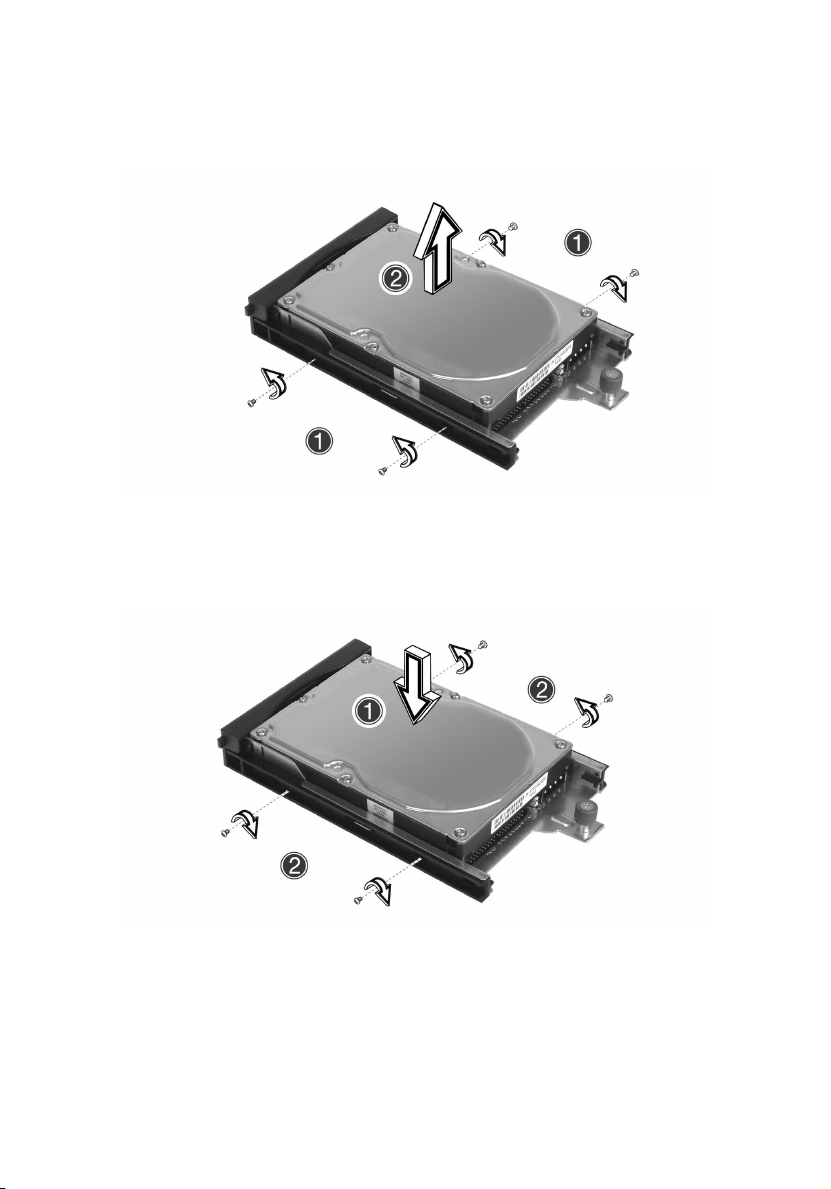

Installing and removing a hard disc drive

Removing a hard disc

1 Remove the system cover. See “To remove the top panel” on page

43 for more information.

2 Remove the front bezel from the system. Press the release buttons

at either end.

3 Disconnect all cables from the back of the hard discs (1) and (2).

Turn the thumbscrew counter-clockwise (3) to release the HDD

tray and gently slide it forward, out of the system (4).

47

Page 58

48

4 Remove the screws that secure the hard disc to the disc tray (1)

and remove the drive from the tray (2). Keep the screws for later

use.

4 Configuring the system

Installing a hard disc

1 Insert the new hard disc drive into the disc tray (1) and secure it

with the four screws you removed in the previous step (2).

Page 59

2 Reinsert the disc tray into the front of the system (1). Turn the

thumbscrew clockwise to secure the disc tray (2), and reconnect all

hard disc cables (3) and (4).

3 Replace the system cover and the front bezel, making sure to

observe the post-installation instructions described on page 41.

49

Page 60

50

4 Configuring the system

Upgrading the CPU

This section includes instructions for removing and installing a CPU.

