Page 1

Acer PH-112

Service Guide

Service guide files a nd updates are availa ble

on the CSD web; for more information,

plea se refer to http://csd.acer .com.tw

100% Recycled Pa per

Page 2

Copyright

Copyright © 2003 by Acer Incorporated. All rights reserved. No part of this publication

may be reproduced, tra nsmitted, tra nscribed, stored in a retrieval syste m, or tra nslated

into any la nguage or computer la nguage, in a ny f orm or by a ny mea ns, ele ctronic,

mechanical, magnetic, optical, che mical, ma nual or otherwise, without the prior written

permission of Acer Incorporated.

Disclaimer

The information in this guide is subject to change without notice.

Acer Incorporated makes no representations or warra nties, e ither expressed or

implied, with respect to the contents here of a nd spe cifically disclai ms a ny warranties

of merchanta bility or fitness f or a ny particular purpose. Any Acer Incorporated software

described in this manual is sold or licensed “as is”. Should the programs prove defec

tive following their purchase, the buyer (a nd not Acer Incorporated, its distributor , or its

dealer) a ssumes the entire cost of all ne cessary servicing, re pair , a nd any incidental or

consequential damages resulting from a ny defect in the software.

Acer is a registered trademark of Acer Corporation.

Intel is a registered trademark of Intel Corporation.

Pentium and Pentium II/III are trade marks of Intel Corporation.

Other brand a nd product n ames are trademark s a nd/or registered trad emarks of the ir respective holders.

Page 3

Conventions

The following conventions are used in this ma nual

segassemneercS.neercsnoraeppatahtsegassemlautcasetoneD

etoN

noitamrofnilanoitiddafoseceipdnastibseviG

.cipottnerrucehtotdetaler

gninraW

morftluserthgimtahtegamadynaotuoystrelA

.snoitcacificepsgniodtonrogniod

noituaC

elbissopdiovaotserusaemyranoituacerpseviG

.smelborperawtfosroerawdrah

tnatropmI

ehtottnavelersnoitcacificepsodotuoysdnimeR

.serudecorpfotnemhsilpmocca

Page 4

Preface

Before using this information and the product it supports, plea se rea d the f ollowing

general information.

1. This Service Guide provide s you with all technical inf ormation relating to the BASIC

CONFIGURA TION decided for Acer’s “global” product offering. To better fit local

market requirements and enhance product competitiveness, your regional office MAY

have decided to extend the functionality of a ma chine (e.g. add-on card, mode m, or

extra memory ca pa bility). These LOCALIZED FEA TURES will NOT be covered

in this generic service guide. In such ca ses, ple ase contact your region al off ices or the

responsible personnel/cha nnel to provide you with further technical details.

2. Plea se note WHEN OR DERING FRU PARTS, that you should check the most up-

to-date information available on your region al web or channel. If, f or whatever reason,

a part number cha nge is ma de, it will not be noted in the printed Service Guide. For

ACER-AUTHORIZED SERVICE PROVIDERS, your Acer office may have a DIFFER

ENT part number code to those given in the FRU list of this printed Service Guide.

You MUST use the list provided by your regional Acer of fice to order FRU parts f or

repair and service of customer machines.

Page 5

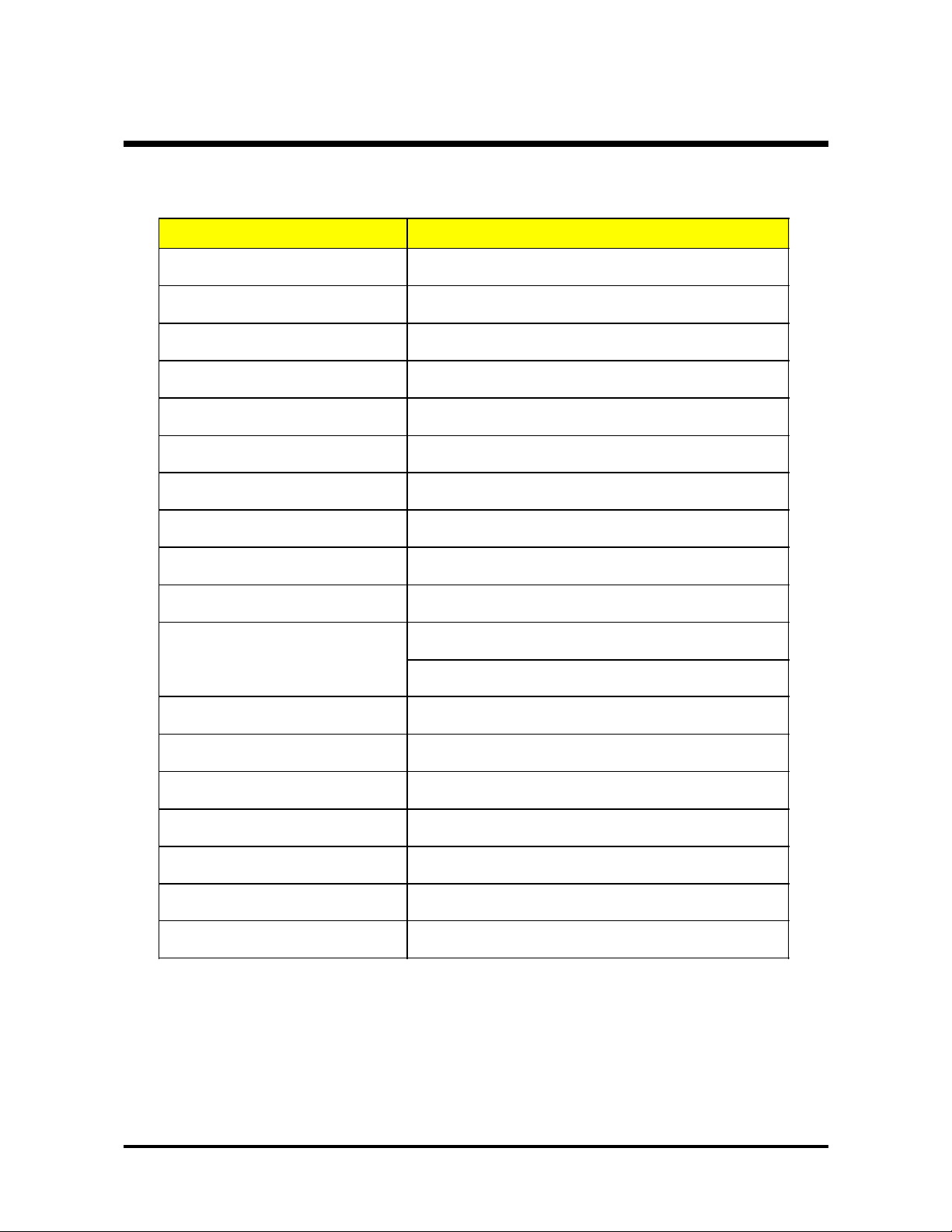

Chapter 1 Syste m Introduction 1

T echnical Spe cification .......................................................................................................1

La mp Specification............................................................................................................. 2

System Block Diagra m .......................................................................................................6

Optics Conceptual Drawing................................................................................................7

Cha pter 2 Firmware Update 8

Setup T ool / Equi pment.......................................................................................................8

Upgrading Procedure .........................................................................................................8

Chapter 3 M achine Dissa ssembly and Re pla cement 10

General Information ...........................................................................................................11

Disassemble Lamp Module...............................................................................................12

Disassemble IO Cover & Top Cover..................................................................................13

Disassemble Speaker & Front Cover ...............................................................................14

Disassemble Front Fan...................................... ...............................................................15

Disassemble Front IR Board & IR Cover...........................................................................16

Disassemble Video IO .......................................................................................................17

Dissassemble Main Board..... ...........................................................................................18

Disassemble Ballast Module & Back IR.............................................................................19

Disassemble Optical Engine..............................................................................................20

Disassemble Back Cover.................................................................................................. 21

Disassemble Back IR Cover , AC Outlet........................................................................... 22

Disassemble Power Module............................................................................................. 23

Disassemble Mylar & Ground Plate.................................................................................. 24

Disassemble Heatsink & DMD Board.............................................................................. 25

Disassemble DMD Assembly & DMD.............................................................................. 26

Disassemble Thermal Board............................................................................................ 27

Disassemble Optical Engine Fan...................................................................................... 28

Exploded Overview............................................................................................................29

Table of Contents

Page 6

Table of Contents

Chapter 4 Trouble shooting 30

Video Signal troubleshooting.............................................................................................31

Operation FunctionTroubleshooting............................................................................... ...34

Power SourceTroubleshooting..........................................................................................35

Function T e st and Align ment...............................................................................................36

Equipment Needed...................................................................................................36

T est Condition......................................................................................... ...................36

T est Display Modes a nd Patterns .....................................................................................37

Compatible Modes ..................................................................................................37

Function Test Display Pattern......................................................................... .........38

Chapter 5 Conne ctor Information 40

Introduction...........................................................................................................................40

Main Board......................................................................................................................... 40

Power Board .....................................................................................................................46

Ballast Board ......................................................................................................................48

Chapter 6 FRU(FieldReplaceable Unit) List 49

FRU List...............................................................................................................................50

Page 7

1 Chapter 1

System Introduction

Chapter

1

Technical Specification

Item Description

Display Type Single Chip DLP Projector

Lamp Type 200 W User Replaceable Lamp

Brightness 1600 Lumen

Contrast Ratio 2000 : 1(Full on / off) (Min)

Resolution(Pixels) 854 x 480

Uniformity 90%

Optical Compensation Light Tunnel

Focal Length 20.2 ~ 24.2 mm

Screen Size 27~324 inches Diagonal

Throw Distance 1.2 ~ 12 Meter

Compatibility

"Horizontal frequency (31~79KHz" )

"Vertical frequency ( 50~85Hz" )

Operation Humidity 80%

Operation Temperature +5 ~ +35C

Sound Noise 30dB(A)(standard mode)/28db(A) (ECO mode)

Power Requirement 100~240v, 50~60Hz

Dimensions ( W x H x D ) 256 x 198 x 92 mm

Weight 2.3 KG (<4.5 lb)

Certification

CE Class B, FCC Class B , VCCI-II , UL , cUL, TUV-GS, C-

tick, PSB, PSE, CB Report, CCC

Page 8

Chapter 1 2

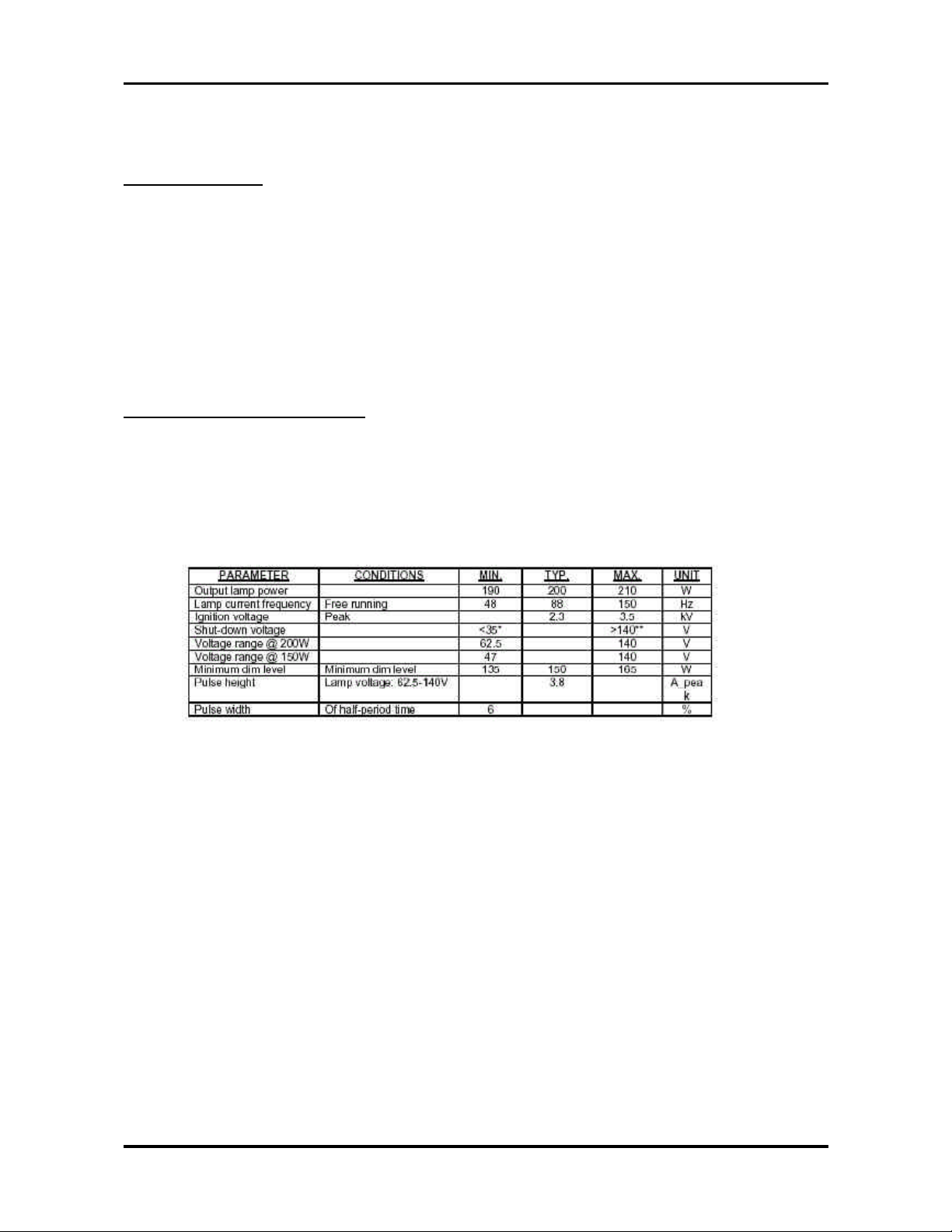

Lamp Specification

1.Product Scope

The product is a lamp system consisting of a short arc burner in a reflector, and a lamp

driver.

Lamp type UHP 200W-150W 1.0

Driver type EUC 200V/01 TopValue

2. SYSTEM SPECIFICATIONS

2.1 Driver conditions

See driver specifications for more information

EUC 200V/01

* If the lamp voltage is below 35V continued over 90s, the driver shuts down.

** If the lamp voltage reaches over 140V, the driver shuts down immediately.

2.2 Run-up time

Run-up time to 80% of the stabilised luminous output is < 60s.

2.3 Ignition

2.3.1 Cold ignition

The criterion for reliable ignition is defined as a maximum of three ignition

failures on 30 attempts per amp however none of these ignition failures

may occur subsequently.

During the ignition phase of the lamp (run-up-time), no cooling of the burner

recommended. Cooling of the burner can lead to ignition failure.

Page 9

3 Chapter 1

It is known that asymmetric cooling after switching the lamp off, can lead to

ignition failure in the next attempt due to condensed mercury on 1 of the electrodes.

Therefore Philips advises to build in multiple attempts (max. 5 for safety reasons) to

start the lamp. Between 2 attempts one has to wait 15s.

Philips suggests after a successful starting attempt to keep the lamp burning for

at least 15 minutes.

The cable has an isolation value of 2.5kV

To limit voltage loss of the ignition pulse, the mutual capacity of the cables may

not exceed 40pF.

To ensure this, Philips recommends to:

Avoid twisted cables

Never tie the cables together

Avoid contact to conductive plates, especially if those are connected to ground

(e.g. via PE)

If possible keep the cables straightened having a mutual distance (of 1 to 2 cm

between the

A suitable electrical enclosure should be provided in the end-product. Creepage

and clearance distances to high voltage parts and traces have to be evaluated in

the end-product. Special consideration has to be given to the distances from earthed

mounting screws to hazardous voltage traces on the lamp driver PCB.

2.3.2 Hot restrike

At max. bulb temperature of 300 oC+ -25oC : 98% ignition reliability of the total

number of switches.

At max. bulb temperature of 300 oC+ -25oC : 99.9% ignition reliability of the total

number of switches.

A restrike of the system can be applied 15 seconds after shut down.

Restrikes of the system can be repeated up to max. 5 times, if the lamp has not

successfully started from the first time.

Philips suggests after a successful starting attempt to keep the lamp burning for at

least 15 minutes.

Page 10

Chapter 1 4

3 LAMP SPECIFICATIONS

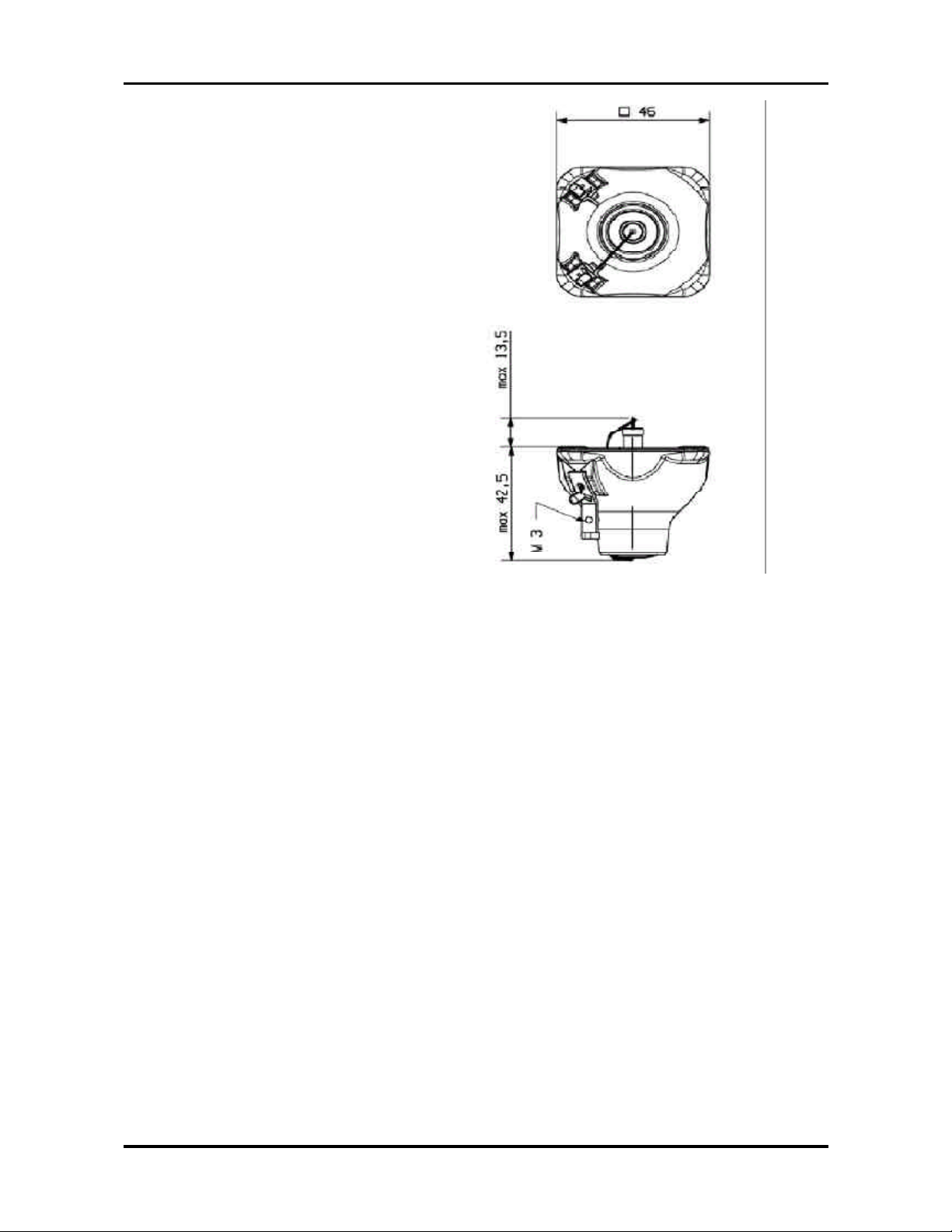

3.1 Dimensions

Reflector type E19

3 Average lamp life and lumen maintenance

(on test & operational conditions see 4.4 and based upon a large sample

population)

When driven at 200W on ballast type EUC 200V/01 and temperature conditions

are fulfilled

(AN 2002-002)

> 85% 500h

> 50% 2000h According to the light specification table (see paragraph 4.5.2)

When driven at 150W on ballast type EUC 200V/01 and temperature conditions

are fulfilled

(AN 2002-002)

> 85% 500h

> 50% 2500h According to the light specification table (see paragraph 4.5.2)

Page 11

5 Chapter 1

4 INSTRUCTION FOR USE

- To replace the lamp, the power should be switched off.

- The burning position is horizontal ± 20°.

- Never touch the burner or reflector mirror with bare hands. If bare hands have touched

it, it should be cleaned with a lint free towel before installing the lamp.