Important! Always observe the ESD precautions when installing

or removing a system component. Refer to page 40.

Removing a CPU

1 Remove the system cover. See “To remove the top panel” on page

43.

2 Locate the CPU/heatsink/air-baffle assembly on the mainboard. See

“Mainboard layout” on page 9.

Warning! The heatsink may be very hot. After opening the

system, allow the heatsink to cool for several minutes if

the system was operating before you removed the cover.

3 Remove the air-baffle from the heatsink, as shown below.

Page 61

4 Loosen the four corner screws that secure the heatsink to the

mainboard (1) and gently remove it (2).

5 Locate and lift the CPU socket locking lever (3) to release the

processor. Gently pull up on the processor (4) to remove it.

51

Page 62

52

4 Configuring the system

Installing a CPU

Having followed the steps above, the CPU socket is empty and you are

ready to install your new processor.

1 Insert the CPU into the mainboard socket (1), making sure the

indicator on the processor is aligned with the indicator on the

socket. Lower the CPU locking lever to secure the processor (2).

Page 63

2 Replace the heatsink over the CPU socket (3) and tighten the four

corner screws (4).

3 Replace the system cover, making sure to observe the post-

installation instructions described on page 41.

53

Page 64

54

4 Configuring the system

Upgrading the system memory

Memory configuration

This section includes instructions for removing and installing a memory

module.

The following table illustrates the greater efficiency of 2-way memory

interleave configurations as compared to a 1-way memory interleave

configuration.

Warning! Functionality issues may be encountered if mixed

memory types are installed on the same server board. DIMM

modules of identical type, banking and stacking technology, and

vendor should be installed in the Altos R310.

Page 65

To re m o v e a DIMM

Before installing a new DIMM in a socket, remove first any previously

installed DIMM from that socket.

Important: Before removing any DIMM from the mainboard,

make sure to create a backup file of all important data.

1 Observe the ESD precautions and pre-installation procedures

described on page 41.

2 Locate the DIMM sockets on the mainboard.

3 Press the holding clips on both sides of the socket outward to

release the DIMM (1).

4 Gently pull the DIMM upward to remove it from the socket (2).

55

Note: Place your forefingers on the top of the DIMM before

pressing the holding clips to gently disengage the DIMM from the

socket.

Page 66

56

4 Configuring the system

To install a DIMM

1 Observe the ESD precautions and pre-installation procedures

described on page 40.

2 Locate the DIMM sockets on the mainboard.

3 Open the clips on the socket.

4 Align and insert the DIMM into the socket (1).

5 Press the holding clips inward to lock the DIMM in place (2).

DIMMs must be installed in the following order: DM1. DM2, DM3 and DM4

Note: The DIMM socket is slotted to ensure proper installation.

If you insert a DIMM but it does not fit easily into the socket, you

may have inserted it incorrectly. Reverse the orientation of the

DIMM and insert it again.

6 Observe the post-installation instructions described on page 41.

Reconfiguring the system memory

The system automatically detects the amount of memory installed.

Run the BIOS setup to view the new value for total system memory and

make a note of it.

Page 67

5 BIOS setup

Page 68

This chapter gives information about the

system BIOS and discusses how to configure

the system by changing the settings of the

BIOS parameters.

Page 69

59

BIOS setup

BIOS setup is a hardware configuration program built into your

system's Basic Input/Output System (BIOS). Since most systems are

already properly configured and optimized, there is no need to run this

utility. You will need to run this utility under the following conditions:

• When changing the system configuration

• When a configuration error is detected by the system and you are

prompted ("Run Setup" message) to make changes to the BIOS

setup

Note: If you repeatedly receive Run Setup messages, the battery

may be bad. In this case, the system cannot retain configuration

values in CMOS. Ask a qualified technician for assistance.

• When redefining the communication ports to prevent any conflicts

• When making changes to the Power Management configuration

• When changing the password or making other changes to the

security setup

BIOS setup loads the configuration values in a battery-backed

nonvolatile memory called CMOS RAM. This memory area is not part

of the system RAM which allows configuration data to be retained

when power is turned off.

Before you run BIOS setup, make sure that you have saved all open

files. The system reboots immediately after you close setup.

Page 70

60

5 BIOS setup

Entering BIOS setup

Power on the server to start the system POST (Power On Self Test)

process. During bootup, press F2 to enter the BIOS setup screen.