- The lamp should be operated on the lamp driver as mentioned in paragraph 1.

- Fast switching cycles will reduce lamp life (e.g. 10min on 10min off).

- Max torque on the side and centre connector: 0.8Nm.

- The screw, which connects the cable with the side connector, may not touch the

reflector surface.

- The set maker must design a lamp house to keep glass pieces in the lamp house.

- Visible arc instability has to be suppressed by set optics.

5 ENVIRONMENTAL LAWS

EU

At end of service life, UHP Lamps should be treated as chemical waste (in view of

mercury content), and be

disposed of in compliance with national regulations/law.

USA

To comply in accordance with the Law of Vermont, that obliges the visible notification

on a lamp in case it

contains mercury, a Hg logo will be added on the reflector of the lamp. Besides the

reflector, also lamp

packaging with destination USA needs to notify the customer that the packaging

contains mercury added

products.

For more information about Hg marking, check the website of the Law of Vermont.

http://www.anr.state.vt.us/dec/ead/mercury/labeling/manufact.htm

Page 12

Chapter 1 6

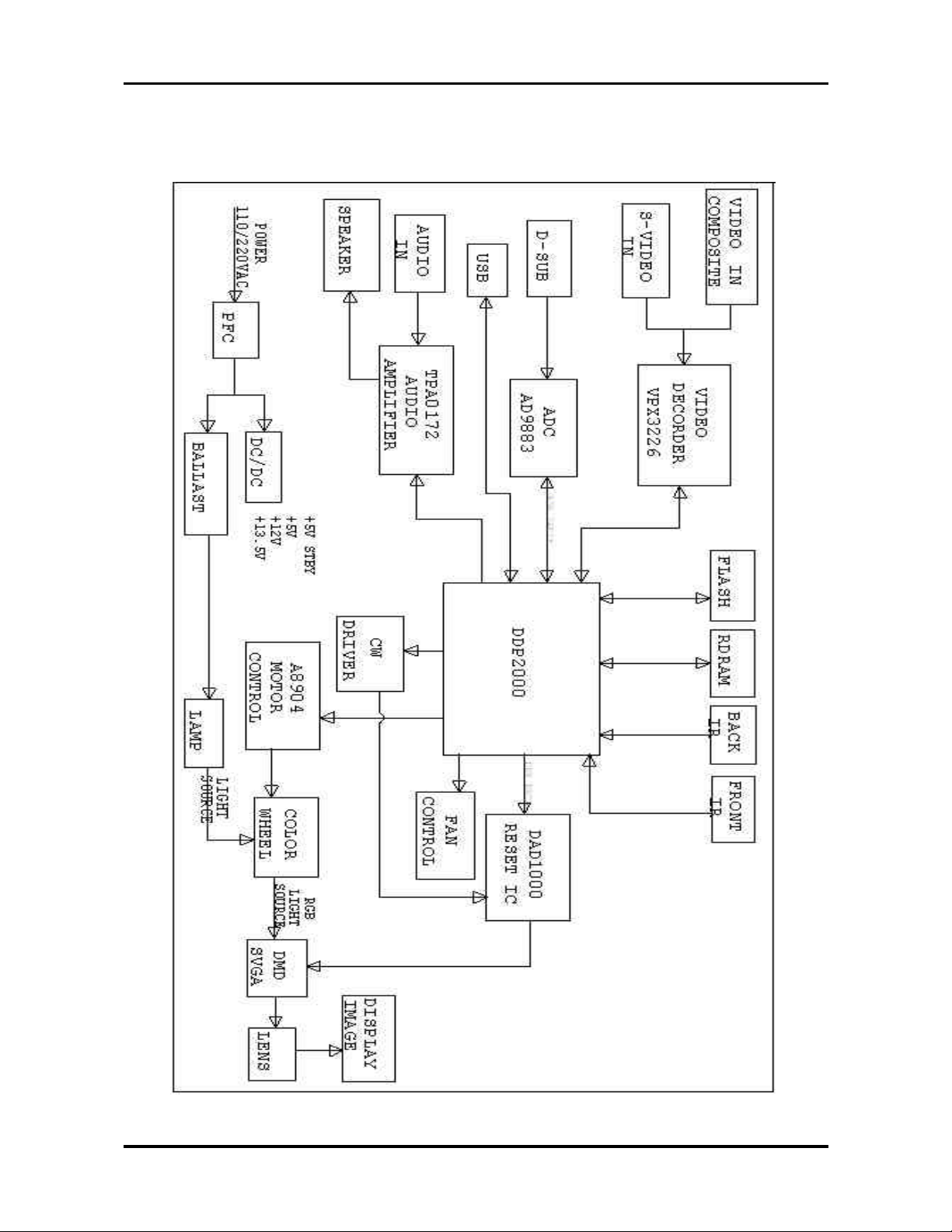

System Block Diagram

Page 13

7 Chapter 1

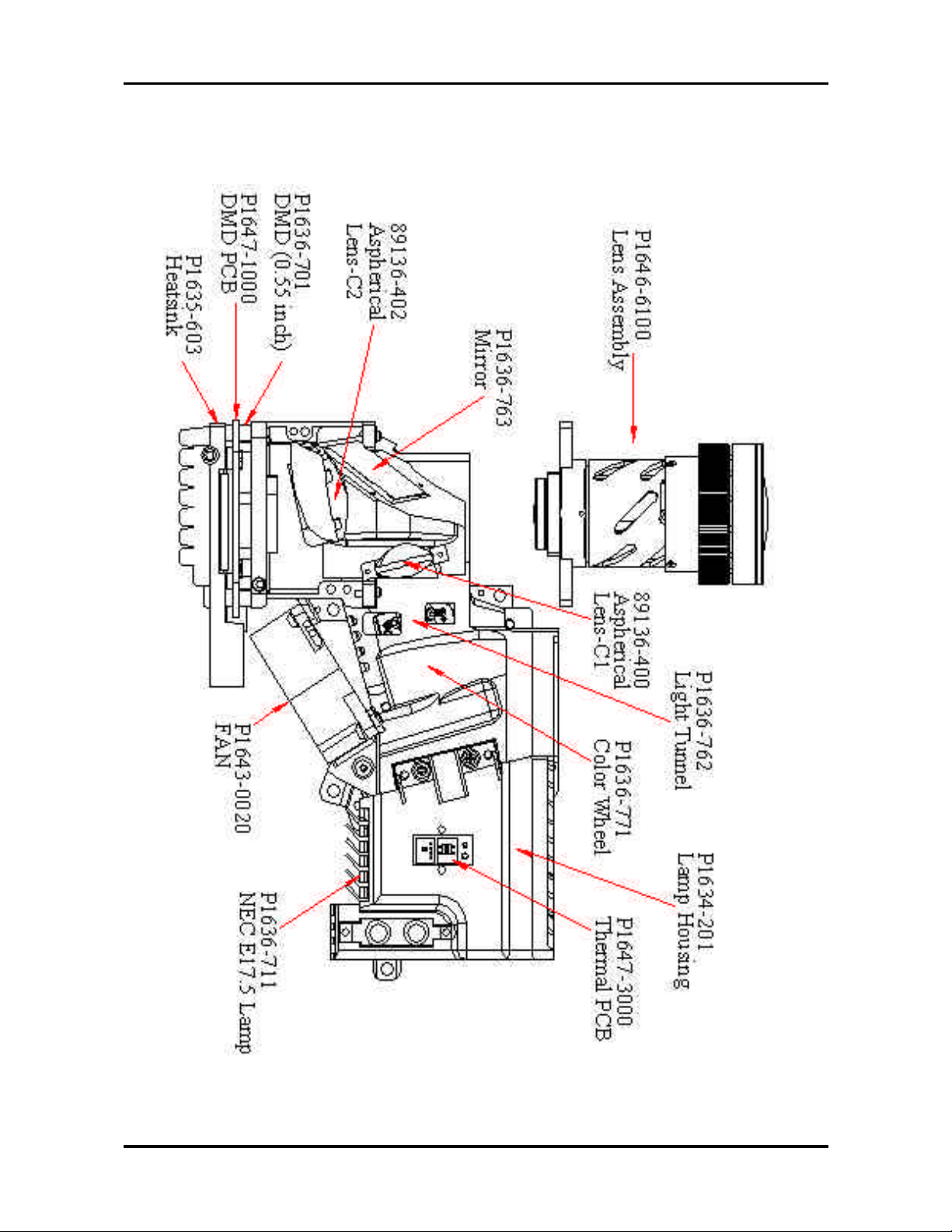

Optics-Con ceptual Drawing

Page 14

Chapter 2 8

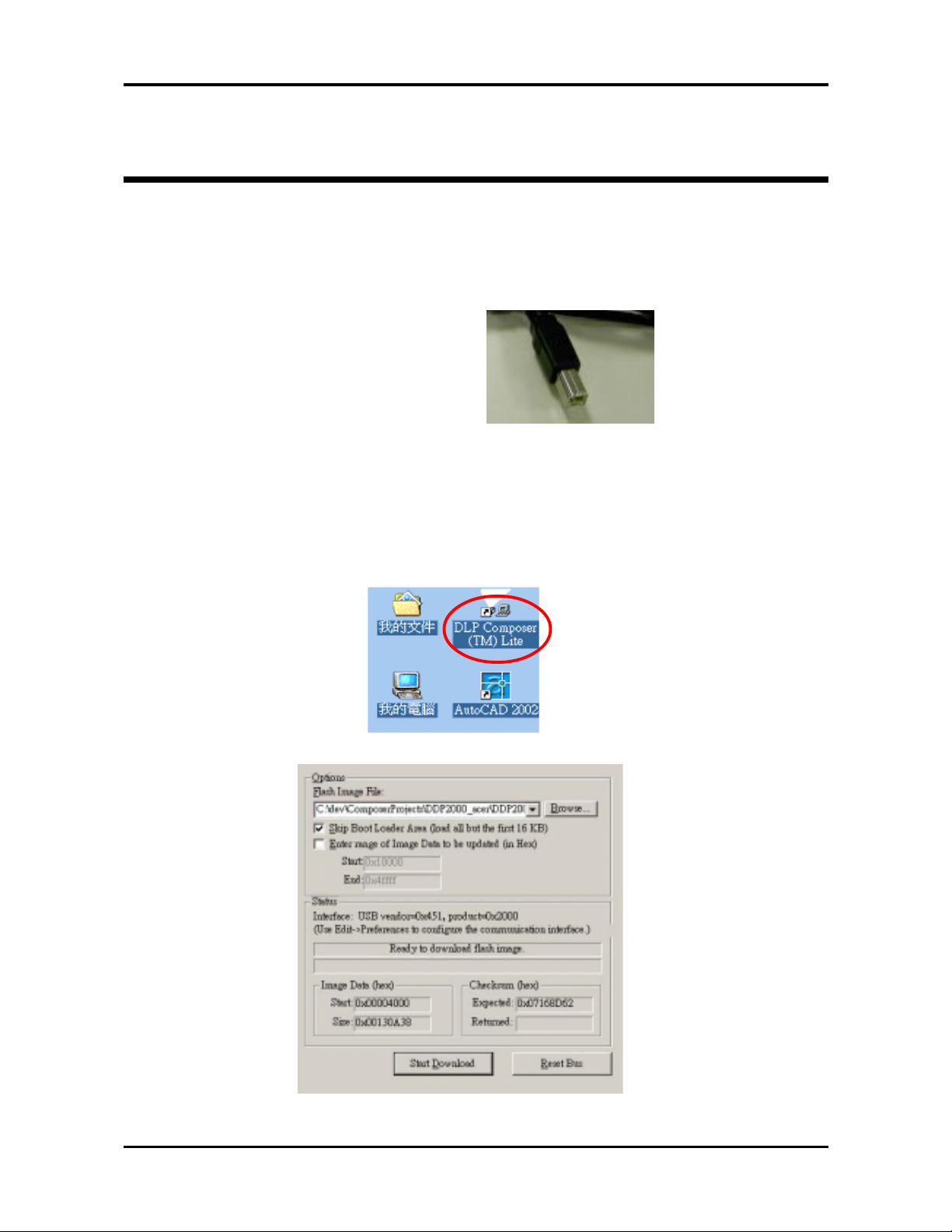

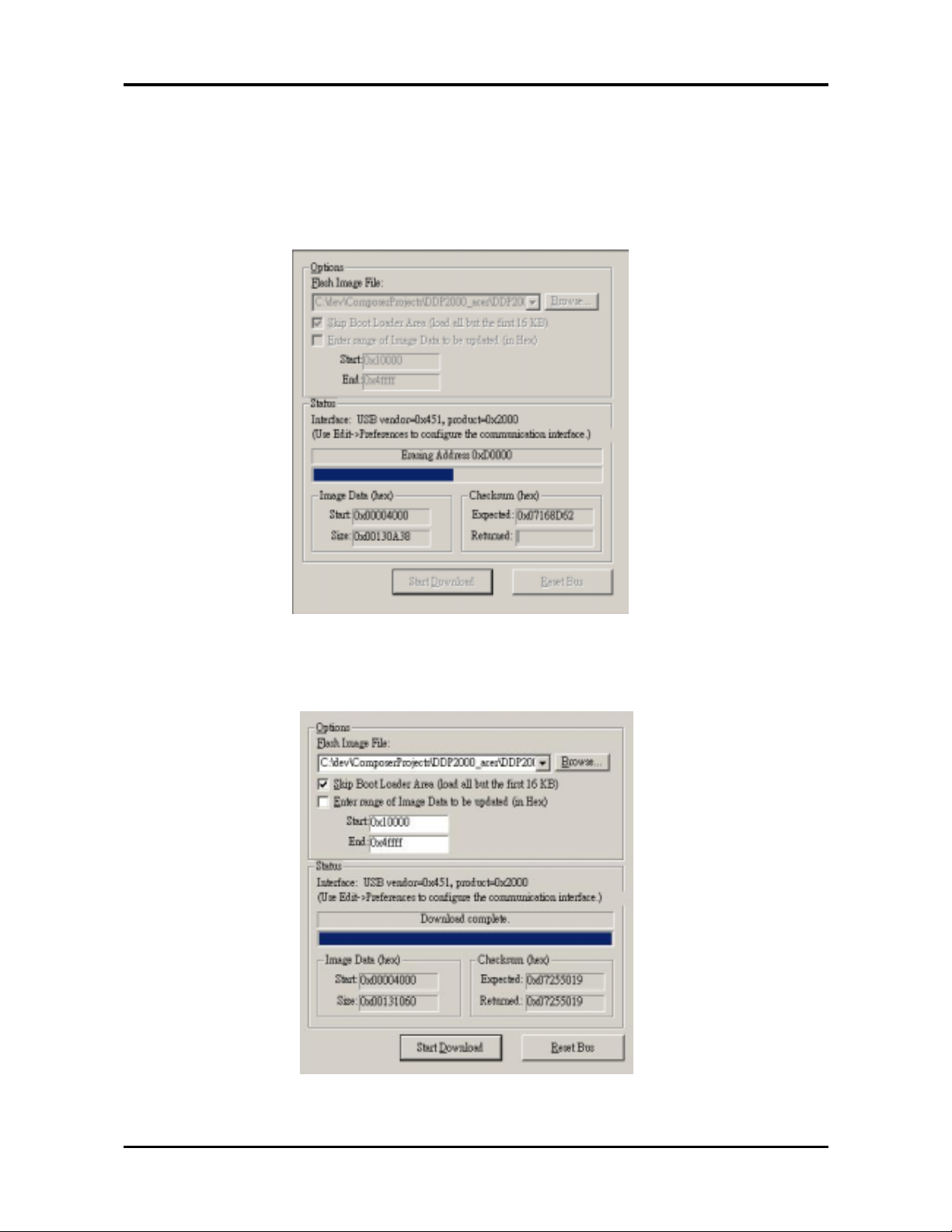

Upgrading Procedure

Firmware Upgrade

This cha pter provide s the equipment needed, setup and upgrading procedure for

Firmware upgrade.

Chapter 2

Setup Tool / Equipment

1. Computer

2. USB Cable (see right picture)

3. Power Coard

1. Connect Download Ca ble to proje ctor

2. Open burning programma (DLP Composer Lite)

Page 15

9 Cha pter 2

3. Pre ss Power a nd Menu button together a nd connect the power cord into the

projector . Tha n release these 2 bottoms .

4. Click the Start Download button and then start to burning of progra m .

5. Completion of Burning tha n remove Power Cord and Burning Cord .

Page 16

Chapter 3 10

Machine Disassembly and Replacement

This section provides disassembly procedures for PH112 DLP Projector. Before you begin any

of these procedures, be sure to turn off the power, computer system, and other attached devices;

then disconnect the power cable from the electronically outlet. Moreover, when you disassemble

the projector, be sure to put the screws in a safe place and separate them according to grouping.

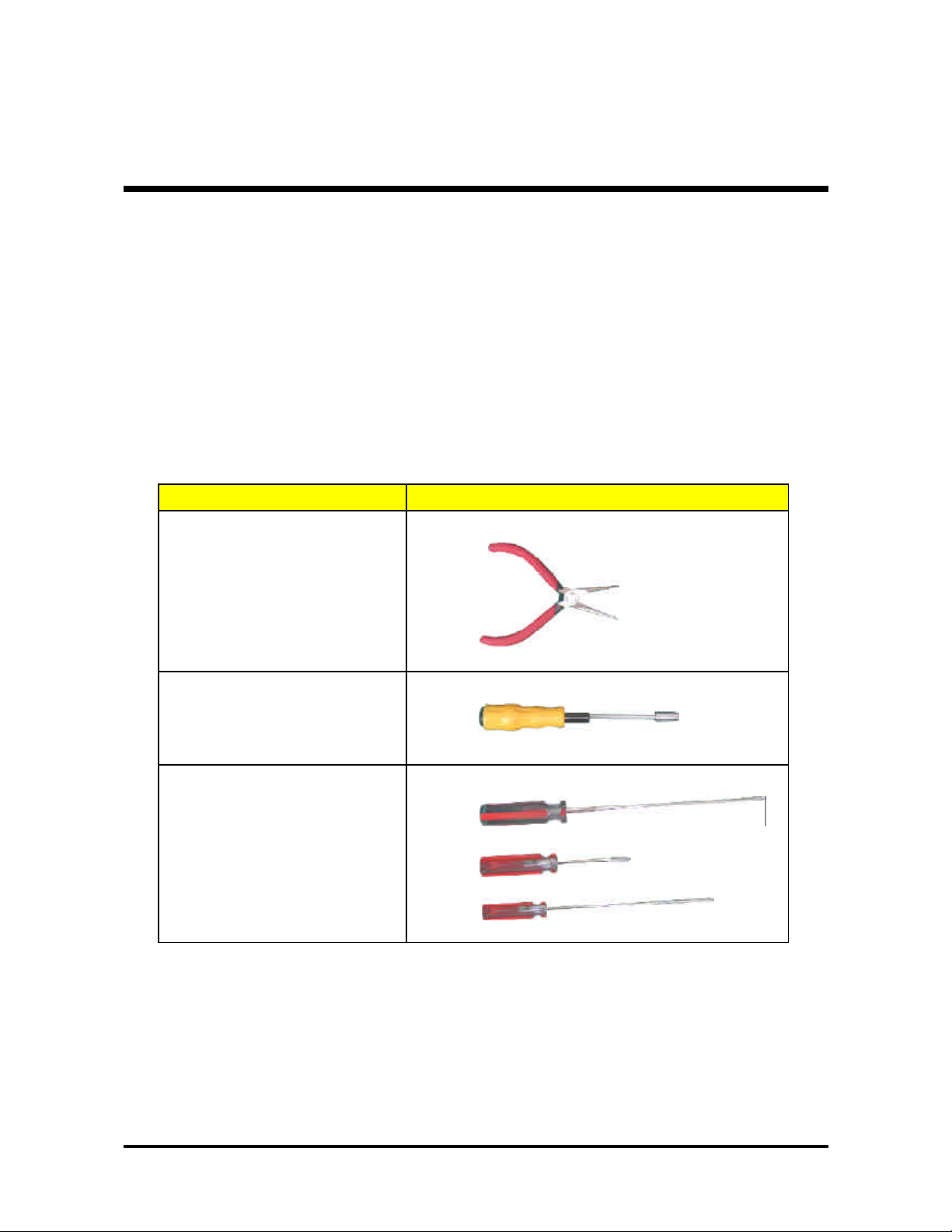

Tool Needed

Chapter

3

Item PHOTO

Long Nose Nipper

Hex Sleeves 5mm

Screw Bit (+) : 107

Screw Bit (+) : 101

Screw Bit (+) : 102

Page 17

11 Chapter 3

General Information

Before Yo u Begin

Before proceeding with the disassembly procedure, make sure that you do the following:

1. Turn off the power to the system and all peripherals.

2. Unplug the AC adapter and all power and signal cables from the system.

3. Wear Anti-static wrist strap.

Page 18

Chapter 3 12

1. Loosen two screws of Lamp Cover

2. Remove Lamp Cover

3. Loosen two screws of Lamp Module .

4. Grasp the lamp handle and pull out Lamp Module

p.s Related notice of replace lamp pls refer to the Lamp Specification section .