Note: You must press F2 while the system is booting. This key

stroke function does not work at any other time.

There are several tabs on the setup screen corresponding to the six

major BIOS menus:

•Main

•Advanced

•Power

• Boot

•Security

• Exit

The parameters on the screens shown in this User’s guide display

default system values. These values may not be the same as those in

your system.

Note the following reminders when moving around the setup screen:

•Use the Left and Right arrow keys to move to the next page or to

return to the previous screen.

• Use the Up and Down arrow keys to select an item.

• Use the + and - keys to select an option.

Note: You can configure a parameter that is enclosed in square

brackets. Grayed-out items have fixed settings and are not

user-configurable.

• Use the Tab key to select a field.

Page 71

61

• Use the Enter key to display a submenu screen.

Note: When a parameter is preceded by a (>), it means that a

submenu screen is available.

• Press F1 for General Help on using the BIOS setup.

• Press F10 to save changes and close the BIOS setup.

• Press Esc to close the BIOS setup without saving changes.

In the descriptive table following each of the screen illustrations,

settings in boldface are the default and suggested parameter settings.

Page 72

62

5 BIOS setup

Main

The Main menu displays basic and important information about the

system. This information is necessary for troubleshooting and may be

required when asking for technical support.

The last two parameters on the screen let you define the system’s time

and date settings. The real-time clock keeps the system date and time.

After setting the date and time, you do not need to enter them every

time you turn on the system. As long as the internal battery remains

good and connected, the clock continues to keep the date and time

accurately even when the power is off.

Parameter Description Option

BIOS Date The date when BIOS was built. [03/04/04]

BIOS Version The version of current BIOS. R01-A3A3

SMBIOS Version Supports DMTF SMBIOS version. 2.3.4

ASF Version Supports DMTF ASF version. 2.0

Page 73

Parameter Description Option

System Time Sets the correct time. [HH:MM:SS]

63

System Date Sets the correct date. [mm/dd/

Legacy Diskette A:

Primary IDE Master

Primary IDE Slave

Secondary IDE Master

Secondary IDE Slave

Third IDE Master

Fourth IDE Master

Display drive type if detected. N/A

yyyy]

Page 74

64

5 BIOS setup

Advanced

The Advanced menu contains parameter values that define how the

system behaves on startup.

Warning! Be cautious in setting parameter values in the

Advanced menu as any incorrect value may cause the

system to malfunction.

Press Enter to enter the submenu screen of the parameters shown in

the screen below.

Page 75

Parameter Description Option

65

PCI Configuration

Peripheral Configuration

Boot Settings Configuration

Event Log Configuration

Console Redirection

System Health Monitoring

ASF Configuration

Large Disk Access Mode DOS

Parallel ATA Both

Serial ATA Enabled

Native Mode Operation Auto

Serial ATA RAID Enabled

Open the submenu to configure these settings by

pressing ‘Enter’.

N/A

Enter is the

only

option.