Disassemble Lamp Module

Note:Unplug all the cord before disaddembling the Projector.

01635-366*2

01635-366*2

Lamp Cover Assembly

Lamp Assembly

Page 19

13 Chapter 3

1. Loosen 4 screws of IO cover.

2. Remove IO cover

3. Loosen 2 screws of Back Cover

Disassemble IO Cover & Top Cover

1. Loosen the 2 screws of Top Cover.

2. Lift up Top Cover directly (Be careful there is a internal wire connect with the main board)

01635-D360-00 *2

01635-B730-00 *2

01635-B730-00 *2

P2038-1550-00

P2035-4510-99

82035-2510-00 *2

Page 20

Chapter 3 14

Disassemble Front Cover

Disassemble Speaker

01635-362 *2

02591-0014-00

02413-0016-00

1. Loosen the screws of Speaker.

2. Life up Speaker.

1. Loosen the 2 screws of Front Cover.

2. Lift up Front Cover directly(Be careful there are three internal wires connect with the main

board)

01635-B730-00 *2

Page 21

15 Chapter 3

Disassemble Front Fan

1. Lift up the Front f Fan Set from front cover directly.

Page 22

Chapter 3 16

Disassemble Front IR Board & IR Cover

P3634-7650-00

P2034-4520-98

01635-3610-00

02595-0029-00

P2447-5100

Page 23

17 Chapter 3

Disassemble Video IO

1. Loosen the screws of Back Cover

2. Loosen back cover.

3. Remove the Video IO.

01635-3610-00 *2

Page 24

Chapter 3 18

Disassemble Main Board

1. Loosen the four screws of Main Board

2. Unplug all wires on the board (Main Board PIN location of connectors pls refer to

Chapter 5 )

3. Remove Main Board

01635-3660-00 *4

P3635-0560-00

01635-3660-00

Page 25

19 Chapter 3

1. Lossen the screw of Back IR board.

2. Remove the Back IR board

3. Lossen the six screws of Ballast Module

4. Unplug all wires on Ballast Module (Ballast Board PIN location of connectors pls refer

to Chapter 5 )

5. Remove the Ballast Module.

Disassemble Ballast Module & Back IR

P4543-1016

01635-3610-00 *2

01635-3660-00 *2

Unplug from Power Module 2Pin Connector

Unplug from Lamp Module Connector

Page 26

Chapter 3 20

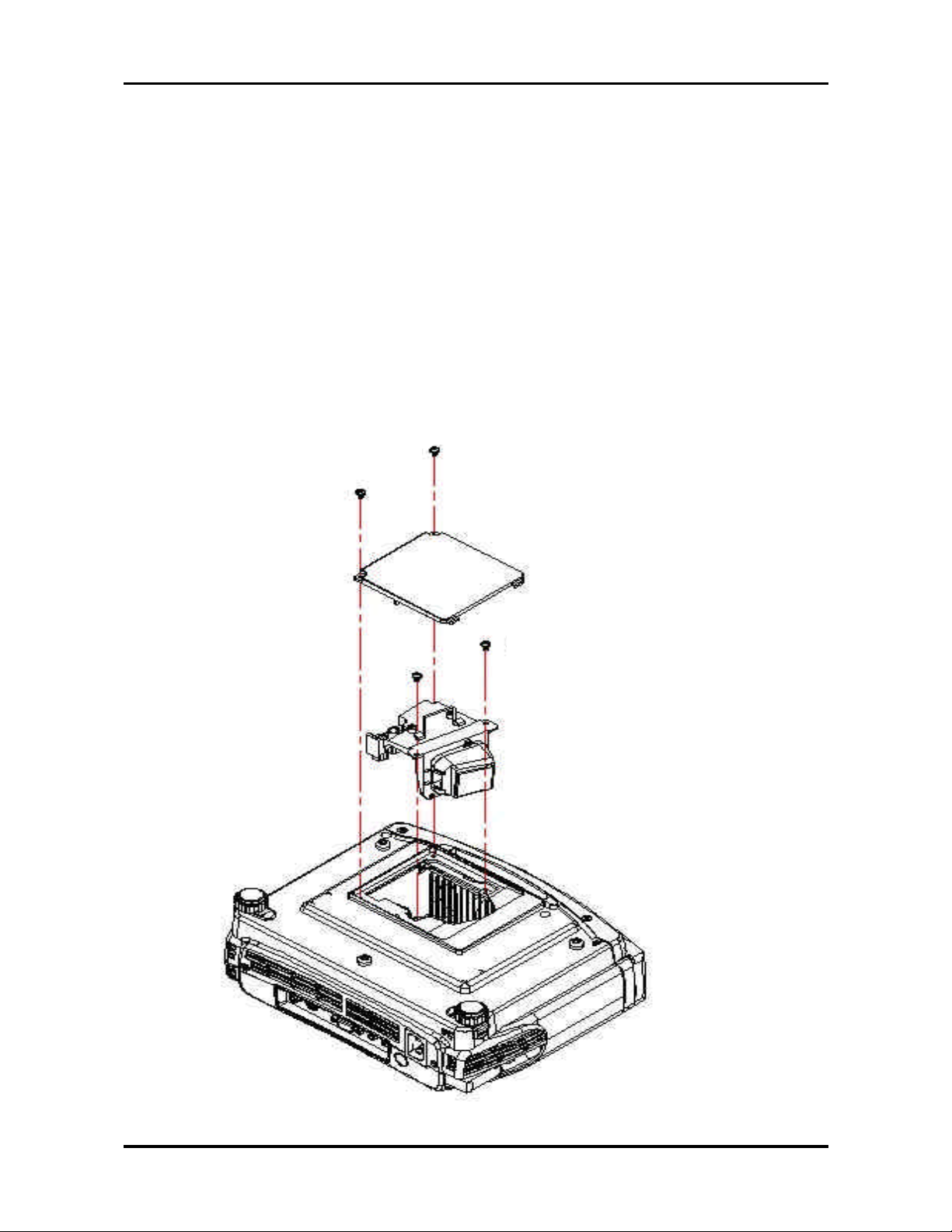

Disassemble Optical Engine

1. Lossen the four screws of Optical Engine

2. Remove the Optical Engine .

01635-A010-00 *4

Page 27

21 Chapter 3

Disassemble Back Cover

1. Loosen the screw of AC Inlet & remove the ring.

2. Remove the Back Cover.

3. 01635-7050-00

4. 01635-A080-00

P5844-0007

Page 28

Chapter 3 22

Disassemble Ba ck IR Cover, AC Outlet

1. Take out the AC Inlet.

2. Take out the Back IR Cover.

02595-0028-00

P2034-4530-98

P2034-4640-00

Page 29

23 Chapter 3

Disassemble Power Module

1. Unplug the wire.

2. Loosen the five screws of Power Module

3. Remove the Power Module.

01635-3610-00 *5

02595-0063-00

b

c

d

e

a

Page 30

Chapter 3 24

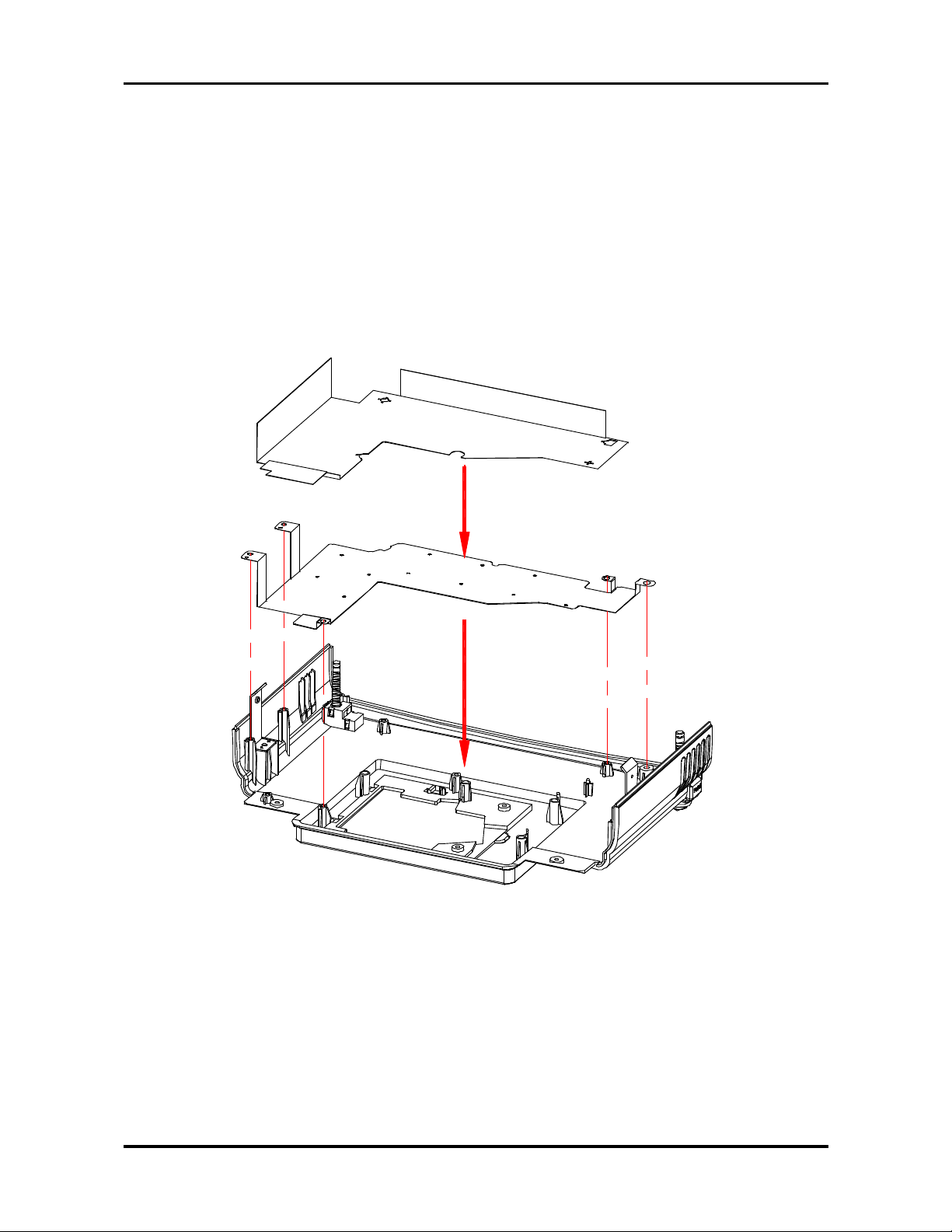

Disassemble Ground Plate & Mylar

1. Lift up the Groung Plate.

2. Then lift up the Mylar.

2. P2035-0500-00

3. P2038-0520-00

Page 31

25 Chapter 3

P1647-1000

01635-C01 *4

P1635-603

P1638-106*2

83034-040

P1638-105

Disassemble Heatsink & DMD Board

1. Loosen the four screws of Heatsink.

2. Tear off the EMI Pad

3. Remove the Heatsink. (Do not Suggest to tear off Thermal Pad and DMD Pad

on Heatsink unless they are damaged)