Disabled

Primary

Secondary

Disabled

Disabled

Page 76

66

5 BIOS setup

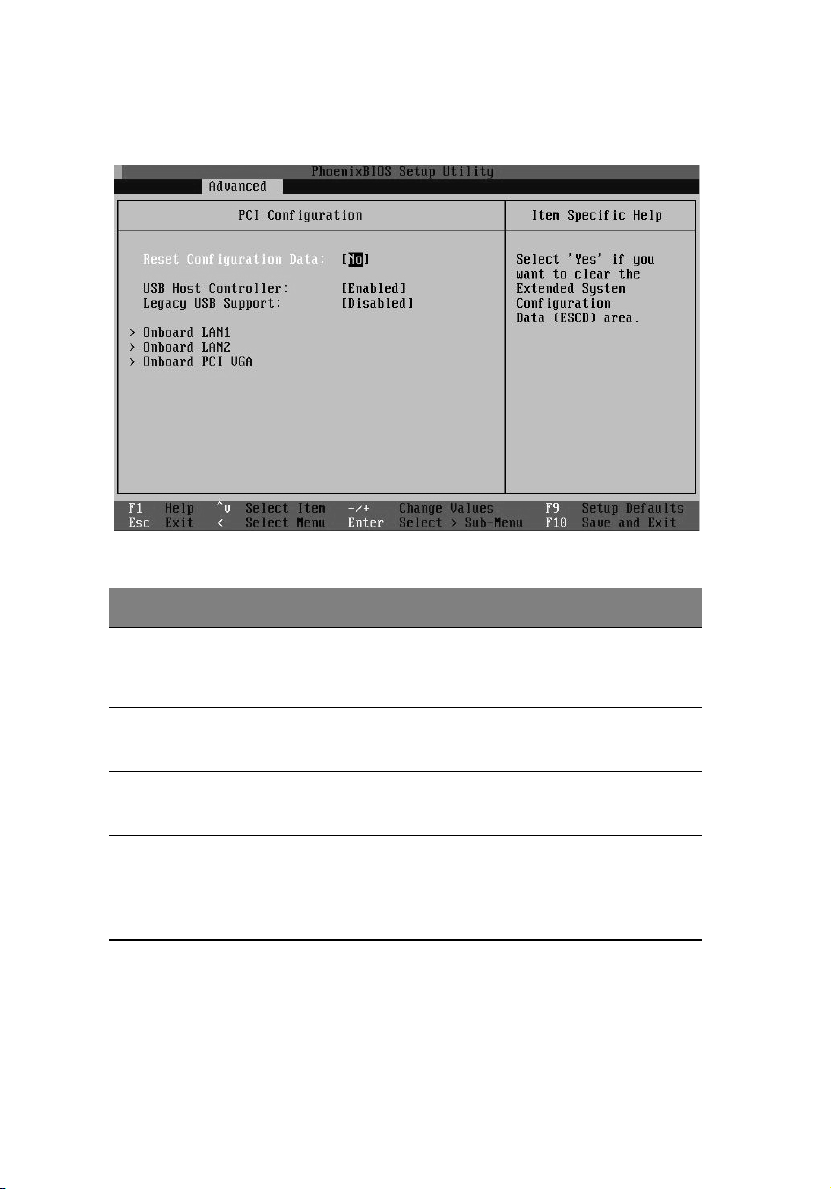

PCI Configuration

Parameter Description Option

Reset

Configuration

Data

USB Host

Controller

Legacy USB

Support

Onboard LAN1

Onboard LAN2

Onboard PCI VGA

No

Yes

Enables or disables the USB function in

Chipset.

Enables or disables support for legacy

USB devices.

Enables or disables onboard devices. N/A

Enabled

Disabled

Auto

Disabled

Enter is

the only

option

Page 77

Peripheral Configuration

The Peripheral Configuration submenu lets you define the parameter

settings for the system’s parallel and serial ports.

Parameter Description Options

67

Serial Port A

Serial Port B

Base I/O

address

Interrupt IRQ 4

Floppy Disk

Controller

Auto

Enabled

Disabled

3F8

2F8

3E8

2E8

IRQ 3

Enabled

Disabled

Page 78

68

Boot Settings Configuration

5 BIOS setup

Parameter Description Option

Quick Boot Allows BIOS to skip certain tests to

decrease the time needed while booting

the system.

Quiet Boot Displays the OEM logo when enabled; dis-

plays normal POST messages when disabled.

Summary

Screen

Hyper

Threading

Technology

Frequency

Ratio

Displays the CPU/Bus ratio of the system. X to 1

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

Page 79

Parameter Description Option

69

Bootup

NumLock

Wait for ‘F1’ if

Error

MPS Support 1.4

Memory Test Performs memory read/write test during

Floppy Check Displays the error message if floppy is not

Sets the Power-on state for NumLock. On

Off

Displays the error message if POST error

occurs.

POST.

detected.

Enabled

Disabled

Enabled

Disabled

Enabled

Disabled

Page 80

70

Event Log Configuration

5 BIOS setup

Parameter Description Option

Event Log

Capacity

Event Log Validity Displays event log status. Valid

Event Logging Allows logging of events and

Clear All Event

Logs

View Event Log Displays detail event log mes-

BIOS POST Even

Logging

Displays event log space status. Space Available

SMI/NMI.

Clears event log area and resets

to ‘No’ at next boot if Yes is

selected.

sages by pressing ‘Enter.’

Allows logging of BIOS POST

events.

Enabled

Disabled

Yes

No

N/A

Enter is the only

option.

Enabled

Disabled

Page 81

Parameter Description Option

71

ECC Event

Logging

PCI Event Logging Allows logging of PCI error

AC Power Lost/

Recovery

Reset Disabled

Memory Bank

Allows logging of ECC events. Enabled

events.

Enables all memory banks at the

next boot. Memory DIMM might

be disabled by memory reduction feature.

Disabled

Enabled

Disabled

Enabled

Disabled

Yes

No

Page 82

72

Console Redirection

5 BIOS setup

Parameter Description Option

Console Redirection Port

Baud Rate Sets the rate of communication. 9600 KB

Ter m inal Ty p e PC ANSI

Selects the system port for console redirection.

COM1

Serial Port A

Serial Port B

Disabled

19.2 KB

38.4 KB

57.6 KB

115.2 KB

VT100+

VT-UTF8

VT100

Page 83

Parameter Description Option

Flow Control No

CTS/RTS

XON/XOFF

CTS/RTS+CD

73

Continue C.R.

after POST

# of video

pages to support

On

Off

1 (Default)

through

8

Page 84

74

5 BIOS setup

System Health Monitoring

The system health monitoring screen displays current information

regarding the system’s CPU status, temperature status and fan status.

There are no user-configurable parameters on this page.

Page 85

Alert Standard Format (ASF) configruation

Parameter Description Option

75

BIOS Boot

Timeout

OS Boot

Timeout

Power-on wait

time

Sets the interval for the BIOS boot watchdog timer.

Sets the interval for the OS boot watchdog timer.

0

1-65535

0

1-65535

60

Page 86

76

Power

5 BIOS setup

Parameter Description Option

ACPI-aware OS Enable or disable ACPI support for

the Operating System.

Power Button

Behavior

AC Lost Handling

Sets the power state after shutdown due to power interrupt. If

set to ‘Off’ the system remains off.

If set to ‘Last State’ the system

returns to its last power state.

Yes

No

4-Sec. Override

Instant On/Off

Last State

Always On

Off

Page 87

Boot

Parameter Description

77

+Removable

Devices

CD-ROM Drive

+Hard Drive

PXE IBA GE Slot

0208 v1216

PXE IBA GE Slot

0430 v1216

Expandable

Allows user to configure Boot Sequence

Page 88

78

5 BIOS setup

Security

The Security menu allows you to safeguard and protect the system

from unauthorized use by setting up access passwords.

Parameter Description Options

Supervisor Password

User Password

Set Supervisor Password

Set User Password

Password On Boot Requires to input password

Displays ‘Installed’ if password is

set.

Sets password by pressing

‘Enter.’

before booting if this value is

enabled.

Clear

Installed

Enter

Enabled

Disabled

Page 89

79

Exit

The Exit menu displays the various options to quit from the BIOS setup.

Highlight any of the exit options then press Enter.

Parameter Description

Exit Saving

Changes

Exit Discarding

Changes

Load Setup

Defaults

Discard

Changes

Save Changes Saves all changes made to BIOS setup without exiting the

Saves changes made and closes the BIOS setup.

Discards changes made and closes the BIOS setup.

Loads the optimal settings for all BIOS setup parameters.

Optimal settings are quite demanding in terms of

resources consumption. If you are using low-speed memory chips or other kinds of low-performance components

and you choose to load these settings, the system might

not function properly.

Discards all changes made on the BIOS setup.

utility.

Page 90

80

5 BIOS setup

Page 91

Appendix A:

Management

software installation

Page 92

This appendix shows you how to install the

ASM and EasyBUILD

TM

software packages.

Page 93

Installing ASM

Acer Server Manager (ASM) consists of the ASM Console and the ASM

Agent. These two components are both required to perform server

management tasks.

System requirements

ASM requires TCP/IP connectivity between the ASM Console and the

ASM Agent.

ASM Agent

• Altos Server System

• Minimum of 128 MB RAM

• SCSI/IDE hard drive with at least 100 MB free hard disk space

• Windows 2000 server/advanced server, Windows server 2003 web/

standard/Enterprise editions, or RedHat Linux 7.3/8.0

ASM Console

• Intel Pentium III (500 MHz) or higher processor

• 128 MB of RAM

• SCSI/IDE hard drive with at least 100 MB free hard disk space

• Microsoft Windows 2000 Professional/XP/Server/Advanced Server

operating system

• Ethernet card

• Windows 2000 professional, Windows XP, Windows 2000 server/

advanced server, Windows server 2003 web/standard/Enterprise

editions

83

System setup

Make sure that your system meets the requirements listed above

before proceeding. You may also want to change your screen to

800 x 600 resolution or higher for optimum viewing.