4. Lift up the DMD Board.

P3447-6000

P1635-6030-00

Page 32

Chapter 3 26

DMD Assembly

02475-0003-10

P1636-701

right angle to

right angle

Disassemble DMD Assembly & DMD

1. Lift up the DMD Assembly

2. Lift up the DMD

02093-0007-00

Page 33

27 Chapter 3

Disassemble Thermal Board

1. Loosen the screw of Thermal Board

2. Remove the Thermal Borad

01635-3530-00

P2235-0000-00

Page 34

Chapter 3 28

P1643-0020

P0335-101 *3

stick on top of joint

P1638-102

and can not protrude

screw the two

this side

screws first

Disassemble Optical Engine Fan

1. Loosen the three screws of Fan

2. Remove the Optical Engine Fan

02394-0011-00

Page 35

Chapter 4 30

Troubleshooting

This chapter provides technicians and people who have an electronic background a primary

description about maintaining the product. Moreover, you can get the appropriate operation

to solve some complicated problems of component repairing and professional problems.

The Troubleshooing se ction focus on below items:

1. Video Signal Troubleshooting

2. Operation Function T roubleshooing

3. Power Source T roubleshooting

Chapter 4

Page 36

31 Cha pter 4

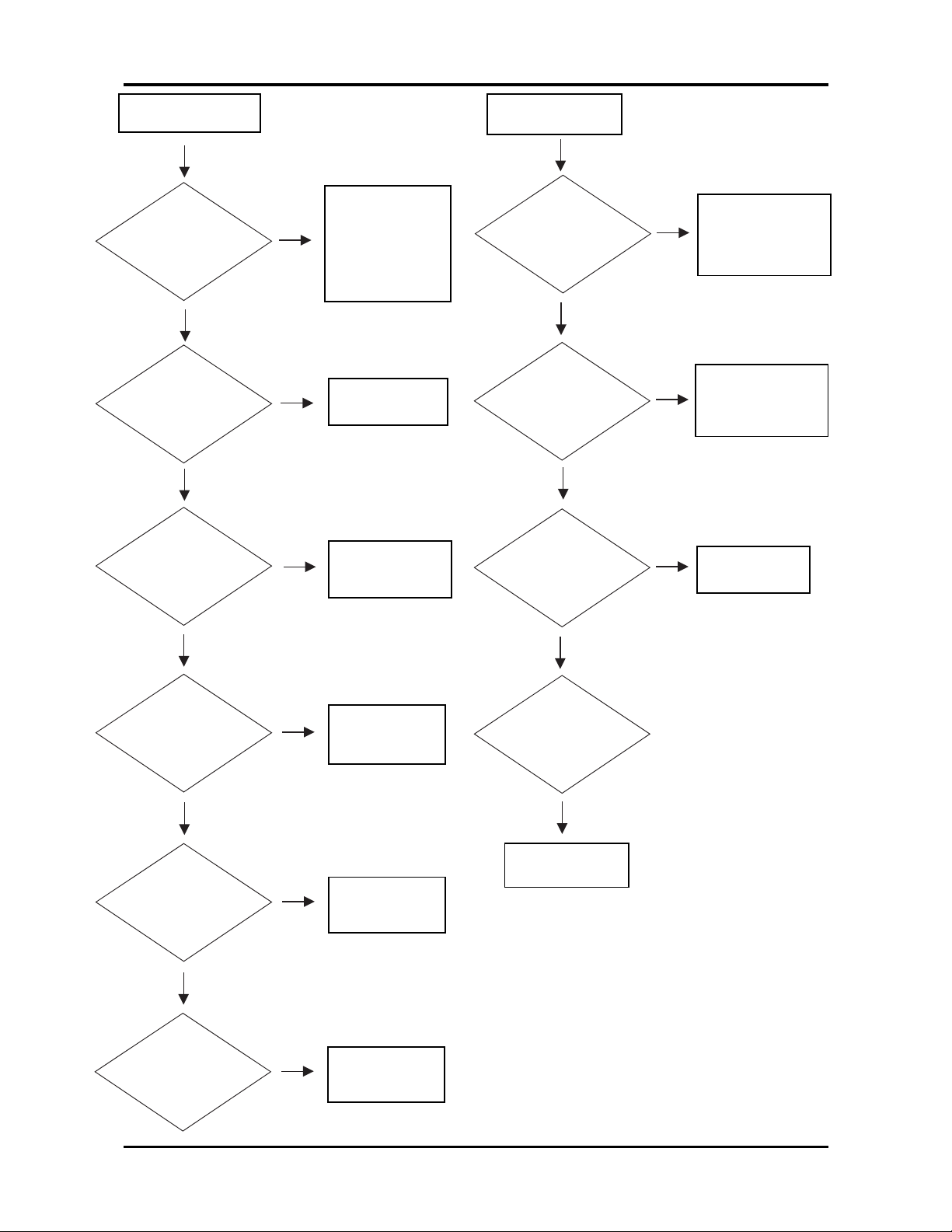

Video Signal

Computer

No Signal

Check

Source

Turn on

Source

Check

Cable

Replace

Cable

Computer

Mode

Input

Change to

Computer

Mode

Change Main

Board

NG

NG

NG

Video

No Signal

Check

Source

Turn on

Source

Check

Cable

Replace

Cable

Video

Mode

Input

Change to

Video Mode

OK

NG

OK

OK

NG

NG

OK

OK

OK

Change Main

Board

Page 37

Chapter 4 32

Fail to light up

Check

La mp

Look up user

manual ,a nd

follow indicative action

Check

Fan

Replace Lamp

Check

Thermal

Sensor

Replace Thermal Sensor

Check

LED indication

Replace Fa n

OK

NG

OK

OK

OK

NG

NG

NG

Repla ce Main

Board

NG

Check

Main Board

No Volume

Check

Speaker

Connector

Speaker

Connector

Become loose

Check

Speaker

Repla ce

Speaker

Check

Main

Board

Repla ce Main

OK

OK

OK

NG

NG

OK

Repla ce

Balla st

NG

Check

Ballast

Check

Top cover’s cable

Replace cable

or connect the

cable ba ck

OK

NG

Page 38

33 Cha pter 4

Color Missing

On Screen

C/W Cable

Connector

Check Cable

Connector

Check

Cable

Repla ce

Cable

Check Main

Board

Change Main

Board

OK

NG

OK

OK

OK

NG

NG

Change Optical

Engine

Page 39

Chapter 4 34

Operation Function:

Remote Control

Failure

Check

Battery

Level

Repla ce Battery

Check

Remote

Control

Repla ce Remote

Control

Check

IR

Replace IR

Main

Board Fail

OK

NG

OK

OK

NG

NG

Button Failure

Check

Button

Repla ce Button

Check

Keypad

Replace Keypad

Replace

Main Board

OK

OK

NG

NG

Check

Top cover’s cable

OK

NG

Replace cable

or connect the

cable back

Page 40

35 Cha pter 4

No Power Source

After Turning On

Check

La mp Cover

Switch

Replace Lamp

Cover or

Reassembly

Check

Power Cord

Check

Top Cover (key

cable..)

Replace

cable or key

Check

Power

Board

Replace M ain

Board

OK

NG

OK

OK

OK

NG

NG

NG

Replace

Power Board

NG

OK

Check

Main

Board

Power Source:

Repla ce Standby

Signal cable NG

Fan failure After

Turning On

Check

Fan

Connector

Fan Connector

Become loose

Check

Inner

Wires

Replace Inner

Wires

Check

Fan

Replace

Fan

Check

Main

Board

Replace

Main Board

OK

NG

OK

OK

NG

NG

NG

OK

Replace Power

Baord

Replace

Power Cord

Page 41

Chapter 4 36

Function Test and Alignment

Equipment Needed

T e st Condition

Page 42

37 Cha pter 4

langiSteserP cnyS noituloseR )zH(Vf )zH(Hf

AGV)-(V,)+(H008x046

065.13

277.73

575.73

583.34

AGVS)+(V,)-(H006x008

651.53

069.73

271.84

579.64

587.35

AGX)-(V,)-(H867x4201

064.84

075.65

5706

0846

583.86

AGXS)+(V,)+(H4201x08210646

Test Display Modes and Patterns

Compatible Modes

Page 43

Chapter 4 38

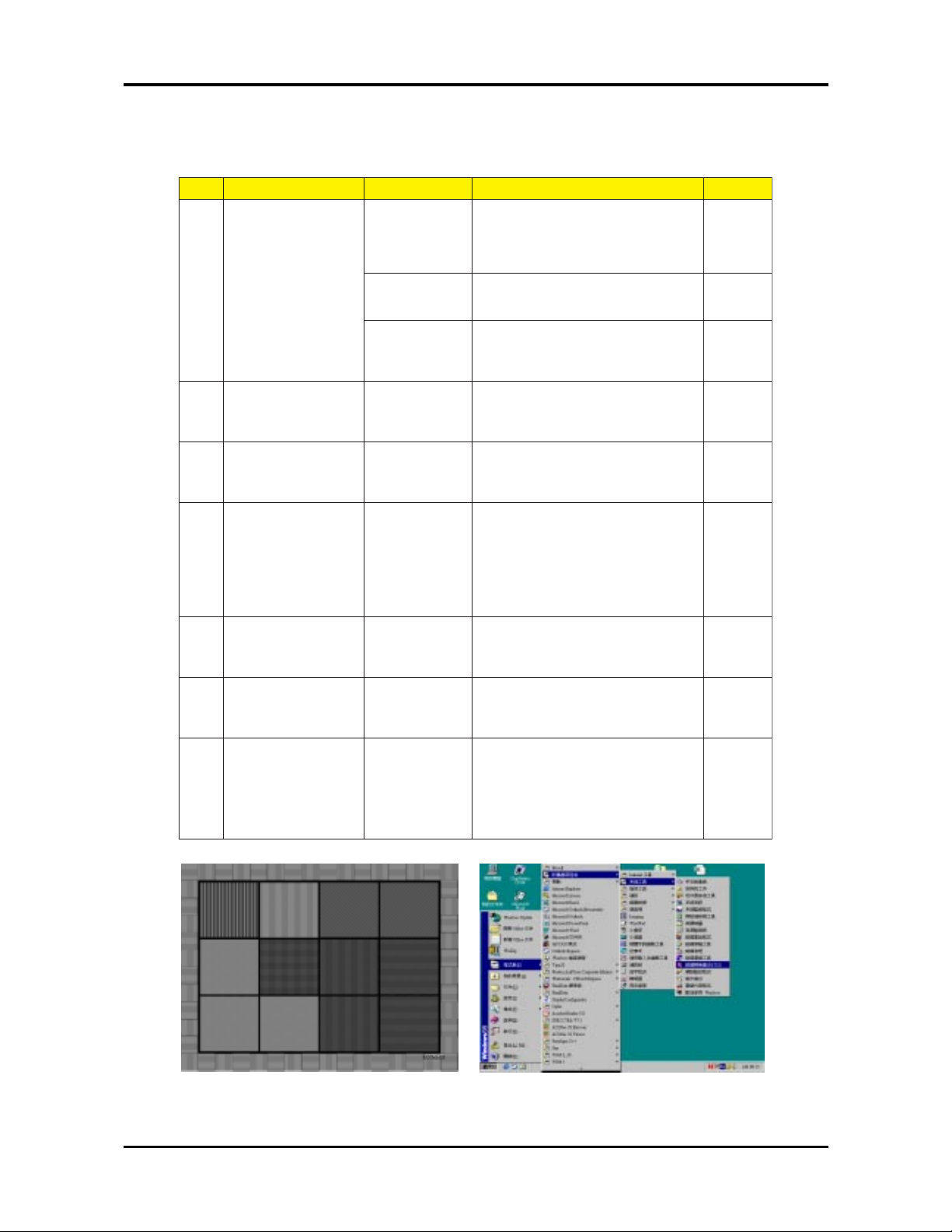

Function Test Display Pattern

metI tnetnoCtseT nrettaP noitacificepS krameR

1pukcehcesioN

serauqs21

PMB"serauqs21"ehttceleS.)1(

ynasierehtfikcehcotelif

foegatsehtgnirudsesion

ehtpugnimrawdna,nogninrut

.rotcejorp

1erugiF

serauqs21

ehtnoraeppasesionehT.)2(

nahtsselebdluohserauqs

.serauqseerht

1erugiF

rekcilf008

PMB"rekcilf008"ehttceleS.)3(

nodrowhcaeterusekaM.elif

tonnseodegamidetcejorpeht

.rekcilf

2erugiF

2pukcehctsuDkcalBlluF

elifPMB"kcalBlluF"ehttceleS)1(

ehtnoegamiehttcejorpot

timorfsretem8.1dnatS.neercs

.sniatsoneraerehterusnedna

3erugiF

3pukcehctsuDetihWlluF

elifPMB"etihWlluF"ehttceleS)1(

ehtnoegamiehttcejorpot

timorfsretem8.1dnatS.neercs

.sniatsoneraerehterusnedna

4erugiF

4pukcehcnoituloseR

dnakcalB

droWetihW

etihwdnakcalb"ehttceleS)1(

ehtesU.elifPMB"drow

detcejorpehttsujdaotrotcejorp

ezismumixamehtotegami

ekamdnaezismuminimdna

sidrowhcaeerus

htobrednuelbahsiugnitsid

.snoitidnoc

Fi erug5

5pukcehcrolocBGRBGR652

elifPMB"BGR652"ehttceleS)1(

foreddalrolocehtfikcehcot

rolocehtsehctamegamieht

.elifehtforeddal

erugiF6

6pukcehctsuDyarGlluF

elifPMB"yarGlluF"ehttceleS)1(

ehtnoegamiehttcejorpot

timorfsretem8.1dnatS.neercs

.sniatsoneraerehterusnedna

7erugiF

7

kcehcegakaelthgiL

pu

yradnuoB

emarF

"ehttceles,redlofehtnokcilC)1(

,elifPMB"emarFyradnuoB

ehtnonottubOTUAehtsserp

dnasenilehtfikcehc,rotcejorp

egamidetcejorpehtfosroloc

ehtnodetneserpsaraelcera

.elifPMB

8erugiF

12 squares Pattern (Figure 1) 800 flicker Pattern (Figure 2)

Page 44

39 Cha pter 4

Full Black Pattern (Figure 3) Full White Pattern (Figure 4)

Gray Pattern (Figure 7) Boundary Frame (Figure 8)

Black and White Word Pattern (Figure 5) 256RGB Pattern (Figure 6)

Page 45

Chapter 5 40

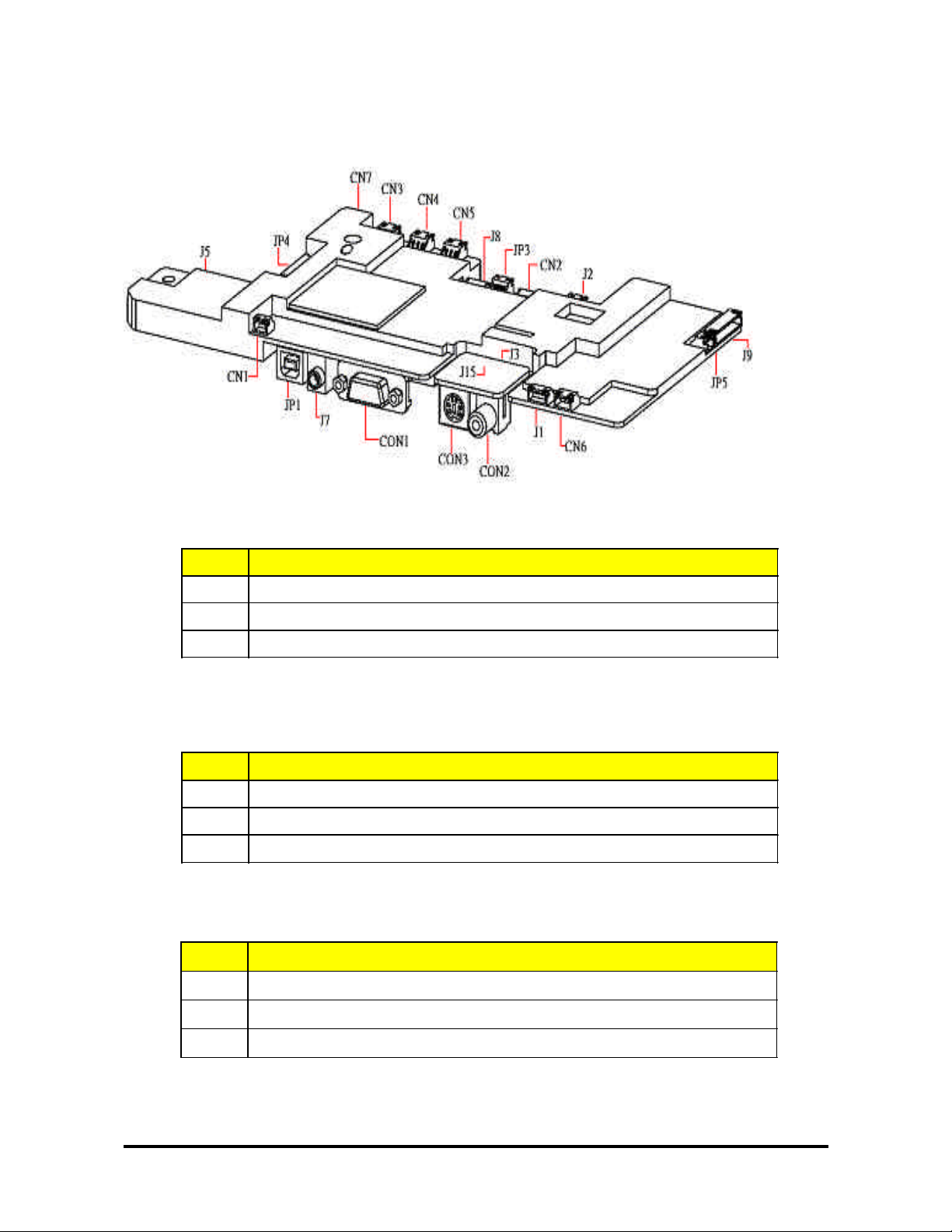

Main Board

Summariz e

Connector Description

CN1 IR

CN2 Keypad control

CN3 Fan

CN4 Fan

CN5 Fan

CN6 Fan

CN7 IR

J1 Ballast control

J2 Thermal

J3 Vidio & S-Video in

J5 DMD connector

J7 Phone jack stereo-R

J8 Color wheel

J9 Power in

J15 Vidio & S-Video in

JP1 USB

JP3 CW index

JP4 Firmware debug

JP5 Standby run

CON1 D-SUB

CON2 Video

CON3 S-video

Connector Information

Introduction

This section provides each connector location on boards, signal and function of each

board. They will be useful for your detecting the defective boards.