Page 94

84

Appendix A: Management software installation

Installing ASM Agent (Windows version)

To install ASM Agent:

1 Log in to the managed server using the Administrator account.

TM

2 Insert the EasyBUILD

Management CD into the server’s CD-ROM

drive.

The installation sequence will automatically begin.

3 Select the option for ASM installation.

The installation wizard will be initialized.

4 Follow all onscreen instructions to complete installation.

For detailed instructions on installing ASM Agent, refer to the

ASM User’s manual.

ASM Agent will auto-launch as a Windows service after rebooting

the system.

Installing ASM Console (Windows version)

To install ASM Console:

1 Log in to the target Windows-based PC using the Administrator

account.

TM

2 Insert the EasyBUILD

CD-ROM drive.

The installation sequence will automatically begin.

3 Select the option for ASM installation.

The installation wizard will be initialized.

4 Follow all onscreen instructions to complete installation.

For detailed instructions on installing ASM Console, refer to the

ASM User’s manual.

Management CD into the computer’s

To launch the program, on the Windows taskbar click on the Start

button, point to programs, select Acer Server Manager then

click Acer Server Manager

Page 95

85

Installing ASM Agent (Linux version)

To install the ASM6 Agent on RedHat Linux 8.0

1 Insert the ASM6 installation CD into your computer's optical drive.

2 Mount the CD-ROM drive with "mount /dev/cdrom /mnt/cdrom"

command. For more information on mount command and the

options, please refer to RedHat Linux user's guide.

3 Change the working directory to ASM6 Linux Agent subdirectory

with the command "cd /mnt/cdrom/LinuxAgent".

4 Type in the command "./asmsetup install" to install the ASM6

Linux Agent. Follow the prompted installation guide, and you can

install the ASM6 Linux Agent with ease.

5 Umount the CD-ROM Drive with "umount /mnt/cdrom" command.

For detailed instructions on installing ASM Agent on Linux systems,

refer to the ASM User’s manual.

ASM agent will auto-launch demon service after rebooting the

system. There is no Linux version of ASM Console.

Page 96

86

Appendix A: Management software installation

Page 97

Appendix B: Rack

installation

Page 98

This appendix shows you how to use the

optional rack mount kit to put your Altos

R310 server into a server rack.

Page 99

89

System rack installation

Important! Observe the electrostatic discharge (ESD) precautions

shown on page 40 when perfoming the following procedures. Do

not attempt the procedures described in the following sections

unless you are a qualified technician.

Equipment rack precautions

Follow the rack manufacturer's safety and installation instructions for

proper rack installation.

The following additional rack safety installation measures should be

considered:

• Anchor the equipment rack

The equipment rack must be anchored to an unmovable suitable

support to prevent the rack from falling over when one or more

systems are fully extended out of the rack assembly. You must also

consider the weight of any other devices installed in the rack

assembly. The equipment rack must be installed according to the

manufacturer's instructions.

• Main AC power disconnect

You are responsible for installing an AC power disconnect for the

entire rack unit. This main disconnect must be readily accessible,

and it must be labeled as controlling power to the entire unit, not

just to the system(s).

• Earth ground the rack installation

To avoid the potential for an electrical shock hazard, the rack

assembly itself must be suitably earth grounded, according to your

local regional electrical codes. This typically will require the rack to

have its own separate earth ground. We recommend you consult a

locally certified electrician.

Page 100

90

Appendix B: Rack installation

• Elevated Operating Ambient Temperature

The maximum operating temperature of the system is 35

Careful consideration should be given to installing the system in

o

an environment compatible with the 35

C (95oF) maximum

ambient temperature.

• Reduced Airflow

The amount of airflow required for the safe operation of the

equipment should not be compromised when installing the system

in a rack.

• Mechanical Loading

Exercise care when mounting the system in a rack to avoid any

accidents.

• Circuit Overloading

Appropriate consideration should be given when connecting the

supply circuit to the system to avoid any circuit overload. The

system nameplate rating should be used when addressing

concerns about circuit overload.

o

C (95oF).

Loading...

Loading...