Chapter

5

Page 46

41 Chapter 5

The Locations of Connectors

PIN# Description

1

PWM

2

Control

3 GND

CN3 , CN4 , Cn5 : FAN

PIN# Description

1

12V_S1

2

FAN_FB3

3

GND_PWM3

J1 :Ballast Control

PIN# Description

1 IR 0

2

GND

3 +3.3 V

CN1 , CN7 : IR

Page 47

Chapter 5 42

PIN# Description

1

GND

2

GND

3 SP_R+

4

SP_R+

5 SP_R-

6

SP_R-

7

SP_L+

8 SP_L+

9

SP_L-

10 SP_L-

11

Keypad_PWR

12

Keypad_Menu

13 Keypad_Up

14

Keypad_Down

15 Keypad_Left

16

Keypad_Right

17

GND

18 GND

19

Power_LED

20 LED_SYS2

21

LED_Lamp1

22

LED_Lamp2

23 P3P3V_STBY_PWR

24

P3P3V_STBY_PWR

25 P3P3V_STBY_PWR

26

Key_Source

27

IR 1

28

Key_Auto

CN2 : Keypad Control

Page 48

43 Chapter 5

CON2 : Video

PIN# Description

1 CVBS

2

AGND

CON3 : S-Video

PIN# Description

1

AGND

2

AGND

3

SVDOY

4 SVDOC

PIN# Description

1

COMPVID

2

AGND

3 SVID_LUM

4

AGND

5

SVID_CHR

6

GND

7 + 3.3 V

8

+ 3.3 V

J3 , J15 : Video & S-Videop IN

PIN# Description

1 + 3.3 V

2

SCL

3

SDA

4

GND

J2 :Thermal

Page 49

Chapter 5 44

J7 : Phone jack Stereo-R

PIN# Description

1

GND

2 AINC_L

3

NC

4 AINC_R

5

NC

CON1 : D_SUB

PIN# Description

1 V- Red

2

V-Green

3

V-Blue

4

NC

5

AGND

6 AGND

7

AGND

8

AGND

9

+5V

10

DSUB_Detect

11 AGND

12 VSDA

13

H-Sync

14

V-Sync

15

VSCL

PIN# Description

1 CW CTR

2

CW Y3

3

CW Y2

4 CW Y1

J8 : Color Wheel

Page 50

45 Chapter 5

JP1 : USB

PIN# Description

1

+5V_STBY

2

GND

3 GND

4

+5V

5 +5V

6

GND

7

+13.5V

8 GND

9

+12.5V

10 GND

J9 : Power Supply

PIN# Description

1

NC

2

USB DATN

3 USB DATP

4

GND

5

GND

6 GND

PowerIn

PIN# Description

1

+3.3V

2 +3.3V

3

+3.3V

4 GND

JP3 : CW Index

PIN# Description

1

STBY_PWR

2 GND

JP3 : CW Index

Page 51

Chapter 5 46

PIN# Description

1

GND

2

GND

3

TMSI

4

TDO1_OUT

5

SYSRSTZ

6

TRSTZ

7

TDI

8

TMS2

9

TCK

10 RTCK

11 TDO2

12 ICE_RSTZ

13 TRACEPKT15

14 TRACEPKT14

15 TRACEPKT13

16 TRACEPKT12

17

TRACEPKT11

18

TRACEPKT10

19

TRACEPKT9

20

TRACEPKT8

21

TRACEPKT7

22

TRACEPKT6

23

TRACEPKT5

24

TRACEPKT4

25 TRACEPKT3

26 TRACEPKT2

27 TRACEPKT1

28 TRACEPKT0

29 TRACECLK

30 TRACESYNC

31

PIPESTAT0

32

PIPESTAT1

33

PIPESTAT2

34

+3.3V

35

+3.3V

36

+3.3V

JP4 : FirmWare Debug

Page 52

47 Chapter 5

Power Board

Summarize

Connector Description

CN101 AC Inout

CN201 +380V Output

CN301 DC Output

The Locations of Connectors

PIN# Description

1

Line

2

NEUTRAL

CN101 : AC Inout

Page 53

Chapter 5 48

PIN# Description

1 +380V

2

GND

CN201 : +380V Output

PIN# Description

1

+5V_STBY

2

GND

3

GND

4

+5V

5

+5V

6 GND

7 +13.5V

8 GND

9 +12.5V

10 GND

11 GND

12 STBY_CTRL

CN301 :DC Output

Page 54

49 Chapter 5

Ballaster Board

Summarize

Connector Description

X1 Power input

X2 SCI & Flag

X3 Connection to lamp

X2: SCI & Flag

X1 : Power input

PIN# Description

1 DC Input voltage

3

GND

The Locations of Connectors

PIN# Description

1 Flag/TxD (coll.)

2

Flag/TxD (emitter)

3

Common+ (anodes)

4

SCI/Sync (cath.)

5 RxD (cath.)

X3: Connection to lamp

PIN# Description

1 LAMP

4

LAMP

Page 55

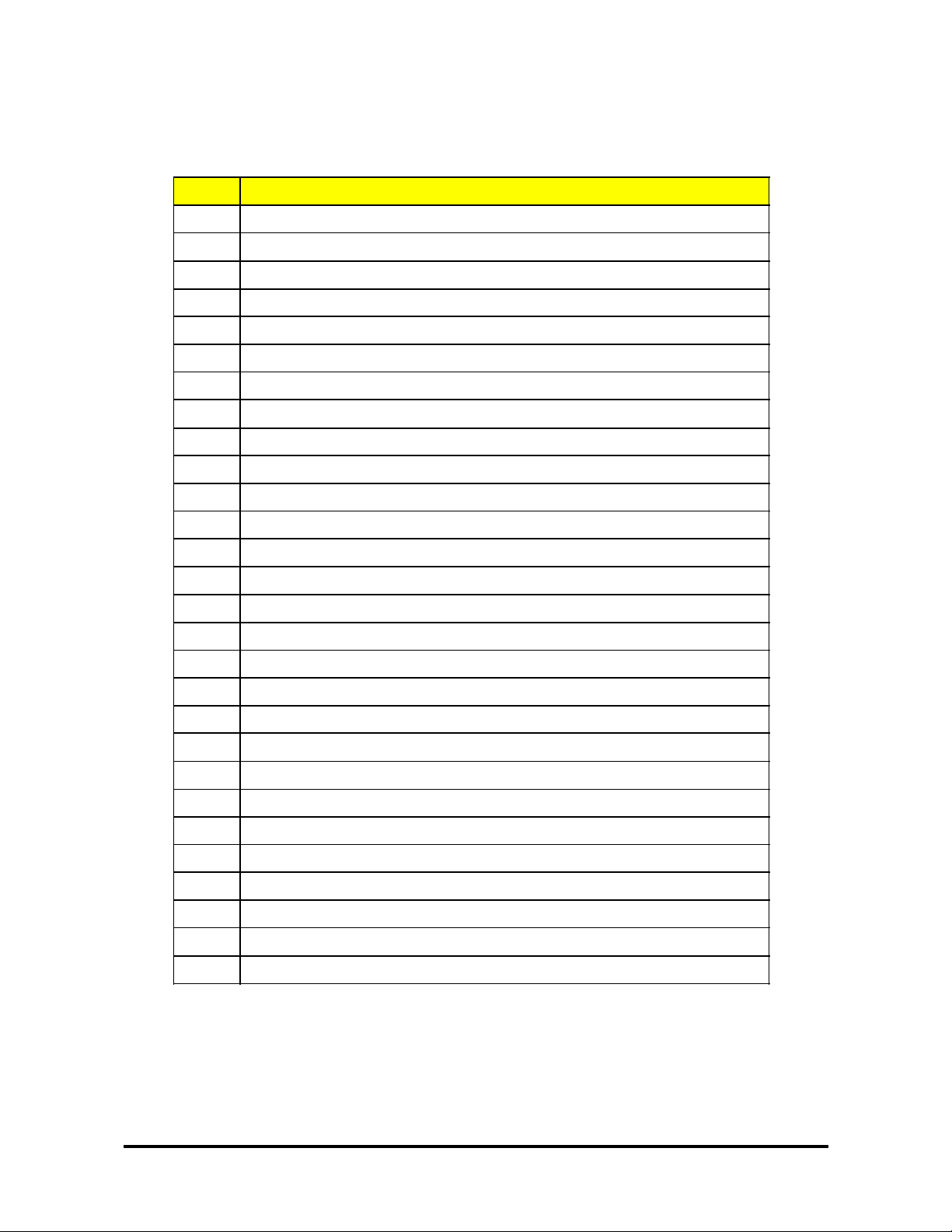

Chapter 6 50

FRU (Field Repla ce a ble Unit) List

This cha pter gives you FRU ( Field Repla ce able Unit ) listing in global configuration of PD-112.

Refer to this chapter whenever ordering for parts to repair or for RMA ( Return Merchandise

Authorization ). Plea se note that WHEN OR DERING FRU PARTS, you should check the most

up-to-date information available on your regional web or cha nnel. For whatever re a son s a part

number change is ma de, it will not be noted on the printed Service Guide. For Acer AUTHORIZED SER VICE PROVIDERS, Acer office may have a DIFFERENT part number code from

those given in the FRU list of this printed Service Guide. You MUST use the local FRU list provided by your regional Acer of fice to order FRU parts for repair a nd service of customer machines.

NOTE : To scrap or to return the defective parts, you should follow the local government

ordinance or regulation s on how to dispose it properly, or follow the rules set by your

regional Acer office on how to return it.

Chapter 6

Page 56

51 Cha pter 6

.oN otohP emaNtraP N/P

1draoBniaM100-4876P

2draoBtsallaB200-4876P

3draoBrewoP300-4876P

4draoBDMD0006-7443P

5draoBRItnorF0015-7442P

6draoBRIkcaB1015-7423P

7TEKCARBROSNES00-0000-5322P

8revocpoT4000-4876P

9revocmottoB5000-4876P

01revoctnorF6000-4876P

FRU List

Page 57

Chapter 6 52

.oN otohP emaNtraP N/P

11revoCkcaB7000-4876P

21revoCRItnorF00-0654-4302P

31EGNOPSOI00-0551-8302P

41etalPOI99-0154-5302P

51revoCpmaL4001-4436P

61tekcoSnip302DMD01-3000-57420

71eludoMpmaL8000-4876P

81enignElacitpO9000-4876P

91)hcni55.0(DMD00-7000-39020

02teSnaFtnorF6001-5476P

Page 58

53 Cha pter 6

.oN otohP emaNtraP N/P

12naFenignE10-1100-49320

22etalPdnuorG00-0050-5302P

32ralyM00-0250-8302P

42knistaeHDMD00-0306-5361P

52ETALPEDIS00-0250-5302P

62revoCneL00-A264-4302P

72rekaepS00-6100-31420

82

niP3eriW

RI-FotB/M

00-9200-59520

92

elbaCCCFeriW

revoCpoTotB/M

00-4100-19520

03

telnICAeriW

rewoPottelnICA

00-8200-59520

Page 59

Chapter 6 54

.oN otohP emaNtraP N/P

13

niP3eriW

RI-BotB/M

00-7200-59520

23

niP5eriW

tsallaBotB/M

00-0300-59520

33

niP2eriW

rewoPottsallaB

00-9100-59520

43

niP4eriW

BM

00-8100-59520

53

niP2+01-niP21eriW

rewoPotB/M

00-3600-59520

63

73

83

93

04

Loading...

Loading...